Waste Tyre Textile Fibre Composite Material: Acoustic Performance and Life Cycle Assessment

Abstract

1. Introduction

2. Materials and Methods

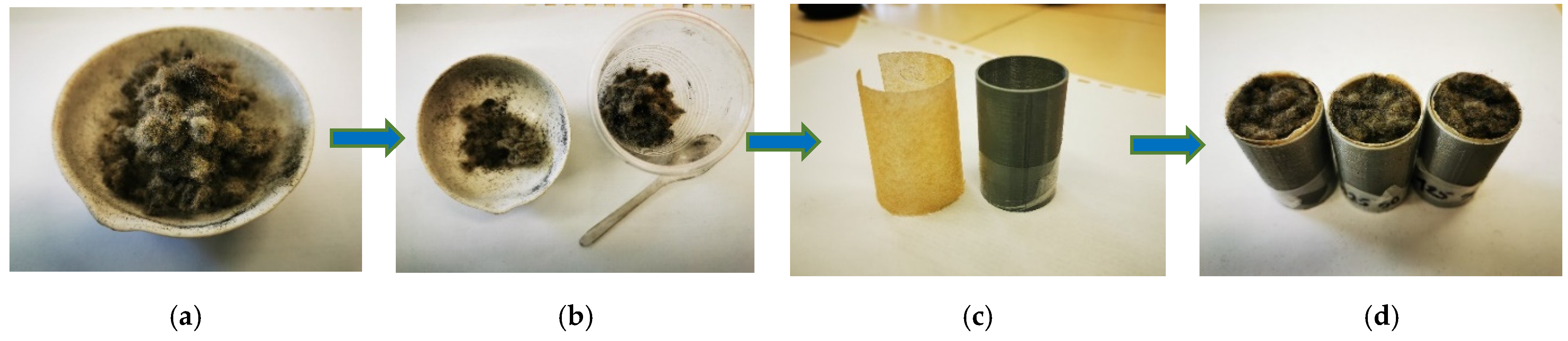

2.1. Method of Sample Preparation

2.2. Method of the Determination of Normal Incidence Sound Absorption Coefficient

2.3. Method of Determination of Airflow Resistivity

2.4. Life Cycle Assessment Methodology

- Goal and Scope

- Functional Unit

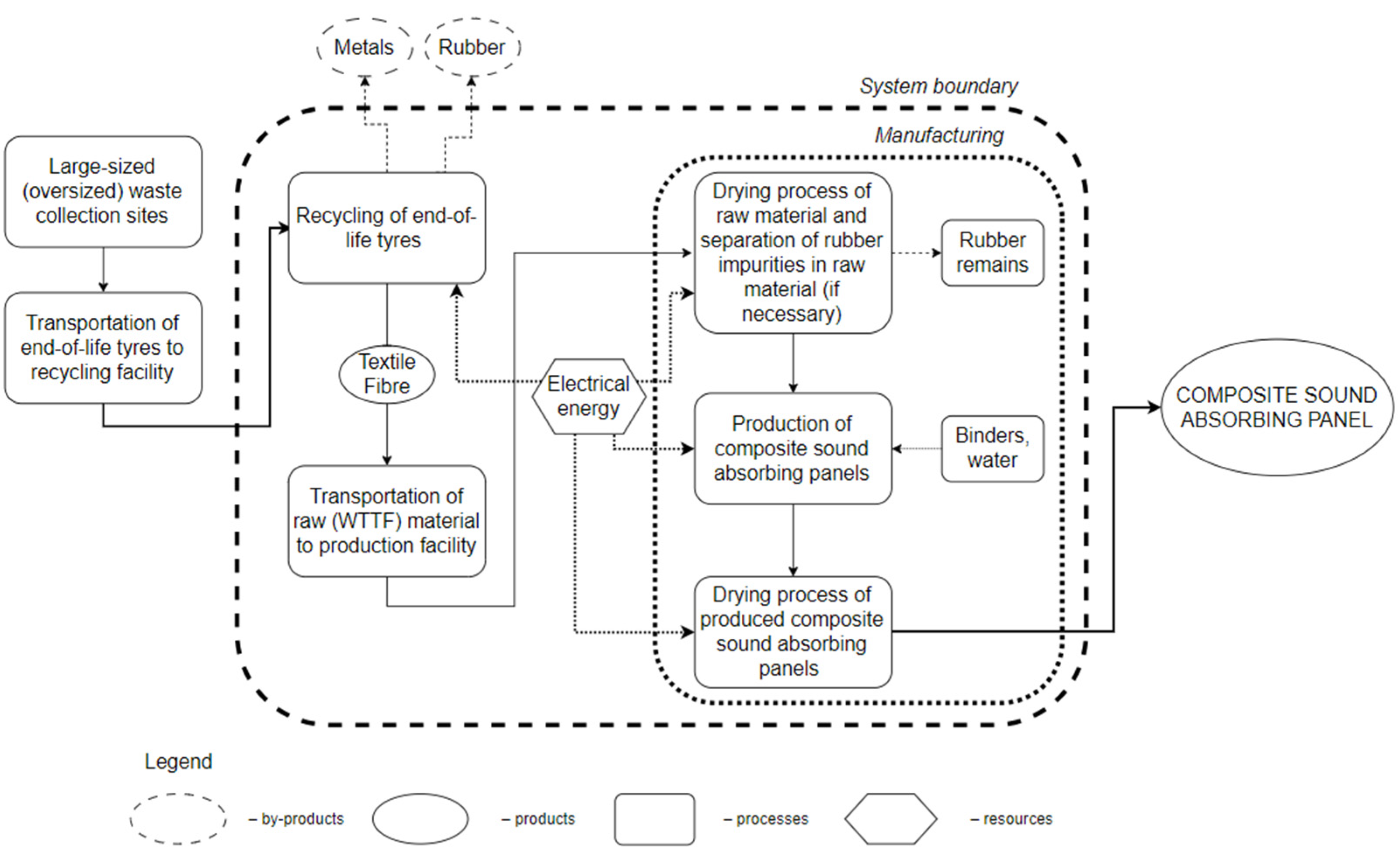

- System Boundaries and Life Cycle Inventory

- Selected Impact Assessment Method

- Damage to human health, expressed as the number of years of life lost and years of life with disability. These values are combined as Disability-Adjusted Life Years (DALYs), an index used by the World Bank and the World Health Organisation. The unit of measurement is years.

- Damage to ecosystems, expressed as the loss of species in a certain area over a certain period of time. The unit of measurement is years.

