Abstract

According to the FAO and WHO, half of the world’s population (nearly eight billion people) is protein deficient. Protein deficiency is the most important nutritional problem in the world. Proteins can be animal- (meat and offal, fish, milk, eggs) or plant- (cereals, legumes, oilseeds) based, microbiologically synthesized (from yeast and a variety of bacteria), and synthetic or artificial (produced after amino acid synthesis). Animal proteins are the most expensive. The systematic incorporation of alternative proteins in the human diet is becoming increasingly urgent as global meat costs rise. Legumes, cereals, seeds, and nuts can all provide protein to the human body. Microalgae are considered to be an excellent source of functional and biologically active nutrients for human nutritional needs. Arthrospira platensis and Chlorella vulgaris are the most popular microalgae on the global market today, both of which are marketed as standalone functional foods containing proteins, vitamins, and minerals. Insects, as a source of dietary protein, differ in protein content from 20 to 75%. Investments in plant-based meat companies exceeded $350 million in 2020. The FAO predicts that the market for edible insects will reach $1.2 billion by 2023. All of these alternative protein sources are becoming more popular in the modern food industry for the production of high-protein foods and dietary supplements. This review aims to be a state-of-the-art study of new and potential sources of dietary proteins.

Keywords:

protein; plants; seaweed; edible insects; essential amino acids; Chlorella; Spirulina; microalgae 1. Introduction

Protein, an essential nutrient, is a biopolymer composed of amino acids linked by peptidic bonds. The term “protein” was first introduced by the Swedish chemist Jöns Jacob Berzelius in 1838. Proteins are involved in various biochemical processes, including catalysis, motricity, coordination of biological processes, hormones, immunity, structure and support of cells, and transport and storage in the body. The body’s requirement for nitrogen and essential amino acids determines the amount of protein required in food [1]. Proteins do not accumulate in human body as a reserve; rather the body excretes them during metabolic process and, notably, the urea cycle. Proteins are constantly decaying and resynthesising in the body, even in a state of dynamic equilibrium. Protein deficiency can cause significant functional disorders. Proteins from food are hydrolyzed in the gastrointestinal tract by proteolytic enzymes into amino acids, which are used to build the body’s proteins. The Centers for Disease Control and Prevention (CDC) defines the human need for protein in grams per kilogram of body weight, and in 2007 published a report “Protein and Amino Acid Requirements in Human Nutrition” (Table 1). In order to obtain the required 14.72 g/kg of essential amino acids, the human body must consume at least three times this amount of protein. For example, 100 g of wheat contains 10.9 g of proteins on a dry matter basis (DMB). From this mass, the body will recover only 4.59 g of essential amino acids, DMB, to repair and maintain muscle tissues, according to the American Dietetic Association and Dietitians of Canada [2]. The Food and Agriculture Organization (FAO) of the United Nations and the CDC reported that half of the world’s population, which is nearly eight billion people, is constantly protein deficient (http://www.fao.org/3/i3253e/i3253e00.htm (accessed on 5 January 2023)). In Russia, according to research [3], there is a decrease in the consumption of complete proteins on a DMB from 80 to 79.8 g/day and in some families no more than 40 g/day, while the consumption of carbohydrates is increasing. In addition, the amount of fat in the diet of Russians significantly exceeds the amount of proteins needed. Such a diet is incompatible with the principles of healthy eating (https://www.gks.ru/bgd/regl/b19_101/Main.htm (accessed on 5 January 2023)).

Table 1.

CDC guidelines for essential amino acids.

Protein deficiency is a major concern in the world. Starvation or low protein intake can cause serious metabolic disorders in the body that cannot be treated with therapeutic methods. The quantitative and qualitative composition of food products in the human diet affects the efficiency of protein metabolism in the body.

However, the growth dynamics of world meat prices, particularly beef, are quite constant. According to The World Bank [4], the price of 1 kg of beef has increased by a ratio of 2.4 in the last 20 years. By the end of 2021, according to analysts, the price was about $4.71/kg, which is $0.9/kg lower than in 2020. Further cost stabilization is anticipated, with an average global price not exceeding $4.8/kg by 2030. It is worth noting that beef has a much higher nutritional value than pork and poultry meat, but it also has a much longer breeding period. Further, pig farming and poultry meat productions are much more likely to be at risk of various diseases, for example, avian flu in Europe, African swine fever in China, etc. The global decline in protein consumption is caused not just by a lack of complete protein, but also by growing protein food prices. As a result, the desire of humanity to extend life expectancy, adherence to the principles of a healthy lifestyle and nutrition, as well as the risks linked to climate change on Earth, make the development of technologies for the creation of alternative protein sources necessary. This review aims to study global trends in the search for promising alternative protein sources.

The scientific novelty of this paper is that for the first time, data on existing protein sources are summarized and systematized, methods for obtaining an alternative protein are described, the composition and properties of plant and animal proteins are compared, and trends in their use are examined. The analysis of scientific publications concerning the problem of protein deficiency, as well as the minimization of the impact of this problem on the health of people around the world in the present and future, served as the foundation for generalization and systematization. For the first time, statistical and research data pertaining to the analysis of producers of various forms of protein as well as the study of various methods to obtain a complete protein were examined; and also for the first time, the authors considered arguments based on leading scientists’ hypotheses about the problem of obtaining proteins and the degree of their assimilation, and formed their own opinion based on the evidence for these hypotheses.

2. General Characteristics of Plant-Based Protein Sources

Proteins can be divided into five categories depending on their origin: animal (meat and offal, fish, milk, eggs), vegetable (cereals, legumes, oilseeds), microalgae, insect, and microbiological (from fungi, yeast, and bacteria). Amino acids are synthesized from plant and animal proteins [6]. The most expensive proteins are those of animal origin (this is due to a long economic cycle, animal diseases, etc.). As meat prices rise around the world, the issue of systematic inclusion of alternative proteins in human diet becomes more pressing. Vegetable proteins are present in the human diet. However, such vegetable proteins are characterized by a deficiency of essential amino acids, an average level of digestibility (about 62–80%), and the presence of antinutrient factors [7,8]. Cereals range in protein content on a DMB from 5 to 25%, depending on the type (Table 2). At the same time, amino acid composition determines nutritional value.

Table 2.

Nutritional value of cereals.

Oatmeal is used in pancakes, kissels, oatmeal coffee, and malt for alcohol production in addition to its regular use as a cereal. Barley is traditionally used to produce flour (10.5 g/100 g), fine-ground barley (10.0 g/100 g), and pearl barley (9.3 g/100 g) groats. Corn contains a lot of carbohydrates, 65–70% of starch, up to 8% of fat, and roughly 10% protein content on a DMB. At the same time, corn contains trace amounts of free amino acids such as lysine. Furthermore, corn is practically devoid of calcium (0.05%), but rich in carotene, B, F, A, and E vitamins [12]. Other cereals have the following protein content on a DMB, including essential amino acids (1.56 g/100 g), bulgur (12.29 g/100 g), buckwheat (13.25 g/100 g), semolina (1.3 g/100 g), couscous (12.76 g/100 g) and millet (11.2 g/100 g). Soybeans have the greatest protein content on a DMB among legumes (up to 30 g/100 g); slightly less protein is found in edamame, green soybeans that are harvested before they ripen (about 22 g of protein). Furthermore, soy is the most abundant in almost all types of essential amino acids. Nuts and seeds are also rich in protein (Table 3, Table 4 and Table 5).

Table 3.

Protein content in seeds and nuts.

Table 4.

Crude protein and essential amino acid content in legumes.

There is no single acknowledged leader-source of protein at this time. This is because any product from which the body may receive protein has both advantages and disadvantages. For example, grains of bread and cereals contain many carbohydrates but at the same time contain a small amount of protein, which necessitates high costs for the production of feed [19]. At the same time, corn contains a small amount of amino acids such as lysine, threonine, aspartic acid, glutamic acid, and arginine. In addition, corn contains almost no calcium (0.05%). Corn is rich in carotene but also B and F vitamins. Corn is the most expensive source of protein among vegetable sources. Barley has a high nutritional value. The protein content of barley can vary from 7 to 24% [12]. Organic substances (protein, fat, and carbohydrates) from barley are digested by an average of 90%. Wheat is rich in vitamins B, P (flavonoids), and protein content on a DMB (10–14%), with a low fiber content. Rye is close to barley and wheat in nutritional and enriching properties. It contains 12–14% protein and a significant amount of minerals. However, the amount of swelling mucus contained in rye grains creates certain difficulties in its use, since rye starch can lead to disruption of digestion processes. Legumes contain 20–35% vegetable proteins on a DMB [20]. However, the proteins of some legumes have low digestibility and some species contain trypsin inhibitors, which adversely affect the proteolytic activity of this enzyme during digestion. Some legumes may contain toxic substances or substances that adversely affect the taste of food [21]. Peas are the most prevalent legume. Their advantage lies in the absence of substances that obstruct digestion; peas can be introduced into feed as they are and without additional processing. One kg of peas contains 218 g of proteins on a DMB (20%) and 14.2 g of lysine. The digestibility of organic matter is very high and reaches 87%. However, it contains a small amount of fat. Thus, all cereal legumes contain a significant amount of protein, but at the same time they are low in fat (except soy). The level of protein in soy is higher than in peas and broad beans, as it contains 32% proteins on a DMB, up to 20% fat, 7% fiber, and 3% lysine. Soy is very actively grown in the USA, Brazil, Argentina, and a number of other countries. Soybeans have been known since the 3rd millennium BC. The feasibility of producing algae as a variety of protein sources is clear, although algae are deficient in methionine and cysteine [22], and some microalgae supplements have been shown to be deficient in other amino acids [23]. The benefit of using seaweed as a food and feed product, as well as a source of industrial raw materials, is now undeniable [24]. Technologies for producing algae, storing, selecting productive strains, and so on, have been known for over 30 years. (http://www.fao.org/3/i3253e/i3253e00.htm (accessed on 5 January 2023)). However, industrial cultivation, for example, in open water, is associated, in particular, with the negative effect of the use of fertilizers, especially in shallow lagoons [24]. Thus the ecological balance is disturbed, the oxygen content in the water decreases, and toxic algae species develop [22]. There are also problems associated with diseases and plants that clog plantations of industrially valuable species of algae. Furthermore, algae have a low digestibility, attributable to the presence of a thick cellulose shell that requires preparatory processing and destruction, as well as the toxicity of individual objects [22].

