Abstract

This study examined the carbon footprints of freshwater fish farming and Euryale ferox seed (gorgon fruit) production, comparing integrated ecological mode and traditional farming practices based on ISO 14067 and PAS 2050 standards. The ecological mode achieved a 24% lower carbon footprint per unit product than traditional practices, driven by reduced material and energy use. Key emission sources included aeration electricity, feed, and wastewater treatment for fish farming, fertilizers, insecticides, and drainage energy for E. ferox planting. The integrated model combining high-density fish ponds and E. ferox pond reduced the overall carbon footprint (Micropterus salmoides: 4.342 kg CO2-eq/kg; E. ferox seed: 0.208 kg CO2-eq/kg) compared to traditional practices (Micropterus salmoides: 5.672 kg CO2-eq/kg; E. ferox seed: 0.297 kg CO2-eq/kg). It also lowered production costs, increased profits, and mitigated GHG emissions by using E. ferox and lotus ponds as treatment facilities and reducing fertilizer use. The ecological model showed lower unit costs and higher profits (Micropterus salmoides: 4.01 RMB/kg vs. 2.46 RMB/kg; E. ferox seed: 2.53 RMB/kg vs. 1.93 RMB/kg) than those of the traditional mode. This study underscores the potential of ecologically integrated modes to mitigate water pollution and carbon emissions in agriculture, offering a sustainable solution to meet the rising demand for aquatic products.

1. Introduction

Global warming and climate change, primarily driven by human activities that increase greenhouse gas (GHG) concentrations, have led to significant impacts such as higher sea levels, altered precipitation patterns, and ecosystem disruptions. These changes threaten agriculture, livestock, and human health [1,2]. Concurrently, as the population increases and the economy evolves, GHG emissions from human activities have increased, further exacerbating climate warming. Agriculture alone has been reported to be responsible for approximately one-third of anthropogenic greenhouse gas emissions [3,4].

Aquaculture, often called blue food and considered a part of the blue revolution, is crucial in providing animal protein. It significantly contributes to food security, human nutrition, and ecological benefits, particularly in developing countries [5,6]. Although greenhouse gas (GHG) emissions from fish are relatively low compared to those from other livestock, such as cattle, the rapidly increasing demand for fish may lead to higher GHG emissions from aquaculture [7,8]. Therefore, analyzing carbon footprints is essential for mitigating these emissions. Ecologically integrated systems, such as rice–fish and vegetable–fish farming, offer a sustainable way to reduce water pollution and GHG emissions and increase soil carbon sequestration [7,9,10,11]. For example, Fang et al. (2023) [12] showed that combining rice and fish farming reduced CH4 and N2O emissions by up to 14% and 31%, respectively, compared to rice monoculture. On the other hand, Euryale ferox, as an aquatic emergent crop, has been reported to enhance carbon sequestration [11]. However, despite these advancements, there exists a paucity of comprehensive analyses regarding the carbon footprint and economic performance of systems that combine fish farming with aquatic emergent crops, particularly in scenarios where the aquatic crop pond functions as a wastewater treatment facility for fish farming.

The carbon footprint measures the total emissions of GHG (e.g., CO2, CH4, and N2O) produced by various supply chains. Analyzing the carbon footprint is a crucial method for assessing the environmental impact of agriculture, as it quantifies GHG emissions throughout the entire life cycle of agricultural products [7]. This study conducts a comprehensive carbon footprint analysis of freshwater fish farming and Euryale ferox seed (gorgon fruit) production, comparing the environmental impacts of ecologically integrated and traditional farming methods. The goal is to identify sustainable practices that can effectively reduce GHG emissions in the aquaculture sector, thereby contributing to global efforts to mitigate climate change. Additionally, the research highlights the potential of ecologically integrated systems as effective strategies for minimizing water pollution and decreasing the carbon footprint in agriculture.

2. Materials and Methods

2.1. Study Area

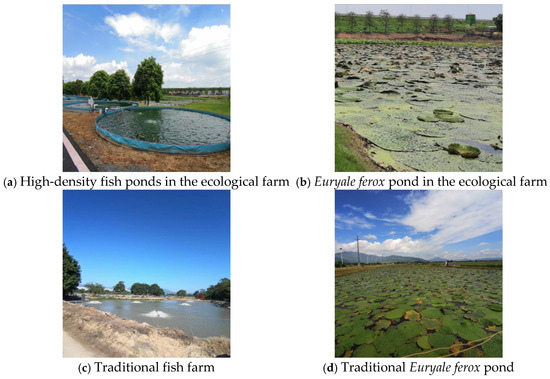

2.1.1. Ecological Farm

The ecological farm featuring a fish pond and E. ferox pond agricultural mode was located in Dinghu District, Zhaoqing City, Guangdong Province (Figure 1a,b). This farm included eight high-density fish ponds, each with a diameter of 10 m (approximately 78.5 m2). Three of these ponds cultivated Micropterus salmoides, while the remaining five were dedicated to Wenqing carp (Cyprinus carpio). The breeding cycle for Wenqing carp lasted about 10 months, while Micropterus salmoides had a shorter cycle of around 7 months. In the spring of 2023, approximately 9000 Micropterus salmoides fingerlings and 15,000 Wenqing carp fries were introduced into the ecological fish ponds. The Micropterus salmoides were harvested when they reached about 0.4 to 0.5 kg, resulting in a total production of approximately 3240 kg. The Wenqing carp were harvested at weights between 0.8 and 1 kg, yielding about 11,475 kg.