- Resource damage, expressed as excess future resource production costs over an indefinite period, subject to a 3% discount rate. The unit of measurement is 2013 USD. It should be kept in mind that the lack of fossil resources does not have constant mid-to-endpoint indicators, but factors that are individual for each material.

3. Results and Discussion

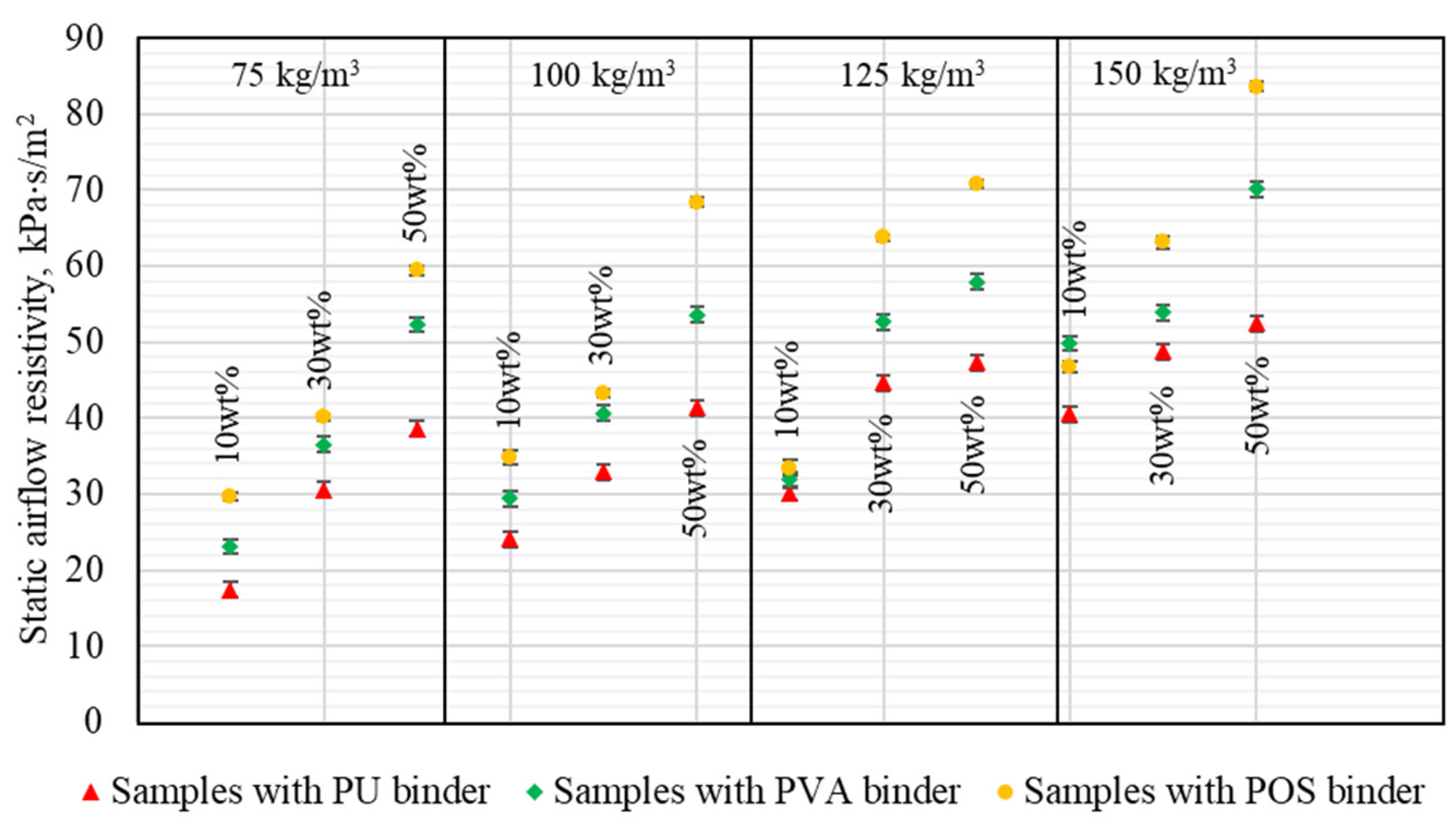

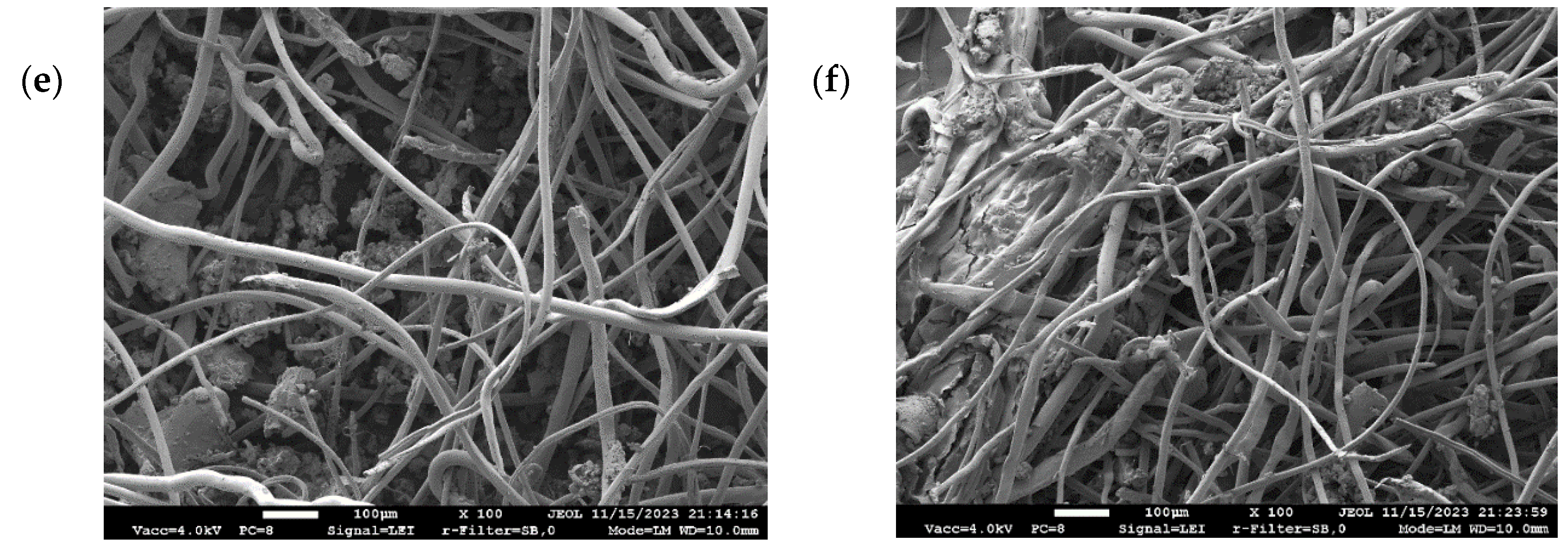

3.1. Airflow Resistivity and SEM Results of Composite Sound Absorbing Panels

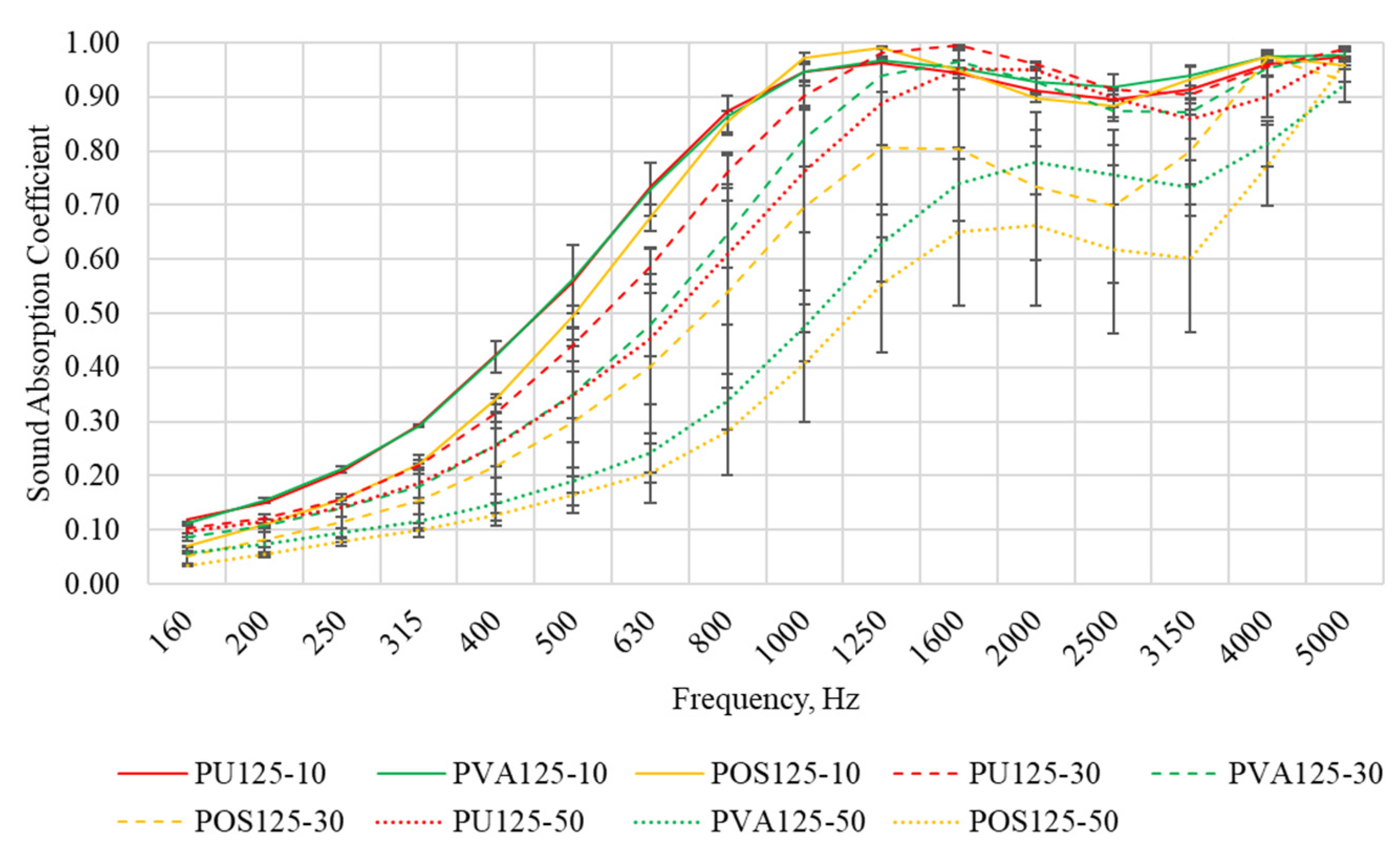

3.2. Characterisation of Acoustic Parameters of Composite Sound Absorbing Panels

3.3. Interpretation of the Results of the Life Cycle Assessment

- Determination of the Functional Unit

- Results of the Life Cycle Inventory

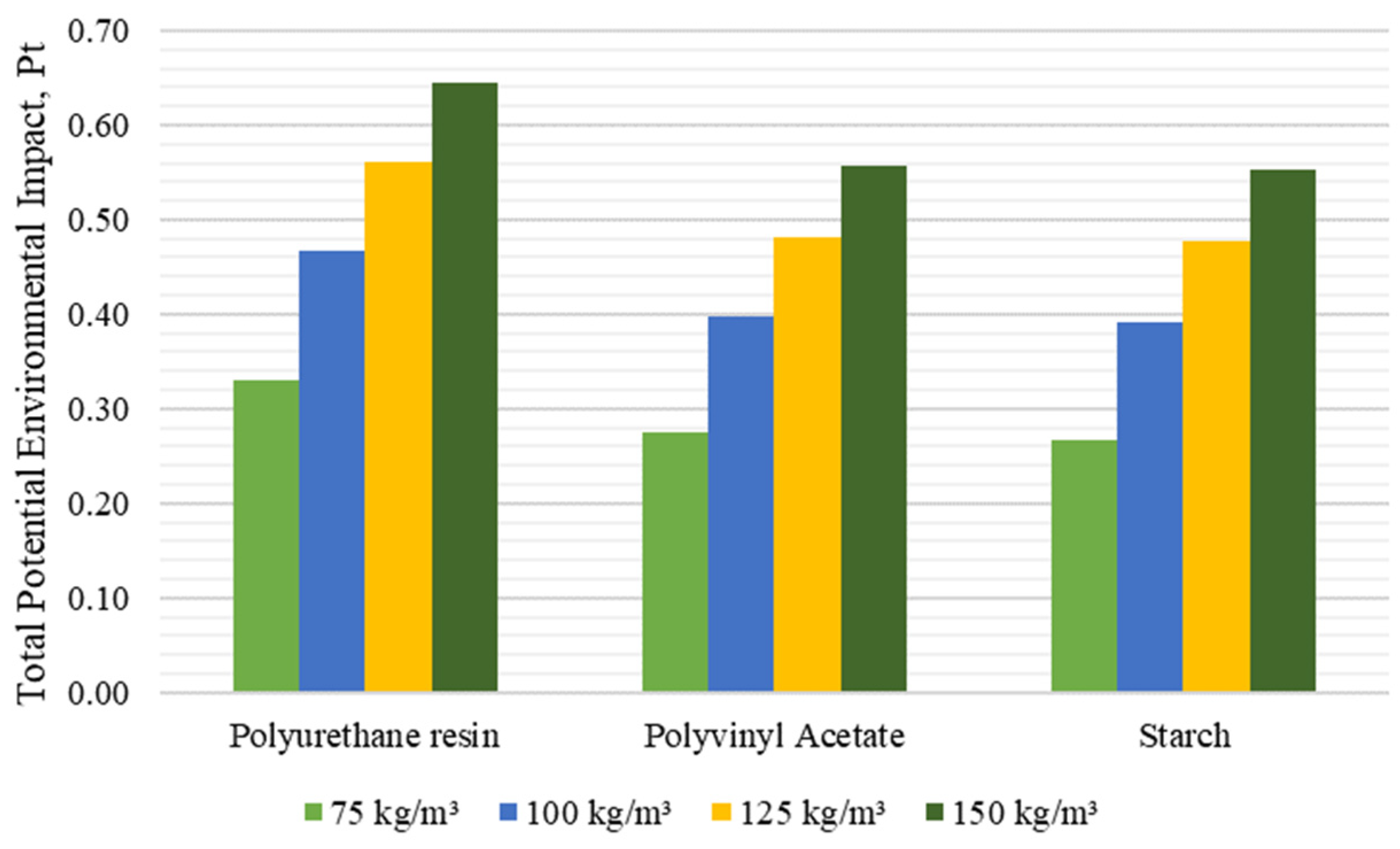

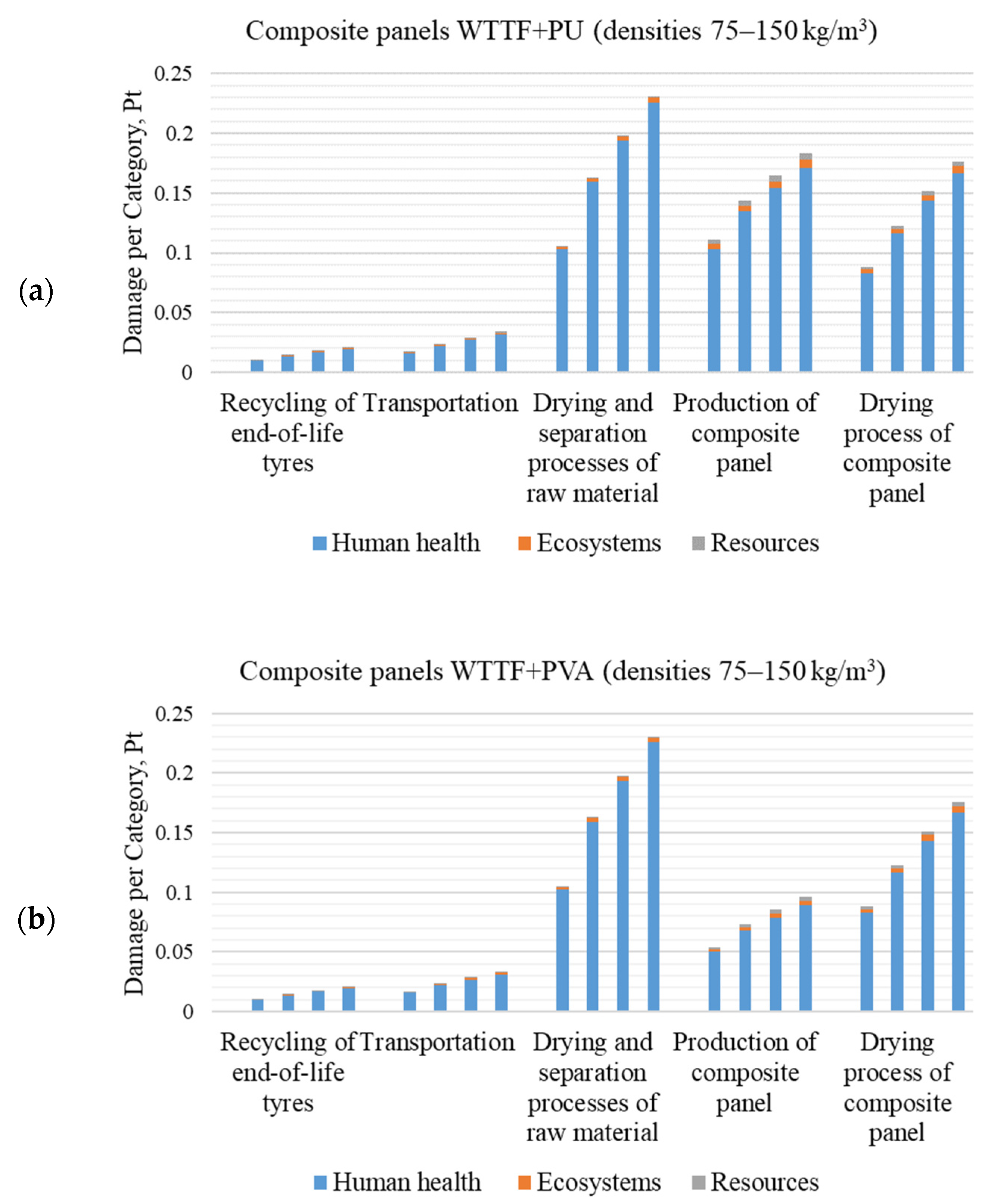

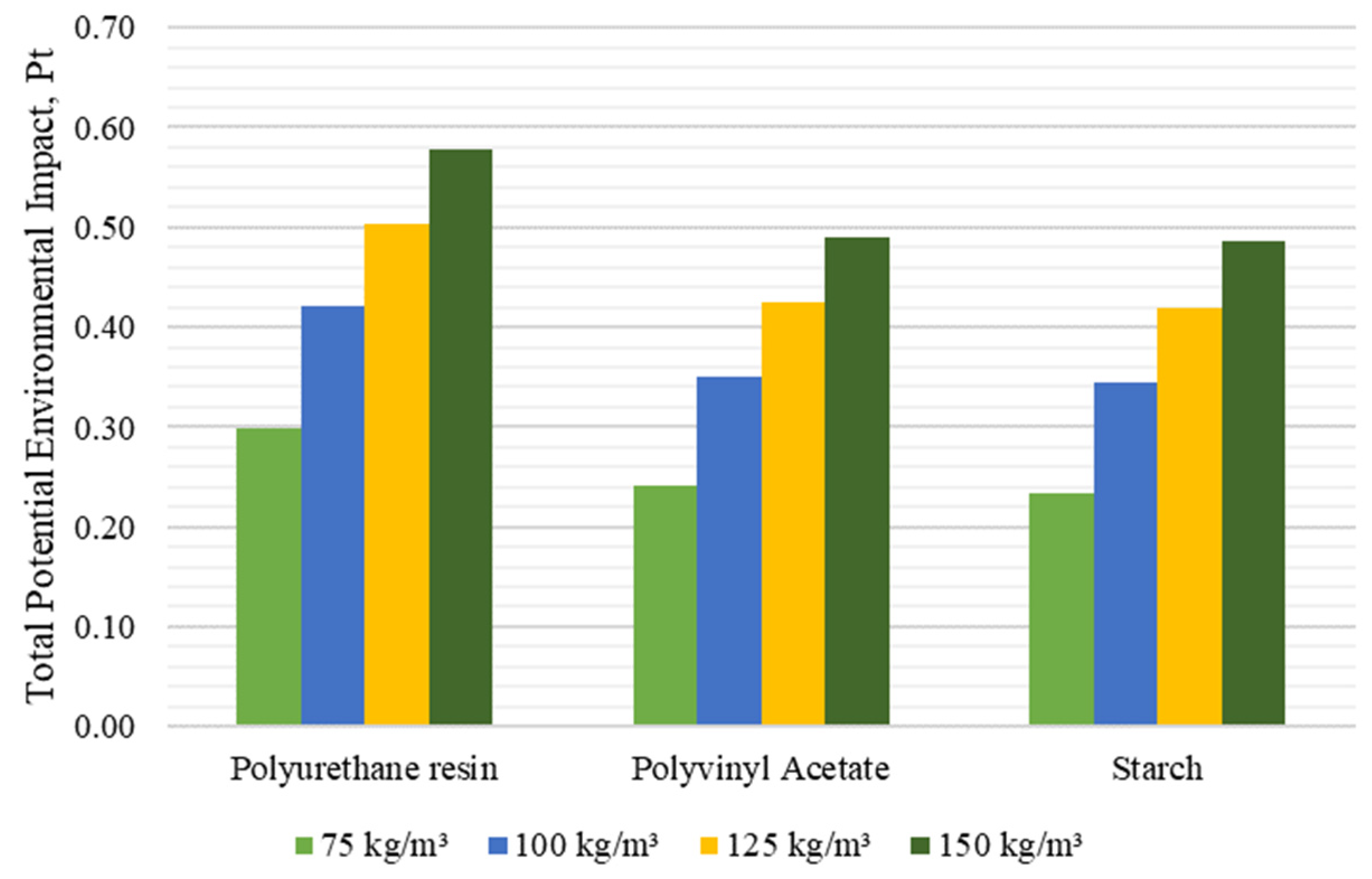

- Life Cycle Impact Assessment and Results Interpretation

