Abstract

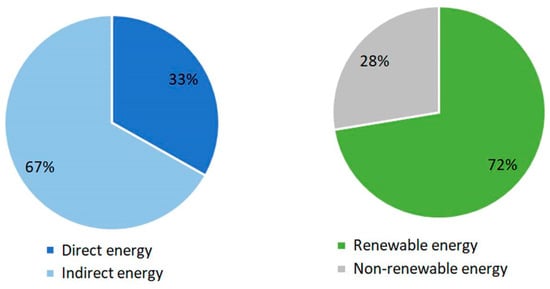

Saffron (Crocus sativus L.) stands as a valuable agricultural commodity, witnessing an increasing market inclination toward environmentally sustainable and eco-friendly products. The current literature on the environmental impact and profitability of saffron cultivation is limited, underscoring a notable gap in comprehending the sustainability aspects of this crop. This study utilized a comprehensive multi-model approach to assess the sustainability of annual saffron cultivation, representing the first global detailed evaluation, conducted within a European context (Southern Italy). Energy analysis, physical and monetized life cycle assessment (LCA), and life cycle costing (LCC) were used for a cradle-to-farm gate assessment. One hectare of cultivated saffron, one saffron production yield (stigma, corm, and flower), and 1 kg of stigma yield were used as functional units. The total energy input was 65,073 MJ ha−1, being 33% direct, 67% indirect, 72% renewable, and 28% non-renewable. The majority (55%) of energy is derived from corm production. For 1 kg of saffron the energy efficiency, specific energy, and productivity were 2.98, 4.64 MJ kg−1, and 0.22 kg MJ−1, respectively, while these values dropped significantly for 1 kg of stigma. The multi-indicator LCA analysis using the ReCiPe 2016 model revealed significant contributions to various environmental impact categories. Results align with prior research, pinpointing fertilization and mechanical operations as the primary drivers of diverse environmental impacts. A noticeable carbon intensity was estimated, with a relevant contribution from corm production and human labor, aspects overlooked in previous LCA studies. Saffron cultivation maintains economic viability, with production costs at EUR 98,435 per ha−1 and a net return margin of EUR 172,680 per ha−1, bolstered by the high market price and by-product revenue. Monetization of LCA results revealed that external costs were EUR 15,509 per ha−1, being only 14% of the total cost. Investments in improving yield and resource efficiency have the potential to increase the eco-efficiency of saffron cultivation.

1. Introduction

Saffron (Crocus sativus L.) is a perennial plant belonging to the Iridaceae family. It is renowned as “red gold” in numerous countries across Asia, Europe, and Australia [1]. Its high market value is attributed to labor-intensive practices during flower harvesting and processing, coupled with a limited yield requiring 150–200 flowers to yield 1 kg of stigma [2]. The three major metabolites influencing saffron quality are crocin, picrocrocin, and safranal [1]. Crocins are responsible for the color and come from the water-soluble glycosidic cis- and trans-carotenoid crocin, glucosyl esters of crocetin. Picrocrocin (C16H26O7) is responsible for the bitter taste of saffron. Chemically, it is a monoterpene glycoside that serves as a precursor of safranal (C10H14O), the major volatile oil in the stigmas of saffron responsible for the unique aroma [3]. Saffron holds a prominent position in various industries, including food, cosmetics, and textile dyeing [4,5]. As of 2020, the worldwide production of saffron was estimated to be 418 tons annually, covering an extensive land area of 121,338 hectares of saffron cultivation [1]. Iran stands out as the foremost producer, contributing up to 94% of the global saffron yield. Predictions indicate that the worldwide saffron market is expected to experience an 8.5% expansion by 2028, largely driven by the increasing demand in the cosmetics industry [6]. In the last decade, Italian farmers have embraced saffron cultivation for enhancing their economic income [7], dedicating over 70 hectares in regions such as Sardegna, Abruzzo, and Tuscany [5].

Saffron production relies on traditional, labor-intensive methods [8], creating job opportunities, especially for women and young individuals [9]. Despite its adaptability to marginal land and low-input farming systems [10], challenges such as a short flowering season, modest yields, manual harvesting, and limited global distribution impact farmers’ income [9]. Investigating sustainability impacts is crucial due to these challenges and the potential decrease in overall environmental benefits with lower yields.

Energy and greenhouse gas (GHG) emissions hold a key role in appraising or comparing the effectiveness of various production systems [10] and determining the environmental sustainability of farming [11]. Saffron production has been subject to scrutiny regarding its energy balance [12,13,14] and GHG emissions [12,13,15,16], emphasizing the need for improved energy management and environmental practices. The environmental impact of crop production extends beyond energy and greenhouse gas emissions, encompassing factors like land use, water consumption, toxicity, resource use, and pollution potential. A holistic approach combining life cycle assessment (LCA) and life cycle costing (LCC) is crucial for thoroughly understanding the eco-efficiency of crop production systems [17]. Generally, there is a limited body of scientific literature addressing environmental impacts via LCA. Previous research has provided a narrow exploration of potential environmental impacts, employing a limited set of indicators and restricting the geographic scope to the Middle East [13,16,18,19]. Few studies have examined the production cost [20], as well as combined energy, economic, and environmental factors, as demonstrated in the other works [15,16,17,18,19,20,21,22,23,24].

The geographical focus of existing LCA studies, primarily in Iran, suggests a gap in research outside of this region, limiting the generalizability of findings to different agricultural contexts. Out of Iran, only Manzo et al. [7] conducted a preliminary assessment of the economic viability of high-quality saffron production for local Italian markets. It is crucial to address this research gap by conducting more comprehensive life cycle thinking studies, especially utilizing methodologies like LCA and LCC. This necessity arises from the need to capture the intricate interplay of diverse factors influencing sustainability, providing a more nuanced understanding of the environmental and economic dimensions associated with various practices and systems.

This study marks the first attempt to explore the farm-level sustainability of saffron cultivation in Europe, providing valuable insights and serving as a reference for future research. Focused on the Italian context, particularly the Basilicata region in southern Italy, the research delves into the energy balance, life cycle environmental impacts, and economic profitability of saffron cultivation at the farm level. Saffron adapts to different environments and, in particular, in the Basilicata region, it represents an innovative agricultural venture. The primary objective is to answer the research question: What is the magnitude of the impacts in saffron cultivation, and what are the main hotspots in terms of agricultural activities within the system? This evaluation goes beyond traditional assessments by conducting a thorough analysis of energy performance and eco-efficiency using a multi-indicator LCA-LCC model. This information empowers experts to gain a more comprehensive understanding of the true sustainability of saffron cultivation within the European context.

2. Materials and Methods

2.1. Saffron Production System in Basilicata Region

In Italy, saffron has a long tradition, primarily in three regions: Abruzzo (Navelli, L’Aquila), Sardinia (province of Medio Campidano), and Tuscany (San Gimignano, Florence Hills, and Maremma), all characterized by the protected designation of origin (PDO) label [3]. The studied saffron system is located in the Basilicata region (40°38′35″ N; 15°58′12″ E; 768 m a.s.l.; Southern Italy). Basilicata is a mountainous region with a surface area of 9992 km2; 47% consists of mountains, 45% of hills, and 8% of plains [25]. The climate is Continental (warm summers and cold winters) in the mountains and Mediterranean (hot summers and mild winters) along the coasts. This characteristic climate is due to the topographic complexity of the region, mainly the presence of the Appennine, which influences precipitation distribution [26]. Saffron adapts to different environments, and in particular, in Basilicata, the mean air temperature of 16 °C, along with minimal precipitation during flower harvesting, allows for high yields [27]. The saffron production area within the Basilicata region spans approximately 7–8 hectares and is primarily concentrated in the province of Potenza. Notably, the majority of cultivation is clustered in the central and northern areas of the western side, with limited saffron farms on the eastern side, including Matera, Irsina, Tricarico, and Bernalda. These saffron crops are typically situated at elevations ranging from 200 to 1000 m above sea level, featuring predominantly small- to medium-sized cultivation plots ranging from 50 to 4000 m2. The largest saffron producer in the region is located in Tricarico, boasting an annual organic yield of approximately 1.5 kg (Figure 1).