Figure 1.

Study areas: (a) high-density fish ponds in the ecological farm; (b) Euryale ferox pond in the ecological farm; (c) traditional fish farm; (d) traditional Euryale ferox pond.

The E. ferox pond covered an area of about 4000 m2, with water depth ranging from 40 to 80 cm, producing around 2100 kg (fresh weight) of seeds in 2023. The growth phase for E. ferox spanned 10 months, from March to December. In this ecological farm, water flowed by gravity from the fish ponds to the E. ferox pond and subsequently to the lotus pond, which served as a wastewater treatment facility for the fish ponds. The water quality in the lotus pond met local aquaculture wastewater discharge standards in 2023. Additionally, the nutrients in the effluent from the fish ponds could replace part of the fertilizers needed for E. ferox growth, and processing scraps from E. ferox seeds were used as feed additives for the Wenqing carp in the fish ponds.

In the ecological farm, a single operator was sufficient to manage fish and duck farming and the cultivation of E. ferox. However, an extra operator was required on the specific days when thinning and harvesting activities occur in the ecological E. ferox pond.

2.1.2. Traditional Fish Farm and E. ferox Pond

The traditional fish farm and E. ferox pond were in the same district close to the ecological farm (Figure 1c,d). The area of a traditional fish pond was approximately 3000 m2 with an average water depth of 1.5 m. About 16,000 Micropterus salmoides fingerlings were transferred to the traditional fish farm in March 2023. The breeding cycle for the traditional fish farm was 12 months for Micropterus salmoides. The Micropterus salmoides were harvested when the fish grew to over 0.5–0.6 kg, producing about 8000 kg. An operator responsible for two additional fish ponds managed the traditional fish pond studied.

The traditional E. ferox pond area was approximately 32,000 m2 with an average water depth of 30 cm. The growth phase was also 10 months, with an annual seed production of 16,800 kg. In the traditional E. ferox pond, a single operator was typically sufficient for routine management. However, during the thinning operations in March, two additional operators were required to assist for 15 days.

2.2. Data Sources

The data on material and energy consumption, price and expense information, and the transportation distances for materials and work commuting used in this study were provided by the relevant agricultural companies and local suppliers through on-site surveys, and operational records. The year 2023 has been selected as the baseline year for the ecological farm and traditional E. ferox ponds. The carbon footprint of traditional fish products was evaluated based on the material and energy consumption data collected over a production cycle that spanned from March 2023 to March 2024. Detailed consumption data can be found in the inventory analysis section of this article (Table 1 and Table 2). Facility depreciation (e.g., galvanized sheets, pumps) was calculated linearly over 10 years, consistent with ISO 14044’s [13] guidance on capital goods allocation. This approach aligns with prior aquaculture LCA studies [14,15].

Table 1.

Materials and energy consumption for fish farming in ecological and traditional modes in 2023.

Table 2.

Materials and energy consumption for Euryale ferox seed production in ecological and traditional modes in 2023.

2.3. Carbon Footprint Accounting Method

2.3.1. Goal and Scope of Definition

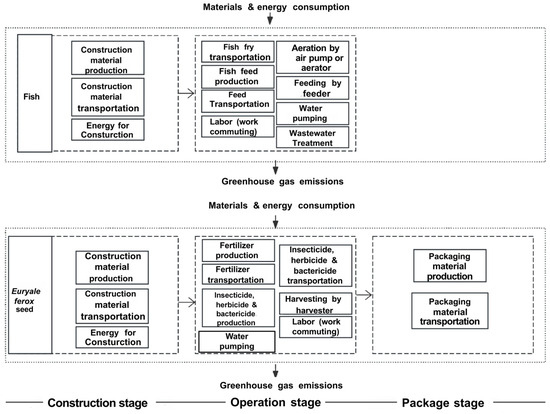

This research aimed to quantitatively compare the carbon footprint associated with material and energy consumption throughout the entire life cycle (from cradle to farm gate) of fish and E. ferox seed production in ecological and traditional agricultural modes. To this end, a specific scope is defined to include several factors: the consumption of construction material, daily operational material and energy use, and energy consumption related to the transportation of materials and labor (work commuting) for fish ponds and E. ferox ponds. The scope also covers material consumption for packaging and the energy required to transport packaging material in E. ferox ponds. However, it is important to note that the carbon footprint associated with fish packaging is excluded from this analysis, as fresh fish does not require packing materials, and buyers typically supply transportation. The specific system boundaries for this study are illustrated in Figure 2. For the comparison between the two agricultural modes, this article uses 1 kg of the finished product as the functional unit.

Figure 2.

The accounting boundaries for carbon footprints of fish and Euryale ferox seed production.

2.3.2. Carbon Footprint Calculation Using Life Cycle Analysis

The carbon footprint framework was developed following the ISO 14067 and ISO 14044 standards [13,16]. While ISO 14067 and ISO 14044 [13,16] do not provide a specific quantification method, this study utilized the emission factor method from PAS 2050 [17], the most widely used approach for carbon footprint analysis [18]. This method calculates GHG emissions by multiplying GHG activity data with GHG emissions or removal factors, as shown in Equation (1):

where

CEi = ACi × EFi

CEi: GHG emissions of material i (kg CO2-eq);

ACi: The input amount of activity data of material i (unit);

EFi: The life cycle GHG emissions factor of material i (kg CO2-eq/unit).

