Effects of Multi-Walled Carbon Nanotubes and Recycled Fine Aggregates on the Multi-Generational Cycle Properties of Reactive Powder Concrete

Abstract

1. Introduction

2. Materials and Methods

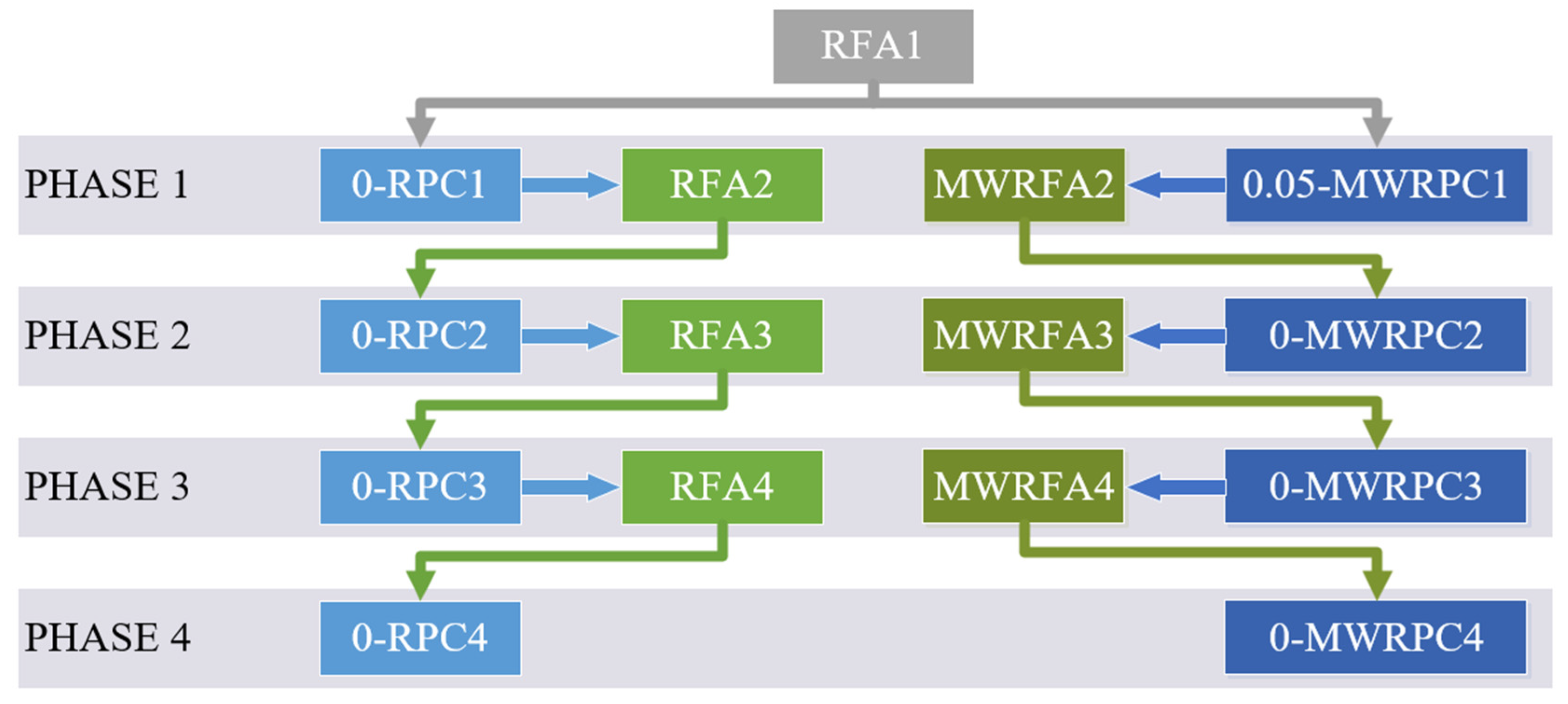

2.1. Multi-Generational Recycled Fine Aggregates and Concretes Preparation

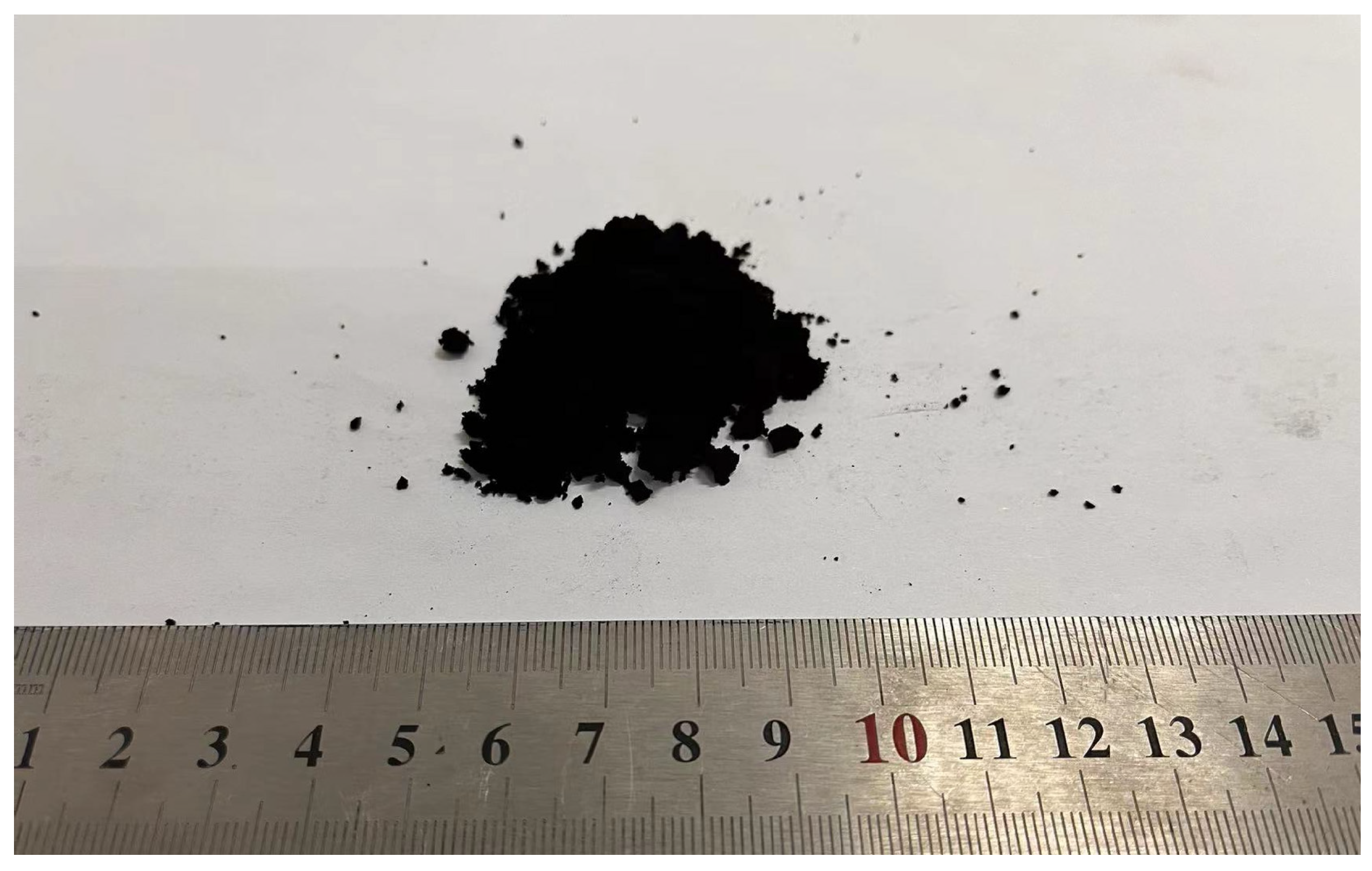

2.2. Materials

2.3. Mix Ratio Design

2.4. Methods

3. Results

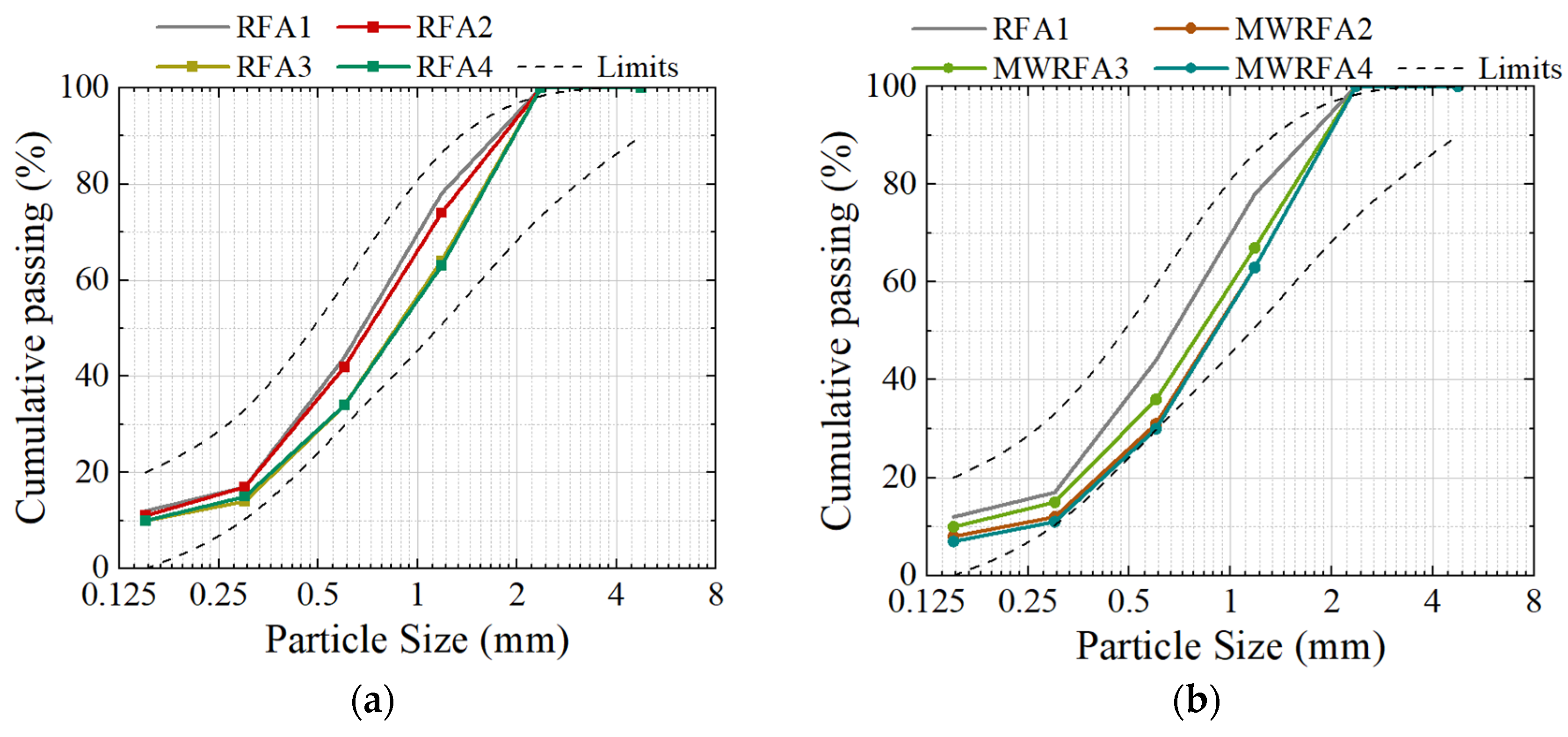

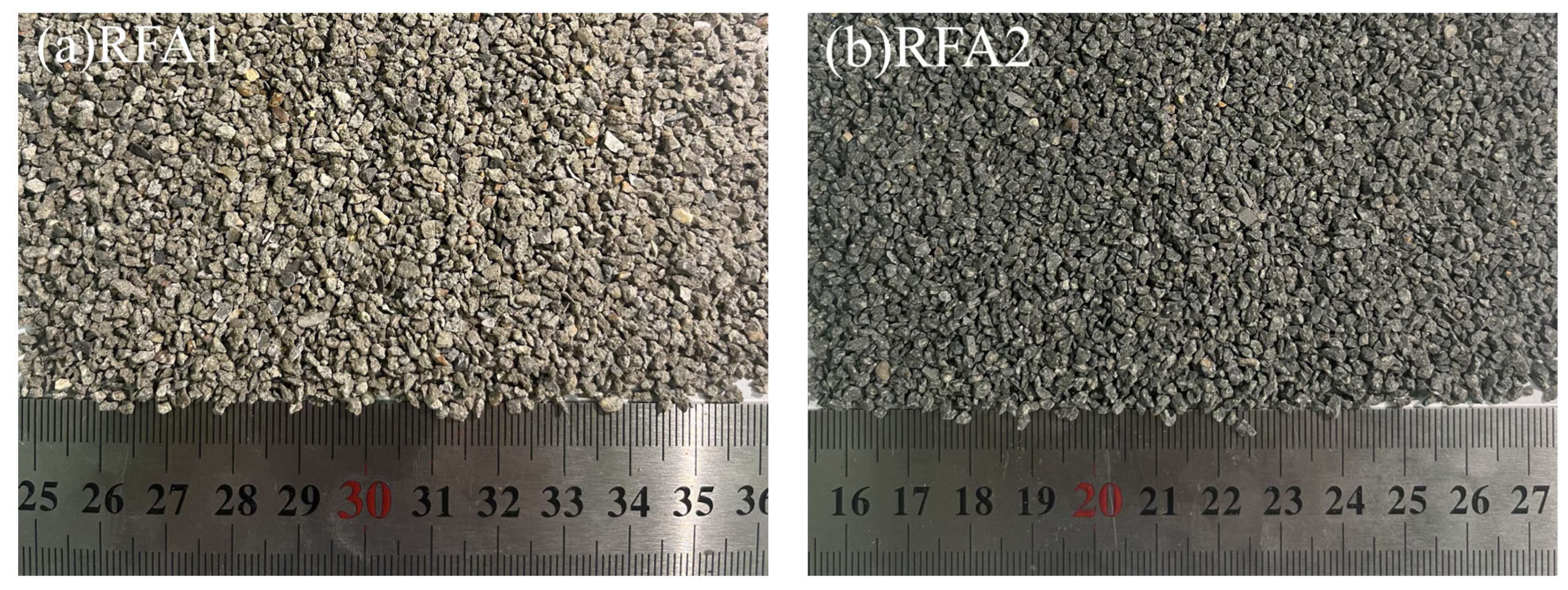

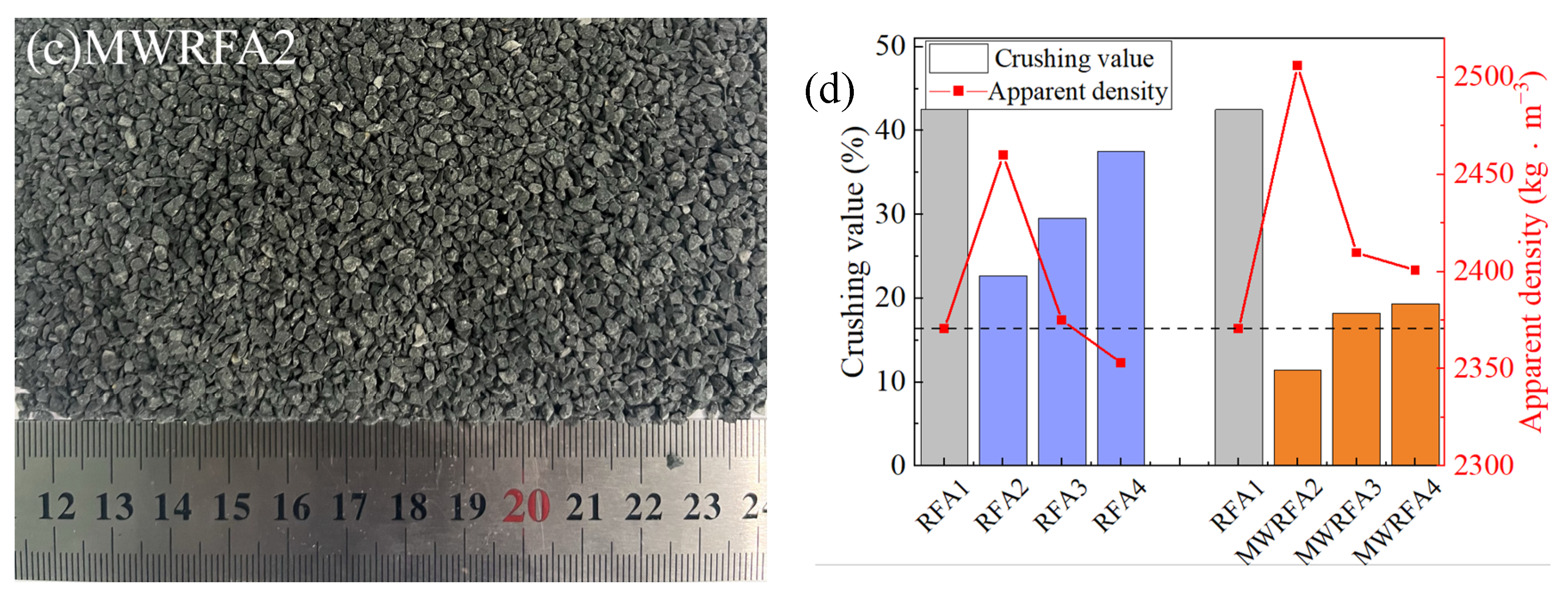

3.1. Effect of MWCNTs on Multi-Generational Recycled Reactive Powder Fine Aggregate

3.2. Effect of MWCNTs on the Mechanical Properties of Multi-Generational Recycled Reactive Powder Concrete

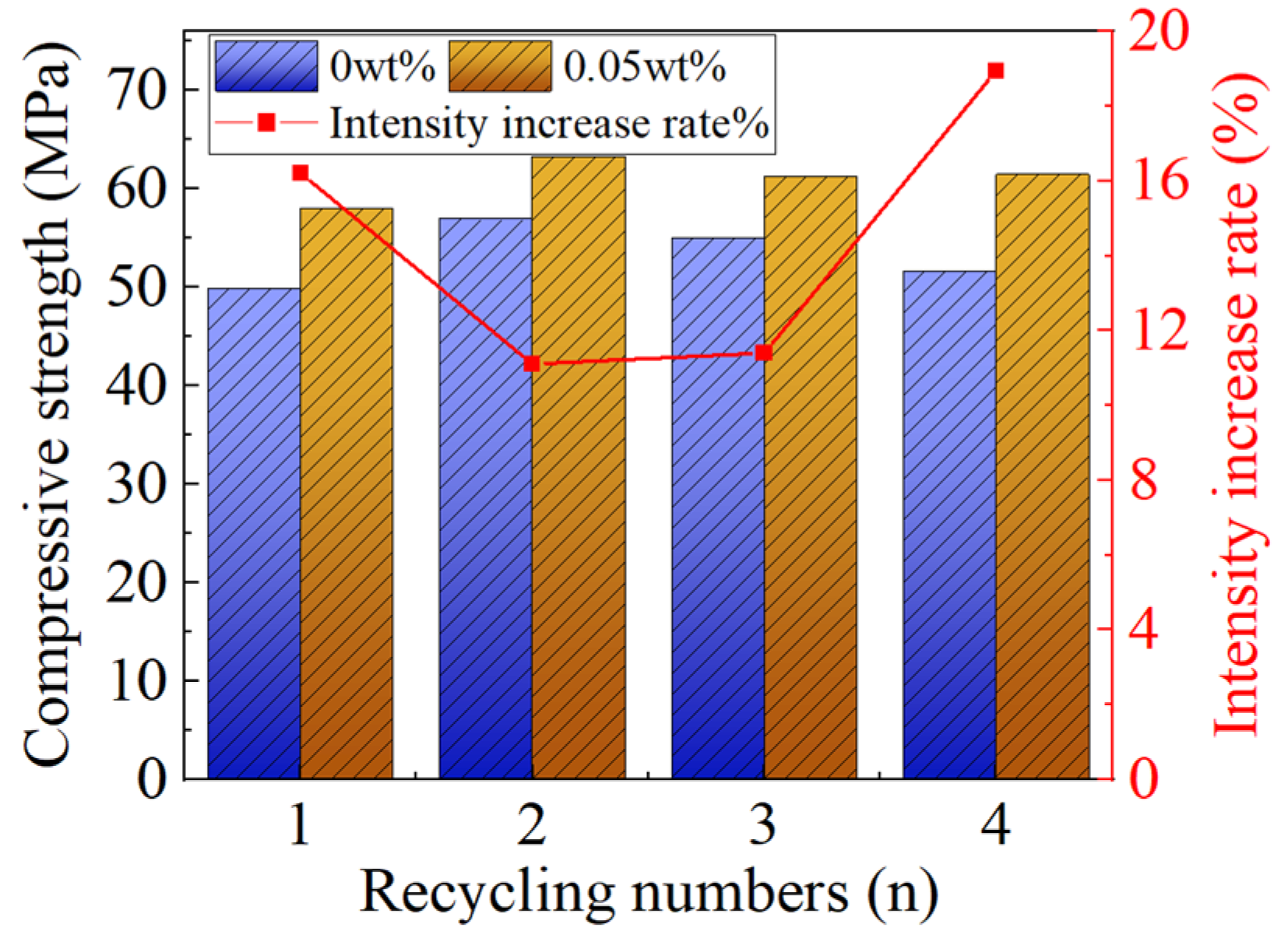

3.2.1. Compressive Strength

- (1)

