Abstract

The growing need for healthy and sustainable food alternatives has led to a rapid increase in vegan burgers on the market. Specifically, plant-based burgers using legumes as a protein substitute are amongst the most widespread choices for consumers. While these products can offer environmental benefits over traditional meat-based options, further optimization in both ecological and economic aspects can be achieved. This study conducted a life cycle assessment (LCA) and life cycle costing (LCC) analysis to evaluate and optimize the environmental and economic life cycle of a legume-based vegan burger. LCA was performed in accordance with the recommendations of the ISO 14040 and 14044 series, and ReCiPe 2016 Hierarchist served as the impact assessment methodology. For this purpose, a base case scenario, relying on imported raw materials and conventional packaging for a legume-based vegan burger, was established to serve as the comparison benchmark, and various alternative scenarios were examined, focusing on minimizing the distance between cultivation and processing areas for key legume ingredients and improving packaging materials. The results indicate that reducing transportation distances for raw ingredients and using bio-polyethylene packaging significantly enhance sustainability. Specifically, the legume-based vegan burger of the base case scenario had a carbon footprint of 1.30 kg CO2 eq. and a total life cycle cost of EUR 2.43 per two pieces. In contrast, the optimized scenario, which incorporated shorter transportation distances and bio-polyethylene packaging, achieved a carbon footprint of 0.51 kg CO2 eq. and a reduced cost of EUR 2.37. The findings of the present work highlight the potential for further environmental and economic improvements in vegan burger production through logistics optimization and selection of climate-friendly packaging solutions, thus contributing to sustainable development.

1. Introduction

The growing need for healthier and more sustainable food choices has significantly influenced the food industry, leading to an increased demand for plant-based innovations [1]. Specifically, the global plant-based food market was valued at approximately USD 41.06 billion in 2022 and is projected to exceed USD 75 billion by 2028, growing at a compound annual growth rate of 10.95% [2]. Vegan burgers, particularly those made from legumes as a primary protein source, have gained substantial popularity due to their lower environmental impact compared to traditional meat-based products [3,4,5]. These plant-based options are often perceived as more sustainable, as they typically require fewer natural resources and generate lower greenhouse gas emissions [6,7]. However, despite their advantages, the production of legume-based vegan burgers still presents environmental and economic challenges, such as high water and land use during legume cultivation, energy-intensive processing methods (e.g., extrusion and texturization), and the logistics of sourcing ingredients, which require further investigation and optimization [8].

One of the main concerns associated with plant-based burger production is the environmental footprint of raw material sourcing and transportation [9]. Many manufacturers rely on imported legumes, which contribute to high transportation emissions and increased overall environmental footprints [10]. Additionally, a holistic approach in the evaluation of the food-packaging unit is needed. Conventional packaging materials, particularly single-use plastics, further exacerbate environmental concerns by generating significant waste and increasing dependency on fossil fuel-based resources [11], and the materials used need to be optimized to minimize food and packaging waste [12]. As a result, optimizing both ingredient sourcing and packaging strategies is essential for improving the overall environmental sustainability of plant-based burgers while maintaining economic feasibility.

From an economic perspective, the cost structure of legume-based vegan burgers is influenced by various factors, including raw material prices, processing expenses, and packaging costs [13,14]. According to a recent report, plant-based meat is, on average, 67% more expensive compared to its animal-based counterparts [15]. The reliance on imported ingredients often introduces price volatility and supply chain uncertainties, which can affect the affordability and market competitiveness of these products [16,17]. Furthermore, although sustainable packaging solutions are available, they often come with higher initial costs, potentially posing economic barriers for manufacturers [18]. Therefore, it is crucial to assess the financial implications of alternative production strategies to ensure both sustainability and economic viability.

Life cycle assessment (LCA) and life cycle costing (LCC) are essential methodologies for evaluating the environmental and economic impacts of food products across their entire life cycle. LCA analyzes inputs, outputs, and environmental effects at each stage, from raw material extraction to disposal, identifying key hotspots like resource use, emissions, and waste, and providing practical recommendations to enhance sustainability [19,20]. LCC, on the other hand, assesses total costs, including investment, operation, and end-of-life expenses, pinpointing financial inefficiencies and optimization opportunities [21,22]. The holistic approach of integrating environmental and economic insights can help stakeholders make informed, sustainable decisions about food production and supply chains.

The main objective of this study was to utilize LCA and LCC methodologies to evaluate and identify strategies for enhancing the environmental and economic sustainability of a legume-based vegan burger. Although numerous studies have explored sustainability in food production, particularly regarding life cycle assessment (LCA) and life cycle costing (LCC), the integration of both methodologies in optimizing plant-based meat alternatives remains limited. Notably, Masi et al. [23] examined LCA-based decision-making in the appliance sector, offering useful insights into how comparative impact analysis can guide product-level environmental optimization. Similarly, Silva et al. [24] proposed a conceptual framework for eco-design in food systems, emphasizing the integration of sustainability across the supply chain. These contributions support the growing recognition of the need for holistic, cross-stage sustainability evaluation frameworks. However, few studies combine LCA and LCC in a practical food production setting. By analyzing a conventional production scenario and comparing it with alternative approaches emphasizing local ingredient sourcing and using sustainable packaging materials, this research seeks to offer recommendations for improving the sustainability and cost-effectiveness of plant-based food products, thus advancing the current knowledge regarding their overall sustainability. Furthermore, the findings of this study are not limited to the examined product but can also be applied to other areas of food production, contributing to broader advancements in sustainable food systems and overall, in sustainable development.

2. Materials and Methods

The LCA study was conducted in accordance with the guidelines established by the ISO 14040 series (ISO 14040:2006 and ISO 14044:2006) [25]. The environmental impact assessment was carried out using the ReCiPe 2016 (Hierarchist) methodology, which converts life cycle inventory data into a comprehensive set of environmental impact scores through characterization factors. The analysis was performed using the LCA for Experts software (version 10.6.2.9), developed by Sphera Solutions GmbH, based in Echterdingen, Stuttgart, Germany.

For the LCC analysis, Microsoft Excel (v15.0) was used to assess all relevant economic flows. This study focused solely on operating expenditures (OPEXs), while capital expenditures (CAPEXs) were excluded. CAPEXs were not included in the analysis since no modifications were made to the production process, allowing the legume-based vegan burger to be manufactured using existing equipment and standard process lines commonly used in the food and beverage industry.

