Multi-Objective Optimal Power Flow Calculation Considering Carbon Emission Intensity

Abstract

:1. Introduction

2. Model Design and Calculation of Carbon Emission Flow in Power System

2.1. Carbon Emission Flow of Power System

2.2. Basic Definition of Carbon Emission Flow in Power System

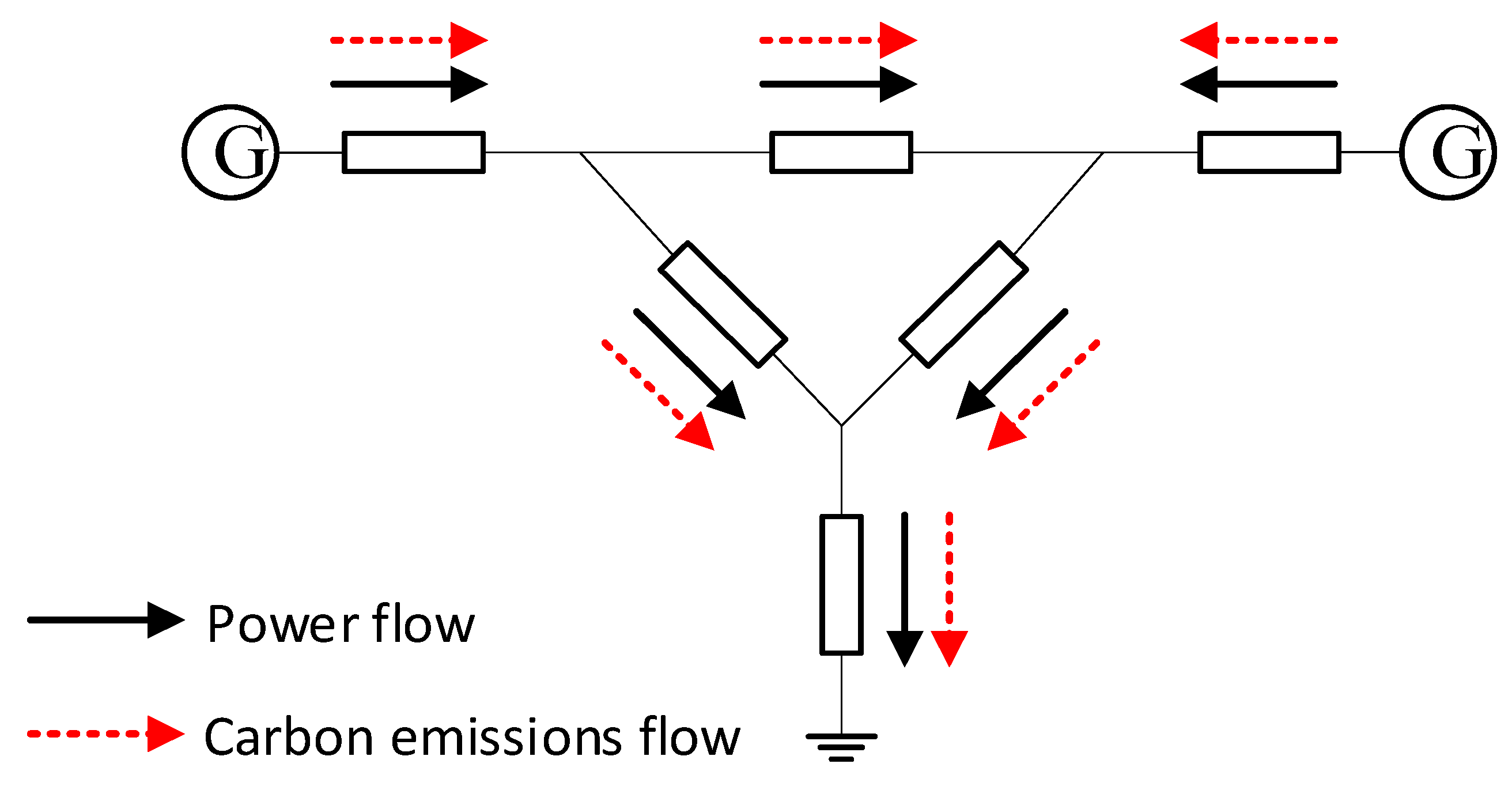

2.2.1. Carbon Emission Flow

2.2.2. Carbon Flow Rate

2.2.3. Branch Carbon Flow Density

2.2.4. Nodal Carbon Intensity

2.3. Calculation Method for Carbon Emission Flow in Power System

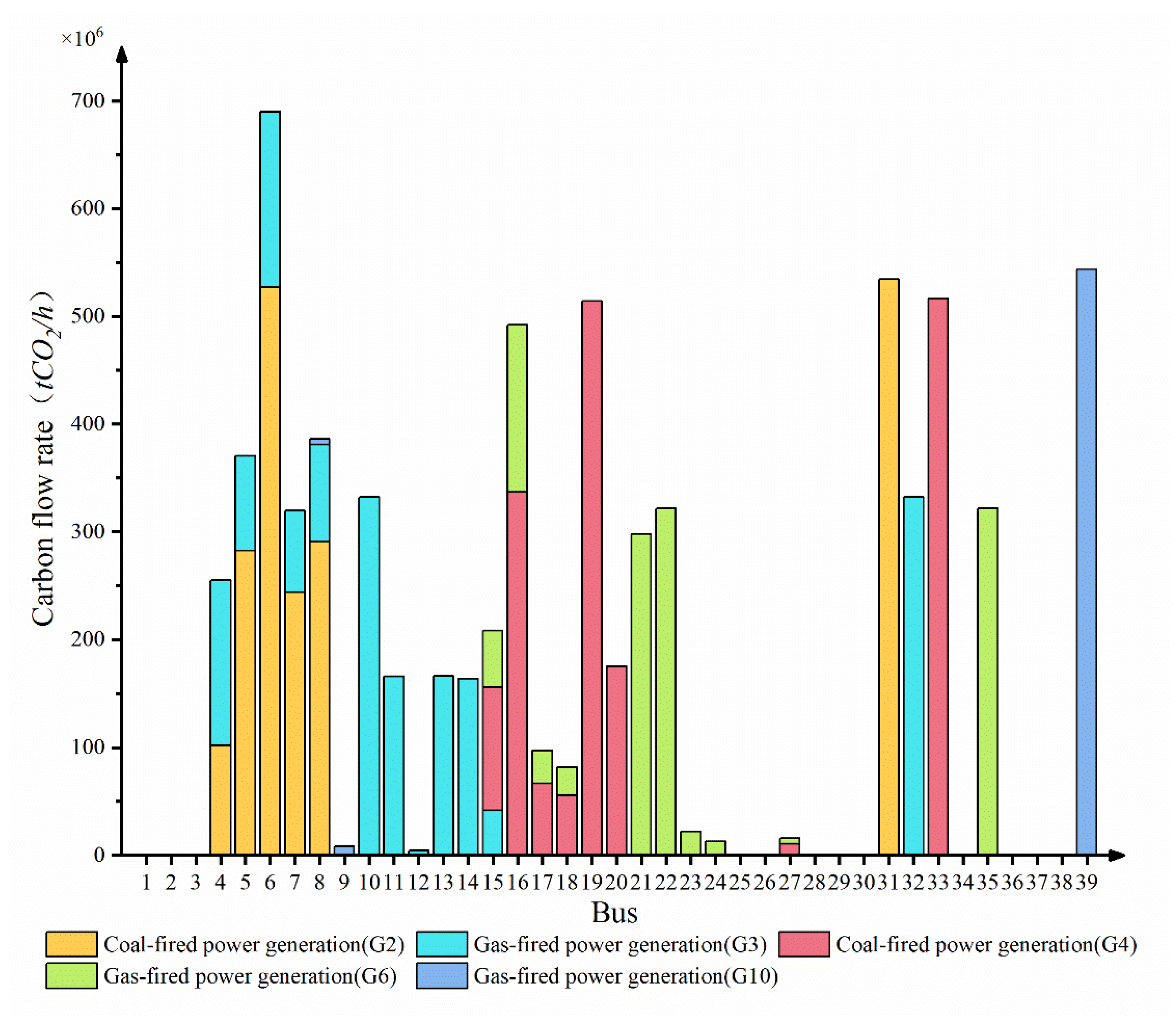

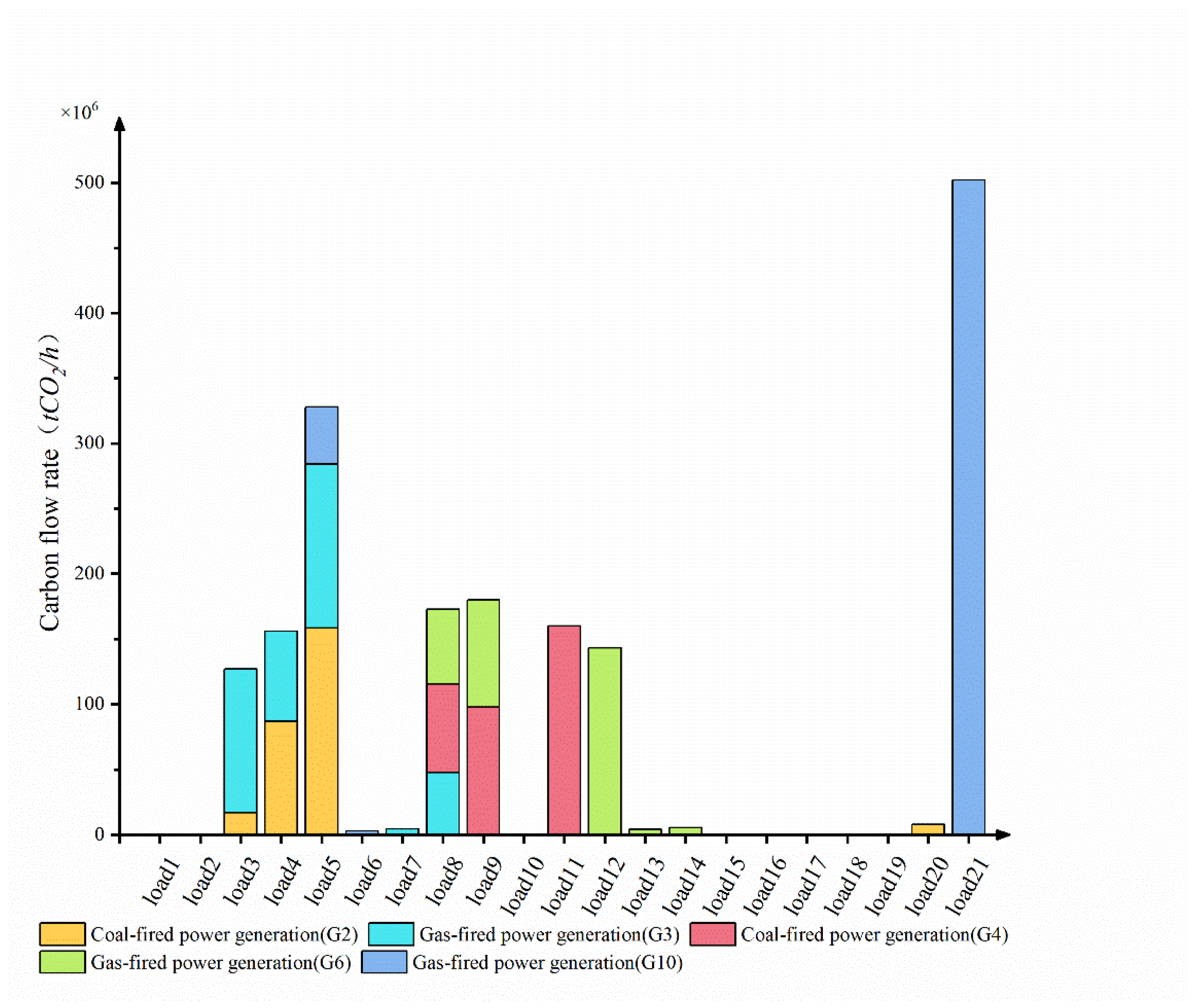

2.4. Correlation Analysis between Power Plant and Node Carbon Flow, Load Carbon Flow

3. Optimal Power Flow Considering Carbon Emission Rate

3.1. Objective Function

- 1.

- Lowest cost of power generation:

- 2.

- The lowest active network loss:

- 3.

- The lowest total carbon flow rate:

3.2. Constraints

3.2.1. Equality Constraints

3.2.2. Inequality Constraints

3.3. Optimal Model Solution

3.3.1. NSGA-III Algorithm

- Initialization. Set the basic variables of the NSGA-III algorithm, including the population size, mutation probability, number of iterations, and crossover probability, etc. Read the node, branch, and power plant data of the power grid. The initial population is obtained according to the constraints of the decision variables and the fitness function. Create a population archive set S.

- Genetic manipulation. Perform selection, crossover, and mutation operations on the parental population to generate the offspring population Q.

- Non-dominated sorting stratification. Merge the parental and offspring populations and execute fast non-dominated sorting, stratify according to the dominance level of the individual, and then put the individual into the archive set S layer by layer until the amount of individuals in set S is not less than the population size.

- Selection of individuals in the critical layer based on reference point. In the NSGA-III algorithm, diversity within the population is preserved by incorporating evenly spread reference points. These reference points are utilized to choose individuals situated in the crucial layer, preventing the optimization process from being trapped in local optima. The pivotal layer within the archive set “S” is referred to as the “critical layer.” Assuming this layer is denoted as the “L-th” layer, the objective is to select “K” individuals from this critical layer (where “K” equals the population size minus the count of individuals present in the preceding “L − 1” layers within set “S”). These chosen individuals from the critical layer, along with individuals from the “L − 1” layer, together constitute a fresh population set.

