1. Introduction

With the deepening of international cooperation in the new industry revolution era, the companies in the semiconductor supply chain work cooperatively and competitively to develop new technology, satisfy customer needs, and maintain the growth of the whole ecosystem. Supply chain risk categorizing is critical since it can help supply chain practitioners distinguish between risk sources [

1]. For manufacturing industries, for example, semiconductor and aircraft stock-keeping units (SKUs) with intermittent demand generate over 40% of total income while occupying around 60% of entire stock investment in standard industrial settings [

2,

3]. It is essential to predict the forthcoming demand status for highly diverse products throughout the distribution management to cut down inventory costs and, in the meantime, maintain flexibility on decisions for supply chain resilience.

While semiconductor companies suffer from shortened life cycles, longer lead times, and higher supply chain fluctuations, artificial intelligence (AI) and big data analytics will assist in human decisions from complex operations to empower business intelligence in demand planning to support inventory management. Supply chain resilience can help companies quickly recover to normal levels in the face of supply chain disruptions [

4]. Big data analytics can explore the impact of supply chain complexities on supply chain resilience [

5]. To resist supply chain risks, high-tech companies urgently need to develop more cost-effective, robust, and dynamic supply chain capabilities [

6]. Different from manufacturing and production companies in the supply chain, most semiconductor distributors still manage trading systems manually, which limits the transmission of data as well as the sharing of information among upstream and downstream supply chain partners [

7]. In the era of supply chain 4.0, a smart supply chain is expected to have superior features such as speed, flexibility, transparency, and real-time inventory monitoring and management [

8,

9,

10,

11]. It is critical for supply chain management to integrate advanced technologies such as big data, blockchain, and AI with human domain knowledge in an opaque and uncertain environment to support resilient decision-making.

This study aims to propose a smart supply chain framework with human judgement, advanced analytics, and optimization techniques to empower supply chain resilience. This framework includes supply chain activities with decision-making schema, execution procedure, data-driven diagnosis, and tornado diagram embedded with plan-do-check-act (PDCA) management cycle, including achieving the viability of intelligent decision-making with limited supply chain information to enhance the empirical implementation in the smart supply chain. Furthermore, an empirical study of demand forecast and risk inference for semiconductor distribution is conducted to validate the proposed framework. The data-driven demand risk reference model to achieve the viability of intelligent decision-making with limited product and customer information will assist Vendor-managed inventory (VMI) decision makers in demand management problems with information deficiency supply chain uncertainty. It can extract customer behaviors for vendor-managed inventory under uncertain demand and market fluctuation to drive collaborative efforts in enhancing demand planning and inventory control efficiency in the semiconductor supply chain.

The remainder of this paper is organized as follows.

Section 2 reviews the related studies on supply chain resilience.

Section 3 presents the data-driven smart resilient supply chain framework.

Section 4 presents an empirical study of semiconductor distribution demand forecast and risk inference for practical validation.

Section 5 makes conclusions regarding the research and conducts discussions on future research directions.

2. Literature Review

An important aspect for all supply chain managers is the capacity of their supply chain to withstand upheavals, disruptions, and unforeseen uncertain events [

12,

13]. Novel resilient decision support system embedded with advanced digital techniques greatly influences the effectiveness of the multi-level supply chain. The entire supply chain will be connected through the Internet of Things (IoT) as a medium in Industry 4.0. In the future of self-thinking supply chains, AI and IoT are the technologies most frequently connected with the expected autonomy and predictive capabilities [

14]. Supply chains are more prone to disruptions caused by natural and man-made uncertain events [

15]. The glitches in supply chains affect operating performance, from parts shortages to reorganizational delays and information technology problems [

16]. Moreover, a resilient supply chain decision support system also facilitates intra-company resource allocation decisions, including order delivery [

17], resource reallocation [

18], sales strategy [

19,

20], warehousing and logistics emissions [

21], inventory management [

22], sourcing technological integration [

23], and spare parts management [

24].

In practice, there is still insufficient information transparency in the upstream and downstream of the whole manufacturing supply chain due to the lack of effective platforms and technology support. An expert evaluation mechanism can be used to make predictions and decisions as the basis for subsequent production and inventory decisions [

25]. Big data analytics can benefit supply chain management capabilities under sufficient information sharing following the capabilities maturity model [

26]. Dominguez et al. [

27] analyzed the impact on supply chain performance of adopting different strategies to implement partial information sharing among heterogeneous retailers. VMI is the best agility inventory approach to deliver products and customer services with minimum delay and satisfy the demand to reduce inventory costs [

28]. VMI facilitates the supply chain information sharing collaboration in that the downstream customer provides demand information to an upstream vendor and leaves the inventory decision to the upstream vendor. Both manufacturer/vendor and customer/retailer benefit from VMI adoption when the inventory holding cost is high [

29]. VMI can be a buffer for the customer to adjust their demand planning and a tool for decision makers in upstream vendors to support capacity allocation and inventory control.