2.1. Goal and Scope

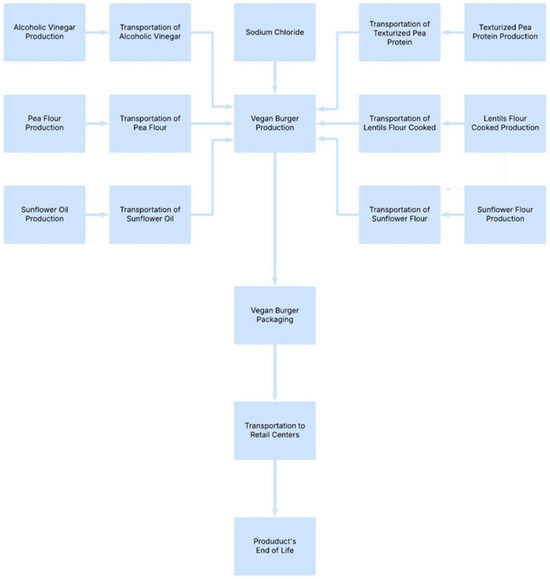

The main goal of the present study is to assess the environmental and economic performance of a legume-based vegan burger as well as to evaluate different scenarios that utilize local sourcing of ingredients and the use of packaging materials in terms of environmental and economic performance. For this purpose, the production of a legume-based vegan burger was assessed (Figure 1) using data provided by Fattoria Solidale del Circeo, an Italian SME company that specializes in the production of legume-based food products. Subsequently, different scenarios were studied based on the transportation distances of the basic legume ingredients (pea protein, pea flour, and lentil flour used in a ratio of 1:2.4:1, respectively) and on the utilization of alternative packaging materials.

Figure 1.

Flowchart of legume-based vegan burger production.

2.2. Functional Unit

The functional unit of the present study was 1 package of legume-based vegan burgers that contained two vegan patties. The details about the ingredient composition of the final product are presented in the Life Cycle Inventory Section.

2.3. System Boundaries

For the assessment of the environmental and economic performance of the legume-based vegan burger, a ‘cradle-to-grave’ approach was selected. Based on the selected system boundaries, the LCA and LCC include the extraction and acquisition of raw materials, the production and packaging of the vegan burger, along with the transportation to the retail centers and the end-of-life phase of the product. The selected approach is particularly effective for evaluating the environmental and economic impacts of the studied product while identifying opportunities for improvement throughout its entire life cycle.

2.4. Data Requirements

The data regarding the production, packaging, transportation to retail center and the end-of-life of the legume-based vegan burger were obtained following communication with Fattoria Soidale del Circeo, with the final product being depicted in Figure 2. Additionally, scientific databases, including LCA for Experts and Ecoinvent, were utilized to obtain the data related to the production of the raw ingredients and the alternative packaging materials. These sources provide a comprehensive representation of all involved processes, and by consistently utilizing the same data sources and assumptions across all stages of the analysis, the potential effects of variability are minimized, ensuring the reliability and accuracy of the findings.

Figure 2.

Legume-based vegan burger product.

2.5. Assumptions and Limitations

The data on production, packaging, transportation, end-of-life stages, and shelf-life were obtained through collaboration with Fattoria Soidale del Circeo. This study is based on a conventional vegan burger producer, with packaged products having a shelf-life of 40 days in most scenarios. Across all scenarios, the core processes remained unchanged, with only the packaging material varying in four alternative cases. More specifically, four different alternative scenarios were studied, with the key assumptions being listed below:

- Polyethylene terephthalate (PET) packaging material:

- Product shelf-life: 40 days.

- Recycling percentage: 50%.

- Bio Polyethylene (bio-PE) packaging material:

- Product shelf-life: 40 days.

- Recycling percentage: 50%.

- Polyethylene (PE) packaging material:

- Product shelf-life: 40 days.

- Recycling percentage: 50%.

- Polylactic acid (PLA) packaging material:

- Product shelf-life: 20 days.

- Recycling percentage: 50%.

Specifically, the recycling percentage of the packaging materials was based on a recent European report, available online via the Statista Research Department [26].

2.6. LCA and LCC Inventory

Table 1 presents the input and output data of every process that is involved in the production of the legume-based vegan burger, as depicted in Figure 1. Table 2 and Table 3 present the transportation distances of the main ingredients, along with the final product, to the company’s facilities, and the inventory utilized in the LCC analysis, respectively.

Table 1.

LCA inventory of the base case scenario.

Table 2.

Transportation distances of the main ingredients and the final product.

Table 3.

LCC inventory of the base case scenario.

A detailed overview of the scenarios studied in the present work is presented in Table 4.

Table 4.

Studied scenarios breakdown.

3. Results and Discussion

3.1. Base Case Scenario

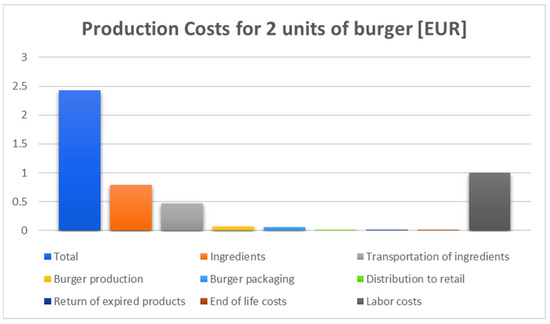

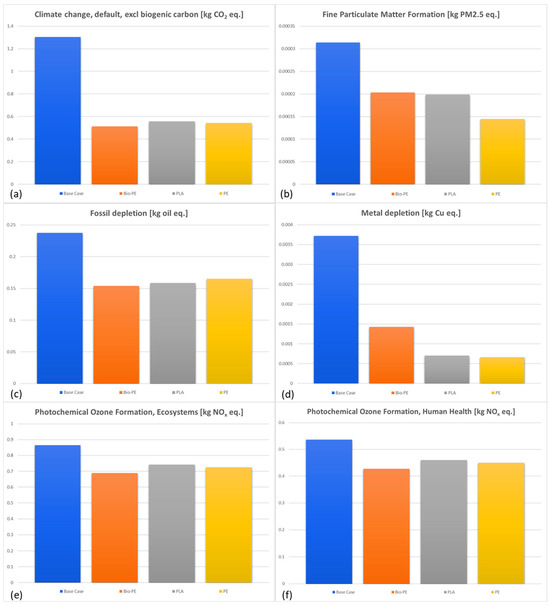

The environmental impact and the breakdown of associated cost flows of the legume-based vegan burger are presented in Figure 3 and Figure 4, respectively.

Figure 3.

Environmental impact of the base case scenario on (a) climate change, default, excluding biogenic carbon (kg CO2 eq.), (b) fine particulate matter formation (kg PM2.5 eq.), (c) fossil depletion (kg oil eq.), (d) metal depletion (kg Cu eq.), (e) photochemical ozone formation, ecosystems (kg NOx eq.), and (f) photochemical ozone formation, human health (kg NOx eq.).

Figure 4.

Total cost and cost per production component for producing 2 pieces of the legume-based burger.

The environmental assessment of the base case scenario for the legume-based vegan burger reveals notable impacts across multiple environmental categories. Among these, climate change, fossil depletion, and fine particulate matter formation emerge as the most significant ones. The largest contributors to these impacts are the production stage and the transportation of the primary legume ingredients. The reliance on imported ingredients increases greenhouse gas (GHG) emissions due to long-distance transportation [27], while fossil-based packaging materials, such as polyethylene terephthalate (PET), further increases the impact of resource depletion [28,29].

The carbon footprint of the base case scenario is estimated at 1.30 kg CO2-equivalent for each package that includes two vegan patties, with transportation playing a major role in these emissions. Moreover, the utilization of fossil-based packaging materials, such as polyethylene terephthalate (PET), further contributes to the product’s environmental burden [28], even when recycled. Additionally, the formation of fine particulate matter is largely associated with fossil fuel combustion during the transportation and production of the primary ingredients, posing air pollution risks [30,31]. The depletion of metal resources, although less significant, arises from the use of industrial machinery in manufacturing processes. Lastly, photochemical ozone formation is driven by nitrogen oxide emissions from fossil fuel combustion, which contributes to ground-level ozone and smog formation [32].