Figure 1.

Flowering phase, plant density, and harvesting saffron flowers in Tricarico (Matera).

2.1.1. Saffron Cultivation: From Soil Preparation to Flower Harvesting

The saffron cultivation system adopts cultivation practices, processing, and transformation techniques learned from centuries-old traditions and experiences gained in other Italian regions (Abruzzo and Sardinia). The soil is prepared by plowing and incorporating organic fertilizers during the processing. The soil preparation entails a thorough plowing to a depth of 25–30 cm, utilizing a plowshare or disc plough. Organic fertilizer, specifically well-matured sheep or cattle manure amounting to approximately 20–30 tons per hectare, is incorporated into the soil through plowing. An effective alternative to animal manure is green manure, an agronomic practice that consists of burying legumes (i.e., field beans), capable of supplying nitrogen, improving the structure of the soil, and increasing the organic matter content. During the vegetative cycle, no chemical fertilizers are used. The subsequent steps include land refinement, leveling, and furrowing operations. Land preparation is carried out using traditional agricultural machinery. Raised beds can be arranged to improve drainage, 80–100 cm apart, on which furrows 10–15 cm wide and 20 cm deep are traced, in which the corms are positioned with the vegetative apex facing upwards. Raised beds can contain one or two rows. The planting depth is 15 cm and can vary according to the soil texture.

The spacing of corms is subject to adjustments according to the cultivation cycle. In the case of an annual cycle, corms are typically situated within the row at intervals of 1 to 2 cm, with a broader spacing of 15 to 30 cm between rows. In contrast, for perennial crops, it is crucial to ensure that the cultivation cycle does not exceed three years to maintain optimal stigma yield [3]. Under these conditions, corms are positioned at intervals of 10 to 15 cm within rows that are spaced 25 to 50 cm apart. The number of corms per hectare typically ranges from 200,000 to 600,000, equivalent to 4 to 10 metric tons per hectare. The corms are planted manually between 10 August and 20 September. Soils are well drained, friable, and characterized by a loam and sandy-loam texture. They are not very calcareous, with a sub-alkaline and neutral pH. Low electrical conductivity and a moderate content of organic matter are preferable [2]. Prior to planting, farmers implement preventive measures by applying copper oxychloride, a fungicide presented in the form of 32% wettable powder, to the corms. The corms are immersed in a solution containing this fungicide at a rate of 0.7 kg per hectoliter of water for a brief period. Following this treatment, the corms are carefully dried in shaded areas to prevent rot and mold formation. Subsequently, they are stored in specialized containers until the time of planting. Approximately 60 to 70 days after being planted, saffron plants begin to bloom. The flower harvest is a gradual process, taking place from mid-October to mid-November. It is conducted during the early morning hours when the flowers are either closed or only partially open. The detachment of the flowers is an operation performed manually with the help of baskets or boxes (Figure 1) by squeezing the flower between the thumb and forefinger of one hand and cutting it with the nails at the base.

2.1.2. Saffron Stigma: From ‘Mondatura’ to Storage

After harvesting, the flowers are taken to a suitable and closed room (laboratory) to undergo ‘mondatura’, which involves separating the stigmas from the rest of the flower during the day. In the case of rain during the harvest, the flowers must be dried using special fans before proceeding to the post-harvest phases. ‘Mondatura’ is a very delicate and laborious phase. It involves opening the flower, cutting the stigma at the base of the three filaments, being careful not to separate them, and eliminating the white-yellow part that holds the stigmas together to the style, aiming to obtain a product of superior quality. The operation requires care and experience because it is necessary to avoid the stigmas that undergo too many manipulations and ensure that they do not present floral residues in the finished product. The drying process of the stigmas must take place at a controlled temperature of 42–45 °C for a variable time, in electric ovens or food dryers. Recently, young female entrepreneurs have played a leading role in this cultivation, mainly in the transformation phase from flower harvesting to stigma production. Drying is considered optimal when the stigmas lose about 80% of their initial weight. After drying and while awaiting packaging, the stigma is stored in hermetically sealed glass containers to minimize exposure to air, moisture, and light. Furthermore, storage must take place, if possible, at a low temperature (10–15 °C) (not exceeding 15 °C) with a relative humidity between 30% and 50% (in cool and dry rooms). Among the cultivation techniques, particular attention is given to weed control, utilizing manual weeding on the row, accompanied by mechanical tillage operations between the rows, and avoiding the use of any type of synthetic herbicide. These interventions are carried out in autumn, before and/or after flowering, and in spring. Irrigation is used only in cases of prolonged drought, especially after planting (beginning of September), to promote the awakening of the corms. The corms are explanted at the end of May–beginning of June, and before being planted, they undergo a cleaning phase, called husking, which consists, first, of the elimination of soil residues, stones, leaves, and other vegetable material and, subsequently, in the detachment of the external tunics and the residue of the mother corm, which can be a source of fungal or bacterial diseases. Moreover, corms undergo a selection process, and those exhibiting malformations, lesions, or signs of phytopathological issues are removed. Furthermore, the same is selected based on the diameter: those intended for planting are the “useful corms”, i.e., with a diameter of at least 2.5 cm, capable of producing flowers (corms in “flower strength”). The smaller ones, called “mezzanelle”, can be replanted only to favor their growth and have corms of useful size the following year because they will hardly produce flowers in the year of planting. After explanting, the corms are stored in dark and well-ventilated rooms (natural ventilation), in special fenestrated and uncovered boxes. During storage, the optimal thermal conditions to guarantee floral differentiation (and therefore a higher yield) must be between 23 and 27 °C, for at least 45–60 days [5]. In addition to the temperature, another important parameter is the relative humidity, which must be between 65 and 85%.

2.2. Methodology

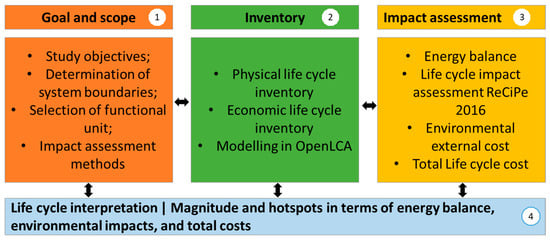

This study aims to combine both LCA and LCC methodologies to examine the economic and environmental implications of annual saffron cultivation. To achieve the study’s objective, the methodology followed a series of common steps outlined in Figure 2, including goal and scope definition, inventory analysis, life cycle impact assessment, and interpretation of results. The approach employed in this study aligns with the methodology specified by Denora et al. [28]. The subsequent sections provide a detailed description of each of these steps.

Figure 2.

LCA-LCC framework for analysis of saffron cultivation.

