Pipe Piles and Key Stratum Modeling for Grouting Reinforcement of Mine Floors under Mining Disturbance and Microseismic Monitoring Evaluation

Abstract

1. Introduction

2. Grouting Reinforcement of Floor Damage Caused by Mining Pipe-Key Stratum Model

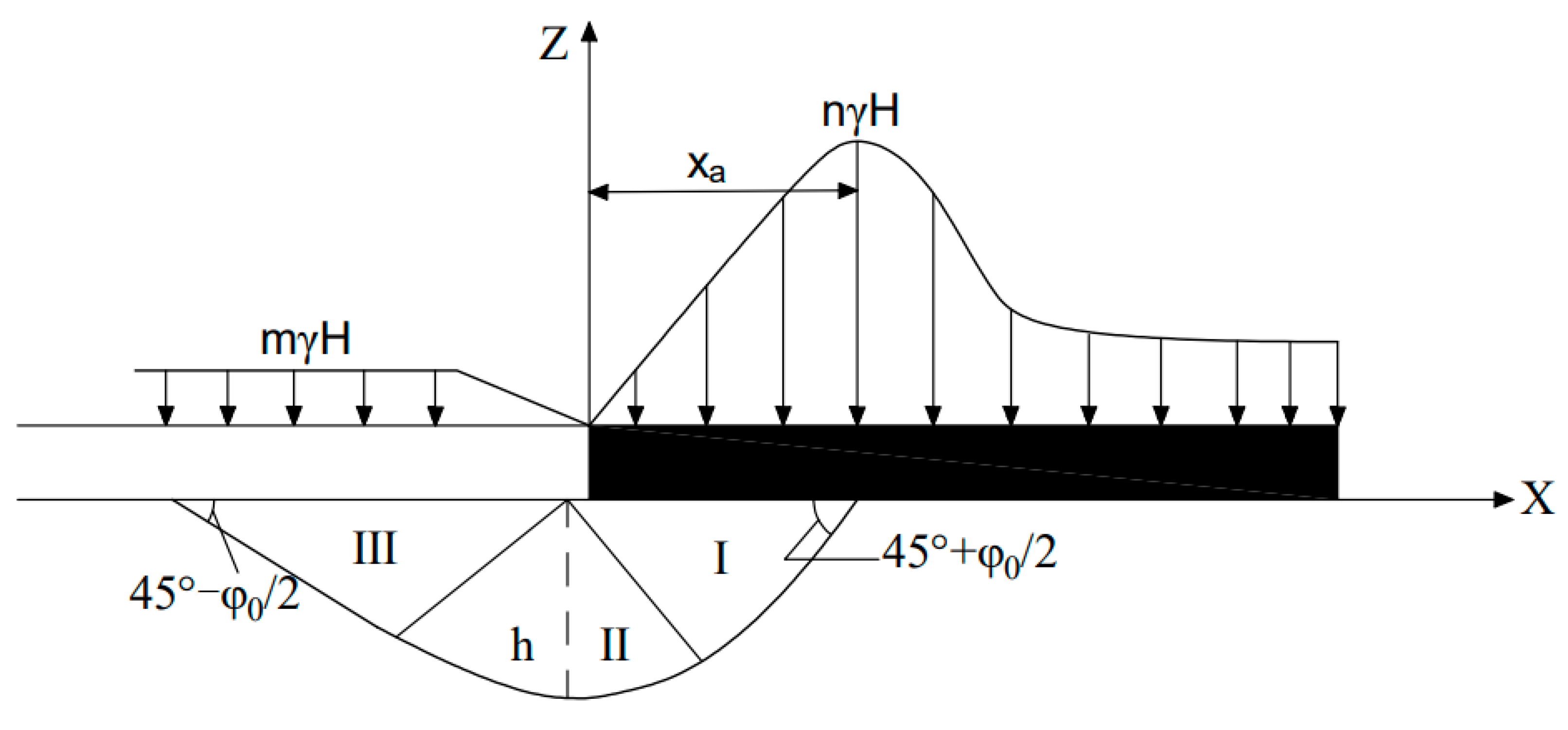