- Scenario of Use of Renewable Energy Sources

- Modelling of Global Warming Potential

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tong, H.; Kang, J. Relationship between Urban Development Patterns and Noise Complaints in England. Environ. Plan. B Urban. Anal. City Sci. 2020, 48, 1632–1649. [Google Scholar] [CrossRef]

- Şentop Dümen, A.; Tamer Bayazıt, N. Enforcement of Acoustic Performance Assessment in Residential Buildings and Occupant Satisfaction. Build. Res. Inf. 2020, 48, 866–885. [Google Scholar] [CrossRef]

- Valentina, L.L.; Arifianto, D.; Azmi, F.U.; Fajar, B.; Nadiroh, A. The Effect of Reverberation Time on Sound Masking Method to Improve Speech Privacy in Open-Plan Offices. J. Phys. Conf. Ser. 2021, 1896, 012005. [Google Scholar] [CrossRef]

- Ulrich, T.; Arenas, J.P. Sound Absorption of Sustainable Polymer Nanofibrous Thin Membranes Bonded to a Bulk Porous Material. Sustainability 2020, 12, 2361. [Google Scholar] [CrossRef]

- Jesic, J.; Okanovic, A.; Panic, A.A. Net Zero 2050 as an EU Priroty: Modeling a System for Efficient Investments in Eco Innovation for Climate Change Mitigation. Energy Sustain. Soc. 2021, 11, 50. [Google Scholar] [CrossRef]

- Sakthivel, S.; Senthil Kumar, S.; Melese, B.; Mekonnen, S.; Solomon, E.; Edae, A.; Abedom, F.; Gedilu, M. Development of Nonwoven Composites from Recycled Cotton/Polyester Apparel Waste Materials for Sound Absorbing and Insulating Properties. Appl. Acoust. 2021, 180, 108126. [Google Scholar] [CrossRef]

- Svoboda, J.; Dvorský, T.; Václavík, V.; Charvát, J.; Máčalová, K.; Heviánková, S.; Janurová, E. Sound-Absorbing and Thermal-Insulating Properties of Cement Composite Based on Recycled Rubber from Waste Tires. Appl. Sci. 2021, 11, 2725. [Google Scholar] [CrossRef]

- Atiénzar-Navarro, R.; del Rey, R.; Alba, J.; Sánchez-Morcillo, V.J.; Picó, R. Sound Absorption Properties of Perforated Recycled Polyurethane Foams Reinforced with Woven Fabric. Polymers 2020, 12, 401. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Acedo-Fuentes, P.; García-Cobos, F.J.; Sánchez-Delgado, F.J.; Mota-López, M.I.; Meneses-Rodríguez, J.M. The Recycling of Surgical Face Masks as Sound Porous Absorbers: Preliminary Evaluation. Sci. Total Environ. 2021, 786, 147461. [Google Scholar] [CrossRef]

- Hassani, P.; Soltani, P.; Ghane, M.; Zarrebini, M. Porous Resin-Bonded Recycled Denim Composite as an Efficient Sound-Absorbing Material. Appl. Acoust. 2021, 173, 107710. [Google Scholar] [CrossRef]

- Lyu, L.; Zhang, D.; Tian, Y.; Zhou, X. Sound-Absorption Performance and Fractal Dimension Feature of Kapok Fibre/Polycaprolactone Composites. Coatings 2021, 11, 1000. [Google Scholar] [CrossRef]

- Shanmugam, V.; Das, O.; Neisiany, R.E.; Babu, K.; Singh, S.; Hedenqvist, M.S.; Berto, F.; Ramakrishna, S. Polymer Recycling in Additive Manufacturing: An Opportunity for the Circular Economy. Mater. Circ. Econ. 2020, 2, 11. [Google Scholar] [CrossRef]