- RPC1 has the lowest compressive strength of 49.93 MPa, failing to reach the expected strength value of cement. It shows that directly using RFA crushed from construction waste to prepare fully recycled concrete with a 100% substitution rate, even with reactive powder, is insufficient to bridge the gap between recycled and natural aggregates’ material properties.

- (2)

- The compressive strength of RPC2, prepared from recycled aggregate after one generation of recycling, reaches a maximum value of 56.97 MPa, 14.1% higher than RPC1. Evidently, after one generation of recycling, the mortar attached to the RFA can improve the total deficiency of the aggregate. The compressive strengths of RPC3 and RPC4 grew by 10.15% and 3.54%, respectively, corresponding with that of RPC1. The enhancement effect of the adsorption mortar shows a decreasing trend, indicating that the adsorption mortar could repair the microcracks of the RFA to a certain extent and fill in the old pores of the RFA, but the reinforcing effect is limited.

- (3)

- The compressive strength change pattern of the MWRPC is analogous to that of RPC when the cycle is not completed more than three times. Among them, the compressive strength of MWRPC1 is the lowest at 58.03 MPa. Compared to RPC1, the number of cycle generations is the same. The compressive strength increased by 16.22%. It can be seen that a dosage of 0.05 wt% of the MWCNTs can improve the compressive strength of the concrete. Meanwhile, when cycling to the fourth generation, the compressive strength of MWRPC4 is 61.50 MPa, similar to the compressive strength of the previous generation, with no significant decreasing trend. In comparison, the decrease of RPC4 of the prior generation is 6.00%. This indicated that MWCNTs could still enhance the compressive strength of concrete under multiple cycles.