Currently, there are no food traditions in most countries for the consumption of edible insects; however, the use of insect protein is gaining popularity [25]. However, the number of countries where insect proteins are becoming more popular is increasing, and, for example, the market in Europe and Asia will grow significantly in the next 5–10 years. In 2002 the FAO (http://www.fao.org/3/i3253e/i3253e00.htm (accessed on 5 January 2023)) studied the nutritional value of several insect species, including the mealworm (Tenebrio molitor). These flour beetle larvae are offered for cultivation in Western Europe. Representatives of this species are endemic, adapted to a temperate climate, have a short life cycle, and are easily bred on farms [26]. The study revealed that beef contains more fat, a little more protein, and a slightly lower calorie value, as well as glutamic acid, lysine, palmitoleic methionine, palmitic, and stearic acids [8]. However, mealworms contain more isoleucine, leucine, tyrosine, alanine, and linoleic acid. Beef and mealworms have similar levels of copper, sodium, potassium, iron, zinc, and selenium, while mealworms have a higher content of vitamins, with the exception of vitamin B12 [8].

Table 5.

Protein content in plant sources.

Table 5.

Protein content in plant sources.

| Plant Source | Protein Content, g/100 g | Sources |

|---|---|---|

| Spirulina | 57.47 | [27] |

| Starch | 6.90 | [27] |

| Garlic | 6.36 | [28] |

| Brussels sprouts | 3.38 | [27] |

| Broccoli | 2.82 | [29] |

| Potatos | 2.00 | [27] |

| Dried apricots | 3.50 | [27] |

| Raisins | 3.07 | [27] |

| Semi-dried dates | 2.45 | [27] |

| Fruits * | 1.0–2.0 | [28] |

| Chilli | 13.46 | [27] |

| Fenugreek | 23.00 | [28] |

| Poppy seeds | 17.99 | [28] |

| Sweet pepper | 10.39 | [27] |

| Thyme | 9.11 | [27] |

| Oregano | 9.00 | [29] |

| Herbs ** | 3.0–4.0 | [29] |

* Bananas, kiwi, cherries, fresh pineapples, oranges, watermelons, grapes, pears, strawberries, cranberries, tangerines, peaches, plums, blueberries, apples. ** Basil, peppermint, cinnamon, mint, dill.

In terms of protein content (Table 5), Spirulina (dry) ranks first among vegetables, with 57.47 g of protein on a DMB per 100 g. At the same time, they are extremely high in essential amino acids content, similar to that of soy among legumes. So, for example, potato flour (starch) is in second place in this group with a protein content of 6.9 g/100 g on a DMB, whereas other legumes have lower but significant protein content on a DMB, such as garlic, Brussels sprouts, broccoli, and potatoes [30]. Dried apricots (dried fruit) are the most abundant among fruits and berries, followed by raisins and semi-dry dates. Bananas, kiwis, and cherries have the lowest protein content as well as fresh pineapples, oranges, watermelons, grapes, pears, strawberries, cranberries, tangerines, peaches, plums, blueberries, and apples, which contain no more than 1 g/100 g. Avocados, classified as either a vegetable or a fruit by experts, have roughly 2.0 g/100 g of proteins on a DMB. Additionally, proteins can be obtained from spices and plants [31]. Despite their high protein content, it is hard to consume 100 g of chili peppers in one meal. Hence these sources, like some vegetables (for example, garlic), should only be regarded as auxiliary. However, it should still be noted that the protein content in spices is significant for fenugreek seeds, poppy seeds, red pepper, thyme, oregano, basil, peppermint, cinnamon, mint, and dill [32].

According to a study published in Environmental Research Letters [33], rising carbon dioxide levels due to global warming are causing a decrease in plant protein due to an increase in the proportion of starch (for example, in rice and wheat). This dynamic could put 150 million people on the planet at risk of protein insufficiency by 2050. Furthermore, scientists have yet to prove why CO2 in the atmosphere reduces the proportion of nutrients in plants, and thus no concept has been developed to stop the decrease in the level of proteins in plants [34].

3. Dietary Proteins from Algae

The species diversity of microalgae (including Cyanobacteria) is very wide—up to 200,000 species, 35,000 of them being actually identified [35]. It is believed that microalgae are the oldest plants in the world, appearing 3.5 billion years ago [36]. Currently, the most common types of microalgae used in various industries are Bacillariophyta (diatoms), Chlorophyta (green microalgae), Chrysophyta (golden microalgae), and Cyanophyta (Cyanobacteria, also called blue-green microalgae). Despite the large number of existing varieties, microalgae have only lately been employed as food or food components. This is due to the absence of standard and effective growing and processing technologies. There are reports of the use of some microalgae dating back to 2000 years ago in China and 500 years ago in Mexico [37,38]. Until the 19th century, the process was territorially local. In 1844, the German botanist Julius von Flotow first cultivated a microalga called Haematococcus pluvialis Flotow, isolated from a damp granite surface [37,39]. At the beginning of the 20th century, Bito et al. isolated the microalgae Chlorella vulgaris from a lake sample in Delft (Netherlands) and established an axenic (single species) culture from this sample [39,40,41,42]. Microalgae have been studied as a novel source of protein since the middle of the twentieth century, and as a source of energy since the 1970s [38]. Microalgae are considered as excellent sources of functional and biologically-active nutrients to meet human nutritional needs, but whole-cell microalgae contain cell walls, membranes, and polysaccharides that limit their full absorption [43]. In contrast, proteins extracted from microalgae are readily available to digestive enzymes, increasing their digestibility by up to 82% [44]. In addition, many microalgae species vary greatly in chemical composition, including amino acid (AA) composition [43] as well as protein degradability and cell wall construction. The tough cell wall of Chlorella sp. (Chlorophyta) and Nannochloropsis sp. (Ochrophyta) resulted in reduced fermentability than other strains in the study on biogas production [39]. Arthrospira platensis (Spirulina) and Chlorella vulgaris (Chlorella) are the most prevalent microalgae on the market today, both of which are marketed as functional foods and contain numerous vitamins and minerals. Marine microalgae proteins have a well-balanced amino acid profile, in which the AA content of some species, such as Dunaliella salina and Nannochloropsis salina, reached 48–51%, which is higher than those of freshwater species, i.e., Chlorella and Spirulina (44.4% and 43.8%) [45]. Chlorella and Spirulina are the algae most often consumed by humans around the world. Chlorella is thought to be beneficial in the prevention, treatment, or relief of common diseases or acute illnesses such as Alzheimer’s, cancer, and others [46]. Barrow and Shahidi [47] conducted a study in the 1940s in which 80 people with leprosy in Venezuela were fed with a Chlorella soup. Patients who ate such a soup reported that their condition had improved and their weight had returned to normal levels. Sathasivam et al. [48] have shown that Chlorella has hepatoprotective and hypocholesterolemic properties in malnutrition and ethionine intoxication, as well as the ability to lower blood sugar levels and increase hemoglobin levels. Furthermore, Chlorella is widely used in farm animal nutrition. Currently, there are more than 70 industrial firms producing about 2000 tons of Chlorella products per year [49]. The most significant producer of Chlorella in the world is located in Taiwan, «Taiwan Chlorella» (about 400 tons of the product per year). Superfood Spirulina (Spirulina sp.) belongs to a blue-green photoautotrophic genus of Cyanobacteria. Its protein content on a DMB reaches 70% of dry weight [50]. In addition, it contains a significant amount of vitamins A, B1, B2, and B12, essential fatty acids, and beneficial pigments such as xanthophyll and carotenoids [51]. A spoonful (7 g) of dried Spirulina biomass contains almost 4 g of proteins on a DMB, 1 g of fat, including PUFAs such as omega-3 and omega-6 fatty acids, and 11%, 15%, and 4% of the required daily allowance (RDA) of vitamin B1, B2, and B3, respectively. It also accounts for 21% and 11% of the RDA corresponding to copper and iron, respectively. In addition, the content of other minerals such as magnesium, manganese, and potassium is sometimes reported. Huang et al. [52] have confirmed that Spirulina can lower blood cholesterol and triglycerides, blood pressure, and helps control blood sugar levels. The WHO recommends adding Spirulina to the diet of NASA astronauts [53]. Researchers [54] have shown that Spirulina contains 67 times more protein than tofu, 1.8 times more calcium than milk, 51 times more iron than spinach, and 31 times more carotene than carrots. Seaweeds and microalgae can be raw materials for the production of dietary proteins. Some of the algae are comparable in protein content to traditional sources such as animal products or soy. For centuries, people living near the sea have used algae for food, particularly in Asian countries. Algae are also used in the modern food industry to produce a variety of products, such as cheese, sausage, pizza, and so on. In Russia, the use of Chlorella, Scenedesmus, and Spirulina species is widespread in the production of animal feed [55]. The main advantage of using algae as a protein source is their high biomass accumulation compared to agricultural plants (up to 70 tons of dry biomass of microalgae per year can be obtained from 1 ha of water surface, compared to 3–4 tons, 6 tons, and 10 tons for wheat, soybeans, and corn, respectively) [56,57,58]. Protein content on a DMB in Spirulina dry biomass can reach up to 65%, while Chlorella and Scenedesmus have lower contents, between 45 and 55%. With the exception of methionine, algae proteins are perfectly balanced in terms of AA, saturated fatty acids, and provitamin A. In general, the content of essential AA in algae have the following values (g per 100 g of proteins on a DMB): valine 5–7, leucine 6–10, isoleucine 4–7, threonine 3–6, methionine 1.5–2.5, lysine 5–10, phenylalanine 3–5, and tryptophan up to 2 [59]. In addition to proteins, microalgae contain a variety of valuable health-promoting compounds such as carbohydrates, polyunsaturated fatty acids, essential minerals, and vitamins, all of which can boost the nutritional value of foods [60,61,62,63].