Another critical characteristic of a resilient supply chain is to revert to its original state of operation after being disturbed [

30]. Supply chains are more susceptible to disruptions caused by natural and human uncertainties recently [

15]. Marinagi et al. [

31] reviewed the key performance indicators that are used for creating a resilient supply chain. The capability of resilience can effectively respond to supply chain disruptions, which can significantly improve firm performance and mitigate the ripple effect [

32,

33]. Supply chain diagnosis can be seen as a tool for handling minor faults or malfunctions of the supplier, customer, central planner, or any other possible supply chain role [

34]. Fault diagnosis is an important technology in modern manufacturing systems to reduce unnecessary costs and supply the essence of manufacturing planning [

35].

However, most of the fault diagnosis approaches proposed for the manufacturing industry focus on the production process; there is still a lack of research on supply chain fault diagnosis as far as the aspect of the system to support decision-making [

36]. Decision makers in resilient supply chain activities need to diagnose deviations to improve efficiency with limited information, personnel experience, and trial and error methods. It is important to integrate the diagnosis approach in decision-making activities for supply chain managers, rather than adopting other methods to address high-tech manufacturing issues, in order to increase efficiency and subsequently reduce costs under the flexible decision-making requirements of a smart supply chain.

3. Smart Resilient Supply Chain Framework

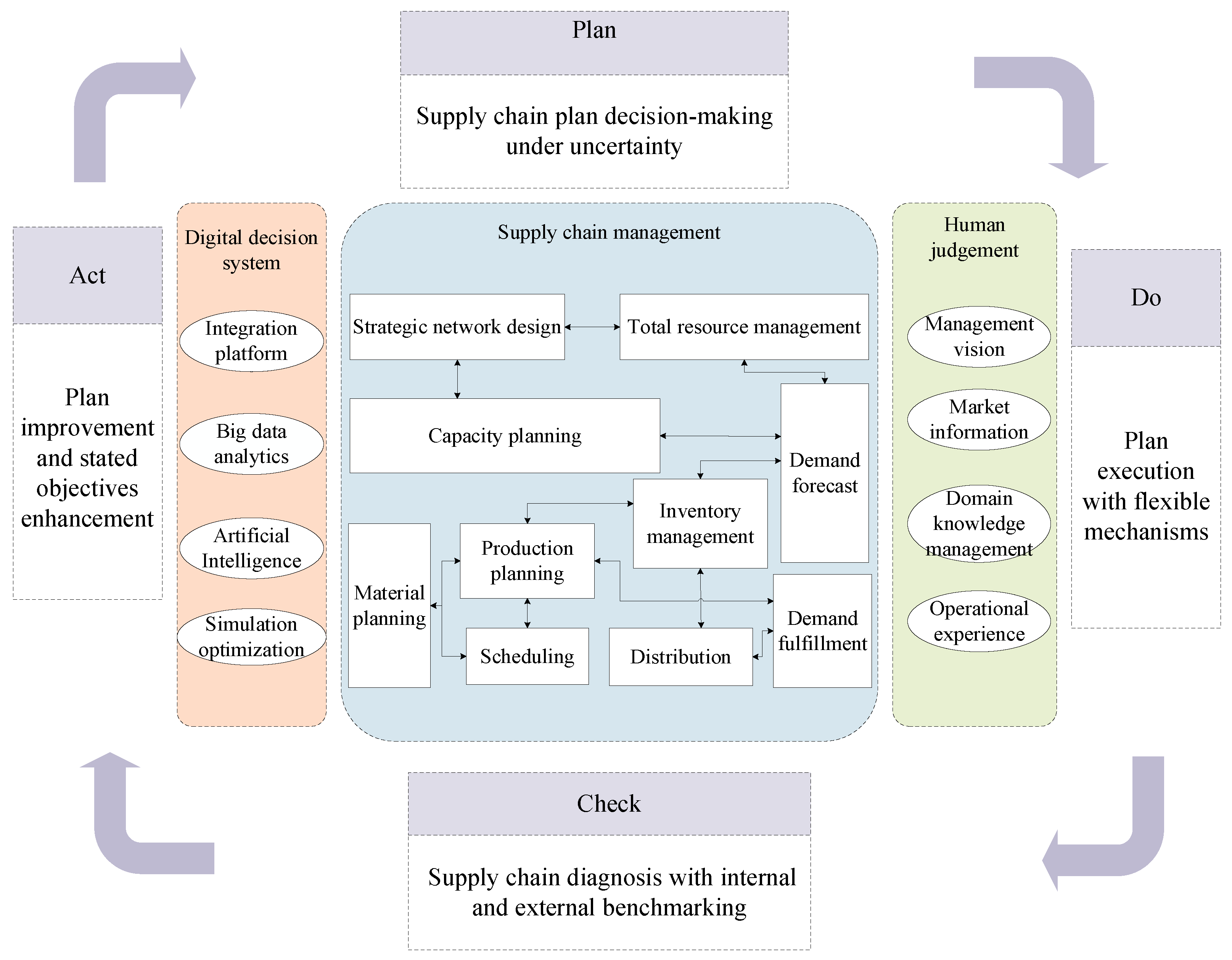

This study develops a research framework as the blueprint of a resilient smart supply chain with a PDCA improvement circle, as illustrated in

Figure 1. The goal of the proposed framework is to integrate software and hardware technologies and the management advantages of domain experts, establish human-system cooperation, and re-create decision-making processes to improve the speed and quality of decision-making responses.

The supply chain system needs to address demand unpredictability, uncertain events, or customer delivery delays in which the multi-time period cannot apply to the planning horizon until supply is insufficient to meet demand. Therefore, decision makers have to consider uncertain situations such as the amount of holding product and production at the manufacturer for meeting fluctuating demands in each period and providing flexibility in supply chain planning under various horizons. The supply chains of manufacturing enterprises produce millions of zettabytes of structured and unstructured data. The information processing of manufacturing supply chains and corporate strategies will be transformed and upgraded on the digital system side through industrial data collection, cloud platforms, and other methods to deal with zettabytes of information in order to obtain effective knowledge as the strategic enterprise guidelines.