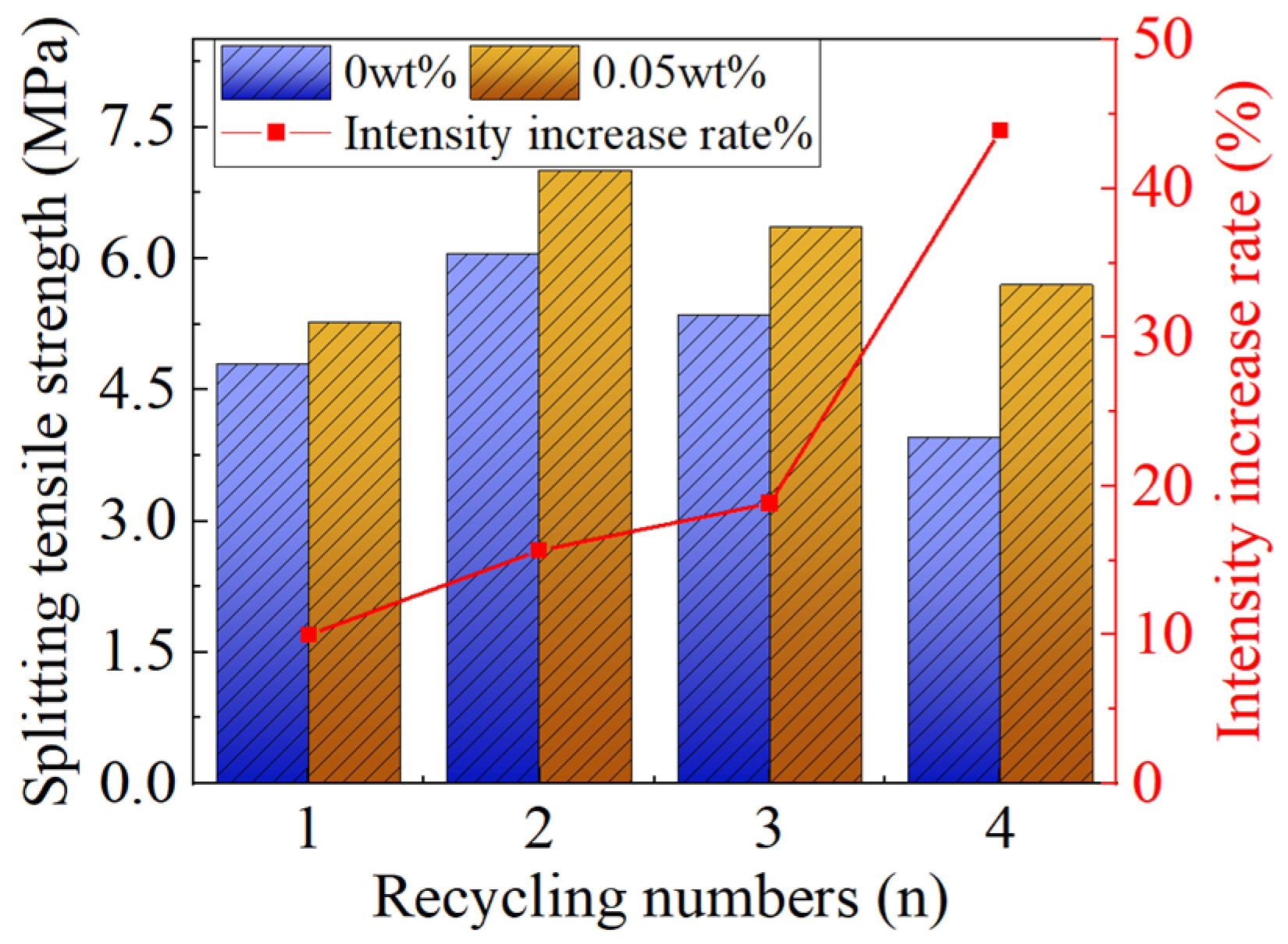

3.2.2. Splitting Tensile Strength

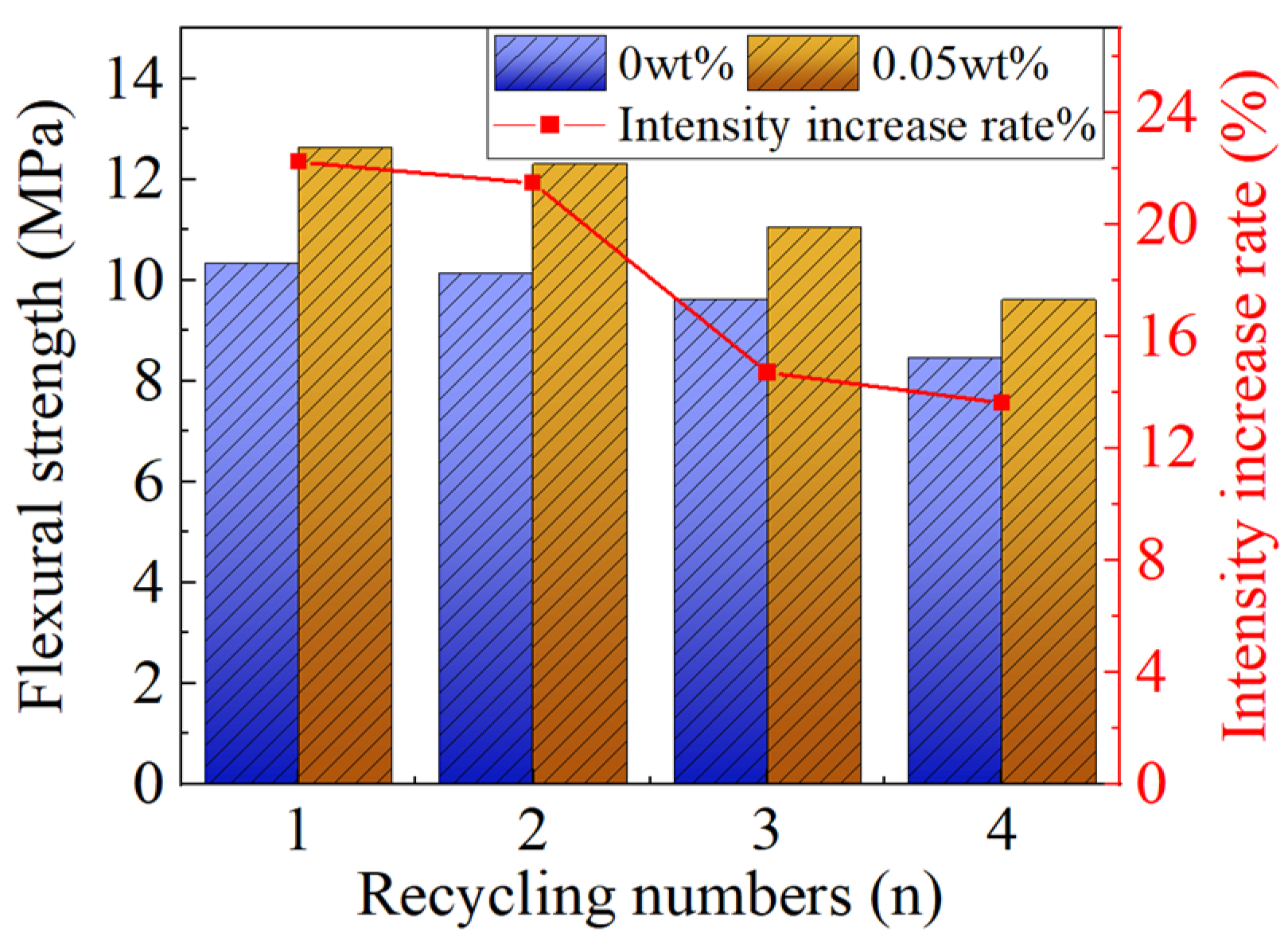

3.2.3. Flexural Strength

3.2.4. Flexure–Compression Ratio

4. Discussion

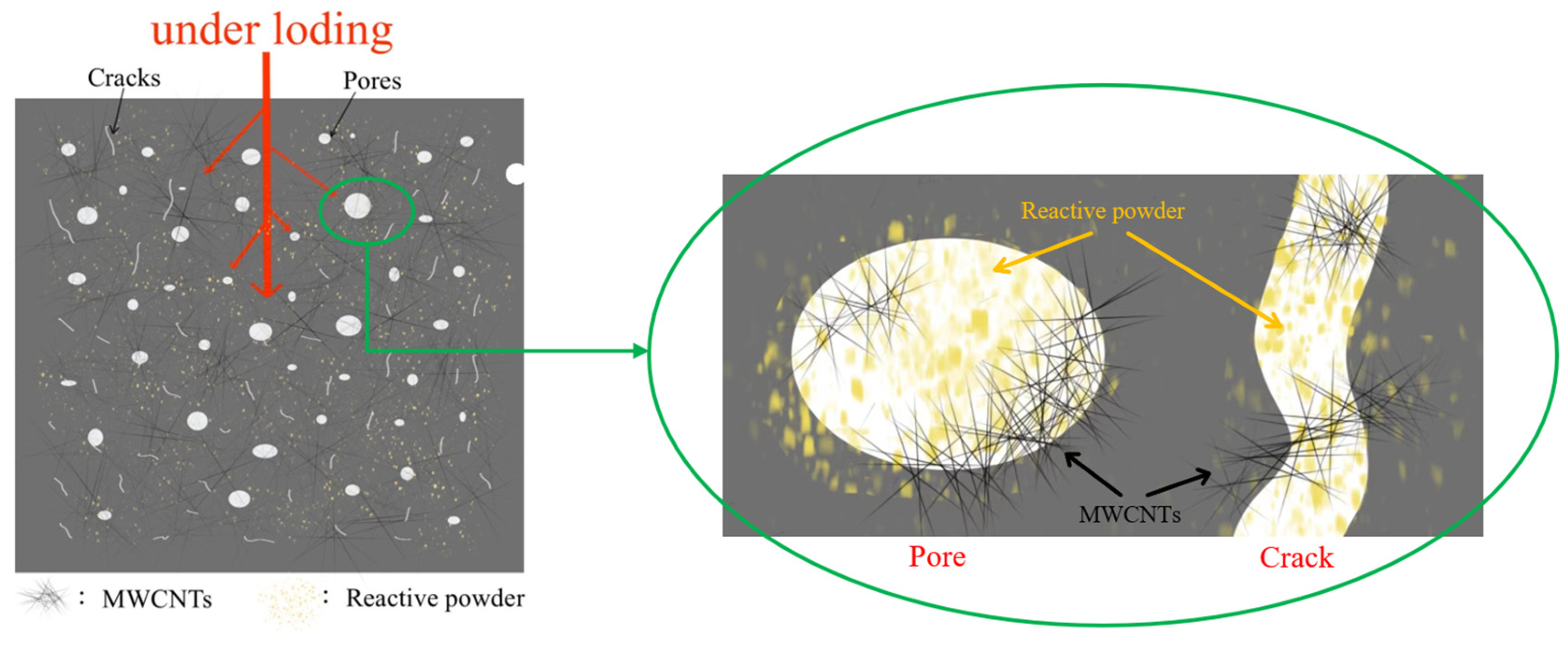

4.1. MWCNTs and Reactive Powder Mechanism Analysis

4.2. Microscopic Mechanism Analysis

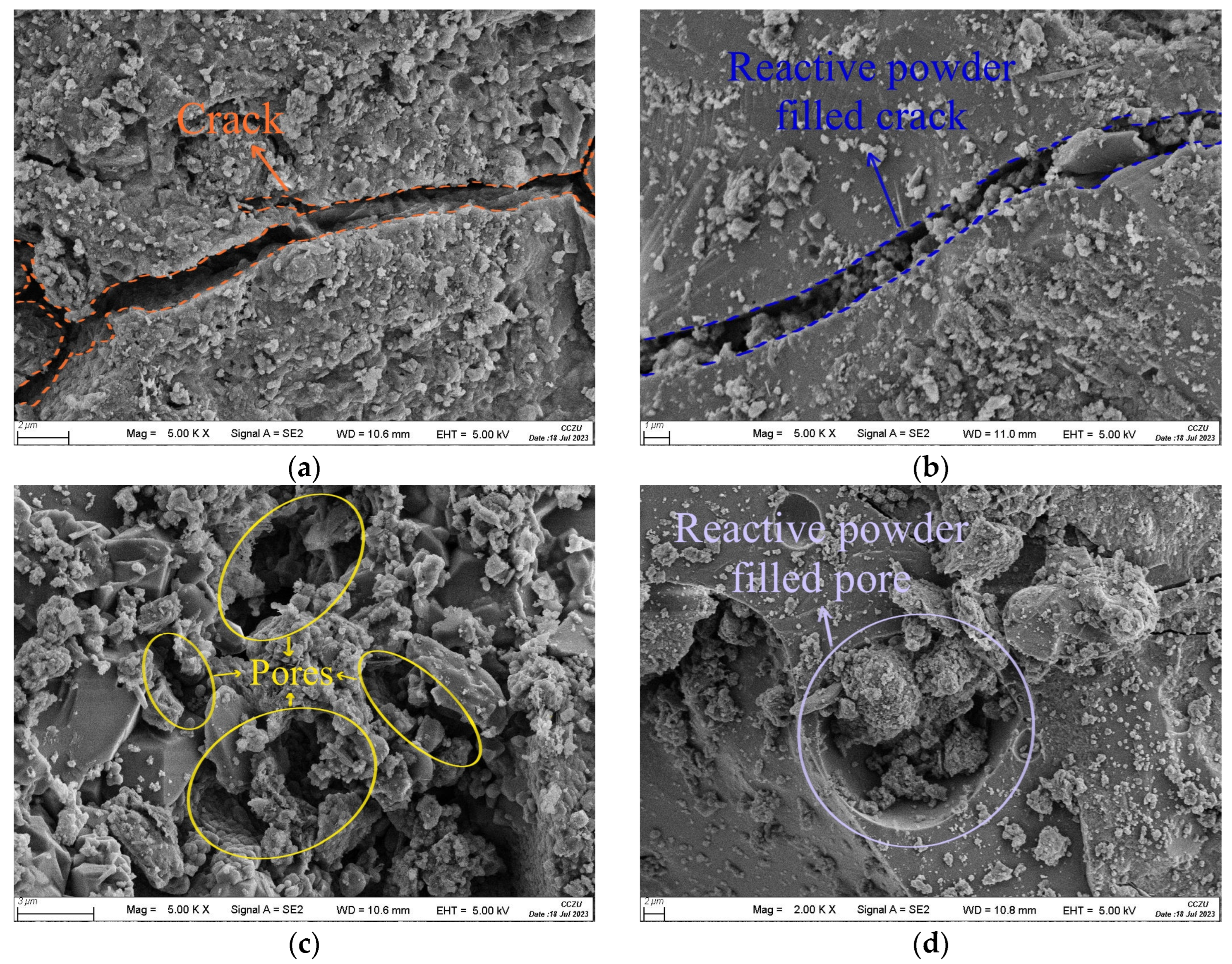

- (1)

- As can be noticed from Figure 10a, for the concrete without MWCNTs and the reactive powder, the RPC1 has apparent cracks. Moreover, in Figure 10b, the newly added reactive powder particles can fill in the cracks in RPC2, effectively reinforce the feeble parts of RPC, and reduce the generation and development of microcracks.

- (2)

- Figure 10c shows the pore morphology of concrete with only reactive powder. With the addition of reactive powder, some original pores in RFA1 are gradually covered by the reactive powder. Figure 10d shows that the pores in RFA2 are significantly reduced compared to RFA1. It indicates that the reactive powder can reduce the content of harmful macropores in the concrete, improve the microscopic pore structure of the concrete, and enhance the compactness of the matrix. This is consistent with the phenomenon of Wu, J.-D. et al. [45] in their study that slag powder and silica fume have a synergistic effect to repair the initial damage of RPC.