Depending on the type of algae, the total amount of protein in the biomass can range from 30% to 70%. Algae cell walls often degrade, releasing proteins, amino acids, and other components. Some algae are known to have soluble proteins in the cytoplasm [64]. Furthermore, chloroplast-bearing algae contain soluble proteins, central pyrenoids, and phytopyroproteins, and some algae, such as Arthrospira plantesis, have thylakoids surrounding the outer cytoplasm that are associated with phycobilisomes [65,66].

There has recently been a surge in research into the processing of microalgae and their use as a protein source [67]. Waghmare et al. [68] proposed a new method for isolating protein from A. plantesis platelets that relied on the interaction of three variables: pressure, temperature, and ultrasound. Using the method developed by the authors increased the protein yield by 229% compared to conventional ultrasound. It is believed that the combined effect of pressure, temperature, and ultrasound destroys cells better and improves mass transfer processes compared to using only ultrasound. Acoustic cavitation affected A. platensis filaments through various mechanisms such as fragmentation, sonoporation, and destruction. These phenomena contributed to a more efficient extraction of proteins from A. platensis. The influence of the concentration of nitrates in the nutrient medium on the aggregation of virion proteins in chlorella was also studied. Under optimized cultivation conditions, the authors achieved a protein content of 44.3% [69].

Many methods for concentrating and isolating proteins from algae are difficult to scale. The three-step separation method is of interest to many researchers because it allows rapid, easy, and scalable enrichment, isolation, and inactivation of proteins from crude samples. The authors of [70] studied the effect of various parameters on the three-phase separation method in optimizing the process of protein isolation from Chlorella pyrenoidosa. In addition, sonication of Chlorella vulgaris microalgae proteins by three-phase separation has been proposed. As a result of additional sonication, the authors achieved a short-term increase in protein content. Three-phase ultrasonic separation is considered to be a more efficient method for isolating biomolecules from microalgae [71].

Seaweeds and microalgae are considered important sources of protein. Some seaweeds and microalgae are known to contain proteins similar to traditional protein sources such as meat, eggs, soybeans, and milk [69]. The use of algae for protein production has a number of advantages over the use of traditional high-protein crops in terms of productivity and nutritional value: seaweed and microalgae have a higher protein content per unit area (2.5–7.5 and 4–15 t/ha/year, respectively) [70]. Land-based agriculture already consumes approximately 75% of the world’s fresh water supply, with animal protein production requiring 100 times the amount of water as plant protein production [71]. Furthermore, algae are subject to significant oxidative and free radical stress as a result of unfavorable environmental conditions and photosynthetic life [68]. This results in the formation of natural defense systems such as pigments (carotenes, chlorophylls, phycobiliproteins, etc.) and polyphenols (catechins, flavanols, phlorotannins, etc.) that provide health benefits when consumed [51].

Protein is an important nutrient in the diet of athletes for repairing and building muscle tissue damaged during exercise, and 1.2–1.7 g of protein per kilogram of body weight is recommended [68]. Algae, which contains all of the essential amino acids, can be a valuable source of protein for people in need, particularly athletes, vegetarians, and people who are allergic to egg and whey proteins [70]. Several businesses have been established to produce protein and lipid-rich algae products [71].

Algae protein content (Table 6) makes it suitable for use as pet food and aquaculture animal feed, etc. It is estimated that 30% of global algae production is used as animal feed, with 50% of spirulina, chlorella, and seaweed biomass, including kelp, being used as a feed additive due to its high nutritional value [69]. It can be included as a source of protein in the diet of poultry, pigs, cattle, sheep, and rabbits. The majority of research on the inclusion of algae in animal feed has been conducted in the poultry industry, with the prospect of increased commercialization [70].

Table 6.

Crude protein content in different types of microalgae.

4. Dietary Proteins from Insects and Other Sources

The edible insect market is one of the fastest growing food protein markets in the twenty-first century. The FAO of the United Nations announced that the market for edible insects was estimated at $400 million in 2018 and will reach $1 billion in 2023 [72]. According to the FAO (http://www.fao.org/3/i3253e/i3253e00.htm (accessed on 5 January 2023)), the protein contents per 100 g of dry weight range from 10 to 17 g (Bombyx mori), from 14 to 18 g (Locusta migratoria, Acridium melanorhodon, Ruspolia Differentens), from 7 to 36 g (Rhynchophorus palmarum, R. phoenicis, Callipogon barbatus), from 14 to 25 g (Tenebrio molitor), from 8 to 25 g (adults crickets), from 13 to 28 g (termites, Ruspolia Differentens) and from 35 to 48 g (Sphenarium purpurascens). Eating insects is frowned upon in many countries, despite the fact that their nutritional value is comparable to traditional meat products [61,62]. In the regions where insects have traditionally been used for food, this is due to custom rather than hunger [72]. Insects can be eaten whole, but they can also be processed into an unrecognizable form (ground into powder form), making it easier to enter markets in countries where insects are considered unfit for human consumption. Lipids derived from insects, products of enzymatic proteolysis of insects, blanched, pasteurized, and sterilized insects, and insects exposed to low-temperature treatments (cooling and freezing), dehydration, and fermentation are all used in the food industry [73]. For example, the red dye carmine (E120), which is now used in yogurt, is an extract of a female cochineal insect [74]. In terms of nutrition, insects have a significant protein content on a DMB ranging from 20 to 75%. Their fat content is from 8 to 50% [25]. According to the WHO, edible insects are highly valuable for their amino acids (phenylalanine, tyrosine, tryptophan, lysine, and threonine) [75]. Insects are consumed at different life stages such as eggs, larvae, pupae, or adults. The main species consumed in order of importance are: beetles (Coleoptera), caterpillars (Lepidoptera), ants, bees, and wasps (Hymenoptera), grasshoppers (Isoptera), locusts (Orthoptera), aphids and grasshoppers (Hymenoptera), termites (Isoptera), flies (Diptera), and some others [73]. Caterpillars, beetles, and Diptera (including flies) are commonly consumed in the larval stage while locusts, bees and wasps, aphids and grasshoppers, and termites are mostly consumed at the adult stage. Oonincx et al. [75] compared five species of insects that are industrially produced in the Netherlands: Pachnoda marginata (in the larval stage), Tenebrio molitor, Blaptica dubia (in the adult stage), Acheta domesticus, and Locusta migratoria [76].

