A Practical Framework for the Design of Low-Carbon and Circular Building Structures

Abstract

1. Introduction

2. Research Methodology Toward the Development of the Low-Carbon Circular Design Framework and Specific Guidance

3. Industry Feedback

4. Framework

- A visual representation of generic strategies for creating Low-carbon circular designs, applicable to both greenfield and brownfield sites. This presentation follows a hierarchical structure familiar to most designers, inspired by aforementioned waste minimization and circular design hierarchies;

- An accessible overview of LCA and circularity, organized into Modules A–D, to introduce the Framework’s layout (to provide a simple guide to carbon calculation for the design engineers;

- A set of generic solutions aimed at achieving low-carbon circular design in alignment with the strategies outlined.

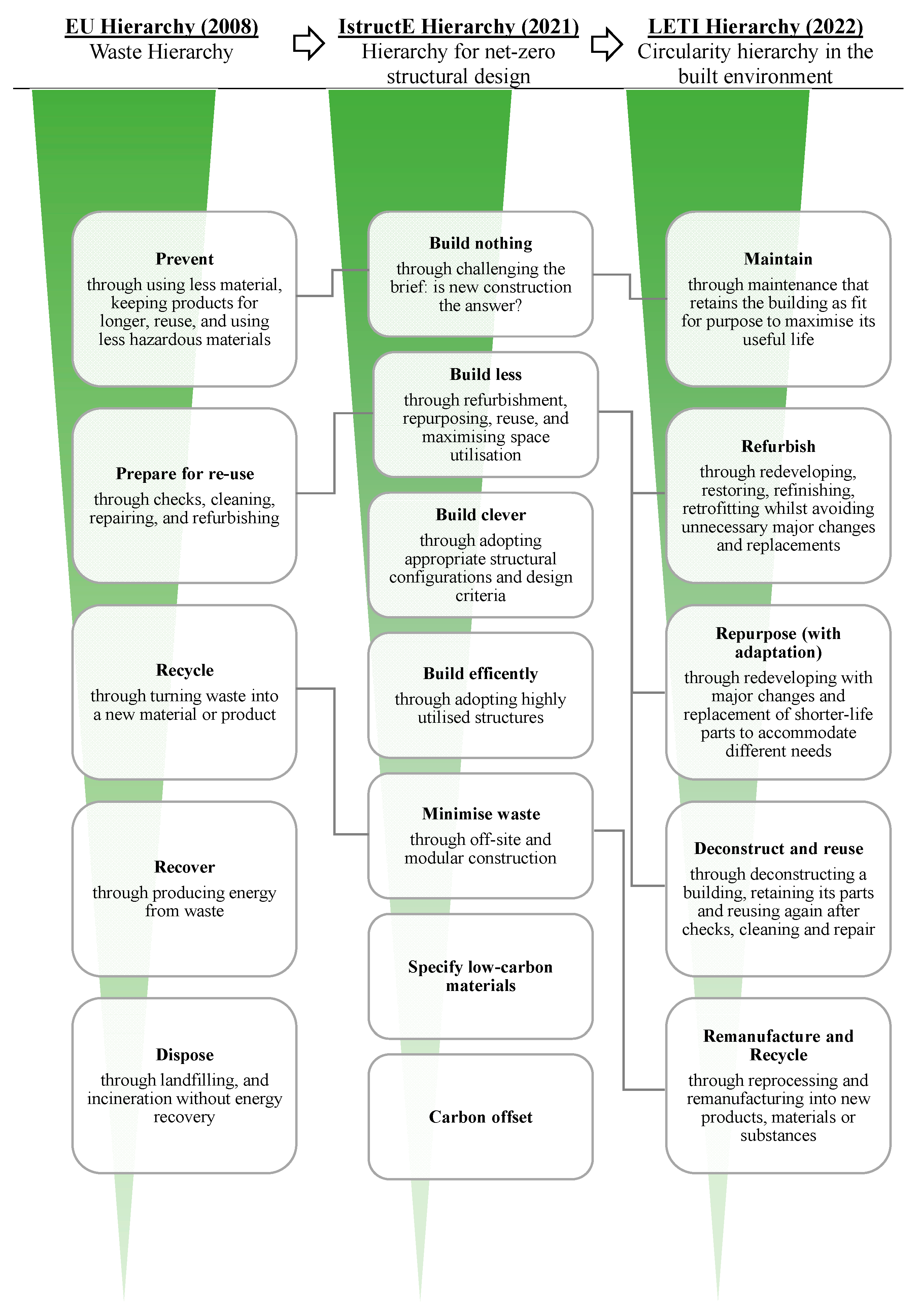

4.1. Hierarchy of Design Strategies

- Simplify language and avoid ambiguity, ensuring self-explanatory clarity;