2.2.1. Goal and Scope

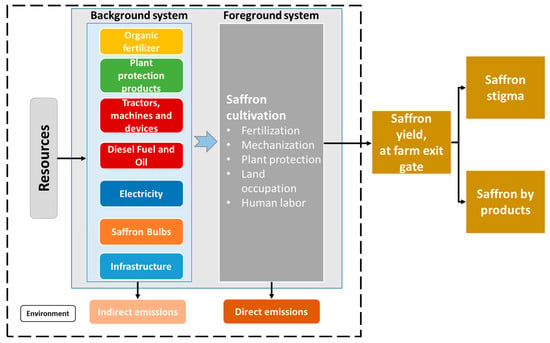

The first phase involves describing the goal and scope, which includes defining the objectives of the study, setting the system boundaries, and determining the functional unit. Saffron is primarily cultivated as a perennial, some producers choose to lift corms every summer, sorting and storing them under dry conditions until replanting, similar to the process used in annual production [29]. While the majority of producers focus on cultivating saffron for its flowers, a subset also engages in the commercialization of corms. This study specifically focuses on the eco-efficiency of annual cultivation, where farmers dig corms annually when they reach dormancy, sell the large corms, and plant new corms in the fall in a new terrain. A cradle-to-farm gate system boundary was designed to determine the energy and environmental footprint and costs of saffron cultivation. The goal of the LCC was to provide a holistic financial analysis of saffron cultivation. The system boundary of saffron production covered all of the stages described in the diagram in Figure 3. The model considers all activities starting with the extraction of materials from the earth (the cradle); production with their upstream contribution; transportation of raw materials to the farm; and farm usage. LCA and LCC results are usually expressed in terms of a functional unit (FU). One hectare of cultivated saffron, one saffron production yield (stigma, corm, and flower), and 1 kg of stigma yield were used as functional units for analysis. The use of these units enabled us to capture and assess two essential aspects: the production intensity on a per-weight basis and the technical efficiency of production in terms of land utilization. This approach facilitated a thorough assessment of saffron production’s eco-efficiency across various dimensions.

Figure 3.

System boundary for LCA-LCC analysis of saffron cultivation.

In saffron production, both primary products and by-products are generated, including the stigma, flower, and corm. The central product is the saffron stigma, derived from the dried stigma of the saffron flower. Corms, considered by-products, result from harvesting saffron flowers. Since the main goal of the farmer is to produce the saffron stigma itself, economic allocation was used to allocate the environmental impacts between the stigma and by-products. Economic allocation is employed to distribute environmental impacts between the primary goal, the saffron stigma, and its by-products. Cultivating saffron on one hectare yields 3.5 kg of saffron stigma, 30 kg of floral waste, and 14,000 kg of corms. The average market prices are EUR 25 per kilogram for saffron stigma, EUR 1.8 per kilogram for dried floral waste, and EUR 18 per kilogram for corms. Consequently, stigma, floral waste, and corms contribute 35%, 22%, and 45% to the environmental impacts, respectively.

2.2.2. Inventory Analysis

In the inventory analysis stage, all data within the system boundaries were collected. LCA data encompassed all energy and material inputs and outputs within the scope of this study (Table 1), while LCC data involved financial cash flows (Table 2). The aggregated information about the inputs needed to produce 1 hectare of saffron was collected from specific farms in the Matera region (Table 1). The data obtained from the farmers included inputs such as corms for sowing, human power, machinery, fuel, organic fertilizers, and plant protection products.

Table 1.

Data on resource input, crop output, and farm-level emissions in annual saffron production in the Basilicata Region, Southern Italy (input and yield data were collected from authors in saffron farms while emission data were calculated using specific models).

Table 2.

Unit cost for crop inputs and market price utilized for economic analysis. Data collected from authors using information obtained from farmers and markets.

In the calculation model, we accounted for the on-site environmental emissions from different practices, i.e., the combustion of fossil fuels by the tractor, application, and decomposition of fertilizers, and plant protection products [30]. The considered nitrogen-based environmental emissions from fertilizers were direct dinitrogen monoxide emissions (0.01 kg N2O-N), indirect N2O from atmospheric deposition (0.09927 kg N2O-N per kg NH3-N), leaching/runoff (0.0075 kg N2O-N per kg NO3-N), nitrate–nitrogen leaching loss (0.2728 kg NO3-N per kg N leached), ammonia volatilization (0.1 kg NH3-N per kgN), and nitrous oxide (0.21 kg NOx per kg N2O). The N2O emission factors were retrieved from the CarbonCloud agricultural model [30]. The phosphate emissions included phosphate PO43− leaching to groundwater (0.07 kg ha−1 yr−1), runoff to surface water (0.175 kg ha−1 yr−1 for open arable land), and phosphorous (P) emissions through water erosion to surface water. Pesticide emissions were calculated from the Ecoinvent database. Emissions from human labor were calculated considering a coefficient of 0.7 kg CO2-eq h−1 of work.

All background process emissions, including the production of fuel, machinery, fertilizers, seeds, etc., were sourced from the Ecoinvent database [31].

The collection of input costs and market prices was carried out to ascertain the overall life cycle costs and profitability of saffron cultivation, as presented in Table 2.

2.2.3. Impact Assessment

The calculations were conducted using OpenLCA v. 2.0.4 [32], advanced open-source software for the sustainability assessment of products and services.

Energy and Environmental Impact Assessment

The energy balance of saffron cultivation was quantified using various input components consumed and energy outputs produced. All the physical input and output components were converted into their respective energy equivalents by multiplying them by their corresponding energy coefficient (Table 3). Various energy parameters including energy use efficiency (EUE) or energy ratio (ER), energy productivity (EP), specific energy (SE), and net energy gain (NEG) were estimated using Equations (1)–(4):

Table 3.

Energy equivalent value of inputs and outputs in saffron production.

The input–output energy ratio (Equation (1)), also known as energy use efficiency, serves as an indicator for assessing the energy efficiency of an agricultural system. An increased ratio signifies improved energy efficiency. Energy productivity (Equation (2)) measures the amount of physical output obtained from each unit of energy consumed, indicating higher productivity with an increased indicator. Specific energy (Equation (3)) is the inverse of energy productivity and defines the energy required to produce one unit of product; an increased indicator indicates lower energy efficiency. Net energy gain (Equation (4)) in energy economics represents the difference between the energy expended and gained in harvesting an energy source. A higher net indicates more energy gain, making it more profitable, and vice versa.

Different types of energy forms (direct/indirect) and sources (renewable/non-renewable) were characterized. The direct energy (DE) forms included human labor, diesel fuel, and electricity, while the indirect energy (IE) was corms, fertilizers, machinery, and plant protection. Renewable energy (RE) was human labor, organic fertilizer, and corms while non-renewable energy was diesel fuel, electricity, chemical fertilizers (NPK), plant protection, and machinery.

An extensive environmental profile was created based on the ReCiPe 2016 [33] life cycle impact assessment method using the emissions in Table 1 and background emissions from the Ecoinvent 3.1 database [34]. ReCiPe is one of the most widely used methods in LCA analysis. It combines the strengths of both midpoint- and endpoint-based life cycle impact assessment approaches, resulting in 18 midpoint and 3 endpoint indicators. The eighteen (18) midpoint indicators were global warming potential (GWP), stratospheric ozone depletion (ODP), ionizing radiation (IRP), photochemical oxidant formation: human health (HOFP), photochemical oxidant formation: ecosystem quality (EOFP), human toxicity potential: cancer (HTPc), human toxicity potential: non-cancer (HTPnc), terrestrial ecotoxicity potential (TETP), freshwater ecotoxicity potential (FETP), marine ecotoxicity potential (METP), freshwater eutrophication potential (FEP), fine particulate matter formation (PMFP), terrestrial acidification (TAP), land use (LU), water consumption potential (WCP), mineral resource scarcity (MRS), and fossil resource scarcity (FFP). Endpoint results are typically shown as an impact on human health (HH), ecosystem quality (EQ), and resource scarcity (RA). The total environmental load panel weighting (human health 400, ecosystem quality 400, and resources 200) was performed at the damage category (endpoint) level to generate a single LCA score.