To empower supply chain resilience, a resilient supply chain management PDCA schema that can support real-time decision-making in regular supply chain activities is proposed with supply chain plan decision-making under uncertainty, plan execution with flexible mechanisms, supply chain diagnosis with internal and external benchmarking, and plan improvement and stated objectives enhancement that can enable a disrupted or broken supply chain to reconstruct itself. The proposed approach integrates the supply chain decision analysis framework, the auxiliary management mechanism, and the PDCA cycle can thus improve the productivity of supply chain management and optimize the use of resources, thereby ensuring the effectiveness of resources and stimulating the workflow of company employees.

The supporting management mechanism of supply chain planning is mainly to make up for the difference between information uncertainty during planning and execution. According to the Deming cycle, the smart supply chain PDCA cycle is divided into four parts: plan, do, check, and act. The plan phase consists of generating a supply chain planning decision-making model and establishing strategic goals and various attribute sub-goals to implement and improve planning. The do phase is for planning execution and creating a flexible mechanism. Through regular monitoring of the factory supply chain management procedure, it can appropriately respond to the situation of unanticipated insufficient inventory and uneven capacity load and performs short-term operations in a timely management method to solve it. The check phase is for monitoring the achievement of objectives and learning internal and external benchmarks. Under the regular inspection of performance indicators, early detection of deviations in the performance of single-factory supply chains and warnings are provided to facilitate improvement. In addition, the benchmarking method is used to enhance factory employees through productivity performance indicators. The act phase is for improving the plan and achieving established goals. Through regular review of performance indicators and benchmark learning, each department is driven to formulate improvement plans to pursue the best benchmark and enhance capacity or inventory as the fundamental of next supply chain planning.

3.1. Plan Phase: Supply Chain Plan Decision-Making under Uncertainty

To overcome the difficulties of insufficient downstream market information and information uncertainty in supply chain decision-making, this study proposes a smart resilient supply chain decision-making framework. Firstly, an appropriate supply chain direction should be determined based on the resourcing of supply chain participants and their partners in order to initiate up-to-date strategies to meet the requirements of various orders. For human managers involved in supply chain activities, if the new decision support system of a company does not increase the satisfaction level of services, the company’s valuable resources will be abused and wasted. It is necessary to examine aspects of this problem, such as decision makers, digital systems, and the supply chain plan context. Therefore, understanding decision makers’ preferences and actual needs is critical for launching or updating supply chain management decisions.