Based on the results regarding the environmental performance of the base case scenario, it is evident that the transportation of the main legume ingredients and the conventional packaging material are among the primary environmental hotspots. Therefore, implementing efficient strategies like the local sourcing of ingredients and the adoption of more sustainable solutions for the packaging material can lead to a significant improvement in the environmental performance of the legume-based vegan burger.

The economic assessment of the base case scenario indicates that labor costs and the acquisition of raw ingredients are the most significant contributors to the total production cost of the legume-based vegan burger. The cost of raw materials, particularly key ingredients such as texturized pea protein and pea flour, represents a substantial portion of the overall expenses. Additionally, while transportation does not account for the largest share of costs, it remains a critical factor due to the long distances required for sourcing primary ingredients, leading to increased logistics expenses. This suggests that optimizing transportation routes or prioritizing locally sourced ingredients could yield both economic and environmental benefits. Overall, the total cost associated with the production of two pieces of the legume-based vegan burger is approximately EUR 2.43, which equals approximately USD 2.75.

Although packaging costs have a relatively lower financial impact compared to labor and raw material acquisition, the environmental footprint resulting from packaging is considerable, particularly due to the use of conventional plastics such as PET [33]. Bio-based options could contribute to improving the overall sustainability of the product [34], even if today, their cost is much higher due to limited supply chains and end-of-life sorting facilities. This holistic approach offers an opportunity to enhance both the economic and environmental performance of legume-based vegan burgers.

3.2. Lentil Flour Scenarios

The results regarding the environmental and economic footprint of different scenarios regarding the transportation of the lentil flour are presented in Figure 5 and Figure 6, respectively.

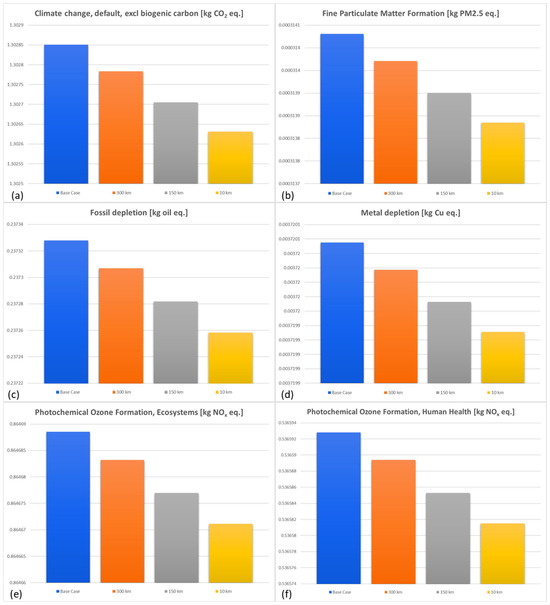

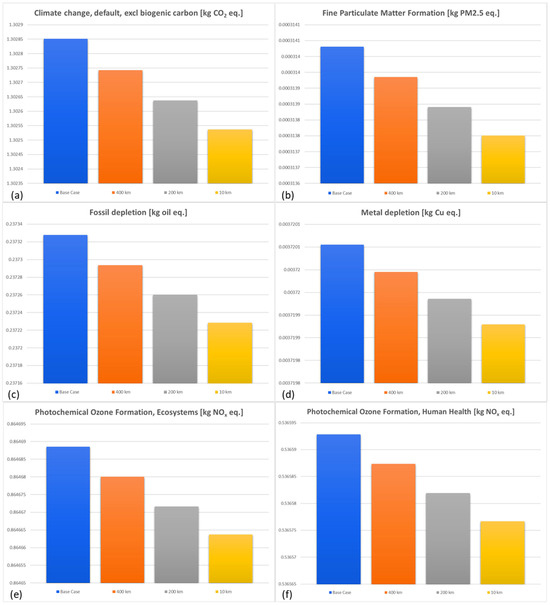

Figure 5.

Environmental impact of the different transportation distances of lentil flour on (a) climate change, default, excluding biogenic carbon (kg CO2 eq.), (b) fine particulate matter formation (kg PM2.5 eq.), (c) fossil depletion (kg oil eq.), (d) metal depletion (kg Cu eq.), (e) photochemical ozone formation, ecosystems (kg NOx eq.), and (f) photochemical ozone formation, human health (kg NOx eq.).

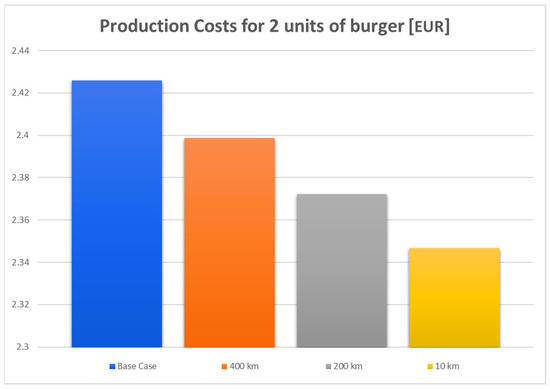

Figure 6.

Total costs associated with the production of 2 pieces of the legume-based vegan burger in the different transportation distances of lentil flour.

Based on the results of the base case scenario, a major factor that influences the environmental footprint of the vegan burger is the transportation distance of its ingredients, with lentil flour being one of the primary ingredients. The analysis evaluates different transportation scenarios, ranging from 426 km in the base case to a more sustainable 10 km alternative.

The results indicate that the minimization of transportation distances can reduce environmental burdens, particularly in terms of climate change impact, fossil depletion, and fine particulate matter formation. Greenhouse gas emissions associated with lentil flour transportation decline sharply as the distance decreases. In the optimized scenario, where the distance is reduced to 10 km, carbon emissions from transportation are reduced by more than 85% compared to the base case. Fossil depletion follows a similar trend, as long-distance transportation requires substantial diesel fuel consumption, which contributes to the depletion of non-renewable resources. The reduction in fine particulate matter emissions is also notable, as shorter transport distances mean fewer diesel truck emissions that contribute to air pollution.

However, due to the small quantities of lentil flour required for the production of the legume-based vegan burger, the minimization of the transportation distance does not significantly improve the overall sustainability of the final product.

A cost breakdown analysis of the different lentil flour transportation scenarios, as illustrated in Figure 6, indicates that reducing transportation distances has a marginal impact on overall production costs. While shorter transportation routes lead to lower fuel consumption and associated expenses, the cost savings remain relatively minor due to the small quantity of lentil flour used in the burger formulation. Consequently, while local sourcing of lentil flour presents both environmental benefits and economic benefits, the impact is limited.

3.3. Pea Protein Scenarios

The results relating to the environmental and economic footprint of different scenarios regarding the transportation of the pea protein are presented in Figure 7 and Figure 8, respectively.

Figure 7.

Environmental impact of the different transportation distances of pea protein on (a) climate change, default, excluding biogenic carbon (kg CO2 eq.), (b) fine particulate matter formation (kg PM2.5 eq.), (c) fossil depletion (kg oil eq.), (d) metal depletion (kg Cu eq.), (e) photochemical ozone formation, ecosystems (kg NOx eq.), and (f) photochemical ozone formation, human health (kg NOx eq.).