Economic Assessment

The economic performance of saffron cultivation was assessed by calculating several key indicators, including the gross return (GR), net return (NR), and the benefit-to-cost (B:C) ratio.

where GVP is the gross value of the production (EUR·ha−1), GR is the gross return (EUR·ha−1), VCP represents the variable cost of production (EUR·ha−1), NR is the net return (EUR·ha−1), TCP stands for the total cost of production as a variable and in fixed production (EUR·ha−1), and BCR is the benefit-to-cost ratio.

The economic output (gross value of production, GVP) for the saffron system, encompassing stigmas, flowers, and corms, was calculated by multiplying the corresponding yield with the respective market price. The variable cost of production (VCP) represented the average expenses incurred in the entire process of saffron cultivation: the cost of hiring human labor, diesel, corms, fertilizers, and pesticides. The costs of renting land and farm equipment were considered fixed costs. All of these costs were determined based on the average unit cost (Table 4) and were related to functional units. At the farm level, there might be substantial hidden costs from life cycle potential environmental impacts [35]. Therefore, the physical LCA results were converted into monetary values to compute the external environmental costs (EECs) and assess their impact on the overall cost. The environmental prices used for external cost analysis (Table 4) were retrieved from the updated Environmental Prices Handbook 2023 [36].

Table 4.

Environmental prices for ReCiPe 2016 midpoints, in EUR2021 per unit.

3. Results and Discussion

3.1. Energy Balance and Performance Indices

The results of the energy assessment are presented in Table 5. The total energy input was calculated at 65,073 MJ ha−1, falling within the literature-reported range of 25,020 MJ ha−1 to 201,866.51 MJ ha−1. Specifically, the energy input is documented as 163,912.09 MJ ha−1 in the Razavi Khorasan province [13], 21,580.18 MJ ha−1 in the northeastern Razavi Khorasan province of Iran [21], 99,236 MJ ha−1 in the eastern region of Iran [16], 25,020 MJ ha−1 in the East Azerbaijan Province of Iran [15], 201,866.51 MJ ha−1 in the Khorasan-e Razavi Province [12], and 43,578.47 MJ ha−1 in the Isfahan Province of Iran [24]. In the Kashmir valley of India [14], the range was reported as 43,3477.94 to 46,983.08 MJ ha−1, depending on the farm size.

Table 5.

Energy indices for saffron production in Southern Italy.

There are two methods for determining energy performance indices in saffron. The first method takes into account all saffron outputs, including stigma, flower, and corm, while the second method focuses solely on saffron stigma. Energy use efficiency, specific energy, and the energy productivity of saffron cultivation (based on stigma + by-products) in Basilicata were calculated as 2.98, 4.64 MJ kg−1, and 0.22 kg MJ−1, respectively (Table 5). However, when focusing solely on saffron stigma, these values were substantially lower at 0.0048, 208.8 MJ kg−1, and 0.000054 kg MJ−1. Other studies have also noted comparable patterns of findings in the energy balance of saffron production, whether considering all outputs or focusing specifically on the stigma. In the context of saffron cultivation in Iran [13], the literature reports energy use efficiency, specific energy, and energy productivity values of 1.12, 13.35 MJ kg−1, and 0.0749 kg MJ−1, respectively, based on the combined metrics of stigma and by-products. Based on saffron stigma only, the values reported were 0.0044, 22.05 MJ kg−1, and 0.0003 kg MJ−1 in the east of Iran [16]; 0.24 (0.0004), 51,235.15 MJ kg−1, and 0.000019 kg MJ−1 in the northeast of Iran [12]; 0.035, 5590.72 MJ kg−1, and 0.00018 kg MJ−1 in the northeast of Iran [22]; and 0.002, 8794.85 MJ kg−1, and 0.00011 kg MJ−1 in the center of Iran [23].

The variations observed in energy input and performance indices during saffron cultivation reflect a complex interplay of geographic, methodological, and agricultural factors, particularly yield. This underscores how diverse geographical regions, farming practices, and methodologies exert significant influence on the energy consumption in saffron cultivation. The calculation of energy for annual cultivation versus perennial cultivation may alter perspectives and the magnitude of impacts. Annual cultivation offers the advantage of reduced weed removal and the enhanced prevention of parasites and diseases due to increased rotation. However, the energy-intensive process of uprooting and planting bulbs and the creation of raised beds is a notable drawback. Nevertheless, the labor-intensive process of uprooting and planting bulbs, along with the construction of raised beds, constitutes a significant drawback, requiring more than 500 h of work and contributing to the overall energy footprint. In perennial cultivation, corms are planted and left undisturbed for an extended period, typically 3 or 4 years. In Italy, 90% of saffron farms do not apply irrigation while just 40% of farms are mechanized [37]. However, in arid and semiarid areas, saffron must be irrigated to achieve satisfactory yield [38]. The provision of water for irrigation, along with the energy expended on pumping and applying the water, constitutes significant energy inputs in crop production. In numerous research investigations, the embodied energy of water has been reported within the range of 0.63 to 1.03 MJ m−3, and for electricity, it varies from 3.6 to 12 MJ kWh−1. With an average saffron irrigation requirement of 3500 m3 ha−1 [38] and an electricity energy demand of 836.5 kWh ha−1 (considering an average pumping depth of 48 m), the energy input is elevated to a range of 5216 to 13,643 MJ ha−1. This example vividly illustrates how the energy input from irrigation, combined with associated energy coefficients, impacts the overall magnitude of the energy footprint and related performance energy indices (i.e., specific energy, efficiency, and productivity). Other changes can be expected if the farm is either entirely mechanized or relies on manual labor, as diesel and human labor involve significantly different energy inputs.

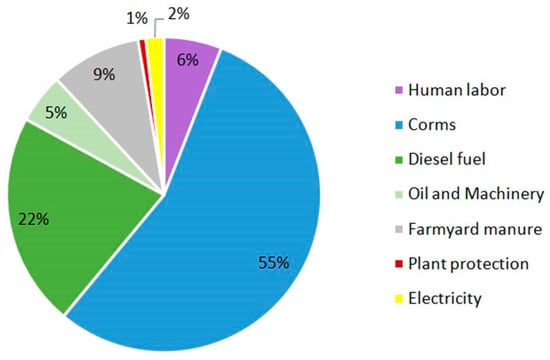

3.1.1. Energy Hotspots

The largest share of energy consumption in saffron production, constituting 55% (35,630 MJ ha−1) of the total input, was attributed to corm production (see Figure 4). Around 22% of the overall energy input was allocated to fuel and machinery for field operations, with fertilization constituting approximately 9%. The substantial energy allocation to corms stemmed mainly from the absence of chemical fertilizers and constrained water and energy usage for irrigation. Similar findings were observed by Mohammadzadeh et al. [15], Bakhtiari et al. [13], and Ali et al. [14] identifying corm production as the primary contributor to the overall energy footprint in saffron cultivation. Additional inputs, including nitrogen, electricity, manure, and human labor, were identified as the most energy-intensive elements in the context of saffron production in Iran.