Current supply chain uncertainty is highly correlated with low information transparency in the upstream and downstream, lengthy production cycle time, shortening of product life cycles, and long lead time for supply chain planning. The types of supply chain uncertainty can be divided into a company’s internal uncertainty, internal supply chain uncertainty, and external supply chain uncertainty. The company’s internal uncertainty is the internal organizational uncertainty of a specific company, including product characteristics, production process, decision-making complexity, organizational behavior problems, and information system. The internal supply chain uncertainty is under the control of the company and its partners, including end customer demand, demand amplification, suppliers, parallel interactions, order forecasting scope, and infrastructure. The uncertainty of external supply chains stems from factors outside the supply chain, including government regulation, competitor behavior, macroeconomic fluctuations, and disasters.

The construction and innovation of the new form of supply chain faces huge challenges. Thus, combining new technologies like AI, IoT, big data analytics, and block chain with the domain knowledge of industrial staff in an opaque and uncertain environment has become a critical issue in supply chain decision-making. The human supply chain judgements include subjective risk preference, operational behaviors, personalities, and latent information in customer characteristics. Decision makers’ judgements are all partially affected by supply chain input, process, and output factors. Through digital information systems, sensors, and IoT technologies, big data on operation processes, such as sales orders, can be collected automatically or semi-automatically. Thus, the behavior of supply chain managers can be recorded during regular operational processes. Human–system cooperation is the key component in the whole decision-making structure. By investigating demand and supply trends in the current market through human beings’ domain knowledge, potential supply chain decisions were identified, and alternative selections for supply chain decisions were converged. Scenario-based tests are conducted to collect data about human behaviors, domain knowledge, and the external environment. Domain experts are asked to test out different scenarios, which are based on their industry experience and individual decision preference for typical supply happenings. In addition, some supply chain influence factors can be extracted from digital systems, including user satisfaction data, which provides candidates for influencing future service innovation. Digital data quality is examined at the outset in this stage. In the data pre-processing stage, outliers, missing data, and other inconsistencies are about to be screened out. Then the clean data will be converted into a specialized format to enable human-system cooperation model construction. These factors should be evaluated based on confidence levels and selected by critical rules. For example, the key impact factor in capacity utilization is the tools and machines cost loss due to the unbalance between capacity management and actual demand. Production information parameters should be set in mathematical optimization models as input information constants to evaluate the cost loss.

The supply chain planning decisions in manufacturing follow the rolling mechanism, so these decisions need to be optimized at all decision points. A greater understanding of data and its source, including enterprise database type, internal operation factors, external market factors, and human subjectivity, helps us reveal insights into supply dynamics. For data collecting and inspecting, basic narrative statistics can be used to examine the distribution of raw data, understand data fields, and explore data leaks and inconsistencies to identify flawed information and discuss with domain experts to correct or delete the information. For data cleaning and conversion, the original data may be inaccurate due to oversight, recording errors, abnormal records, recording methods inconsistency, etc. Unreasonable data will lead to inaccuracies in subsequent analysis and result in erroneous or meaningless outputs. The frequently occurring data problems and corresponding pretreatment steps are sorted out. In uncertain environment characterization, the uncertainty generated from both internal and external environments but hardly tested by the digital system is considered uncertain human variables. Demand and capacity uncertainty are the two main categories of these uncertainties. These uncertainties come from the subjective judgment of the domain experts and the lack of data. The confidence of these uncertain predictions can be measured by confidence or other variables.

3.2. Do Phase: Plan Execution with Flexible Mechanisms

In the do phase of decision-making and management of the smart supply chain, self-assessment of the target performance value is conducted to help decision makers smoothly generate an execution plan and finish it with a flexible mechanism. The first key procedure is the self-evaluation operation. Through the project promotion group, a supply chain planning meeting is held to enable relevant colleagues to understand the implementation methods, advantages, and scoring methods of the smart supply chain to improve performance and form self-evaluation standards. It is crucial for the supply chain management department to conduct internal self-assessment operations, review the implementation profile of supply chain operational activities, execute a comprehensive inventory control, and evaluate its own abilities. The second is to master the projects that need to be strengthened and improved by evaluating the scores of self-assessment results. By reviewing the implementation of business activities one by one, including goals and time, business contractors can be appropriately planned. During the execution process, the problems are recorded, collected, and classified to meet the needs of subsequent performance analysis, operational information management, further review, and analysis of the supply chain management competitiveness. The plan’s progress can be improved by managing the projects that need improvement and strengthening and ensuring implementation.