- Continue Steps 2 to 4 until the prescribed number of iterations is reached. Finally, output the Pareto front [33].

3.3.2. Pareto Optimal Set Decision Making

- Obtain a collection of optimal Pareto solution sets through the NSGA-III algorithm, that is, the indicator matrix P(m,n) (suggesting that there are a total of m solutions, with each solution comprising n indicators), and subsequently allocate a weight αn to each indicator within the solution set n (indicates that the weight of the nth index is αn).

- Standardize the indicator matrix and assign weights to each element to derive the weighting matrix K.

- 3.

- Consider the minimum element in each column of the weighting matrix as the optimal solution for index n, denoted as , and the maximum element as the worst solution for index n, denoted as . Compute the distance of each solution in the weighting matrix to the optimal and worst solutions, denoted as, and , respectively.

- 4.

- Compute the proximity index R for each solution within the Pareto solution set with respect to the optimal level. Select the solution corresponding to the maximum R value as the objective function value to achieve optimal power flow.

4. Case Studies

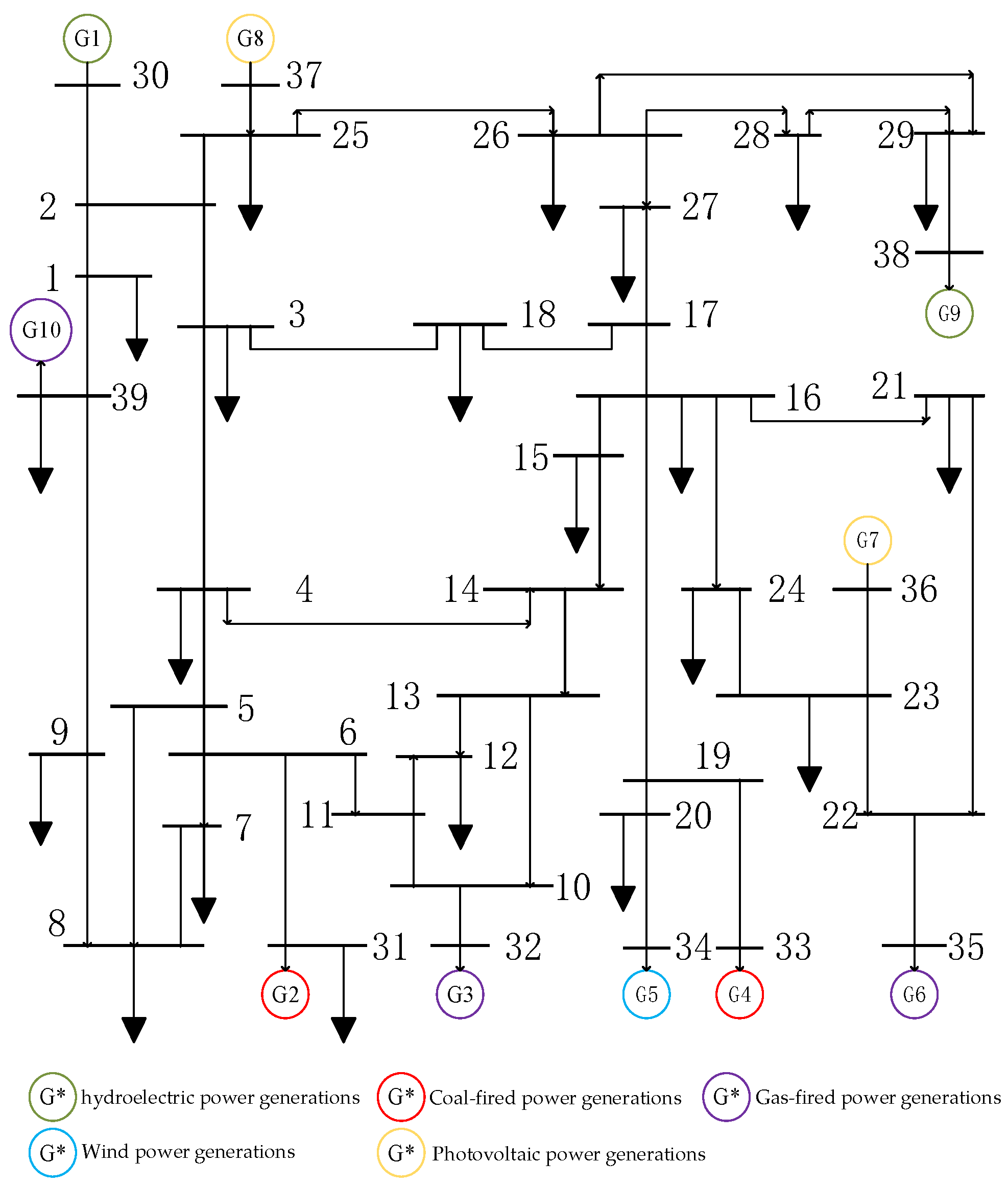

4.1. Basic Data

4.2. Example Setting and Analysis

5. Conclusions

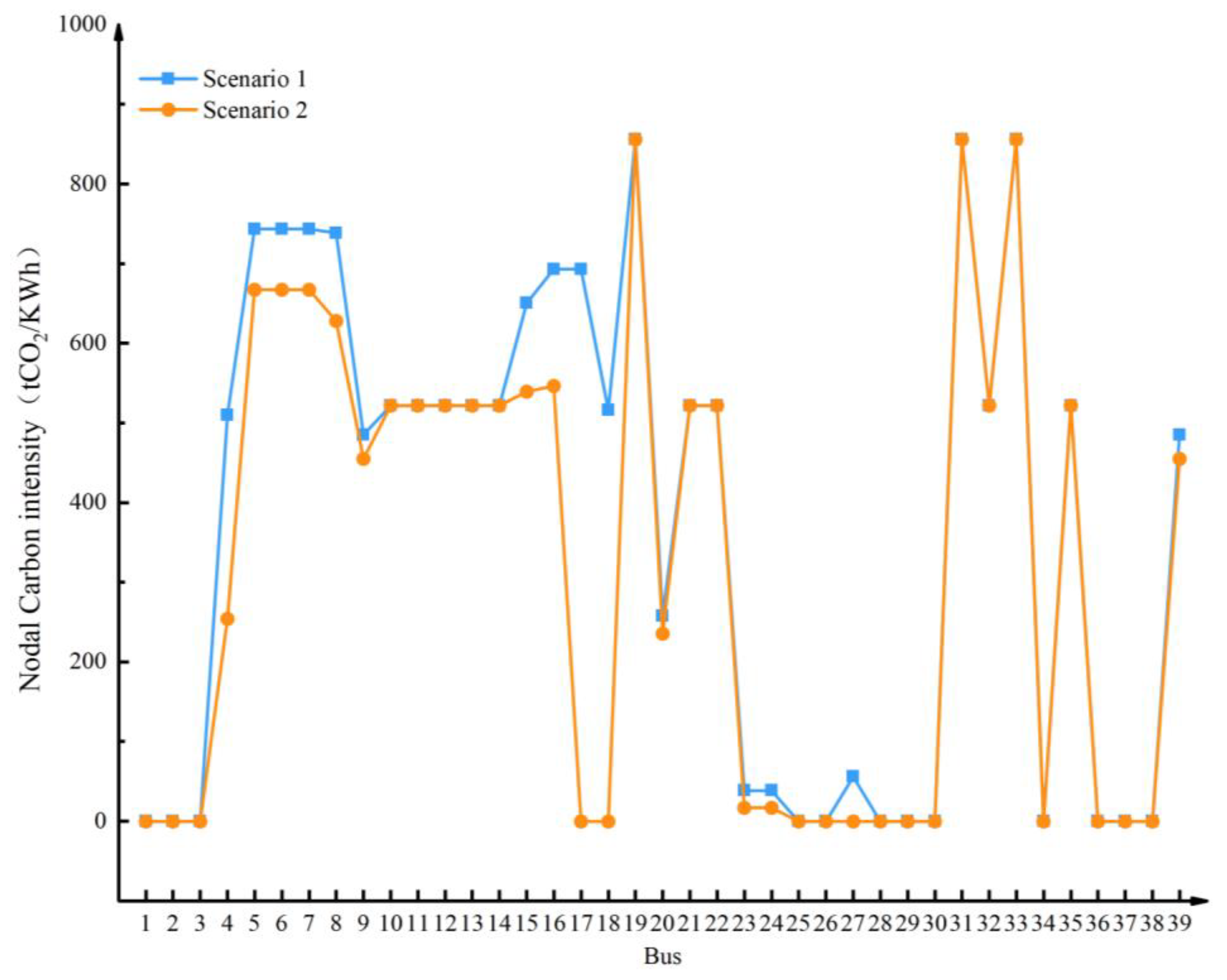

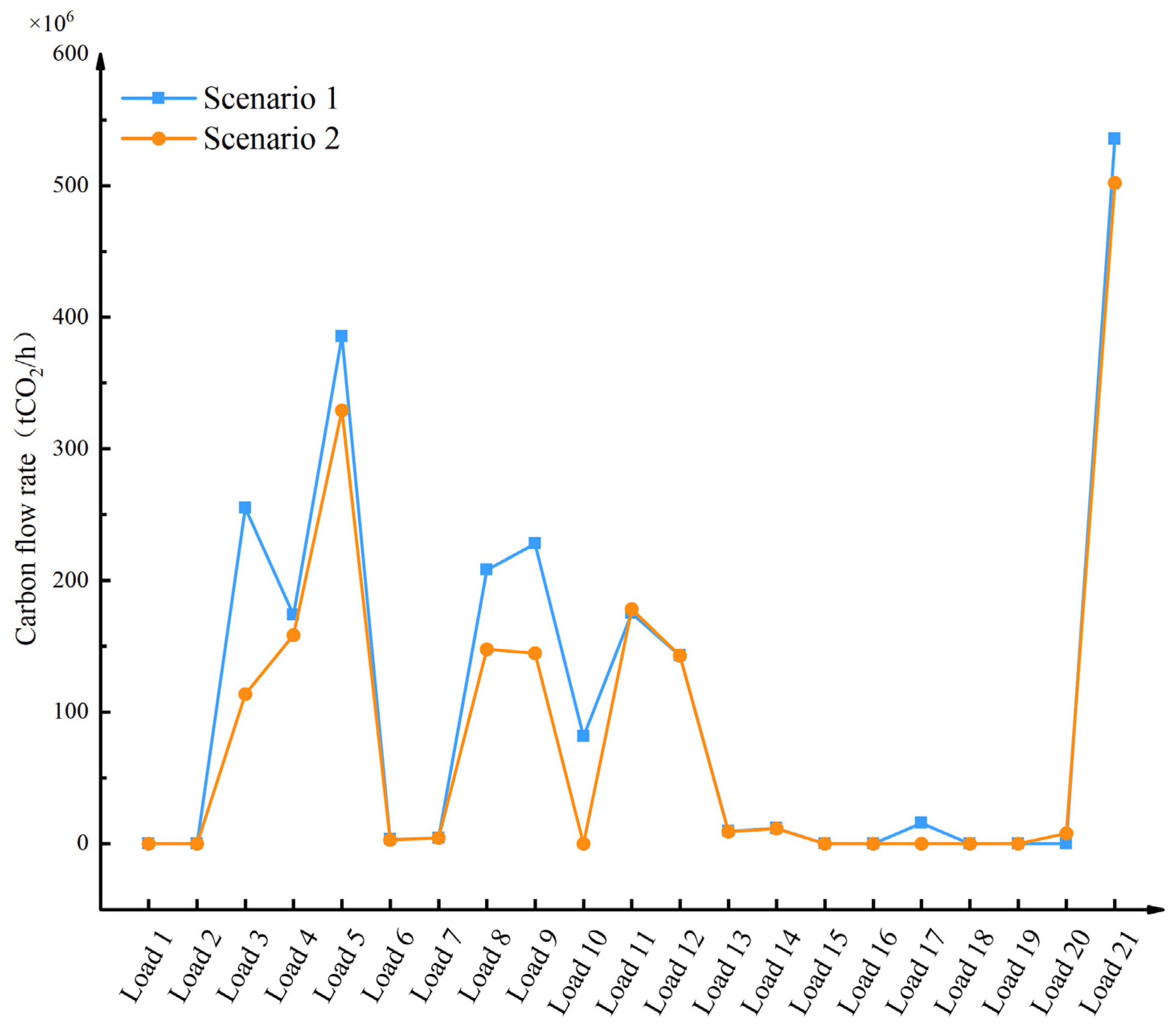

- The numerical simulation results of the IEEE39 bus system show that, with an increase in the economy cost by only 1.94%, the method proposed can reduce carbon emissions by 20.00%.

- The optimal Pareto front can provide multiple sets of output schemes, which can be more comprehensive and flexible for each scheduling of various resources.