Figure 8.

Total costs associated with the production of 2 pieces of the legume-based vegan burger in the different transportation distances of pea protein.

The transportation of pea protein plays a crucial role in determining the environmental footprint of the legume-based vegan burger. The study examines various scenarios in which the transport distance of pea protein is progressively reduced from 604 km in the base case to an optimized 10 km scenario. The findings indicate that minimizing transportation distances leads to a significant reduction in environmental burdens, particularly in terms of climate change impact, fossil fuel depletion, and fine particulate matter formation.

As the transport distance decreases, greenhouse gas emissions decline considerably, with CO2-equivalent emissions from pea protein transportation dropping by more than 85% in the optimized scenario, as observed in the scenarios evaluating the transportation distance of lentil flour. Similarly, fossil depletion is notably reduced, as shorter transport routes lower diesel fuel consumption, thereby decreasing reliance on non-renewable energy sources. Additionally, the reduction in air pollution-related impacts, such as fine particulate matter emissions, highlights the environmental benefits of minimizing long-distance transportation.

However, despite the considerable reductions in transportation-related emissions, the overall impact of this optimization on the final product’s sustainability remains limited due to the relatively small proportion of pea protein used to produce the legume-based burger. While sourcing pea protein from local suppliers presents clear environmental advantages, its contribution to the total footprint of the product must be considered in the broader context of the entire supply chain.

The cost analysis of different transportation distances for pea protein, as shown in Figure 8, yields results similar to those observed for lentil flour. While reducing the transport distance from 604 km to an optimized 10 km scenario leads to savings in fuel consumption and logistics, the overall impact on the total production cost remains minimal. This is primarily due to the relatively small proportion of pea protein used in the burger formulation. However, as with lentil flour, sourcing pea protein locally, in conjunction with other sustainability optimizations, can contribute to incremental cost reductions and environmental benefits, emphasizing the importance of a holistic approach to supply chain optimization.

3.4. Pea Flour Scenarios

The results regarding the environmental and economic footprint of different scenarios regarding the transportation of the pea flour are presented in Figure 9 and Figure 10, respectively.

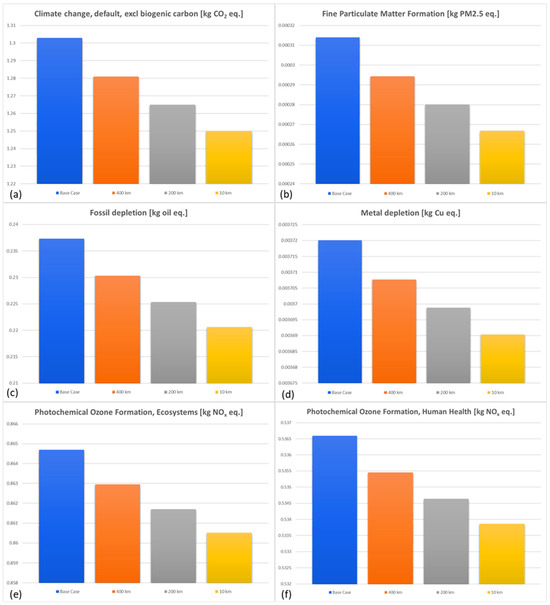

Figure 9.

The environmental impact of the different transportation distances of pea flour on (a) climate change, default, excluding biogenic carbon (kg CO2 eq.), (b) fine particulate matter formation (kg PM2.5 eq.), (c) fossil depletion (kg oil eq.), (d) metal depletion (kg Cu eq.), (e) photochemical ozone formation, ecosystems (kg NOx eq.), and (f) photochemical ozone formation, human health (kg NOx eq.).

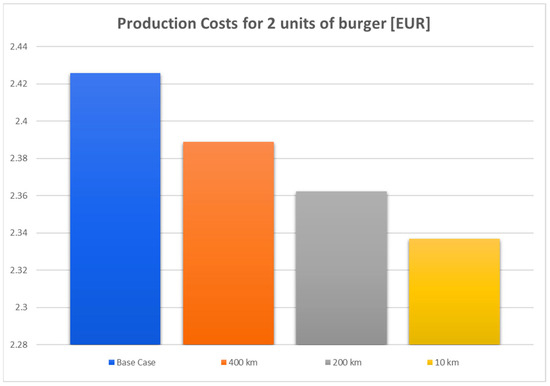

Figure 10.

Total costs associated with the production of 2 pieces of the legume-based vegan burger in light of the different transportation distances of pea flour.

Pea flour is a key ingredient in the legume-based vegan burger, and its transportation distance plays a significant role in shaping the overall environmental footprint of the product. In the base case scenario, pea flour is transported over a 678 km distance, leading to substantial greenhouse gas emissions, fossil fuel consumption, and air pollution. To evaluate the potential improvements in sustainability, the study examines different transportation scenarios where the distance is progressively reduced to 400 km, 200 km, and finally 10 km in the optimized case.

The results indicate that minimizing the transportation distance of pea flour has a more pronounced impact on environmental performance compared to lentil flour and pea protein. This is primarily due to the high ratio of pea flour used in the formulation, making its transportation a more significant contributor to the product’s overall environmental footprint. As the distance decreases, climate change impact, fossil depletion, and photochemical ozone formation are substantially reduced. The carbon footprint from pea flour transportation alone drops by more than 80% in the optimized scenario, with the total value rising up to 1.25 kg CO2 eq., which constitutes a 3.8% decrease compared to the obtained value of the base case scenario, thus demonstrating the strong influence of transportation logistics on the sustainability of the final product.

Fossil fuel consumption also declines noticeably as transportation distances are shortened, directly decreasing the depletion of non-renewable energy sources. Additionally, emissions contributing to photochemical ozone formation, which can lead to smog and air quality deterioration, are significantly reduced in shorter transportation routes. The environmental benefits of minimizing the transportation of pea flour are therefore more evident compared to those of other ingredients, as the reduction in emissions has a greater effect on the overall sustainability of the legume-based vegan burger.

Unlike lentil flour and pea protein, for which reducing transportation distances results in relatively marginal improvements due to their lower quantities in the formulation, pea flour constitutes a major portion of the final product. As a result, minimizing its transportation distance is a highly effective strategy for improving the environmental sustainability of the product. These findings emphasize that local sourcing of pea flour should be prioritized over that of other ingredients in order to achieve the greatest environmental benefits. By focusing on reducing transport emissions for the most impactful ingredients, manufacturers can significantly lower the carbon footprint and overall environmental burden of plant-based food production.

Figure 10 showcases the financial impact of different transportation distances for pea flour, revealing a more noticeable cost reduction compared to other ingredients. As pea flour constitutes a substantial portion of the product’s formulation, minimizing transportation distances from 678 km to 10 km results in more significant financial savings. The reduction in logistics expenses contributes to a lower overall cost per functional unit, underscoring the importance of prioritizing local sourcing for high-quantity ingredients. This finding supports the conclusion that strategic ingredient procurement can simultaneously enhance both economic and environmental performance.