All insects were frozen using liquid nitrogen, ground in a blender, and freeze dried [76]. After that, the protein content in the raw materials was estimated with the Dumas method. Characteristics of the composition of edible insects of some species are presented in Table 7. The measured protein content on a DMB of the five insect species may be relatively higher than their real protein content, since the amount of nitrogen is also bound in the exoskeletons as chitin. The measured protein content on a DMB of the insect species tested (about 20%) in this study is comparable to that of beef (18.4%), chicken (22.0%), and fish (18.3%) [25]. Moreover, the measured insect protein content on a DMB was higher than that of lamb (15.4%), pork (14.6%), eggs (13%), and milk (3.5%), but lower than soy (36.5%) [77]. Studies of the nutritional value of edible insects have been conducted for a long time. In 1997, Skotnicka et al. conducted a study of 78 edible insect species representing twenty-three families from the Mexican state of Oaxaca [78]. The study included Diptera, Orthoptera, Hemiptera, Homoptera, Lepidoptera, Coleoptera, and Hymenoptera. Prior to this study, only 45 species of insects were considered as edible [79]. The highest percentage of protein (82%) was found in wasps (Polybia C.C.). High protein content on a DMB (more than 60%) was noted in grasshoppers and wasps of the genus Brachygastra and Cicada (Proarna sp.). Overall, half of the species analyzed (59) contained more than 50% protein. It should be noted that the digestibility of insect proteins is high and ranges from 76% to 98%. Growing edible insects for human consumption has several advantages. In terms of feeding efficiency, farming insects is nearly four times more efficient than pigs and more than twelve times more efficient than cattle (compared to the house cricket, Acheta domesticus) [74]. Farming edible insects for protein has a lower environmental impact than raising cattle due to lower greenhouse gas production and NH3 emissions [74]. Finally, feed for insects can be produced from a wider range of plants [63]. Although entomologists and zoologists have studied intact edible insects, there is still very little information on the characteristics and functionality of extracted insect proteins from a food science standpoint. Eating insects is an ancient tradition in Asian countries, and ancient Chinese literature describes many different types of edible insects, as well as methods for collecting and cooking them [80]. The number of technology patents for inventions in cultivating and processing insects has been increasing annually over the past 20 years due to the widespread use of insects in food products [81]. Chinese caterpillar fungus (currently not recommended as a common food for consumption by the China Food and Drug Administration [82]) and moths are used as food in China. Feces excreted by several caterpillars that eat certain types of plants are used to produce tea, which in some parts of the country is considered extremely beneficial [83]. Silkworm larvae and adults (Bombyx mori L. and Antheraea pernyi Guerin-M eneville) used for textile production are also frequently eaten. A well-known edible insect is the bamboo worm in southern China and South Asia [84,85]. Butterfly larvae are less common in China but Shi et al. [86] provide data on their nutritional value. Long-horn beetles, larvae, dung beetles, and water beetles are also eaten in China, as are diving beetles [87,88]. Fifty-nine registered beetle species are used in China as food, feed, or medicine [62]. Mealworms (Tenebrio molitor L.) are widely grown in China for human consumption, although earlier these larvae were usually grown for bird feed [89], cockroaches (P. americana L.), and used as a raw material for some drugs [90,91]. Several species of ants are edible and are also used in traditional Chinese medicine [92]. Scientific studies [93] have confirmed that some insects and their extracts are involved in immune regulation and contain antioxidant compounds. The exact functions of insect chitin and other polysaccharides in human physiology continue to be studied, although some promising results [94] with water-soluble insect polysaccharides indicate benefits for immune regulation and antioxidant and antitumor functions. It is crucial to remember that insects, as well as food products derived from them, can cause severe allergic reactions. As a result, despite the growing scientific importance of employing edible insects for food, including for their valuable sources of protein, much more research is required in this area. In Asian countries, where insects are consumed at a much higher rate than anywhere else on the planet, 92% of insects are collected from natural habitats. Depending on the insect species, management with varied degrees of rigor and regulatory restrictions are required. A study by van Huis and Oonincx [62] proposed a general classification of insects found in wildlife: (1) insects with high flight and migration activity, which are pests for agricultural crops and forests, as well as capable of carrying microbes pathogenic to humans (their breeding should be strictly controlled); (2) insects that are not characterized by high flight and migration activity, which do not cause serious harm to nature and humans; and (3) safe for humans and the environment. Currently, approximately 92% of edible insects are harvested and collected from the wild around the world [95], including locusts and palm weevils in Thailand [96,97]. Moreover, excessive removal of insects from wildlife can create risks to the biodiversity of their habitats [98]. As a result, it is critical to do research not only on the features of extracting vital nutrients from insects, but also on developing an ethical technique for their production, comparable to that of typical farm animals.

A study [99] was conducted to evaluate the effect of nutritional supplements derived from insects in powder form as a protein source on plasma amino acid profiles, amino acid transport in the intestine, and sensitivity in a piglet model. Groups of piglets received the basal diet (control), control diet plus Tenebrio molitor (TM), control diet plus Musca domestica larvae (MDL), and control diet plus Zophobas morio (ZM). Plasma free amino acid levels were stable, comparable between feeding groups, except that lysine levels were significantly reduced with MDL and ZM supplementation in the first phase (p < 0.05). Research results showed that consumption of the insect-based supplement improved prophase (phase 1) amino acid metabolism by upregulating the mTOR sensing gene and signaling pathway in the intestinal mucosa of piglets by targeting various receptors. This result suggested that insect powder could be a promising source of protein deposition [99].

The nutritional and functional properties of protein in cricket, locust, and silkworm pupae powders were determined in a study [100], specifically the approximate composition of macronutrients, total amino acid composition, protein pH solubility, and SDS-PAGE/densitometry. Cricket pupae powders contained >70 g crude protein/100 g sample powder (dry matter basis) and silkworm pupae powder >50 g crude protein/100 g sample powder (dry matter basis). Insect powders exceed the FAO/WHO/UNU guidelines for eight of the nine essential amino acids for adults. Using pH-solubility precipitation, protein can be efficiently isolated from insects, yielding isolates with high nutritional and functional qualities [100]. In general, all species of edible insects (e.g., T. molitor, A. diaperinus, Z. morio, A. domesticus, B. dubia) have been found to have nutritional value (Table 7).

Table 7.

Composition of edible insects of some species.

Table 7.

Composition of edible insects of some species.

| Insect | Moisture, % | Crude fat, % | Crude Protein *, % (Including Chitin Nitrogen) | Other Components, % (e.g., Carbohydrates, Minerals, and Vitamins) | Sources |

|---|---|---|---|---|---|

| T. molitor | 63.5 ± 1.8 | 9.9 ± 1.0 | 19.1 ± 1.3 | 7.5 ± 2.2 | [101] |

| A. diaperinus | 64.5 ± 1.0 | 8.5 ± 0.2 | 20.6 ± 0.1 | 6.4 ± 1.0 | [102] |

| Z. morio | 59.9 ± 5.4 | 16.0 ± 0.7 | 20.7 ± 0.3 | 3.4 ± 5.5 | [103] |

| A. domesticus | 70.8 ± 2.0 | 3.6 ± 0.4 | 21.5 ± 0.5 | 4.1 ± 2.1 | [77] |

| B. dubia | 67.4 ± 2.1 | 7.7 ± 0.1 | 19.3 ± 0.9 | 5.6 ± 2.3 | [76] |

* DMB. Data presented as a mean ± SD (n = 3).

Microbiologically synthesized proteins are traditionally used in animal nutrition. In Russia, about one million tons of feed microbial products with a protein content on a DMB of up to 60% are produced annually [21]. The main raw materials for the production of microbial protein are paraffins extracted from oil [104].

Another paper [105] presents the results of assessing the effect of the level of feed intake on the efficiency of microbial protein synthesis in the rumen (EMPS), nitrogen excretion (N), and nitrogen balance in twelve 18-month-old Boran bulls (Bos indicus) with an initial average live weight of 183 kg (standard deviation 15.2). The experiment was performed in a full 4 × 4 Latin square design with four dietary regimens tested over four periods. Each period lasted 5 weeks, of which 3 weeks were for adaptation and 2 weeks for sample collection; separated by 2 weeks of refeeding. Bulls were fed at 100%, 80%, 60%, and 40% of their metabolic maintenance energy requirement. For the same grass hay intake, duodenal microbial crude protein flux was 41% higher in bulls fed 100% than in bulls fed 80% (p < 0.001). Cattle fed low-quality plant-based diets have very low EMPS and therefore microbial protein availability reduces the negative effects of low nutrient and energy intake during periods of feed shortage [105].

In bacteria, DNA is packaged into the cell bacterial chromosome during microbiological synthesis. DNA molecules are transcribed into RNA. Transcription is a way to extract information from DNA and create RNA. RNA acts as an intermediary between DNA and proteins, allowing the DNA to remain safely in one part of the microbial cell while the RNA copy takes on more risky activities [106]. The RNA then moves to a part of the microbial cell called the ribosome, the protein-producing factory found in all cells, from humans to bacteria. The ribosome will scan the RNA and add amino acids to the protein that it produces. When the ribosome reaches the end of the RNA, the protein is released. This process is called microbial synthesis. In bacteria, transcription and translation are often linked. When a piece of RNA is created, it immediately enters the ribosome to start producing the real protein [107].

Paprin, a protein derived from yeasts of the cultivated genus Candida, and which used paraffin oil products as carbon substrate, was produced in the Soviet Union in the 1970s [20]. Gaprin, a technology for extracting protein from the bacterial species Methylococcus capsulatus, was also developed [57]. However, in the last century, such production caused significant harm to the environment and was closed in the 1990s. Today in Russia, Biopraktika is the only company (Moscow, Russia, https://biopraktika.ru (accessed on 5 January 2023)) still producing bioproteins from bacteria using methane as carbon substrate and as nitrogen source [104]. Biopraktika’s microbial proteins are typically not purified and obtained from dried yeast using carbohydrates. Organic nitrogen from urea was used as a source of nitrogen [20,108,109]. This type of protein is usually added to the main feed rations of animals. In general, microbial protein can be obtained from natural gas, methanol, and crop waste [19,26,110].

Proteins artificially synthesized (by changing DNA) are only permitted for scientific research in Russia. However, in this group, proteins are considered not as important elements of nutrition for the body, but as substances capable of performing certain specified functions in the cells of a living organism [22].

5. Development of the Alternative Protein Market: Advantages and Disadvantages

According to a Good Food Industry report (https://gfi.org/wp-content/uploads/2021/05/COR-SOTIR-Plant-based-meat-eggs-and-dairy-2021-0504-1.pdf (accessed on 5 January 2023)) on retail sales, new product developments, investment analytics, scientific and technological advances, and consumers of plant-based products (meat, eggs, dairy products), global retail sales of plant-based meat exceeded $4.2 billion in 2020, an increase of nearly 24% compared to 2019 [21]. More than 800 companies around the world produce plant-based products that directly replace animal ones, or have a line of products focused on such products. A record $2.2 billion was invested in manufacturing facilities in 2020 (more than ever in a single year in the history of industry), nearly half of all capital invested in industry since 1980. The number of new unique investors in production spaces has increased by 44% since 2019 [46]. Investments in plant-based meat companies exceeded $350 million in 2020 which is almost six times more than in 2019, and nearly the double of previous total investments in the industry [26]. Firms that produce alternative food items throughout the world range from small start-ups to big multinational food companies and traditional meat producers [12]. The legal framework continues to evolve in industry. For example, in the state of Virginia (United States) in 2020, a court dismissed a lawsuit demanding special labeling of products based on vegetable raw materials, as well as a lawsuit with a ban on the use of “dairy terms” on products from vegetable raw materials. The European Parliament also rejected a proposal in 2020 that would ban all common meat-related terms from plant-based food labels in all 27 countries of the European Union.