2.3.3. Exclusions

This study excludes direct and indirect GHG sources that contribute insignificantly to emissions (less than 5% of the total) and are not technically feasible or cost effective to quantify as in the previous study [14]. Specifically, direct GHG emissions from fish farming have been omitted from the analysis. Continuous aeration maintained dissolved oxygen levels, suppressing anaerobic decomposition of organic matter [19]. In traditional ponds, the sediment (including fish excrement) was exposed to air and treated with lime during disinfection after the fish was harvested, further inhibiting CH4 generation. In the ecological mode, the fish excrement was discharged into the Euryale ferox pond, which contains effluent oxygen from the fish pond.

Secondly, because some of the feed for Wenqing carp consisted of grass and processing scraps from E. ferox seeds sourced from the same farm, only the carbon footprint of the purchased feed was calculated for the Wenqing carp culture.

Thirdly, there was no available dataset for the emission factors (EF) of water-regulating agents used in fish farming, primarily consisting of EM bacteria. Additionally, the total usage amount of these agents (54 kg) was relatively minor compared to the quantities of fish feed and lime used for disinfection. As a result, we followed the approach of Chang et al. (2017) [14] and assigned a zero emission factor, calculating only the carbon footprint associated with their transportation.

Finally, neither fish farming nor E. ferox planting is labor intensive. The operator spent about 2 to 3 h per day on fish farming. For the planting of E. ferox, fertilization, and pesticide spraying occur only 3 to 5 times a year. Consequently, only the GHG emissions from work commuting were calculated for the labor force. Furthermore, in the ecological mode, only one operator was needed for fish and duck farming and E. ferox planting. Therefore, to avoid double counting, the GHG emissions from the labor force for E. ferox planting were considered zero in the ecological mode.

2.3.4. Emission Factors

Due to a lack of literature or standard references for the carbon emission factors of aerators, feeders, E. ferox seed harvesters, and pumps, these devices were collectively classified as small power motors (power < 10 kW). The carbon emission factor for small power motors represented the emission factors from the above-mentioned equipment. The carbon emission factors for other relevant materials and energy sources mentioned in this article primarily come from the CPCD database [20], the Environmental Protection Administration (2018) [21], and previous studies including Wang et al. (2022) [22], Wilfart et al. (2023) [23], Yu et al. (2024) [24], Xu et al. (2022) [25], and Zhang et al. (2016) [26]. The carbon emission factor related to electricity was based on data from the Ministry of Ecology and Environment (2024) [27]. Since both Micropterus salmoides and rainbow trout are freshwater carnivorous fish, and no available data for the emission factor of fish feed for Micropterus salmoides could be found, the emission factor for rainbow trout feed was used as a substitute in this study. The specific selection of carbon emission factors is detailed in Table 3.

Table 3.

Emission factors for each emission source.

2.3.5. GHG Emissions from Labor

The operators’ daily travel distance and work days were estimated to determine the emission factor associated with the labor force. For the ecological farm, the operator traveled an average distance of 14 km daily (two round trips per day) for 10 months using an electric motorcycle for fish pond operations and worked 4–5 h daily. The GHG emissions associated with labor for the ecological fish ponds were allocated proportionally between the fish ponds and the duck pond, as the same operator managed them.

In the case of the traditional fish pond, the labor force was estimated to involve one operator who traveled an average distance of 8 km daily on an electric motorcycle on working days throughout the year. The GHG emissions attributed to labor were distributed among three traditional fish ponds since the operator was also responsible for managing two additional fish ponds. For the conventional E. ferox pond, the labor force was assessed based on one operator working daily during the harvesting month and every three days for the remaining 8.5 months. Moreover, three operators participated in thinning operations for 15 days in March, each traveling an average of 7 km daily by gasoline motorcycle.

2.4. Expense for Labor

In the ecological model, the workload associated with managing the E. ferox pond was significantly lower than that of the fish ponds and the duck pond, as detailed in Section 2.3.3. The maintenance of the E. ferox pond was integrated into the responsibilities of the single operator who oversees all fish ponds and the duck pond. Duplication in cost accounting was prevented by calculating the labor costs only for the additional operator who worked on the days of thinning and harvesting operations in the ecological E. ferox pond.

3. Results

3.1. Comparative Analysis of Carbon Footprints: Ecological vs. Traditional Fish Ponds

The overall carbon footprint per unit product of Micropterus salmoides in the ecological mode was 4.342 kg CO2-eq/kg, lower than that (5.672 kg CO2-eq/kg) in the traditional mode. For Wenqing carp, the carbon footprint in the ecological mode was calculated to be 3.391 kg CO2-eq/kg. During the construction phase, the ecological mode generally had a higher carbon footprint than the traditional method, primarily due to construction materials like galvanized sheets and waterproof membranes, significantly contributing to the ecological (high-density aquaculture) mode. However, this trend reversed in the operational stage, with a carbon footprint of 3.918 kg CO2-eq/kg for Micropterus salmoides in the ecological mode versus 5.635 kg CO2-eq/kg in the traditional mode.

In both ecological and traditional farming modes, GHG emissions during the operational stage were the main contributors to the carbon footprint of the products, accounting for 90.24% to 94.23% in the ecological mode and 99.34% in the traditional mode (Table 4). In contrast, GHG emissions from the construction stage were relatively minor, contributing only 5.77% to 9.76% in the ecological mode and 0.66% in the traditional mode when depreciation was considered. In both ecological and conventional fish farming, the primary sources of carbon emissions were electricity consumption for aeration and fish feed (Table 4). Specifically, GHG emissions from electricity used for aeration were the most significant contributors to the carbon footprint, representing 47.73% to 48.98% in the ecological mode and 56.33% in the traditional mode. Fish feed was the second-largest source of GHG emissions, contributing 39.93% to 45.00% in the ecological mode and 30.57% in the conventional mode.