- Lederer, J.; Gassner, A.; Kleemann, F.; Fellner, J. Potentials for a Circular Economy of Mineral Construction Materials and Demolition Waste in Urban Areas: A Case Study from Vienna. Resour. Conserv. Recycl. 2020, 161, 104942. [Google Scholar] [CrossRef]

- Meys, R.; Frick, F.; Westhues, S.; Sternberg, A.; Klankermayer, J.; Bardow, A. Towards a Circular Economy for Plastic Packaging Wastes—The Environmental Potential of Chemical Recycling. Resour. Conserv. Recycl. 2020, 162, 105010. [Google Scholar] [CrossRef]

- Jayanti, A.; Widyarko. Fast Fashion Synthetic Fabric Waste as an Alternative Noise Absorbent Material. AIP Conf. Proc. 2021, 2376, 080008. [Google Scholar] [CrossRef]

- Caniato, M.; Cozzarini, L.; Schmid, C.; Gasparella, A. A Sustainable Acoustic Customization of Open Porous Materials Using Recycled Plastics. Sci. Rep. 2022, 12, 10955. [Google Scholar] [CrossRef] [PubMed]

- Vilniškis, T.; Januševičius, T. Sound Insulation Properties of Sound-Reduction Louvers with Innovative Devulcanized Rubber. Arch. Acoust. 2024, 10. [Google Scholar] [CrossRef]

- Astrauskas, T.; Januševičius, T.; Grubliauskas, R. Acoustic Panels Made of Paper Sludge and Clay Composites. Sustainability 2021, 13, 637. [Google Scholar] [CrossRef]

- Ružickij, R.; Vasarevičius, S.; Januševičius, T.; Grubliauskas, R. The Reuse Method of Waste Tyre Textile Fibers for Sound Absorption Applications. In Proceedings of the 2022 International Conference and Utility Exhibition on Energy, Environment and Climate Change (ICUE), Pattaya, Thailand, 26–28 October 2022. [Google Scholar] [CrossRef]

- Sugimoto, N.; Sugimoto, N. Fatigue Analysis and Rapid Design Process of Anti-Vibration Rubber Parts for Automobiles. SAE Tech. Pap. Ser. 2024, 1, 2255. [Google Scholar] [CrossRef]

- Apaza Apaza, F.R.; Vázquez, V.F.; Paje, S.E.; Saiz, L.; Gulisano, F.; Gallego, J. The Potential Effect of Crumb Rubber on the Maximum Sound Absorption Performance of Asphalt Mixtures. Constr. Build. Mater. 2023, 389, 131789. [Google Scholar] [CrossRef]

- Tarafdar, A.; Oh, M.J.; Nguyen-Phuong, Q.; Kwon, J.H. Profiling and Potential Cancer Risk Assessment on Children Exposed to PAHs in Playground Dust/Soil: A Comparative Study on Poured Rubber Surfaced and Classical Soil Playgrounds in Seoul. Environ. Geochem. Health 2020, 42, 1691–1704. [Google Scholar] [CrossRef] [PubMed]

- Landi, D.; Marconi, M.; Meo, I.; Germani, M. Reuse Scenarios of Tires Textile Fibers: An Environmental Evaluation. Procedia Manuf. 2018, 21, 329–336. [Google Scholar] [CrossRef]

- Valdes-Vidal, G.; Calabi-Floody, A.; Mignolet-Garrido, C.; Bravo-Espinoza, C. Enhancing Fatigue Resistance in Asphalt Mixtures with a Novel Additive Derived from Recycled Polymeric Fibers from End-of-Life Tyres (ELTs). Polymers 2024, 16, 385. [Google Scholar] [CrossRef] [PubMed]

- Khosh, B.; Atapour, H. Assessment of Mechanical Behavior of Sprayed Concrete Reinforced with Waste Tire Textile Fibers. Sci. Rep. 2024, 14, 8873. [Google Scholar] [CrossRef] [PubMed]

- Fareghian, M.; Afrazi, M.; Fakhimi, A. Soil Reinforcement by Waste Tire Textile Fibers: Small-Scale Experimental Tests. J. Mater. Civil. Eng. 2022, 35, 04022402. [Google Scholar] [CrossRef]

- Ruzickij, R.; Grubliauskas, R. Sound Absorption: Dependence of Rubber Particles Impurities in Tyre Textile Fibre. Environ. Clim. Technol. 2022, 26, 331–340. [Google Scholar] [CrossRef]

- Ong, T.K.; Choo, H.L.; Lee, S.M.; Kong, K.Y. Oil Palm Wastes as Sustainable Sound Absorbing Particleboard. IOP Conf. Ser. Mater. Sci. Eng. 2020, 815, 012010. [Google Scholar] [CrossRef]

- Bhingare, N.H.; Prakash, S. Effect of Polyurethane Resin Addition on Acoustic Performance of Natural Coconut Coir Fiber. J. Nat. Fibers 2022, 19, 2902–2913. [Google Scholar] [CrossRef]

- Tie, T.S.; Mo, K.H.; Putra, A.; Loo, S.C.; Alengaram, U.J.; Ling, T.C. Sound Absorption Performance of Modified Concrete: A Review. J. Build. Eng. 2020, 30, 101219. [Google Scholar] [CrossRef]

- Tran, M.H.; Lee, E.Y. Production of Polyols and Polyurethane from Biomass: A Review. Environ. Chem. Lett. 2023, 21, 2199–2223. [Google Scholar] [CrossRef]

- Yong, Q.; Liao, B.; Huang, J.; Guo, Y.; Liang, C.; Pang, H. Preparation and Characterization of a Novel Low Gloss Waterborne Polyurethane Resin. Surf. Coat. Technol. 2018, 341, 78–85. [Google Scholar] [CrossRef]

- Tigabe, S.; Atalie, D.; Gideon, R.k. Physical Properties Characterization of Polyvinyl Acetate Composite Reinforced with Jute Fibers Filled with Rice Husk and Sawdust. J. Nat. Fibers 2022, 19, 5928–5939. [Google Scholar] [CrossRef]

- Diyana, Z.N.; Jumaidin, R.; Selamat, M.Z.; Ghazali, I.; Julmohammad, N.; Huda, N.; Ilyas, R.A. Physical Properties of Thermoplastic Starch Derived from Natural Resources and Its Blends: A Review. Polymers 2021, 13, 1396. [Google Scholar] [CrossRef] [PubMed]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, Mechanical and Thermal Properties of Green Composites Reinforced with Natural Fibers Waste. Polymers 2020, 12, 654. [Google Scholar] [CrossRef] [PubMed]