- Integrate impactful design strategies into a unified chart, distinguishing between circular and low-carbon strategies instead of merging them, to provide distinct and clearly defined guidance;

- Offer strategies for both new building designs and alterations/removal of existing buildings, tailored to greenfield (new building) and brownfield (existing building) sites, respectively, emphasizing the unique considerations of each;

- Mirror LETI’s (2022) hierarchy for new buildings, “Design for longevity” to achieve a lifespan exceeding 50 years with minimal initial carbon investment. This is accomplished through maintenance, refurbishment, and retention of buildings, aligning with IStructE’s principle of “Build nothing”. Next, “Design for adaptability” is emphasized for buildings intended to accommodate future changes, recognizing that this may require higher upfront carbon investment. When future adaptability is not viable, “design for disassembly and deconstruction” is recommended to facilitate the reuse of components or elements, consistent with LETI’s fourth hierarchy stage. If reuse is not possible, recycling and remanufacturing after demolition become the last resort. Nevertheless, selecting recyclable materials during the design phase ensures that, even without reuse, materials can still be processed sustainably at the end of their lifecycle;

- Highlight the connection between current circular building strategies and their future implementations, facilitated by incorporating Construction 4.0 elements into the chart, advocating for the integration of advanced circular and low-carbon solutions using Industry 4.0 technologies. This ensures comprehensive data management throughout the building lifecycle, optimizing efficiency, and sustainability.

Construction 4.0 Strategy in Hierarchy of Design Strategies

- Supports circular and low-carbon strategies: As an individual strategy, Construction 4.0 encompasses many novel solutions such as Monitoring 4.0, circular design, and advanced LCA significantly enhancing construction sustainability and critically contributing to circular, low-carbon, and sustainable building design. For example, Monitoring 4.0 can inform decisions about the type and amount of materials needed, reducing waste and promoting the use of sustainable alternatives. Moreover, by prolonging the lifespan of structures through effective maintenance, Monitoring 4.0 reduces the need for new constructions, thereby conserving resources and minimizing environmental impacts.

- Bridges greenfield and brownfield strategies: Construction 4.0 will facilitate the transformation of brownfield to greenfield buildings, linking all strategies together and allowing advanced optimization methodologies to achieve the best possible solution efficiently. As a result, the advantages of circular and low-carbon strategies in designing sustainable buildings will be greater than the sum of their parts. For example, when Monitoring 4.0 becomes more widely available, the safety factors used in the design codes can be safely lowered, as those safety factors are suggested using conservative assumptions and rare event scenarios that might not be relevant to the majority of structures. On the other hand, special-purpose future new structures with elevated demands will benefit from a deeper understanding of the response of existing buildings to loads. Another example is that Construction 4.0 offers advanced technologies (e.g., advanced BIM and digital twin) as a platform carrying digital material passports that facilitate the deconstruction of existing buildings and the reuse of elements from brownfield buildings in greenfield buildings. This goes beyond extending the lifespan of existing buildings or refurbishing or repurposing existing buildings. This means that elements of existing buildings will be disassembled in a sustainable way and used in new construction projects elsewhere. In this case, in an ideal situation where the deconstruction rate is not less than the new build rate, and existing elements remain undamaged during the deconstruction and reuse process, there is no need for virgin materials. Carbon emissions from existing buildings will be significantly reduced (or net zero achieved), demolition will be replaced by deconstruction, and construction and demolition waste will be significantly reduced.

4.2. Low-Carbon and Circular Design Solutions

5. Specific Guidance

6. Balancing Sustainable Building Design Strategies and Addressing Conflicts

- Conflict with each other;

- Affect the end-of-life scenario of the building; or

- Impact building performance (e.g., structural integrity, fire resistance, seismic resilience, durability, acoustic performance, etc.).