Table 4.

Carbon footprints of fish produced in ecological and traditional modes.

During the operation phase, the energy consumption for aeration in ecological (high-density aquaculture) mode was lower than in traditional mode, reducing GHG emissions (Table 4). Furthermore, wastewater treatment services accounted for the third-largest percentage (10.70%) of the carbon footprint in the conventional mode. In the ecological mode, the wastewater from fish ponds was treated by the E. ferox pond and the lotus pond, eliminating the need for external wastewater treatment services. Consequently, this component of the carbon footprint was calculated as zero, contributing to the lower overall carbon footprint associated with the ecological mode.

3.2. Comparative Analysis of Carbon Footprints: Ecological vs. Traditional E. ferox Ponds

The carbon footprint per unit of E. ferox seed in ecological mode was 0.208 kg CO2-eq/kg, representing a reduction of approximately 30% compared to the traditional mode (0.297 kg CO2-eq/kg) (Table 5). During the construction stage, the ecological mode exhibited a slightly higher carbon footprint per unit product (0.046 kg CO2-eq/kg) than the traditional mode (0.021 kg CO2-eq/kg). This difference was primarily due to the varying requirements for water pumps based on production scales. Nevertheless, in the operation stage, the carbon footprint of the ecological mode (0.158 kg CO2-eq/kg) was lower than the traditional mode (0.272 kg CO2-eq/kg).

Table 5.

Carbon footprints of Euryale ferox seed in ecological and traditional modes.

In both ecological and traditional E. ferox ponds, the operation stage accounted for a significant portion of the total carbon footprint, comprising 75.97% in the ecological mode and 91.52% in the traditional mode (Table 5). The corresponding figures during the construction phase were 21.88% and 6.98%, respectively, with depreciation included. In ecological mode, the principal sources of carbon emissions were insecticide use (27.48%), electricity consumed by water pumps for drainage (23.92%), and compound fertilizer (15.27%). In contrast, the top three contributors to the carbon footprint in the traditional mode were fertilizer (47.51%), insecticide (30.62%), and electricity consumed by water pumps for drainage (5.82%).

The carbon emission sourced from fertilizers in ecological mode (0.032 kg CO2-eq/kg) was significantly lower than that of the traditional mode (0.141 kg CO2-eq/kg) (Table 5). This decrease may be due to the nutrients in the effluent from the high-density fish ponds, which partially replaced fertilizers in ecological mode. Conversely, the carbon footprint associated with electricity used by the water pumps for drainage in the ecological mode (0.050 kg CO2-eq/kg) was slightly higher compared to the traditional mode (0.017 kg CO2-eq/kg). This increase could be linked to the dual function of the E. ferox pond, which also served as a wastewater treatment facility for the fish ponds, resulting in a greater volume of water needing to be drained in the ecological mode. The carbon footprints from insecticide use were relatively similar across both modes.

3.3. Total Carbon Footprints in Ecological and Traditional Modes for the Production of Micropterus salmoides and E. ferox Seed

The ecological mode effectively reduced material usage, energy consumption, and carbon emissions (Table 4 and Table 5). The total carbon footprint for the high-density fish pond (Micropterus salmoides) and E. ferox pond in the ecologically integrated mode was 4.550 kg CO2-eq/kg (4.342 kg CO2-eq/kg + 0.208 kg CO2-eq/kg). This figure is notably lower than the combined carbon footprint of the traditional fish pond and E. ferox pond, which was 5.969 kg CO2-eq/kg (5.672 kg CO2-eq/kg + 0.297 kg CO2-eq/kg), representing a reduction of about 24%.

In both ecological and traditional modes, the carbon footprints from the operational stage were substantially higher than those from the construction stage. The ecologically integrated mode benefited from relatively low electricity consumption for aeration, reduced fertilizer requirements, and lower requirements for wastewater treatment services, all contributing to its lower carbon footprint than the traditional mode. Nevertheless, the common significant contributors to carbon footprint in both modes included electricity for aeration, feed for fish, and insecticides for E. ferox seed production.

3.4. Cost and Profit Analysis of Fish Production: Ecological vs. Traditional Fish Ponds

As presented in Table 6, the unit production cost of Micropterus salmoides in the ecological model (15.99 RMB/kg) was lower than that in the traditional model (19.14 RMB/kg), despite the higher initial construction costs associated with the ecological system. Although the market price of Micropterus salmoides in the traditional model (21.6 RMB/kg) was higher than that in the ecological model (20 RMB/kg) due to the larger fish size, the ecological model demonstrated superior profitability. Specifically, the profit per unit product of Micropterus salmoides in the ecological model was 4.01 RMB/kg, compared to 2.46 RMB/kg in the traditional model. For Wenqing carp, the profit per unit product in the ecological model reached 45.22 RMB/kg.

Table 6.

Cost and benefit of fish production in ecological and traditional modes.

Among the various cost components, compound feed accounted for the highest proportion of expenses in both models, ranging from 45.72% to 67.46% of total costs. The second largest expenditure was electricity for aeration (16.07–24.51%), contributing 2.38–3.12 RMB/kg in the ecological model and 4.69 RMB/kg in the traditional model. Water treatment constituted the third-largest cost in the traditional model (9.87%). In contrast, this cost was significantly reduced in the ecological model due to the integration of E. ferox and lotus ponds that effectively treated effluent from fish ponds. Labor costs ranked as the fourth-largest expense in the traditional model (9.14%), whereas these costs were lower in the ecological model. This reduction can be attributed to the shared labor arrangement, wherein a single operator managed all fish ponds and the integrated duck pond, distributing labor costs more efficiently.