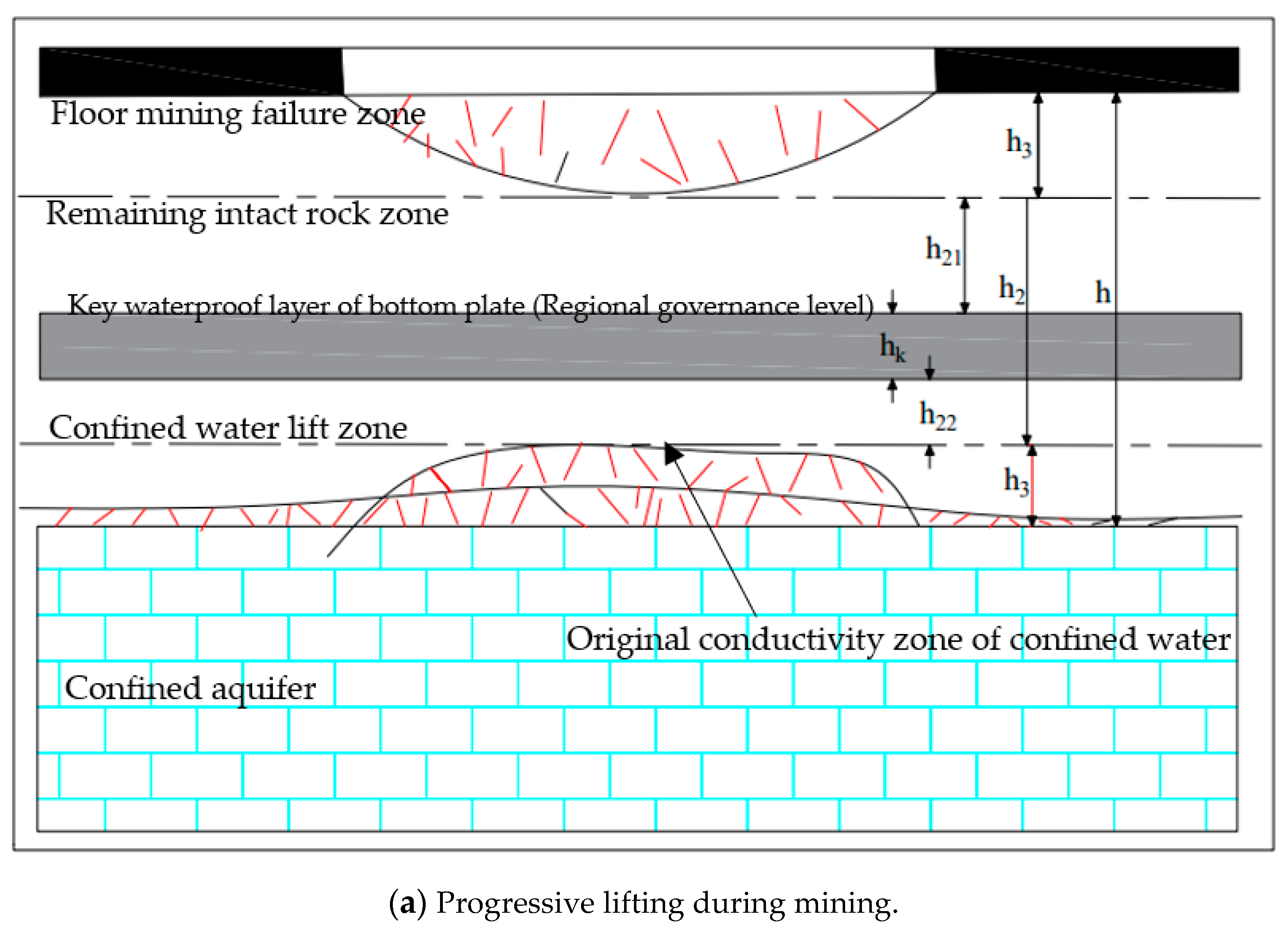

2.1. Floor Failure Zones

2.2. Pipe Pile-Key Stratum Model

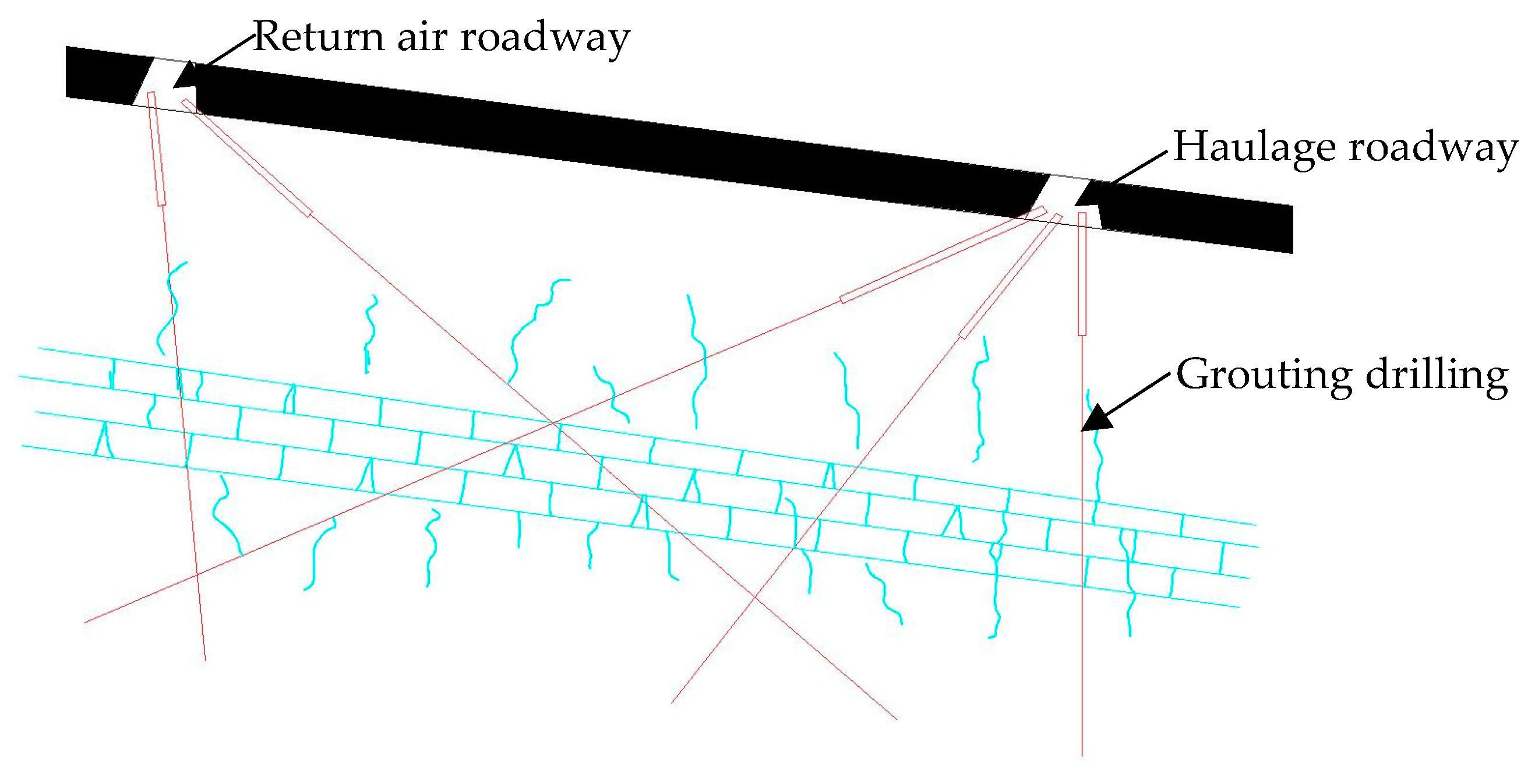

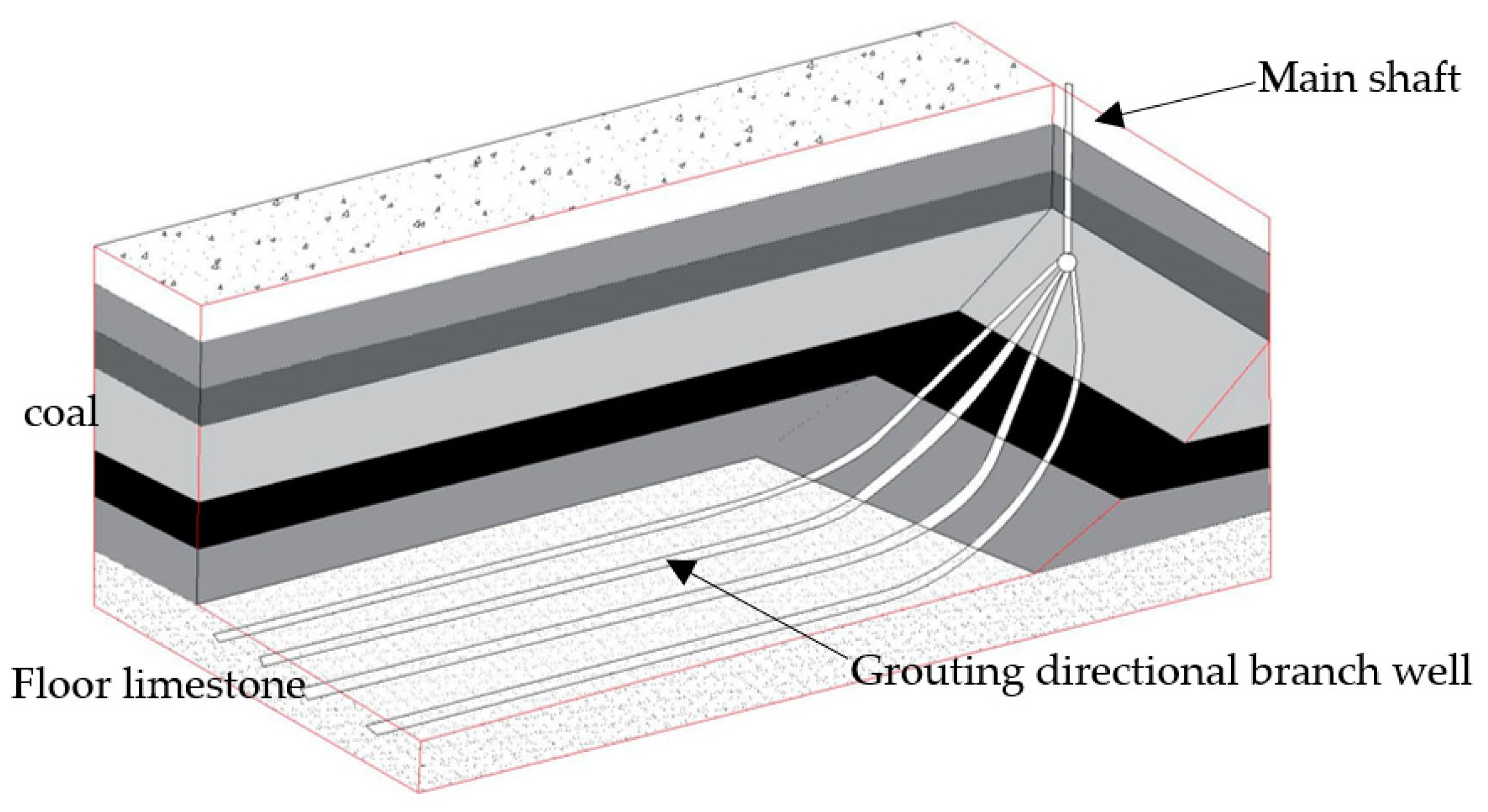

3. Model of “Pipe Pile” Reinforced by Cross-Layer Drilling and Grouting

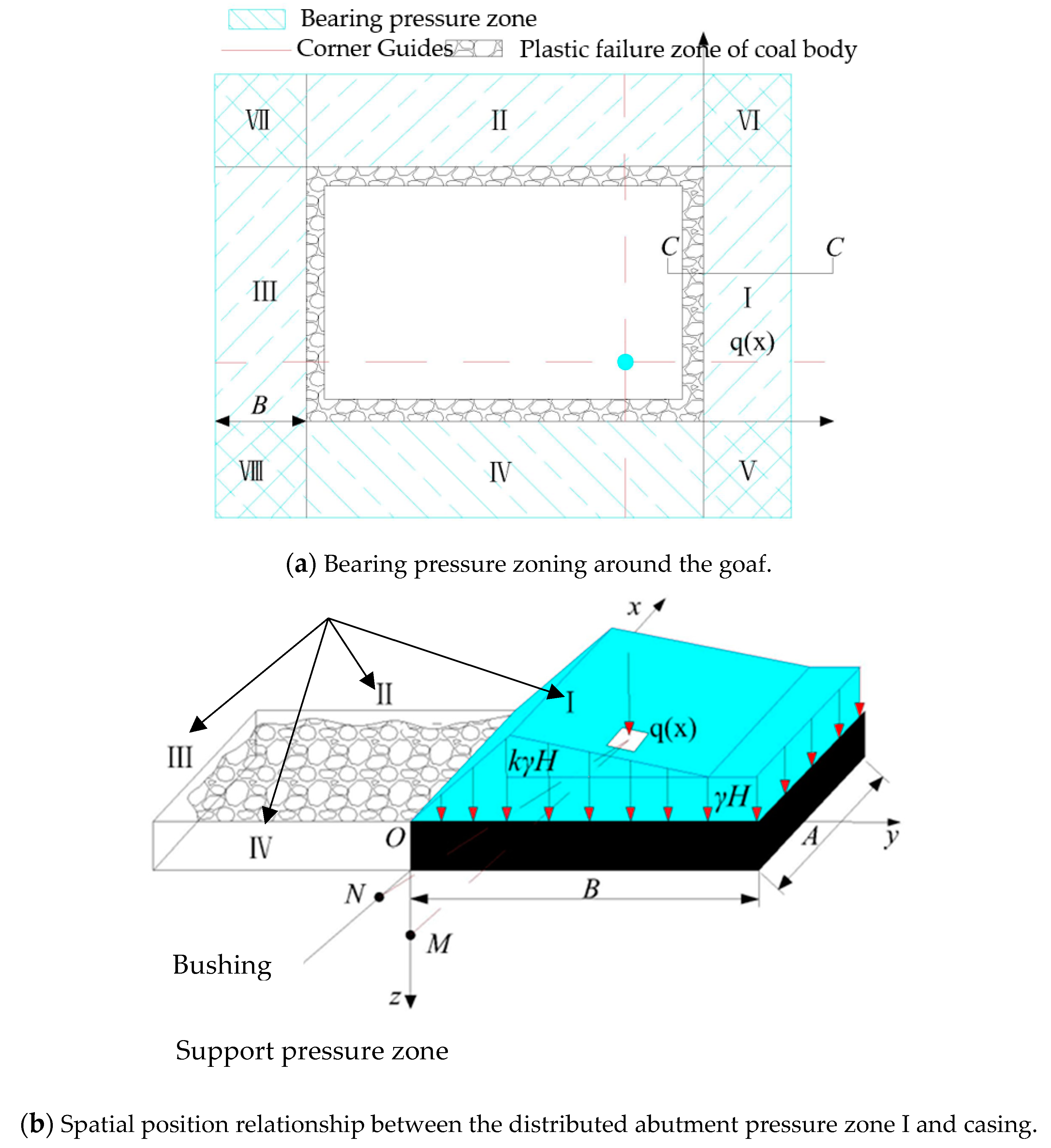

