Statistical and Mathematical Modeling for Predicting Caffeine Removal from Aqueous Media by Rice Husk-Derived Activated Carbon

Abstract

1. Introduction

2. Material and Methods

2.1. Preparation of the Adsorbent

2.2. Batch Studies

2.3. Adsorption Isotherms and Adsorption Kinetics

2.4. Statistical and Mathematical Modeling of the Adsorption Process

3. Results

3.1. Textural Properties

3.2. Investigation of Effective Parameters on the Adsorption

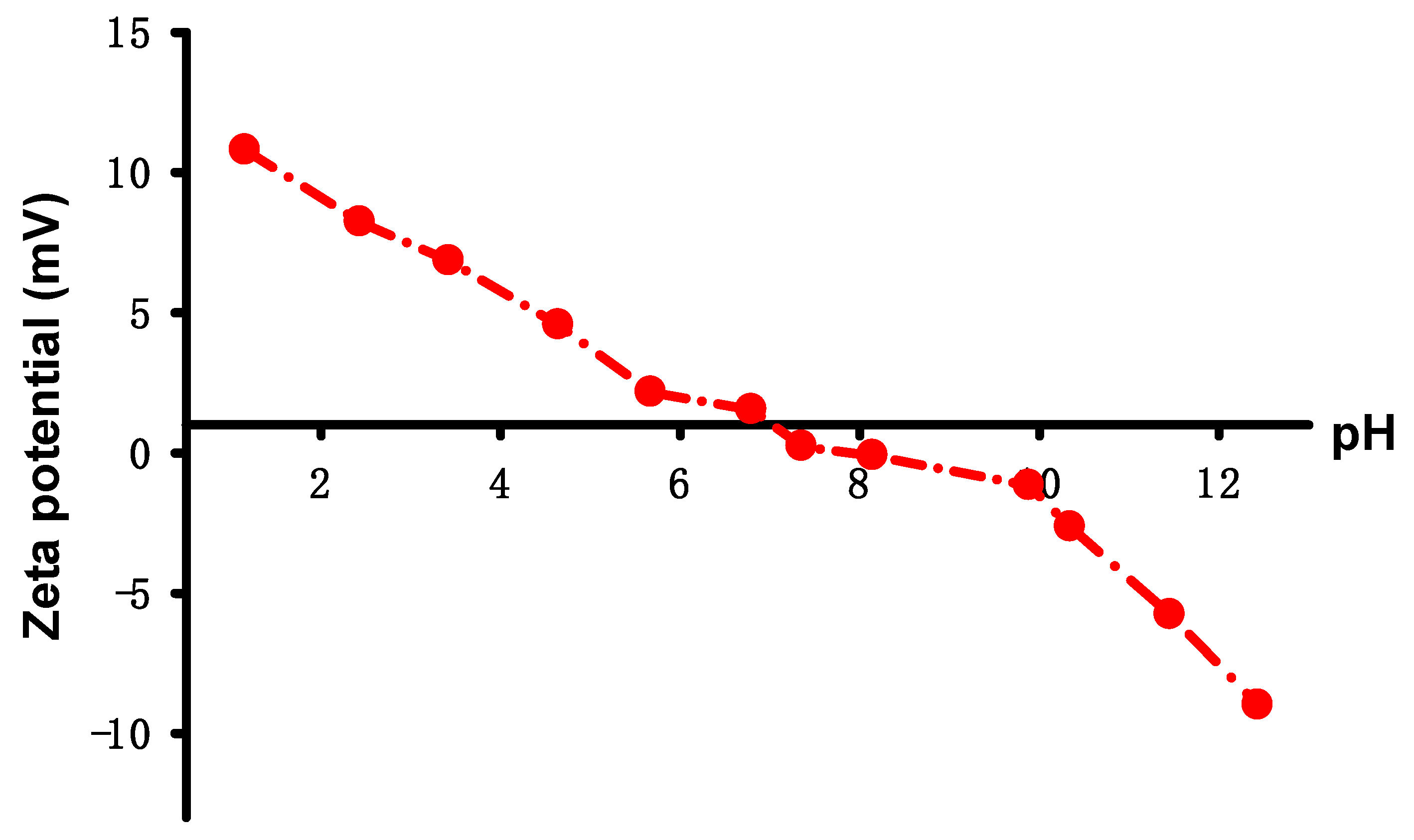

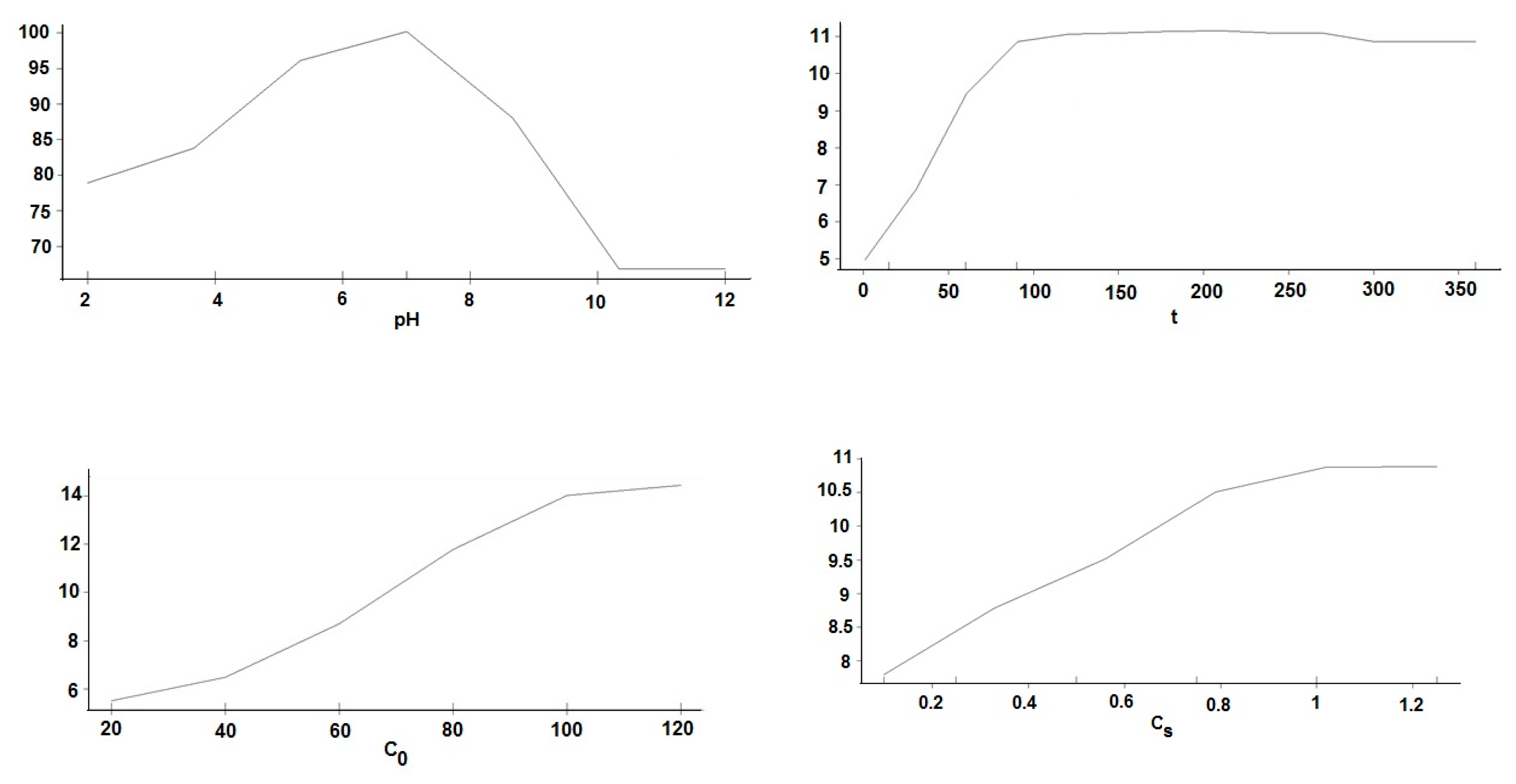

3.2.1. Effect of pH

3.2.2. Effect of Contact Time

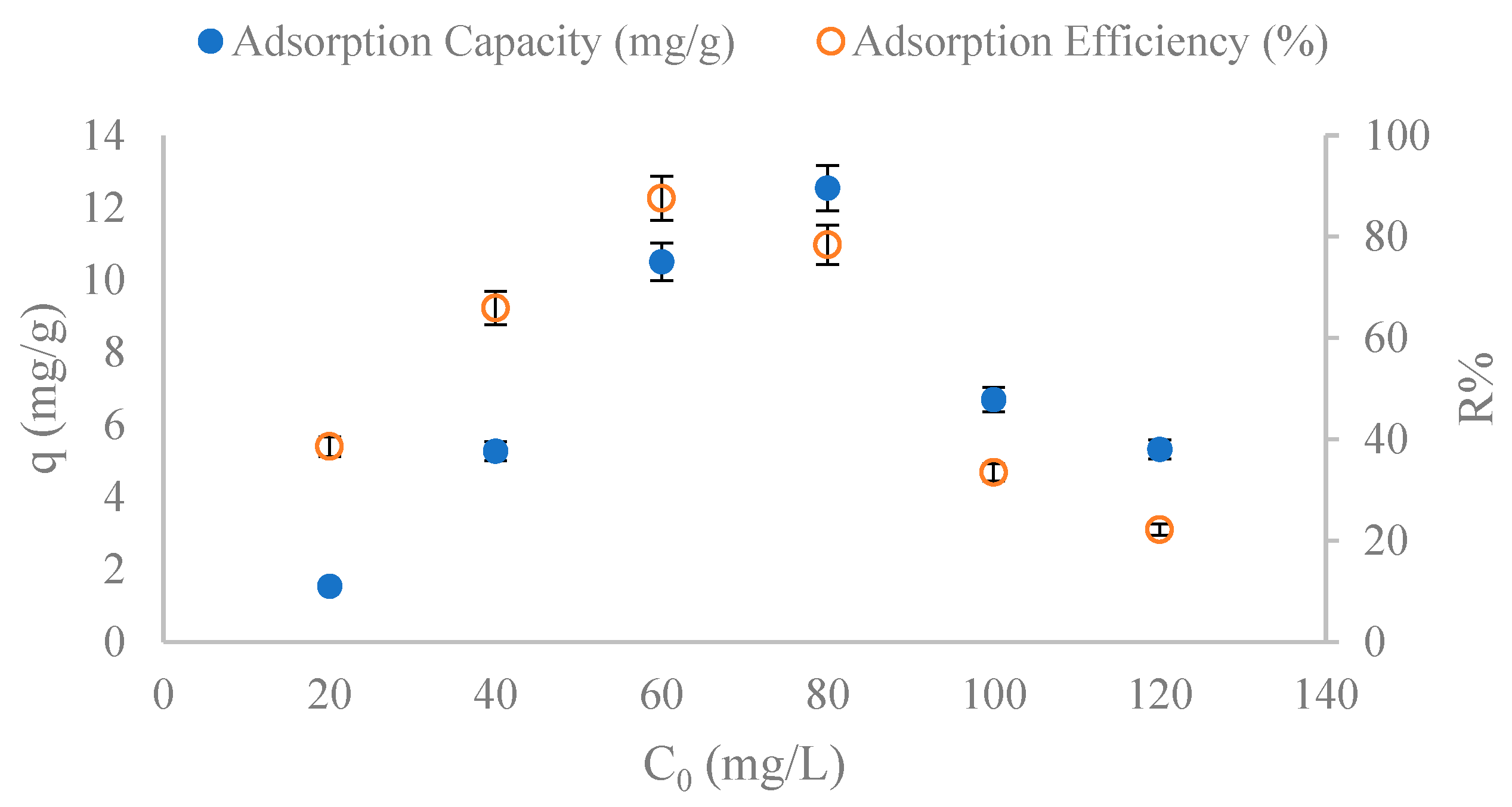

3.2.3. Effect of Initial Concentration of Caffeine

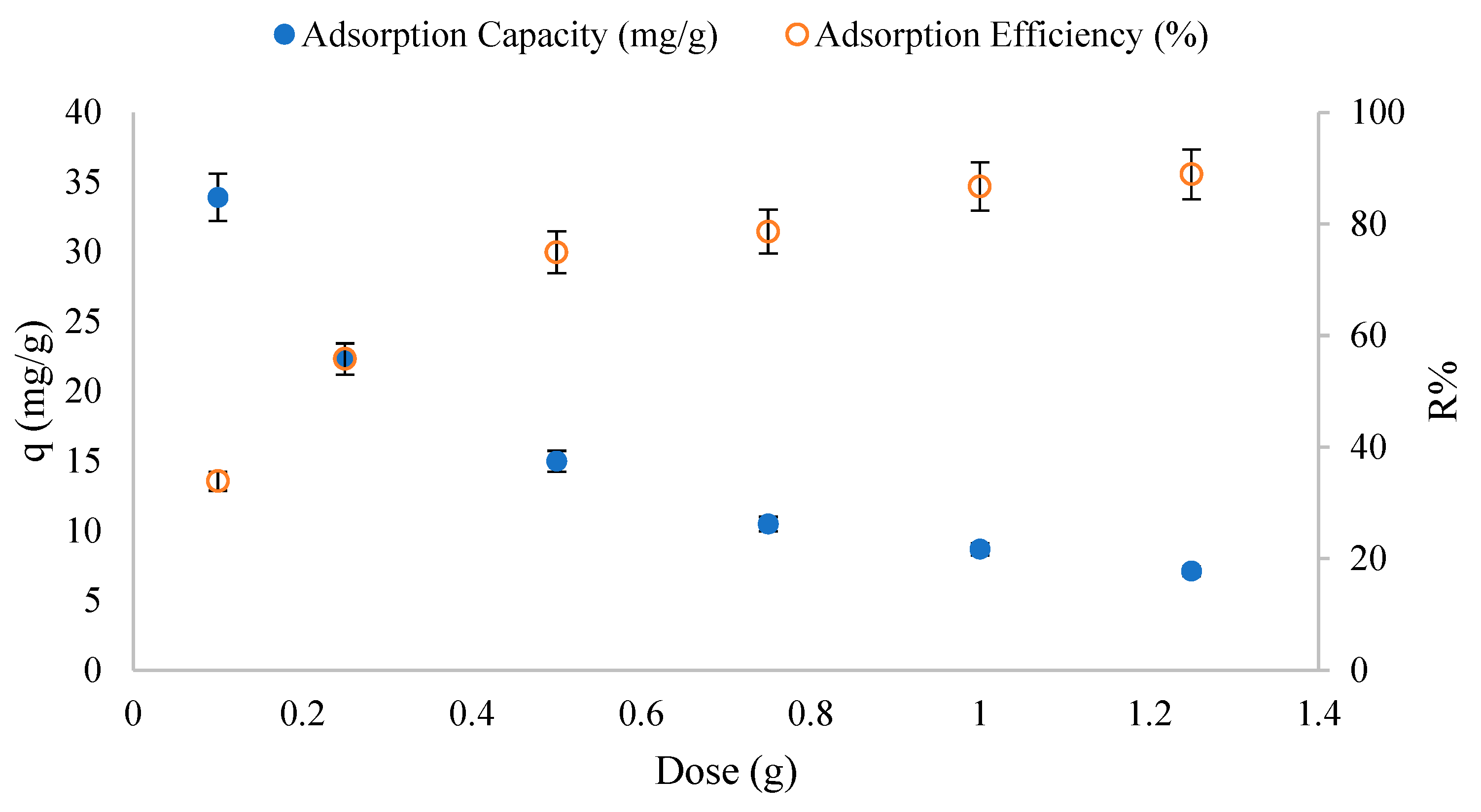

3.2.4. Effect of RHAC Adsorbent Dose

3.3. Adsorption Models

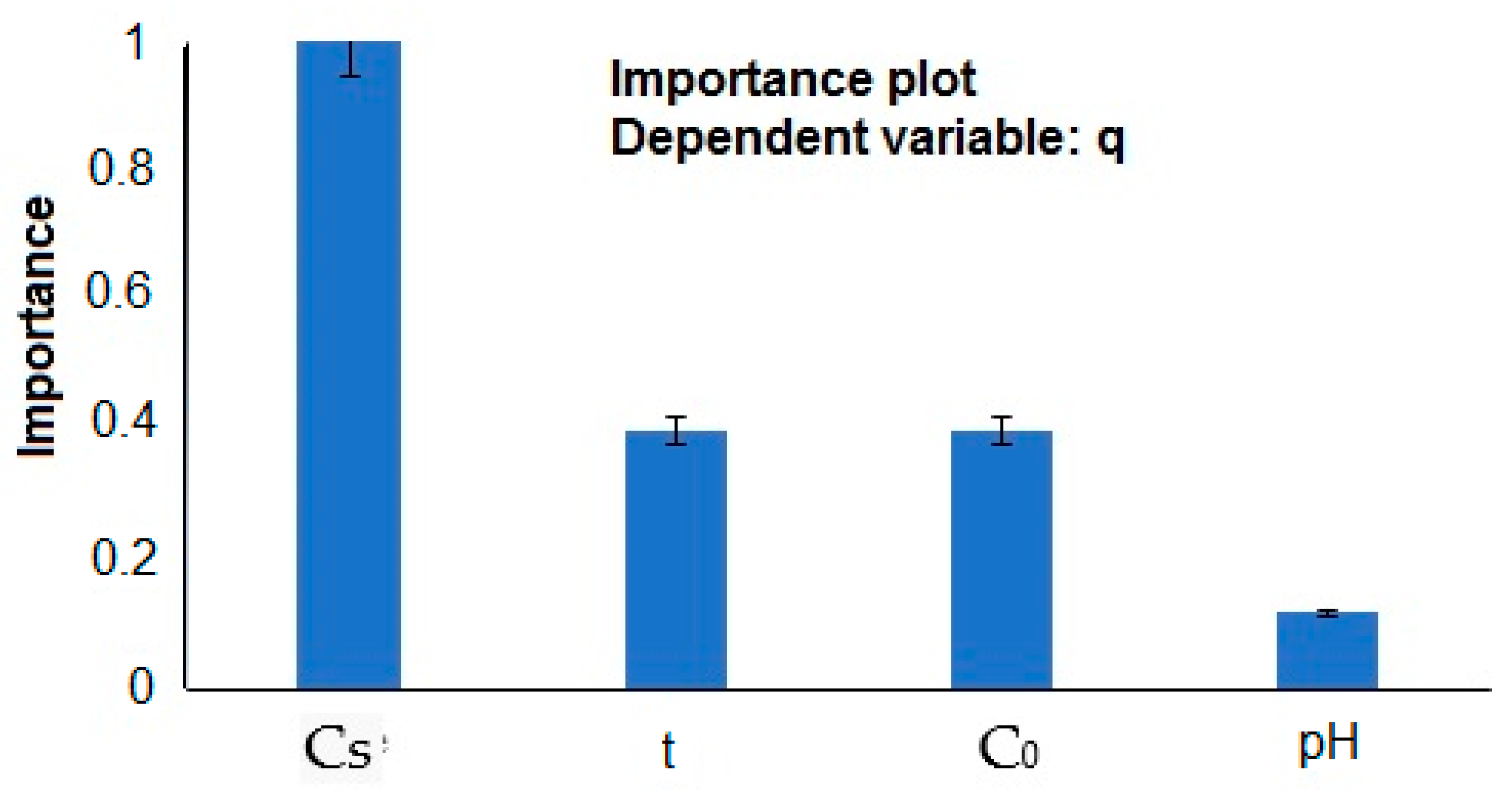

3.4. Statistical and Mathematical Modeling Results