- Ricciardi, P.; Belloni, E.; Cotana, F. Innovative Panels with Recycled Materials: Thermal and Acoustic Performance and Life Cycle Assessment. Appl. Energy 2014, 134, 150–162. [Google Scholar] [CrossRef]

- Secchi, S.; Asdrubali, F.; Cellai, G.; Nannipieri, E.; Rotili, A.; Vannucchi, I. Experimental and Environmental Analysis of New Sound-Absorbing and Insulating Elements in Recycled Cardboard. J. Build. Eng. 2016, 5, 1–12. [Google Scholar] [CrossRef]

- Casadesús, M.; Álvarez, M.D.; Garrido, N.; Molins, G.; Macanás, J.; Colom, X.; Cañavate, J.; Carrillo, F. Environmental Impact Assessment of Sound Absorbing Nonwovens Based on Chicken Feathers Waste. Resour. Conserv. Recycl. 2019, 149, 489–499. [Google Scholar] [CrossRef]

- Nagy, B.; Marosvolgyi, M.; Szalay, Z. Global Warming Potential of Building Constructions Based on Heat and Moisture Transport Analysis. Therm. Sci. 2021, 26, 3285–3296. [Google Scholar] [CrossRef]

- ISO 10534-2:2023; Acoustics—Determination of Acoustic Properties in Impedance Tubes—Part 2: Two-Microphone Technique for Normal Sound Absorption Coefficient and Normal Surface Impedance. International Standard. ISO: Geneva, Switzerland, 1998; pp. 1–28.

- ISO.9053-1:2018; Acoustics—Determination of Airflow Resistance—Part 1: Static Airflow Method. International Standard. ISO: Geneve, Switzerland, 2018; pp. 1–20.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Standard. ISO: Geneva, Switzerland, 2022.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines—Amendment 1. International Standard. ISO: Geneva, Switzerland, 2017.

- PRé Sustainability. SimaPro Database Manual Methods Library; PRé Sustainability: Amersfoort, The Netherlands, 2020. [Google Scholar]

- Yang, Y.; Chen, Z.; Chen, Y.; Zhang, L.; Lu, H. Effect of Physical and Subsequent Processing Parameters of Glass Fiber Felts on Sound Insulation. J. Text. Inst. 2017, 109, 614–619. [Google Scholar] [CrossRef]

- Bozkurt, T.S.; Yılmaz Demirkale, S. Investigation and Development of Sound Absorption of Plasters Prepared with Pumice Aggregate and Natural Hydraulic Lime Binder. Appl. Acoust. 2020, 170, 107521. [Google Scholar] [CrossRef]

- Abdi, D.D.; Monazzam, M.; Taban, E.; Putra, A.; Golbabaei, F.; Khadem, M. Sound Absorption Performance of Natural Fiber Composite from Chrome Shave and Coffee Silver Skin. Appl. Acoust. 2021, 182, 108264. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous Materials for Sound Absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Asadi, M.; Ohadi, A.; Keshavarz, R. Effect of Non-Acoustic Properties on the Sound Absorption of Polyurethane Foams. J. Theor. Appl. Vib. Acoustics 2015, 1, 122–132. [Google Scholar] [CrossRef]

- Liu, X.; Xiong, X.; Pang, J.; Wu, L.; Zhang, H. Airflow Resistivity Measurement and Sound Absorption Performance Analysis of Sound-Absorb Cotton. Appl. Acoust. 2021, 179, 108060. [Google Scholar] [CrossRef]

- Seddeq, H.S. Factors Influencing Acoustic Performance of Sound Absorptive Materials. Aust. J. Basic. Appl. Sci. 2009, 3, 4610–4617. [Google Scholar]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12–8477. [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. Sound Absorbing Properties of Materials Made of Rubber Crumbs. J. Acoust. Soc. Am. 2008, 123, 3037. [Google Scholar] [CrossRef]

- Zhou, R.; Zhao, S.; Luo, M.; Meng, X.; Ma, J.; Liu, J. MFCC Based Real-Time Speech Reproduction and Recognition Using Distributed Acoustic Sensing Technology. Optoelectron. Lett. 2024, 20, 222–227. [Google Scholar] [CrossRef]

- Lomte, A.; Sharma, B.; Drouin, M.; Schaffarzick, D. Sound Absorption and Transmission Loss Properties of Open-Celled Aluminum Foams with Stepwise Relative Density Gradients. Appl. Acoust. 2021, 193, 19. [Google Scholar] [CrossRef]

- Quek, C.S.; Ngadi, N.; Ahmad Zaini, M.A. The Oil-Absorbing Properties of Kapok Fibre—A Commentary. J. Taibah Univ. Sci. 2020, 14, 507–512. [Google Scholar] [CrossRef]

- Nasruddin; Setianto, W.B.; Yohanes, H.; Atmaji, G.; Lanjar; Yanto, D.H.Y.; Wulandari, E.P.; Wiranata, A.; Ibrahim, B. Characterization of Natural Rubber, Styrene Butadiene Rubber, and Nitrile Butadiene Rubber Monomer Blend Composites Loaded with Zinc Stearate to Be Used in the Solid Tire Industry. Appl. Sci. 2023, 13, 1277. [Google Scholar] [CrossRef]

- Mostoni, S.; Milana, P.; Di Credico, B.; D’arienzo, M.; Scotti, R. Zinc-Based Curing Activators: New Trends for Reducing Zinc Content in Rubber Vulcanization Process. Catalysts 2019, 9, 664. [Google Scholar] [CrossRef]

- Monteiro, H.; Ribeiro, I.; Gonçalves, M.; Iten, M.; Caetano, N.S. Life Cycle Energy and Carbon Analysis of a Road-Safety Barrier Produced Using Recycled Tire Rubber. Energy Rep. 2022, 8, 270–276. [Google Scholar] [CrossRef]

- Mora, C.; McKenzie, T.; Gaw, I.M.; Dean, J.M.; von Hammerstein, H.; Knudson, T.A.; Setter, R.O.; Smith, C.Z.; Webster, K.M.; Patz, J.A.; et al. Over Half of Known Human Pathogenic Diseases Can Be Aggravated by Climate Change. Nat. Clim. Chang. 2022, 12, 869–875. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Lin, W.; Xiao, Y.; Yu, B.; Wang, W. Advancements in Flame-Retardant Systems for Rigid Polyurethane Foam. Molecules 2023, 28. [Google Scholar] [CrossRef] [PubMed]

- Smith, S.J.; Pitchera, H.; Wigley, T.M.L. Global and Regional Anthropogenic Sulfur Dioxide Emissions. Glob. Planet. Chang. 2001, 29, 99–119. [Google Scholar] [CrossRef]