6.1. Navigating Complex Decision Making in Low-Carbon Circular Building Design

6.2. Low-Carbon Circular Building Design Flowchart

7. Case Studies

7.1. Carbon and Waste Reduction Goals

7.2. Low-Carbon Strategies and Solutions Selection Criteria

- Retain the material and structural systems for building superstructures to achieve a 50% reduction in carbon emissions;

- Minimize material and structural systems replacement for achieving net-zero carbon;

- Ensure that the alternative substructure is suitable for the building site conditions;

- Confirm that the selected solutions are available and implementable in Aotearoa New Zealand.

8. Life Cycle Assessment

- A1–A3: Manufacture of materials.

- A4: Transport of materials to site.

- A5: Construction works, and waste generated onsite.

- C1: Deconstruction and demolition

- C2: Transport of materials to waste facility.

- C3–C4: Waste processing and disposal of materials.

- D: Emissions associated with recycling of materials at end of life.

8.1. End of Life Scenarios

8.2. Functional Unit

8.3. Inventory Analysis and Life Cycle Impact Assessment

9. Results and Discussions

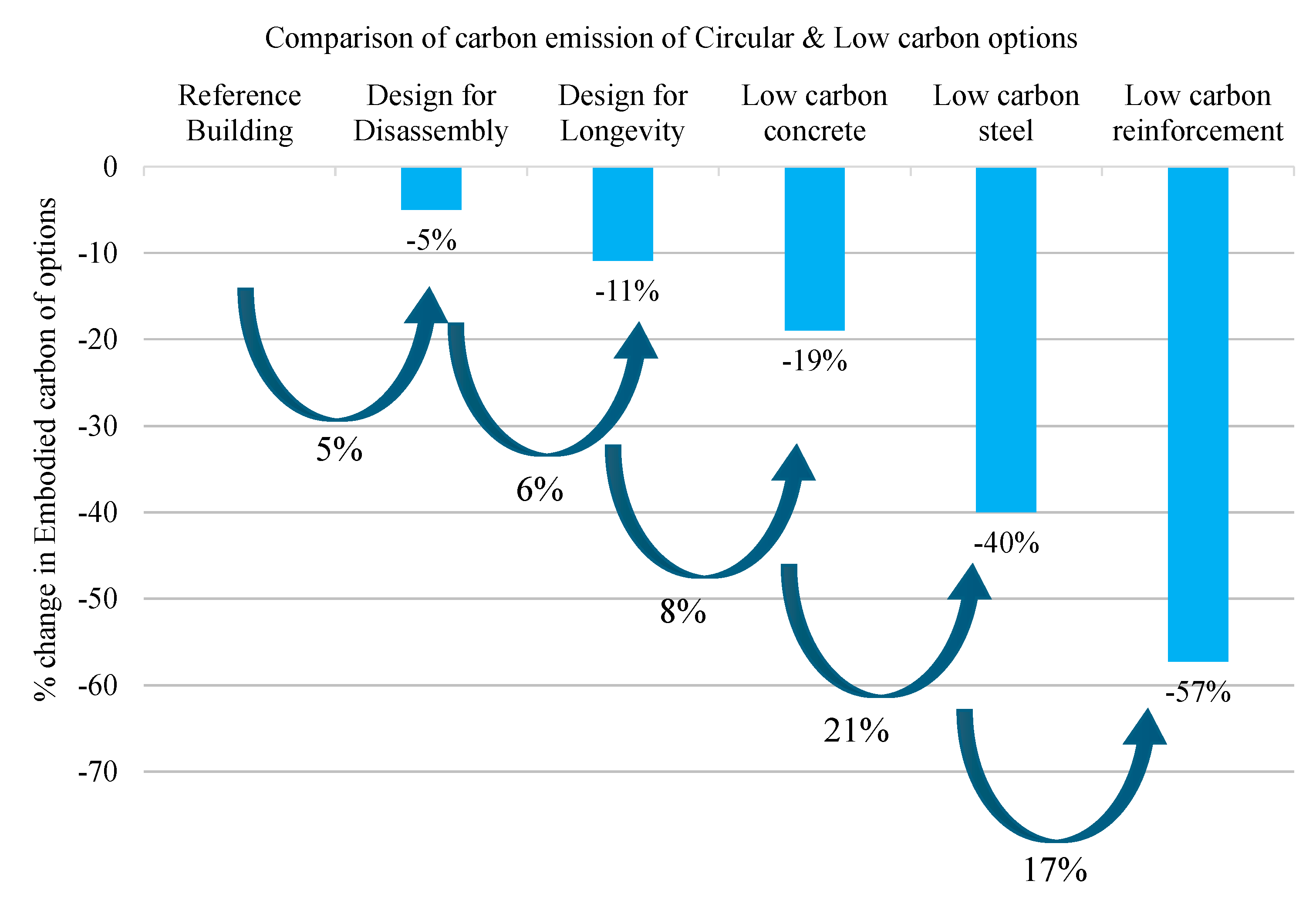

9.1. Circular and Low-Carbon Strategies and Solutions for Achieving a 50% Reduction in Whole-of-Life Carbon Emissions

9.1.1. Superstructure

9.1.2. Substructure

9.2. Low-Carbon and Circular Strategies and Solutions for Achieving a Net Zero Whole-of-Life Carbon Emissions

10. Future Research

11. Conclusions

- The Framework unified existing circular and low-carbon strategies into a simple, hierarchical chart. Additionally, it introduced a novel Construction 4.0 strategy that also serves as a bridge between greenfield and brownfield strategies, linking them together seamlessly.

- While Construction 4.0 offers valuable solutions for circular and low-carbon design, its greatest potential lies in bridging greenfield and brownfield strategies. This integration has the potential to greatly enhance sustainable building design, construction, and operation by creating a platform for future innovation and implementation of novel sustainable building solutions;

- In addition to circular and low-carbon design strategies, the Framework encompasses solutions related to these strategies, along with practical LCA to enhance awareness and deliver basic LCA knowledge.

- A specific guidance for steel, steel–concrete and steel–timber hybrid low-rise buildings, serving as a pilot to the Framework, was developed. It will be used by industry experts, researchers, and building designers. Feedback from users will guide revisions to both the Framework and the specific guidance, addressing identified gaps and improving their efficiency for sustainable building design;

