Abstract

Concrete recycling to produce aggregates is crucial in reducing the demand for virgin materials in the construction industry, particularly for the most widely used building material—concrete. A potential solution to enhance the quality of recycled aggregates involves the removal of the adhered cement paste from their surfaces. In this study, samples of industrial demolished concrete were selectively separated into recycled sands and aggregates while removing the hydrated cement paste. The recycled materials were characterized to assess their suitability for structural concrete production. The behavior and underlying mechanisms of recycled sands and aggregates proved to be identical, irrespective of their size. Water absorption emerged as a key parameter for evaluating the purity and quality of these materials. The statistical analysis revealed that when the water absorption of recycled aggregates and sand falls below 5%, the compressive strength may, at most, decrease by 15% (97.5% confidence) at any replacement level. Consequently, they can entirely replace virgin materials without a significant negative impact on fresh or hardened concrete properties at a constant cement content. Concrete samples with recycled materials had comparable workability, strength, and durability characteristics to references with virgin materials. The production of high-quality recycled aggregates and sand can facilitate complete concrete recycling and hence significantly contribute to virgin materials preservation, thus making concrete more sustainable.

1. Introduction

Concrete is the most produced man-made material [1], and its demand is expected to grow further [2] with the ongoing industrial and social developments. Because of the high volume produced, concrete has a significant environmental impact despite its very low specific CO2 emissions and embodied energy [3]. In addition, the production of concrete consumes a significant number of natural resources, such as sand and aggregates, which make up approximately 80% of its weight. The remaining 20% are shared among water and cement, whose production is associated with hard-to-abate CO2 emissions. The reduction of CO2 emissions associated with cement production and the preservation of virgin materials are hence of utmost importance to lower the environmental impact of concrete. Concrete recycling has the potential to meet this ambition [4] as concrete is fully recyclable.

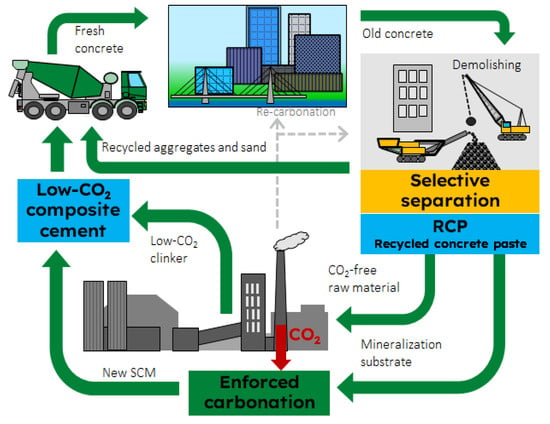

Selective separation and enforced carbonation are two new technologies that, when combined, could address both the CO2 emissions and the consumption of natural resources. Enforced carbonation makes use of recycled concrete paste (RCP) generated by the improved recycling technology (“selective separation”), which yields RCP, recycled sand (RS), and recycled aggregates (RA) as targeted products. The laboratory results in [5,6] and industrial trials [7,8] show that due to the fast and robust carbonation kinetics during the enforced carbonation, RCP can efficiently be used for carbon capture and CO2 mineralization directly from untreated industrial flue gases. The carbonation reaction turns the RCP into a rapidly reacting pozzolanic material, which can be used as a supplementary cementitious material (SCM) for cement production. The composite cement obtained thus has a lower clinker factor and consequently lower embodied CO2. This overall circular approach is summarized in Figure 1.

Figure 1.

Selective separation paves the way to fully circular concrete and decreases cement CO2 emission. Old concrete is first demolished and selectively separated. The RCP (recycled concrete paste) rich in hydrated cement is either reused as a decarbonated raw material for the kiln or carbonated (red arrow) into cRCP (“carbonated RCP”) that is further used as an SCM to blend with clinker. A low-CO2 composite cement is thus obtained. This composite cement can be mixed with the selectively separated aggregates and sand previously obtained to produce new structural concrete.

In this paper, we studied a large sample of RS and RA produced by the selective separation technology at an industrial scale. We analyzed the following:

- -

- The properties and quality of the selectively separated RS and RA: their density, water absorption, particle size, and shape distribution.

- -

- The impact of these RS and RA on the performance of structural grade concrete mixes: their workability, compressive strength, and durability.

Regarding the quality of the RA and RS produced by selective separation, they were cleaner than those produced by conventional recycling technologies: the porous hydrated cement paste was better removed from their surfaces. Because the selective separation process specifically aims to separate the RCP out of the sand and aggregates, the residue left on the RS and RA is lower than in conventional recycling.

Regarding the impact of RS and RA on concrete performance, the drop in workability is small and can be handled with a common optimization of admixture dosage and/or packing. The loss in compressive strength is lower than 15% when the water absorption of the RS and RA is lower than 5%, irrespective of the replacement level, including the complete replacement of virgin sand by RS, which is an unprecedented result. The shrinkage, freeze-thaw, scaling, carbonation, and chloride migration tests showed that concrete made with 50% RS and RA achieve comparable durability as concrete mixes made with virgin materials.

1.1. Conventional Recycling and Conventional Recycled Concrete Aggregates

Although concrete is fully recyclable and recycling technologies have evolved significantly to increase the value of the recovered products, conventional recycling mainly focuses on the quality of coarse aggregates. The fine fraction below 2 or 4 mm is commonly known as recycled concrete fines (RCF), which is composed of multi-phase particles containing hydrated cement paste and fine aggregates.

Before concrete recycling, concrete needs to be separated from foreign elements, such as steel reinforcement, bituminous materials, bricks, insulation, gypsum panels, roofing elements, etc. The execution of primary separation during selective deconstruction is necessary to obtain clean concrete for the recycling process, independent of the technique used downstream. Nevertheless, a minor percentage of waste like wood, plastics, or bricks is unavoidable as no industrial process is 100% efficient.

The recycling process starts with primary crushing, typically using horizontal impact crushers or jaw crushers, where size reduction below 100 mm and steel reinforcement removal using a magnetic separator take place. The outcome results in fine fractions (<4 mm) and coarse fractions (<50/60 mm), which are afterward used as feedstock in a second crushing step, typically using the same crushing equipment. This final size reduction is followed by a screening process to allow for the production of recycled aggregates and the fine fraction, which is afterward mixed with the fines produced in the primary crushing. The size reduction is focused on maximizing the yield of the coarse fraction to decrease the production of fines that are later difficult to valorize. The quality, i.e., the composition and fineness of the RCF, varies widely depending on the original concrete source as well as on the recycling process applied. However, irrespective of these variations, the content of hydrated cement paste of RCF is too high for the efficient use of this fraction in concrete production and too low for efficient CO2 mineralization.

Even the coarse recycled concrete aggregates from the conventional recycling process show a reduction in specific gravity, an increase in porosity, the crushing index, high water absorption, and a weak interfacial transition zone [9] compared to virgin materials. This makes their use in concrete production challenging, requiring higher cement dosages [10] than an equivalent concrete made of natural aggregates. The inferior properties of recycled concrete coarse and fine aggregates result in their restricted usage in concrete production. A review of national standards [11] reveals that most countries limit coarse recycled concrete aggregates to 20%, and the usage of fine aggregates is completely prohibited in structural concrete in most countries.

Various methods to improve the properties of recycled concrete aggregates were proposed and investigated (see, e.g., [9,12] and references therein), but many fail to provide an economically feasible solution (e.g., thermal treatment or polymer treatment) and/or a clear environmental benefit (e.g., treatment with lime, extra cement or acid treatment). The RCF is hence mainly considered a by-product and is intended for low-grade applications [13].

As a result of the problematic added-value utilization of the RCF and limited applicability of coarse recycled aggregates in concrete production, end-of-life concrete is usually used in low-grade applications, such as road base construction or backfilling and other earth works [11,13]. For such utilizations, it is not essential to separate the RCP from the sand and aggregates, and a simple size reduction suffices to reuse all fractions from old concrete. However, such reuse is suboptimal and non-circular as the CO2 reduction potential of the old cement, as well as the high-grade sand and aggregates present in the old concrete, are removed from the concrete value chain. In contrast, selective separation technology paves the way to fully recycle and utilize concrete waste by producing cleaner RS and RA suitable for their reuse in concrete production and the RCP to lower the CO2 footprint of cement production.

1.2. Selective Separation

The selective separation process aims to recover clean aggregates, clean sand, and the RCP as three distinct products. It is achieved in a low-intensity attrition-driven crushing process by taking advantage of the difference in strength and stiffness between natural minerals and the porous hydrated cement paste. In this process, cracks preferentially propagate through the cement paste while sand and aggregate particles remain intact. Liberated particles are then sheared in a material bed, which leads to attrition at their surfaces, resulting in a cleaning effect. Similar to the crack propagation, the hydrated cement paste attrits preferentially as its bond to the aggregates is weaker than the aggregate strength itself. Tam et al. [14] further discuss and elaborate on working principles and examples of potentially suitable technologies.

As in conventional recycling, selective separation starts with the primary crushing with steel reinforcement removal. The complete fraction below 100 mm is then fed into the low-intensity crushing step, which can take place in multiple devices such as a vibrating cone crusher, vertical shaft impactor, modified jaw crusher, or vertical roller mill. After the crushing, the output material is separated into individual fractions using a cascade of sieves and separators. A part of the output can also be recirculated back into the selective crusher to further improve products’ quality or to improve the stability of the crushing process.

The RCP obtained is a powdery material with fineness comparable to cement and contains about half or more of cement hydrates. The RCP yield varies between 1 and 15 wt.-% with respect to the feed, depending on the technology used and process parameters set. The RCP can be recycled back to cement production in multiple ways, such as decarbonated raw material for clinker production, filler for cement production, raw material for the production of reactive slag-like glass for cement production, or enforced carbonation [15]. The last pathway is a combination of carbon capture technology and the production of a reactive SCM and is the most effective recycling pathway with respect to the CO2 avoided and energy spent [15].

1.3. Paper Novelty, Scope, and Organization

Our data statistically prove that the limiting properties of the recycled aggregates are related to the high content of hydrated cement paste in these materials, exemplified by their high water absorption compared to virgin materials [13]. As the selective separation removes more of the adhered cement paste than the conventional separation, it improves the quality of RA and RS and produces materials not yet systematically described in the literature. A further novelty of this article is the focus on field concrete rather than lab concrete. According to an extensive review of the use of recycled fine aggregates in concrete [13], there are only a few case studies using a diversity of demolished concrete from the field. Most of the available research works deal with lab-made materials, which are different from concrete recycled in the field. Our aim was to gather a large data set, enabling a robust statistical analysis of results and providing a technical basis for a subsequent standardization process to enable the commercial use of the novel recycled materials. The data set includes the properties of the material as well as their impact on fresh and hardened concrete properties, including durability testing.