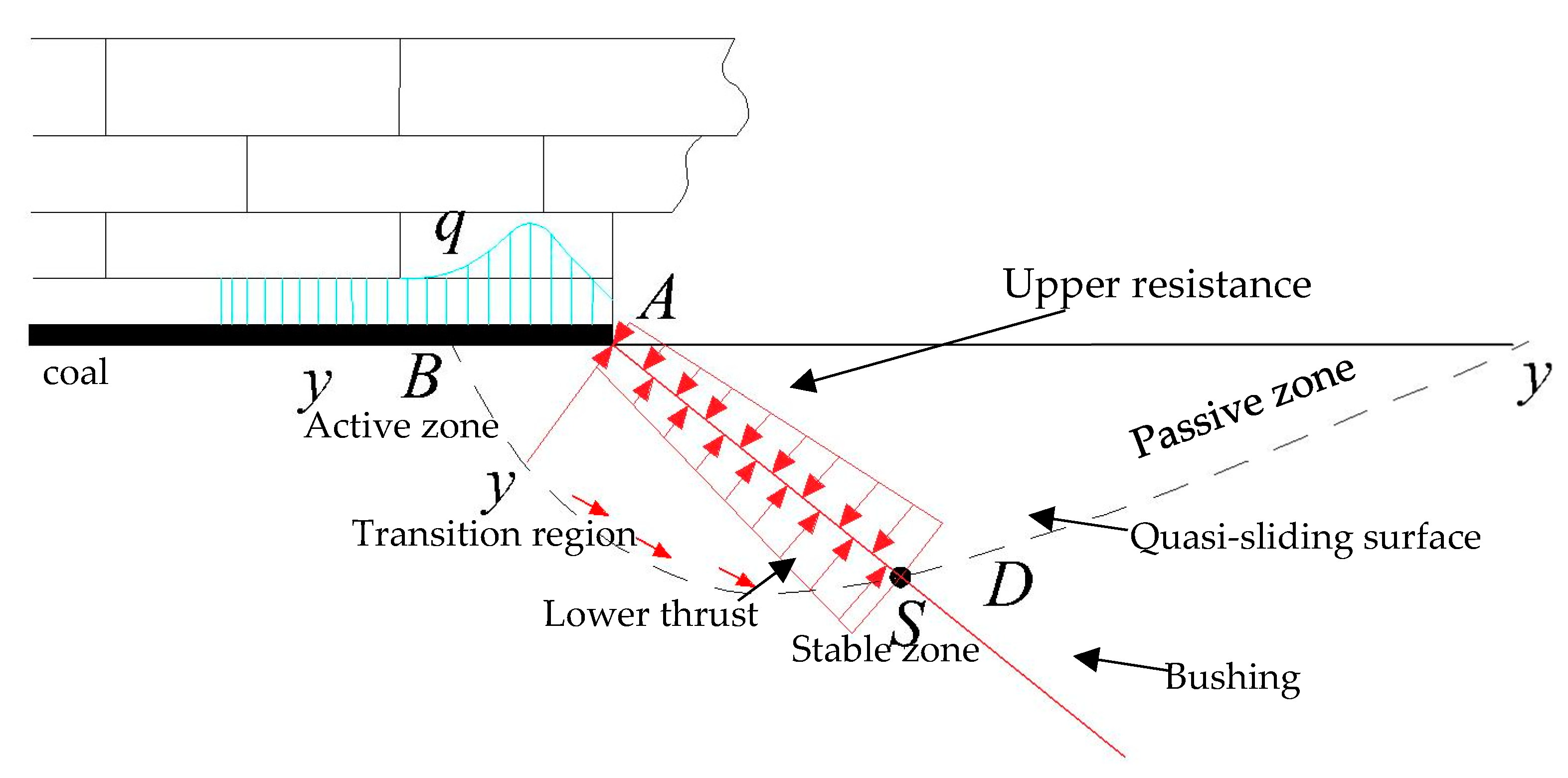

3.1. Spatial Stress Characteristics of Casings under Distributed Abutment Pressure

3.2. Stress Solution of Arbitrary Point on Casing in Space

- 1.

- Normal stress at one point on the casing.

- 2.

- Shear stress at one point on casing.