- The analysis of the carbon flow rate correlation between power plants, nodes, and loads in the power system can also perform small-scale low-carbon optimization on the loads mounted on a node.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Bus | Generation Type | Active Output (MW) | Reactive Output (MVAr) | Power Generation Cost (Yuan/MWh) | Carbon Intensity (tCO2/KWh) | ||

|---|---|---|---|---|---|---|---|

| Max | Min | Max | Min | ||||

| 30 | Hydroelectric power generation | 1040 | 0 | 400 | 140 | 335.1 | 0 |

| 31 | Coal-fired power generation | 646 | 0 | 300 | −100 | 260.1 | 856 |

| 32 | Gas-fired power generation | 725 | 0 | 300 | 150 | 452.0 | 522 |

| 33 | Coal-fired power generation | 652 | 0 | 250 | 0 | 260.1 | 856 |

| 34 | Wind power generation | 508 | 0 | 167 | 0 | 460.1 | 0 |

| 35 | Gas-fired power generation | 687 | 0 | 300 | −100 | 452.0 | 522 |

| 36 | Photovoltaic power generation | 580 | 0 | 240 | 0 | 387.7 | 0 |

| 37 | Photovoltaic power generation | 564 | 0 | 250 | 0 | 387.7 | 0 |

| 38 | Hydroelectric power generation | 865 | 0 | 300 | −150 | 331.5 | 0 |

| 39 | Gas-fired power generation | 1100 | 0 | 300 | −100 | 452.0 | 522 |

| Bus | Bus Type | Active Load (MW) | Reactive Load (MVAr) | Voltage Amplitude | |

|---|---|---|---|---|---|

| (p.u.) | |||||

| 1 | PQ BUS | 97.60 | 44.20 | 1.06 | 0.94 |

| 2 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 3 | PQ BUS | 322.00 | 2.40 | 1.06 | 0.94 |

| 4 | PQ BUS | 500.00 | 184.00 | 1.06 | 0.94 |

| 5 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 6 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 7 | PQ BUS | 233.80 | 84.00 | 1.06 | 0.94 |

| 8 | PQ BUS | 522.00 | 176.60 | 1.06 | 0.94 |

| 9 | PQ BUS | 6.50 | −66.60 | 1.06 | 0.94 |

| 10 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 11 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 12 | PQ BUS | 8.53 | 88.00 | 1.06 | 0.94 |

| 13 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 14 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 15 | PQ BUS | 320.00 | 153.00 | 1.06 | 0.94 |

| 16 | PQ BUS | 329.00 | 32.30 | 1.06 | 0.94 |

| 17 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 18 | PQ BUS | 158.00 | 30.00 | 1.06 | 0.94 |

| 19 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 20 | PQ BUS | 680.00 | 103.00 | 1.06 | 0.94 |

| 21 | PQ BUS | 274.00 | 115.00 | 1.06 | 0.94 |

| 22 | PQ BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 23 | PQ BUS | 247.50 | 84.60 | 1.06 | 0.94 |

| 24 | PQ BUS | 308.60 | −92.20 | 1.06 | 0.94 |

| 25 | PQ BUS | 224.00 | 47.20 | 1.06 | 0.94 |

| 26 | PQ BUS | 139.00 | 17.00 | 1.06 | 0.94 |

| 27 | PQ BUS | 281.00 | 75.50 | 1.06 | 0.94 |

| 28 | PQ BUS | 206.00 | 27.60 | 1.06 | 0.94 |

| 29 | PQ BUS | 283.50 | 26.90 | 1.06 | 0.94 |

| 30 | PV BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 31 | Balance BUS | 9.20 | 4.60 | 1.06 | 0.94 |

| 32 | PV BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 33 | PV BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 34 | PV BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 35 | PV BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 36 | PV BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 37 | PV BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 38 | PV BUS | 0.00 | 0.00 | 1.06 | 0.94 |

| 39 | PV BUS | 1104.00 | 250.00 | 1.06 | 0.94 |

| Branch | From | To | Resistance (p.u.) | Reactance (p.u.) | Susceptance (p.u.) | Ratio | Max MVA |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 2 | 3.50 × 10−3 | 4.11 × 10−2 | 0.6987 | 0 | 600 |