3.5. Packaging Material Scenarios

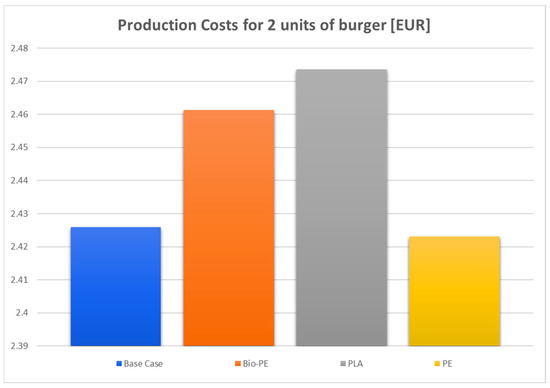

The results regarding the environmental and economic footprint of different scenarios regarding the utilization of a bio-based packaging material are presented in Figure 11 and Figure 12, respectively.

Figure 11.

Environmental impact of the different packaging materials on (a) climate change, default, excluding biogenic carbon (kg CO2 eq.), (b) fine particulate matter formation (kg PM2.5 eq.), (c) fossil depletion (kg oil eq.), (d) metal depletion (kg Cu eq.), (e) photochemical ozone formation, ecosystems (kg NOx eq.), and (f) photochemical ozone formation, human health (kg NOx eq.).

Figure 12.

Total costs associated with the production of 2 pieces of the legume-based vegan burger utilizing alternative packaging materials.

Apart from the transportation of the major legume ingredients, packaging materials play a critical role in determining the overall environmental impact of the legume-based vegan burger. The base case scenario utilizes a conventional PET (polyethylene terephthalate) packaging material, which is derived from fossil fuels and contributes to resource depletion, greenhouse gas emissions, and waste accumulation. To explore more sustainable alternatives, the study evaluates the impact of switching to bio-polyethylene (Bio-PE), polylactic acid (PLA) packaging and another conventional packaging material in the form of polyethylene (PE).

The results reveal that both the alternative Bio-PE and PLA packaging materials and the PE significantly reduce environmental burdens compared to conventional PET. Specifically, the carbon footprint of packaging materials is reduced by approximately 61% when bio-based alternatives are used. Bio-PE, derived from renewable biomass sources, demonstrates a particularly strong environmental performance by lowering reliance on petroleum-based plastics [35]. Similarly, PLA, a biodegradable polymer derived from plant starch, further reduces fossil fuel dependency and offers improved end-of-life disposal options [36]. However, it is important to note that these studies do not take into account the current challenges in the implementation of bio-based end-of-life solutions, and the limited supply of such materials which make the economic cost much higher than that of conventional plastic [37].

Fossil depletion is substantially lower in Bio-PE and PLA scenarios, as these materials do not require extensive extraction and processing of petroleum-based feedstocks [38]. Additionally, fine particulate matter formation, which is linked to industrial emissions from plastic production, is considerably lower in bio-based packaging options [39]

Overall, based on the results of the scenarios studying the effect of different packaging materials, it is evident that transitioning from conventional fossil-based plastics to Bio-PE packaging provides an optimal balance between sustainability and functionality. This shift offers manufacturers an effective strategy for reducing their environmental footprint while maintaining packaging durability and performance.

The economic assessment of alternative packaging materials, illustrated in Figure 11, highlights the potential cost implications of switching from PET to Bio-PE, PLA, and PE. While bio-based packaging solutions, in the short term, will incur higher initial costs compared to conventional PET, their environmental advantages justify their adoption. Among the evaluated options, Bio-PE emerges as a particularly effective alternative, offering a balance between sustainability and cost-effectiveness. Despite slight increases in packaging-related costs, the overall financial impact remains manageable, reinforcing the feasibility of adopting more sustainable packaging solutions without compromising economic viability.

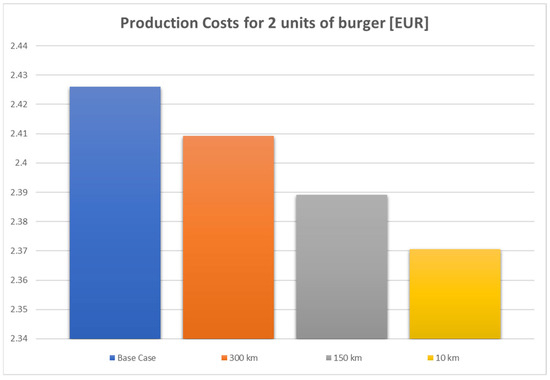

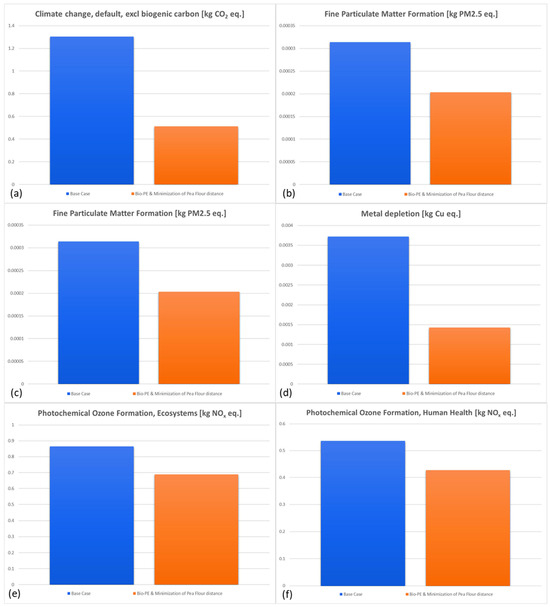

3.6. Optimum Scenario

To further enhance the environmental performance of the legume-based vegan burger, a final scenario was developed which incorporated the optimum conditions for both pea flour transportation distance and packaging materials. These specific conditions were selected based on their significant impact on sustainability and cost-effectiveness. Among the various transportation scenarios evaluated, minimizing the distance for pea flour had the most substantial effect on reducing the economic footprint, as this ingredient constitutes a major component of the burger formulation. By sourcing pea flour from a closer location, transportation costs and associated emissions were significantly lowered, making it the most impactful ingredient in terms of cost reduction.

Similarly, when assessing alternative packaging materials, bio-based polyethylene (Bio-PE) emerged as the most environmentally beneficial option. Compared to conventional PET packaging, Bio-PE demonstrated a considerable reduction in fossil fuel depletion and greenhouse gas emissions, while maintaining functionality and durability. This made it the optimal choice for minimizing the environmental footprint of the final product. However, more work evaluating end-of-life and food waste reduction is needed to fully determine the optimal biomaterial choice.

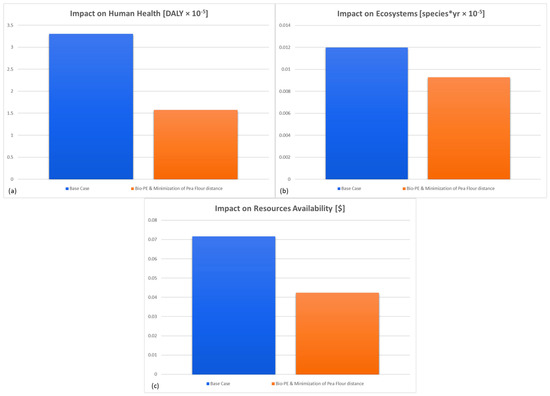

The results of this optimized scenario, which integrates both reduced pea flour transportation distances and the adoption of Bio-PE packaging, are presented in Figure 13, Figure 14 and Figure 15, showcasing the overall improvements in sustainability and cost efficiency.