3.3. Mechanical Mechanism of Casing Filled with Slurry

4. “Key Layer” Model of Ground Area Governance

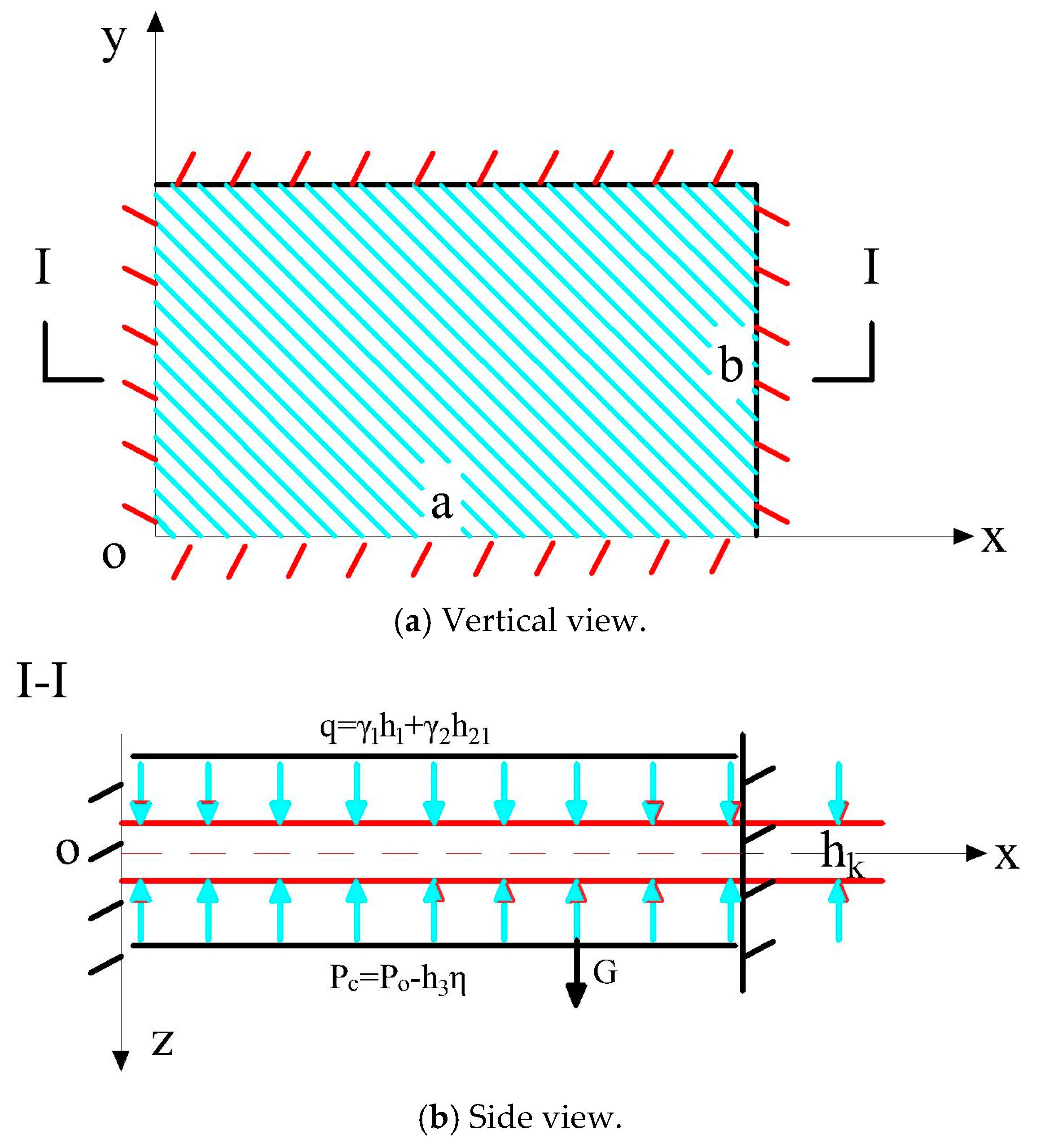

4.1. Mechanical Model of “Key Waterproof Layer”

4.2. Hydraulic Criteria for Water Inrush of “Key Water-Resisting Layer”

4.3. Analysis of Water Resistance Performance of “Key Water Resistance Layer”

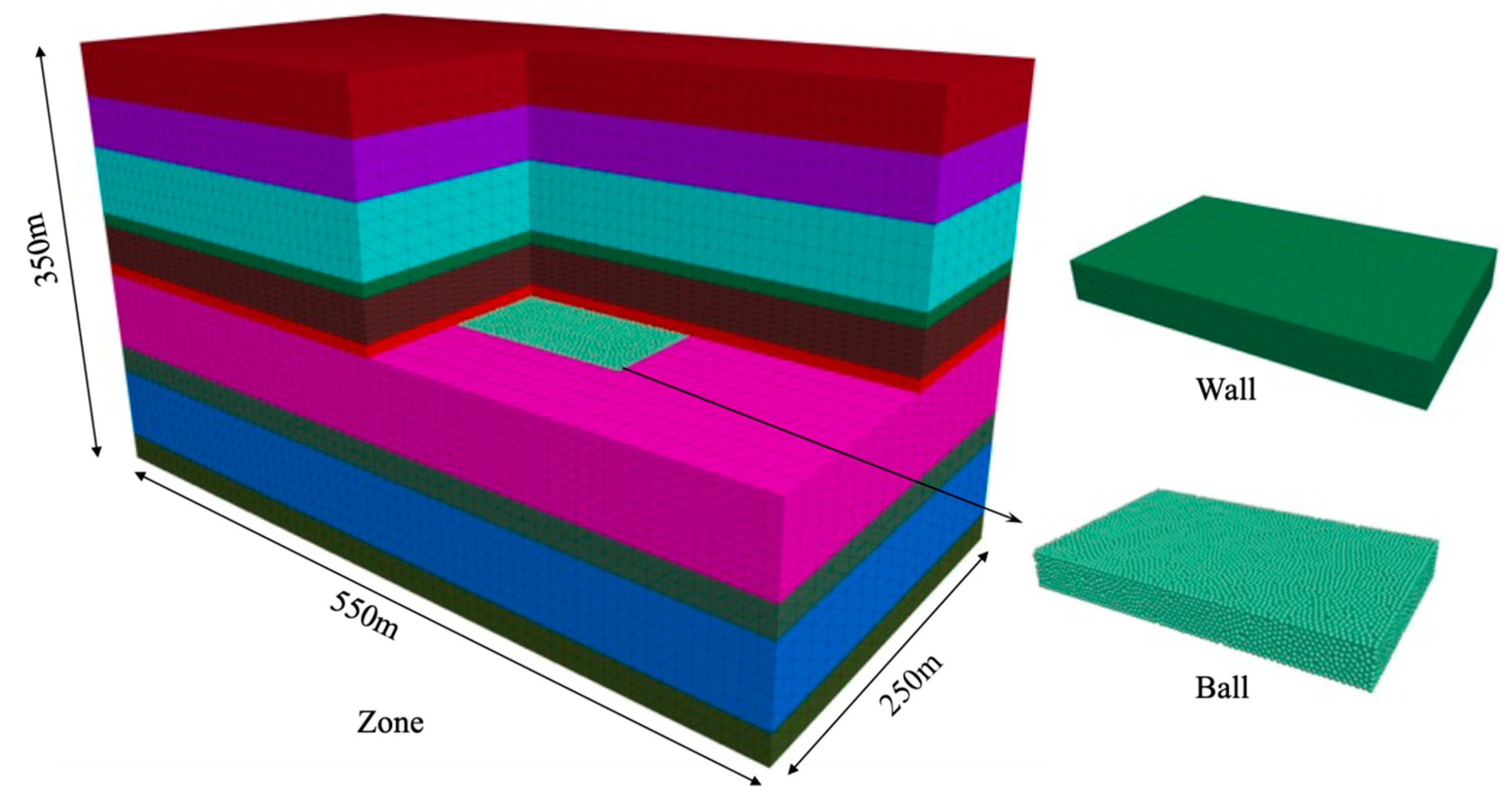

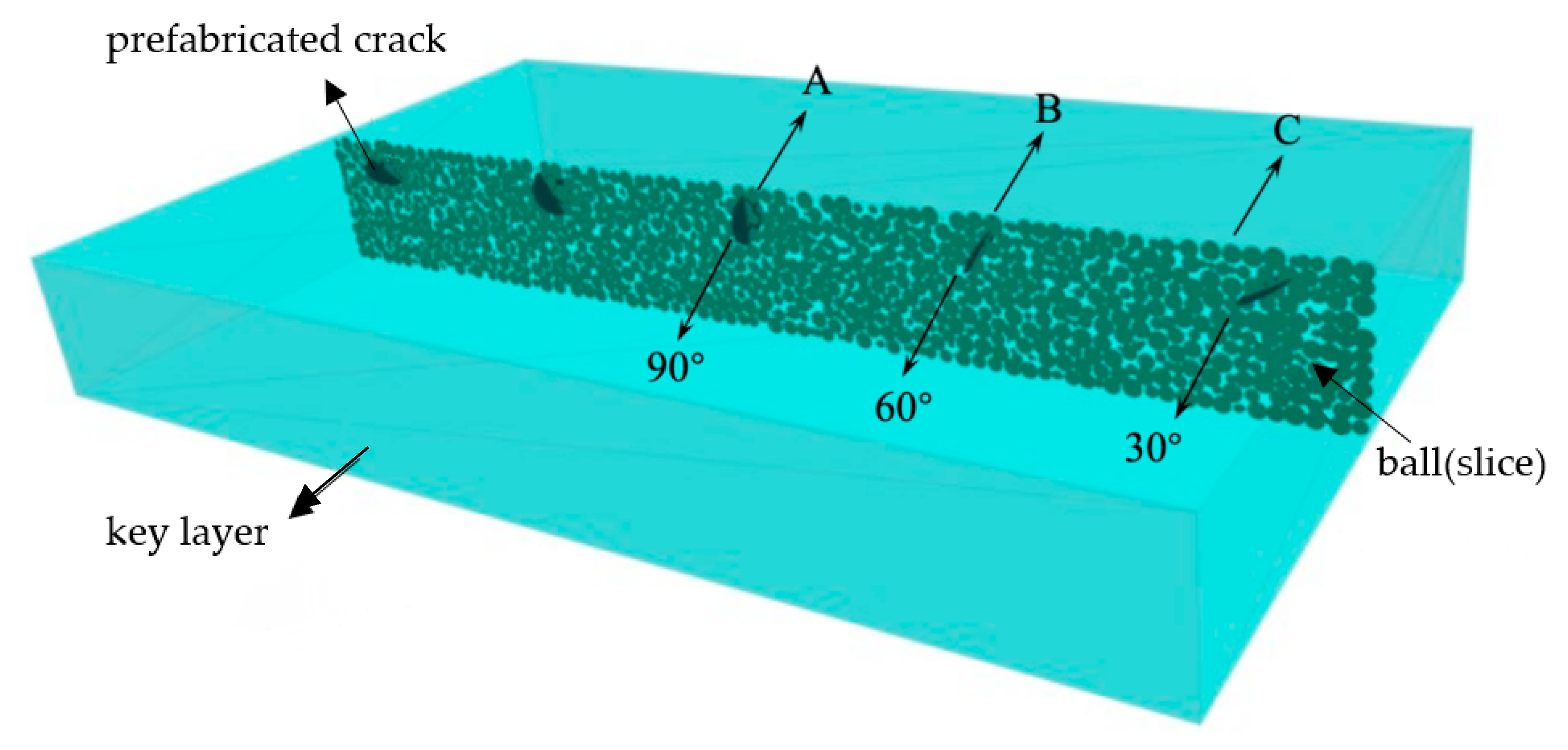

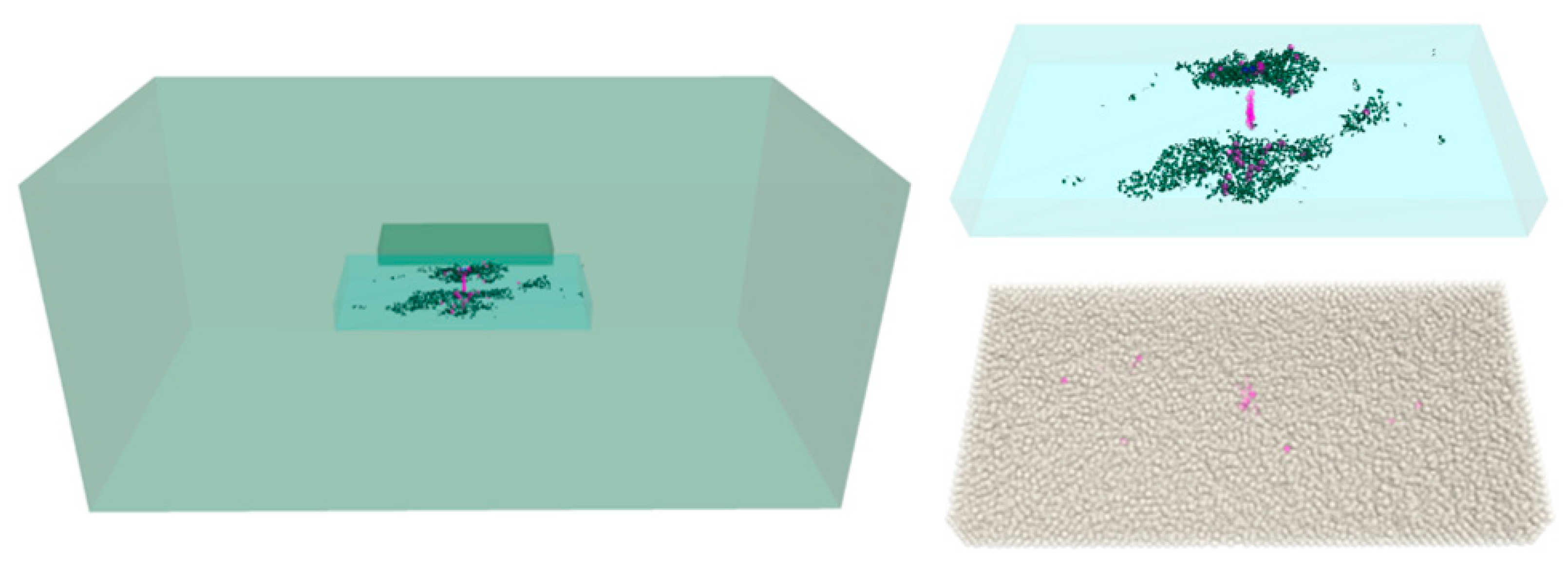

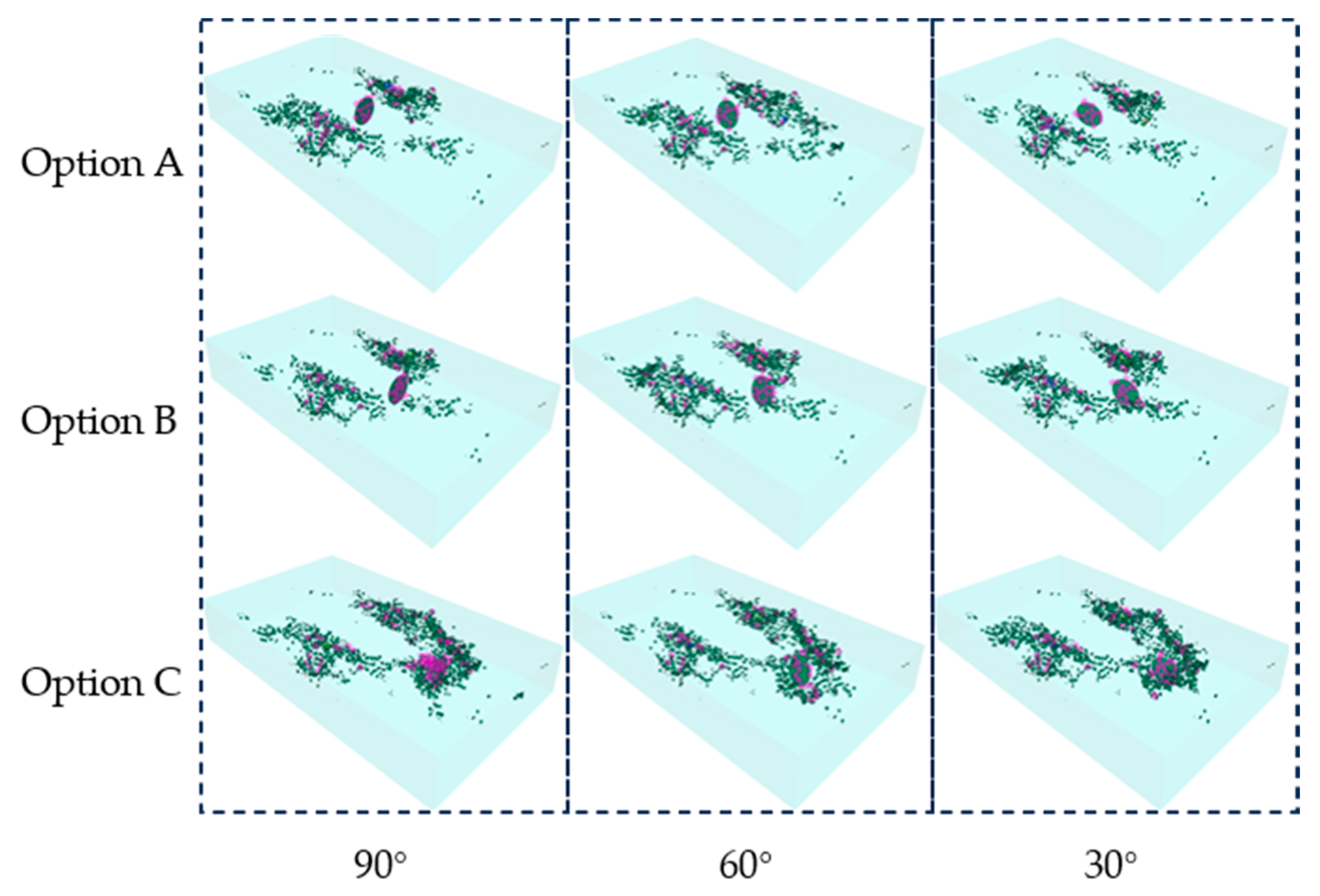

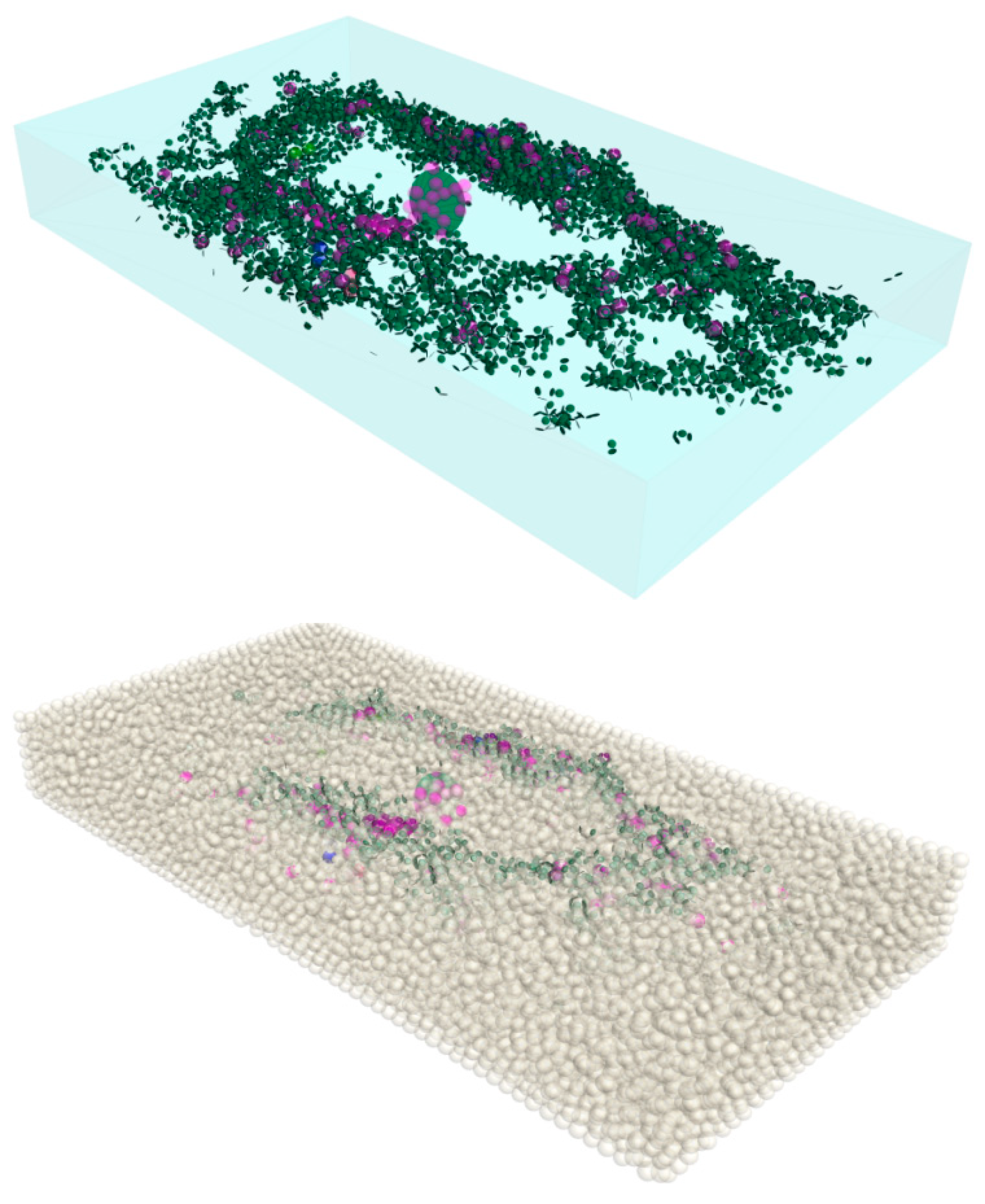

4.4. Numerical Analysis of Crack Propagation Law of a Coupling Model of “Key Layer” in Regional Governance

4.4.1. Model Construction

4.4.2. Simulation Scheme and Result Analysis

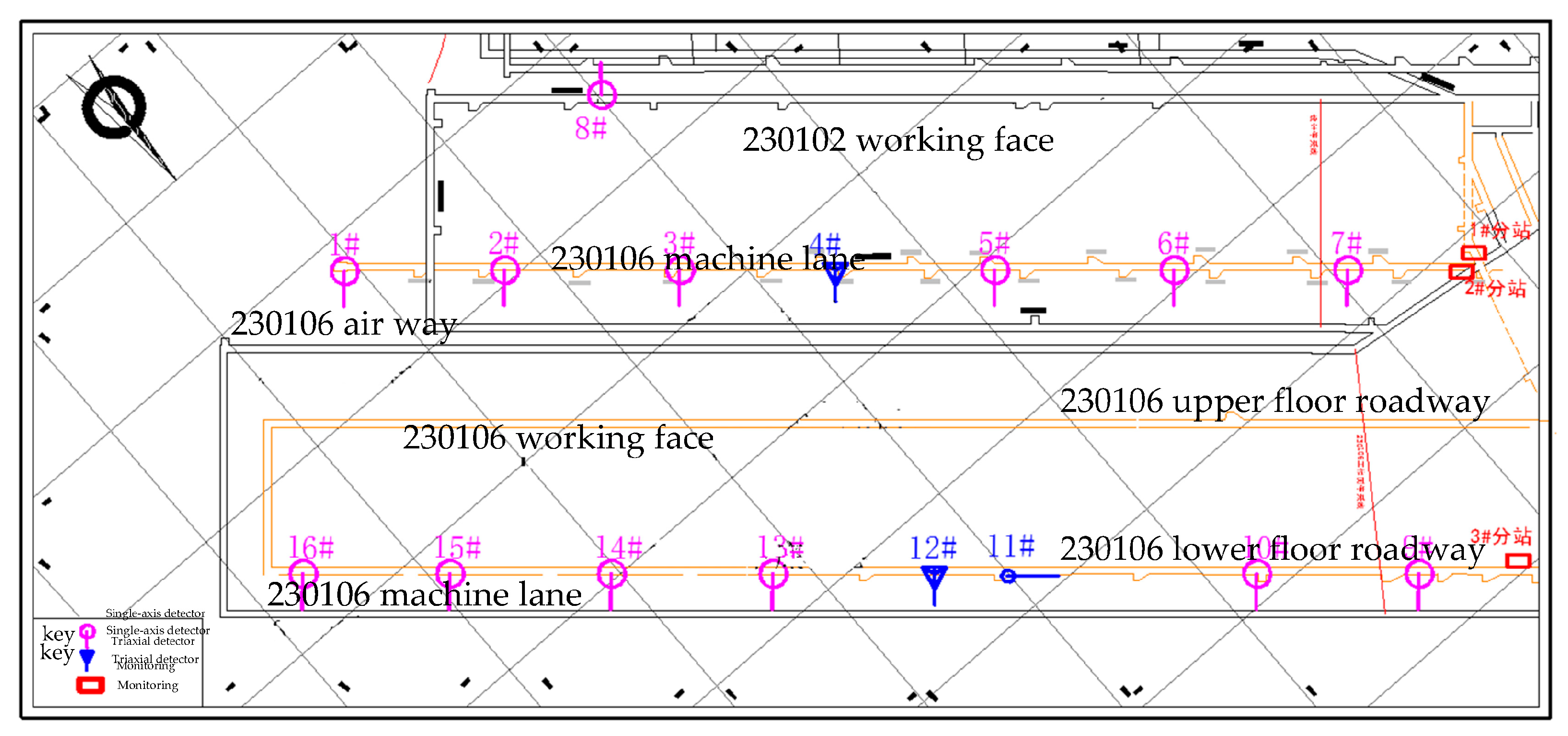

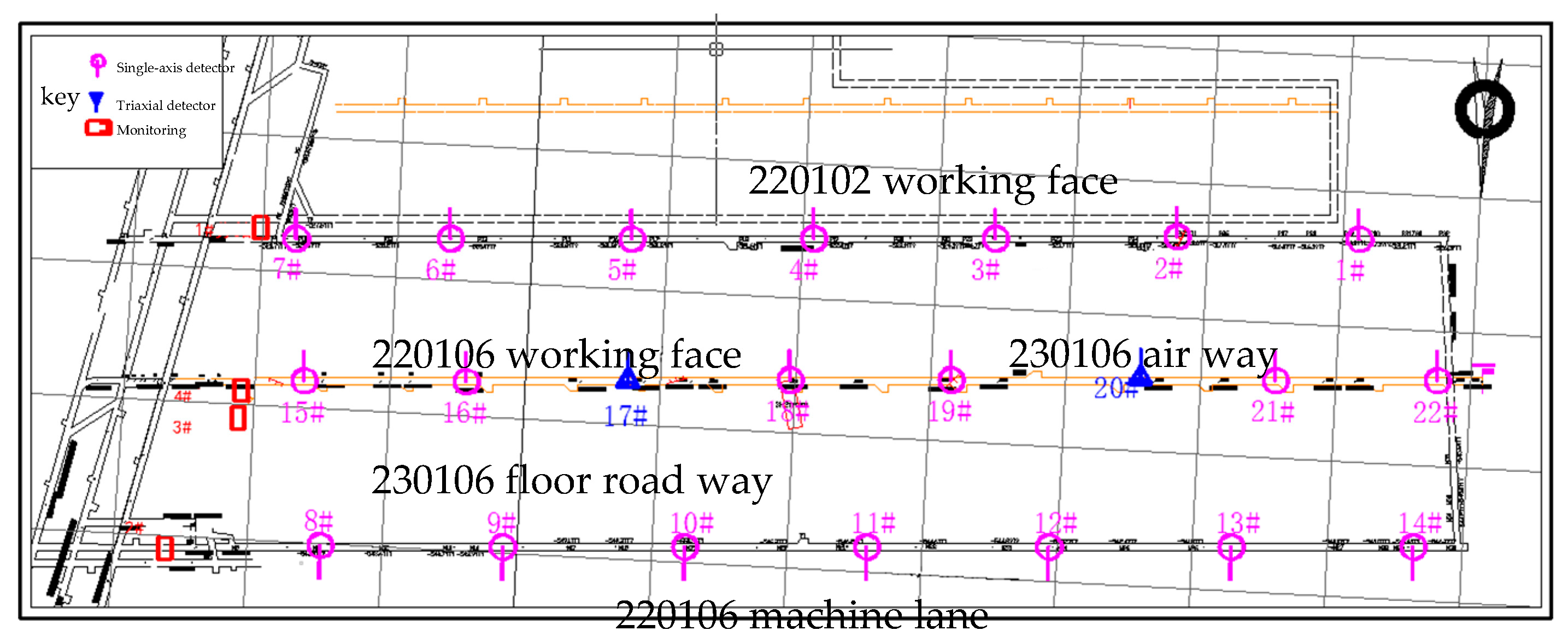

5. Microseismic Response Characteristics of Floor Grouting Reinforcement

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dong, C.L.; Mou, P.-Y.; Li, Q.-X.; Fang, J.; Zhao, J.G.; Hao, Y.J.; Zheng, D.Z. Development Trend and Technology of Coal Floor Grouting Reinforcement Drilling Construction. Coal Sci. Technol. 2014, 42, 27–31. [Google Scholar]