- Lansche, J.; Awiszus, S.; Latif, S.; Müller, J. Potential of Biogas Production from Processing Residues to Reduce Environmental Impacts from Cassava Starch and Crisp Production—A Case Study from Malaysia. Appl. Sci. 2020, 10, 2975. [Google Scholar] [CrossRef]

- Pagliaro, M. Renewable Energy in Russia: A Critical Perspective. Energy Sci. Eng. 2021, 9, 950–957. [Google Scholar] [CrossRef]

- Johnsson, F.; Kjärstad, J.; Rootzén, J. The Threat to Climate Change Mitigation Posed by the Abundance of Fossil Fuels. Clim. Policy 2019, 19, 258–274. [Google Scholar] [CrossRef]

| Sample | WTTF, wt% | PU, wt% | PVA, wt% | H2O, wt% | POS and H2O Ratio |

|---|---|---|---|---|---|

| PU-10 | 90 | 10 | – | – | – |

| PU-30 | 70 | 30 | – | – | – |

| PU-50 | 50 | 50 | – | – | – |

| PVA-10 | 90 | – | 5 | 5 | – |

| PVA-30 | 70 | – | 15 | 15 | – |

| PVA-50 | 50 | – | 25 | 25 | – |

| POS-10 | 90 | – | – | – | 1:10 |

| POS-30 | 70 | – | – | – | 1:10 |

| POS-50 | 50 | – | – | – | 1:10 |

| Density, kg/m3 | 75 | 100 | 125 | 150 |

| Functional Unit (for 1 m2 panel), kg (eq) | 4.40 | 6.15 | 7.58 | 8.82 |

| Process | End-of-life tyre recycling | |||||

| Input | ||||||

| Amount | Comments | |||||

| Materials/Components | Measurement Unit | 75 kg/m3 | 100 kg/m3 | 125 kg/m3 | 150 kg/m3 | |

| End-of-life tyres | kg | 64.76 | 90.71 | 111.77 | 130.20 | To recycle 1 tonne of end-of-life tyres, 150 kWh of electrical energy (data from the recycling facility) |

| Electrical energy | kWh | 0.67 | 0.94 | 1.16 | 1.35 | |

| Output | ||||||

| Recycling residues | kg | 0.65 | 0.91 | 1.12 | 1.30 | 1.0% of the total amount |

| Metals | kg | 9.5 | 13.2 | 16.3 | 19.0 | 14.75% of the total amount |

| Rubber | kg | 50.2 | 70.3 | 86.6 | 100.9 | 78.25% of the total amount |

| Waste tyre textile fibre | kg | 4.49 | 6.29 | 7.75 | 9.02 | 7.0% of the total amount |

| Process | Waste tyre textile fibre transportation to the composite sound absorbing panel production facility | |||||

| Amount of cargo transportation (WTTF) | tkm | 1.45 | 2.03 | 2.49 | 2.90 | Small-capacity truck (diesel, 3.5 litres, up to 7.5 tons, EURO5 standard; fibre transport distance 320 km, binder 11 km) |

| Amount of cargo transportation (binders) | tkm | 6.36 × 10−5 | 8.32 × 10−5 | 9.64 × 10−5 | 1.07 × 10−4 | |

| Process | Production of composite sound absorbing panels | |||||

| Input | ||||||

| Waste tyre textile fibre (with packaging) | kg | 4.54 | 6.33 | 7.79 | 9.07 | The quantity required for the production of one panel |

| Electrical energy | kWh | 1.49 | 2.18 | 2.59 | 2.98 | Electricity is used for fibre drying (amount determined by electricity consumption metre) |

| Polyurethane binder with hardener (with packaging) | kg | 0.70 | 0.92 | 1.06 | 1.18 | The amount of binder required for the production of one panel |

| Polyvinyl acetate (with packaging) | kg | 0.50 | 0.72 | 0.86 | 0.98 | The amount of binder required for the production of one panel |

| Starch (with packaging) | kg | 0.42 | 0.64 | 0.78 | 0.90 | The amount of binder required for the production of one panel |

| Tap water | kg | 0.80 | 1.23 | 1.52 | 1.76 | For PVA and starch dilution |

| Electrical energy | kWh | 5.76 | 8.04 | 9.91 | 11.52 | Electricity is used to dry the composite sound absorbing panel (amount determined by electricity consumption metre) |

| Parchement paper | kg | 0.10 | 0.10 | 0.10 | 0.10 | For lining the mould |

| Electrical energy | kWh | 0.04 | 0.05 | 0.06 | 0.08 | Electricity is used to mix the components (amount determined by electricity consumption metre) |

| Output | ||||||

| Rubber residues | kg | 0.40 | 0.63 | 0.77 | 0.90 | Residues of rubber impurities after sieving (disposed) |

| WTTF transportation bags | kg | 0.05 | 0.05 | 0.05 | 0.05 | PE bags |

| Polyurethane resin and hardener packages | kg | 0.30 | 0.30 | 0.30 | 0.30 | FE packaging |

| Polyvinyl acetate packaging | kg | 0.10 | 0.10 | 0.10 | 0.10 | PET packaging |

| Starch packaging | kg | 0.02 | 0.02 | 0.02 | 0.02 | Paper bag |

| Parchement paper | kg | 0.10 | 0.10 | 0.10 | 0.10 | |

| Waste tyre textile fibre | kg | 0.09 | 0.13 | 0.15 | 0.18 | 2.0% unused balance during production |

| Composite sound absorbing panel | kg | 4.40 | 6.15 | 7.58 | 8.82 | Final product (mass corresponds to functional unit) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ružickij, R.; Romagnoli, F.; Grubliauskas, R. Waste Tyre Textile Fibre Composite Material: Acoustic Performance and Life Cycle Assessment. Sustainability 2024, 16, 6281. https://doi.org/10.3390/su16156281

Ružickij R, Romagnoli F, Grubliauskas R. Waste Tyre Textile Fibre Composite Material: Acoustic Performance and Life Cycle Assessment. Sustainability. 2024; 16(15):6281. https://doi.org/10.3390/su16156281

Chicago/Turabian StyleRužickij, Robert, Francesco Romagnoli, and Raimondas Grubliauskas. 2024. "Waste Tyre Textile Fibre Composite Material: Acoustic Performance and Life Cycle Assessment" Sustainability 16, no. 15: 6281. https://doi.org/10.3390/su16156281

APA StyleRužickij, R., Romagnoli, F., & Grubliauskas, R. (2024). Waste Tyre Textile Fibre Composite Material: Acoustic Performance and Life Cycle Assessment. Sustainability, 16(15), 6281. https://doi.org/10.3390/su16156281