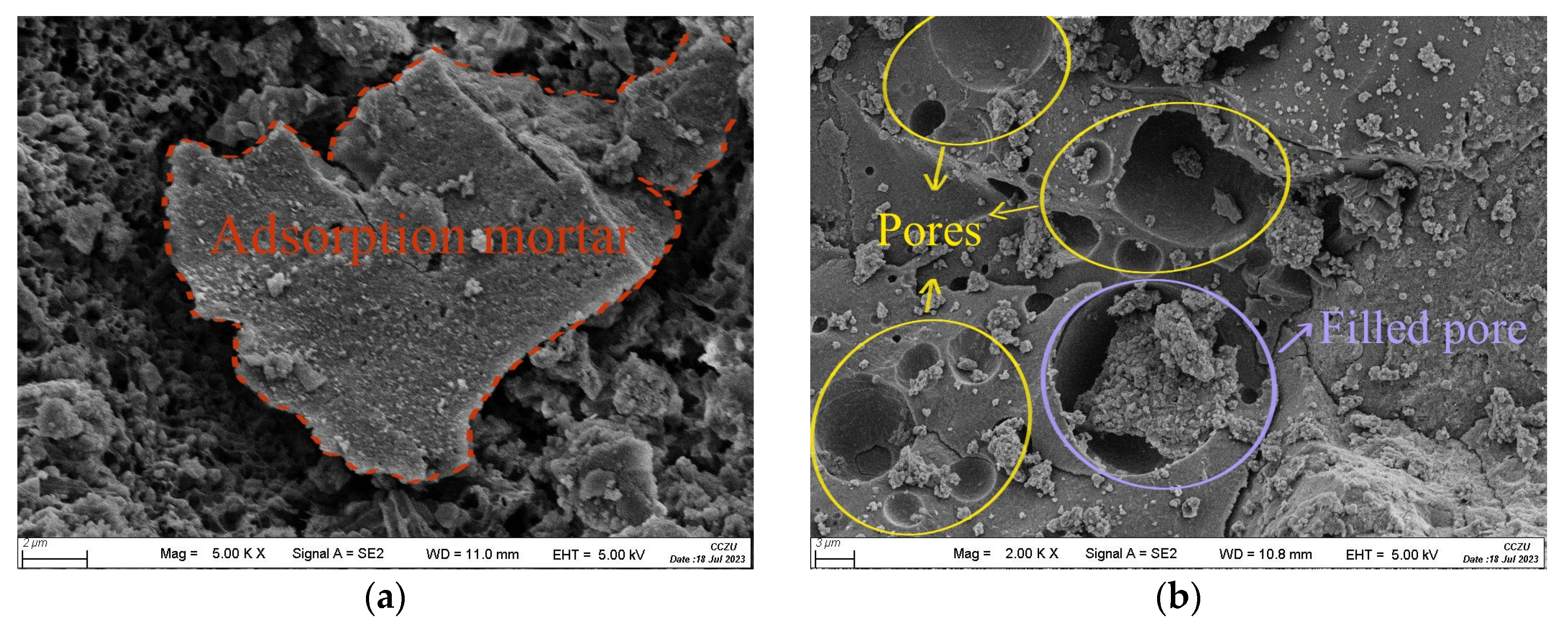

- (3)

- After four cycles, as the adsorbed mortar content increases, as can be noticed from Figure 11a,b, the cracks around the adsorption mortar and the internal primary pores increase, resulting in the gradual weakening or even loss of the gain effect of the reactive powder on the structural integrity of the concrete, and the overall strength of the concrete begins to decrease.

- (4)

- After blending MWCNTs, it can be seen from Figure 11c that MWCNTs can fill in the micropores, microcracks, and other defects inside the concrete to make up for the original defects of the recycled aggregates. Also, the disordered and densely packed MWCNTs can form a fiber mesh structure system, strengthen the connection between the concrete and the components of the reactive powder, improve the structure of the cement matrix, and slow down the tip stress concentration effect at the internal cracks of the concrete, thereby effectively enhancing its mechanical properties. This is similar to the conclusion reached by Hong, S.-H. et al. [46] that MWCNTs are able to bridge microcracks and retard damage progression. Moreover, there are polarization and adsorption effects between MWCNTs and cement particles. Therefore, MWCNTs attract cement particles and make them become attached. It means that MWCNTs provide more nucleation sites for cement hydration, increase the hydration rate, and strengthen the integrality of the hydration products of the cement, so they have a pronounced enhancement impact on the development of the strength properties of concrete. Zhang, Y. et al. [47] also found that MWCNTs were able to enhance the interfacial properties of reactive powders, such as fly ash, in concrete, thereby improving the hydration properties of reactive powders.

- (5)

- As shown in Figure 11d, there is still a tiny amount of MWCNTs with good compatibility between the interface of the MWCNTs and the matrix after four cycles, slowing down the magnitude of the concrete strength decline and giving full play to the reinforcing influence of the MWCNTs on the regenerated concrete with multi-generational recycling.

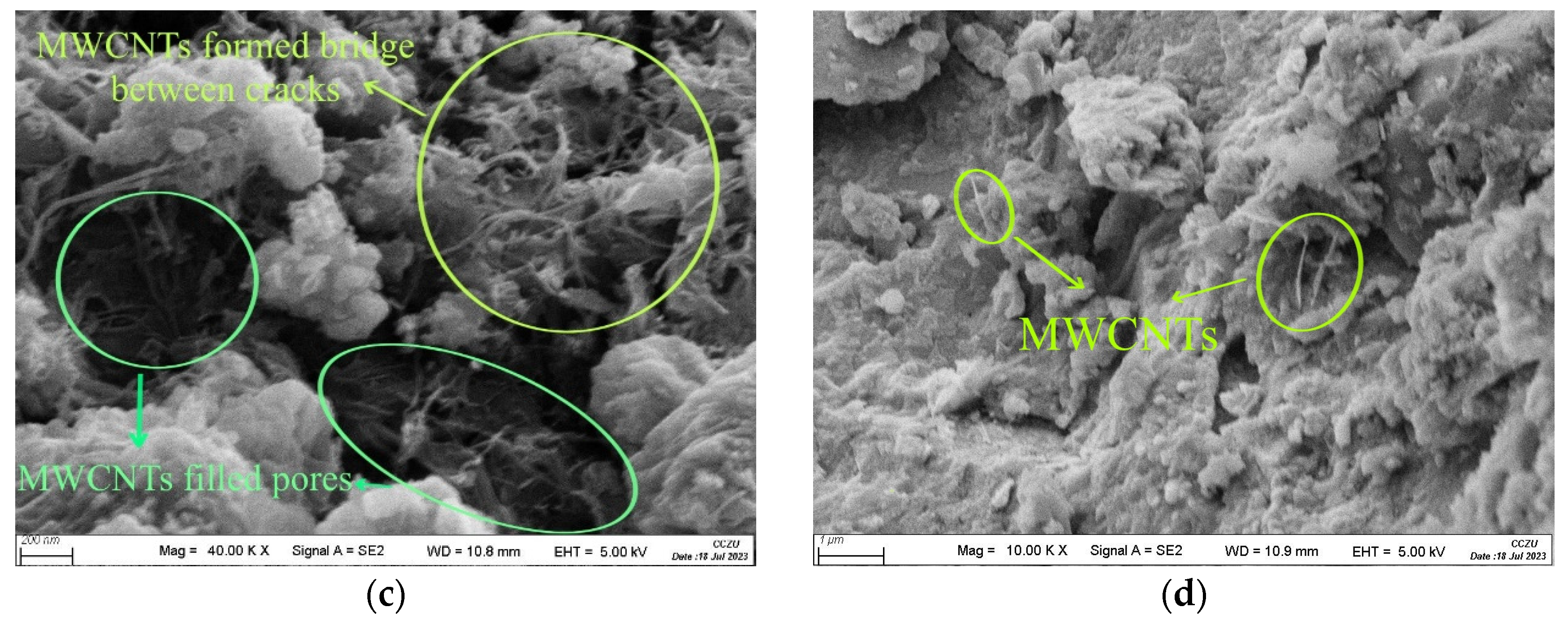

- (6)