- Indraratna, B.; Nemcik, J.A.; Gale, W.J. Review and interpretation of primary floor failure mechanism at a longwall coal mining face based on numerical analysis. Geotechnique 2000, 50, 547–557. [Google Scholar] [CrossRef]

- Mo, S.; Sheffield, P.; Corbett, P.; Ramandi, H.L.; Oh, J.; Canbulat, I.; Saydam, S. A numerical investigation into floor buckling mechanisms in underground coal mine roadways. Tunn. Undergr. Space Technol. 2020, 103, 103497. [Google Scholar] [CrossRef]

- Li, N.; Zhang, M.; Ye, J.-L.; Liu, C. Experimental investigation on residual stress distribution in zirconium/titanium/steel tri-metal explosively welded composite plate after cutting and welding of a cover plate. J. Manuf. Process. 2021, 64, 455–463. [Google Scholar] [CrossRef]

- Sakhno, I.; Liashok, I.; Svitlana, S.; Oleksandr, I. Method for controlling the floor heave in mine roadways of underground coal mines. Min. Miner. Depos. 2022, 16, 1–10. [Google Scholar] [CrossRef]

- Yu, X.; Han, J.; Shi, L.; Wang, Y.; Zhao, Y. Application of a BP neural network in predicting destroyed floor depth caused by underground pressure. Environ. Earth Sci. 2017, 76, 535. [Google Scholar] [CrossRef]