- A low-carbon and circular building design Hierarchy is proposed to design low-carbon buildings using the Framework and specific guidance.

- The results of the reference building and low-carbon solutions demonstrate that it is feasible to achieve a 57% reduction in carbon without changing materials or compromising structural or building performance.

- To achieve a net-zero building, one of the employed solutions was replacing the steel–concrete composite flooring system with a steel–timber hybrid flooring system, which may affect the structural and building performance compared to the reference building. However, the carbon reduction resulting from the reduced weight of the building and subsequently reduced building material offsets the carbon emissions required to address the structural and building performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Organization. Climate Change and Health. 2023. Available online: https://www.who.int/news-room/fact-sheets/detail/climate-change-and-health#:~:text=Key%20facts,highly%20susceptible%20to%20climate%20change (accessed on 1 May 2025).

- Guggemos, A.A.; Horvath, A. Decision-support tool for assessing the environmental effects of constructing commercial buildings. J. Archit. Eng. 2006, 12, 187–195. [Google Scholar] [CrossRef]

- De Lassio, J.; França, J.; Espirito Santo, K.; Haddad, A. Case study: LCA methodology applied to materials management in a Brazilian residential construction site. J. Eng. 2016, 2016, 8513293. [Google Scholar] [CrossRef]

- Thinkstep-anz. The Carbon Footprint of New Zealand’s Built Environment: Hotspot or Not? Thinkstep-anz: South Perth, WA, Australia, 2018. [Google Scholar]

- Andisheh, K. Development of steel circularity passport: Literature review, research gaps, and program rules in New Zealand. Waste Manag. Bull. 2024, 2, 11–27. [Google Scholar] [CrossRef]

- ShahMohammadi, A.; Andisheh, K.; Coyle, C. A Low-Carbon Circular Design Guidance Framework for Building Designers; Heavy Engineering Research Association (HERA): Auckland, New Zealand, 2024; Available online: https://hera.org.nz/groundbreaking-low-carbon-circular-design-guidance-now-here/ (accessed on 1 May 2025).

- ShahMohammadi, A.; Andisheh, K.; Coyle, C.; El Sarraf, R.; Balador, Z.; Lack-Roberts, A.; Ellis, G.; Grindley, J.; McCluskey, Z.; Riley-Smith, H.; et al. Low Carbon Circular Design Guide for Steel and Hybrid Low-Rise Buildings; Heavy Engineering Research Association (HERA): Auckland, New Zealand, 2024; Available online: https://hera.org.nz/product/hera-r4-166/ (accessed on 1 May 2025).