To validate the practical results and their interpretations of supply chain plan decision-making approaches, domain experts are invited to provide domain knowledge regarding the rules derived from data analytics and informed by the integrated decision model. Result interpretation of decision outcomes in empirical studies provides support for decision makers in creating new planning concepts and identifying influence factors to support knowledge systemization. Because of rapid changes in supply chain patterns and market trends, the derived advised options provide useful insights for defining the appropriate supply chain decision-making. The decision-making under the uncertainty model requires occasional replication to provide a new direction for knowledge system updating to support practical guidelines and provide new management insights for human managers. An empirical study is an effective way for overall judgement and measurement in supply chain decision-making. Leveraging companies’ available internal and external resources and identifying their technological capabilities and limitations are crucial to determine feasible supply chain strategies on the market. On one hand, human managers can give practical implications through actual operation activities. On the other hand, there are objective statistical measurements to evaluate the performance of integrated decision-making outcomes.

3.3. Check Phase: Data-Driven Supply Chain Diagnosis with Internal and External Benchmarking

As supply chains continue to migrate to support the complex characteristics of state-of-the-art business models, identifying the root cause of failures can be much more challenging. The setting of multiple human participants and the complex processes are too complicated for supply chain managers with different backgrounds to diagnose and resolve problems efficiently and effectively.

The design and operation of supply chain diagnosis problems are becoming increasingly complicated due to the problem complexity and information limitation in the evolution of manufacturing technology and business model. Downstream companies cannot suffer from machine instability or operational downtime in business processes and need timely technical services. Participants in supply chain activities influence each other due to the peculiarities of the manufacturing process. Various solutions map to the same anomalous problem, such as inventory shortage. Moreover, the abnormal situation information of supply chain planning is recorded by operational managers or other employees in a small quantity and poor quality. In practice, the manual decision mechanism based on human judgement cannot find solutions and may delay operation process and final delivery date.

The niche for the supply chain fault diagnosis problem is to construct a supply chain diagnosis decision model to turn personal experiences into an effective systematic analytics approach, which can reduce diagnostic time and maintain solution consistency to improve supply chain operational efficiency. Sources of uncertain events are defined based on the discussion with domain experts to improve the recommendation effectiveness of decision strategies. Each type of anomaly has its own corresponding source of failure, including specific influencing factors or uncertainties, which are difficult to monitor, but can be analyzed based on characteristic phenomena and expertise. Experienced domain experts have their own handling procedures for frequently occurring anomalies as personal knowledge rather than digital information systems. The solution to this problem is to standardize diagnostic methods and encode lengthy text narratives.

Through practical investigation and analysis, decision-making recommendations are generated from experts, and a quantitative structure can be adopted to grasp the influence relationship of various factors. The supply chain fault inference prediction model is constructed based on historical fault cases processing data as a basis for comprehensive judgment. In the process of inference model construction, historical fault cases are collected using a series of extractions, including underlying data, analytical methods, and processing methods to distinguish possible states. The failure-cause diagram between factors is trained based on the experience and knowledge of domain experts to explore contingency relationships between key factors.