Figure 13.

Comparison of the environmental impacts of the base case scenario and the optimum scenario on (a) climate change, default, excluding biogenic carbon (kg CO2 eq.), (b) fine particulate matter formation (kg PM2.5 eq.), (c) fossil depletion (kg oil eq.), (d) metal depletion (kg Cu eq.), (e) photochemical ozone formation, ecosystems (kg NOx eq.), and (f) photochemical ozone formation, human health (kg NOx eq.).

Figure 14.

Comparison of the ReCiPe endpoints between the base case and the optimum scenarios on (a) impact on human health [DALY × 10−5], (b) impact on ecosystems [species*yr ×10−5], (c) impact on resources availability [$].

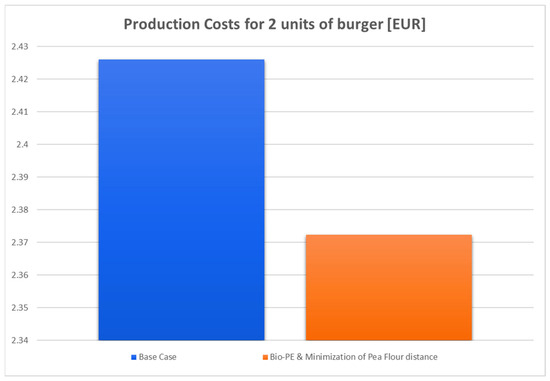

Figure 15.

Comparison of the total costs associated with the production of 2 pieces of the legume-based vegan burger between the base case and the optimum scenarios.

The comparative analysis between the base case scenario and the optimized scenario demonstrates significant improvements in sustainability through targeted interventions. The optimized scenario incorporates two major modifications: local ingredient sourcing (lentil flour, pea protein, and pea flour) and the adoption of Bio-PE packaging. The results show substantial reductions in environmental impacts across all categories, validating the effectiveness of these optimizations.

The most pronounced improvement is in climate change impact, where the carbon footprint of the product is reduced from 1.30 kg CO2-equivalent per package to just 0.51 kg CO2-equivalent. This translates to a 60% reduction in greenhouse gas emissions, which is primarily driven by the minimization of transportation-related emissions and the transition to bio-based packaging. Fossil depletion also sees a major reduction due to decreased reliance on petroleum-derived plastics and long-distance transportation.

Air pollution-related impacts, such as fine particulate matter formation, decrease by over 50%, further reinforcing the benefits of localized ingredient sourcing and sustainable packaging. These findings highlight the potential for supply chain optimization and sustainable packaging adoption as effective strategies for improving the environmental and economic performance of plant-based food products. By implementing these changes, manufacturers can achieve substantial sustainability benefits without compromising financial viability.

The ReCiPe endpoint analysis provides a comprehensive evaluation of the environmental impacts of the base case and optimized scenarios across three major impact categories: human health, ecosystem quality, and resource depletion. The results indicate that the optimized scenario significantly reduces environmental burdens in all three areas, demonstrating the effectiveness of the proposed sustainability interventions.

In terms of human health, the optimized scenario achieves a 55% reduction in environmental burden, primarily due to decreased particulate emissions and lower exposure to air pollutants associated with long-distance transportation. The improvement in air quality and reduction in fine particulate matter contribute to lower health risks for populations exposed to transportation-related emissions.

Ecosystem quality also sees notable improvements, with a 50% reduction in environmental damage. The decrease in fossil fuel extraction and transportation emissions helps mitigate habitat destruction and biodiversity loss, contributing to better overall ecological health. Furthermore, the resource depletion impact category shows a reduction of over 60%, highlighting the effectiveness of shifting to bio-based packaging and reducing reliance on non-renewable fossil resources.

These results underscore the substantial benefits of local ingredient sourcing and sustainable packaging adoption in achieving environmental sustainability. The findings reinforce that integrating circular economy principles into plant-based food production can lead to significant reductions in carbon footprint, resource consumption, and overall environmental impact.

The comparative cost analysis between the base case and optimized scenario, as depicted in Figure 15, demonstrates that the implementation of local ingredient sourcing and Bio-PE packaging not only improves environmental performance but also leads to cost efficiencies. The optimized scenario results in a reduction in total life cycle cost from EUR 2.43 to EUR 2.37 per package, primarily due to savings in transportation and logistics. This finding underscores the potential for simultaneous financial and environmental gains through targeted supply chain optimizations. By integrating these improvements, manufacturers can enhance product sustainability while maintaining or even reducing production costs.

3.7. Literature Comparison

Table 5 presents a direct comparison of the environmental performance of the studied vegan burger to other similar products published in the literature.

Table 5.

Environmental performance of various plant-based burgers.

According to the findings of Table 5, it is evident that the base scenario exhibited a slightly higher carbon footprint compared to similar plant-based products. On the other hand, all plant-based burgers exhibited a significantly lower carbon footprint compared to their animal-based counterparts. However, the optimization of ingredient sourcing and the utilization of environmentally friendly packaging materials significantly improves the environmental performance, further solidifying the need for optimization of plant-based products in terms of environmental performance.

3.8. Limitations and Challenges of the Present Work

While this study provides a comprehensive assessment of the environmental and economic impacts associated with the production of a legume-based vegan burger, several areas remain open for future research to strengthen the robustness and applicability of the findings. The primary focus was placed on the major legume ingredients, given their significant contribution to the product’s mass and overall impact. However, minor ingredients—such as sunflower flour, sunflower oil, and alcoholic vinegar—can also influence environmental and economic outcomes. Expanding local sourcing to include all ingredients may further enhance the sustainability of plant-based burgers.

The packaging scenarios examined in this study were limited to commercially viable and technically compatible materials (Bio-PE, PLA, and PE). Nonetheless, innovative alternatives such as edible films and fungal-based materials represent emerging solutions worth exploring in future analyses. Moreover, this research is based on a real-world Italian SME that already operates with existing equipment, making capital expenditures (CAPEXs) unnecessary within this context. As such, while the findings offer valuable insights, they may vary slightly when applied to different geographical regions or production systems requiring new investments.

Lastly, the study focuses primarily on production and supply chain optimizations, without addressing consumer-facing factors such as market acceptance, price elasticity, and regulatory incentives. These elements should be further investigated to better support manufacturers and inform policy decisions in the context of sustainable food production [45].

4. Conclusions

The primary objective of this study was to assess the environmental and economic footprint of a legume-based vegan burger and identify optimization strategies through a life cycle assessment (LCA) and life cycle costing (LCC) approach. Key contributors to the product’s environmental footprint were identified as the transportation of major ingredients—particularly pea flour—and the use of conventional packaging materials. Economically, labor and raw material costs were found to be the most significant drivers of the total life cycle cost.

Targeted optimization strategies, including the local sourcing of pea flour and the adoption of bio-based polyethylene (Bio-PE) packaging, yielded substantial improvements. The optimized scenario reduced the carbon footprint per package from 1.30 kg CO2 eq. to 0.51 kg CO2 eq., and the total life cycle cost dropped from EUR 2.43 to EUR 2.37, thus demonstrating that environmental improvements can align with economic efficiency.

