The Environmental Impacts of Bar Soap Production: Uncovering Sustainability Risks with LCA Analysis

Abstract

1. Introduction

2. Data Collection and Assumptions

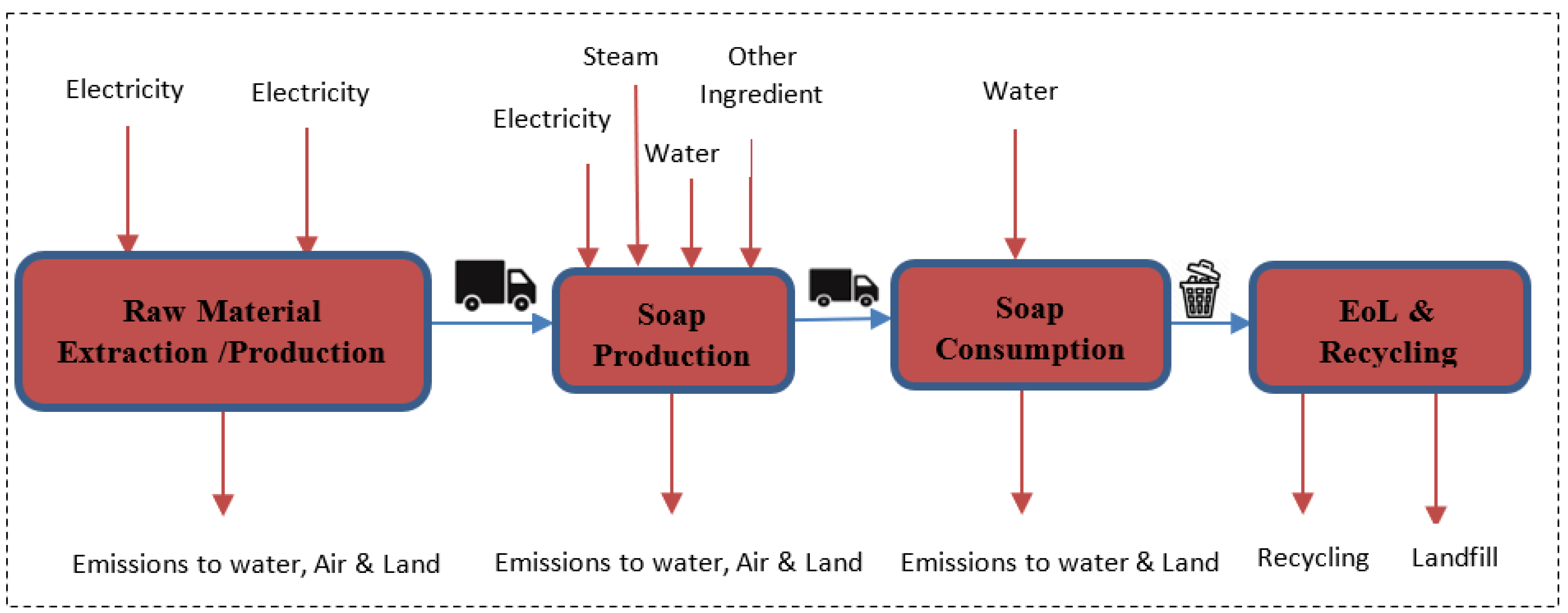

2.1. Product Life Cycle

2.2. Saponification

2.3. Manufacturing and Distribution

2.4. Product Use and Disposal

3. Methodology

3.1. Manufacturing Process

3.2. Life Cycle Inventory

3.3. Modeling on Software

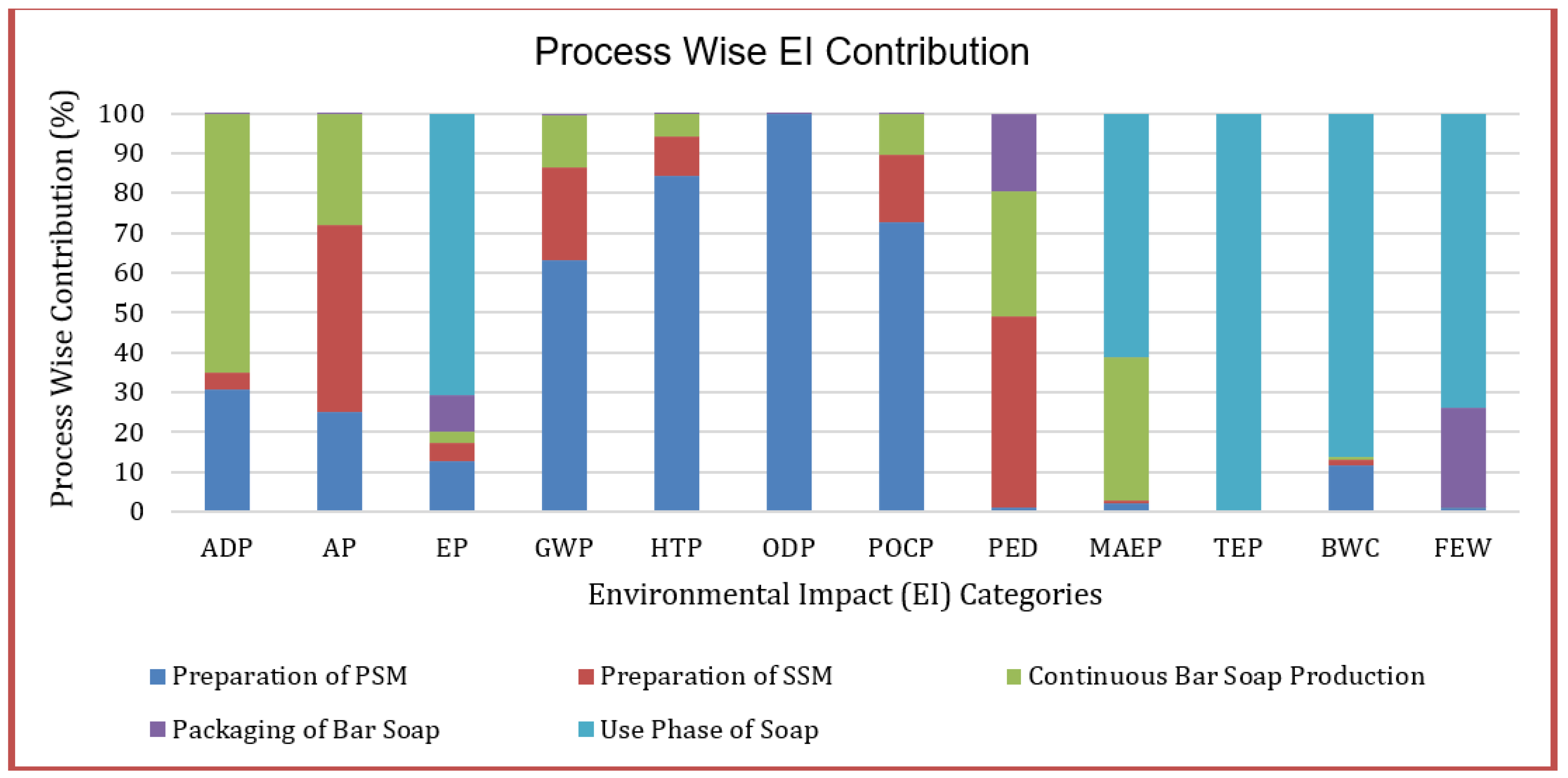

4. Results and Discussion

4.1. Abiotic Depletion Potential

4.2. Acidification Potential

4.3. Eutrophication Potential

4.4. Global Warming Potential

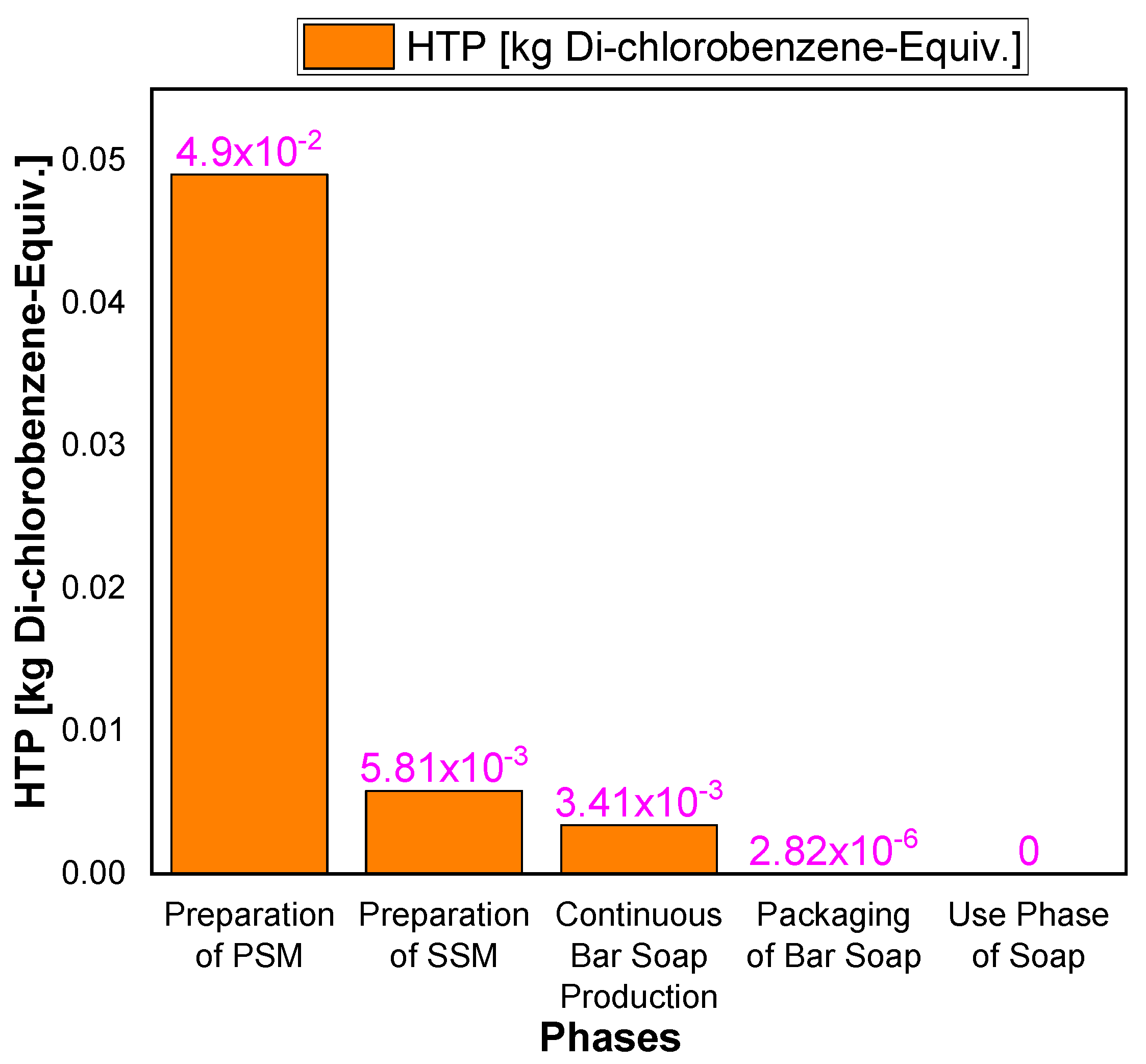

4.5. Human Toxicity Potential

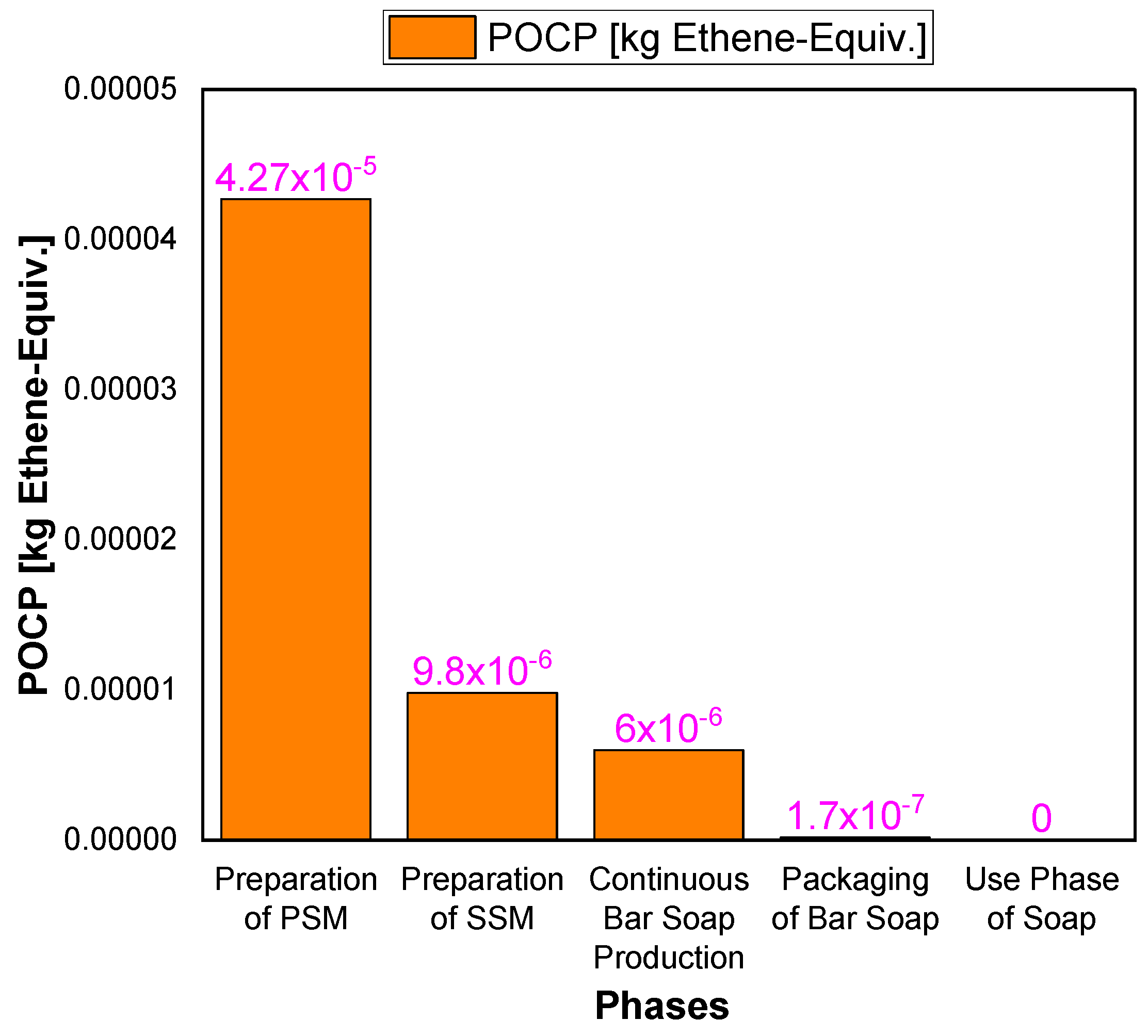

4.6. Photochemical Ozone Creation Potential

4.7. Ozone Layer Depletion Potential

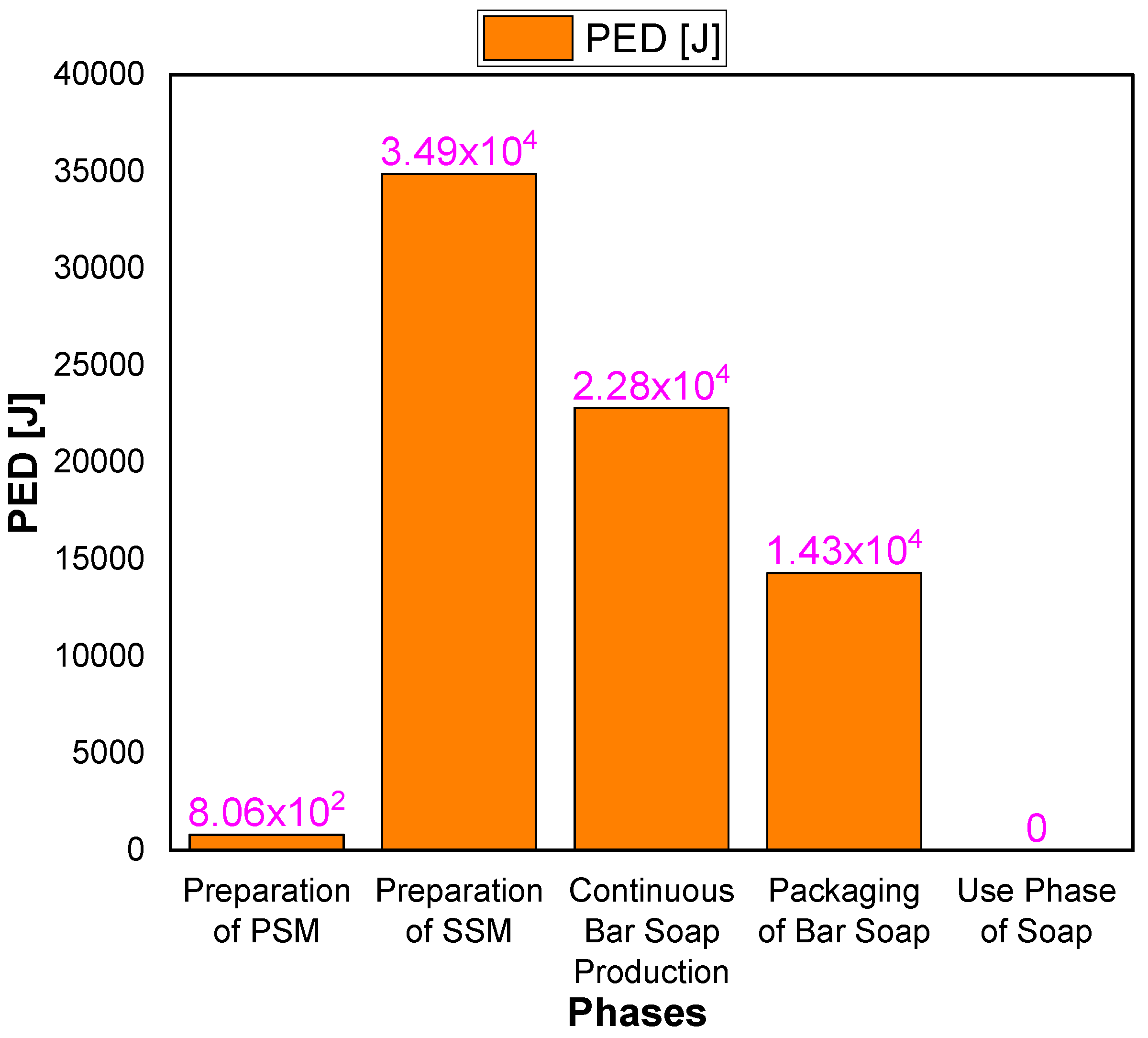

4.8. Primary Energy Demand