Figure 4.

Process energy inputs relative to the total energy input in saffron production in Italy.

3.1.2. Energy Forms and Types

Figure 5 illustrates the breakdown of energy usage into categories of direct, indirect, renewable, and non-renewable sources. The results revealed that the share of energy input consumed from direct and indirect energy is 33% and 67%, respectively. When categorizing the energy sources into renewable and non-renewable, it becomes apparent that 72% of the overall energy input is derived from renewable sources, while the remaining 28% is sourced from non-renewable origins. Bakhtiari et al. [13], Sahabi et al. [21], and Mohammadzadeh et al. [15] also reported comparable findings, with renewable and indirect energy sources having higher shares than non-renewable and direct energy sources, respectively. Ali et al. [14] reported indirect energy to be higher than direct energy. On the other hand, Khorramdel et al. [19] observed a higher proportion of renewable energy compared to non-renewable energy but a higher share of direct energy compared to non-direct energy. Saeidi et al. [23] observed more direct energy but a higher proportion of non-renewable energy compared to renewable energy. In summary, the comparison reveals consistent patterns in the dominance of renewable and indirect energy sources, but variations exist in the proportion and share of direct, indirect, renewable, and non-renewable energy among different studies.

Figure 5.

The share of direct/indirect and renewable/non-renewable energy inputs from total energy input in saffron production in Italy.

3.2. Environmental Profile Using LCA

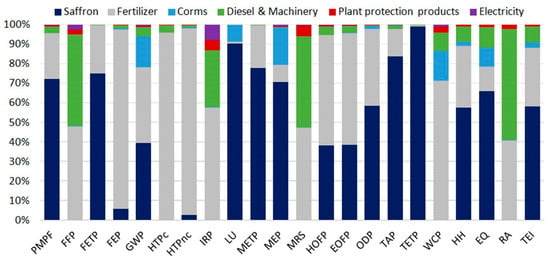

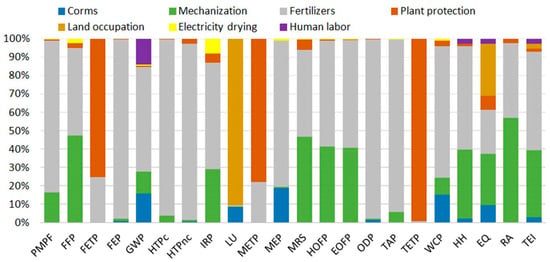

The results of the environmental footprint are summarized in Table 6. The hotspots are given in Figure 6 and Figure 7. The results of LCA provide a comprehensive overview of the environmental impacts associated with the evaluated saffron system. The environmental impact most typically observed and monitored concerning saffron cultivation is the release of greenhouse gas (GHG) emissions or global warming potential (GWP). In our study, the mean GWP value was determined to be 9747.9 kg CO2-eq ha−1, which translates to 2164 kg CO2-eq per kilogram of saffron stigma. GWP is notably influenced (Figure 6 and Figure 7) by emissions of corm production (30%), dinitrogen monoxide (15%), fuel combustion (6%), and human labor (12%). In the eastern region of Iran, Bakhtiari et al. [13] documented a global warming potential (GWP) of 2325.51 kg CO2-eq ha−1. Khanali et al. [16] reported a GWP of 1816 kg CO2-eq ha−1 per year for saffron cultivation in Southern Khorasan, considering an average yield of 4.591 kg ha−1 or 395.6 kg CO2-eq kg−1 of saffron. Khanali et al. [16] found a GWP of 1332.72 kg CO2-eq ha−1 or 296.16 kg CO2-eq kg−1. In East Azerbaijan Province, Iran, Mohammadzadeh et al. [15] reported a GWP of 646.2 kg CO2-eq ha−1 or 203.3 kg CO2-eq kg−1. Khorramdel et al. [12] assessed global warming, acidification, and eutrophication, reporting values of 115.41 kg CO2-eq, 0.35 kg SO2-eq, 0.58 kg NOx-eq, and 0.20 kg PO4-eq for each kilogram of flower yield. In Razavi Khorasan province, Iran, Rezvani Moghaddam et al. [39] documented 4315.4 kg CO2-eq kg−1 and 5262.67 kg CO2-eq kg−1 of flower yield for low-input (as a local production system) and conventional (as a high-input farming system) saffron systems, respectively. The reported GWP values for saffron cultivation in the studied area appear relatively high when compared to earlier studies, signaling a notable carbon intensity in saffron production. Our study specifically centers on the annual cultivation of saffron, assuming the annual transplantation of new corms. Moreover, the variability in greenhouse gas emission coefficients across different years introduces further diversity in results. Additionally, the incorporation of factors like corm production and human labor in calculating greenhouse gas emissions, often neglected in previous LCA studies, significantly contributes to the observed disparities.

Table 6.

Life cycle environmental impacts of saffron production in Southern Italy. Own elaboration using OpenLCA v. 2.0.4 software, ReCiPe 2016 model, and Ecoinvent 3.1 database.

Figure 6.

Relative contributions of processes to the different environmental indicators of saffron production in Italy. Abbreviations: global warming potential (GWP), stratospheric ozone depletion (ODP), ionizing radiation (IRP), photochemical oxidant formation: human health (HOFP), photochemical oxidant formation: ecosystem quality (EOFP), human toxicity potential: cancer (HTPc), human toxicity potential: non-cancer (HTPnc), terrestrial ecotoxicity potential (TETP), freshwater ecotoxicity potential (FETP), marine ecotoxicity potential (METP), freshwater eutrophication potential (FEP), fine particulate matter formation (PMFP), terrestrial acidification (TAP), land use (LU), water consumption potential (WCP), mineral resource scarcity (MRS), fossil resource scarcity (FFP), human health (HH), ecosystem quality (EQ), resource availability (RA), and total environmental impact (TEI).

Figure 7.

Relative contributions of processes to the different environmental indicators of saffron production in Italy. Abbreviations: global warming potential (GWP), stratospheric ozone depletion (ODP), ionizing radiation (IRP), photochemical oxidant formation: human health (HOFP), photochemical oxidant formation: ecosystem quality (EOFP), human toxicity potential: cancer (HTPc), human toxicity potential: non-cancer (HTPnc), terrestrial ecotoxicity potential (TETP), freshwater ecotoxicity potential (FETP), marine ecotoxicity potential (METP), freshwater eutrophication potential (FEP), fine particulate matter formation (PMFP), terrestrial acidification (TAP), land use (LU), water consumption potential (WCP), mineral resource scarcity (MRS), fossil resource scarcity (FFP), human health (HH), ecosystem quality (EQ), resource availability (RA), and total environmental impact (TEI).

The terrestrial acidification was 174.55 kg SO2-eq ha−1 and freshwater eutrophication was 8.71 kg P-eq ha−1. The potential amount of fine particulate matter formation, ionizing radiation, stratospheric ozone depletion, and marine eutrophication were calculated as 32.19 kg PM2.5 eq ha−1, 130.6 kBq Co-60 eq ha−1, 0.1121 kg CFC11 eq ha−1, and 13.7 kg N eq ha−1, respectively. The major contributors to PMPF are ammonia volatilization (59%) and diesel emissions (13%). In the case of TAP, the predominant sources of impacts are primarily attributed to ammonia volatilization (79%). Toxicity is primarily associated with pesticide emissions. Furthermore, the photochemical oxidation formation potential for both humans and the ecosystem is influenced by diesel combustion emissions. At the endpoint level, the values of damage to human health, the ecosystem, and resources were 0.068 DALY, 0.000207 species.yr, and 303.4 USD2013. The total environmental load expressed as a single score after aggregating across life cycle impact categories was 1264.7 point ha−1 or 280.8 per kg of stigma. The calculated values for these indicators contribute to a more comprehensive understanding of the overall environmental footprint of saffron cultivation in our specific context.