This paper fills this gap and provides a systematic assessment of the quality of these materials for a broad range of demolished concrete sources, processing technologies, and product qualities, including their suitability for the production of structural concrete. As a broad range of tested materials originated from different selective separation techniques and demolished concrete sources, the tested materials are anonymized. Only the impacts that the technologies had on the produced materials and resulting concrete performance were investigated; the ranking and assessing the technologies is out of the paper’s scope.

The paper is organized as follows: in its first part, the properties of RS and RA are assessed. The particle size and shape distribution, surface dry density, and water absorption are measured on two reference sands and aggregates and three families of RS and RA. A strong relationship between water absorption and density for both studied fractions is established. In the second part, the performance of concrete produced with the RS and RA at 25–100% replacement levels is assessed. The workability, compressive strength, and durability (drying shrinkage, carbonation, chloride resistance, and freeze-thaw resistance) are found to be comparable with that of reference concrete whenever the water absorption is lower than 5%.

2. Materials and Methods

The materials and methods used are listed in Table 1 and Table 2, respectively. The motivation behind these was to compare the impact of recycled sands and aggregates on concrete performance with reference mixes containing natural aggregates and sand.

Table 1.

Overview of materials used in concrete mixes.

Table 2.

Overview of methods applied. Further characterization methods for aggregates are provided in Supplementary Materials.

2.1. Natural Sands and Aggregates

Two types of natural sands were used to provide a robust basis for comparison. One fluvial 0/2 mm sand and one crushed quartzite 0/2 mm sand were used. The second sand is less rounded and has a higher content of microfines (<63 μm): 11% versus 0.6% for the fluvial one. The high content of microfines of crushed sand is characteristic of manufactured sand if it is not washed or air-classified. This fraction is composed mainly of quartz. Some clay and clay-like minerals are also present in the microfines (mainly Illite type of clays). The PSD of the quartz microfines is included in the Supplementary Materials, Figure S4. The sand equivalent of the quarzitic sand was 95.5, and it had a methylene blue value of 0.27 g/100 g.

In Germany, DIN EN 12620 [24] and DIN 1045-2 [25] specify the limit of fines content in fine aggregate for concrete application to be less than 3%. However, in countries where manufactured sand is commonly used, like the UK, Spain, or France, this limit is established from 16% up to 22%, depending on the rock type and the exposure class of the concrete.

For comparison purposes, the fluvial reference sand, Rheinsand 0/2 mm, which has low microfines content (0.6% < 63 μm), was considered in the study. This is because all RS produced contain a reduced fines proportion since all selective separation processes aim to maximize the recovery of the RCP. The sand equivalent of the fluvial Rheinsand 0/2 mm was 90.0.

Regarding coarse aggregates, only crushed quartzitic aggregates were used.

RA and RS were produced in trials using industrial demolished concrete sourced from Germany, France, Belgium, and the Netherlands. For each trial location, at least 100 tons of demolished concrete was sourced. The selective separation technologies used were purely mechanical dry processes. They included vertical shaft impactors [26], vertical roller mills, vibrating cone crushers, cone crushers, and combinations thereof. Most of the trials were carried out using industrial equipment with a throughput of around 100 tons per hour. Some of the trials or some of the process stages were carried out on a semi-industrial scale (~1 ton per hour throughput), with the demolished concrete being pre-crushed to 20 mm. A multi-step processing that includes serial processing in a single crusher operated at different settings or a two-step process involving two different crushers was also included.

In most cases, the separation of the selectively crushed concrete into individual fractions took place directly as a part of the trial. However, in some cases, only a mixed crushed material was produced. In the latter cases, the sieving took place in a laboratory, and fractions smaller than 125 μm were removed from the RS samples to simulate the industrial RCP recovery. The separation was dry, and the materials used were unwashed.

2.2. Characterization of Recycled Materials

Similar to natural materials, the evaluation of the physical and mechanical properties of the recycled aggregate is crucial for assessing its suitability for its use in concrete. The characterization of the recycled aggregate properties aims to assess and understand their impact on concrete workability and strength. The characterization included standard methods such as measurement of density (EN 1097-6 [27]), water absorption (EN 1097-6), particle size distribution (PSD, EN 933-1 [28]), and particle shape analysis using optical methods. Complementary characterization methods of the recycled materials, such as packing density measurements, analysis of chemical constituents, frost, and fragmentation resistance are provided in the Supplementary Materials.

The shape, texture, and angularity of the particles were also evaluated by dynamic image analysis of the recycled sand and aggregate particles carried out with a Camsizer Retsch X2. Particles fall in the field of view of two high-resolution cameras at different magnifications, which capture the particle shadows. The images are recorded at a rate of over 300 images per second and analyzed with the dedicated manufacturer software (Microtrac Retsch GmbH, Haan, Germany). The sphericity and aspect ratio were determined for each RS. The sphericity of a particle is defined as [29] , where P is the measured perimeter of a particle projection, and A is the measured area covered by the particle projection. The aspect ratio is calculated as the minimum particle breadth over its maximum length, , where Xc,min is the shortest chord out of the measured set of maximum chords Xc, and XFe,max is the longest Féret diameter out of the measured set of Féret diameters of each particle projection. Symmetric shapes have a high aspect ratio, whereas elongated shapes result in low aspect ratio values [30].

2.3. Concrete Mix Design and Mixing

The cement used was CEM I 42.5 R. Its physical, chemical, and mineralogical composition, as well as the strength development, are provided in the Supplementary Materials in Table S4 and Figure S4, respectively.

The cement content and water/cement ratio were kept constant at 350 kg/m3 and 0.55, respectively. The strength and consistency classes were selected based on the statistics reported by the German Ready-Mixed Concrete Industry [31] to represent the concrete type with the highest market share. The design of the reference concrete targets a strength class C30/37 and F3 consistency according to EN 206 [32] with 16 mm maximum coarse aggregate. Two reference mixes for assessing RS were defined, differing in the fine aggregates used:

- Reference Mix 1 with fluvial sand 0/2 mm (Rheinsand) and crushed quartzite coarse fractions.

- Reference Mix 2 with crushed quartzite 0/2 mm sand and crushed quartzite coarse fractions.

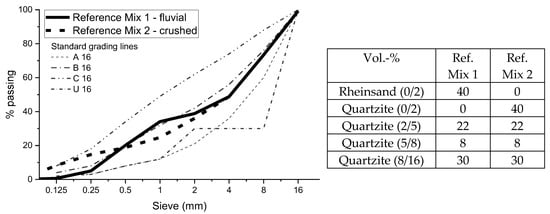

The resulting grading lines of the reference mixes are shown in Figure 2, while the PSD of reference materials is in Figure 3. The natural sand or natural aggregates were partially replaced in 25% (volumetric) steps by RS and RA, respectively.

Figure 2.

Grading lines of reference mixes: Mix 1 made with fluvial sand (Rheinsand) and quarzitic coarse aggregates; Mix 2 made with quarzitic fine and coarse aggregates. Mixing proportions of individual fractions are given in the table.

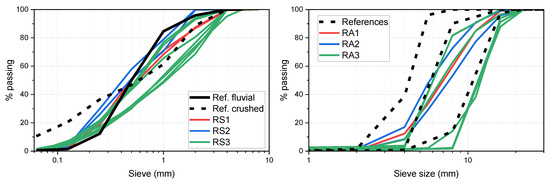

Figure 3.

Particle size distribution of selected sands (left) and aggregates (right) used in this study. The two reference sands differ, especially in content of fines.

The superplasticizer used to achieve the targeted workability was a commercial high-range water reducer based on PCE (polycarboxylate ether). Due to the higher fines content in the quarzitic sand than in the fluvial sand, the reference mix using the quarzitic sand required a higher admixture dosage to reach the F3 consistency.

No further grading optimization was conducted. The superplasticizer dosage was kept at a similar level as used in the reference mixes for the sand substitution, but a slight adjustment was made where necessary to achieve the targeted F3 consistency. Dosages of superplasticizer of all mixes are provided in Table A5, Table A6, Table A7, Table A8 and Table A9 in Appendix A.

The effective w/c ratio was kept constant by using aggregates in an oven-dry state and compensating for the water absorption of the natural or recycled aggregates by a pre-saturation approach. This consisted of pre-saturating the recycled materials for a determined period prior to mixing. The presoaking period was calculated per recycled aggregate type using a graduated measuring cylinder. The procedure is described in Annex E of EN 1097-6 and designed for the determination of the apparent particle density of lightweight aggregates and short soaking times. The reading of the volume of aggregate and water in the cylinder was measured every 10 min for a testing period of 1 h until the reading was constant. This testing time was considered based on previous experiences with lightweight aggregates, where the water absorption in concrete is often assumed to be in the range of 90–100% after being submerged in water for 1 h [33].

All recycled materials samples showed the highest absorption level during the first 30 min, after which the reading level remained constant. The pre-soaking times were hence 20 or 30 min for RS and 10–30 min for RA. Values determined for each material are summarized in Appendix A, Table A2.

The mixing procedure, described in Appendix A in detail, was divided into two steps for the addition of water. Two-thirds of the total mixing water was added into the recycled aggregate to allow most of the water absorption to take place before adding the rest of the mix constituents, including the remaining water. This method indicated a performance improvement compared with the approach of adding the water all at once [34].

2.4. Concrete Performance: Workability, Strength, and Durability

After the mixing was completed, the fresh concrete density (EN 12350-6), air content (EN 12350-7), and flow table over 90 min (EN 12350-5) were measured. The samples were cast directly after the measurement of the fresh concrete properties. Concrete cubes for dry density (EN 12390-7) and compressive strength testing (EN 12390-3, 100 mm cubes) were demolded after 24 h and stored in 20 °C water until the testing age of 2, 7, and 28 days. At 2 and 7 days, 3 cubes were tested while 6 samples were tested after 28 days to further improve data representativeness.

Regarding durability, a single sample of each material family, i.e., 3 recycled sands and 3 recycled aggregates, were tested, and the replacement levels were as follows:

- 50% RS;

- 50% RA;

- Parallel replacement of 50% RS and 50% RA.

The replacements were only performed in Reference Mix 1 with the fluvial Rheinsand for the durability mixes.

For the rapid chloride migration (RCM) test, a reduced w/c ratio of 0.45 was used. This was to comply with the maximum w/c ratio required by the exposure classes XS2 and XS3, defined in EN 206.

Shrinkage measurements were performed using the Graff–Kauffmann method, following EN 12390-16, where the measurement started after demolding and continued for one year. The carbonation test was conducted according to EN 12390-10, where three concrete beams were produced from each mix and stored in a curing chamber at a natural condition of 20 °C and 65% relative humidity. Chloride resistance was tested using the rapid chloride migration (RCM) test according to NT Build 492. Freeze-thaw resistance without the presence of a de-icing agent was determined by CEN/TS 12390-9 and internal structural damage (CIF test) following CEN /TR 15177 [35]. The test methods, curing regimes, and dimensions of the specimens are described in Appendix A in detail.