4.9. Bluewater Consumption

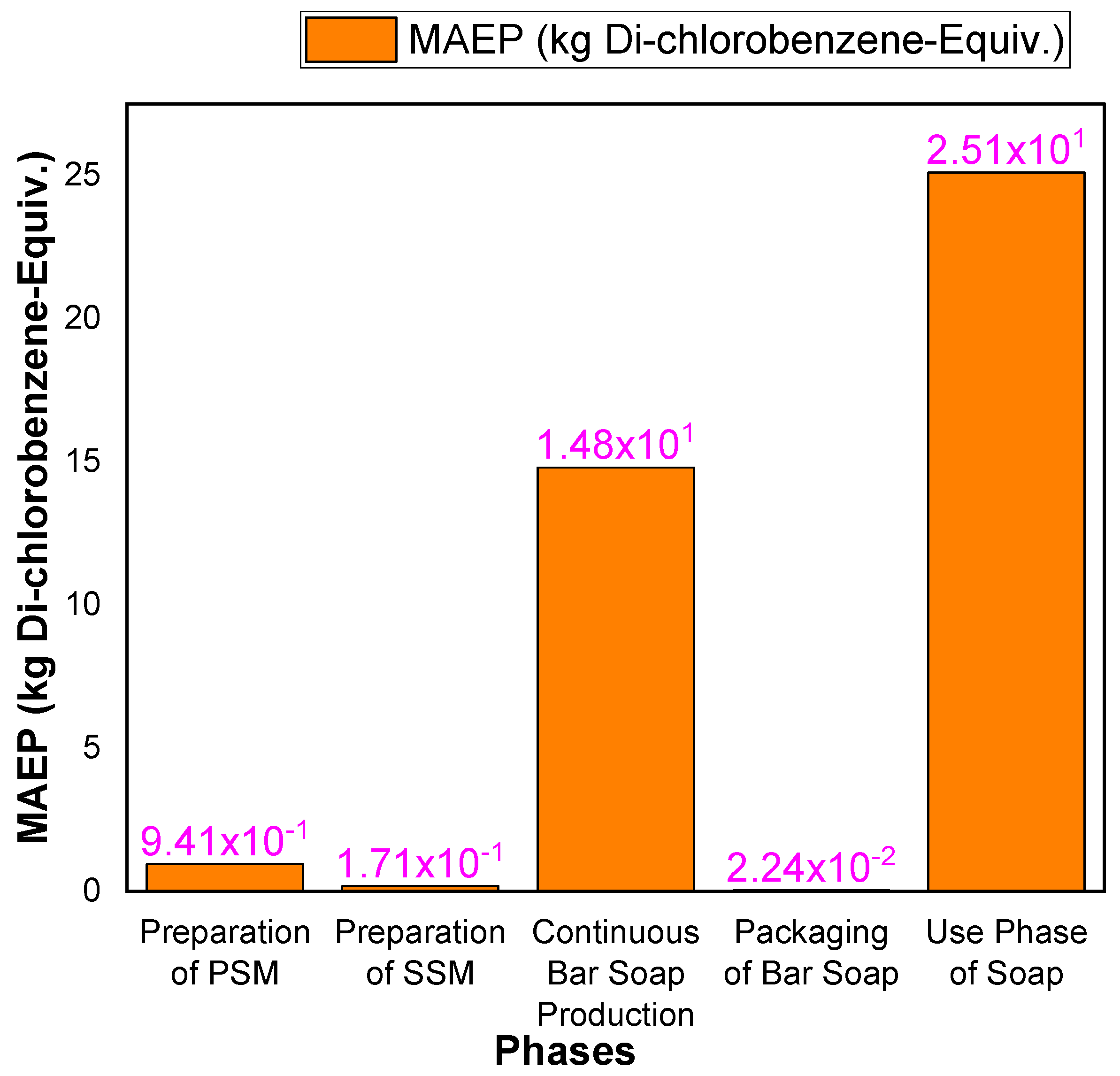

4.10. Marine Aquatic Ecotoxicity Potential

4.11. Terrestrial Ecotoxicity Potential

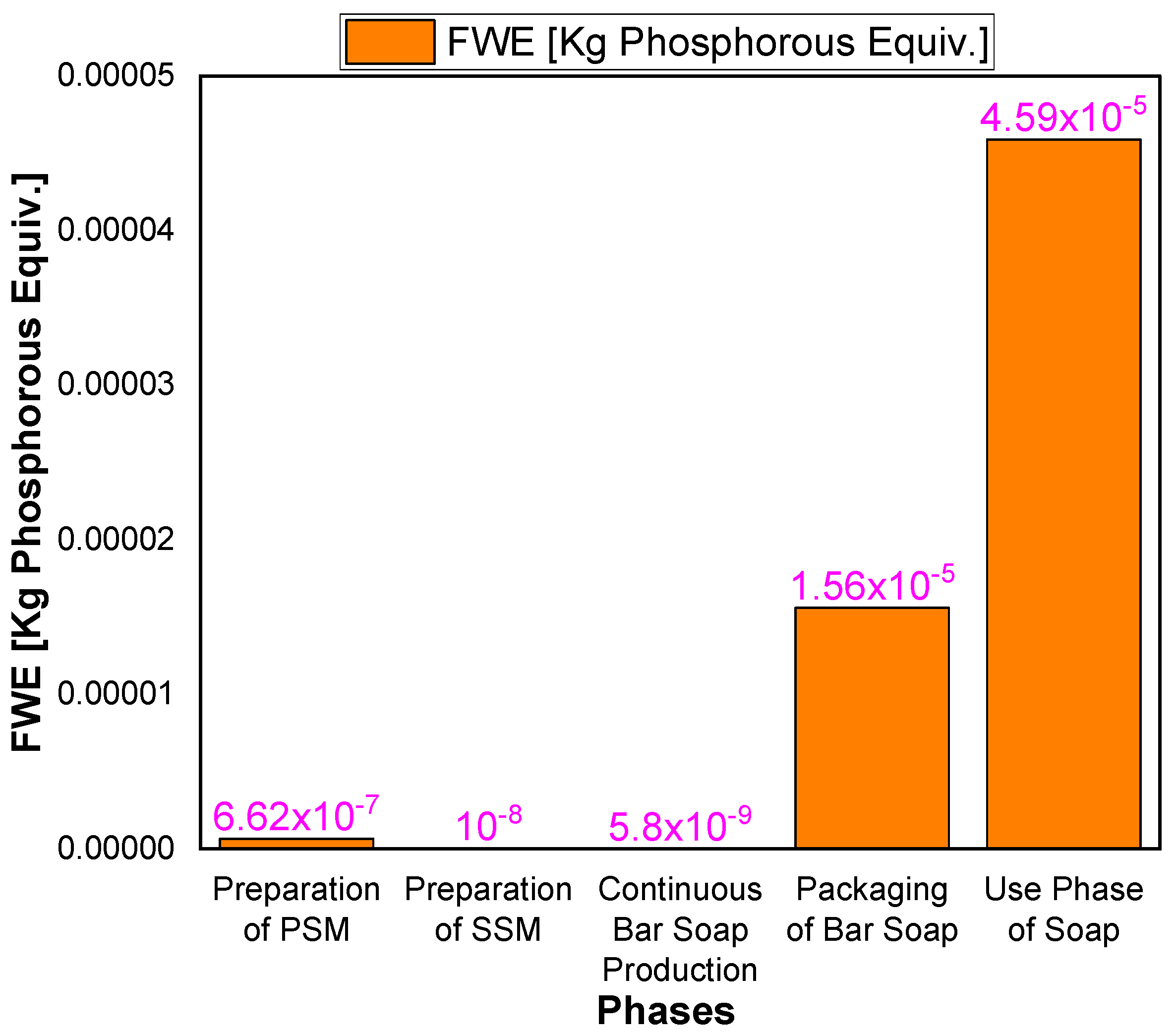

4.12. Freshwater Eutrophication

5. Critical Discussion

6. Conclusions and Outlook

- The site-specific emission factor for electricity is computed based on the contribution of electricity supplied from a power plant.

- The GaBi version 8: 2015 specific database is used for evaluating environmental emissions. The latest software database may produce variations in the results.

- This study is based on average data. In case of individual purchase decisions, the parameters influencing the results might differ from the assumed average data.