Saffron cultivation, as illustrated in Figure 6, significantly contributes to environmental factors, constituting 72% of fine particulate matter formation (PMPF), 33% of global warming potential (GWP), 80% of land occupation, and 84% of terrestrial acidification (TAP). Additionally, it plays a substantial role in impacts related to toxicity. Notably, fertilizers (manure) and diesel fuel consistently emerged as the primary drivers of environmental impact across multiple impact categories (Figure 7). Fertilization, for instance, accounted for 40% of the total GWP, 83% of the PMPF, 71% of the WCP, 94% of the TAP, 97% of the FEP, and the HTPc. Diesel fuel and machinery utilized for mechanized operations contributed 12% to the total GWP, 6% to TAP, 16% to PMPF, and 47% to FFP. The emissions associated with corm production had the most substantial effect on GWP (16%), MEP (19%), WCP (15%), and land use (9%). In contrast, human labor contributed 1372 kg CO2-eq ha−1 or 14% of the total GWP.

Assessing the performance of saffron cultivation across diverse countries or regions introduces variations in agricultural practices, input materials, and climatic conditions. These variations can significantly impact the environmental footprint of saffron production, affecting factors such as energy use, emissions, and resource consumption. Consequently, LCA results may vary based on geographic location, influencing the reliability and generalizability of the findings. Changes in methodologies over time can introduce variability in LCA results, affecting the reliability of assessments and the generalizability of findings across different time periods. Results from various LCA studies may not be directly comparable due to differences in methods, data, and assumptions. Nevertheless, it is essential to systematically examine result patterns. Bakhtiari et al. [13] reported that the main GHG emission resources were electricity for pumping water (46.54%) and chemical fertilizers (31.56%), followed by diesel fuel and machinery (17.32%). Khanali et al. [16] found that chemical fertilizers, as well as farmyard manure, played a substantial role in both off-farm and on-farm GHG emissions. Khanali et al. [16] revealed that fertilizers contributed to 94% of the global warming potential (GWP), 80% of abiotic resource depletion, over 50% of acidification, and 40% of photochemical ozone formation. According to Esfahani and Khazaee [40], nitrogen fertilizer accounted for 46% of the saffron ecological footprint index, while human labor contributed to 43%. While some studies [15,39] did not provide detailed information on system hotspots [16,37], the overall consensus underscores the pivotal role of nitrogen fertilization and mechanization in shaping the environmental impact of saffron production.

3.3. Economic Results Using LCC

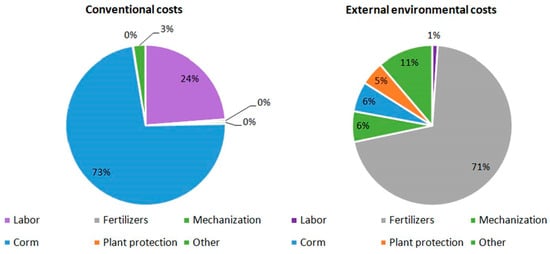

The economic indices of saffron cultivation are shown in Table 7. The gross value of production was estimated at EUR 267.500 per ha−1. Per hectare, the total variable costs per hectare were EUR 82,435 per ha−1, while the total cost of production was EUR 94,820 per ha−1. Among the variable costs, corms and human labor accounted for the largest amount with 73% and 24%, respectively.

Table 7.

Analysis of economic indicators for saffron cultivation in Southern Italy.

The comprehensive environmental cost for cultivating one hectare of saffron was determined to be EUR 15,509, which translates to approximately EUR 3443 per kilogram of stigma. Our analysis (Figure 8) indicates that external environmental costs (hidden costs) constitute 14% of the total cost associated with saffron cultivation. In contrast to conventional cost analysis, the examination of external costs reveals that 71% of these costs can be attributed to fertilizers. These external environmental costs represent the monetized impacts of saffron cultivation on the environment, capturing broader environmental repercussions associated with the production process—often overlooked in market prices. The inclusion of these external environmental costs in the analysis provides a more comprehensive understanding of the actual costs involved. The substantial presence of external environmental costs indicates that the true cost of saffron cultivation is higher than what is reflected in the internal costs incurred by farmers. To enhance the well-being of society at large, the objective should be to maximize net returns while minimizing external costs. The significant presence of external environmental costs suggests the need for policy interventions to internalize these costs and incentivize sustainable practices. This could involve the implementation of environmental regulations, market-based instruments, or incentives for adopting environmentally friendly practices to ensure that the true cost of saffron cultivation reflects its environmental impact. The net return was estimated at EUR 172,680 per ha−1. Comparatively, studies by Manzo et al. [7] and Mohammadzadeh et al. [15] reported different economic figures. Manzo et al. [7] reported EUR 27,822 per ha−1 (29,695 USD/ha) as the total cost of saffron production referring to the entire 5-year cycle. The authors of [15] reported that the total cost of production was EUR 3059.7 per ha−1 (3255 $ ha−1). Sahabi et al. [21] estimated the gross value of production per hectare in the saffron system to be EUR 7268 per ha−1 (USD 8352.23 per ha−1).

Figure 8.

Share of processes on conventional and external environmental costs for saffron cultivation in Southern Italy.

4. Conclusions

This study comprehensively examines the energy balance, environmental footprint, and economic profitability of saffron cultivation in an Italian context. Overall, the study thoroughly examines and explains the research questions by employing rigorous methodologies, contextualizing findings, conducting multi-dimensional analyses, interpreting results critically, and outlining future research directions. The analysis of energy consumption underscores a significant overall input (65,073 MJ ha−1), primarily driven by corm production, which is largely indirect (67%) but predominantly renewable (72%). The environmental analysis, using a multi-indicator LCA model, reveals substantial contributions to various environmental impact categories, aligning with prior research that identifies fertilization and mechanical operations as primary drivers. Notably, this study diverges from contemporary LCA trends by emphasizing the significant role of labor and corm production in certain environmental impacts of saffron cultivation. The decision on the assessment scope plays a crucial role in interpreting the reported energy and environmental performance, with a comprehensive cultivation approach yielding more favorable metrics. In terms of economics, the cultivation of saffron remains viable, even with the lower yield of stigmas, thanks to its high market price and revenue generated from by-products. A streamlined evaluation of total costs, incorporating both conventional LCC results (internal cost) and monetized environmental impacts (external cost), revealed that internal costs (i.e., farmer costs) carry greater significance.

The findings underscore that the inclusion of labor and corm production in future saffron cultivation studies contributes to a more nuanced understanding of the economic and environmental dimensions of saffron production. Overall, improving resource efficiency and productivity has the potential to enhance the sustainability of saffron cultivation. Selecting high-quality corms, optimizing planting density, utilizing organic fertilizers, and implementing effective planting and post-harvest practices contribute to heightened efficiency, enhanced yields, and the promotion of sustainable saffron production practices.