3. Results and Discussion

The results are interpreted and discussed in the light of their underlying mechanisms and the current state of the art reported in the literature. Two lines are followed: first, the quality of recycled materials obtained by selective separation compared to conventional recycling and natural ones, and second, the performance of structural concrete produced from selectively separated materials.

3.1. Density and Water Absorption

Conventionally recycled materials have lower density and higher water absorption than natural ones [13]. This happens because the hardened cement paste that adheres to the aggregate fractions is porous and has a lower density than natural sands and aggregates. Consequently, as the adhered mortar content increases, the recycled material density progressively decreases.

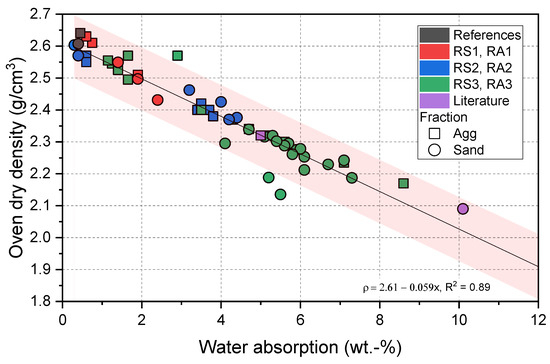

This explanation is confirmed by Figure 4, where densities are plotted against the water absorptions. Independent of the sizes, types and sources of the recycled materials, there is an overall and strong correlation between the oven-dry density and the water absorption of RS and RA, with R2 of 0.89.

Figure 4.

Strong relationship between water absorption and oven-dry density of the RS (circles) and the RA (squares) collected. “Literature” labels the mean values of density and water absorption of recycled sand and aggregates reported in [34]. The shaded area shows a 95% confidence interval. The tested materials have lower water absorption than the literature values.

The densities of reference fractions of the Rheinsand and the crushed quarzitic aggregates are higher than 2.6 g/cm3, and the water absorption is 0.5%. Some materials, namely “1” and “2”, reached the lowest water absorption (0.5%) and the highest densities (2.5 to 2.63 g/cm3), which are close to the reference aggregates. On the other hand, the R3, which was produced with other setups and a range of feed materials, shows more scattered results in both the water absorption and densities.

The results obtained are significantly better than the average data for RS and RA produced by conventional technologies reported in the literature (labeled “Literature” in Figure 4). A review of 50 RS samples and 300 RA reported in [34] achieved an average dry density of 2.09 g/cm3 and 2.32 g/cm3, whereas the water absorption was 10.1% and 5% for RS and RA, respectively. In [13], the average water absorption of 40 recycled sands is around 9%, and in [36], it is 13%.

Aggregates and sand in the demolished concrete are usually of high quality because fluvial materials were historically used. However, recovering pure fine particles from demolished concrete is expensive and technically limited with conventional recycling. Consequently, conventionally recycled aggregates and sand particles always contain adhered cement paste or multi-phase mortar-like particles. Because the hydrated cement paste is porous, softer, and weaker than the clean aggregates and sand, it impairs the properties of recycled materials and, hence, the resulting concrete.

The amount of adhered cement pastes can be assessed by two macroscopic measurements: density and water absorption. A strong correlation between the water absorption and density of the recycled materials was found. Also, the natural materials fall on the same regression line as the recycled materials (c.f. Figure 4), and the assumption of dense natural aggregates of a similar density used to produce old concrete is confirmed. This further agrees with the mineralogical analysis that showed the presence of quartz, calcite, dolomite, and feldspars, all with a density of around 2.6–2.8 g/cm3. Assuming that a model cement paste formed by reacting 100 g of cement with a density of 3.2 g/cm3 and binding 40 g of chemically bound water with a density of 1.33 g/cm3, with a porosity of 30 vol.-% corresponding to an old Portland cement paste with w/c of 0.5 [37], a bulk density of 1.8 g/cm3 and water absorption of 13 wt.-% are obtained. This point (x = 13% and y = 1.8 g/cm3) lies on the regression line of Figure 4, further supporting the findings. Most importantly, the presented results, as well as their mechanistic explanation point out that recycled aggregates and sand follow the same relationship, irrespective of the size or grading. For practical applications, the strong correlation between water absorption and dry density could suggest that these methods can be used interchangeably to characterize the recycled aggregates and sand. However, water absorption is seen as the preferred option as it is more closely linked to the open porosity volume in the cement paste and the expected performance in concrete. The density might be easily altered by the presence of dense materials such as iron-rich minerals or basalt, leading to false-positive results.

3.2. Particle Size Distribution

The size and shape of the recycled materials depend on the processing method and the shape of the original virgin materials. The PSD of the materials studied is shown in Figure 3. The particle size range of the RS1 and RS2 is 0/2 mm, which is like that of the reference sands, whereas the particle size range of RS3 is 0/4 mm. The grading of RS1 has a similar distribution to the Rheinsand at the lower end, below 0.5 mm, while particles larger than 0.5 mm are closer to the quarzitic sand. RS2 has a similar tendency but is slightly finer than RS1. RS3 sands show a coarser and more scattered distribution.

RA1 and RA2 have a grading close to the reference quartzite 5/8 mm, whereas RA3 shows a coarser and scattered distribution. The scatter is related to the different production processes and process settings of the selective separation. RS3 and RA3 were produced in a full-scale setup with a throughput of 100 t/h, which resulted in the lowest crushing of the original aggregates and sand and hence in the coarser PSDs. When upscaled to a comparable throughput, the products from processes 1 and 2 are expected to become coarser, respectively, of a broader PSD, as well. For a given process and process parameters, a continuous and reproducible PSD was obtained.

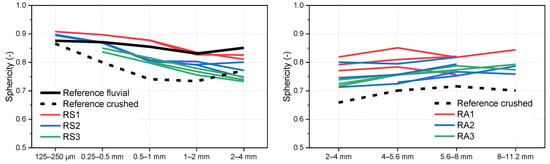

3.3. Particle Shape Analysis

Figure 5 summarizes the sphericity of RS and RA and compares it to the references. Since there are several definitions of the size of a particle, the xc,min was chosen for comparison since its measurement is directly comparable with the results obtained by sieving [30]. The RS and RA have similar sphericities as the reference materials. The good shape achieved by packing density tests (Supplementary Materials, Figure S1) is confirmed by the Camsizer. RS1 sands exhibited similar or superior particle shape and texture to the fluvial Rheinsand. Similar trends were shown in RS2 sands, where the Camsizer indicates a well-shaped RS, closer to the fluvial Rheinsand than to the crushed rock. The RS3 sands resulted in a good shape and texture, which falls between the references crushed and fluvial material. As also observed in the loose packing density, the particle shape becomes closer to the quarzitic sand as the particle size increases. The high sphericity of recycled materials from selective separation is expected as the original sand and aggregates were mostly fluvial, their crushing in the process is limited, and the attrition is also expected to increase the sphericity.

Figure 5.

Sphericity of RS (left) and RA (right) particles from dynamic image analysis (Camsizer, see Section 2.2. for details on the method) for individual particle fractions. Recycled materials are more spherical than the referenced crushed sand and aggregates.

3.4. Additional Analyses

The results of the loose and compacted packing density tests, analysis of chemical constituents, resistance to fragmentation, and freeze-thaw resistance are provided in Supplementary Materials. The results were consistent with the findings reported here, and the recycled aggregates and sands fulfilled the limits of the given methods. The exception is the content of polycyclic aromatic hydrocarbons (PAH), which was exceeded in the feed concrete used to produce RA2 and RS2. The higher content of PAH is likely linked to contamination of the feed-demolished concrete by asphalt. The presence of bituminous materials generally leads to a performance reduction, as is described by various authors, such as a severe decline in consistency [38] and a lower compressive [39,40] and flexural strengths [38]. This might be linked to a weaker bond at the interface between the recycled aggregate and the cement paste [38,40].

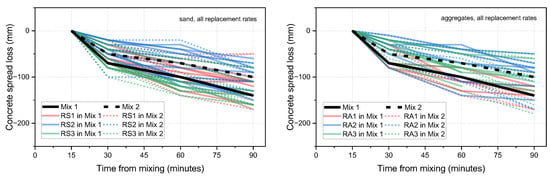

3.5. Concrete—Workability

The evaluation of the concrete consistency over time is presented in Figure 6 as a loss of concrete spread over time. The raw results, as well as the superplasticizer dosage of each mix, are provided in Table A5, Table A6, Table A7 and Table A8 in Appendix A. The losses after a 90 min fall between −50 and −170 mm were that of the references were −100 mm for crushed sand and −140 mm for the fluvial sand. Considering that the results were obtained without any grading optimization (the grading of the recycled materials slightly differs from the natural ones) and with adjusted admixture dosages, the overall impact of recycled materials is assessed as minor and non-systematic. The trend is similar for all mixes, independent of the replacement rate or whether the aggregates are natural or recycled. For most of the mixes, especially below 75% of replacement, no adjustments to the SP dosage were needed at all. At higher replacement rates, the superplasticizer dosage was adjusted as the impact of different grading and surface properties of recycled materials became more pronounced. Still, the adjustments of up to a few tens of % in both directions are assessed as minor, except for RA2.2 materials, which required a significantly higher superplasticizer dosage, possibly due to the high PAH content mentioned above. Still, after the adjustment of the initial workability, its loss for RA2.2-containing mixes does not stand out among the bulk results.

Figure 6.

Workability loss of concrete mixes with varying replacement levels over 90 min. Left: recycled sand; right: recycled aggregates. The trend over time is similar for all mixes, irrespective of the replacement rate.

The adopted approach to concrete mix design and mixing procedure has proven to be efficient in minimizing the impact of recycled materials on fresh concrete properties. Due to pre-soaking of the recycled materials and compensation for this water in the mix design (constant effective water-to-cement ratio), the workability retention of concrete with recycled materials matched that of reference mixes. The fluctuations in the initial workability could be easily compensated by a grading optimization, which has not been addressed in this study, and/or by superplasticizer dosage adjustment. The insensitivity of workability retention to the presence of saturated recycled materials suggests that the internal porosity of the hydrated cement paste does not influence the fresh concrete mixes once pre-saturated. However, such an approach also required the usage of oven-dried materials, which is not transferable to the industrial scale. Precise monitoring of saturation degrees of recycled materials is required to add the right amount of suction water. Although the negative impact of water absorption can be compensated for, recycled materials with low water absorption are still preferred. Negative impacts resulting from inaccuracy in the determination of the suction water amount, its dosing, as well as effects from the suction process during concrete mixes will be lower for such materials.