| 2 | 1 | 39 | 1.00 × 10−3 | 2.50 × 10−2 | 0.75 | 0 | 1000 |

| 3 | 2 | 3 | 1.30 × 10−3 | 1.51 × 10−2 | 0.2572 | 0 | 500 |

| 4 | 2 | 25 | 7.00 × 10−3 | 8.60 × 10−3 | 0.146 | 0 | 500 |

| 5 | 2 | 30 | 0.00 | 1.81 × 10−2 | 0 | 1.025 | 900 |

| 6 | 3 | 4 | 1.30 × 10−3 | 2.13 × 10−2 | 0.2214 | 0 | 500 |

| 7 | 3 | 18 | 1.10 × 10−3 | 1.33 × 10−2 | 0.2138 | 0 | 500 |

| 8 | 4 | 5 | 8.00 × 10−4 | 1.28 × 10−2 | 0.1342 | 0 | 600 |

| 9 | 4 | 14 | 8.00 × 10−4 | 1.29 × 10−2 | 0.1382 | 0 | 500 |

| 10 | 5 | 6 | 2.00 × 10−4 | 2.60 × 10−3 | 0.0434 | 0 | 1200 |

| 11 | 5 | 8 | 8.00 × 10−4 | 1.12 × 10−2 | 0.1476 | 0 | 900 |

| 12 | 6 | 7 | 6.00 × 10−4 | 9.20 × 10−3 | 0.113 | 0 | 900 |

| 13 | 6 | 11 | 7.00 × 10−4 | 8.20 × 10−3 | 0.1389 | 0 | 480 |

| 14 | 6 | 31 | 0.00 | 2.50 × 10−2 | 0 | 1.07 | 1800 |

| 15 | 7 | 8 | 4.00 × 10−4 | 4.60 × 10−3 | 0.078 | 0 | 900 |

| 16 | 8 | 9 | 2.30 × 10−3 | 3.63 × 10−2 | 0.3804 | 0 | 900 |

| 17 | 9 | 39 | 1.00 × 10−3 | 2.50 × 10−2 | 1.2 | 0 | 900 |

| 18 | 10 | 11 | 4.00 × 10−4 | 4.30 × 10−3 | 0.0729 | 0 | 600 |

| 19 | 10 | 13 | 4.00 × 10−4 | 4.30 × 10−3 | 0.0729 | 0 | 600 |

| 20 | 10 | 32 | 0.00 | 2.00 × 10−2 | 0 | 1.07 | 900 |

| 21 | 12 | 11 | 1.60 × 10−3 | 4.35 × 10−2 | 0 | 1.006 | 500 |

| 22 | 12 | 13 | 1.60 × 10−3 | 4.35 × 10−2 | 0 | 1.006 | 500 |

| 23 | 13 | 14 | 9.00 × 10−4 | 1.01 × 10−2 | 0.1723 | 0 | 600 |

| 24 | 14 | 15 | 1.80 × 10−3 | 2.17 × 10−2 | 0.366 | 0 | 600 |

| 25 | 15 | 16 | 9.00 × 10−4 | 9.40 × 10−3 | 0.171 | 0 | 600 |

| 26 | 16 | 17 | 7.00 × 10−4 | 8.90 × 10−3 | 0.1342 | 0 | 600 |

| 27 | 16 | 19 | 1.60 × 10−3 | 1.95 × 10−2 | 0.304 | 0 | 600 |

| 28 | 16 | 21 | 8.00 × 10−4 | 1.35 × 10−2 | 0.2548 | 0 | 600 |

| 29 | 16 | 24 | 3.00 × 10−4 | 5.90 × 10−3 | 0.068 | 0 | 600 |

| 30 | 17 | 18 | 7.00 × 10−4 | 8.20 × 10−3 | 0.1319 | 0 | 600 |

| 31 | 17 | 27 | 1.30 × 10−3 | 1.73 × 10−2 | 0.3216 | 0 | 600 |

| 32 | 19 | 20 | 7.00 × 10−4 | 1.38 × 10−2 | 0 | 1.06 | 900 |

| 33 | 19 | 33 | 7.00 × 10−4 | 1.42 × 10−2 | 0 | 1.07 | 900 |

| 34 | 20 | 34 | 9.00 × 10−4 | 1.80 × 10−2 | 0 | 1.009 | 900 |

| 35 | 21 | 22 | 8.00 × 10−4 | 1.40 × 10−2 | 0.2565 | 0 | 900 |

| 36 | 22 | 23 | 6.00 × 10−4 | 9.60 × 10−3 | 0.1846 | 0 | 600 |

| 37 | 22 | 35 | 0.00 | 1.43 × 10−2 | 0 | 1.025 | 900 |

| 38 | 23 | 24 | 2.20 × 10−3 | 3.50 × 10−2 | 0.361 | 0 | 600 |

| 39 | 23 | 36 | 5.00 × 10−4 | 2.72 × 10−2 | 0 | 1 | 900 |

| 40 | 25 | 26 | 3.20 × 10−3 | 3.23 × 10−2 | 0.531 | 0 | 600 |

| 41 | 25 | 37 | 6.00 × 10−4 | 2.32 × 10−2 | 0 | 1.025 | 900 |

| 42 | 26 | 27 | 1.40 × 10−3 | 1.47 × 10−2 | 0.2396 | 0 | 600 |

| 43 | 26 | 28 | 4.30 × 10−3 | 4.74 × 10−2 | 0.7802 | 0 | 600 |

| 44 | 26 | 29 | 5.70 × 10−3 | 6.25 × 10−2 | 1.029 | 0 | 600 |

| 45 | 28 | 29 | 1.40 × 10−3 | 1.51 × 10−2 | 0.249 | 0 | 600 |

| 46 | 29 | 38 | 8.00 × 10−4 | 1.56 × 10−2 | 0 | 1.025 | 1200 |

References

- Xi, J. Speech at the General Debate of the 75th United Nations General Assembly. People’s Daily, 23 September 2020; edition 003. [Google Scholar] [CrossRef]

- Kang, C.; Du, E.; Li, Y.; Zhang, N.; Chen, Q.; Guo, H.; Wang, P. ‘Carbon perspective’ of new power systems: Scientific issues and research framework. Power Syst. Technol. 2022, 46, 821–833. [Google Scholar] [CrossRef]

- Tianhua, M.; Qiaoyan, B.; Jun, X.; Deqiang, G. Low-carbon power dispatching and benefit allocation considering carbon emission allowance. Autom. Electr. Power Syst. 2016, 40, 49–55. [Google Scholar]

- Hao, X.; Kong, Y. Analysis of the low-carbon transformation path of the power sector under the goal of carbon neutrality. Compr. Util. Resour. China 2022, 40, 179–182. [Google Scholar]

- Guo, X.; Lou, S.; Wu, Y.; Wang, Y. Low-carbon Operation of Combined Heat and Power Integrated Plants Based on Solar-assisted Carbon Capture. J. Mod. Power Syst. Clean Energy 2022, 10, 1138–1151. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Zuo, D.; Wang, Y. Research on low-carbon transformation of power system under the background of double carbon. Electr. Appl. Ind. 2023, 268, 40–44. [Google Scholar]

- Xu, B.; Zhang, G.; Li, K.; Li, B.; Chi, H.; Yao, Y.; Fan, Z. Reactive power optimization of a distribution network with high-penetration of wind and solar renewable energy and electric vehicles. Prot. Control Mod. Power Syst. 2022, 7, 801–813. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, X.; Fu, W.; Chen, X.; Hu, S.; Zhang, L.; Xia, Y. An Optimal Combining Attack Strategy Against Economic Dispatch of Integrated Energy System. IEEE Trans. Circuits Syst. II Express Briefs 2023, 70, 246–250. [Google Scholar] [CrossRef]

- Li, K.; Han, X. Distributed algorithm of real-time optimal power flow for distribution network with distributed energy resource. Autom. Electr. Power Syst. 2020, 44, 54–61. [Google Scholar]

- Zhang, N.; Zhang, K.; Li, Q.; Liu, J.; Zhao, J.; Sun, G. Optimal power flow calculation of power system containing TCPST based on improved MCCIPM. Electr. Power Eng. Technol. 2021, 40, 144–150. [Google Scholar] [CrossRef]

- Zhu, J.P.; Huang, Y.; Ma, L. Assessment on Distributed Generation Accommodation Capability for Distribution Network Based on Uncertain Optimal Power Flow. Autom. Electr. Power Syst. 2022, 46, 46–54. [Google Scholar]

- Riaz, M.; Hanif, A.; Masood, H.; Khan, M.A.; Afaq, K.; Kang, B.G.; Nam, Y. An Optimal Power Flow Solution of a System Integrated with Renewable Sources Using a Hybrid Optimizer. Sustainability 2021, 13, 13382. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, J.; Li, G.; Zhang, B. Low-Carbon Power Dispatch Based on Evolutionary Algorithm with Adaptive Weight. In Proceedings of the 2011 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 25–28 March 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, Y.; Zhang, X.; Cao, Y.; Zhang, M. A Day-Ahead Scheduling Planning Model for Wind Power Systems Considering the Impact of Carbon Emission Quotas. Power Syst. Technol. 2014, 38, 2114–2120. [Google Scholar] [CrossRef]

- Han, H.; Wei, T.; Wu, C.; Xu, X.; Zang, H.; Sun, G.; Wei, Z. A Low-Carbon Dispatch Strategy for Power Systems Considering Flexible Demand Response and Energy Storage. Front. Energy Res. 2022, 10, 883602. [Google Scholar] [CrossRef]

- Li, J.; He, X.; Li, W.; Zhang, M.; Wu, J. Low-carbon optimal learning scheduling of the power system based on carbon capture system and carbon emission flow theory. Electr. Power Syst. Res. 2023, 218, 109215. [Google Scholar] [CrossRef]

- Dong, Y.; Shan, X.; Yan, Y.; Leng, X.; Wang, Y. Architecture, Key Technologies and Applications of Load Dispatching in China Power Grid. J. Mod. Power Syst. Clean Energy 2022, 10, 316–327. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, L.; Dong, X. Bi-level emission reduction model of the hybrid power market based on Carbon Emission Flow Theory and source-load coordination. Appl. Sci. 2023, 13, 9100. [Google Scholar] [CrossRef]