The study is of practical and theoretical significance, advancing sustainability assessment methods by integrating LCA and LCC in saffron cultivation, thereby enhancing the understanding of sustainability in saffron farming systems. The practical implications of the study’s findings extend to offering guidance for the promotion of sustainable agricultural practices, particularly in saffron cultivation. Stakeholders, including farmers and agricultural businesses, can utilize the insights to optimize resource efficiency, improve productivity, and reduce environmental impacts, facilitating the practical implementation of sustainable farming methods. Concurrently, policymakers can leverage these insights to craft policies that incentivize and endorse sustainable agricultural practices, emphasizing resource efficiency and addressing environmental externalities within farming systems. The study’s integrated approach has practical applications in real-world settings, supporting the development and implementation of agricultural policies. However, there are some limitations and potential sources of bias in the study design that should be considered. Firstly, the study only focuses on one case study in Italy, which limits the generalizability of the findings to other regions and contexts. Future research should consider conducting multi-regional studies to capture the variability of saffron cultivation practices and environmental impacts across different countries and regions. Secondly, the study only considers the annual cultivation of saffron, which may not be representative of all saffron cultivation practices. Perennial cultivation, for example, may have different environmental and economic impacts that were not captured in this study. Thirdly, the study relies on data provided by a limited number of saffron farms, which may not be representative of all saffron farms in Italy or other regions. The use of multiple data sources and farms would increase the robustness and reliability of the study findings. Finally, the study does not consider the social and cultural dimensions of saffron cultivation, such as the impact on local communities and cultural heritage. In summary, context-specific assessments are crucial for understanding saffron production sustainability, accounting for regional variability, incorporating local practices and knowledge, and informing tailored policies and management strategies. This approach ensures that sustainability assessments are relevant, actionable, and effective in addressing specific challenges and opportunities associated with saffron cultivation in different regions.

Author Contributions

Conceptualization, A.M. and K.C.; methodology, A.M.; software, K.C.; validation, V.C., L.C. and D.C.; formal analysis, A.M. and K.C.; investigation, V.C., L.C. and D.C.; resources, V.C. and M.P.; data curation, A.M. and L.C.; writing—original draft preparation, A.M. and L.C.; writing—review and editing, A.M., K.C., V.C., M.P., D.C., P.D. and L.C.; visualization, K.C., V.C., M.P., D.C., P.D. and L.C.; supervision, V.C. and M.P.; project administration, V.C.; funding acquisition, V.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

Acknowledgments

We want to express our gratitude to the farm “Zafferano città di Tricarico” for providing us with data and photos of the flowering and harvesting phases.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| DALY | Disability-Adjusted Life Year |

| EOFP | Ecosystem ozone formation |

| EUE | Energy use efficiency |

| EP | Energy productivity |

| FEP | Freshwater eutrophication |

| FFP | Fossil fuel scarcity |

| GWP | Global warming |

| HOFP | Human health ozone formation |

| HTPc | Human carcinogenic toxicity |

| HTPnc | Human non-carcinogenic toxicity |

| IRP | Ionizing radiation |

| ISO | International Organization for Standardization |

| LCA | Life cycle assessment |

| LCC | Life cycle costing |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| LU | Land use |

| MEP | Marine eutrophication |

| METP | Marine ecotoxicity |

| ODP | Stratospheric ozone depletion |

| PMPF | Particulate matter formation |

| SE | Specific energy |

| SOP | Mineral resource scarcity |

| TAP | Terrestrial acidification |

| TETP | Terrestrial ecotoxicity |

| WCP | Water consumption |

References

- Kothari, D.; Thakur, R.; Kumar, R. Saffron (Crocus Sativus L.): Gold of the Spices—A Comprehensive Review. Hortic. Environ. Biotechnol. 2021, 62, 661–677. [Google Scholar] [CrossRef]

- Cardone, L.; Castronuovo, D.; Perniola, M.; Cicco, N.; Candido, V. Saffron (Crocus Sativus L.), the King of Spices: An Overview. Sci. Hortic. 2020, 272, 109560. [Google Scholar] [CrossRef]

- Cardone, L.; Candido, V.; Perniola, M.; Cicco, N.; Castronuovo, D. Effect of Geographical Origin and Dimension of Corms on Saffron Production in Basilicata Region (Southern Italy). Acta Hortic. 2021, 1326, 311–315. [Google Scholar] [CrossRef]

- Giupponi, L.; Ceciliani, G.; Leoni, V.; Panseri, S.; Pavlovic, R.; Lingua, G.; Di Filippo, A.; Giorgi, A. Quality Traits of Saffron Produced in Italy: Geographical Area Effect and Good Practices. J. Appl. Bot. Food Qual. 2019, 92, 336–342. [Google Scholar] [CrossRef]

- Molina, R.V.; Valero, M.; Navarro, Y.; Guardiola, J.L.; García-Luis, A. Temperature effects on flower formation in saffron (Crocus sativus L.). Sci. Hortic. 2005, 103, 361–379. [Google Scholar] [CrossRef]

- Grand View Research. Saffron Market Size, Share & Trends Analysis Report By Application (Cosmetics, Food, Medical), By Grade (Grade I, II, III, IV), By Region (APAC, MEA, North America, Europe), and Segment Forecasts, 2020–2028. Available online: https://www.gminsights.com/industry-analysis/saffron-market?gclid=CjwKCAiAtt2tBhBDEiwALZuhAKLdraA1J12jnR5qDoODpwlDk0Ggy3rU4FSTw7g5KzPYXqq77d8qshoCeKkQAvD_BwE (accessed on 15 October 2023).

- Manzo, A.; Panseri, S.; Bertoni, D.; Giorgi, A. Economic and Qualitative Traits of Italian Alps Saffron. J. Mt. Sci. 2015, 12, 1542–1550. [Google Scholar] [CrossRef]

- Tahiri, A.; Mazri, M.A.; Karra, Y.; Ait Aabd, N.; Bouharroud, R.; Mimouni, A. Propagation of Saffron (Crocus Sativus L.) through Tissue Culture: A Review. J. Hortic. Sci. Biotechnol. 2023, 98, 10–30. [Google Scholar] [CrossRef]

- Asil, H.; Taşgin, S.; Çelik, M.; Çelik, F. Effects of Different Growing Media on the Corm Yield and Properties of Saffron (Crocus Sativus L.) in Field and Greenhouse Conditions. Mustafa Kemal Üniv. Tarım Bilim. Derg. 2022, 27, 174–184. [Google Scholar] [CrossRef]

- Nassi o Di Nasso, N.; Bosco, S.; Di Bene, C.; Coli, A.; Mazzoncini, M.; Bonari, E. Energy Efficiency in Long-Term Mediterranean Cropping Systems with Different Management Intensities. Energy 2011, 36, 1924–1930. [Google Scholar] [CrossRef]

- Liu, C.; Cutforth, H.; Chai, Q.; Gan, Y. Farming Tactics to Reduce the Carbon Footprint of Crop Cultivation in Semiarid Areas. A Review. Agron. Sustain. Dev. 2016, 36, 69. [Google Scholar] [CrossRef]

- Khorramdel, S.; Nassiri Mahallati, M.; Latifi, H.; Farzaneh Belgerdi, M.R. Comparison between Energy, Environmental and Economical Indicators of Irrigated Wheat and Saffron Agroecosystems in Khorasan-e Razavi Province. J. Saffron Res. 2020, 8, 29–54. [Google Scholar] [CrossRef]

- Bakhtiari, A.A.; Hematian, A.; Sharifi, A. Energy Analyses and Greenhouse Gas Emissions Assessment for Saffron Production Cycle. Environ. Sci. Pollut. Res. 2015, 22, 16184–16201. [Google Scholar] [CrossRef]