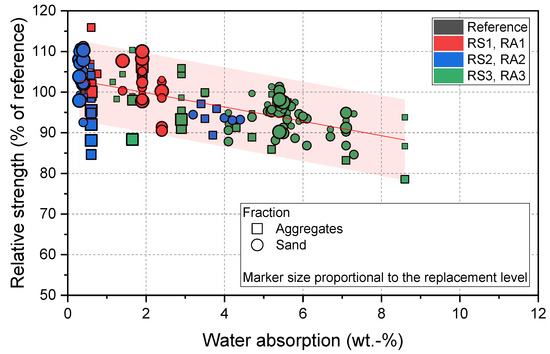

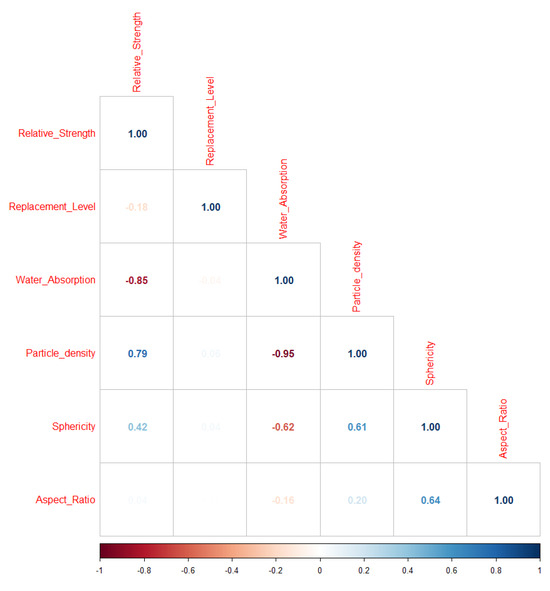

3.6. Concrete—Compressive Strength

The evaluation of the compressive strength in relation to the most significant statistical variable, water absorption, is presented in Figure 7. The results are provided as relative since the strength of reference mixes slightly differed—Reference Mix 1 with fluvial sand achieved 49.9 MPa and Reference Mix 2 with crushed sand 53.8 MPa at 28 days. The detailed table of compressive strength results is provided in Appendix A. The statistical analysis of the factors that influence the compressive strength at 28 days is shown in Table 3. Additional variables, i.e., saturated surface density and particle density, were not used in the analyses as they are highly correlated to the water absorption (R > 80%). Similarly, the aspect ratio was not used as it is correlated with sphericity (R = 95%). The correlation of all variables is shown in Figure A2 in Appendix A. Only three variables are found to have a statistically significant effect with more than 95% confidence: water absorption, replacement level, and sphericity. The other two were not found to be significant.

Figure 7.

Relative compressive strength at 28 days as a function of the water absorption. The shaded area is the individual 95% confidence envelope. Below 5% of water absorption, the relative strength is at least 85% with 97.5% confidence, irrespective of the replacement level, sphericity, technology/grading, and particle size (sand/aggregate).

Table 3.

Statistical analysis of strength influencing factors. A lower p-value indicates a higher effect.

Water absorption has a particularly low p-value with a clear linear negative trend on strength (Figure 7). This is expected as the higher the water absorption, the higher the amount of paste that adheres to the particles, and therefore, the higher the amount of weak bonds where fracture may be initiated and may propagate during the strength testing. This explanation is also consistent with the second significant variable, the replacement level. The sphericity comes third with a p-value of almost 5. The technology and grading are confounded as each technology produces a different grading line, mostly related to its scale, as discussed earlier. The p-value lies between 5 and 10, which is a noticeable effect and expected as it is well-known that the grading influences the overall packing density and therefore strength.

The difference in the strength between the reference mixes is 3.9 MPa, which corresponds to ~7% of the strength. Materials with water absorption of about 5% show a comparable effect on average as the trendline drops from about 103% at zero water absorption to about 96% at 5% water absorption. In other words, replacing crushed natural sand with fluvial sand has a similar effect as the replacement by recycled materials with 5% water absorption. Figure 7 also shows the 95% confidence envelope at ±15% (±4.8 MPa) from the trendline and under the assumption of homoscedastic variance. The envelope shows that below 5% of water absorption, 85% or more of the relative strength is kept with 97.5% of confidence. This conclusion holds irrespective of the replacement level, sphericity, technology/grading, and fraction (sand/aggregate).

In contrast to the workability retention, a clear impact of the presence of the porous hydrated cement paste on concrete strength was observed. Consistent with the meta-analysis [34], the incorporation of recycled aggregates leads to a strength reduction. In [15], Dhir observed that mixes with 100% RS are likely to lie between 102% and 54% of the control and 100% RA to lie between 112% and 60%.

The strength reduction was observed to depend on the type and quality of the recycled aggregate, the latter being related to the water absorption capacity [34]. In the data presented here, the impact of water absorption on strength reduction could be clearly seen and statistically proven. It supports the established explanation that the old cement paste and its interfaces to the aggregates and sand are the weakest links, reducing the strength. This effect cannot be overcome by saturation of the paste’s porosity. Since the reduction is proportional to the water absorption, an acceptance limit can be defined. Setting the acceptance limit to 85% of strength with 97.5% confidence, a threshold for water absorption of 5 wt.-% is obtained. Again, the same mechanistic explanation is valid for both fractions—sand and aggregates. The statistical assessment result and, hence also the threshold value are identical. At the threshold water absorption level of 5 wt.-%, the average impact on strength is identical to replacing crushed virgin sand with fluvial one, i.e., identical to the difference in strength of the reference mixes. The replacement level was found to be the second most important parameter influencing the strength reduction. For a given material and water absorption, a higher replacement level results in more porosity and interfaces added to concrete. However, a closer look at the data present in Figure 7 reveals that the negative effect of a higher replacement rate on strength is mostly related to aggregates, as most of the square data points are below the regression line while the circles are above. RA2 at higher replacement levels especially caused a disproportionally large strength reduction despite the low water absorption of these fractions. On the contrary, sands RS2 produced in the same selective separation process from the same feed material improved strength even at the highest replacement level of 100%. A similar tendency is also observed for some RA3 and RS3 materials. The data collected do not offer a clear explanation for this behavior.

For conventionally produced recycled aggregates, higher substitution rates typically result in compressive strength reduction [41,42], which needs to be compensated by lowering the w/c ratio and hence impairing the workability and/or use of more cement. The effect is more pronounced for fines as their water absorption is higher [42].

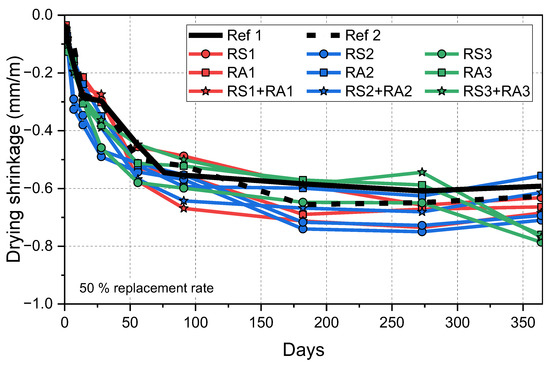

3.7. Concrete—Durability

Overall, mixes with recycled materials reached a comparable performance to the reference mixes in the durability properties tested.

Drying shrinkage of mixes with recycled materials (see Figure 8) followed the same evolution as the reference mixes during the first year. However, the replacement of natural materials with recycled ones showed a tendency to increase shrinkage by up to 0.1 mm/m. For materials RS3 and RA3, an acceleration of shrinkage after 9 months is observed. The reason for such a behavior is not known.

Figure 8.

Drying shrinkage development of mixes with 50 RA, 50 RS, or 50 of both RA + RS compared to the reference mixes. The overall trends of all mixes are similar.

Drying shrinkage is the visco-elastic response to the capillary tension of water imposed by external humidity loss and the internal loss due to cement hydration. Microstructures with more cement paste and/or porosity result in higher shrinkage. Additionally, the sand and aggregates reduce the shrinkage because of their stiffness. Accordingly, the use of recycled aggregate is expected to lead to greater shrinkage deformations as the paste content increases and the stiffness of aggregates reduces [42,43]. The collected results confirmed this trend as the shrinkage of mixes with recycled materials tends to be, on average, higher than that of the references. Furthermore, materials RS3 and RA3, with the highest water absorption, shrunk the most. Still, the differences were small in the absolute figures and are in common ranges [44,45].

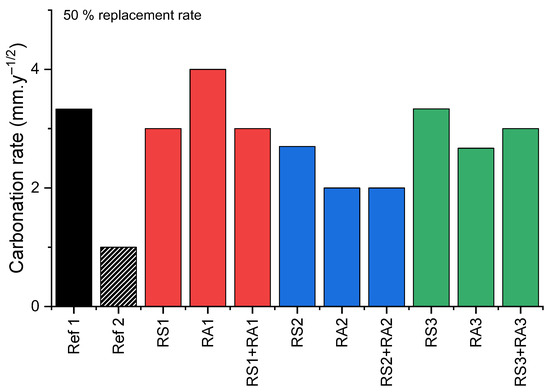

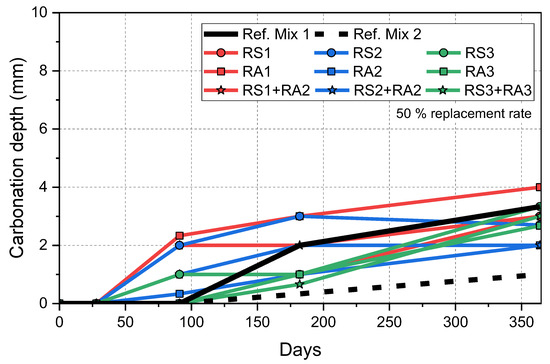

Carbonation depths evolve with the expected square root of time dependency (Figure A1) and result in carbonation rates (Figure 9) comparable to the reference with the fluvial sand. In most of the mixes with recycled materials, initially, higher carbonation depths after 90 days were measured in comparison with the reference mixes. The effect vanished with carbonation time. The carbonation rates measured are within the usual range for comparable systems [45,46].

Figure 9.

Carbonation rates evaluated from the carbonation depth after 1 year. Variation between references is larger than between the mixes with recycled materials.

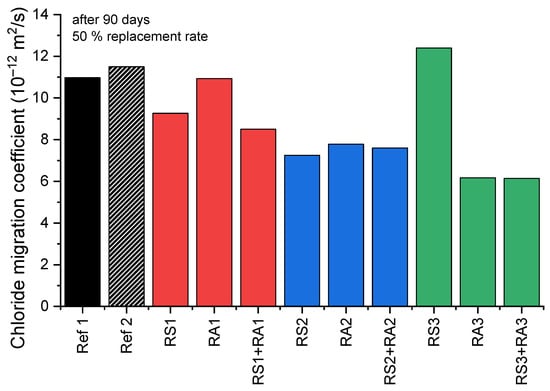

The chloride migration coefficients (Figure 10) stayed within the common range for CEM I concrete of a given w/c ratio. The use of recycled materials resulted in a moderated improvement in chloride resistance, except for RA1 and RS3. The impact was, however, small compared to the one of SCM usage or w/c ratio change [47].