- Jiang, G.; Wang, B.; Xu, P. A method for power flow calculation and optimal dispatch of gas–thermal–electricity multi energy system considering unit commitment. Energy Rep. 2023, 9, 718–727. [Google Scholar] [CrossRef]

- Fakih, S.; Mabrouk, M.T.; Batton-Hubert, M.; Lacarrière, B. Bi-level and multi-objective optimization of renewable energy sources and storage planning to support existing overloaded electricity grids. Energy Rep. 2023, 10, 1450–1466. [Google Scholar] [CrossRef]

- Chen, H.; Mao, W.; Zhang, R.; Yu, W. Power System Source-Load Coordinated Low-Carbon Optimal Dispatch Based on Carbon Emission Flow Theory. Power Syst. Prot. Control 2021, 49, 1–11. [Google Scholar] [CrossRef]

- Zhou, T.; Kang, C.; Xu, Q.; Chen, Q. Preliminary Theoretical Investigation on Power System Carbon Emission Flow. Autom. Electr. Power Syst. 2012, 36, 38–43+85. [Google Scholar]

- Zhou, T.; Kang, C.; Xu, Q.; Chen, Q. Preliminary Investigation on a Method for Carbon Emission Flow Calculation of Power System. Autom. Electr. Power Syst. 2012, 36, 44–49. [Google Scholar]

- Li, Y.; Liu, Q.; Zhang, Z.; Liu, J. Calculation method of carbon emission flow based on grid power distribution. Power Grid Technol. 2017, 41, 840–844. [Google Scholar] [CrossRef]

- Zhou, T.; Kang, C.; Xu, Q.; Chen, Q.; Xin, J.; Wu, Y. Analysis on Distribution Characteristics and Mechanisms of Carbon Emission Flow in Electric Power Network. Autom. Electr. Power Syst. 2012, 36, 39–44. [Google Scholar]

- Cao, D.; Hu, W.; Xu, X.; Wu, Q.; Huang, Q.; Chen, Z.; Blaabjerg, F. Deep reinforcement learning based approach for optimal power flow of distribution networks embedded with renewable energy and storage devices. J. Mod. Power Syst. Clean Energy 2021, 9, 1101–1110. [Google Scholar] [CrossRef]

- Yang, N.; Dong, Z.; Wu, L.; Zhang, L.; Shen, X.; Chen, D.; Zhu, B.; Liu, Y. A Comprehensive Review of Security-constrained Unit Commitment. J. Mod. Power Syst. Clean Energy 2022, 10, 562–576. [Google Scholar] [CrossRef]

- Nan, Y.; Di, Y.; Zheng, Z.; Jiazhan, C.; Daojun, C.; Xiaoming, W. Research on Modelling and Solution of Stochastic SCUC under AC Power Flow Constraints. IET Gener. Transm. Distrib. 2018, 12, 3618–3625. [Google Scholar] [CrossRef]

- Zhu, M.; Xu, C.; Dong, S.; Tang, K.; Gu, C. An integrated multi-energy flow calculation method for electricity-gas-thermal integrated energy systems. Prot. Control Mod. Power Syst. 2021, 6, 65–76. [Google Scholar] [CrossRef]

- Yang, N.; Qin, T.; Wu, L.; Huang, Y.; Huang, Y.; Xing, C.; Zhang, L.; Zhu, B. A multi-agent game based joint planning approach for electricity-gas integrated energy systems considering wind power uncertainty. Electr. Power Syst. Res. 2022, 204, 107673. [Google Scholar] [CrossRef]

- Deb, K.; Jain, H. An evolutionary many-objective optimization algorithm using reference-point-based nondominated sorting approach, Part I: Solving Problems with Box Constraints. IEEE Trans. Evol. Comput. 2014, 18, 577–601. [Google Scholar] [CrossRef]

- Zhang, R.; Feng, X.; Ma, G. Production scheduling and transportation optimization of prefabricated components considering carbon emissions based on NSGA-Ⅲ algorithm. J. Eng. Manag. 2023, 37, 153–158. [Google Scholar] [CrossRef]

- Gu, Q.; Luo, J.; Li, X. Multi-objective evolutionary algorithm based on niche. Comput. Eng. Appl. 2023, 59, 126–139. [Google Scholar]

- Zhao, Q.; Bai, Q.; Nie, K.; Wang, H.; Zeng, X. Multi-objective optimal allocation of regional water resources based on NSGA-Ⅲ algorithm and TOPSIS decision. J. Drain. Irrig. Mech. Eng. 2022, 40, 1233–1240. [Google Scholar]

- Hwang, C.-L.; Lai, Y.-J.; Liu, T.-Y. A new approach for multiple objective decision making. Comput. Oper. Res. 1993, 20, 889–899. [Google Scholar] [CrossRef]

- Xu, P.; Fu, W.; Lu, Q.; Zhang, S.; Wang, R.; Meng, J. Stability analysis of hydro-turbine governing system with sloping ceiling tailrace tunnel and upstream surge tank considering nonlinear hydro-turbine characteristics. Renew. Energy 2023, 210, 556–574. [Google Scholar] [CrossRef]

- Zhang, Z.; Ban, M.; Guo, D.; Chen, Q.; Jiang, H. A model for Carbon dioxide emission characteristics of coal-fired units for environmental-economic dispatch research. J. Shanghai Jiao Tong Univ. 2021, 55, 1663–1672. [Google Scholar] [CrossRef]

- Zhang, S. Research on the Economics of Wind Power Project Investment Based on KWH Cost and Development Potential—Taking Fujian Luoyuan Bay Wind Farm as an Example. China Price Superv. Anti Monop. 2023, 69–72. [Google Scholar]

- Li, X.; Gao, Y. Application status and benefit analysis of hub airport PV power generation project. Sol. Energy 2022, 5–11. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, J.; Zhao, C. Low-carbon power planning with gas-fired units based on carbon trading. J. Sol. Energy Sin. 2020, 41, 92–98. [Google Scholar]