- Baker-Brown, D. The Reuse Atlas: A Designer’s Guide Towards the Circular Economy; RIBA Publishing: London, UK, 2017. [Google Scholar]

- Cheshire, D. The Handbook to Building a Circular Economy; RIBA Publishing: London, UK, 2021. [Google Scholar]

- LETI. Circular Economy and Carbon in Construction; LETI: London, UK, 2021. [Google Scholar]

- LETI. Circular Economy for the Built Environment: A Summary; LETI: London, UK, 2022. [Google Scholar]

- European Parliament; Council of the European Union. Waste and Repealing Certain Directives (Directive 2008/98/EC). Article 4. 2008. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj/eng (accessed on 1 May 2025).

- The Institution of Structural Engineers (IStructE). The Hierarchy of Net Zero Design; IStructE: London, UK, 2021. [Google Scholar]

- BSI (British Standards Institution). PAS 2080:2023, Carbon Management in Buildings and Infrastructure; BSI: London, UK, 2023. [Google Scholar]

- Addis, W.; Schouten, J. Design for Reconstruction, Principles of Design to Facilitate Reuse and Recycling. 2004. Available online: https://trid.trb.org/View/783851 (accessed on 1 May 2025).

- Greater London Authority. London Plan Guidance: Circular Economy Statements; Greater London Authority: London, UK, 2022. [Google Scholar]

- Cheshire, D. Building Revolutions: Applying the Circular Economy to the Built Environment; RIBA Publishing: London, UK, 2019. [Google Scholar]

- Baker-Brown, D.; Gowler, P.; Arnold, W. Circular Economy and Reuse: Guidance for Designers; IStructE: London, UK, 2023. [Google Scholar]

- Han, X.J.; Yu, J.L.; Xia, Y.; Wang, J.J. Spatiotemporal characteristics of carbon emissions in energy-enriched areas and the evolution of regional types. Energy Rep. 2021, 7, 7224–7237. [Google Scholar] [CrossRef]

- Xi, C.; Cao, S.-J. Challenges and future development paths of low carbon building design: A review. Build 2022, 12, 163. [Google Scholar] [CrossRef]

- GB/T 51366-2019; Standard for Building Carbon Emission Calculation. MOHURD: Beijing, China, 2019.

- Gan, V.J.L.; Cheng, J.C.P.; Lo, I.M.C.; Chan, C.M. Developing a CO2-e accounting method for quantification and analysis of embodied carbon in high-rise buildings. J. Clean. Prod. 2017, 141, 825–836. [Google Scholar] [CrossRef]

- Dani, A.A.; Roy, K.; Andisheh, K.; Lim, J.B.P. Investigating life cycle assessment practices in the building and construction industry in New Zealand. Build. Environ. 2025; under review. [Google Scholar]

- Lei, X.; Zhao, K. Exploring and assessing construction companies’ ESG performance in sustainability. Glob. NEST J. 2024, 26, 1–9. [Google Scholar] [CrossRef]

- EN 15978; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Standards: Pilsen, Czech Republic, 2011.

- Andisheh, K.; Mehrjoo, A.; Moaveni, B.; Eftekhar Azam, S. Structural Health Monitoring of In-Service Buildings: Foundation to Construction 4.0; HERA: Auckland, New Zealand, 2025. [Google Scholar]

- Wang, H.J.; Zeng, Z.T. A multi-objective decision-making process for reuse selection of historic buildings. Expert Syst. Appl. 2010, 37, 1241–1249. [Google Scholar] [CrossRef]

- Roijers, D.M.; Whiteson, S.; Brachman, R.; Stone, P. Multi-Objective Decision Making; Morgan and Claypool: San Rafael, CA, USA, 2017; pp. 9–17. [Google Scholar]

- Lei, X.; Xu, X. The ‘Spider Web’ of Venture Capital: An Invisible Force Driving Corporate Green Technology Innovation. Technol. Soc. 2025, 82, 102882. [Google Scholar] [CrossRef]

- Royal Institute of British Architects. Plan of Work. 2020. Available online: https://www.architecture.com/knowledge-and-resources/resources-landing-page/riba-plan-of-work (accessed on 1 May 2025).

- ISO 14040; Environmental Management Life Cycle Assessment Principal and Framework. ISO (International Organisation for Standardization): Genova, Switzerland, 2006.