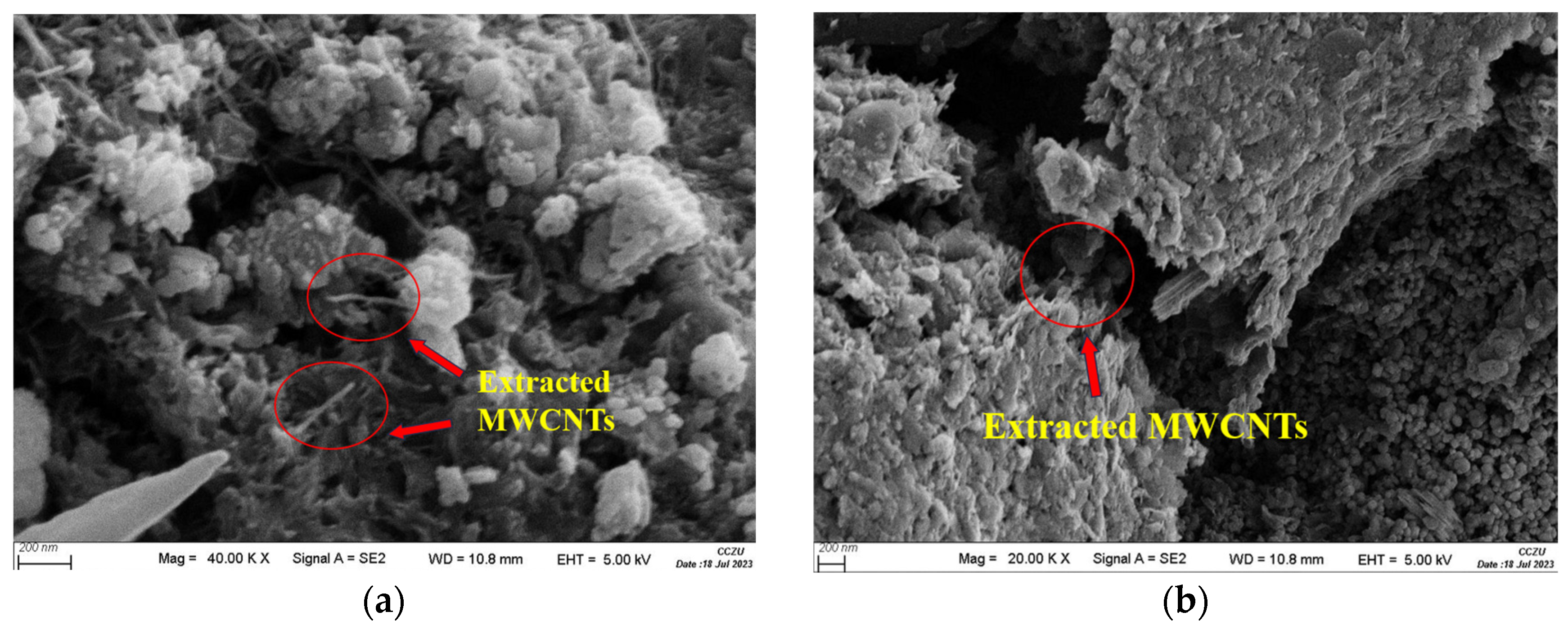

- In Figure 12a, MWCNTs being pulled out of the MWRFA can be seen. When MWCNTs are evenly dispersed and effectively bonded with the matrix, they can take part of the load and reduce the stress concentration of the matrix, resulting in the weakening of the energy stored as cracks in the MWRFA, thus preventing the further expansion of those cracks. Figure 12b shows MWCNTs being pulled out at the cracks of the MWRPC. It is probable that, as MWCNTs lap the pores and cracks of the cementitious materials, they strengthen the weak parts of the MWRPC and reduce the generation and extension of microcracks, thereby reducing the degradation performance.

5. Conclusions

- (1)

- The addition of reactive powder reduced the water absorption of the RFA, increased the apparent density of the RFA, and optimized the load resistance of the RFA compared to fine aggregate recycled from construction waste. Adding MWCNTs further enhanced the physical properties of reactive powder RFA, with the best results in the second generation, when the water absorption and crushing values were reduced by 32% and 73%, respectively, and the apparent density increased by 5.7%. Multiple cycles weakened the enhancement effect, and MWCNTs slowed down the decrease.

- (2)

- The quality of the RFA directly determines the recyclability of concrete, and the use of MWRFA containing MWCNTs shows superior mechanical properties. MWCNTs can improve the microstructural morphology, such as microcracks and micropores inside the concrete, which is favorable to the practical synergistic bearing of reactive powder and MWCNTs so that the MWCNTs can increase the compressive strength by 11.1–19.0%, the splitting tensile strength by 10–43.9%, the flexural strength by 9.6–22.2%, and the fold-to-compression ratio by 5.2–9.4%.

- (3)

- When the number of cycles was exceeded twice, the compressive strength, split tensile strength, and flexural strength decreased. The effect of the reactive powder gain weakened, but the mechanical properties of the MWRPC containing MWCNTs were still higher than those of its control group. The residual MWCNTs inhibited the development of defects, and the mutual solid bond with the matrix made the concrete maintain good mechanical properties.

- (4)

- SEM images further demonstrated that the reactive powder could cover some original defects in the RFA. However, the increase of additional mortar would weaken the effect of reactive powder on the concrete gain. In the precycling stage, MWCNTs can form a fiber mesh structure system, which synergizes with the active powder to enhance the mechanical properties of concrete. In the late stage of cycling, the MWCNTs are dispersed in the cementitious matrix to form bridges in the matrix and enhance the recyclability of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- da Rocha, C.G.; Sattler, M.A. A discussion on the reuse of building components in Brazil: An analysis of major social, economical and legal factors. Resour. Conserv. Recycl. 2009, 54, 104–112. [Google Scholar] [CrossRef]

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Yuan, H.; Shen, L. Trend of the research on construction and demolition waste management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef] [PubMed]

- Nalon, G.H.; Santos, R.F.; de Lima, G.E.S.; Andrade, I.K.R.; Pedroti, L.G.; Ribeiro, J.C.L.; Franco de Carvalho, J.M. Recycling waste materials to produce self-sensing concretes for smart and sustainable structures: A review. Constr. Build. Mater. 2022, 325, 126658. [Google Scholar] [CrossRef]

- Di Maria, A.; Eyckmans, J.; Van Acker, K. Downcycling versus recycling of construction and demolition waste: Combining LCA and LCC to support sustainable policy making. Waste Manag. 2018, 75, 3–21. [Google Scholar] [CrossRef]

- Tan, R.; Wu, Y.; Su, P.; Liao, R.; Zhang, J. Optimal dynamic incentive mechanism design for construction and demolition waste recycling with Bayesian learning. J. Clean. Prod. 2023, 412, 137371. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, X.; Liu, Q.; Zhang, H.; Duan, Z. Evolvement and research progress of concept for fully recycled concrete. J. Archit. Civ. Eng. 2021, 38, 1–15. [Google Scholar]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Ma, Z.; Shen, J.; Wang, C.; Wu, H. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 104629. [Google Scholar] [CrossRef]

- Yu, Y.; Lin, L. Modeling and predicting chloride diffusion in recycled aggregate concrete. Constr. Build. Mater. 2020, 264, 120620. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Xu, Z.; Long, H.; Liu, Q.; Yu, H.; Zhang, X.; Hui, D. Mechanical properties and durability of geopolymer concrete based on fly ash and coal gangue under different dosage and particle size of nano silica. Constr. Build. Mater. 2023, 387, 131622. [Google Scholar] [CrossRef]

- Moein, M.M.; Saradar, A.; Rahmati, K.; Rezakhani, Y.; Ashkan, S.A.; Karakouzian, M. Reliability analysis and experimental investigation of impact resistance of concrete reinforced with polyolefin fiber in different shapes, lengths, and doses. J. Build. Eng. 2023, 69, 106262. [Google Scholar] [CrossRef]

- Hansen, T.C.; Narud, H. Strength of recycled concrete made from crushed concrete coarse aggregate. Concr. Int. 1983, 5, 79–83. [Google Scholar]

- Lu, Z.; Lu, J.; Liu, Z.; Sun, Z.; Stephan, D. Influence of water to cement ratio on the compatibility of polycarboxylate superplasticizer with Portland cement. Constr. Build. Mater. 2022, 341, 127846. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Salahuddin, H.; Qureshi, L.A.; Nawaz, A.; Raza, S.S. Effect of recycled fine aggregates on performance of Reactive Powder Concrete. Constr. Build. Mater. 2020, 243, 118223. [Google Scholar] [CrossRef]

- Ghosal, M.; Chakraborty, A.K. Engineering the properties of nanomaterials for its use in cement concrete. Mater. Today Proc. 2021, 46, 7502–7506. [Google Scholar] [CrossRef]

- Luo, Z.; Zhi, T.; Liu, X.; Yin, K.; Pan, H.; Feng, H.; Song, Y.; Su, Y. Effects of different nanomaterials on the early performance of ultra-high performance concrete (UHPC): C–S–H seeds and nano-silica. Cem. Concr. Compos. 2023, 142, 105211. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jittin, V.; Syed Ahmed Kabeer, K.I.; Thomas, B.S. Influence of synthesized nanomaterials in the strength and durability of cementitious composites. Case Stud. Constr. Mater. 2023, 18, e02197. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N.C. Comparative effects of pristine and ball-milled graphene oxide on physico-chemical characteristics of cement mortar nanocomposites. Constr. Build. Mater. 2016, 115, 256–268. [Google Scholar] [CrossRef]

- Salvetat, J.-P.; Bonard, J.-M.; Thomson, N.; Kulik, A.; Forro, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Treacy, M.J.; Ebbesen, T.W.; Gibson, J.M. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 1996, 381, 678–680. [Google Scholar] [CrossRef]