- The results are only valid for the geographical scope of this study (India). Different parameters strongly depend on the country or climatic conditions. Examples of those parameters are: electricity supply and consumer behavior (washing habits).

- For road transport, country-specific pollution norms are considered.

- The variation in consumer use of washing soap was not addressed in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| SM | Sustainable manufacturing |

| FMCG | Fast-moving consumer goods |

| ISO | International Organization for Standardization |

| CML | Centrum voor Milieukunde Leiden |

| J | joule |

| kg | kilogram |

| d | day |

| ADP | Abiotic Depletion |

| AP | Acidification Potential |

| EP | Eutrophication Potential |

| GWP | Global Warming Potential |

| HTP | Human Toxicity Potential |

| ODP | Ozone Layer Depletion Potential |

| POCP | Photochemical Ozone Creation Potential |

| PED | Primary Energy Demand |

| MAEP | Marine Aquatic Ecotoxicity Potential |

| TEP | Terrestrial Ecotoxicity Potential |

| BWC | Blue Water Consumption |

| FEP | Freshwater Eutrophication |

| SSM | Secondary Soap Mix |

| PSM | Primary Soap Mix |

| TRI | toxic release inventory |

| DCB | Dichlorobenzene |

| Sb | Antimony |

| VOCs | volatile organic compounds |

| CFCs | Chlorofluorocarbons |

| EoL | End-of-Life |

References

- Malviya, S. HUL, P&G, Nirma Lose Market Share to Small Local Brands. Econ. Times 2017. [Google Scholar]

- Singh, C.; Osbahr, H.; Dorward, P. The Implications of Rural Perceptions of Water Scarcity on Differential Adaptation Behaviour in Rajasthan, India. Reg. Environ. Chang. 2018, 18, 2417–2432. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhang, Y.; Liu, X. Life Cycle Assessment of Horizontal-Axis Washing Machines in China. Int. J. Life Cycle Assess. 2016, 21, 15–28. [Google Scholar] [CrossRef]

- Chirani, M.R.; Kowsari, E.; Teymourian, T.; Ramakrishna, S. Environmental Impact of Increased Soap Consumption during COVID-19 Pandemic: Biodegradable Soap Production and Sustainable Packaging. Sci. Total Environ. 2021, 796, 149013. [Google Scholar] [CrossRef] [PubMed]

- TechSci Research. India Soap Market, by Form, by Distribution Channel, by Application, by Region, by Company, Competition, Forecast & Opportunities, FY2016–FY2026; TechSci Research: Noida, India, 2020. [Google Scholar]

- Talic, S.; Shah, S.; Wild, H.; Gasevic, D.; Maharaj, A.; Ademi, Z.; Li, X.; Xu, W.; Mesa-Eguiagaray, I.; Rostron, J.; et al. Effectiveness of Public Health Measures in Reducing the Incidence of COVID-19, SARS-CoV-2 Transmission, and COVID-19 Mortality: Systematic Review and Meta-Analysis. BMJ 2021, 375, e068302. [Google Scholar] [CrossRef] [PubMed]