- EN 15804; Sustainability of Construction Works – Environmental Product Declarations – Core Rules for the Product Category of Construction Products. CEN (European Committee for Standardization): Brussels, Belgium, 2019.

- Dowdell, D.C.; Berg, B.L.; Butler, J.; Pollard, A.R. New Zealand Whole-Building Whole-of-Life Framework: LCAQuick v3. 4-a Tool to Help Designers Understand How to Evaluate Building Environmental Performance; BRANZ: Judgeford, New Zealand, 2020. [Google Scholar]

- HERA (New Zealand Heavy Engineering Research Association). Report R5-89. Steel Recycling; HERA: Auckland, New Zealand, 2022. [Google Scholar]

- Saade, M.R.M.; Yahia, A.; Amor, B. Is crushed concrete carbonation significant enough to be considered as a carbon mitigation strategy? Environ. Res. Lett. 2022, 17, 104049. [Google Scholar] [CrossRef]

- RICS. Code of Measuring Practice, 6th ed.; Royal Institution of Chartered Surveyors: London, UK, 2015; Available online: https://www.rics.org/profession-standards/rics-standards-and-guidance/sector-standards/real-estate-standards/code-of-measuring-practice (accessed on 1 May 2025).

- EPD. Various Material Environmental Product Declarations. 2024. Available online: https://epd-australasia.com/ (accessed on 1 May 2025).

- Tokazhanov, G.; Galiyev, O.; Lukyanenko, A.; Nauyryzbay, A.; Ismagulov, R.; Durdyev, S.; Turkyilmaz, A.; Karaca, F. Circularity assessment tool development for construction projects in emerging economies. J. Clean. Prod. 2022, 362, 132293. [Google Scholar] [CrossRef]

| Field | Strategy | Strategy Definition | Solutions |

|---|---|---|---|

| Low- Carbon (New and Existing) | Less Material Usage | This strategy focuses on minimizing material usage to reduce upfront carbon emissions, without compromising the performance and integrity of the structure. | Optimize Concrete Strength Class |

| Maximize Utilization and Minimize Over-specifying | |||

| Minimize Irregularities and Transfers | |||

| Efficient Structural Choices | |||

| Utilize Higher-Strength Steel | |||

| Lower Carbon Intensity | This strategy focuses on maximizing the utilization of materials with lower embodied carbon content. | Optimize Concrete Strength Class | |

| Maximize Utilization and Minimize Over-specifying | |||

| Minimize Irregularities and Transfers | |||

| Efficient Structural Choices | |||

| Circular (New buildings) | Design for Longevity | Design that maximizes building lifetimes through maintenance, repair, or refurbishment without compromising structural integrity by using durable materials and seismic/fire-resilient design principles. | Durability |

| Seismic resilience | |||

| Fire resilience | |||

| Design for Adoptability | Design that ensures buildings can be easily repurposed to meet future needs by incorporating adaptability and anticipating changes, extending their useful life and reducing the need for new construction. It accommodates potential alterations within the building’s design life. | Spatial flexibility and increased loading allowance | |

| Adoptable to future vertical expansion | |||

| Design for Disassembly | Design that enables non-destructive dismantling of buildings for component and material reclamation, prioritizing mechanical connections over permanent bonds and allowing easy replacement or upgrades, in synergy with Design for adaptability. | Reversible connections | |

| Design in layers | |||

| Design with Circular Materials | Design focused on non-virgin sources such as reclaimed or highly recycled materials, prioritizing reusability and recyclability for virgin materials, and emphasizing the use of EPDs and material passports for lifecycle transparency and traceability. | Utilize reclaimed materials | |

| Construction 4.0 | Construction 4.0 is an innovative approach that uses advanced technologies, digitalization, and sustainable practices to reduce carbon emissions and improve environmental performance in building projects. | Use material passports | |

| Utilize BIM | |||

| Prepare for digital twin | |||

| Structural Health Monitoring | |||

| Circular (Existing Buildings) | Reuse through Retention or Refurbishment | Building life extension through restoration, refinishing, and futureproofing, while preserving most of the building’s fabric and minimizing major replacements. This may include retrofitting to enhance carbon efficiency. | A wide variety of solutions are available, but to leverage their advantages, it is crucial to: identify building potential, engage early with clients, and conduct a general and loading assessment of the building. |

| Adaptive Reuse through Repurpose | Building life extension through significant alterations or refurbishment, transforming spaces by updating components with shorter lifespans to meet diverse needs, such as converting industrial areas into residential spaces or vice versa. | ||