Figure 10.

Chloride migration coefficient determined by the RCM test after 90 days of curing. The chlorid resistance of the mixes with recycled materials is higher than the references, with the exception of RS3.

Compared to drying shrinkage, carbonation and chloride ingress are slow processes localized to the concrete surface. The resistance of concrete to carbonation and chloride ingress is mostly related to the permeability of hydrated cement paste and its composition [42]. Because of the higher porosity of the adhered paste than the bulk paste, recycled materials could accelerate the ingress processes if the amount of adhered paste was high enough for the high porous regions to percolate. The resistance of concrete to ingress phenomena has been marginally influenced. This is due to the constant w/c ratio and cement type [42], as well as the high quality of selective separation for recycled materials. The findings are consistent with [47], where 50% of recycled concrete sand had no impact on the chloride profile in diffusion tests for concrete with w/c 0.45 and w/c 0.55. Generally, the carbonation and chloride ingress resistance was comparable to the reference mixes. Initially, carbonation depths and chloride migration coefficients show a higher scatter. This is likely due to an easier percolation of preferred ingress paths via the adhered cement paste in a less dense microstructure and shallower ingress depths. As the microstructure densifies with time and ingress depth increases, the percolation becomes less relevant. As a result, the scatter of results decreases, and the resistance of concrete with recycled materials approaches that of reference mixes at later ages.

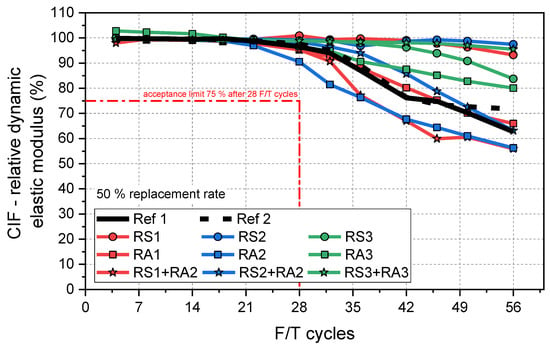

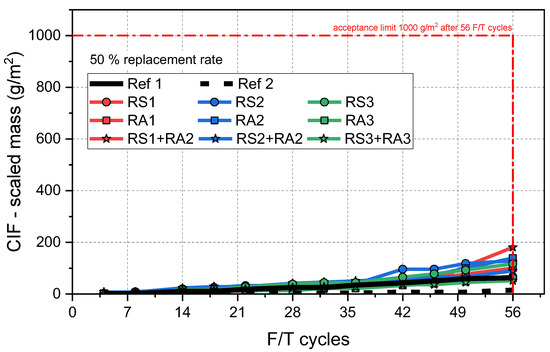

Freeze-thaw resistance of all mixes was largely within the acceptance limits according to BAW [48] as shown in Figure 11 and Figure 12. These are defined as a maximal loss of dynamic elastic modulus of 25% after freeze-thaw cycles and a maximum scaled mass of 1000 g/m2 after 56 cycles. The observed differences fall within the typical experimental scatter.

Figure 11.

Loss of relative elastic modulus according to the CIF test. The red dashed line shows the acceptance limit of 75% after 28 freeze-thaw cycles. All mixes fulfilled the acceptance limit.

Figure 12.

Scaling according to the CIF test. The red dashed line shows the acceptance limit of 1000 g/m2 after 56 freeze-thaw cycles. All mixes fulfilled the acceptance limit with a margin.

3.8. Summary

Overall, the results show that the recycled materials obtained from the selective separation process can be used for structural ready-mix concrete without any significant impact on concrete performance if the water absorption remains below 5 wt.-%. This finding is valid irrespective of the origin of demolished concrete recycled, applied technology, or size of recycled material fraction (sand or coarser aggregates). The results of the durability tests qualify the recycled materials for structural concrete applications, in contrast to many conventional recycled materials. As for the strength, the adhered cement paste and the interface to sand and aggregates might present a weak spot in the hardened microstructure. The porous paste might facilitate transport processes and reduce the local strength and stiffness of concrete, facilitating cracking, which might have a negative impact on durability. The selective separation seems to be indeed effective in removing the adhered cement paste so that the negative effect on concrete performance is minimized. The effectivity of the paste removal is consistently demonstrated by the low water absorption levels achieved, which correspond to the dry density increase toward that of virgin aggregates. It is also consistent with the composition of the RCP recovered showing its enrichment in cement hydrates [15]. It is further supported by the limited impact of recycled aggregates and sand tested on fresh and hardened properties of concrete as long as the water absorption remains low.

The selective separation hence addresses the need to remove the adhered cement paste from aggregates in an economically feasible way [9,49]. It enables the complete recycling of old concrete back to concrete and cement production and thus significantly contributes to its sustainability [4]. Already today, the construction industry is responsible for more than 50% of material extracted and for a third of global landfills [9]. Concrete demand is further expected to grow. To make this grow more suitable, it is of utmost importance to make it as circular and low carbon as possible. The selective separation has the potential to play an important role in this endeavor as it addresses three key pain points:

- High-quality RS and RA are recovered from concrete, which can be used for the production of concrete of the same or even superior quality than the old concrete. Conventional recycling results in the production of high volumes of low-quality fines that do not have any circular and value-added use.

- It is an economically feasible solution as it is a mechanical process with low energy demands (~10 kWh per ton of demolished concrete [15]), which replaces secondary crushing in the conventional process.

- The RCP produced can be valorized to reduce the CO2 footprint of cement, the most CO2intensive constituent of concrete, further improving the environmental as well as economic benefits.

4. Conclusions

Conventional concrete recycling does not take advantage of the full potential of concrete recyclability. Although the use of coarse recycled concrete aggregates for concrete production is well established, finer fractions are not yet circularly valorized in the circular economy. Therefore, established recycling technologies do not focus on the quality of these fractions.

Selective separation can yield high-quality recycled aggregates, sands, and pastes for concrete and cement production. In this paper, selectively separated recycled aggregates and sands from industrially sourced demolished concrete were characterized, and their suitability for concrete production was assessed. The key conclusions are as follows:

- Water absorption of the recycled materials is the key quality parameter linking the efficiency of the selective separation with the performance of the materials in concrete;

- A threshold water absorption level of 5 wt.-% has been identified below, which recycled materials can replace primary aggregates and sand up to 100% without significantly compromising the fresh and hardened properties of concrete;

- There is no difference between recycled aggregates and recycled sand concerning their suitability for concrete production, as well as the underlying phenomena influencing it;

- Durability of concrete with recycled sand and aggregates from selective separation was not negatively influenced;

- Recycled sands and aggregates obtained by selective separation are suitable for producing structural concrete.

This paper presents strong evidence that selective separation enables the complete circularity of concrete as the RCP can be valorized in cement production and recycled aggregates and sand in concrete production, contributing to a more sustainable build environment. These conclusions should nevertheless be assessed in the light of several limitations of our investigation. A single concrete mix design with a single type of cement and superplasticizer was used. The laboratory-scale concrete mix design and mixing procedure were adapted to the research aim of the paper, which does not fully reflect the industrial concrete production practices. In industrial concrete production, the drying and pre-saturation of materials are not feasible, and the materials need to be used “as received”. A broad deployment of selective technologies and an increased use of recycled materials, especially recycled sands, for concrete production requires further investigations and verifications in field trials.

Furthermore, several important properties, such as the impact of high-quality recycled aggregates and sand on the visco-elastic behavior of concrete and structures made from it or the topic of alkali–silica reaction, were not addressed in this paper. Although both these phenomena can be expected to be uncritical due to the low content of cement paste and a limited crushing process of the natural aggregates during the selective separation, further research is needed to confirm these expectations.

Finally, as the selective separation utilizes the differences in strength between hardened cement paste and aggregates, it is only feasible for normal-weight concrete of normal strength. In the case of lightweight concrete, aggregates are typically softer than the cementitious matrix and will be crushed and ground in the process instead of being recovered. Similarly, normal aggregates might be weaker than the cementitious matrix in an ultra-high-performance concrete, again resulting in their cracking. For these materials, an efficient recycling strategy needs to be developed. However, for common concrete constituting the majority of volumes produced, selective separation is suitable.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su16020814/s1, Figure S1. Loose packing density of RS1 (a), RS2 (b), and RS3 (c) and (d) compared with reference sands. Figure S2. LCPC packing density of RS1 (a), RS2 (b), and RS3 (c) compared with reference sands. Figure S3. LCPC and loose packing density of RA1 (a), RA2 (b), and RA3 (c) and (d) compared with reference aggregates. Figure S4. Particle size distribution of cements used and of microfines from reference sands. Table S1. Shape index, flakiness index, Los Angeles abrasion resistance and freeze-thaw test of references and RA samples tested. Table S2. Chemical constituent analysis of recycled concrete used as feed material. Table S3. Physical, chemical, and mineralogical composition of cement and microfines < 63 μm of Quartzite reference and RS1. Cement properties are average of 4 different batches used during the experimental program. Refs. [50,51] cited in Supplementary Materials part.

Author Contributions

Methodology, J.S. and E.V.S.; Software, A.O.; Validation, N.P.; Formal analysis, J.S., A.O. and E.V.S.; Investigation, E.V.S. and N.P.; Resources, J.S.; Data curation, A.O.; Writing—original draft, J.S., A.O., E.V.S. and N.P.; Writing—review & editing, J.S. and A.O.; Visualization, J.S. and A.O.; Supervision, J.S.; Project administration, J.S. All authors have read and agreed to the published version of the manuscript.

Funding

Parts of this research were funded by the German Federal Ministry of Education and Research (BMBF) grant nr. 033RC026A.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are provided in Appendix A and Supplementary Materials.

Conflicts of Interest

All authors were employed by the company Heidelberg Materials AG. All authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

RCP = recycled concrete paste, RS = recycled sand, RA = recycled aggregates, PSD = particle size distribution.

Appendix A

Table A1.

Mix design of reference mixes Ref. Mix 1 and Ref Mix.2.

Table A1.