- TechSci Research. Global Soaps Market, by Type (Liquid Soaps and Bar Soaps), by Distribution Channel (Modern Trade, Traditional Trade and Online), by Region, by Company, Competition, Forecast & Opportunities, 2025; TechSci Research: Noida, India, 2020. [Google Scholar]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Villota-Paz, J.M.; Osorio-Tejada, J.L.; Morales-Pinzón, T. Comparative life cycle assessment for the manufacture of bio-detergents. Environ. Sci. Pollut. Res. 2023, 30, 34243–34254. [Google Scholar] [CrossRef]

- Giagnorio, M.; Amelio, A.; Grüttner, H.; Tiraferri, A. Environmental Impacts of Detergents and Benefits of Their Recovery in the Laundering Industry. J. Clean. Prod. 2017, 154, 593–601. [Google Scholar] [CrossRef]

- Francke, I.C.M.; Castro, J.F.W. Carbon and Water Footprint Analysis of a Soap Bar Produced in Brazil by Natura Cosmetics. Water Resour. Ind. 2013, 1–2, 37–48. [Google Scholar] [CrossRef]

- Van Lieshout, K.G.; Bayley, C.; Akinlabi, S.O.; von Rabenau, L.; Dornfeld, D. Leveraging life cycle assessment to evaluate environmental impacts of green cleaning products. Procedia CIRP 2015, 29, 372–377. [Google Scholar] [CrossRef]

- Rosen, M.A.; Kishawy, H.A. Sustainable Manufacturing and Design: Concepts, Practices and Needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- Kishawy, H.; Hegab, H.; Saad, E. Design for Sustainable Manufacturing: Approach, Implementation, and Assessment. Sustainability 2018, 10, 3604. [Google Scholar] [CrossRef]

- Daraban, A.E.O.; Negrea, C.S.; Artimon, F.G.P.; Angelescu, D.; Popan, G.; Gheorghe, S.I.; Gheorghe, M. A Deep Look at Metal Additive Manufacturing Recycling and Use Tools for Sustainability Performance. Sustainability 2019, 11, 5494. [Google Scholar] [CrossRef]

- Khasreen, M.; Banfill, P.F.; Menzies, G. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Awasthi, A.K.; Cheela, V.R.S.; D’Adamo, I.; Iacovidou, E.; Islam, M.R.; Johnson, M.; Miller, T.R.; Parajuly, K.; Parchomenko, A.; Radhakrishan, L.; et al. Zero Waste Approach towards a Sustainable Waste Management. Resour. Environ. Sustain. 2021, 3, 100014. [Google Scholar] [CrossRef]

- Martindale, W.; Duong, L.; Jagtap, S. Food Industry 4.0; CABI: Wallingford, UK, 2022; ISBN 9781789248425. [Google Scholar]

- Karwacka, M.; Ciurzyńska, A.; Lenart, A.; Janowicz, M. Sustainable Development in the Agri-Food Sector in Terms of the Carbon Footprint: A Review. Sustainability 2020, 12, 6463. [Google Scholar] [CrossRef]

- Salem, A.; Hopkins, C.; Imad, M.; Hegab, H.; Darras, B.; Kishawy, H.A. Environmental Analysis of Sustainable and Traditional Cooling and Lubrication Strategies during Machining Processes. Sustainability 2020, 12, 8462. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Krolczyk, G.M.; Mandal, U.K.; Mondal, S.P. Eco-Friendly Cutting Fluids in Minimum Quantity Lubrication Assisted Machining: A Review on the Perception of Sustainable Manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 249–280. [Google Scholar] [CrossRef]

- Jha, M.K.; Das, P.P.; Gupta, S.; Chaudhary, V.; Gupta, P. Complementing the Circular Economy with a Life Cycle Assessment of Sustainable Hydrogels and Their Future Prospects. In Sustainable Hydrogels; Elsevier: Amsterdam, The Netherlands, 2023; pp. 489–503. [Google Scholar]

- Sun, L.; Qin, L.; Taghizadeh-Hesary, F.; Zhang, J.; Mohsin, M.; Chaudhry, I.S. Analyzing Carbon Emission Transfer Network Structure among Provinces in China: New Evidence from Social Network Analysis. Environ. Sci. Pollut. Res. 2020, 27, 23281–23300. [Google Scholar] [CrossRef] [PubMed]

- Yip, W.S.; Zhou, H.; To, S. A Critical Analysis on the Triple Bottom Line of Sustainable Manufacturing: Key Findings and Implications. Environ. Sci. Pollut. Res. 2023, 30, 41388–41404. [Google Scholar] [CrossRef]

- Wen, H.; Liang, W.; Lee, C.-C. China’s Progress toward Sustainable Development in Pursuit of Carbon Neutrality: Regional Differences and Dynamic Evolution. Environ. Impact Assess. Rev. 2023, 98, 106959. [Google Scholar] [CrossRef]

- Wang, E.-Z.; Lee, C.-C. The Impact of Clean Energy Consumption on Economic Growth in China: Is Environmental Regulation a Curse or a Blessing? Int. Rev. Econ. Financ. 2022, 77, 39–58. [Google Scholar] [CrossRef]

- Ulvenblad, P.; Ulvenblad, P.; Tell, J. An Overview of Sustainable Business Models for Innovation in Swedish Agri-Food Production. J. Integr. Environ. Sci. 2019, 16, 1–22. [Google Scholar] [CrossRef]

- Gustavo, J.U.; Pereira, G.M.; Bond, A.J.; Viegas, C.V.; Borchardt, M. Drivers, Opportunities and Barriers for a Retailer in the Pursuit of More Sustainable Packaging Redesign. J. Clean. Prod. 2018, 187, 18–28. [Google Scholar] [CrossRef]

- Muthu, S.S. Environmental Impacts of the Use Phase of the Clothing Life Cycle. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2015; pp. 93–102. [Google Scholar]