| Reclaim | Deconstruction for reclamation according to a disassembly plan, cleaning and repairing components, and aiming to minimize reprocessing or remanufacturing. This approach facilitates material reclamation for future use, with a preference for on-site reuse before considering off-site options. | Selective and non-destructive dismantling is used to disassemble buildings according to a planned process, followed by cleaning and repairing components to minimize reprocessing or remanufacturing. | |

| Recycle and Rebuild | Demolition with recycling is essential when other options are infeasible, recovering recyclable and reusable materials through sorting to minimize landfill waste. Recycling reprocesses end-of-life materials into new products or substances for original or alternative uses. | Partial demolition, and utilize deconstruction methodologies |

| Strategy | Solutions | Definition of the Solution |

|---|---|---|

| Design for Disassembly | Reversible connections | Replacing welded shear studs by high-strength bolt studs to enable steel beams can be disassembled and reused. |

| Design for Longevity | Seismic resilience using reuseable low-damage MRF | Moment Resisting Steel Frame with OSHJs to enable the structure to withstand and recover from seismic events while minimizing damage and the environmental impact associated with their construction, maintenance, and repair. |

| Seismic resilience using reuseable low-damage concrete shear walls | Post-tensioned dissipative rocking concrete shear walls to enable the structure to withstand and recover from seismic events while minimizing damage and the environmental impact associated with their construction, maintenance, and repair. | |

| Low Carbon Intensity | Specify Low-Carbon Steel | Utilizing low embodied carbon structural steel |

| Specify Low-Carbon Concrete | Utilizing low embodied carbon concrete materials | |

| Specify Low-carbon Reinforcement | Utilizing low embodied carbon steel reinforcement | |

| Specify Certified Sustainable Timber | Replace steel–concrete composite with steel–timber hybrid flooring systems |

| Key Inputs Material Category | Carbon Intensity Data Source |

|---|---|

| Concrete | Allied Concrete Ltd.: 2019 (Dunedin, New Zealand); EPD—ready mixed concrete using Holcim supplied cement (EPD Registration No. S-P-00555), version 1.0, accessed from www.epd-australasia.com on 1 May 2025. The Allied Concrete EPD 2019 for 30MPa concrete has been used in LCA modeling as it is close to the baseline (for Auckland, corresponding to 344 kgCO2eq/m3). The baseline is provided by the Infrastructure Sustainability Council (ISC) in 2020 from the Materials Calculator NZ 2.0. |

| Low-carbon concrete (EC40) | Firth Industries Ltd. (2020); EPD—for ready-mixed concrete (EPD Registration No. S-P-02050), accessed from www.epd-australasia.com on 1 May 2025. Not provided in Firth EPD (ci2). Provided by Firth based on outputs from EC3 Embodied Carbon Concrete Calculator tool. |

| Reinforcing steel | Pacific Steel (NZ) Ltd. (2018), EPD—Seismic (EPD Registration No. S-P-01002), accessed from www.epd-australasia.com |

| Low-carbon reinforcing steel | NatSteel Holdings Pte Ltd. (2023), EPD—(Berg EN EPD No. 000379), accessed from www.greenbooklive.com on 1 May 2025 |

| Structural steel | Data source: Liberty (OneSteel Manufacturing Pty Ltd.) (2020), EPD—hot rolled structural and rail (EPD Registration No. S-P-01547); version 1, accessed from www.epd-australasia.com on 1 May 2025. |

| Low-carbon structural steel | Hyundai (2019): EPD—Section Shape Steel from UL Environment (declaration no. 4789119110.101.1), accessed from https://spot.ul.com/ on 1 May 2025. |

| CLT | Data source: Red Stag (2022); EPD—Cross-laminated timber (CLT) (EPD Registration No.: S-P-03711), accessed from www.epd-australasia.com on 1 May 2025 |

| No. | Strategy | Solution | Superstructure Carbon Emission (kgCO2eq/m2) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Life Cycle Modulus | Total (Non-Biogenic) | Biogenic | Carbon Reduction % | Cumulative Carbon Reduction % | |||||

| A | C | D | |||||||

| Reference Building | 377 | 14 | −143 | 248 | 0 | Not Applicable | |||

| 1 | Design for disassembly | Reversible connection in flooring systems | 377 | 13 | −153 | 237 | 0 | 5 | 5 |