3.4. Act Phase: Plan Improvement and Stated Objectives Enhancement

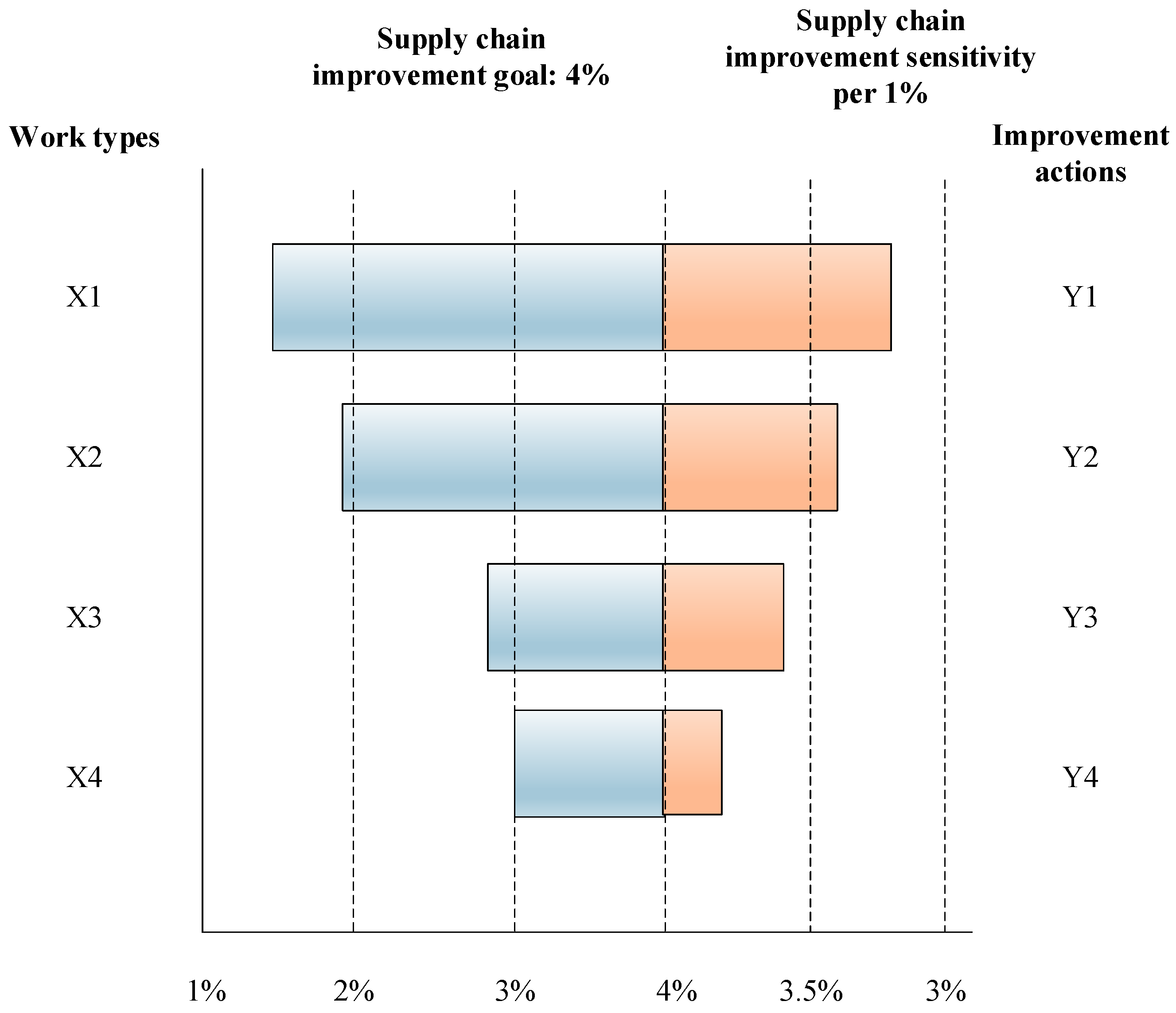

In the act phase, supply chain managers need to analyze improvement opportunities to improve supply chain efficiency. Through the comparison of monthly plant performance indicators, supply chain managers can use sensitivity analysis methods, such as tornado diagrams, to identify possible improvement opportunities in order to facilitate the operating unit to increase total resource management productivity. The tornado diagram is one of the methods to display the sensitivity analysis [

37]. It is used to compare the relative importance of variables with high uncertainty and relatively stable variables. It is also used in analyzing the risk-taking scenarios at specific risks that can have greater benefits than negative impacts. The

Y-axis of the tornado diagram displays uncertain variables at their base values, while the

X-axis contains the correlation of the uncertainty to a quantified output. Thus, the diagram contains a horizontal bar but is ordered vertically to show the uncertainties that have decreasing correlations from the base values.

Indeed, as seen in

Figure 2, work types are uncertainty involved in supply chain objectives enhancement while improvement actions are the potential optimization direction. The

X-axis shows the efficiency of a specific supply chain activity in the left part, improvement sensitivity per 1% in the right, and improvement goal in the middle. Therefore, in order to achieve the improvement goal of 4% supply chain efficiency, the estimated improvement time of the left half of the activity is allocated according to the weight, and the improvement of the right half is sequentially followed from the top to the bottom. It can be obtained, so long as the company can reduce X1, X2, X3, and X4, they can successfully achieve their optimization goals. As for the proposed improvement action, after discussing with the domain experts, the pre-improvement items in the left half of

Figure 2 are listed on the right side of the tornado diagram, and the improvement plan can be launched item by item, and the results can be tracked.

4. Empirical Study of Semiconductor Distribution Demand Forecast and Risk Inference

Following the proposed framework, an empirical study of demand forecast and risk inference for semiconductor distribution is conducted as a validation. This empirical research was conducted at the world’s leading semiconductor distribution organization, using demand planning decision-making methods and big data analysis to extract the customer behavior of suppliers to manage inventory under uncertain demand and market fluctuations. Semiconductor distribution companies engage in a typical business in the supply chain that purchases semiconductors from manufacturers and sells them to users, such as consumer electrical appliances or industrial equipment makers. As the midstream participator in the supply chain to provide a one-stop, convenient shopping service and value-added service, semiconductor distributors cope with a small number of customer companies engaging in business-to-consumer commerce.