- Shi, X.; Zhou, H.; Sun, X.; Cao, Z.; Zhao, Q. Floor damage mechanism with cemented paste backfill mining method. Arab. J. Geosci. 2021, 14, 80. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, Y.; Liu, W.; Li, Q. Research on floor heave of roadway in deep mining. Chin. J. Rock Mech. Eng. 2004, 23, 2396–2401. [Google Scholar]

- Tang, S.; Tang, C. Numerical studies on tunnel floor heave in swelling ground under humid conditions. Int. J. Rock Mech. Min. Sci. 2012, 55, 139–150. [Google Scholar] [CrossRef]

- Zuliang, Z.; Yiliang, T.; Xinrong, L. Occurrence mechanism and control technology of the floor heave disaster for soft-rock tunnel. Disaster Adv. 2012, 5, 987–992. [Google Scholar]

- Zhai, J.; Liu, D.; Li, G.; Wang, F. Floor failure evolution mechanism for a fully mechanized longwall mining face above a confined aquifer. Adv. Civ. Eng. 2019, 2019, 8036928. [Google Scholar] [CrossRef]

- Nemcik, J.A.; Indraratna, B.; Gale, W. Floor failure analysis at a longwall mining face based on the multiple sliding block model. Geotech. Geol. Eng. 2000, 18, 175–192. [Google Scholar] [CrossRef]