- Patel, M.K.; Theiß, A.; Worrell, E. Surfactant Production and Use in Germany: Resource Requirements and CO2 Emissions. Resour. Conserv. Recycl. 1999, 25, 61–78. [Google Scholar] [CrossRef]

- Kumar, L.R.; Yellapu, S.K.; Tyagi, R.D.; Zhang, X. A Review on Variation in Crude Glycerol Composition, Bio-Valorization of Crude and Purified Glycerol as Carbon Source for Lipid Production. Bioresour. Technol. 2019, 293, 122155. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, R.M.S.R.; Kassim, A.H.M.; Anda, M.; Dallas, S. A Monitoring of Environmental Effects from Household Greywater Reuse for Garden Irrigation. Environ. Monit. Assess. 2013, 185, 8473–8488. [Google Scholar] [CrossRef]

- Gaurav, G.; Kumar, V.; Bihari singh, A.; Gupta, S.; Meena, M.L.; Dangayach, G.S.; Kumar Jindal, M. Life Cycle Assessment of Extraction of Edible Oil from Mustard Seeds: A Case Study of an Oil Industry. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Guinee, J.B. Handbook on Life Cycle Assessment Operational Guide to the ISO Standards. Int. J. Life Cycle Assess. 2002, 7, 311. [Google Scholar] [CrossRef]

- Shafiei, S.; Salim, R.A. Non-renewable and renewable energy consumption and CO2 emissions in OECD countries: A comparative analysis. Energy Policy 2014, 66, 547–556. [Google Scholar] [CrossRef]

- Brandao, M.; Heijungs, R.; Cowie, A.R. On quantifying sources of uncertainty in the carbon footprint of biofuels: Crop/feedstock, LCA modelling approach, land-use change, and GHG metrics. Biofuel Res. J. 2022, 9, 1608–1616. [Google Scholar] [CrossRef]

- Lacy, P.; Rutqvist, J. Waste to Wealth: The Circular Economy Advantage; Palgrave Macmillan: London, UK, 2015; Volume 91. [Google Scholar]

- Vanapalli, K.R.; Samal, B.; Dubey, B.K.; Bhattacharya, J. Emissions and environmental burdens associated with plastic solid waste management. In Plastics to Energy; William Andrew Publishing: Norwich, NY, USA, 2019; pp. 313–342. [Google Scholar]

- Das, P.P.; Singh, A.; Mishra, M.K.; Chaudhary, V.; Gupta, S.; Gupta, P. Life Cycle Assessment and Environmental Impact of Plastic Waste. In Biodegradability of Conventional Plastics; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–16. [Google Scholar]

- Aghbashlo, M.; Hosseinzadeh-Bandbafha, H.; Shahbeik, H.; Tabatabaei, M. The role of sustainability assessment tools in realizing bioenergy and bioproduct systems. Biofuel Res. J. 2022, 9, 1697–1706. [Google Scholar] [CrossRef]

| Reference | Title | Product/Process | System Boundary | Functional Unit | Software Used | Methodology | Country | Impact Categories | Outcomes |

|---|---|---|---|---|---|---|---|---|---|

| [10] Villota-Paz et al., 2023 | Comparative life cycle assessment for the manufacture of bio-detergents | Biodegradable detergents | Cradle-to-gate | 1 L detergent | SimaPro v9 | ReCiPe-2016 | Colombia | PED GWP POCP PED MAEP TEP BWC | Liquid detergent presented better environmental performance than traditional detergents in all the impact categories, except for the fossil resource scarcity category. |

| [11] Giagnorio et al., 2017 | Environmental impacts of detergents and benefits of their recovery in the laundering industry | Detergents Production and industrial washing systems | Cradle-to-grave | 1 kg detergent | Simapro v8 | Recipe | Italy | PED and GWP | The results show that the production of detergents has a wide impact distribution, with the ecosystem being the most affected impact category. |

| [12] Francke and Castro 2013 | Carbon and water footprint analysis of a soap bar produced in Brazil by Natura Cosmetics | Soap Bar | Cradle-to-grave | 450 g of soap | Calculation | IPCC—Intergovernmental Panel on Climate Change | Latin America | Carbon Footprints (CF) And Water Footprints (WF) | Analysis reveals that the total for the soap bar was 741 g CO2e, while the WF was 1.581 l, 1.587 l, and 3.672 l for the green, blue, and gray components, respectively. |

| [13] Van Lieshout et al., 2015 | Leveraging Life Cycle Assessment to evaluate environmental impacts of green cleaning products | All-purpose cleaner, hand wash, dish soap), and Ecover (dish soap) | Cradle-to-grave | 1 kg Cleaning Products | Simapro v8 | ReCiPe | USA | ADP AP EP GWP HTP ODP POCP PED MAEP TEP BWC | Results show that hand wash and dish soap, given their high percentage, significantly contribute to the product’s environmental impacts. |

| Category | Inputs | Outputs | ||||

|---|---|---|---|---|---|---|

| Stage 1: Steam Production | Substance | Amount | Unit | Substance | Amount | Unit |

| Coal (Indonesian bituminous) | 0.025 | kg | Steam (150 °C) | 0.150 | kg | |

| Water | 0.150 | kg | Ash | 0.002 | kg | |

| Coal Pulveriser | 805.68 | J | Clinker | 0.002 | kg | |

| Wood (Plywood, Timber) | 0.006 | kg | SOx | 0.019 | kg | |

| NOx | 0.004 | kg | ||||

| Fixed Carbon By-Product | 0.018 | kg | ||||

| Other Volatile Matter | 0.007 | kg | ||||

| Coal and Wood Moisture | 0.001 | kg | ||||

| Stage 2: PSM | Caustic Soda | 0.130 | kg | Primary Soap Mix | 0.802 | kg |

| Acid Oil (Ester) | 0.600 | kg | Steam (110 °C) | 0.150 | kg | |

| Water | 0.091 | kg | Drain | 0.022 | kg | |

| Steam (130 °C) | 0.150 | kg | Water Vapor | 0.004 | kg | |

| Stage 3: SSM | Primary Soap Mix | 0.802 | kg | Secondary Soap Mix | 1.003 | kg |