The relevance of protein food and its production is determined by the lack of synthesis of a number of protein components in the human body [29]. The lifestyle of most people on the planet, especially in developed countries, dictates new requirements for the composition and nutritional value of the human diet (reducing fat and calories, increasing proteins and fiber). Proteins are one of the most expensive components of human nutrition to produce [21]. Livestock production costs are growing in Russia and throughout the world. Alternative vegetable proteins, even under the assumption that they are equal in composition and nutritional value, as well as the production of meat products of animal origin, are associated with several problems, difficulties and limitations (extensive development of agriculture is no longer acceptable, and intensive development is associated with the risks of soil deterioration) [55]. All these factors make the search for alternatives to meat and vegetable (traditional) protein production relevant. The market for alternative protein meat and dairy products is one of the fastest growing in the world. The production of algae or edible insects requires significantly less investment than the cultivation of farm animals or even protein-rich plants in order to obtain 1 kg of protein [109].

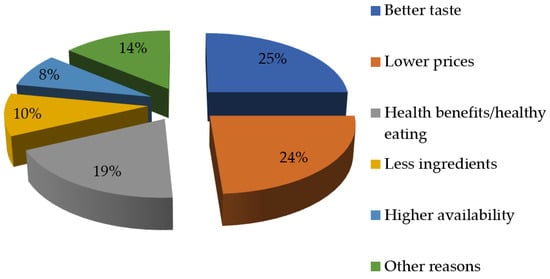

However, in general, the price of artificial meat is not inferior to the price of natural meat (https://gfi.org/wp-content/uploads/2021/05/COR-SOTIR-Plant-based-meat-eggs-and-dairy-2021-0504-1.pdf, accessed on 18 February 2023). In 2020, Intel and UBS conducted surveys among consumers in the United States to find out why people did not like artificially grown meat and dairy products (https://gfi.org/wp-content/uploads/2021/05/COR-SOTIR-Plant-based-meat-eggs-and-dairy-2021-0504-1.pdf, accessed on 8 February 2023). In the results, the “high price of artificial meat” was only ranked 2nd among the reasons (25% of respondents), while 27% noted that they did not like the taste, 20% did not like the texture, 11% noted that in terms of composition it was not a similar substitute for meat, another 11% said that it had too many ingredients, 7% were not sure about the producers, and 4% had never heard of such products. Similar results [20] were shown by polls in Germany and the UK (Figure 1). The market for alternative proteins for the food sector in Russia is still in its early stages. Currently, only one company produces artificial meat [26]. Its turnover is growing, but in general, the volume of activity cannot be compared with the results of even average global producers. Experts note that the companies that can develop production technologies will be successful in the production of alternative proteins in the world market [55]. Additionally, they will need to persuade the public that the alternative protein, which comes in specific textures and taste, is safe for consumption, and that it will be readily available at a reasonable price.

Figure 1.

Consumers in the US, Germany, and the UK: factors that may generate interest in plant-based meats.

The process of replacing animal proteins with plant proteins depends on the structural and processing properties of isolated plant proteins [111]. One study evaluated proteins from plant sources (e.g., peas) obtained by dry (air separation combined with electromagnetic) and wet (isoelectric point precipitation) separations at the process-function-product level. The results showed that there is a significant difference in the purity of isolated plant proteins obtained by dry (72.3 ± 0.7 g/100 g) and wet (89.2 ± 0.5 g/100 g) separations. High performance liquid chromatography, SDS gel electrophoresis, and fluorescence analysis showed that dry separated proteins retained their native structure and confirmed excellent solubility and water absorption, resulting in a porous and soft meat analogue. Although the wet separation resulted in protein denaturation, the content of essential amino acids was closer to the recommended level. Due to the higher purity, wet separated proteins had better emulsifying and foaming properties, and the resulting structure was harder than in dry separated proteins. This study allowed a deeper study of plant proteins obtained by dry and wet separation from peas and their potential use in the development of meat analogues [111].

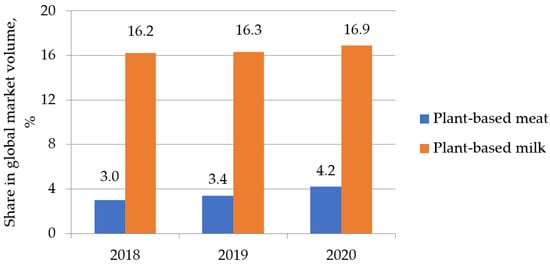

According to the State of the Industry Report [66], the introduction of new brands of plant-based meat and dairy products in the United States is on a steady upward trend (Figure 2).

Figure 2.

Dynamics of the emergence of new brands of plant-based meat and dairy products in the United States, 2018–2020.

Edible insects are currently considered as a potential source of protein in food [112]. The media attention and legitimacy of its use has resulted in a significant increase in entrepreneurial activity regarding the sale of insects around the world. However, the industry still faces many challenges. Which consumer markets will be interested in eating products made from insects is unknown during the commercialization process. Lack of such direction may result in underwhelming business outcomes, lost profits, unfavorable cost effectiveness, and ineffective market strategies. Studies [112] found that there are many reasons why consumers agree to buy edible entomophagy: (a) environmental benefits, (b) cost-effectiveness, (c) social security, (d) health and nutritional benefits, and (e) benefits for gastrointestinal health. These studies, however, fall short of adequately describing which market penetrations boost metrics like sales and profits. This implies that, while the factors influencing consumer purchasing decisions have been identified, the question of who these consumers are and how products are sold to them based on their information consumption and decision-making methods remains unanswered. Consumer market segmentation, defined as the process of identifying similar people based on consumer characteristics in one or more ways, is used to determine product placement and is a common marketing strategy. Typically, four variables are involved in market segmentation. The most common are demographic, geographic, psychological, and behavioral factors. In the edible insect market, segmentation of the market based on consumer value seems appropriate, as consumers of edible insects are aware of the many benefits and risks [113].

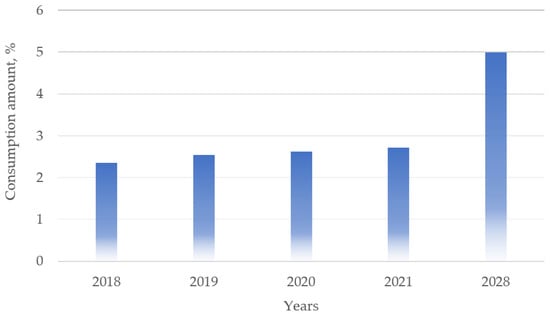

The algae products market is segmented by source (brown, red, green, and blue-green algae); by type of product (protein, alginate, carrageenan, carotenoids, lipids, and other types of products); by application (personal care, food and beverage, nutritional supplements, pharmaceuticals, pet food, and other applications); and by geography (North America, Europe, South America, Asia-Pacific, Middle East, and Africa). Since algae promotes immunity, the post-COVID-19 situation is predicted to lead to a surge in sales of algae supplements. Figure 3 presents data [114] on the increase in the use of algae in various market segments by years, from 2018 to 2028. The main players in the market for the production and sale of algae are Cargill, O-BASF, DSM, ADS, and Accel [114].

Figure 3.

Dynamics of algae consumption (%) in the Asian region 2018 to 2028.

The microalgae market also demonstrates the rising dynamics. The development of the market began in the 1950s in Japan and a little later in Taiwan [104]. It all started with the production of Chlorella. Another plant was established in Mexico in the 1970s, and at the end of the 20th century in India. Currently, China is the industry’s leader, accounting for over 75% of the global market [83]. The share of the Russian market of microalgae producers is currently statistically insignificant. The demand for microalgae is increasing as a result of the exponential demand for healthy nutrition. In 2021 the volume of the world market was $164 million, which is almost 20% more than in 2016 [104]. Many analysts anticipate that by 2050, the market share of microalgae as protein sources will be at least 20% [108,109,110]. Seaweeds are sold fresh, ground, or dried in sealed, airtight packaging. Laminaria is a brown algae species with over 30 subspecies. The Sea of Okhotsk is acknowledged as the best habitat for these algae, and Japan is the undisputed leader in production. It is consumed fresh, dried, pickled, canned, and thermally treated [104]. Porphyra/Pyropia company, based in Tokyo, Japan, is the world’s largest Laminaria producer. Companies processing Nori, which is traditionally used in rolls and sushi, are located in Japan, Korea, and China. Crushed Nori can also be added to noodles or rice [108]. The Japanese company Marutoku nori Co., LTD, Tokyo, Japan, is the largest company involved in the extraction and selling of nori seaweed. Wakame brown seaweed grows on underwater rocks and can reach a length of 2 m. Until the 1990s, wakame were mostly found in the northern waters of Japan, China, and Korea, but they are now also found along the warm coasts of Italy, Spain, the United States, Australia, and Argentina. Wakame can be consumed fresh, dried, and pickled [104]. Hijiki algae has been used in cooking since ancient times and is found in the warm seas of the Pacific Ocean. South Korea is now the leading producer. They are exported only in dried form. The largest exporter is the Korean company Sambuja (Kunsan, South Korea). The largest producers of algae products in Russia are NPKF DEKOS (biologically active additives without ethyl alcohol content); DEL RIOS (dietary supplement without ethyl alcohol, fish oil, biafishenol, seaweed); NPK Tikhookeanskiye tekhnologii (Japanese dry Laminaria, produced using low-temperature technology); Komfort kompleks (Fucus seaweed); BIOLA (biologically active food supplement, brown seaweed extract without alcohol and ozone-depleting substances); and SPK FAUNA (gel-like food product from brown seaweed (https://exportv.ru/zavod/vodorosli-ot-proizvoditelya.html (accessed on 5 January 2023)). Unlike producers of artificial meat, milk, and eggs, as well as microalgae producers, which are often medium or big companies, the insect food industry in Asian countries, where it is most popular, is dominated by family or individual farms that gather insects in the wild [34]. The prices of edible insects vary between rural and urban areas [33]. In Thailand, dealers purchase insects from farmers and sell them as food to wholesalers, who subsequently sell the goods to street vendors and/or stores. As such, the final price can be six times higher. Overall, the FAO estimates the market for edible insects at $400 million per year and forecasts growth to $1.2 billion by 2023 [26]. The major players in the global market are Entomotech (Almeria, Spain), Meertens (Buren, Netherlands), Agriprotein (Cape Town, UK-South Africa), Ynsect (Amiens, France), Proteinsect (Amsterdam, Netherlands), Protix (Bergen op Zoom, Netherlands), Enterra (Toronto, Canada), and Big Cricket Farms (New York, NY, USA) [26].