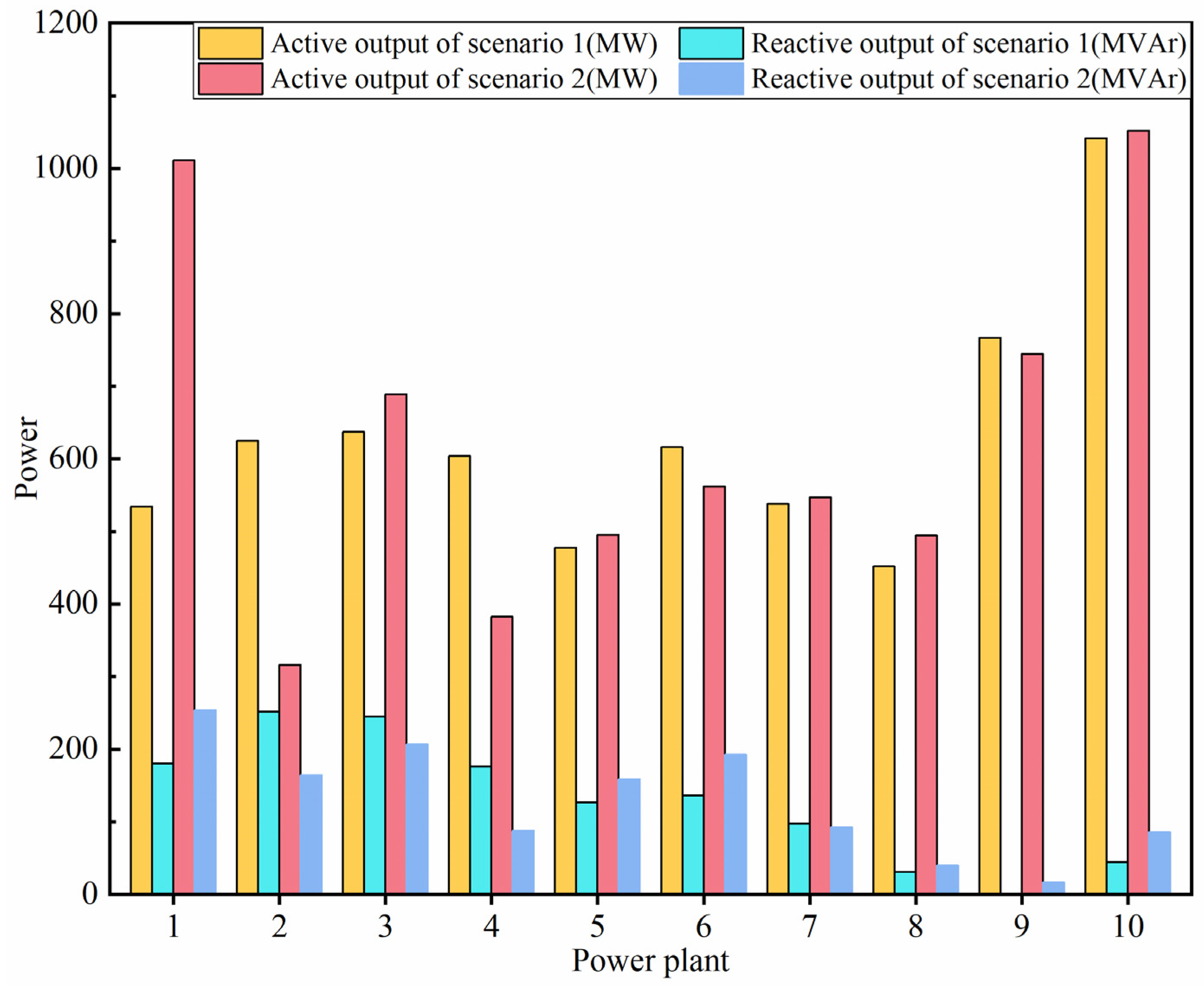

| Bus | Generation Type | Active Output (MW) | Reactive Output (MVAr) |

|---|---|---|---|

| 30 | Hydroelectric power generation | 534.00 | 180.64 |

| 31 | Coal-fired power generation | 624.75 | 251.54 |

| 32 | Gas-fired power generation | 636.91 | 245.05 |

| 33 | Coal-fired power generation | 603.75 | 176.16 |

| 34 | Wind power generation | 477.88 | 126.62 |

| 35 | Gas-fired power generation | 615.99 | 135.94 |

| 36 | Photovoltaic power generation | 537.97 | 97.68 |

| 37 | Photovoltaic power generation | 451.70 | 31.07 |

| 38 | Hydroelectric power generation | 766.98 | −6.43 |

| 39 | Gas-fired power generation | 1041.99 | 44.51 |

| Population Size | Maximum Number of Iterations | Cross Ratio | Mutation Ratio | Mutation Probability |

|---|---|---|---|---|

| 200 | 100 | 0.8 | 0.2 | 0.02 |

| Order | Power Generation Cost (Million CNY) | Active Network Loss (MW) | Total Carbon Flow Rate (×109 tCO2/h) | Proximity Index |

|---|---|---|---|---|

| 1 | 2.440 | 39.878 | 1.8007 | 0.737 |

| 2 | 2.453 | 43.561 | 1.7191 | 0.7262 |

| 3 | 2.443 | 42.970 | 1.7490 | 0.722 |

| 4 | 2.439 | 43.301 | 1.7424 | 0.728 |

| 5 | 2.444 | 42.580 | 1.7614 | 0.725 |

| Bus | Generation Type | Active Output (MW) | Reactive Output (MVAr) |

|---|---|---|---|

| 30 | Hydroelectric power generation | 1011.07 | 254.01 |

| 31 | Coal-fired power generation | 316.35 | 164.31 |

| 32 | Gas-fired power generation | 688.86 | 206.66 |

| 33 | Coal-fired power generation | 382.40 | 87.54 |

| 34 | Wind power generation | 495.57 | 158.96 |

| 35 | Gas-fired power generation | 561.94 | 192.43 |

| 36 | Photovoltaic power generation | 546.92 | 92.45 |

| 37 | Photovoltaic power generation | 494.49 | 39.83 |

| 38 | Hydroelectric power generation | 744.35 | 16.54 |

| 39 | Gas-fired power generation | 1052.16 | 85.70 |

| Scenario | Power Generation Cost (Million CNY) | Active Network Loss (MW) | Total Carbon Flow Rate (×109 tCO2/h) |

|---|---|---|---|

| 1 | 2.3936 | 37.698 | 2.25 × 109 |

| 2 | 2.4400 | 39.878 | 1.80 × 109 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Ma, H.; Wang, B.; Alharbi, A.M.; Wang, H.; Ma, F. Multi-Objective Optimal Power Flow Calculation Considering Carbon Emission Intensity. Sustainability 2023, 15, 16953. https://doi.org/10.3390/su152416953

Wang G, Ma H, Wang B, Alharbi AM, Wang H, Ma F. Multi-Objective Optimal Power Flow Calculation Considering Carbon Emission Intensity. Sustainability. 2023; 15(24):16953. https://doi.org/10.3390/su152416953

Chicago/Turabian StyleWang, Gangfei, Hengrui Ma, Bo Wang, Abdullah M. Alharbi, Hongxia Wang, and Fuqi Ma. 2023. "Multi-Objective Optimal Power Flow Calculation Considering Carbon Emission Intensity" Sustainability 15, no. 24: 16953. https://doi.org/10.3390/su152416953

APA StyleWang, G., Ma, H., Wang, B., Alharbi, A. M., Wang, H., & Ma, F. (2023). Multi-Objective Optimal Power Flow Calculation Considering Carbon Emission Intensity. Sustainability, 15(24), 16953. https://doi.org/10.3390/su152416953