Mix design of reference mixes Ref. Mix 1 and Ref Mix.2.

| Materials | Unit | Ref. Mix 1 | Ref. Mix 2 |

|---|---|---|---|

| CEM I 4.,5 R | [kg/m3] | 350 | 350 |

| (w/c)eff | [-] | 0.55 | 0.55 |

| Rheinsand 0/2 mm | [kg/m3] | 704 | - |

| Quartzite 0/2 mm | - | 717 | |

| Quartzite 2/5 mm | 392 | 392 | |

| Quartzite 5/8 mm | 143 | 143 | |

| Quartzite 8/16 mm | 535 | 535 | |

| Sika Viscocrete-2014 | [bwoc.] | 0.5 | 1.2 |

Appendix A.1. Soaking Times and Mixing Procedure

Table A2.

Pre-soaking time determined for RS and RA by the graduated measuring cylinder.

Table A2.

Pre-soaking time determined for RS and RA by the graduated measuring cylinder.

| Recycled Sand | RS1.1 | RS2.1 | RS2.2 | RS3.1 | RS3.2 | RS3.3 | RS3.4 | RS3.5 | RS3.6 | RS3.7 | RS3.9 |

| Pre-soaking time (min.) | 30 | 20 | 20 | 30 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Recycled Aggregate | RA1.1 | RA2.1 | RA2.2 | RA3.1 | RA3.2 | RA3.3 | RA3.4 | RA3.5 | RA3.6 | RA3.7 | RA3.9 |

| Pre-soaking time (min.) | 20 | 20 | 20 | 30 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

Table A3.

Concrete mixing procedure.

Table A3.

Concrete mixing procedure.

| Mixing Procedure |

|---|

| • Add all recycled aggregates into the mixer and presoak them with 2/3 of the mixing water |

| • Add the rest of the aggregates and the cement into the pan mixer |

| • Mix for 20 s. Add the rest of the water while mixing |

| • Add the admixture within 10 s |

| • Mix until 210 s |

| • Suction break of 380 s |

| • Mix for 30 s |

| • Total mixing time of 620 s |

| Determine the fresh concrete measurements: temperature, consistency, density, and air content. |

Appendix A.2. Durability Tests

Table A4.

List of durability tests, curing regimes, specimen dimensions, and testing age.

Table A4.

List of durability tests, curing regimes, specimen dimensions, and testing age.

| Durability Test | Test Method | Curing | Specimens | Testing Age | Mix Design | |

|---|---|---|---|---|---|---|

| Time | Temp. (°C) /RH (%) | |||||

| Shrinkage | EN 12390-16 | 1 day under water, 20 °C/65% until measurement | Concrete beams 10 × 10 × 50 cm | 1, (3), 7, 14, 28, 56, 90, 180, and 365 days of drying | Same as used for RC mixes assessed | |

| Natural Carbonation | EN 12390-10 | 28 days under water, 20 °C/65% until measurement | Concrete beams 10 × 10 × 50 cm | 1, 3, 6, 12, and 24 months of storage at 20 °C/65 | Same as used for RC mixes assessed | |

| Rapid chloride migration test | NT Build 492 | under water 20 °C until testing age | Concrete discs Ø: 10 cm. H: 5 cm | 28 days, 90 days, 180 days | w/c 0.45 | |

| Freeze-thaw resistance CIF test | CEN/TS 12390-9 | 1 day in mold, 6 days under water, 21 days: 20 °C/65% | Concrete slab 15 × 15 × 7 cm | Scaling: 14, 28, 42, and 56 cycles RDM: 0, 14, 28, 42, ans 56 cycles | Same as used for RC mixes assessed | |

Appendix A.2.1. Carbonation Resistance

The carbonation test was conducted according to EN 12390-10, where three concrete beams were produced of each mix and stored in a curing chamber at natural conditions at 20 °C and 65 rh. The depth of carbonation was determined on freshly broken specimens by spraying 1 indicator solution on the fracture surface of the beam. The indicator used was thymolphthalein. Its transition rate on the pH ranges from 9.3 to 10.5. Below this, pH is colorless, and above, it shows a blue color. The colorless depth is a measure of the carbonation depth.

Figure A1.

Development of carbonation depths in concrete with 50 RA, 50 RS, and 50 of both RA + RS replaced compared to the reference mixes.

Appendix A.2.2. Rapid Chloride Migration Tests

Chloride resistance was tested using the rapid chloride migration (RCM) test according to NT Build 492. The penetration of chloride ions through the concrete is determined under the influence of an external electrical potential applied. Therefore, the resistance of the tested material to chloride penetration is measured by the chloride migration coefficient, Dnssm (non-steady-state migration coefficient, m2/s), which is directly calculated from the penetration depth.

Samples tested (Ø 100 mm, H = 50 mm) are stored in lime-saturated water until the age of 28 days. They are cut out of cylinders (Ø 100 mm, H = 200 mm). Before starting the test, concrete samples are preconditioned in a vacuum container saturated with a Ca(OH)2 solution. The test is carried out in a cell, which is filled with anolyte solution, Ca(OH)2, and a catholyte solution, NaCl. A voltage of 30 V is applied axially across the specimen and forces the chloride ions of the catholyte solution to migrate into the specimen. After a certain test duration, the specimens are split in two halves and then sprayed with silver nitrate solution as an indicator. Consequently, in the zone where chlorides are present, a white silver chloride precipitation is clearly visible, and the chloride migration coefficient can be calculated from the penetration depth front.

Appendix A.2.3. Freeze-Thaw Resistance without De-Icing Salt

Freeze-thaw resistance without the presence of a de-icing agent was determined by the CIF test. This test was conducted by measuring the dynamic modulus of elasticity (dynamic E-modulus) and the loss of mass over 56 freeze-thaw cycles. To calculate the dynamic E-modulus, the fundamental transverse frequency was measured before and after applying freeze-thaw cycles. Additionally, scaling tests and mass loss were performed to test how samples withstand freeze-thaw cycles by comparing the surface of the samples tested. The combination of both tests enabled the investigation of the internal as well the external damage of a specimen.

Samples were slabs with dimensions 150 mm × 150 mm × 70 mm made from cubes. Before starting the FT cycling, the sample was exposed to water uptake in de-ionized water. The temperature during the cycles was between −20 °C and 20 °C.

The relevant criterion for evaluating the inner damage, according to BAW [40], is the number of cycles before the damage criterion is reached. The concrete is considered to be damaged if the relative dynamic modulus of elasticity is less than 75. To pass the test, 28 cycles have to withstand without damage.

Appendix A.3. Results—Concrete Fresh Properties and Strength

Table A5.

Fresh and hardened properties of Ref. Mix 1 and RS mixes, made with fluvial sand (Rheinsand) and quartzite aggregates.

Table A5.

Fresh and hardened properties of Ref. Mix 1 and RS mixes, made with fluvial sand (Rheinsand) and quartzite aggregates.

| Replacement Rate | RS Mix | Air Entrained (%) | Fresh Density (kg/m³) | SP Dosage (% Bwoc) | Flow (mm) | Compressive Strength (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 min. | 30 min. | 60 min. | 90 min. | 2 days | 7 days | 28 days | |||||

| Reference Rheinsand | 3.2 | 2389 | 0.5 | 480 | 410 | 380 | 340 | 32.0 | 41.5 | 49.9 | |