| Sodium Silicate | 0.270 | kg | Water | 0.013 | kg | |

| Salt | 0.007 | kg | Water Vapor | 0.005 | kg | |

| Water | 0.020 | kg | Glycerol | 0.077 | kg | |

| Compressed Air | 0.021 | kg | Steam converted to water | 0.150 | kg | |

| Steam (110 °C) | 0.150 | kg | ||||

| Power Blender | 34,912.8 | J | ||||

| Dye and Fragrance | 0.003 | L | ||||

| Stage 4: Soap Production | Secondary soap Mix | 1.004 | kg | Solid Soap | 1 | kg |

| Water flow in floater | 0.25 | kg | Water Vapor | 0.004 | kg | |

| Motor to rotate Floater | 6042.6 | J | ||||

| Pump | 2417.04 | J | ||||

| Conveyor Motors | 3222.72 | J | ||||

| Rolling mill Motors | 4834.08 | J | ||||

| Conveyor Motors | 3222.72 | J | ||||

| Printing rollers’ motor | 805.68 | J | ||||

| Cutter Motors | 1611.36 | J | ||||

| Conveyor Motors | 537.12 | J | ||||

| Packer | 67.14 | J | ||||

| Cutter | 67.14 | J | ||||

| Energy | 22,827.6 | J | ||||

| Stage 5: Packaging | Polyethylene | 0.005 | kg | |||

| Corrugated Box | 0.017 | kg | ||||

| Environmental Indicator | Preparation of PSM | Preparation of SSM | Continuous Bar Soap Production | Packaging of Bar Soap | Use Phase of Soap | Total | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Abiotic Depletion (ADP elements) [kg Sb-Equiv.] | 3.15 × 10−8 | 4.29 × 10−9 | 6.70 × 10−8 | 3.39 × 10−11 | 1.03 × 10−7 | |||||||

| Acidification Potential (AP) [kg SO2-Equiv.] | 1.17 × 10−4 | 2.20 × 10−4 | 1.29 × 10−4 | 1.55 × 10−6 | 4.68 × 10−4 | |||||||

| Eutrophication Potential (EP) [kg Phosphate-Equiv.] | 2.50 × 10−5 | 9.53 × 10−6 | 5.46 × 10−6 | 1.81 × 10−5 | 1.40 × 10−4 | 1.98 × 10−4 | ||||||

| Global Warming Potential (GWP) [kg CO2-Equiv.] | 4.88 × 10−2 | 1.78 × 10−2 | 1.03 × 10−2 | 3.09 × 10−4 | 7.72 × 10−2 | |||||||

| Human Toxicity Potential (HTP) [kg Di-chlorobenzene-Equiv.] | 4.90 × 10−2 | 5.81 × 10−3 | 3.41 × 10−3 | 2.82 × 10−6 | 5.82 × 10−2 | |||||||

| Ozone Layer Depletion Potential (ODP) [kg R11-Equiv.] | 1.58 × 10−8 | 3.15 × 10−15 | 1.85 × 10−15 | 7.68 × 10−13 | 1.58 × 10−8 | |||||||

| Photochemical Ozone Creation Potential (POCP) [kg Ethene-Equiv.] | 4.27 × 10−5 | 9.80 × 10−6 | 6.00 × 10−6 | 1.70 × 10−7 | 5.87 × 10−5 | |||||||

| Primary Energy Demand (PED) [J] | 8.06 × 10+2 | 3.49 × 10+4 | 2.28 × 10+4 | 1.43 × 10+4 | 7.28 × 10+4 | |||||||

| Marine Aquatic Ecotoxicity Potential (MAEP) [kg Di-chlorobenzene-Equiv.] | 9.41 × 10−1 | 1.71 × 10−1 | 1.48 × 10+1 | 2.24 × 10−2 | 2.51 × 10+1 | 4.10 × 10+1 | ||||||

| Terrestrial Ecotoxicity Potential (TEP) [kg 1,4-DB Equiv.} | 1.36 × 10−6 | 7.64 × 10−7 | 4.49 × 10−7 | 3.53 × 10−10 | 2.18 × 10−1 | 2.18 × 10−1 | ||||||

| Blue Water Consumption (BWC) [m3 Equiv.] | 1.22 × 10−1 | 1.44 × 10−2 | 8.47 × 10−3 | 2.43 × 10−7 | 9.00 × 10−1 | 1.04 × 10+0 | ||||||

| Fresh water Eutrophication (FWE) [kg Phosphorous Equiv.] | 6.62 × 10−7 | 1.00 × 10−8 | 5.80 × 10−9 | 1.56 × 10−5 | 4.59 × 10−5 | 6.22 × 10−5 | ||||||

| Impact Profile | Lowest | Highest | ||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaurav, G.; Dangayach, G.S.; Meena, M.L.; Chaudhary, V.; Gupta, S.; Jagtap, S. The Environmental Impacts of Bar Soap Production: Uncovering Sustainability Risks with LCA Analysis. Sustainability 2023, 15, 9287. https://doi.org/10.3390/su15129287

Gaurav G, Dangayach GS, Meena ML, Chaudhary V, Gupta S, Jagtap S. The Environmental Impacts of Bar Soap Production: Uncovering Sustainability Risks with LCA Analysis. Sustainability. 2023; 15(12):9287. https://doi.org/10.3390/su15129287

Chicago/Turabian StyleGaurav, Gaurav, Govind Sharan Dangayach, Makkhan Lal Meena, Vijay Chaudhary, Sumit Gupta, and Sandeep Jagtap. 2023. "The Environmental Impacts of Bar Soap Production: Uncovering Sustainability Risks with LCA Analysis" Sustainability 15, no. 12: 9287. https://doi.org/10.3390/su15129287

APA StyleGaurav, G., Dangayach, G. S., Meena, M. L., Chaudhary, V., Gupta, S., & Jagtap, S. (2023). The Environmental Impacts of Bar Soap Production: Uncovering Sustainability Risks with LCA Analysis. Sustainability, 15(12), 9287. https://doi.org/10.3390/su15129287