The findings of this study contribute to sustainable food production by addressing key challenges related to ingredient sourcing and packaging sustainability. By demonstrating the effectiveness of targeted supply chain interventions, this research supports the transition toward more sustainable plant-based food products. Additionally, the methodologies applied in this study can serve as a model for similar food production systems, promoting further advancements in sustainable ingredient procurement and eco-friendly packaging solutions. These strategies align with broader sustainability goals, such as reducing carbon emissions, minimizing resource depletion, fostering a circular economy in food manufacturing, and promoting sustainable development.

Author Contributions

Conceptualization, T.K., F.D. and M.C.; methodology, T.K. and F.D.; software, T.K. and F.D.; validation, C.B. and M.K.; formal analysis, T.K., F.D. and N.R.N.; investigation, T.K. and F.D.; resources, M.C., M.B.d.S. and V.R.; data curation, T.K., F.D. and N.R.N.; writing—original draft preparation, T.K. and F.D.; writing—review and editing, N.R.N., C.B. and M.K.; visualization, T.K. and F.D.; supervision, C.B. and M.K.; project administration, M.K.; funding acquisition, M.C. and M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Horizon Europe, VALPRO Path project from Horizon Europe Research and Innovation program grant number 101059824.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

Authors Marco Berardo di Stefano and Vincenza Ruggiero are employed by Fattoria Soidale del Circeo cooperativa sociale, St. Lungo Ufente, 04014 Pontina LT, Italy. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationship that could be construed as a potential conflict of interest.

References

- de Villiers, M.; Cheng, J.; Truter, L. The Shift Towards Plant-Based Lifestyles: Factors Driving Young Consumers’ Decisions to Choose Plant-Based Food Products. Sustainability 2024, 16, 9022. [Google Scholar] [CrossRef]

- Research and Markets Plant-Based Food Market Overview, 2023–2028. Available online: https://www.researchandmarkets.com/reports/5853382/plant-based-food-market-overview-28#:~:text=According%20to%20the%20research%20report,%25%20CAGR%20by%202023%2D28./ (accessed on 2 March 2025).

- Andreani, G.; Sogari, G.; Marti, A.; Froldi, F.; Dagevos, H.; Martini, D. Plant-Based Meat Alternatives: Technological, Nutritional, Environmental, Market, and Social Challenges and Opportunities. Nutrients 2023, 15, 452. [Google Scholar] [CrossRef]

- Gastaldello, A.; Giampieri, F.; De Giuseppe, R.; Grosso, G.; Baroni, L.; Battino, M. The Rise of Processed Meat Alternatives: A Narrative Review of the Manufacturing, Composition, Nutritional Profile and Health Effects of Newer Sources of Protein, and Their Place in Healthier Diets. Trends Food Sci. Technol. 2022, 127, 263–271. [Google Scholar] [CrossRef]

- Goldstein, N.; Reifen, R. The Potential of Legume-Derived Proteins in the Food Industry. Grain Oil Sci. Technol. 2022, 5, 167–178. [Google Scholar] [CrossRef]

- Bryant, C.J. Plant-Based Animal Product Alternatives Are Healthier and More Environmentally Sustainable than Animal Products. Future Foods 2022, 6, 100174. [Google Scholar] [CrossRef]

- Xu, X.; Sharma, P.; Shu, S.; Lin, T.-S.; Ciais, P.; Tubiello, F.N.; Smith, P.; Campbell, N.; Jain, A.K. Global Greenhouse Gas Emissions from Animal-Based Foods Are Twice Those of Plant-Based Foods. Nat. Food 2021, 2, 724–732. [Google Scholar] [CrossRef]

- Vignesh, K.; Yadav, D.K.; Wadikar, D.D.; Semwal, A.D. Exploring Sustenance: Cereal Legume Combinations for Vegan Meat Development. Sustain. Food Technol. 2023, 2, 32–47. [Google Scholar] [CrossRef]

- Tang, M.; Miri, T.; Soltani, F.; Onyeaka, H.; Al-Sharify, Z.T. Life Cycle Assessment of Plant-Based vs. Beef Burgers: A Case Study in the UK. Sustainability 2024, 16, 4417. [Google Scholar] [CrossRef]

- Avetisyan, M.; Hertel, T.; Sampson, G. Is Local Food More Environmentally Friendly? The GHG Emissions Impacts of Consuming Imported versus Domestically Produced Food. Env. Resour. Econ. 2014, 58, 415–462. [Google Scholar] [CrossRef]

- Prasanna Kumar, M.; Vijayakumar, A.; Govindarasu, P.; Mudamootoo, J.; Lavanya, P.; Ramkumar, R.; Sangeetha, N. Replacement of Conventional Packaging Materials with Green Polymers. In Green Materials for Active Food Packaging; ul Islam, S., Shahid, M., Eds.; Springer Nature: Singapore, 2025; pp. 197–227. ISBN 978-981-96-0369-5. [Google Scholar]

- Dörnyei, K.R.; Uysal-Unalan, I.; Krauter, V.; Weinrich, R.; Incarnato, L.; Karlovits, I.; Colelli, G.; Chrysochou, P.; Fenech, M.C.; Pettersen, M.K.; et al. Sustainable Food Packaging: An Updated Definition Following a Holistic Approach. Front. Sustain. Food Syst. 2023, 7. [Google Scholar] [CrossRef]

- das Mercês, Z.d.C.; Salvadori, N.M.; Evangelista, S.M.; Cochlar, T.B.; de Oliveira Rios, A.; de Oliveira, V.R. Hybrid and Plant-Based Burgers: Trends, Challenges, and Physicochemical and Sensory Qualities. Foods 2024, 13, 3855. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, S.A.; Khalifa, I.; Yin, T.; Morsy, M.K.; Khoder, R.M.; Salauddin, M.; Farzana, W.; Sharma, S.; Khalid, N. Valorization of Plant Proteins for Meat Analogues Design—A Comprehensive Review. Eur. Food Res. Technol. 2024, 250, 2479–2513. [Google Scholar] [CrossRef]

- Good Food Institute. State of the Industry Report, Plant-Based Meat, Seafood, Eggs, and Dairy. 2022. Available online: https://gfi.org/resource/plant-based-meat-eggs-and-dairy-state-of-the-industry/ (accessed on 3 March 2025).