- Li, J.B.; Xu, Y.C.; Wang, X.M. The effect of flexural behavior of the grouting reinforcement casing on coal seam floor deformation. J. Min. Saf. Eng. 2017, 34, 336–341. [Google Scholar]

- Wang, P.; Zhao, Y.; Jiang, Y.; Zhang, C.; Zhang, D.; Yang, J.; Liu, W.; Zhai, J. Characteristics and control technology of water inrush from deep coal seam floor above confined aquifer in Xingdong coal mine. J. China Coal Soc. 2020, 45, 2444–2454. [Google Scholar]

- Kong, H.L.; Chen, Z.Q.; Bu, W.K.; Wang, B.; Wang, L.Z. A primary exploration on the relationships among loading key strata, water-resisting key strata and seepage key strata. J. China Coal Soc. 2008, 33, 485–488. [Google Scholar]

- Li, X.; Chen, S.; Wang, S.; Zhao, M.; Liu, H. Study on in situ stress distribution law of the deep mine: Taking Linyi mining area as an example. Adv. Mater. Sci. Eng. 2021, 2021, 5594181. [Google Scholar] [CrossRef]

- Jian, S. Failure characteristics of floor “three-zone” along the inclined direction of coal seam. J. Min. Saf. Eng. 2014, 31, 115. [Google Scholar]