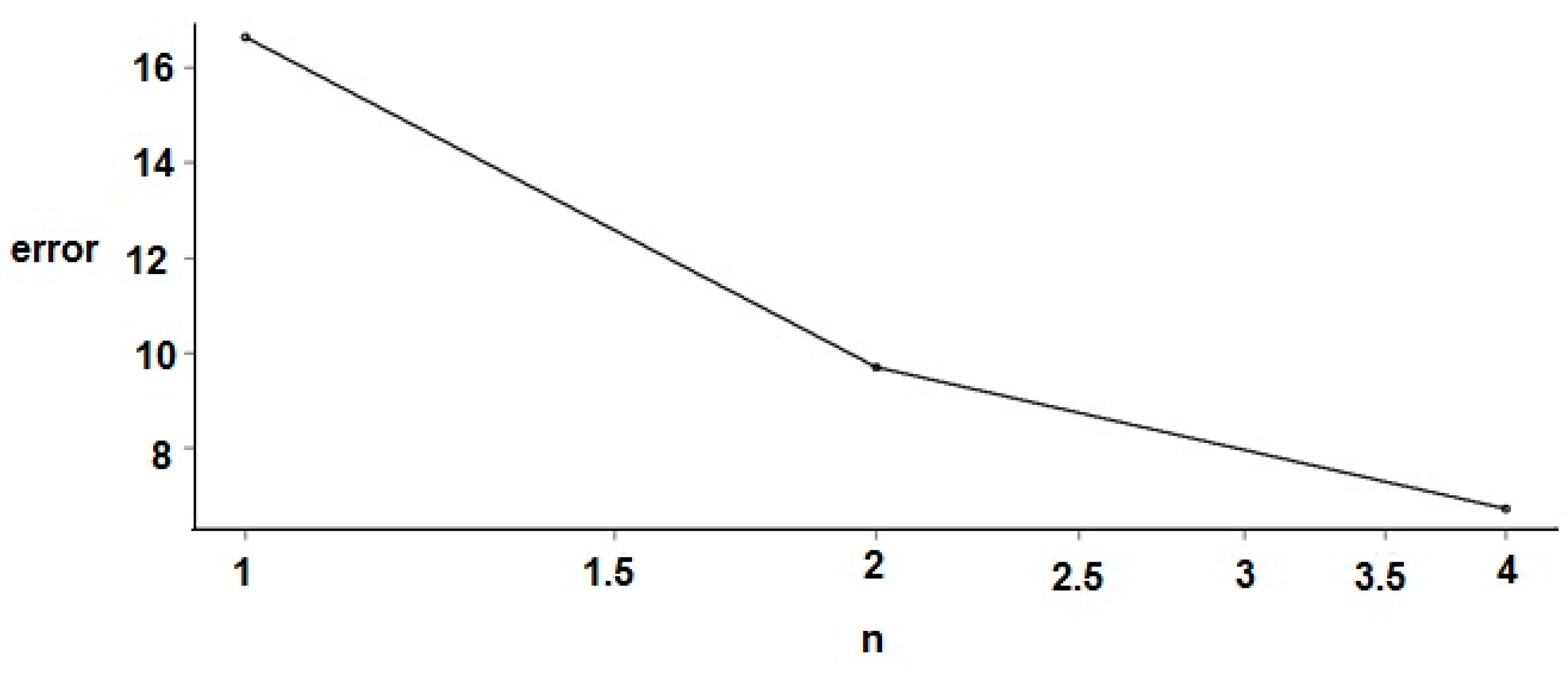

3.5. Comparison of Models

3.6. Comparison with Other Adsorbents

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.H.; Huang, Y.H.; Wen, C.C.; Wang, Y.H.; Chen, W.L.; Chen, L.C.; Tsay, H.J. Movement disorder and neuromuscular change in Zebrafish embryos after exposure to caffeine. Neurotoxicol. Teratol. 2008, 30, 440–447. [Google Scholar] [CrossRef] [PubMed]

- Pollack, A.Z.; Louis, G.M.B.; Sundaram, R.; Lum, K.J. Caffeine consumption and miscarriage: A prospective cohort study. Fertil. Steril. 2010, 93, 304–306. [Google Scholar] [CrossRef]

- Glassmeyer, S.T.; Furlong, E.T.; Kolpin, D.W.; Cahill, J.D.; Zaugg, S.D.; Werner, S.L.; Meyer, M.T.; Kryak, D.D. Transport of chemical and microbial compounds from known wastewater discharges: Potential for use as indicators of human fecal contamination. Environ. Sci. Technol. 2005, 39, 5157–5169. [Google Scholar] [CrossRef]