- Chung, J.Y.; Bryant, C.J.; Asher, K.E. Plant-Based Meats in China: A Cross-Sectional Study of Attitudes and Behaviours. J. Human. Nutr. Diet. 2023, 36, 1090–1100. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Razzaq, A.; Yu, Z.; Shah, A.; Sharif, A.; Janjua, L. Disruption in Food Supply Chain and Undernourishment Challenges: An Empirical Study in the Context of Asian Countries. Socioecon. Plann Sci. 2022, 82, 101033. [Google Scholar] [CrossRef]

- Gustavo, J.U.; Pereira, G.M.; Bond, A.J.; Viegas, C.V.; Borchardt, M. Drivers, Opportunities and Barriers for a Retailer in the Pursuit of More Sustainable Packaging Redesign. J. Clean. Prod. 2018, 187, 18–28. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M.; Svanström, M. LCA Methodology. In Life Cycle Assessment of Forest Products: Challenges and Solutions; Springer International Publishing: Cham, Switzerland, 2016; pp. 15–23. ISBN 978-3-319-44027-9. [Google Scholar]

- Sazdovski, I.; Bala, A.; Fullana-i-Palmer, P. Linking LCA Literature with Circular Economy Value Creation: A Review on Beverage Packaging. Sci. Total Environ. 2021, 771, 145322. [Google Scholar] [CrossRef]

- Bachmann, T.M.; van der Kamp, J.; Bianchi, M.; Pihkola, H.; Saavedra del Oso, M. Life Cycle Costing as Part of a Life Cycle Sustainability Assessment of Products: Methodology and Case Studies. Int. J. Life Cycle Assess. 2024, 29, 1863–1879. [Google Scholar] [CrossRef]

- Ishimoto, Y.; Wulf, C.; Schonhoff, A.; Kuckshinrichs, W. Life Cycle Costing Approaches of Fuel Cell and Hydrogen Systems: A Literature Review. Int. J. Hydrogen Energy 2024, 54, 361–374. [Google Scholar] [CrossRef]

- Masi, R.F.d.; Marialuisa, M.; Ruggiero, S.; Vanoli, G.P.; Savino, M.M. Managing the Life Cycle Assessment for High-Performance Refrigerators through a Comparative Analysis of the Impacts. Int. J. Manuf. Technol. Manag. 2023, 37, 452–479. [Google Scholar] [CrossRef]

- Silva, B.Q.; Vasconcelos, M.W.; Smetana, S. Conceptualisation of an Ecodesign Framework for Sustainable Food Product Development across the Supply Chain. Environments 2023, 10, 59. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization [ISO]: London, UK, 2006.

- Statista Research Department. Recycling Rate of Plastic Packaging Waste in Italy 2013–2023; Statista: Berlin, Germany, 2025; Available online: https://www.statista.com/statistics/910898/recycling-rate-of-plastic-packaging-waste-in-italy/ (accessed on 4 March 2025).

- Striebig, B.; Smitts, E.; Morton, S. Impact of Transportation on Carbon Dioxide Emissions from Locally vs. Non-Locally Sourced Food. Emerg. Sci. J. 2019, 3, 222–234. [Google Scholar] [CrossRef]

- Gomes, T.S.; Visconte, L.L.Y.; Pacheco, E.B.A.V. Life Cycle Assessment of Polyethylene Terephthalate Packaging: An Overview. J. Polym. Environ. 2019, 27, 533–548. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Das, S.; Pal, D.; Sarkar, A. Particulate Matter Pollution and Global Agricultural Productivity. In Sustainable Agriculture Reviews 50: Emerging Contaminants in Agriculture; Kumar, S.V., Singh, R., Lichtfouse, E., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 79–107. ISBN 978-3-030-63249-6. [Google Scholar]

- Yousuf, M.U.; Siddiqui, M.A.; Kumar, M.; Umair, M. Life Cycle Assessment of Lignite-Fueled Ultra-Supercritical Coal-Fired Power Plant with Evaluation of Solar Energy Integration. Fuel 2025, 385, 134079. [Google Scholar] [CrossRef]

- Preiss, P. Photochemical Ozone Formation. In Life Cycle Impact Assessment; Hauschild, M.Z., Huijbregts, M.A.J., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 115–138. ISBN 978-94-017-9744-3. [Google Scholar]

- Bałazińska, M.; Kruczek, M.; Bondaruk, J. The Environmental Impact of Various Forms of Waste PET Bottle Management. Int. J. Sustain. Dev. World Ecol. 2021, 28, 473–480. [Google Scholar] [CrossRef]

- Donkor, L.; Kontoh, G.; Yaya, A.; Bediako, J.K.; Apalangya, V. Bio-Based and Sustainable Food Packaging Systems: Relevance, Challenges, and Prospects. Appl. Food Res. 2023, 3, 100356. [Google Scholar] [CrossRef]

- Soo, X.Y.D.; Muiruri, J.K.; Wu, W.-Y.; Yeo, J.C.C.; Wang, S.; Tomczak, N.; Thitsartarn, W.; Tan, B.H.; Wang, P.; Wei, F.; et al. Bio-Polyethylene and Polyethylene Biocomposites: An Alternative toward a Sustainable Future. Macromol. Rapid Commun. 2024, 45, 2400064. [Google Scholar] [CrossRef] [PubMed]

- Sikorska, W.; Musioł, M.; Zawidlak-Węgrzyńska, B.; Rydz, J. End-of-Life Options for (Bio)Degradable Polymers in the Circular Economy. Adv. Polym. Technol. 2021, 2021, 6695140. [Google Scholar] [CrossRef]

- Uysal-Unalan, I.; Sogut, E.; Realini, C.E.; Cakmak, H.; Oz, E.; Espinosa, E.; Morcillo-Martín, R.; Oz, F.; Nurmi, M.; Cerqueira, M.A.; et al. Bioplastic Packaging for Fresh Meat and Fish: Current Status and Future Direction on Mitigating Food and Packaging Waste. Trends Food Sci. Technol. 2024, 152, 104660. [Google Scholar] [CrossRef]

- Singh, N.; Ogunseitan, O.A.; Wong, M.H.; Tang, Y. Sustainable Materials Alternative to Petrochemical Plastics Pollution: A Review Analysis. Sustain. Horiz. 2022, 2, 100016. [Google Scholar] [CrossRef]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.-B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-Based Packaging: Materials, Modifications, Industrial Applications and Sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Dettling, J.; Hester, J.; Moses, R. Comparative Environmental LCA of the Impossible Burger with Conventional Ground Beef Burger, Final Report; Quantis: Lausanne, Switzerland, 2019. [Google Scholar]

- Smetana, S.; Mathys, A.; Knoch, A.; Heinz, V. Meat Alternatives: Life Cycle Assessment of Most Known Meat Substitutes. Int. J. Life Cycle Assess. 2015, 20, 1254–1267. [Google Scholar] [CrossRef]

- Smetana, S.; Profeta, A.; Voigt, R.; Kircher, C.; Heinz, V. Meat Substitution in Burgers: Nutritional Scoring, Sensorial Testing, and Life Cycle Assessment. Future Foods 2021, 4, 100042. [Google Scholar] [CrossRef]

- Keoleian, G.A.; Heller, M.C. Beyond Meat’s Beyond Burger Life Cycle Assessment: A Detailed Comparison Between a Plant-Based and an Animal-Based Protein Source; University of Michigan: Ann Arbor, MI, USA, 2018. [Google Scholar]

- Saerens, W.; Smetana, S.; Van Campenhout, L.; Lammers, V.; Heinz, V. Life Cycle Assessment of Burger Patties Produced with Extruded Meat Substitutes. J. Clean. Prod. 2021, 306, 127177. [Google Scholar] [CrossRef]

- Shen, C.; Wu, X.; Zhang, E.; Liu, Y. Factors Impacting Plant-Based Meat Product Consumption: A Consumer Survey Conducted in a New First-Tier City in China. Foods 2024, 13, 3496. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).