| 25% | RS1.1 | 3.4 | 2284 | 0.5 | 460 | 400 | 360 | 320 | 32.8 | 42.1 | 49.8 |

| RS1.2 | 2.6 | 2314 | 0.5 | 460 | 390 | 350 | 350 | 32.7 | 41.7 | 50.3 | |

| RS2.1 | 3.9 | 2306 | 0.5 | 480 | 450 | 420 | 400 | 30.7 | 41.9 | 51.4 | |

| RS2.2 | 3.4 | 2308 | 0.5 | 440 | 400 | 370 | 330 | 33.5 | 42.1 | 49.6 | |

| RS3.1 | 2.7 | 2294 | 0.5 | 380 | 370 | 360 | 340 | 29.8 | 40.2 | 48.0 | |

| RS3.10 | 3 | 2299 | 0.5 | 470 | 450 | 410 | 380 | 27.3 | 35.9 | 45.0 | |

| RS3.11 | 3.7 | 2314 | 0.5 | 400 | 370 | 350 | 340 | 31.1 | 39.3 | 45.9 | |

| RS3.12 | 3 | 2270 | 0.5 | 440 | 430 | 380 | 350 | 30.5 | 39.1 | 45.1 | |

| RS3.13 | 2.3 | 2320 | 0.5 | 490 | 480 | 450 | 420 | 26.4 | 36.1 | 47.6 | |

| RS3.14 | 4.2 | 2288 | 0.5 | 430 | 410 | 390 | 370 | 19.4 * | 37.3 | 46.3 | |

| RS3.15 | 2.3 | 2322 | 0.5 | 480 | 440 | 420 | 400 | 29.3 | 33.3 | 46.5 | |

| RS3.16 | 3.6 | 2295 | 0.5 | 480 | 440 | 400 | 380 | 29.4 | 38.8 | 45.7 | |

| RS3.17 | 2.4 | 2323 | 0.5 | 490 | 460 | 450 | 420 | 28.6 | 38.4 | 46.8 | |

| RS3.18 | 2.5 | 2315 | 0.5 | 480 | 440 | 420 | 410 | 29.9 | 38.7 | 46.5 | |

| RS3.19 | 2.3 | 2321 | 0.5 | 470 | 440 | 430 | 420 | 19.5 * | 39.1 | 48.6 | |

| RS3.20 | 3.8 | 2290 | 0.5 | 440 | 430 | 400 | 380 | 20.2 * | 38.7 | 45.3 | |

| RS3.21 | 2.5 | 2314 | 0.5 | 460 | 450 | 420 | 400 | 20.2 * | 41.0 | 47.2 | |

| RS3.22 | 2.7 | 2315 | 0.5 | 450 | 430 | 390 | 390 | 30.4 | 40.8 | 49.7 | |

| RS3.23 | 2.8 | 2311 | 0.5 | 430 | 410 | 400 | 380 | 32.4 | 41.4 | 47.3 | |

| RS3.24 | 3.4 | 2301 | 0.5 | 440 | 410 | 370 | 360 | 30.3 | 38.8 | 48.3 | |

| RS3.25 | 2.4 | 2322 | 0.5 | 470 | 420 | 390 | 390 | 32.4 | 43.0 | 48.5 | |

| AVG | 3.0 | 2306 | 0.5 | 454 | 425 | 397 | 378 | 30.4 | 39.4 | 47.5 | |

| STD | 0.6 | 14 | 0.0 | 28 | 28 | 29 | 30 | 1.9 | 2.3 | 1.8 | |

| 50% | RS1.1 | 3.1 | 2301 | 0.5 | 510 | 460 | 430 | 390 | 31.0 | 41.2 | 50.5 |

| RS1.2 | 2.6 | 2321 | 0.5 | 450 | 390 | 360 | 340 | 32.3 | 41.3 | 51.2 | |

| RS1.3 | 3 | 2320 | 0.5 | 430 | 420 | 400 | 380 | 32.7 | 40.1 | 50.1 | |

| RS2.1 | 3.9 | 2290 | 0.6 | 480 | 410 | 360 | 320 | 35.8 | 47.4 | 51.1 | |

| RS2.2 | 4.6 | 2275 | 0.7 | 470 | 390 | 360 | 340 | 33.8 | 46.1 | 51.2 | |

| RS2.4 | 2.2 | 2312 | 0.5 | 480 | 460 | 430 | 410 | 19.3 * | 37.7 | 46.5 | |

| RS2.5 | 2.8 | 2310 | 0.5 | 470 | 460 | 430 | 400 | 32.6 | 40.0 | 46.7 | |

| RS2.6 | 3 | 2319 | 0.5 | 470 | 460 | 410 | 400 | 31.6 | 37.0 | 47.1 | |

| RS2.7 | 2.1 | 2324 | 0.5 | 500 | 460 | 450 | 410 | 30.1 | 37.2 | 46.5 | |

| RS3.1 | 4.4 | 2267 | 0.5 | 360 | 330 | 320 | n.a. | 32.3 | 41.2 | 47.9 | |

| RS3.10 | 2.3 | 2304 | 0.5 | 450 | 420 | 400 | 360 | 16.7 * | 35.9 | 43.5 | |

| RS3.11 | 4.1 | 2275 | 0.5 | 460 | 440 | 420 | 400 | 26.4 | 36.0 | 43.8 | |

| RS3.12 | 4.1 | 2270 | 0.5 | 390 | 350 | 330 | 290 | 25.9 | 38.6 | 43.3 | |

| RS3.13 | 1.5 | 2324 | 0.5 | 570 | 520 | 490 | 460 | 16.6 * | 35.1 | 42.7 | |

| RS3.14 | 4.5 | 2260 | 0.5 | 420 | 390 | 370 | 360 | 29.2 | 39.2 | 47.2 | |

| RS3.15 | 2.3 | 2307 | 0.5 | 480 | 450 | 420 | 400 | 28.4 | 37.3 | 46.6 | |

| RS3.16 | 2.7 | 2161 | 0.5 | 410 | 390 | 380 | 340 | 29.7 | 40.3 | 48.1 | |

| RS3.17 | 2.4 | 2305 | 0.5 | 430 | 420 | 420 | 400 | 28.5 | 38.0 | 43.3 | |

| RS3.18 | 2.7 | 2302 | 0.5 | 440 | 410 | 370 | 360 | 29.2 | 39.4 | 46.9 | |

| RS3.19 | 2.6 | 2304 | 0.5 | 440 | 460 | 410 | 400 | 29.8 | 38.7 | 44.2 | |

| RS3.20 | 4.6 | 2258 | 0.5 | 400 | 380 | 330 | 320 | 30.2 | 39.0 | 44.4 | |

| RS3.21 | 2.6 | 2291 | 0.5 | 500 | 450 | 440 | 390 | 27.4 | 34.9 | 42.2 | |

| RS3.22 | 3.1 | 2289 | 0.5 | 420 | 420 | 390 | 380 | 30.2 | 40.0 | 46.8 | |

| RS3.23 | 2.2 | 2308 | 0.5 | 460 | 430 | 390 | 380 | 21.0 * | 40.2 | 46.5 | |

| RS3.24 | 3.5 | 2294 | 0.5 | 420 | 410 | 380 | 340 | 28.9 | 37.0 | 47.5 | |

| RS3.25 | 3.3 | 2284 | 0.5 | 440 | 420 | 410 | 380 | 31.2 | 38.8 | 44.0 | |

| AVG | 3.1 | 2291 | 0.5 | 452 | 423 | 396 | 374 | 30.3 | 39.1 | 46.5 | |

| STD | 0.9 | 32 | 0.0 | 42 | 39 | 39 | 36 | 2.3 | 2.8 | 2.7 | |

| 75% | RS1.1 | 3.4 | 2284 | 0.5 | 440 | 410 | 360 | 330 | 29.7 | 39.2 | 48.8 |

| RS1.2 | 2.6 | 2314 | 0.5 | 470 | 420 | 400 | 360 | 33.6 | 42.6 | 50.0 | |

| RS1.3 | 3.4 | 2315 | 0.5 | 410 | 380 | 350 | 340 | 25.6 * | 46.0 | 53.7 | |

| RS2.1 | 4.6 | 2273 | 0.7 | 440 | 360 | 320 | n.a. | 33.7 | 44.8 | 50.9 | |

| RS2.2 | 5.5 | 2247 | 0.7 | 450 | 390 | 320 | 310 | 34.6 | 46.4 | 53.9 | |

| RS3.1 | 3.9 | 2264 | 0.5 | 380 | 370 | 340 | n.a. | 29.7 | 38.7 | 47.6 | |

| RS3.2 | 3.3 | 2270 | 0.5 | 470 | 450 | 420 | 400 | 28.9 | 39.1 | 47.5 | |

| RS3.6 | 2.8 | 2276 | 0.5 | 500 | 430 | 390 | 370 | 29.9 | 39.0 | 48.2 | |

| AVG | 3.7 | 2280 | 0.6 | 445 | 401 | 363 | 352 | 31.4 | 42.0 | 50.1 | |

| STD | 0.9 | 22 | 0.1 | 35 | 29 | 35 | 29 | 2.2 | 3.2 | 2.4 | |

| 100% | RS1.1 | 3.3 | 2273 | 0.5 | 470 | 400 | 340 | 310 | 29.6 | 39.0 | 48.8 |

| RS1.2 | 2.5 | 2305 | 0.5 | 480 | 440 | 410 | 380 | 31.9 | 39.8 | 50.0 | |

| RS1.3 | 2.2 | 2325 | 0.4 | 470 | 440 | 430 | 420 | 22.6 * | 44.9 | 53.7 | |

| RS2.1 | 4.8 | 2259 | 0.9 | 450 | 380 | 320 | n.a. | 33.7 | 43.5 | 50.9 | |

| RS2.2 | 5.6 | 2244 | 0.9 | 440 | 360 | 320 | n.a. | 34.7 | 48.1 | 53.9 | |

| RS3.1 | 5.8 | 2201 | 0.5 | 480 | 460 | 440 | 390 | 13.8 * | 30.4 | 42.2 | |

| AVG | 4.0 | 2268 | 0.6 | 465 | 413 | 377 | 375 | 32.5 | 41.0 | 49.9 | |

| STD | 1.4 | 40 | 0.2 | 15 | 36 | 51 | 40 | 1.9 | 5.6 | 3.9 | |

* 1-day compressive strength results, not used for calculation of averages (AVG) and standard deviations (STD) of the subgroups.

Table A6.

Fresh and hardened properties of Ref. Mix 2 and RS mixes, made with quarzitic fine and coarse aggregates.

Table A6.

Fresh and hardened properties of Ref. Mix 2 and RS mixes, made with quarzitic fine and coarse aggregates.

| Replacement Rate | RS Mix | Air Entrained (%) | Fresh Density (kg/m³) | SP Dosage (% Bwoc) | Flow (mm) | Compressive Strength (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 min. | 30 min. | 60 min. | 90 min. | 2 days | 7 days | 28 days | |||||

| Reference Quarzitic sand | 2.1 | 2353 | 1.2 | 430 | 380 | n.a. | 330 | 35.9 | 46.0 | 53.8 | |