- Dafouz, R.; Caceres, N.; Rodriguez-Gil, J.L.; Mastroianni, N.; de Alda, M.L.; Barcelo, D.; de Miguel, A.G.; Valcárcel, Y. Does the presence of caffeine in the marine environment represent an environmental risk? A regional and global study. Sci. Total Environ. 2018, 615, 632–642. [Google Scholar] [CrossRef]

- Ghecham, F.Z.; Guergazi, S.; Achour, S. Removal of caffeine by coagulation-flocculation with aluminum sulfate and effect of metal salts. LARHYSS J. 2018, 34, 115–126. [Google Scholar]

- Muthukumar, H.; Shanmugam, M.K.; Dash, S.S.; Gummadi, S.N. Comparison of Biological and Physicochemical Techniques for Treatment of Coffee Wastewater—A Comprehensive Review. In Biological Treatment of Industrial Wastewater; Shah, M.P., Ed.; Royal Society of Chemistry: London, UK, 2021; pp. 391–409. [Google Scholar]

- Jamil, S.; Loganathan, P.; Kandasamy, J.; Listowski, A.; McDonald, J.A.; Khan, S.J.; Vigneswaran, S. Removal of organic matter from wastewater reverse osmosis concentrate using granular activated carbon and anion exchange resin adsorbent columns in sequence. Chemosphere 2020, 261, 127549. [Google Scholar] [CrossRef] [PubMed]

- Raj, R.; Tripathi, A.; Das, S.; Ghangrekar, M.M. Removal of caffeine from wastewater using electrochemical advanced oxidation process: A mini review. CSCEE 2021, 4, 100129. [Google Scholar] [CrossRef]

- Bahrami, M.; Amiri, M.J.; Koochaki, S. Removal of caffeine from aqueous solution using multi-wall carbon nanotubes: Kinetic, isotherm, and thermodynamics studies. Pollution 2017, 3, 539–552. [Google Scholar]

- Bahrami, M.; Amiri, M.J.; Mahmoudi, M.R.; Koochaki, S. Modeling caffeine adsorption by multi-walled carbon nanotubes using multiple polynomial regression with interaction effects. J. Water Health 2017, 15, 526–535. [Google Scholar] [CrossRef]

- Rossi, M.M.; Matturro, B.; Amanat, N.; Rossetti, S.; Petrangeli Papini, M. Coupled Adsorption and Biodegradation of Trichloroethylene on Biochar from Pine Wood Wastes: A Combined Approach for a Sustainable Bioremediation Strategy. Microorganisms 2022, 10, 101. [Google Scholar] [CrossRef]

- Chwastowski, J.; Staroń, P.; Pięta, E.; Paluszkiewicz, C. Bioremediation of Crystal Violet by Organic Matter and Assessment of Antimicrobial Properties of the Obtained Product. Sustainability 2023, 15, 67. [Google Scholar] [CrossRef]

- Li, L.; Zou, J.; Han, Y.; Liao, Z.; Lu, P.; Nezamzadeh-Ejhieh, A.; Liu, J.; Peng, Y. Recent advances in Al(iii)/In(iii)-based MOFs for the detection of pollutants. New J. Chem. 2022, 46, 19577–19592. [Google Scholar] [CrossRef]