| 2 | Design for longevity | Seismic resilience (steel frame design) | 377 | 13 | −169 | 221 | 0 | 6 | 11 |

| 3 | Low carbon intensity | Specify Low-carbon concrete | 356 | 14 | −169 | 201 | 0 | 8 | 19 |

| Specify Low-carbon structural steel | 166 | 17 | −33 | 150 | 0 | 21 | 40 | ||

| Specify Low-carbon reinforcing rebs | 80 | 17 | 9 | 106 | 0 | 17 | 57 | ||

| No. | Strategy (Associated Solutions) | Type of Foundation [Site Specific Characteristics] | Substructure Carbon Emission (kgCO2eq/m2) | |||||

|---|---|---|---|---|---|---|---|---|

| Life Cycle Modulus | Total (Non-Biogenic) | Biogenic | Carbon Reduction % | |||||

| A | C | D | ||||||

| Reference building | Raft Foundation [Shallow foundations are possible, Assumed gravels near surface, ultimate bearing capacity of 600 kPa, Minimal geotechnical risk] | 236 | 0 | 0 | 236 | 0 | Not Applicable | |

| L2: Less material usage (L2.4 Efficient structural choices) | 32 9.3 m Screw Piles, ground beams and slab [Bearing capacity is less than option 1, but founding on shallow gravels is possible] | 119 | 0 | 0 | 119 | 0 | 50 | |

| A1–A3 (kg CO2 e) | A–D (kg CO2 e) | |

| Normal Steel (Pacific Steel) | 2.39 × 105 | 1.61 × 105 |

| Normal Concrete (Baseline 2020) | 1.43 × 105 | 1.43 × 105 |

| Sum (normal) | 3.82 × 105 | 3.04 × 105 |

| Low Carbon Rebars (Natsteel) | 3.30 × 104 | 3.16 × 104 |

| Low Carbon Concrete (EC40%) | 8.55 × 104 | 8.55 × 104 |

| Sum (low-carbon) | 1.19 × 105 | 1.17 × 105 |

| Reduction by using low-carbon steel and concrete simultaneously | 69% | 62% |

| No. | Strategy | Solution | Superstructure Carbon Emission (kgCO2eq/m2) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Life Cycle Modulus | Total (Non-Biogenic) | Biogenic | Carbon Reduction % | Cumulative Carbon Reduction % | |||||

| A | C | D | |||||||

| Reference Building | 377 | 14 | −143 | 248 | 0 | Not Applicable | |||

| 1 | Design for disassembly | Reversible connection in flooring systems | 377 | 13 | −153 | 237 | 0 | 5 | 5 |

| 2 | Design for longevity | Seismic resilience (steel frame design) | 377 | 13 | −169 | 221 | 0 | 6 | 11 |

| Seismic resilience (concrete wall design) | 377 | 13 | −186 | 204 | 0 | 9 | 20 | ||

| 3 | Low carbon intensity | ow-carbon concrete in superstructure | 356 | 14 | −186 | 184 | 0 | 8 | 28 |

| Specify low-carbon structural steel | 166 | 17 | −50 | 133 | 0 | 21 | 49 | ||

| Specify low-carbon reinforcing rebs | 80 | 17 | −5 | 92 | 0 | 17 | 66 | ||

| Steel–timber hybrid floor | 77 | 13 | −5 | 85 | −93 | 44 | 103 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andisheh, K.; ShahMohammadi, A.; Coyle, T. A Practical Framework for the Design of Low-Carbon and Circular Building Structures. Sustainability 2025, 17, 5337. https://doi.org/10.3390/su17125337

Andisheh K, ShahMohammadi A, Coyle T. A Practical Framework for the Design of Low-Carbon and Circular Building Structures. Sustainability. 2025; 17(12):5337. https://doi.org/10.3390/su17125337

Chicago/Turabian StyleAndisheh, Kaveh, Amir ShahMohammadi, and Troy Coyle. 2025. "A Practical Framework for the Design of Low-Carbon and Circular Building Structures" Sustainability 17, no. 12: 5337. https://doi.org/10.3390/su17125337

APA StyleAndisheh, K., ShahMohammadi, A., & Coyle, T. (2025). A Practical Framework for the Design of Low-Carbon and Circular Building Structures. Sustainability, 17(12), 5337. https://doi.org/10.3390/su17125337