3.5. Cost and Profit Analysis of E. ferox Seed Production: Ecological vs. Traditional Fish Ponds

Table 7 illustrates that the profit per unit product for E. ferox seed production in the ecological model (2.53 RMB/kg) exceeded that in the traditional model (1.93 RMB/kg) despite the higher initial construction costs of the ecological system. Land rental represented the largest proportion of expenses in both models, accounting for 68.33–72.17% of total costs. The second-highest expenditure in the traditional model was labor costs (20.30%), which were substantially reduced in the ecological model (6.68%). This reduction was attributed to the management of the E. ferox pond being integrated with the operation of fish and duck ponds, requiring only one additional operator during thinning and harvesting periods. The third-largest cost in the traditional model was the expense of compound fertilizers (3.52%). However, this cost was lower in the ecological model, as nutrients from fish pond effluent were partially utilized as a natural fertilizer source. This synergy between fish and E. ferox production in the ecological model contributed to overall cost savings and enhanced economic viability.

Table 7.

Cost and benefit of E. ferox seed in ecological and traditional modes.

4. Discussion

4.1. Merit of Ecological Mode in Reducing Carbon Footprint

The ecological mode integrating high-density fish ponds and the Euryale ferox pond achieved a remarkable 24% reduction in the overall carbon footprint per unit product compared to the traditional mode. The carbon footprints per unit product for Micropterus salmoides in the ecological and traditional farming modes were 4.342 kg CO2-eq/kg and 5.672 kg CO2-eq/kg, respectively. Correspondingly, the carbon footprint per unit product for Wenqing carp in the ecological mode was calculated to be 3.391 kg CO2-eq/kg. These values are at the low end of the carbon footprint range (1.9–9.9 kg CO2-eq/kg) of freshwater fish aquaculture in China, as Xu et al. (2022) [28] reported. Further, the carbon footprint of Micropterus salmoides in this study is comparable to those of other carnivorous fish, such as salmon, ranging from 2.863 to 6.576 kg CO2-eq/kg [7,8]. Likewise, the carbon footprint of Wenqing carp in this study is lower than the average value for global carp aquaculture (cyprinids, 3.730 kg CO2-eq/kg) [7,8]. The above figures demonstrate that the ecological pond has merit in producing fish at a low carbon footprint for human consumption.

Our findings align with previous research on integrated ecological systems, such as rice–fish and fish–vegetable co-culture systems, which significantly reduce greenhouse gas (GHG) emissions. For example, Chen et al. (2020) [10] reported that the global warming potential (GWP) of fish–vegetable co-culture (aquaponics) systems was 45.7% lower than that of vegetable monoculture (hydroponics) systems. Similarly, Fang et al. (2023) [12] found that integrating rice and fish farming reduced methane (CH4) and nitrous oxide (N2O) emissions by up to 14% and 31%, respectively, compared to rice monoculture. In the rice–fish co-culture system, the reduction in GHG emissions was primarily due to the activity of fish, which increased the dissolved oxygen (DO) levels in the rice paddies, as reported by Fang et al. (2023) [12]. In our study, the reduction in carbon footprint per unit product was primarily driven by lower material and energy use, particularly in the operational stage, similar to the fish–vegetable co-culture (aquaponics) system described by Chen et al. (2020) [10].

4.2. Sensitivity Analysis of Critical Parameters

4.2.1. Comparison of the Carbon Footprint of Fish Products Under Climate Change Scenarios

GHG emissions from wastewater treatment services constituted the third-largest carbon footprint associated with the traditional fish production mode (Table 4). Under climate change scenarios, this proportion may rise due to an increased likelihood of heavy rainfall and extreme precipitation events, which can negatively impact water quality in traditional fish ponds [29,30]. These events require additional energy to replace contaminated pond water with fresh water and to treat the polluted water, thus emitting more GHG. Although the adverse impact of rainfall on water quality could be mitigated by water-treatment chemicals in the traditional fish farm, the extra drainage required to prevent fish escape during rainstorm events also resulted in additional energy consumption and GHG emissions associated with drainage and wastewater treatment. Local meteorological records show four rainstorm events in 2023 and five in 2024. By simulation, an increase in rainstorm events from four to six or eight within a single production cycle due to climate change would increase the proportion of GHG emissions from wastewater treatment in fish production from 10.70% to 13.40% and 15.95%, respectively.

In contrast, the high-density fish ponds in ecological farms do not receive runoff from farmland, and their walls, made of galvanized sheets, effectively prevent soil from entering the pond. Moreover, fish excrement is removed daily by discharging the bottom 10% of the water into the E. ferox pond. As a result, the adverse effects of heavy rainfall on the water quality of high-density fish ponds are minimal, eliminating the need for wastewater treatment during rainstorms, as is the case for traditional fish ponds. Thus, the ecological mode is more resilient and better equipped to challenges from climate change. Last, a well-designed fish pond that utilizes gravity-fed pipes for automatic drainage of excess water can further conserve energy during storm events.