- Amiri, M.J.; Bahrami, M.; Beigzadeh, B.; Gil, A. A response surface methodology for optimization of 2, 4-dichlorophenoxyacetic acid removal from synthetic and drainage water: A comparative study. Environ. Sci. Pollut. Res. 2018, 25, 34277–34293. [Google Scholar] [CrossRef]

- Zheng, M.; Chen, J.; Zhang, L.; Cheng, Y.; Lu, C.; Liu, Y.; Singh, A.; Trivedi, M.; Kumar, A.; Liu, J. Metal organic frameworks as efficient adsorbents for drugs from wastewater. Mater. Today Commun. 2022, 31, 103514. [Google Scholar] [CrossRef]

- Pan, Y.; Rao, C.; Tan, X.; Ling, Y.; Singh, A.; Kumar, A.; Li, B.; Liu, J. Cobalt-seamed C-methylpyrogallol[4]arene nanocapsules-derived magnetic carbon cubes as advanced adsorbent toward drug contaminant removal. Chem. Eng. J. 2022, 433, 133857. [Google Scholar] [CrossRef]

- Zhong, Y.; Chen, C.; Liu, S.; Lu, C.; Liu, D.; Pan, Y.; Sakiyama, H.; Muddassir, M.; Liu, J. A new magnetic adsorbent of eggshell-zeolitic imidazolate framework for highly efficient removal of norfloxacin. Dalton Trans. 2021, 50, 18016–18026. [Google Scholar] [CrossRef] [PubMed]

- Menya, E.; Olupot, P.W.; Storz, H.; Lubwama, M.; Kiros, Y. Synthesis and evaluation of activated carbon from rice husks for removal of humic acid from water. Biomass Convers. Biorefin. 2022, 12, 3229–3248. [Google Scholar] [CrossRef]

- de Souza, C.C.; de Souza, L.Z.M.; Yılmaz, M.; de Oliveira, M.A.; da Silva Bezerra, A.C.; da Silva, E.F.; Machado, A.R.T. Activated carbon of Coriandrum sativum for adsorption of methylene blue: Equilibrium and kinetic modeling. Clean. Mater. 2022, 3, 100052. [Google Scholar] [CrossRef]

- Jjagwe, J.; Olupot, P.W.; Menya, E.; Kalibbala, H.M. Synthesis and application of Granular activated carbon from biomass waste materials for water treatment: A review. J. Bioresour. Bioprod. 2021, 6, 292–322. [Google Scholar] [CrossRef]

- Ricciardi, P.; Cillari, G.; Carnevale Miino, M.; Collivignarelli, M.C. Valorization of agro-industry residues in the building and environmental sector: A review. Waste Manag. Res. 2020, 38, 487–513. [Google Scholar] [CrossRef]

- Bushra, R.; Mohamad, S.; Alias, Y.; Jin, Y.; Ahmad, M. Current approaches and methodologies to explore the perceptive adsorption mechanism of dyes on low-cost agricultural waste: A review. Microporous Mesoporous Mater. 2021, 319, 111040. [Google Scholar] [CrossRef]

- Hidayat, N.; Suhartini, S.; Arinda, T.; Elviliana, E.; Melville, L. Literature review on ability of agricultural crop residues and agro-in-dustrial waste for treatment of wastewater. IJROWA 2022, 11, 553–585. [Google Scholar]

- Bahrami, M.; Amiri, M.J. Nitrate removal from contaminated waters using modified rice husk ash by Hexadecyltrimethylammonium bromide surfactant. React. Kinet. Mech. Catal. 2022, 135, 459–478. [Google Scholar] [CrossRef]

- Shukla, N.; Sahoo, D.; Remya, N. Biochar from microwave pyrolysis of rice husk for tertiary wastewater treatment and soil nourishment. J. Clean. Prod. 2019, 235, 1073–1079. [Google Scholar] [CrossRef]

- Ghosh, G.C.; Samina, Z.; Chakraborty, T.K. Adsorptive removal of Cr (VI) from aqueous solution using rice husk and rice husk ash. Desalin. Water Treat. 2018, 130, 151–160. [Google Scholar] [CrossRef]

- Scapin, E.; Maciel, G.P.S.; Polidoro, A.S.; Lazzari, E.; Jacques, R. Activated carbon from rice husk biochar with high surface area. Biointerface Res. Appl. Chem. 2020, 11, 10265–10277. [Google Scholar]

- Danish, M.; Birnbach, J.; Ibrahim, M.M.; Hashim, R.; Majeed, S.; Tay, G.S.; Sapawe, N. Optimization study of caffeine adsorption onto large surface area wood activated carbon through central composite design approach. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100594. [Google Scholar] [CrossRef]

- Elewa, A.M.; Amer, A.A.; Attallah, M.F.; Gad, H.A.; Al-Ahmed, Z.A.M.; Ahmed, I.A. Chemically Activated Carbon Based on Biomass for Adsorption of Fe (III) and Mn (II) Ions from Aqueous Solution. Materials 2023, 16, 1251. [Google Scholar] [CrossRef] [PubMed]

- Amiri, M.J.; Roohi, R.; Gil, A. Numerical simulation of Cd(II) removal by ostrich bone ash supported nanoscale zero-valent iron in a fixed-bed column system: Utilization of unsteady advection-dispersion-adsorption equation. J. Water Process Eng. 2018, 25, 1–14. [Google Scholar] [CrossRef]

- Amiri, M.J.; Abedi-Koupai, J.; Jalali, S.M.J.; Mousavi, S.F. Modeling of fixed-bed column system of Hg (II) ions on ostrich bone ash/nZVI composite by artificial neural network. J. Environ. Eng. ASCE 2017, 143, 04017061. [Google Scholar] [CrossRef]