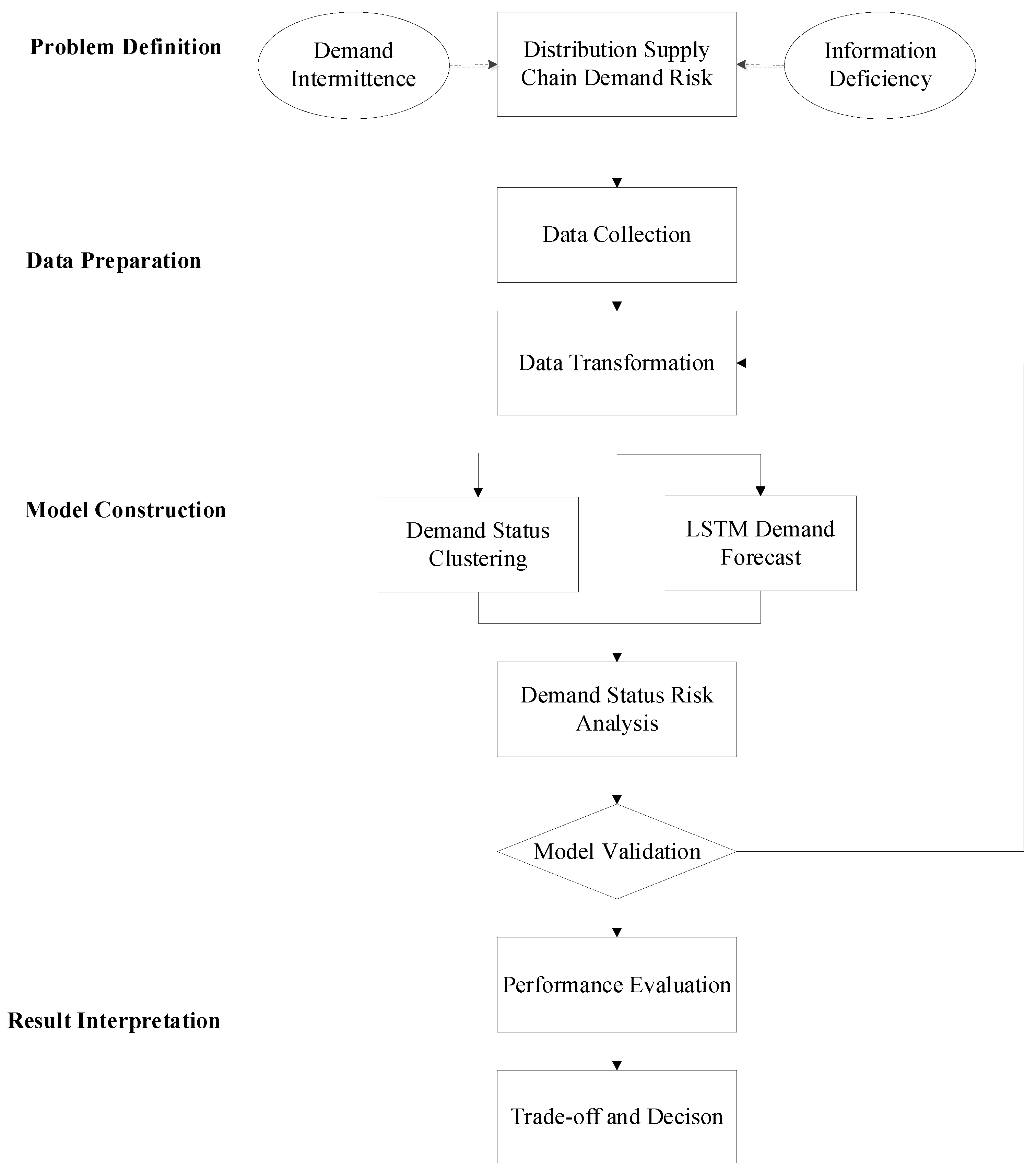

The case company provides demand creation, technical support, turnkey solutions, warehousing logistics, and e-commerce as value-added services to meet the needs of different customers, such as original design manufacturers, original equipment manufacturers, electronic manufacturing service providers, and other small- and medium-sized enterprises. In order to cope with the shortage of downstream information and demand for semiconductor products, this study proposes a semiconductor demand risk analysis framework, including four stages: problem definition, data preparation, model construction, and result interpretation, as shown in

Figure 3.

4.1. Problem Definition

Semiconductor products, such as integrated circuits, are made as part of electronic end-products such as laptops, tablets, and cell phones. Considering the rapid change of customer demand according to the shortened product life cycle, constructing an inventory risk analysis approach for the different product demand statuses of various products turns out to be a challenge. In industrial operations, inventory managers make demand planning decisions based on customer feedback and personal domain judgment in the VMI system. However, these predictions are highly variable due to uncertainty in customer behavior and personal subjective preferences.