4.2.2. Impact of Fish Feeds and Fish Species on Carbon Footprint

As shown in Table 4, fish feed is the second most significant contributor to the carbon footprint in fish farming (Table 4). Emission factors for different types of fish feeds vary widely due to the various percentages of fish meal and fish oil used, from carp (omnivorous fish) at 1.071 kg CO2-eq/kg [22] and rainbow trout (freshwater carnivorous fish) at 1.387 kg CO2-eq/kg [23] to salmon (migratory carnivorous fish) at 3.532 kg CO2-eq/kg [15,22]. If the feed ingredients used for salmon were applied to Micropterus salmoides in this study, fish feed would emerge as the most significant contributor to GHG emissions in both ecological (62.86%) and traditional (52.85%) farming modes. This change would increase carbon footprints for fish products, from 4.342 to 7.023 kg CO2-eq/kg (ecological mode) and from 5.672 to 8.353 kg CO2-eq/kg (traditional mode).

Improving fish feed ingredients to enhance the feed conversion ratios or replacing some animal proteins (e.g., fishmeal and fish oil) with plant-based proteins is an effective strategy to mitigate carbon emissions from feed production. Wilfart et al. (2023) [23] have demonstrated that the ecologically designed multi-objective feed can reduce GHG emissions by 40% compared to the traditional feed. Secondly, herbivorous or omnivorous fish species typically exhibit lower carbon footprints than their carnivorous counterparts. For instance, global GHG emissions for omnivorous cyprinids ranged from 2.398 to 4.952 kg CO2-eq/kg, while carbon emissions for salmon ranged from 2.863 to 6.576 kg CO2-eq/kg [7,8]. In this study, the carbon footprint of omnivorous Wenqing Carp was remarkably lower than that of the carnivore Micropterus salmoides, primarily due to the substantial differences in fish feed composition and their corresponding carbon emission factors. Choosing herbivorous or omnivorous fish could also be a potential way to diminish the carbon emissions per unit of fish product.

4.3. Energy Use and Management in Fish Production

As can be seen from Table 4, electricity for aeration constitutes the most significant portion (47.73–56.33%) of the carbon footprint in fish production. This finding aligns with that of Arbour et al. (2024) [31], which indicated that electricity consumption contributed 90% of all midpoint environmental impacts, including climate change potential, in marine aquaponic production of shrimp, red orache, minutina, and okahajiki. Similarly, Zoli et al. (2024) [32] also reported that electricity was the major contributor to environmental impacts (over 50%) in the integrated multi-trophic aquaporin system producing fish (Dicentrarchus labrax and Sparus aurata) and halophytic plants (Salicornia europaea, and Beta vulgaris subsp.). However, fish feed was pinpointed as the primary contributor in their traditional mode. A practical and energy-saving aeration system would contribute to reducing carbon emissions. Transitioning from conventional electricity sources to cleaner alternatives, such as solar energy, is another effective strategy to diminish the carbon footprint in fish production. For example, Song et al. (2019) [15] demonstrated that GHG emissions from Atlantic salmon produced from recirculating aquaculture systems (RASs) using electricity from hydropower (3.730 kg CO2-eq/kg) were only about half of that using electricity from fossil fuel (7.010 kg CO2-eq/kg). Furthermore, using durable facilities can reduce the GHG emissions associated with the construction stage due to a lower depreciation rate.

4.4. Discussion on GHG Emissions and Management Strategies in E. ferox Seed Production

In the context of E. ferox seed production, the main contributors to carbon emissions were compound fertilizer, insecticide, and electricity consumption for water drainage (Table 5), which aligns with Tarigan et al. (2025) [33], who found that fertilizer was a key source of GHG emissions in palm oil and rapeseed oil production. The ecological mode’s lower carbon footprint than the traditional one was primarily due to nutrients in the fish pond effluent replacing part of the fertilizers required for the E. ferox pond. To mitigate GHG emissions, adopting energy-efficient equipment and utilizing clean energy can be instrumental. Furthermore, synchronizing the cultivation cycle of fish with the planting season of E. ferox offers an opportunity for integrated management. Specifically, from January (after harvesting) to March (pre-seedling emergence), the water in the E. ferox pond can be drained to facilitate the drying and disinfection of the seedlings. This practice may reduce the prevalence of pests and diseases in the following year, reducing the use of insecticides and the associated carbon footprint.

4.5. Discussion on Social Sustainability and International Context

While our study primarily focuses on environmental and economic aspects, social sustainability is also important. The ecological model’s shared labor structure demonstrates reduced labor costs through integrated management, such as one operator overseeing fish, duck, and E. ferox ponds, which indirectly supports employability efficiency in smallholder systems. However, explicit analysis of capacity building or farmer perceptions was beyond the scope of this study. Future research should incorporate surveys to quantify social acceptance and assess metrics like farmer training costs, gender roles in labor allocation, and cultural acceptance of high-density aquaculture.

4.6. Limitations and Future Directions

This study did not account for direct CH4 emissions from fish excrement due to aerobic pond conditions and post-harvest disinfection practices. While this aligns with current LCA conventions for aerated systems, future work should incorporate in situ CH4 monitoring to validate this assumption. Additionally, the unavailability of region-specific emission factors for certain inputs (e.g., water-regulating agents) required substitutions (e.g., zero-emission assumption), which may introduce minor uncertainties. Data were sourced from a single farm; future studies should validate findings across multiple regions and years.