- Beigzadeh, B.; Bahrami, M.; Amiri, M.J.; Mahmoudi, M.R. A new approach in adsorption modeling using random forest regression, Bayesian multiple linear regression, and multiple linear regression: 2, 4-D adsorption by a green adsorbent. Water Sci. Technol. 2020, 82, 1586–1602. [Google Scholar] [CrossRef]

- Shoba, G.; Shobha, G. Water Quality prediction using data mining techniques: A survey. Int. J. Eng. Comput. Sci. 2017, 3, 6299–6306. [Google Scholar]

- Soleimanpour, S.M.; Mesbah, S.H.; Hedayati, B. Application of CART decision tree data mining to determine the most effective drinking water quality factors (case study: Kazeroon plain, Fars province). Iran. J. Health Environ. 2018, 11, 1–14. [Google Scholar]

- Bedoui, A.; Lazar, N.A. Bayesian empirical likelihood for ridge and lasso regressions. Comput. Stat. Data Anal. 2020, 145, 106917. [Google Scholar] [CrossRef]

- Loh, W.Y. Classification and regression trees. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2011, 1, 14–23. [Google Scholar] [CrossRef]

- Gordon, L. Using classification and regression trees (CART) in SAS® enterprise miner TM for applications in public health. Public Health 2013, 089, 1–8. [Google Scholar]

- Sharma, H.; Kumar, S. A survey on decision tree algorithms of classification in data mining. Int. J. Sci. Res. 2016, 5, 2094–2097. [Google Scholar]

- Rostamian, R.; Heidarpour, M.; Mousavi, S.F.; Afyuni, M. Removal of calcium and magnesium by activated carbons produced from agricultural wastes. Adv. Environ. Biol. 2014, 8, 202–208. [Google Scholar]

- Couto, O.M., Jr.; Matos, I.; da Fonseca, I.M.; Arroyo, P.A.; da Silva, E.A.; de Barros, M.A.S.D. Effect of solution pH and influence of water hardness on caffeine adsorption onto activated carbons. Can. J. Chem. Eng. 2015, 93, 68–77. [Google Scholar] [CrossRef]

- Mestre, A.S.; Bexiga, A.S.; Proença, M.; Andrade, M.; Pinto, M.L.; Matos, I.; Fonseca, I.M.; Carvalho, A.P. Activated carbons from sisal waste by chemical activation with K2CO3: Kinetics of paracetamol and ibuprofen removal from aqueous solution. Bioresour. Technol. 2011, 102, 8253–8260. [Google Scholar] [CrossRef]

- Moreno-Castilla, C. Adsorption of organic molecules from aqueous solutions on carbon materials. Carbon 2004, 42, 83–94. [Google Scholar] [CrossRef]

- Alghamdi, A.A.; Al-Odayni, A.B.; Saeed, W.S.; Al-Kahtani, A.; Alharthi, F.A.; Aouak, T. Efficient adsorption of lead (II) from aqueous phase solutions using polypyrrole-based activated carbon. Materials 2019, 12, 2020. [Google Scholar] [CrossRef] [PubMed]

- Kuang, Y.; Zhang, X.; Zhou, S. Adsorption of methylene blue in water onto activated carbon by surfactant modification. Water 2020, 12, 587. [Google Scholar] [CrossRef]

- Girish, C.R.; Murty, V.R. Mass transfer studies on adsorption of phenol from wastewater using Lantana camara, forest waste. Int. J. Chem. Eng. 2016, 2016, 5809505. [Google Scholar] [CrossRef]

- Oliveira, E.N.; Meneses, A.T.; de Melo, S.F.; Dias, F.M.R.; Perazzini, M.T.B.; Perazzini, H.; Meili, L.; Soletti, J.I.; Carvalho, S.H.V.; Bispo, M.D. Highly effective adsorption of caffeine by a novel activated carbon prepared from coconut leaf. Environ. Sci. Pollut. Res. 2022, 29, 50661–50674. [Google Scholar] [CrossRef]

- Correa-Navarro, Y.M.; Giraldo, L.; Moreno-Piraján, J.C. Dataset for effect of pH on caffeine and diclofenac adsorption from aqueous solution onto fique bagasse biochars. Data Brief 2019, 25, 104111. [Google Scholar] [CrossRef]

- Carabineiro, S.A.C.; Thavorn-Amornsri, T.; Pereira, M.F.R.; Figueiredo, J.L. Adsorption of ciprofloxacin on surface-modified carbon materials. Water Res. 2011, 45, 4583–4591. [Google Scholar] [CrossRef]

- Sotelo, J.L.; Ovejero, G.; Rodríguez, A.; Álvarez, S.; García, J. Study of natural clay adsorbent sepiolite for the removal of caffeine from aqueous solutions: Batch and fixed-bed column operation. Water Air Soil Pollut. 2013, 224, 1466. [Google Scholar] [CrossRef]