6. Conclusions

Protein deficiency affects nearly half of the world’s population, making it the most serious nutritional issue on the planet. Proteins can be of animal (meat, cheese, fish, milk, eggs) or vegetable (cereals, legumes, oilseeds) origin, microbial (from yeast and various bacteria), or synthetic or artificial (amino acid synthesis). As the global price of meat rises, it becomes increasingly difficult to incorporate it into the human diet. Microorganisms are considered an excellent source of functional and bioactive nutrients for human nutritional needs. The most popular probiotics on the global market are microalgae metabolites, which are positioned as independent functional products containing vitamins and minerals in amounts ranging from 20% to 75%. Investment in plant-based meat companies surpassed $350 million in 2020, and the edible insect market is expected to reach $1.2 billion by 2023. In the modern food industry, all of these protein sources are becoming more and more popular for use in high-protein foods and supplements.

Author Contributions

Conceived and designed the research: V.D., S.S. and O.B.; analyzed and interpreted the data: O.B., S.I., A.P. and P.M.; contributed reagents, materials, analysis tools, or data: S.S., O.K. and E.K.; writing—review and editing: O.B., S.I. and P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Higher Education of the Russian Federation, project number FZWM-2023-0003 (agreement No. 075-03-2023-002, 13 January 2023).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are included in the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Joint FAO/WHO/UNU. Expert Consultation on Protein and Amino Acid Requirements in Human Nutrition; World Health Organization: Geneva, Switzerland, 2007. Available online: https://apps.who.int/iris/handle/10665/43411 (accessed on 5 January 2023).

- Application of Risk Analysis to Food Standards Issues; Report of the Joint FAO/WHO Expert Consultation: Geneva, Switzerland, 1995; pp. 13–17.

- Food Consumption in Households in 2018. Report of the Federal Statistics Service of Russia; World Health Organization: Geneva, Switzerland, 1995; Available online: https://www.gks.ru/bgd/regl/b19101/Main.htm (accessed on 5 January 2023).

- Baum, J.I.; Kim, I.Y.; Wolfe, R.R. Protein Consumption and the Elderly: What Is the Optimal Level of Intake? Nutrients 2016, 8, 359. [Google Scholar] [CrossRef] [PubMed]

- Centers for Disease Control and Prevention (CDC). The State of Aging and Health in America 2013; Centers for Disease Control and Prevention, Ed.; US Department of Health and Human Services, CDC: Atlanta, GA, USA, 2013.

- Aragão, C.; Gonçalves, A.T.; Costas, B.; Azeredo, R.; Xavier, M.J.; Engrola, S. Alternative Proteins for Fish Diets: Implications beyond Growth. Animals 2022, 12, 1211. [Google Scholar] [CrossRef]

- World Bank Group. Commodity Markets Outlook, October 2020; World Bank: Washington, DC, USA, 2020; Available online: https://openknowledge.worldbank.org/handle/10986/34621 (accessed on 5 January 2023).

- Romnov, D. Nutritional values, what’s going on with world food prices. Gazeta.ru 2021, 224, 1247–1259. [Google Scholar]

- Molfetta, M.; Celano, G.; Minervini, F. Functional, Nutritional, and Sensory Quality of Mixed Flours-Based Breads as Compared to Durum Wheat Semolina-Based Breads. Foods 2021, 10, 1613. [Google Scholar] [CrossRef]

- Previtali, M.A.; Mastromatteo, M.; Conte, A.; De Vita, P.; Ficco, D.B.; Del Nobile, M.A. Optimization of durum wheat bread from a selenium-rich cultivar fortified with bran. J. Food Sci. Technol. 2016, 53, 1319–1327. [Google Scholar] [CrossRef]

- De Angelis, M.; Minervini, F.; Siragusa, S.; Rizzello, C.G.; Gobbetti, M. Wholemeal wheat flours drive the microbiome and functional features of wheat sourdoughs. Int. J. Food Microbiol. 2019, 302, 35–46. [Google Scholar] [CrossRef] [PubMed]

- Zunjare, R.; Muthusamy, V.; Bhat, J.; Mehta, B.; Sharma, D.; Talukder, M.; Chhabra, R.; Katral, A.; Dutta, S.; Chand, G.; et al. Biofortification of Maize for Nutritional Security. In Biofortification of Staple Crops; Kumar., S., Dikshit., H.K., Mishra., G.P., Singh., A., Eds.; Springer: Singapore, 2022; Volume 6. [Google Scholar] [CrossRef]

- Woodruff, M. The Best Seeds and Nuts for Protein. Available online: https://masonfit.com/best-seeds-nuts-for-protein/ (accessed on 5 January 2023).

- Seeds High in Protein: Which Have The Most? Available online: https://vegfaqs.com/seeds-high-in-protein/ (accessed on 5 January 2023).

- Tu, X.H.; Wu, B.F.; Xie, Y.; Xu, S.L.; Wu, Z.Y.; Lv, X.; Wei, F.; Du, L.Q.; Chen, H. A comprehensive study of raw and roasted macadamia nuts: Lipid profile, physicochemical, nutritional, and sensory properties. Food Sci. Nutr. 2021, 9, 1688–1697. [Google Scholar] [CrossRef] [PubMed]

- Margier, M.; Georgé, S.; Hafnaoui, N.; Remond, D.; Nowicki, M.; Du Chaffaut, L.; Amiot, M.-J.; Reboul, E. Nutritional Composition and Bioactive Content of Legumes: Characterization of Pulses Frequently Consumed in France and Effect of the Cooking Method. Nutrients 2018, 10, 1668. [Google Scholar] [CrossRef] [PubMed]

- Aremu, M.; Audu, S.; Gav, B. Comparative Review of Crude Protein and Amino Acids of Leguminous Seeds Grown in Nigeria. Int. J. Mol. Sci. 2017, 3, 88–97. [Google Scholar] [CrossRef]

- Nosworthy, M.G.; Medina, G.; Franczyk, A.J.; Neufeld, J.; Appah, P.; Utioh, A.; Frohlich, P.; House, J.D. Effect of Processing on the In Vitro and In Vivo Protein Quality of Beans (Phaseolus vulgaris and Vicia Faba). Nutrients 2018, 10, 671. [Google Scholar] [CrossRef]

- Poutanen, K.S.; Kårlund, A.O.; Gómez-Gallego, C.; Johansson, D.P.; Scheers, N.M.; Marklinder, I.M.; Eriksen, A.K.; Silventoinen, P.C.; Nordlund, E.; Sozer, N.; et al. Grains—A major source of sustainable protein for health. Nutr. Rev. 2022, 80, 1648–1663. [Google Scholar] [CrossRef] [PubMed]

- Kyle, G. State of the Industry Report. Plant-Based Meat, Eggs, and Dairy. 2020. Available online: https://gfi.org/wp-content/uploads/2021/05/COR-SOTIR-Plant-based-meat-eggs-and-dairy-2021-0504-1.pdf (accessed on 26 December 2022).

- Belik, S.N.; Morgul, E.V.; Kryuchkova, V.V.; Avetisyan, Z.E. Products of microbial synthesis in solving protein deficiency. East. Eur. Sci. J. 2016, 7, 122–129. Available online: https://cyberleninka.ru/article/n/produkty-mikrobnogo-sinteza-v-reshenii-problemy-belkovogo-defitsita (accessed on 5 January 2023). (In Russian).