4.2. Data Preparation

The empirical dataset includes a set of 30 types of semiconductor products, recording 98 weekly demand observations in the case company. The historic demand data show large variability and high discontinuity frequency. According to Syntetos et al. [

38], 25 of 30, almost 83%, of semiconductor product demand patterns used in this paper are intermittent and lumpy. In the data preprocessing stage, three component demand series that have less than five pick-up points are removed since it is the baseline for model fitting. The left 27 series are classified into two parts: 78 observations as training data and the left 20 observations as testing data. The problem now is how to establish an effective demand risk management mechanism for all products according to the various characteristics of all products. Since the demand variance between products is quite large, original demand data were transformed by min-max normalization so that the entire range of values of customer demand from the min to the max are mapped to the range 0 to 1:

4.3. Model Construction

The model construction part consists of VMI demand status clustering, long short-term memory (LSTM) demand forecast, and demand state risk analysis. K-means algorism is adopted for VMI demand clustering with an iterative refinement technique to justify the risk level for historical demand status data. Given an initial set , the algorithm proceeds by alternating between two steps:

First, assign each demand observation to the cluster with the “nearest” mean that has the least squared Euclidean distance:

where each

is assigned to exactly one

, even if it could be assigned to two or more of them.

Then update the clustering result by calculate the new centroids of the observations in the new clusters.

Secondly, the neural network is structured into three layers and used LSTM with a special structure in the recursive layer to predict forthcoming customer demand for different products. The memory area consists of memory cells and gates. The gate is set to control the transmission of messages. LSTM computes the input

according to the following formula to the output

with

.

where

represents a weight matrix;

represents a vector of errors;

represents a logic and transfer function;

is the input layer vector;

is the forgetting layer vector;

is the output layer vector;

is the cell activation vector; and

is the output activation vector. These vectors are in all the same dimensions.

denotes the element-to-element multiplication;

devotes a hyperbolic tangent function as the activation functions for cell input and cell output;

devotes the network output activation function.

After getting demand predictions from the LSTM model, the k-nearest neighbor (KNN) approach is devoted to classifying the risk level of new demand status. The input of KNN classification is the demand pattern and risk level in the previous eight weeks. The neighbors are taken from a set of historic demand pattern objects to which the risk class belongs. The output of this model is a risk class membership belonging to high, medium–high, medium–low, and low to support decision-making in inventory management.

4.4. Result Interpretation

The historic time series data is classified into training data and testing data for the purpose of performance validation. Training data is set up for model construction, and the estimated parameters in the forecast model are embedded in the framework. While testing data is to evaluate the overall demand risk status prediction performance. Since this demand risk model is for inventory management and underestimation is worse than oversupply, a recall and revised recall measure index are adopted in this study for result evaluation.

where A + 1 means a risk level higher than level A.

For performance evaluation, this study compares the forecast results by three error measurements, including mean absolute scaled error (MASE), root mean square error (RMSE), and mean absolute error (MAE). This study compared the forecast result of the LSTM model with the moving average (MA) model, which was the forecast model used in the empirical company. Three other classical intermittent forecast methods, including Croston [

39], TSB [

40], and SBA [

41], were also compared as benchmark methods. It can be found in

Table 1 that the proposed LSTM performed better than all four benchmark forecast models.

The demand status risk levels prediction confusion matrix is shown in

Table 2. In total, there are 758 demand statuses in the testing data set to validate the proposed model. The final VMI demand risk prediction evaluated by the recall and revised recall are listed in

Table 3. From the risk prediction performance, the revised recalls for four risk levels are 0.825, 0.754, 0.854, and 0.824, respectively, which implies that the proposed model can predict accurately or overestimate a little for all demand types. Thus, the demand risk inference decision-making approach with big data analytics can extract customer behaviors for vendor-managed inventory under uncertain demand and market fluctuation.

Through a data-driven demand risk analysis approach with machine learning techniques, demand planning decision makers will be able to control the inventory quantity and enhance order allocation based on customer behavior information extraction. Based on the demand risk reference result, the production plan and distribution/production capacity of each foundry for production can be determined with flexible decision-making. The production cost in one period affects the company’s profitability and pricing strategy in the next period. Production planning and the scheduling system should automatically assign products to different machines for production to minimize machine idle time, product waiting time, and production cycle time, as an empirical implementation for intelligent production. Thus, semiconductor companies will be able to integrate the upstream and downstream information effectively to decrease management loss and partially implement flexible decision-making. More research can be done to engage other parts of supply chain management, including inventory control and logistics strategies that extend demand planning solutions to formulate an entire resilient supply chain infrastructure.