- Zhang, Z.; Zhang, N.; Shimada, H.; Sasaoka, T.; Wahyudi, S. Optimization of hard roof structure over retained goaf-side gateroad by pre-split blasting technology. Int. J. Rock Mech. Min. Sci. 2017, 100, 330–337. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, S.; Qin, Y.; Hu, X.; Cheng, J. Experimental study on the goaf flow field of the “U + I” type ventilation system for a comprehensive mechanized mining face. Int. J. Min. Sci. Technol. 2015, 25, 1003–1010. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, P.; Shang, J.; Yao, D.; Wu, R.; Ou, Y.; Tian, Y. Comprehensive research on the failure evolution of the floor in upper mining of deep and thick coal seam. J. Appl. Geophys. 2022, 206, 104774. [Google Scholar] [CrossRef]

- Zuo, J.; Wu, G.; Du, J.; Lei, B.; Li, Y. Rock Strata Failure Behavior of Deep Ordovician Limestone Aquifer and Multi-level Control Technology of Water Inrush Based on Microseismic Monitoring and Numerical Methods. Rock Mech. Rock Eng. 2022, 55, 4591–4614. [Google Scholar] [CrossRef]

- Goodman, R.E.; Kieffer, D.S. Behavior of rock in slopes. J. Geotech. Geoenviron. Eng. 2000, 126, 675–684. [Google Scholar] [CrossRef]

- Zhai, M.; Bai, H.; Wu, L.; Wu, G.; Yan, X.; Ma, D. A reinforcement method of floor grouting in high-water pressure working face of coal mines: A case study in Luxi coal mine, North China. Environ. Earth Sci. 2022, 81, 28. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, J.; Zhang, S.; Zhang, Y.; Yang, F.; Li, M. An experimental and analytical research on the evolution of mining cracks in deep floor rock mass. Pure Appl. Geophys. 2020, 177, 5325–5348. [Google Scholar] [CrossRef]

- Cao, S. Research Progress of Modern Mining Theory and Technology; Chongqing University Press: Chongqing, China, 2020. [Google Scholar]

- Jiang, L.; Kong, P.; Shu, J.; Fan, K. Numerical analysis of support designs based on a case study of a longwall entry. Rock Mech. Rock Eng. 2019, 52, 3373–3384. [Google Scholar] [CrossRef]

- Chun, X.Y.; Yang, Y. New Progress on Floor Grouting Reinforcement Technology of Water Control in Coal Mining Face. Coal Sci. Technol. 2014, 42, 98–101+120. [Google Scholar]

- Jiang, F.X.; Ye, G.X.; Wang, C.W.; Zhang, D.Y.; Guan, Y.Q. Application of High-Precision Microseismic Monitoring Technique to Water Inrush Monitoring in Coal Mine. Chin. J. Rock Mech. Eng. 2008, 27, 1932–1938. [Google Scholar]

- Feng, X.; Ding, Z.; Hu, Q.; Zhao, X.; Ali, M.; Banquando, J.T. Orthogonal Numerical Analysis of Deformation and Failure Characteristics of Deep Roadway in Coal Mines: A Case Study. Minerals 2022, 12, 185. [Google Scholar] [CrossRef]

- Yang, T.; Zhang, J. Experimental research on simulation material for water-resisting soil layer in mining physical simulation. Adv. Mater. Sci. Eng. 2020, 2020, 3456913. [Google Scholar] [CrossRef]

- Pang, Z.; Zhang, X.; Chen, J.; Li, F. Application and Research of Gangue Partial-Filling Mining Method in Preventing Water Inrush from Floor. Geofluids 2022, 2022, 6464564. [Google Scholar] [CrossRef]

- Xu, Y.; Ma, L.; Ngo, I.; Zhai, J. Prediction of the height of water-conductive fractured zone under continuous extraction and partial backfill mining method—A case study. Sustainability 2022, 14, 6582. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, J.; Zhang, X.; Ning, J.; Zhang, Y. Distribution characteristics of floor pore water pressure based on similarity simulation experiments. Bull. Eng. Geol. Environ. 2020, 79, 4805–4816. [Google Scholar] [CrossRef]

- Thai, H.-T.; Choi, D.-H. A refined plate theory for functionally graded plates resting on elastic foundation. Compos. Sci. Technol. 2011, 71, 1850–1858. [Google Scholar] [CrossRef]

- Liang, Y.; Sun, D. Study on the composed rock beam theory of strata movement and its application. Chin. J. Rock Mech. Eng. 2002, 21, 654–657. [Google Scholar]

- Zhao, C.; Zhao, Z.; Song, W. Numerical Simulation on the Process of Water Inrush from Mining Floor with Fault Structure. Min. Res. Dev. 2018, 38, 80–84. [Google Scholar]

- Rong, H.; Bai, H. Pore structure characteristics of the relative water-resisting layer on the top of the Ordovician in Longgu Coal Mine. Int. J. Min. Sci. Technol. 2014, 24, 657–661. [Google Scholar] [CrossRef]

| Density (kg/m3) | Particle Diameters(mm) | Ball–Ball Contact Modulus (GPa) | Ball Stiffness Ratio | Parallel-bond Modulus (GPa) | Parallel-Bond Stiffness Ratio | Ball Friction Coefficient | Parallel-Bond Shear Strength (MPa) | Parallel-Bond Normal Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| 2000 | 0.2–0.25 | 2 | 0.8 | 2 | 0.8 | 0.1 | 0.7 | 0.5 |

| Name of Rock Stratum | Density/(Kg/m3) | K/GPa | G/GPa | C/MPa | φ/(°) | Tensile Strength/MPa |

|---|---|---|---|---|---|---|

| Fine sandstone | 2700 | 2.82 | 5.30 | 1.28 | 32 | 5.14 |

| Coal seam | 1940 | 12.68 | 1.21 | 2.68 | 23 | 1.50 |

| Siltstone | 2495 | 9.13 | 7.22 | 4.42 | 37 | 5.08 |

| Mudstone | 2700 | 6.13 | 5.92 | 3.24 | 37 | 2.08 |

| Sandy mudstone | 2570 | 5.13 | 6.24 | 1.55 | 27 | 4.08 |

| Fine sandstone Sandy mudstone | 2780 | 8.13 | 3.22 | 3.41 | 34 | 3.08 |

| Siltstone | 2495 | 9.13 | 7.22 | 4.42 | 37 | 5.08 |

| Horizon | Frequency of Microseismic Events (nos.) 230102 Working Face 220106 Working Face | |

|---|---|---|

| 1 coal bottom-1 ash top | 9379 | 17,387 |

| C3 I limestone | 1967 | 659 |

| C3 II limestone | 77 | 0 |

| C3 III limestone | 0 | 0 |

| Ordovician limestone | 0 | 0 |

| total | 11,423 | 18,046 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Liu, S.; Guo, D.; Li, Y.; Song, W.; Wang, Y.; Liu, Y. Pipe Piles and Key Stratum Modeling for Grouting Reinforcement of Mine Floors under Mining Disturbance and Microseismic Monitoring Evaluation. Sustainability 2023, 15, 9294. https://doi.org/10.3390/su15129294

Zhang D, Liu S, Guo D, Li Y, Song W, Wang Y, Liu Y. Pipe Piles and Key Stratum Modeling for Grouting Reinforcement of Mine Floors under Mining Disturbance and Microseismic Monitoring Evaluation. Sustainability. 2023; 15(12):9294. https://doi.org/10.3390/su15129294

Chicago/Turabian StyleZhang, Dangyu, Shiqi Liu, Dongyu Guo, Yubao Li, Wenxuan Song, Yiming Wang, and Yang Liu. 2023. "Pipe Piles and Key Stratum Modeling for Grouting Reinforcement of Mine Floors under Mining Disturbance and Microseismic Monitoring Evaluation" Sustainability 15, no. 12: 9294. https://doi.org/10.3390/su15129294

APA StyleZhang, D., Liu, S., Guo, D., Li, Y., Song, W., Wang, Y., & Liu, Y. (2023). Pipe Piles and Key Stratum Modeling for Grouting Reinforcement of Mine Floors under Mining Disturbance and Microseismic Monitoring Evaluation. Sustainability, 15(12), 9294. https://doi.org/10.3390/su15129294