5. Conclusions

The ecological model integrating high-density fish ponds and E. ferox pond has achieved a remarkable 24% reduction in the overall carbon footprint per unit product compared to the traditional mode, with Micropterus salmoides exhibiting a carbon footprint of 4.342 kg CO2-eq/kg and E. ferox seed 0.208 kg CO2-eq/kg, both lower than the traditional mode (5.672 kg CO2-eq/kg for Micropterus salmoides and 0.297 kg CO2-eq/kg for E. ferox seed). This model not only reduced production costs and increased profits for both fish and E. ferox seed production but also effectively mitigated GHG emissions from electricity consumption for aeration, wastewater treatment, and fertilizers by utilizing E. ferox pond and lotus pond as treatment facilities, with the nutrients in fish pond effluent partially replacing fertilizers for the E. ferox pond. Additionally, the ecological model demonstrated lower unit product costs for Micropterus salmoides (15.99 RMB/kg vs. 19.14 RMB/kg) and higher profits (4.01 RMB/kg vs. 2.46 RMB/kg for Micropterus salmoides). In contrast, in the traditional model, E. ferox seed production profits were 2.53 RMB/kg vs. 1.93 RMB/kg. Data were sourced from a single farm; future studies should validate findings across multiple regions.

This study advances sustainable agriculture by demonstrating how integrated ecological aquaculture models can significantly reduce carbon emissions, optimize resource use, enhance economic returns, and promote circular nutrient management. The findings contribute to defining, measuring, and promoting sustainable aquaculture practices aligned with global carbon neutrality and food security goals by quantifying both environmental and economic benefits. Based on these findings, we recommend incorporating ecologically integrated models into regional low-carbon agricultural policies to cut emissions and promote sustainable farming.

Author Contributions

Conceptualization, J.L. and G.Y.; data curation, J.L.; formal analysis, G.L. and L.S.; funding acquisition, G.Y. and J.Q.; investigation, J.L. and G.L.; methodology, J.L. and G.L.; project administration, L.X. and J.Q.; resources, L.X. and L.S.; supervision, G.Y.; validation, Y.C.; writing—original draft, J.L.; writing—review and editing, G.Y. and Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Department of Science and Technology of Guangdong Province (2020B121201014), Innovation Team for Waste Resource Utilization and Environmental Health under the Background of Carbon Peak and Carbon Neutrality, Zhaoqing University (TD202408).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors appreciate the assistance of the staff of the ecologically integrated farm, the traditional fish farm, and the traditional E. ferox farm in collecting activity data. Additionally, we appreciate the valuable contributions of the editors and anonymous reviewers in enhancing the quality of this paper.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| GHG | Greenhouse gas |

| CE | GHG emissions of material |

| AC | The input amount of activity data of material |

| EF | The life cycle GHG emissions factor of material |

References

- Araujo, A.F.D.; Caldas, L.R.; Hasparyk, N.P.; Toledo Filho, R.D. Low-Carbon Bio-Concretes with Wood, Bamboo, and Rice Husk Aggregates: Life Cycle Assessment for Sustainable Wall Systems. Sustainability 2025, 17, 2176. [Google Scholar] [CrossRef]

- Singh, V. Global Warming and Climate Change. In Textbook of Environment and Ecology; Singh, V., Ed.; Springer Nature: Singapore, 2024; pp. 283–295. [Google Scholar]

- Wang, Y. Ecological agricultural production mode and carbon footprint accounting based on low carbon economy. Proc. Indian Natl. Sci. Acad. 2022, 88, 796–801. [Google Scholar] [CrossRef]

- Crippa, M.; Solazzo, E.; Guizzardi, D.; Monforti-Ferrario, F.; Tubiello, F.N.; Leip, A. Food systems are responsible for a third of global anthropogenic GHG emissions. Nat. Food 2021, 2, 198–209. [Google Scholar] [CrossRef]

- Gephart, J.A.; Henriksson, P.J.G.; Parker, R.W.R.; Shepon, A.; Gorospe, K.D.; Bergman, K.; Eshel, G.; Golden, C.D.; Halpern, B.S.; Hornborg, S.; et al. Environmental performance of blue foods. Nature 2021, 597, 360–365. [Google Scholar] [CrossRef]

- Roy, K.; Vrba, J.; Kaushik, S.J.; Mraz, J. Nutrient footprint and ecosystem services of carp production in European fishponds in contrast to EU crop and livestock sectors. J. Clean. Prod. 2020, 270, 122268. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, H.; Jin, J.; Zhu, X.; Han, D.; Xie, S. Towards a low-carbon footprint: Current status and prospects for aquaculture. Water Biol. Secur. 2024, 3, 100290. [Google Scholar] [CrossRef]

- MacLeod, M.J.; Hasan, M.R.; Robb, D.H.F.; Mamun-Ur-Rashid, M. Quantifying greenhouse gas emissions from global aquaculture. Sci. Rep. 2020, 10, 11679. [Google Scholar] [CrossRef]

- Batır, E.; Metin, Ö.; Yıldız, M.; Özel, O.T.; Fidan, D. Sustainable land-based IMTA: Holistic management of finfish, mussel, and macroalgae interactions, emphasizing water quality and nutrient dynamics. J. Environ. Manag. 2024, 372, 123411. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Zhu, G.; Kim, H.J.; Brown, P.B.; Huang, J.-Y. Comparative life cycle assessment of aquaponics and hydroponics in the Midwestern United States. J. Clean. Prod. 2020, 275, 122888. [Google Scholar] [CrossRef]

- Xiao, L.; Chen, S.; Han, F.; Wang, T.; Li, Y.; Li, W.; Yuan, G.; Wu, J. Unveiling carbon dynamics in year-round waterlogged pond fields: Insights into soil organic carbon accumulation and sustainable management. Carbon Res. 2025, 4, 14. [Google Scholar] [CrossRef]