- Dresselhaus, M.; Dresselhaus, G.; Charlier, J.-C.; Hernandez, E. Electronic, thermal and mechanical properties of carbon nanotubes. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2004, 362, 2065–2098. [Google Scholar] [CrossRef] [PubMed]

- Chia, L.; Huang, Y.; Xia, W.; Lu, P.; Zhang, D. Carbon nanotube (CNT) reinforced cementitious composites using carboxymethyl cellulose (CMC) treatment for enhanced dispersion, mechanical, and piezoresistive properties. Constr. Build. Mater. 2023, 377, 131104. [Google Scholar] [CrossRef]

- Gao, Y.; Jing, H.; Zhou, Z.; Shi, X.; Li, L.; Fu, G. Roles of carbon nanotubes in reinforcing the interfacial transition zone and impermeability of concrete under different water-to-cement ratios. Constr. Build. Mater. 2021, 272, 121664. [Google Scholar] [CrossRef]

- Safari Tarbozagh, A.; Rezaifar, O.; Gholhaki, M.; Abavisani, I. Magnetic enhancement of carbon nanotube concrete compressive behavior. Constr. Build. Mater. 2020, 262, 120772. [Google Scholar] [CrossRef]

- Tošić, N.; Peralta Martínez, D.; Hafez, H.; Reynvart, I.; Ahmad, M.; Liu, G.; de la Fuente, A. Multi-recycling of polypropylene fibre reinforced concrete: Influence of recycled aggregate properties on new concrete. Constr. Build. Mater. 2022, 346, 128458. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, H.; Liu, J.; Xu, S.; Chen, Z. Experimental Study on the Salt Freezing Durability of Multi-Walled Carbon Nanotube Ultra-High-Performance Concrete. Materials 2022, 15, 3188. [Google Scholar] [CrossRef] [PubMed]

- Yaprak, H.; Aruntaş, H.; Demir, I.; Şimşek, O.; Durmuş, G. Effects of the fine recycled concrete aggregates on the concrete properties. Int. J. Phys. Sci. 2011, 6, 2455–2461. [Google Scholar]

- Cartuxo, F.; de Brito, J.; Evangelista, L.; Jiménez, J.R.; Ledesma, E.F. Rheological behaviour of concrete made with fine recycled concrete aggregates—Influence of the superplasticizer. Constr. Build. Mater. 2015, 89, 36–47. [Google Scholar] [CrossRef]

- Leite, M.B.; Figueire do Filho, J.G.L.; Lima, P.R. Workability study of concretes made with recycled mortar aggregate. Mater. Struct. 2013, 46, 1765–1778. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Li, B.; Chen, P.; Yin, S.; Yi, H. The effect of additional water amount on the workability and mechanical properties of concrete with recycled fine aggregates. Mater. Rep. 2024, 38, 22070217. Available online: https://kns.cnki.net/kcms/detail/50.1078.TB.20230322.1345.008.html (accessed on 25 January 2024).

- Vesmawala, G.R.; Vaghela, A.R.; Yadav, K.D.; Patil, Y. Effectiveness of polycarboxylate as a dispersant of carbon nanotubes in concrete. Mater. Today Proc. 2020, 28, 1170–1174. [Google Scholar] [CrossRef]

- JGJ/T 70-2009; Standard for Test Method of Performance on Building Mortar. Standards Press of China: Beijing, China, 2009. Available online: https://www.doc88.com/p-1921921443853.html (accessed on 1 June 2009).

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Standards Press of China: Beijing, China, 2020. Available online: https://www.doc88.com/p-99359464764071.html (accessed on 13 November 2020).

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standards Press of China: Beijing, China, 2021. Available online: https://www.doc88.com/p-08773985826297.html (accessed on 31 December 2021).

- Zhang, H.; Cao, S.; Yilmaz, E. Carbon nanotube reinforced cementitious tailings composites: Links to mechanical and microstructural characteristics. Constr. Build. Mater. 2023, 365, 130123. [Google Scholar] [CrossRef]

- Wu, J.-D.; Guo, L.-P.; Fei, X.-P.; Lyu, B.-C.; Chen, B. Synergistic effects of silica fume and slag on the microstructure and mechanical behaviors of ultra-high-strength and high-ductility cementitious composites. Constr. Build. Mater. 2023, 367, 130169. [Google Scholar] [CrossRef]

- Hong, S.-H.; Choi, J.-S.; Yoo, S.-J.; Yoon, Y.-S. Structural benefits of using carbon nanotube reinforced high-strength lightweight concrete beams. Dev. Built Environ. 2023, 16, 100234. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, W. Enhancing effect of carbon nanotubes on the performance of concrete containing surface-treated fly ash cenosphere. Constr. Build. Mater. 2023, 406, 133322. [Google Scholar] [CrossRef]

| Fine Aggregate | Fineness Modulus | Moisture Content/% | Water Absorption/% |

|---|---|---|---|

| RFA1 | 2.5 | 2.8 | 7.9 |

| RFA2 | 2.6 | 3.1 | 5.7 |

| RFA3 | 2.8 | 2.9 | 6.2 |

| RFA4 | 2.8 | 2.7 | 7.1 |

| MWRFA2 | 2.9 | 2.8 | 5.4 |

| MWRFA3 | 2.7 | 2.9 | 5.5 |

| MWRFA4 | 2.9 | 2.7 | 6.1 |

| Diameter/nm | Length/μm | Purity/% | Ash Content/% | Effective Density/(g/cm3) | Specific Surface Area/(g/cm2) | Young’s Modulus/(TPa) | Bending Strength/(GPa) |

|---|---|---|---|---|---|---|---|

| 10–20 | 5–50 | >85 | <2 | 0.06–0.1 | 160–210 | 1.8 | 14.2 ± 10.8 |

| Concrete | Material/(kg·m−3) | Polycarbonate Super-Plasticizer/wt% | Total Water–Cement Ratio | MWCNTs/wt% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | RFA | Fly Ash | Silica Fume | Slag Powder | Water | Additional Water | ||||

| RPC1 | 630 | 1050 | 210 | 105 | 105 | 210 | 29 | 2.3 | 0.23 | 0 |

| RPC2 | 630 | 1050 | 210 | 105 | 105 | 210 | 10 | 2.3 | 0.21 | 0 |

| RPC3 | 630 | 1050 | 210 | 105 | 105 | 210 | 15 | 2.3 | 0.21 | 0 |

| RPC4 | 630 | 1050 | 210 | 105 | 105 | 210 | 24 | 2.3 | 0.22 | 0 |

| MWRPC1 | 630 | 1050 | 210 | 105 | 105 | 210 | 29 | 2.3 | 0.23 | 0.05 |

| MWRPC2 | 630 | 1050 | 210 | 105 | 105 | 210 | 10 | 2.3 | 0.21 | 0 |

| MWRPC3 | 630 | 1050 | 210 | 105 | 105 | 210 | 10 | 2.3 | 0.21 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Liu, X.; Ma, X.; Liu, G. Effects of Multi-Walled Carbon Nanotubes and Recycled Fine Aggregates on the Multi-Generational Cycle Properties of Reactive Powder Concrete. Sustainability 2024, 16, 2084. https://doi.org/10.3390/su16052084

Wu H, Liu X, Ma X, Liu G. Effects of Multi-Walled Carbon Nanotubes and Recycled Fine Aggregates on the Multi-Generational Cycle Properties of Reactive Powder Concrete. Sustainability. 2024; 16(5):2084. https://doi.org/10.3390/su16052084

Chicago/Turabian StyleWu, Heng, Xibin Liu, Xirui Ma, and Guifeng Liu. 2024. "Effects of Multi-Walled Carbon Nanotubes and Recycled Fine Aggregates on the Multi-Generational Cycle Properties of Reactive Powder Concrete" Sustainability 16, no. 5: 2084. https://doi.org/10.3390/su16052084

APA StyleWu, H., Liu, X., Ma, X., & Liu, G. (2024). Effects of Multi-Walled Carbon Nanotubes and Recycled Fine Aggregates on the Multi-Generational Cycle Properties of Reactive Powder Concrete. Sustainability, 16(5), 2084. https://doi.org/10.3390/su16052084