- Ali, M.; Lohan, S.K.; Rasool, D.; Danish, Z.; Kumar, R.; Faisal, S.; Balkhi, A.A. Energy Use Pattern in Saffron (Crocus Sativus ‘Kashmirianus’) Production in Kashmir. Acta Hortic. 2018, 145–152. [Google Scholar] [CrossRef]

- Mohammadzadeh, A.; Damghani, A.M.; Vafabakhsh, J.; Deihimfard, R. Environmental and Economic Analysis of Saffron and Canola Production Systems: In East Azerbaijan Province of Iran. Int. J. Plant Prod. 2018, 12, 73–83. [Google Scholar] [CrossRef]

- Khanali, M.; Movahedi, M.; Yousefi, M.; Jahangiri, S.; Khoshnevisan, B. Investigating Energy Balance and Carbon Footprint in Saffron Cultivation—A Case Study in Iran. J. Clean. Prod. 2016, 115, 162–171. [Google Scholar] [CrossRef]

- Mitrović, I.; Todorović, M.; Marković, M.; Mehmeti, A. Eco-Efficiency Analysis of Rainfed and Irrigated Maize Systems in Bosnia and Herzegovina. J. Water Clim. Change 2023, 14, 4489–4505. [Google Scholar] [CrossRef]

- Mollafilabi, A.; Khoramdel, S.; Aminghafori, A.; Hosseini, M. Evaluation of Environmental Impacts for Saffron Agroecosystems of Khorasan Based on Nitrogen Fertilizer by Using Life Cycle Assessment (LCA). J. Saffron Res. 2014, 2, 152–166. [Google Scholar] [CrossRef]

- Khorramdel, S.; Nassiri Mahallati, M.; Soltan Ahmadi, A.; Hooshmand, M.; Mostafavi, M.J. Evaluation of Carbon Footprint for Saffron Production Systems in Khorasan Provinces. Saffron Agron. Technol. 2021, 9, 249–267. [Google Scholar] [CrossRef]

- Dastranj, M.; Sepaskhah, A.R.; Kamgar-Haghighi, A.A. Rainfall and Its Distribution Influences on Rain-Fed Saffron Yield and Economic Analysis. Theor. Appl. Clim. 2019, 137, 3139–3147. [Google Scholar] [CrossRef]

- Sahabi, H.; Feizi, H.; Karbasi, A. Is Saffron More Energy and Economic Efficient than Wheat in Crop Rotation Systems in Northeast Iran? Sustain. Prod. Consum. 2016, 5, 29–35. [Google Scholar] [CrossRef]

- Yarami, N.; Sepaskhah, A.R. Water Productivity and Economic Analysis of Saffron Under Different Irrigation Water Salinity, Manure Application Rates and Planting Methods. Int. J. Plant Prod. 2018, 12, 139–147. [Google Scholar] [CrossRef]

- Saeidi, E.; Dehkordi, A.L.; Nabavi-Pelesaraei, A. Potential for Optimization of Energy Consumption and Costs in Saffron Production in Central Iran through Data Envelopment Analysis and multi-objective Genetic Algorithm. Env. Prog. Sustain. Energy 2022, 41, e13857. [Google Scholar] [CrossRef]

- Khanali, M.; Shahvarooghi Farahani, S.; Shojaei, H.; Elhami, B. Life Cycle Environmental Impacts of Saffron Production in Iran. Environ. Sci. Pollut. Res. 2017, 24, 4812–4821. [Google Scholar] [CrossRef]

- Coluzzi, R.; D’emilio, M.; Imbrenda, V.; Giorgio, G.A.; Lanfredi, M.; Macchiato, M.; Ragosta, M.; Simoniello, T.; Telesca, V. Investigating Climate Variability and Long-Term Vegetation Activity across Heterogeneous Basilicata Agroecosystems. Geomat. Nat. Hazards Risk 2019, 10, 168–180. [Google Scholar] [CrossRef]

- Piccarreta, M.; Lazzari, M.; Pasini, A. Trends in Daily Temperature Extremes over the Basilicata Region (Southern Italy) from 1951 to 2010 in a Mediterranean Climatic Context. Int. J. Climatol. 2015, 35, 1964–1975. [Google Scholar] [CrossRef]

- Cardone, L.; Castronuovo, D.; Perniola, M.; Cicco, N.; Candido, V. Evaluation of Corm Origin and Climatic Conditions on Saffron (Crocus Sativus L.) Yield and Quality. J. Sci. Food Agric. 2019, 99, 5858–5869. [Google Scholar] [CrossRef] [PubMed]

- Denora, M.; Candido, V.; D’Antonio, P.; Perniola, M.; Mehmeti, A. Precision Nitrogen Management in Rainfed Durum Wheat Cultivation: Exploring Synergies and Trade-Offs via Energy Analysis, Life Cycle Assessment, and Monetization. Precis. Agric. 2023, 24, 2566–2591. [Google Scholar] [CrossRef]

- Amine Ayari, M.; Denis, M.-P.; Landry, G.-A.; Lapointe, L. Cultivation of Saffron (Crocus Sativus L.) in Cold Climates. Can. J. Plant Sci. 2022, 102, 608–627. [Google Scholar] [CrossRef]

- CarbonCloud Calculating GHG Emissions at Farm-Gate. Available online: https://carboncloud.com/agricultural-model/ (accessed on 15 September 2023).

- Ecoinvent Database Version 3.1 Swiss Centre for Life Cycle Inventories, Switzerland. Available online: https://www.ecoinvent.org/database/ecoinvent-371/ecoinvent-371.html (accessed on 18 September 2023).

- Green Delta Open LCA Version 2.0.4., Green Delta GmbH, Germany. Available online: https://www.openlca.org/download/ (accessed on 18 September 2023).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wenet, G. Overview and Methodology. Data Quality Guideline for the Ecoinvent Database Version 3. Ecoinvent Report 1 (v3); The ecoinvent Centre: St. Gallen, Switzerland, 2013. [Google Scholar]

- Canaj, K.; Mehmeti, A.; Berbel, J. The Economics of Fruit and Vegetable Production Irrigated with Reclaimed Water Incorporating the Hidden Costs of Life Cycle Environmental Impacts. Resources 2021, 10, 90. [Google Scholar] [CrossRef]

- CE Delft. Handboek Milieuprijzen 2023; CE Delft: Delft, The Netherlands, 2023. [Google Scholar]

- Giupponi, L.; Leoni, V.; Sala, S.; Giorgi, A.; Bertoni, D. Saffron Growing in Italy: A Sustainable Secondary Activity for Farms in Hilly and Sub-Mountain Areas. Int. J. Agric. Sustain. 2023, 21, 2270263. [Google Scholar] [CrossRef]

- Koocheki, A.; Fallahi, H.-R.; Jami-Al-Ahmadi, M. Saffron Water Requirements. In Saffron; Elsevier: Amsterdam, The Netherlands, 2020; pp. 67–92. [Google Scholar]

- Rezvani Moghaddam, P.; Khorramdel, S.; Farshchin, S. Comparison of Environmental Effects of Conventional and Low Input Saffron Production Systems in Razavi Khorasan by Using the Life Cycle Assessment Methodology. Iran. J. Field Crops Res. 2022, 20, 29–44. [Google Scholar] [CrossRef]

- Esfahani, S.M.J.; Khazaee, J. Application of Multifunctional Ecological Footprint in Sustainability Analysis of Saffron Production in Southern Khorasan. Saffron Agron. Technol. 2019, 7, 491–503. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).