- Gordalina, M.; Pinheiro, H.M.; Mateus, M.; da Fonseca, M.M.R.; Cesário, M.T. Macroalgae as Protein Sources—A Review on Protein Bioactivity, Extraction, Purification and Characterization. Appl. Sci. 2021, 11, 7969. [Google Scholar] [CrossRef]

- Pliego-Cortés, H.; Wijesekara, I.; Lang, M.; Bourgougnon, N.; Bedoux, G. Current Knowledge and Challenges in Extraction, Characterization and Bioactivity of Seaweed Protein and Seaweed-Derived Proteins. Adv. Bot. Res. 2020, 95, 289–326. [Google Scholar] [CrossRef]

- Faye, B.; Webber, H.; Naab, J.B.; MacCarthy, D.S.; Adam, M.; Ewert, F.; Lamers, J.P.A.; Schleussner, C.-F.; Ruane, A.; Gessner, U.; et al. Impacts of 1.5 versus 2.0 °C on cereal yields in the West African Sudan Savanna. Environ. Res. Lett. 2018, 13, 034014. [Google Scholar] [CrossRef]

- Tang, C.; Yang, D.; Liao, H. Edible insects as a food source: A review. Food Prod. Process. Nutr. 2019, 1, 8. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, M.; Barroso, F.G.; Fabrikov, D.; Sánchez-Muros, M.J. In vitro crude protein digestibility of insects: A review. Insects 2022, 13, 682. [Google Scholar] [CrossRef]

- Alcorta, A.; Porta, A.; Tárrega, A.; Alvarez, M.D.; Vaquero, M.P. Foods for Plant-Based Diets: Challenges and Innovations. Foods 2021, 10, 293. [Google Scholar] [CrossRef]

- Grossmann, L.; Weiss, J. Alternative Protein Sources as Technofunctional Food Ingredients. Food Sci. Technol. 2021, 2021, 12. [Google Scholar] [CrossRef]

- Marinangeli, C.P.F.; House, J.D. Potential impact of the digestible indispensable amino acid score as a measure of protein quality on dietary regulations and health. Nutr. Rev. 2017, 75, 658–667. [Google Scholar] [CrossRef]

- Hosseinkhani, N.; McCauley, J.I.; Ralph, P.J. Key challenges for the commercial expansion of ingredients from algae into human food products. Algal. Res. 2022, 64, 102696. [Google Scholar] [CrossRef]

- Boukid, F.; Rosell, C.M.; Rosene, S.; Bover-Cid, S.; Castellari, M. Non-animal proteins as cutting-edge ingredients to reformulate animal-free foodstuffs: Present status and future perspectives. Crit. Rev. Food Sci. Nutr. 2021, 62, 6390–6420. [Google Scholar] [CrossRef] [PubMed]

- López-Pedrouso, M.; Lorenzo, J.M.; Cantalapiedra, J.; Zapata, C.; Franco, J.M.; Franco, D. Aquaculture and by-products: Challenges and opportunities in the use of alternative protein sources and bioactive compounds, Aquaculture and By-Products: Challenges and Opportunities in the Use of Alternative Protein. Curr. Bioact. Compd. 2020, 92, 127–185. [Google Scholar] [CrossRef]

- Mérillon, J.-M.; Ramawat, K.G. Bioactive Molecules in Food: Reference Series in Phytochemistry; Springer Nature: London, UK, 2019. [Google Scholar] [CrossRef]

- Samtiya, M.; Aluko, R.E.; Dhewa, T. Plant food anti-nutritional factors and their reduction strategies: An overview. Food Prod. Process. Nutr. 2020, 2, 1–4. [Google Scholar] [CrossRef]

- Wolkers, H.; Barbosa, M.; Kleinegris, D.M.M.; Bosma, R.; Wijffels, R.H. Microalgae: The green gold of the future? In Large-Scale Sustainable Cultivation of Microalgae for the Production of Bulk Commodities; Harmsen., P., Ed.; Propress: Wageningen, the Netherlands, 2011; pp. 1–34. [Google Scholar]

- Christaki, E.; Florou-Paneri, P.; Bonos, E. Microalgae: A novel ingredient innutrition. Int. J. Food Sci. Nutr. 2011, 62, 794–799. [Google Scholar] [CrossRef] [PubMed]

- Becker, W. Microalgae in human and animal nutrition. In Handbook of Microalgal Culture; Richmond, A., Hoboken, N.J., Eds.; Blackwell Publishing Ltd.: Oxford, UK, 2004; pp. 312–351. [Google Scholar]

- Spolaore, P.; Joannis-Cassan, C.; Duran, E.; Isambert, A. Commercial applications of microalgae. J. Biosci. Bioeng. 2006, 101, 87–96. [Google Scholar] [CrossRef]

- Grossmann, L.; Hinrichs, J.; Weiss, J. Cultivation and downstream processing of microalgae and cyanobacteria to generate protein-based technofunctional food ingredients. Crit. Rev. Food Sci. Nutr. 2020, 60, 2961–2989. [Google Scholar] [CrossRef]

- Jeurissen, S.M.F.; Buurma-Rethans, E.J.M.; Beukers, M.H.; Jansen-van der Vliet, M.; van Rossum, C.T.M.; Sprong, R.C. Consumption of plant food supplements in the Netherlands. Food Funct. 2018, 9, 179–190. [Google Scholar] [CrossRef]

- van Hunsel, F.P.A.M.; van der Kooi, D.; van de Koppel, S.; Kroes, B.H.; Woerdenbag, H.J. Analysis of Reports on Adverse Drug Reactions Related to Herbal Medicinal Products and Herbal Supplements in the Netherlands Received by the National Pharmacovigilance Centre. Lareb. Drug Saf. 2022, 45, 651–661. [Google Scholar] [CrossRef]

- Bito, T.; Okumura, E.; Fujishima, M.; Watanabe, F. Potential of Chlorella as a Dietary Supplement to Promote Human Health. Nutrients 2020, 12, 2524. [Google Scholar] [CrossRef]

- Tibbetts, S.M.; Patelakis, S.J.; Whitney-Lalonde, C.G.; Garrison, L.L.; Wall, C.L.; MacQuarrie, S.P. Nutrient composition and protein quality of microalgae meals produced from the marine prymnesiophyte Pavlova sp. 459 mass-cultivated in enclosed photobioreactors for potential use in salmonid aquafeeds. J. Appl. Phycol. 2019, 32, 239–318. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, C.; Xu, C. Nutritional evaluation of two marine microalgae as feedstock for aquafeed. Aqua. Res. 2020, 51, 946–956. [Google Scholar] [CrossRef]

- Caporgno, M.P.; Mathys, A. Trends in microalgae incorporation into innovativefood products with potential health benefits. Front. Nutr. 2018, 5, 58. [Google Scholar] [CrossRef]

- Rani, K.; Sandal, N.; Sahoo, P.K. A comprehensive review on chlorella-itscomposition, health benefits, market and regulatory scenario. J. Pharm. Innov. 2018, 7, 584–589. [Google Scholar]

- Barrow, C.J.; Shahidi, F. Marine Nutraceuticals and Functional Foods; CRC Press: Boca Raton, FL, USA, 2007; pp. 27–39. [Google Scholar]

- Sathasivam, R.; Radhakrishnan, R.; Hashem, A.; Abd Allah, E.F. Microalgae metabolites: A rich source for food and medicine. Saudi J. Biol. Sci. 2019, 26, 709–722. [Google Scholar] [CrossRef] [PubMed]

- Soletto, D.; Binaghi, L.; Lodi, A.; Carvalho, J.C.M.; Converti, A. Batch and fed-batchcultivations of Spirulina platensis using ammonium sulphate and urea asnitrogen sources. Aquaculture 2005, 243, 217–224. [Google Scholar] [CrossRef]

- Yen, A.L. Conservation of Lepidoptera used as human food and medicine. Curr. Opin. Insect. Sci. 2015, 12, 102–108. [Google Scholar] [CrossRef]

- Bleakley, S.; Hayes, M. Algal Proteins: Extraction, Application, and Challenges Concerning Production. Foods 2017, 6, 33. [Google Scholar] [CrossRef]

- Huang, H.; Liao, D.; Pu, R.; Cui, Y. Quantifying the effects of spirulina supplementation on plasma lipid and glucose concentrations, body weight, and blood pressure. Diabetes Metab. Syndr. Obes. 2018, 11, 729–742. [Google Scholar] [CrossRef]

- Tanveer, A. Spirulina-Food of the Future. In Innovation, Educational Announcement; BioNatural Healing College: Riverside, CA, USA, 2019; pp. 1–5. [Google Scholar]

- Weilan, S.; Reham, E.; Mostafa, E.-S.; Abdelfatah, A.; Hamed, E. Pharmaceutical applications and consequent environmental impacts of Spirulina (Arthrospira): An overview. Grasas Y Aceites 2019, 70, 292. [Google Scholar] [CrossRef]

- Kirpenko, N.; Leontieva, T. Biotechnological prospects of microalgae. Biotechnol. Acta 2019, 12, 25–34. [Google Scholar] [CrossRef]

- Bendif, E.M.; Probert, I.; Schroeder, D.C.; de Vargas, C. On the description of Tisochrysis lutea gen. nov. sp. nov. and Isochrysis nuda sp. nov. in the Isochrysidales, and the transfer of Dicrateria to the Prymnesiales (Haptophyta). J. Appl. Phycol. 2013, 25, 1763–1776. [Google Scholar] [CrossRef]

- Suresh, P.; Kudre, T.G.; Johny, L.C. Sustainable valorization of seafood processing by-product/discard. In Waste to Wealth; Singhania, R.R., RAgarwal, A., Kumar, R.P., Sukumaran, R.K., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 111–139. [Google Scholar]

- Hamed, I.; Özogul, F.; Regenstein, J.M. Industrial applications of crustacean by-products (chitin, chitosan, and chitooligosaccharides): A review. Trends Food Sci. Technol. 2016, 48, 40–50. [Google Scholar] [CrossRef]

- Šimat, V.; Vlahović, J.; Soldo, B.; Mekinić, I.G.; Čagalj, M.; Hamed, I.; Skroza, D. Production and characterization of crude oils from seafood processing by-products. Food Biosci. 2020, 33, 100484. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Heimann, K.; Zhang, W. Protein recovery from underutilised marine bioresources for product development with nutraceutical and pharmaceutical bioactivities. Mar. Drugs 2020, 18, 391. [Google Scholar] [CrossRef]

- Pateiro, M.; Munekata, P.E.; Domínguez, R.; Wang, M.; Barba, F.J.; Bermúdez, R.; Lorenzo, J.M. Nutritional profiling and the value of processing by-products from gilthead sea bream (Sparus aurata). Mar. Drugs 2020, 18, 101. [Google Scholar] [CrossRef] [PubMed]