| 25% | RS1.1 | 1.8 | 2351 | 1.2 | 420 | 380 | 360 | 340 | 36.7 | 49 | 55.5 |

| RS1.2 | 2.6 | 2314 | 1.2 | 510 | 430 | 400 | 340 | 36.5 | 48.1 | 55.4 | |

| RS2.1 | 2.1 | 2345 | 1.2 | 460 | 420 | 340 | 300 | 38.6 | 50.8 | 55.6 | |

| RS2.2 | 2.1 | 2344 | 1.2 | 420 | 400 | 330 | 290 | 39.6 | 51.5 | 59.3 | |

| RS3.1 | 2.2 | 2331 | 1.2 | 400 | 380 | 380 | 320 | 32.1 | 43.6 | 52.1 | |

| RS3.2 | 1.3 | 2355 | 1.2 | 460 | 410 | 390 | 350 | 35.6 | 44.6 | 54.4 | |

| RS3.6 | 2.3 | 2328 | 1.2 | 570 | 530 | 520 | 480 | 32.1 | 46.4 | 49.1 | |

| RS3.10 | 2.6 | 2329 | 1.2 | 500 | 470 | 440 | 430 | 31.1 | 41.4 | 49.5 | |

| RS3.11 | 2.1 | 2345 | 1.2 | 490 | 470 | 460 | 440 | 31.1 | 41.5 | 51.0 | |

| RS3.12 | 2.4 | 2318 | 1.2 | 430 | 410 | 360 | 330 | 25.0 * | 41.6 | 50.0 | |

| RS3.13 | 2.8 | 2328 | 1.2 | 570 | 520 | 500 | 480 | 28.6 | 38.9 | 47.7 | |

| AVG | 2.2 | 2335 | 1.2 | 476 | 438 | 407 | 373 | 34.2 | 45.2 | 52.7 | |

| STD | 0.4 | 13 | 0.0 | 56 | 50 | 61 | 68 | 3.5 | 4.0 | 3.4 | |

| 50% | RS1.1 | 2.1 | 2336 | 1.2 | 500 | 440 | 370 | 360 | 38.2 | 49.1 | 56.5 |

| RS1.2 | 1.0 | 2361 | 0.5 | 390 | 350 | 330 | n.a. | 32.1 | 43.4 | 53.0 | |

| RS2.1 | 2.5 | 2324 | 1.2 | 460 | 390 | 340 | 320 | 36.7 | 47.9 | 56.6 | |

| RS2.2 | 2.8 | 2325 | 1.2 | 470 | 410 | 350 | 320 | 36.7 | 47.9 | 59.6 | |

| RS3.1 | 2.8 | 2303 | 1.2 | 460 | 420 | 400 | 380 | 33.8 | 45.0 | 53.8 | |

| RS3.2 | 1.3 | 2355 | 1.2 | 520 | 470 | 450 | 420 | 33.1 | 44.0 | 51.4 | |

| RS3.6 | 2.3 | 2328 | 0.6 | 370 | 320 | 290 | n.a. | 32.8 | 41.6 | 49.1 | |

| RS3.10 | 1.8 | 2317 | 1.2 | 570 | 530 | 500 | 460 | 27.9 | 37.7 | 46.9 | |

| RS3.11 | 2.7 | 2325 | 1.2 | 520 | 480 | 460 | 430 | 30.3 | 40.5 | 48.7 | |

| RS3.12 | 3.3 | 2297 | 1.2 | 380 | 380 | 370 | 350 | 22.4 * | 43.2 | 48.5 | |

| AVG | 2.3 | 2327 | 1.1 | 464 | 419 | 386 | 380 | 33.5 | 46.3 | 43.5 | |

| STD | 0.7 | 19 | 0.3 | 63 | 60 | 63 | 49 | 3.1 | 2.9 | 3.3 | |

| 75% | RS1.1 | 2.4 | 2318 | 1 | 430 | 360 | 340 | 280 | 38.8 | 50.9 | 53.9 |

| RS1.2 | 3.2 | 2300 | 0.5 | 390 | 360 | 340 | 340 | 33.4 | 44.8 | 48.9 | |

| RS2.1 | 2.7 | 2317 | 1.2 | 490 | 410 | 350 | 330 | 36.0 | 48.0 | 57.3 | |

| RS2.2 | 3.4 | 2307 | 1.2 | 490 | 390 | 350 | 330 | 36.6 | 48.6 | 58.3 | |

| RS3.1 | 2.7 | 2300 | 1.2 | 400 | 370 | 350 | 330 | 34.5 | 45.9 | 53.2 | |

| RS3.6 | 2.9 | 2277 | 0.6 | 460 | 410 | 360 | 350 | 31.0 | 41.1 | 48.3 | |

| AVG | 2.9 | 2303 | 1.0 | 443 | 383 | 348 | 327 | 35.1 | 46.6 | 53.3 | |

| STD | 0.3 | 14 | 0.3 | 40 | 21 | 7 | 22 | 2.5 | 3.1 | 3.8 | |

| 100% | RS1.1 | 2.4 | 2321 | 1.2 | 510 | 440 | 370 | 340 | 39.7 | 47.6 | 58.7 |

| RS2.1 | 3.3 | 2297 | 1.2 | 510 | 470 | 400 | 340 | 34.7 | 48.1 | 58.6 | |

| RS2.2 | 3.9 | 2292 | 1.2 | 470 | 390 | 360 | 310 | 36.5 | 47.5 | 55.8 | |

| RS3.1 | 1.7 | 2309 | 1.2 | 600 | 500 | 500 | 470 | 32.1 | 42.8 | 50.6 | |

| AVG | 2.8 | 2305 | 1.2 | 523 | 450 | 408 | 365 | 35.8 | 46.5 | 55.9 | |

| STD | 0.8 | 11 | 0.0 | 48 | 41 | 55 | 62 | 2.8 | 2.1 | 3.3 | |

* 1-day compressive strength results, not used for calculation of averages (AVG) and standard deviations (STD) of the subgroups.

Table A7.

Fresh and hardened properties of Ref. Mix 1 and RA mixes, made with fluvial sand (Rheinsand) and quartzite aggregates.

Table A7.

Fresh and hardened properties of Ref. Mix 1 and RA mixes, made with fluvial sand (Rheinsand) and quartzite aggregates.

| Replacement Rate | RA Mix | Air Entrained (%) | Fresh Density (kg/m³) | SP Dosage (% Bwoc) | Flow (mm) | Compressive Strength (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 min. | 30 min. | 60 min. | 90 min. | 2 days | 7 days | 28 days | |||||

| Reference Rheinsand | 3.2 | 2389 | 0.5 | 480 | 410 | 380 | 340 | 32.0 | 41.5 | 49.9 | |

| 25% | RA1.1 | 3.4 | 2284 | 0.6 | 450 | 380 | 370 | 330 | 35.2 | 46.6 | 53.5 |

| RA2.1 | 2.6 | 2314 | 0.5 | 500 | 470 | 410 | 400 | 31.8 | 42.0 | 50.4 | |

| RA2.2 | 3.9 | 2306 | 0.5 | 490 | 420 | 390 | 360 | 32.3 | 42.9 | 53.1 | |

| RA3.1 | 3.1 | 2301 | 0.5 | 490 | 460 | 460 | 400 | 29.5 | 38.5 | 49.3 | |

| RA3.2 | 3.4 | 2308 | 0.5 | 440 | 410 | 370 | 350 | 32.9 | 42.9 | 52.8 | |

| RA3.3 | 2.7 | 2294 | 0.5 | 540 | 460 | 400 | 390 | 33.3 | 42.5 | 51.4 | |

| RA3.4 | 3.0 | 2299 | 0.5 | 500 | 450 | 390 | 380 | 32.4 | 42.6 | 50.1 | |

| RA3.5 | 3.7 | 2314 | 0.3 | 480 | 440 | 410 | 400 | 31.0 | 42.4 | 50.8 | |

| RA3.6 | 3.0 | 2270 | 0.5 | 550 | 480 | 450 | 380 | 33.0 | 41.5 | 55.4 | |

| RA3.7 | 2.3 | 2320 | 0.5 | 550 | 480 | 440 | 380 | 31.9 | 42.9 | 52.6 | |

| RA3.8 | 4.2 | 2288 | 0.5 | 440 | 430 | 400 | 390 | 22.7 * | 40.8 | 49.9 | |

| RA3.9 | 2.3 | 2322 | 0.5 | 450 | 420 | 400 | 370 | 30.2 | 41.3 | 52.4 | |

| RA3.10 | 3.6 | 2295 | 0.5 | 440 | 420 | 390 | 370 | 26.9 | 34.7 | 43.3 | |

| RA3.11 | 2.4 | 2323 | 0.5 | 480 | 450 | 420 | 400 | 25.6 | 33.5 | 46.6 | |

| RA3.12 | 3.8 | 2281 | 0.5 | 490 | 430 | 440 | 420 | 29.4 | 38.6 | 49.6 | |

| RA3.13 | 2.6 | 2292 | 0.5 | 470 | 440 | 420 | 390 | 30.2 | 38.7 | 47.3 | |

| RA3.14 | 2.7 | 2315 | 0.5 | 460 | 450 | 420 | 390 | 29.1 | 40.4 | 49.7 | |

| RA3.15 | 2.5 | 2313 | 0.5 | 480 | 450 | 440 | 420 | 29.4 | 39.9 | 46.4 | |

| AVG | 3.1 | 2302 | 0.5 | 483 | 441 | 412 | 384 | 30.8 | 42.6 | 39.5 | |

| STD | 0.6 | 15 | 0.1 | 35 | 25 | 26 | 22 | 2.3 | 2.2 | 2.9 | |

| 50% | RA1.1 | 3.8 | 2278 | 0.8 | 470 | 440 | 360 | 340 | 33.4 | 44.7 | 53.0 |

| RA1.2 | 3.3 | 2308 | 0.8 | 490 | 440 | 410 | 370 | 29.0 | 38.8 | 47.4 | |

| RA2.1 | 3.4 | 2289 | 0.5 | 480 | 410 | 400 | 370 | 33.1 | 44.7 | 49.7 | |

| RA2.2 | 3.2 | 2304 | 0.5 | 470 | 390 | 340 | 290 | 33.8 | 45.2 | 51.0 | |

| RA2.4 | 2.7 | 2297 | 0.3 | 400 | 370 | 340 | 340 | 30.4 | 39.2 | 46.8 | |

| RA2.5 | 2.0 | 2312 | 0.5 | 520 | 500 | 450 | 430 | 31.1 | 41.1 | 48.5 | |

| RA2.6 | 2.0 | 2302 | 0.5 | 520 | 490 | 490 | 450 | 23.1 * | 40.3 | 46.6 | |

| RA2.7 | 2.2 | 2305 | 0.5 | 510 | 490 | 470 | 460 | 29.9 | 39.2 | 47.9 | |

| RA3.1 | 2.0 | 2375 | 0.5 | 510 | 480 | 410 | 410 | 32.4 | 41.1 | 52.2 | |

| RA3.10 | 4.9 | 2217 | 0.5 | 480 | 460 | 420 | 400 | 25.6 | 33.5 | 39.2 | |

| RA3.11 | 4.6 | 2263 | 0.5 | 440 | 420 | 390 | 370 | 23.4 * | 39.7 | 48.6 | |

| RA3.12 | 3.7 | 2247 | 0.4 | 480 | 460 | 430 | 410 | 17.9 * | 36.0 | 42.9 | |

| RA3.13 | 2.9 | 2263 | 0.5 | 480 | 440 | 410 | 390 | 29.2 | 37.5 | 44.4 | |

| RA3.14 | 2.5 | 2306 | 0.5 | 470 | 450 | 420 | 400 | 20.5 * | 40.3 | 49.9 | |

| RA3.15 | 3.7 | 2264 | 0.5 | 390 | 390 | 390 | 380 | 29.1 | 37.1 | 45.5 | |

| AVG | 3.1 | 2289 | 0.5 | 474 | 442 | 409 | 387 | 30.6 | 39.9 | 47.6 | |

| STD | 0.9 | 35 | 0.1 | 37 | 39 | 41 | 43 | 2.3 | 3.2 | 3.5 | |

| 75% | RA1.1 | 4.4 | 2245 | 0.7 | 490 | 410 | 360 | 350 | 33.0 | 43.8 | 49.5 |

| RA1.2 | 2.6 | 2303 | 0.5 | 470 | 450 | 430 | 410 | 31.8 | 41.0 | 52.0 | |

| RA2.1 | 3.6 | 2267 | 0.6 | 430 | 380 | 350 | 330 | 30.5 | 38.8 | 46.4 | |

| RA2.2 | 3.5 | 2272 | 0.5 | 410 | 370 | 330 | n.a. | 31.3 | 41.7 | 50.5 | |

| RA3.1 | 2.1 | 2344 | 0.3 | 440 | 420 | 400 | 390 | 27.2 | 39.6 | 48.9 | |

| AVG | 3.2 | 2286 | 0.5 | 448 | 406 | 374 | 370 | 31.8 | 41.0 | 49.5 | |

| STD | 0.8 | 34 | 0.1 | 29 | 29 | 36 | 32 | 2.0 | 1.7 | 1.9 | |

| 100% | RA1.1 | 5.2 | 2217 | 0.6 | 450 | 370 | 340 | 330 | 29.8 | 40.8 | 45.9 |

| RA1.2 | 2.0 | 2293 | 0.5 | 460 | 440 | 430 | 420 | 20.0 * | 42.9 | 53.0 | |

| RA2.1 | 5.5 | 2292 | 0.7 | 430 | 410 | 380 | 370 | 33.8 | 38.3 | 45.9 | |

| RA2.2 | 4.0 | 2249 | 0.5 | 450 | 380 | 330 | n.a. | 28.8 | 40.4 | 47.6 | |

| RA3.1 | 1.9 | 2336 | 0.3 | 470 | 450 | 420 | 390 | 26.4 | 37.3 | 44.1 | |

| AVG | 3.7 | 2277 | 0.5 | 452 | 410 | 380 | 378 | 29.7 | 39.9 | 47.3 | |