- Fang, X.; Wang, C.; Xiao, S.; Yu, K.; Zhao, J.; Liu, S.; Zou, J. Lower methane and nitrous oxide emissions from rice-aquaculture co-culture systems than from rice paddies in southeast China. Agric. For. Meteorol. 2023, 338, 109540. [Google Scholar] [CrossRef]

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Chang, C.C.; Chang, K.C.; Lin, W.C.; Wu, M.H. Carbon footprint analysis in the aquaculture industry: Assessment of an ecological shrimp farm. J. Clean. Prod. 2017, 168, 1101–1107. [Google Scholar] [CrossRef]

- Song, X.; Liu, Y.; Pettersen, J.B.; Brandão, M.; Ma, X.; Røberg, S.; Frostell, B. Life cycle assessment of recirculating aquaculture systems: A case of Atlantic salmon farming in China. J. Ind. Ecol. 2019, 23, 1077–1086. [Google Scholar] [CrossRef]

- ISO 14067; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification and Communication. International Organization for Standardization: Geneva, Switzerland, 2018.

- PAS 2050:2008; Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services. British Standards Institution: London, UK, 2008.

- Chen, W.; Xie, Y.; Wang, C.; Geng, Y.; Tan, X. Coupling Coordination Analysis of Water, Energy, and Carbon Footprints for Wastewater Treatment Plants. Sustainability 2025, 17, 2594. [Google Scholar] [CrossRef]

- Yu, W.; Liu, R.; Zhu, K.; Hao, X. Variable emission factors of CH4 and N2O from WWTPs: A model-based analysis on available data. Environ. Res. 2025, 264, 120380. [Google Scholar] [CrossRef]

- China Urban Greenhouse Gas Emission Working Group. China Product Life Cycle Greenhouse Gas Emission Coefficient Database. 2025. Available online: http://lca.cityghg.com/ (accessed on 28 September 2024).

- Environmental Protection Administration. Environmental Protection Administration Carbon Footprint Calculation Platform. 2018. Available online: https://cfp-calculate.tw/cfpc/WebPage/LoginPage.aspx (accessed on 26 September 2024).

- Wang, S.; Cheng, L.; Liu, X. Comparative study on the carbon footprints of extruded and pelleted feed and their potential for carbon reduction: A case study of grass carp feed. J. Clean. Prod. 2022, 381, 135192. [Google Scholar] [CrossRef]

- Wilfart, A.; Garcia-Launay, F.; Terrier, F.; Soudé, E.; Aguirre, P.; Skiba-Cassy, S. A step towards sustainable aquaculture: Multiobjective feed formulation reduces environmental impacts at feed and farm levels for rainbow trout. Aquaculture 2023, 562, 738826. [Google Scholar] [CrossRef]

- Yu, Z.; Jiao, W.; Min, Q. Carbon footprints of tea production in smallholder plantations: A case study of Fenghuang Dancong tea in China. Ecol. Indic. 2024, 158, 111305. [Google Scholar] [CrossRef]

- Xu, C.; Chen, Z.; Ji, L.; Lu, J. Carbon and Nitrogen Footprints of Major Cereal Crop Production in China: A Study Based on Farm Management Surveys. Rice Sci. 2022, 29, 288–298. [Google Scholar] [CrossRef]

- Zhang, G.; Lu, F.; Huang, Z.; Chen, S.; Wang, X. Estimations of application dosage and greenhouse gas emission of chemical pesticides in staple crops in China. Chin. J. Appl. Ecol. 2016, 27, 2875–2883. [Google Scholar]

- Ministry of Ecology and Environment. Announcement on the Release of the Electricity CO2 Emission Factor for the Year 2021. 2024. Available online: https://www.mee.gov.cn/xxgk2018/xxgk/xxgk01/202404/t20240412_1070565.html (accessed on 28 September 2024).

- Xu, C.; Su, G.; Zhao, K.; Xu, X.; Li, Z.; Hu, Q.; Xue, Y.; Xu, J. Current status of greenhouse gas emissions from aquaculture in China. Water Biol. Secur. 2022, 1, 100041. [Google Scholar] [CrossRef]

- Jia, Z.; Chang, X.; Duan, T.; Wang, X.; Wei, T.; Li, Y. Water quality responses to rainfall and surrounding land uses in urban lakes. J. Environ. Manag. 2021, 298, 113514. [Google Scholar] [CrossRef] [PubMed]

- Moreira, C.V.M.; Costa, M.R.A.d.; Becker, V. Impacts of extreme precipitation events in water quality: A scientometric analysis in global scale. Acta Limnol. Bras. 2023, 35, e17. [Google Scholar] [CrossRef]

- Arbour, A.J.; Chu, Y.T.; Brown, P.B.; Huang, J.Y. Life cycle assessment on marine aquaponic production of shrimp, red orache, minutina and okahajiki. J. Environ. Manag. 2024, 353, 120208. [Google Scholar] [CrossRef]

- Zoli, M.; Rossi, L.; Bacenetti, J.; Aubin, J. Upscaling and environmental impact assessment of an innovative integrated multi-trophic aquaponic system. J. Environ. Manag. 2024, 369, 122327. [Google Scholar] [CrossRef]

- Tarigan, S.; Pradiko, I.; Darlan, N.H.; Kristanto, Y. Carbon Footprint Comparison of Rapeseed and Palm Oil: Impact of Land Use and Fertilizers. Sustainability 2025, 17, 1521. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).