- van Huis, A. Potential of insects as food and feed in assuring food security. Annu. Rev. Entomol. 2013, 58, 563–583. [Google Scholar] [CrossRef]

- Koyande, A.K.; Chew, K.W.; Rambabu, K.; Tao, Y.; Chu, D.-T.; Show, P.-L. Microalgae: A potential alternative to health supplementation for humans. Food Sci. Hum. Wellness 2019, 8, 16–24. [Google Scholar] [CrossRef]

- Schade, S.; Stangl, G.I.; Meier, T. Distinct microalgae species for food—Part 2: Comparative life cycle assessment of microalgae and fish for eicosapentaenoic acid (EPA), docosahexaenoic acid (DHA), and protein J. Appl. Phycol. 2020, 32, 2997–3013. [Google Scholar] [CrossRef]

- El-Naggar, N.E.A.; Hussein, M.H.; Shaaban-Dessuuki, S.A.; Dalal, S.R. Production, extraction and characterization of Chlorella vulgaris soluble polysaccharides and their applications in AgNPs biosynthesis and biostimulation of plant growth Sci. Rep. 2020, 10, 3011. [Google Scholar] [CrossRef]

- Vernèsa, L.; Abert-Viana, M.; El Maâtaouib, M. Application of ultrasound for green extraction of proteins from spirulina. Mechanism, optimization, modeling, and industrial prospects. Ultrason. Sonochem. 2019, 54, 48–60. [Google Scholar] [CrossRef] [PubMed]

- Xie, T.; Xia, Y.; Zeng, Y.; Li, X.; Zhang, Y. Nitrate concentration-shift cultivation to enhance protein content of heterotrophic microalga Chlorella vulgaris: Over-compensation strategy. Bioresour. Technol. 2017, 233, 247–255. [Google Scholar] [CrossRef] [PubMed]

- Waghmare, A.G.; Salve, M.K.; LeBlanc, J.G.; Arya, S.S. Concentration and characterization of microalgae proteins from Chlorella pyrenoidosa Bioresour. Bioprocess 2016, 3, 16. [Google Scholar] [CrossRef]

- Chia, S.R.; Chew, K.W.; Zaid, H.F.M.; Chu, D.-T.; Tao, Y.; Show, P.L. Microalgal Protein Extraction from Chlorella vulgaris FSP-E Using Triphasic Partitioning Technique with Sonication. Front. Bioeng. Biotechnol. 2019, 7, 396. [Google Scholar] [CrossRef]

- Chew, K.W.; Chiaa, S.R.; Leeb, S.Y.; Lee, S.Y. Enhanced microalgal protein extraction and purification using sustainable microwave-assisted multiphase partitioning technique Chem. Eng. J. 2019, 367, 1–8. [Google Scholar]

- Andreeva, A.; Budenkova, E.; Babich, O.; Sukhikh, S.; Ulrikh, E.; Ivanova, S.; Prosekov, A.; Dolganyuk, V. Production, Purification, and Study of the Amino Acid Composition of Microalgae Proteins. Molecules 2021, 26, 2767. [Google Scholar] [CrossRef]

- Liceaga, A.M. Processing insects for use in the food and feed industry. Curr. Opin. Insect. Sci. 2021, 48, 32–36. [Google Scholar] [CrossRef]

- Amarender, R.V.; Bhargava, K.; Dossey, A.T.; Gamagedara, S. Lipid and protein extraction from edible insects—Crickets (Gryllidae). LWT 2020, 125, 109222. [Google Scholar] [CrossRef]

- Janssen, R.H.; Vincken, J.P.; van den Broek, L.A.; Fogliano, V.; Lakemond, C.M. Nitrogen-to-Protein Conversion Factors for Three Edible Insects: Tenebrio molitor, Alphitobius diaperinus, and Hermetia illucens. J. Agric. Food Chem. 2017, 65, 2275–2278. [Google Scholar] [CrossRef]

- Oonincx, D.G.A.B.; van Itterbeeck, J.; Heetkamp, M.J.W.; van den Brand, H.; van Loon, J.J.A. An Exploration on Greenhouse Gas and Ammonia Production by Insect Species Suitable for Animal or Human Consumption. PLoS ONE 2010, 5, e14445. [Google Scholar] [CrossRef]

- Borges, S.; Sousa, P.; Pintado, M. Insects as Food Sources. In Reference Module in Food Science; Elsevier: Amsterdam, the Netherlands, 2023. [Google Scholar] [CrossRef]

- Levi, J.; Martinez, A.; Itzhak, J.-J. The high level of protein content reported in insects for food and feed is overestimated. J. Food Compost. Anal. 2017, 62, 184–188. [Google Scholar] [CrossRef]

- Skotnicka, M.; Karwowska, K.; Kłobukowski, F.; Borkowska, A.; Pieszko, M. Possibilities of the Development of Edible Insect-Based Foods in Europe. Foods 2021, 10, 766. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Chen, X.-M.; Zhao, M.; He, Z.; Sun, L.; Wang, C.-Y.; Ding, W.-F. Edible insects in China: Utilization and prospects. Insect Sci. 2017, 25, 184–198. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.J.; Xiang, J.B. Prospect for development and exploitation of insect food. J. Anhui Agric. Sci. 2006, 33, 1728–1729. [Google Scholar]

- van Huis, A.; Oonincx, D.G.A.B. The environmental sustainability of insects as food and feed. A review. Agron. Sustain. Dev. 2017, 37, 43. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, L.; Wang, J.; Wang, W.; Niyati, N.; Guo, Y.; Wang, X. Chinese caterpillar fungus (Ophiocordyceps sinensis) in China: Current distribution, trading, and futures under climate change and overexploitation. Sci. Total Environ. 2021, 755 Pt 1, 142548. [Google Scholar] [CrossRef]

- Gao, R.R.; Hu, Y.T.; Dan, Y.; Hao, L.J.; Liu, X.; Song, J.Y. Chinese herbal medicine resources: Where we stand. Chin. Herb Med. 2019, 12, 3–13. [Google Scholar] [CrossRef]

- Hopping, K.A.; Chignell, S.M.; Lambin, E.F. The demise of caterpillar fungus in the Himalayan region due to climate change and overharvesting. Proc. Natl. Acad. Sci. USA 2018, 115, 11489–11494. [Google Scholar] [CrossRef]

- He, J. Harvest and trade of caterpillar mushroom (Ophiocordyceps sinensis) and the implications for sustainable use in the Tibet Region of Southwest China. J. Ethnopharmacol. 2018, 221, 86–90. [Google Scholar] [CrossRef]

- Shi, J.Y.; Pu, Z.Y.; Yao, J.; Li, Z.W.; Liu, Y.T.; Zheng, H. Research and Development on Nutrition of Butterflies; Science Press: Beijing, China, 2015; pp. 23–37. [Google Scholar]

- Deyrup, S.T.; Stagnitti, N.C.; Perpetua, M.J.; Wong-Deyrup, S.W. Drug Discovery Insights from Medicinal Beetles in Traditional Chinese Medicine. Biomol. Ther. 2021, 29, 105–126. [Google Scholar] [CrossRef]

- Kong, B.H. New Technology of Food Quality and Safety Testing; Science Press: Beijing, China, 2013; pp. 254–345. [Google Scholar]

- Liu, Y.S.; Wang, F.B.; Cui, J.X.; Zhang, L. Recent status and advances on study and utilization of Tenebrio molitor. Environ. Entomol. 2010, 32, 106–114. [Google Scholar]

- Ma, H.; Li, X.; Che, H.; Fan, H.; Liu, Q.; Xia, H. The inhibitory effect of Periplaneta americana L. on hepatocellular carcinoma: Explore the anti-hepatocellular carcinoma active site and its mechanism of action. J. Ethnopharmacol. 2022, 291, 114884. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.X.; Wu, Z.Q. Effects of forage nutritional components on the feeding and reproduction of the female adults of American cockroach. J. Fujian Agric. For. Univ. 2006, 35, 239–242. [Google Scholar]

- Gao, Y.-Y.; Geng, F.-N.; Chen, S.-M.; Ma, X.-Y. Advances in research on active ingredients and related pharmacology of periplaneta americana Chinese. Chin. J. Exp. Tradit. Med. Formulae 2021, 24, 240–250. [Google Scholar]

- Zhang, X.; Ruan, J.; Ma, Z. Research on history and present situation of medicinal insect resources in China. Chin. J. Bioprocess Eng. 2019, 17, 615–622. [Google Scholar]

- Feng, Y.; Chen, X.M.; Zhao, M. Edible Insects of China; Science Press: Beijing, China, 2016; pp. 38–47. [Google Scholar]

- Yen, A.L. Insects as food and feed in the Asia Pacific region: Current perspectives and future directions. J. Insects Food Feed 2015, 1, 33–55. [Google Scholar] [CrossRef]

- Hanboonsong, Y.; Jamjanya, T.; Durst, P.B. Six-legged Livestock: Edible Insect Farming, Collection and Marketing in Thailand; FAO of the United Nations Regional Office for Asia and the Pacific: Bangkok, Thailand, 2013; pp. 13–16. [Google Scholar]

- Stice, C.; Basu, A. Ocean foods ecosystems for planetary survival in the anthropocene. In World Nutrition Forum: Driving the Protein Economy; Erber, A.G.: Vena, Austria, 2016; pp. 301–320. [Google Scholar]

- Lucakova, S.; Branyikova, I.; Hayes, M. Microalgal proteins and bioactives for food, feed, and other applications. Appl. Sci. 2022, 12, 4402. [Google Scholar] [CrossRef]