| Model | Equation | Parameter and Dimension |

|---|---|---|

| Kinetic models | ||

| PFO | Kf (1/min) qe (mg/g) | |

| PSO | Ks (mg/g min) qe (mg/g) | |

| Elovich | α (mg g−1 min−1) β (g mg−1) | |

| FP | a (mg g−1) | |

| Isotherm models | b (h−1) | |

| Langmuir | qm (mg/g) b (L/mg) | |

| Freundlich | KF (mg/g)(mg/L)−n n: model exponent (–) | |

| R-P | kR (L g−1) α (L mg−1)β β (-) |

| Model | Parameters | R2 | RMSE |

|---|---|---|---|

| Kinetic models | |||

| PFO | Kf = 0.023 1/min qe = 11.77 mg/g | 99.41 | 0.63 |

| PSO | Ks = 0.002 mg/g min qe = 13.58 mg/g | 99.16 | 0.76 |

| Elovich | α = 0.75 mg g−1 min−1 β = 0.34 g mg−1 | 98.45 | 1.02 |

| FP | a = 2.06 mg g−1 b = 0.32 h−1 | 97.01 | 1.42 |

| Isotherm models | |||

| Langmuir | qm = 239.67 mg/g b = 0.002 L/mg | 99.68 | 3.31 |

| Freundlich | KF = 0.76 (mg/g)(mg/L)−n n = 1.11 | 99.74 | 0.96 |

| R-P | kR = 0.71 L g−1 α = 0.08 (L mg−1) β β = 0.38 | 99.72 | 0.99 |

| Factor | %IncMSE | IncNodePurity |

|---|---|---|

| pH | 18.88 | 78.88 |

| time | 29.13 | 168.54 |

| C0 | 30.45 | 306.22 |

| Dose (Cs) | 10.66 | 92.09 |

| Parameter | I1 | I2 | Mean Rank |

|---|---|---|---|

| C0 | 1 | 1 | 1 |

| time | 2 | 2 | 2 |

| pH | 3 | 4 | 3.5 |

| Dose (Cs) | 4 | 3 | 3.5 |

| P(B! = 0|Y) | Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | |

|---|---|---|---|---|---|---|

| Intercept | 1.0000000 | 1.0000000 | 1.00000 | 1.0000000 | 1.0000000 | 1.0000000 |

| pH | 0.4499508 | 1.0000000 | 0.00000 | 0.0000000 | 1.0000000 | 0.0000000 |

| Time | 0.7578746 | 1.0000000 | 1.00000 | 0.0000000 | 0.0000000 | 0.0000000 |

| C0 | 0.9986494 | 1.0000000 | 1.00000 | 1.0000000 | 1.0000000 | 1.0000000 |

| Cs | 0.9094843 | 1.0000000 | 1.00000 | 1.0000000 | 1.0000000 | 0.0000000 |

| BF | NA | 0.2788726 | 1.00000 | 0.6294309 | 0.1655664 | 0.1153485 |

| PostProbs | NA | 0.3752000 | 0.33630 | 0.1411000 | 0.0557000 | 0.0388000 |

| R2 | NA | 0.6334000 | 0.62280 | 0.5659000 | 0.5764000 | 0.4589000 |

| Dim | NA | 5.0000000 | 4.00000 | 3.0000000 | 4.0000000 | 2.0000000 |

| Logmarg | NA | −94.40509 | −93.12809 | −93.59103 | −94.92647 | −95.28789 |

| Post Mean | Post SD | Post p (B! = 0) | 2.5% | 97.5% | Beta | |

|---|---|---|---|---|---|---|

| Intercept | 9.253 | 0.572 | 1.000 | 8.047 | 10.419 | 9.253 |

| pH | −0.145 | 0.300 | 0.449 | −0.921 | 0.357 | −0.145 |

| time | 0.006 | 0.0049 | 0.757 | −0.0002 | 0.015 | 0.006 |

| C0 | 0.121 | 0.0303 | 0.998 | 0.0596 | 0.185 | 0.121 |

| Cs | 7.526 | 3.805 | 0.909 | 0.000 | 13.672 | 7.526 |

| Estimate | Std. Error | t Value | Pr(>|t|) | |

|---|---|---|---|---|

| Intercept | −2.796 | 3.473 | −0.805 | 0.428 |

| pH | −0.323 | 0.373 | −0.865 | 0.395 |

| t | 0.008 | 0.004 | 2.010 | 0.055 |

| C0 | 0.115 | 0.028 | 4.060 | 0.000 ** |

| Cs | 8.212 | 3.085 | 2.662 | 0.013 * |

| R2 | RMSE | 1:1 Line Coefficient | Variables Rank | |

|---|---|---|---|---|

| CART | Cs > t > C0 > pH | |||

| RFR | 0.9517 | 2.28 | 0.9570 | C0 > t > pH, Cs |

| BMLR | 0.8775 | 13.14 | 2.0162 | C0 > Cs > t > pH |

| MLR | 0.9237 | 3.01 | 1.0064 | C0 > Cs |

| LR | 0.9166 | 3.01 | 0.8968 | |

| RR | 0.9223 | 2.90 | 0.9057 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahrami, M.; Amiri, M.J.; Mahmoudi, M.R.; Zare, A. Statistical and Mathematical Modeling for Predicting Caffeine Removal from Aqueous Media by Rice Husk-Derived Activated Carbon. Sustainability 2023, 15, 7366. https://doi.org/10.3390/su15097366

Bahrami M, Amiri MJ, Mahmoudi MR, Zare A. Statistical and Mathematical Modeling for Predicting Caffeine Removal from Aqueous Media by Rice Husk-Derived Activated Carbon. Sustainability. 2023; 15(9):7366. https://doi.org/10.3390/su15097366

Chicago/Turabian StyleBahrami, Mehdi, Mohammad Javad Amiri, Mohammad Reza Mahmoudi, and Anahita Zare. 2023. "Statistical and Mathematical Modeling for Predicting Caffeine Removal from Aqueous Media by Rice Husk-Derived Activated Carbon" Sustainability 15, no. 9: 7366. https://doi.org/10.3390/su15097366

APA StyleBahrami, M., Amiri, M. J., Mahmoudi, M. R., & Zare, A. (2023). Statistical and Mathematical Modeling for Predicting Caffeine Removal from Aqueous Media by Rice Husk-Derived Activated Carbon. Sustainability, 15(9), 7366. https://doi.org/10.3390/su15097366