Investigating the Remanufacturing Potential of Dye-Sensitized Solar Cells

Abstract

:1. Introduction

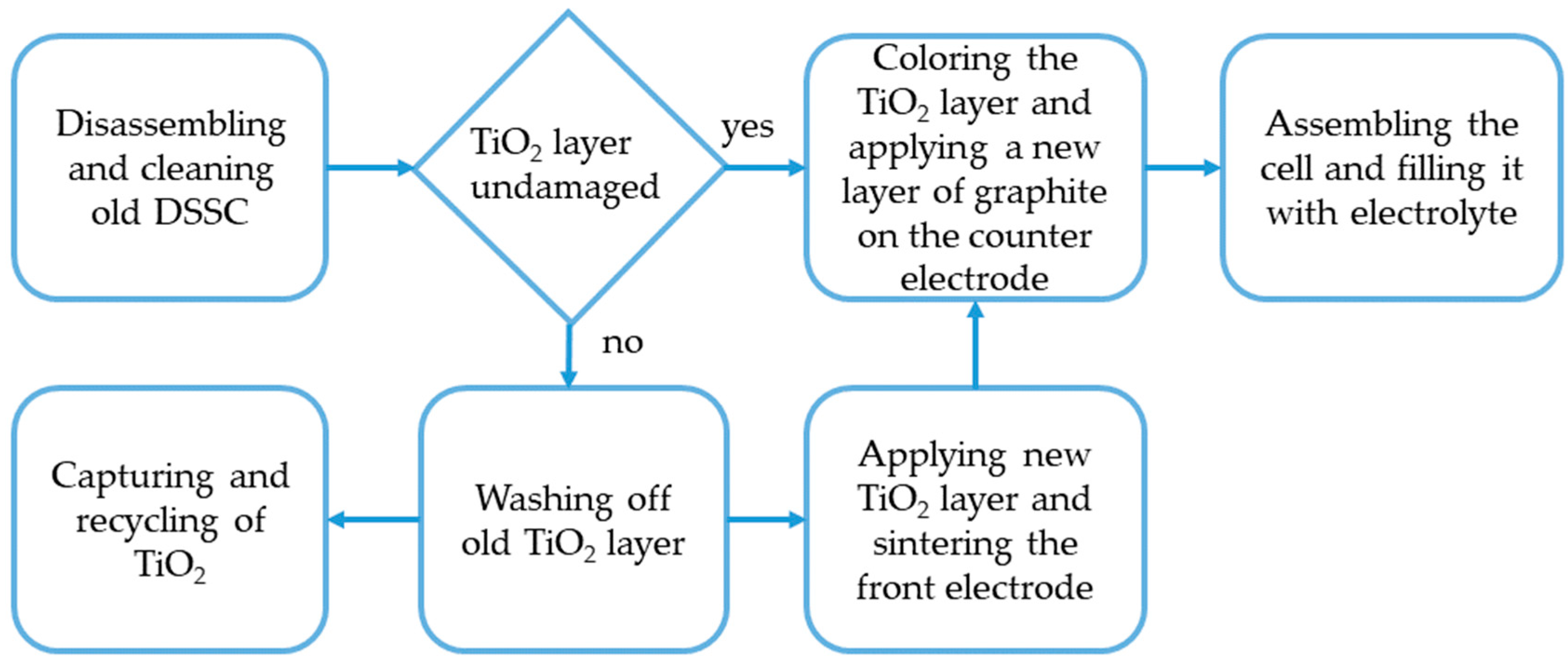

2. Materials and Methods

2.1. Four Generations of Commercially Applied TiO2 Layers

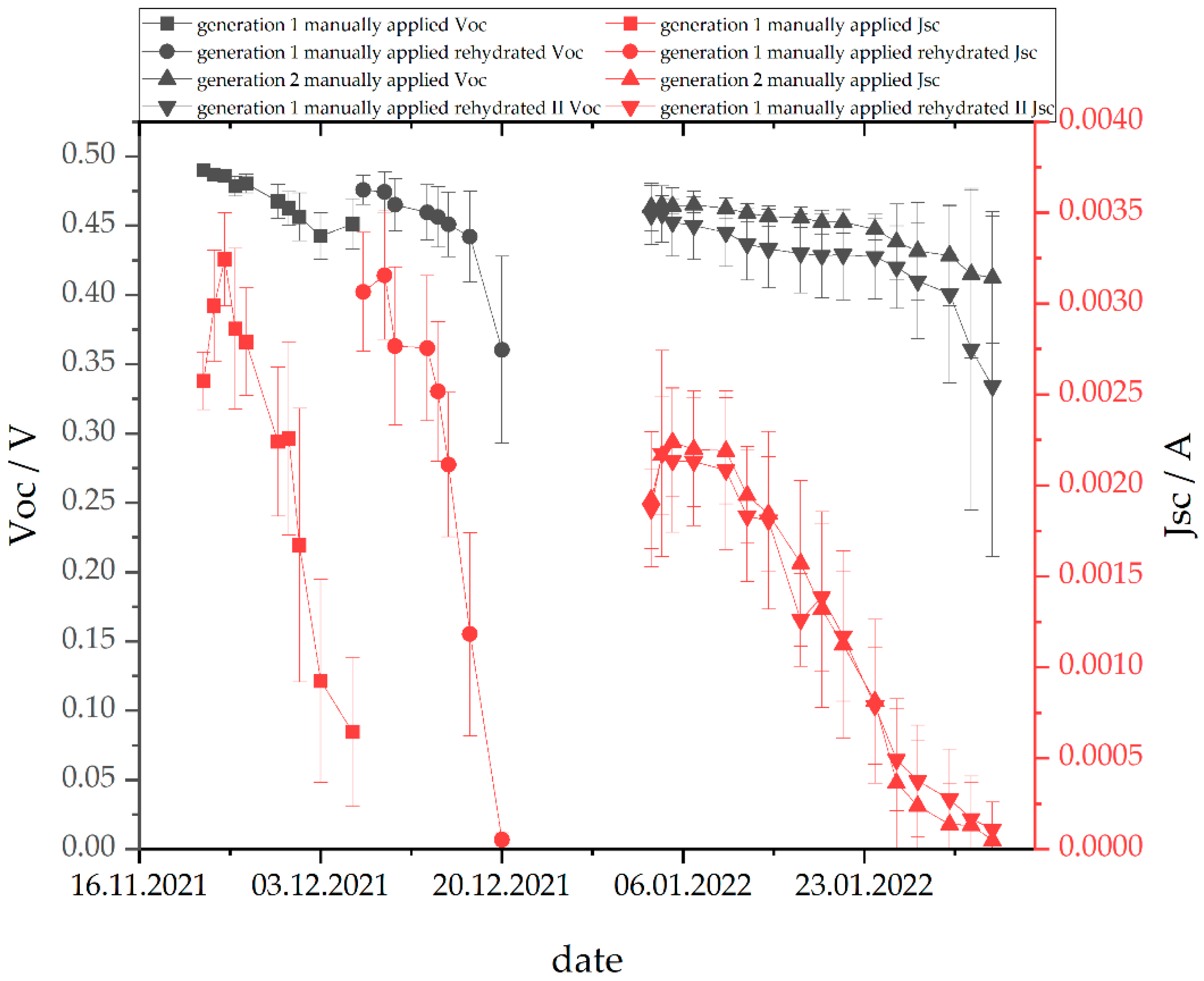

2.2. Two Generations of Manually Applied TiO2 Layers

2.3. Remanufactured DSSCs from 2015

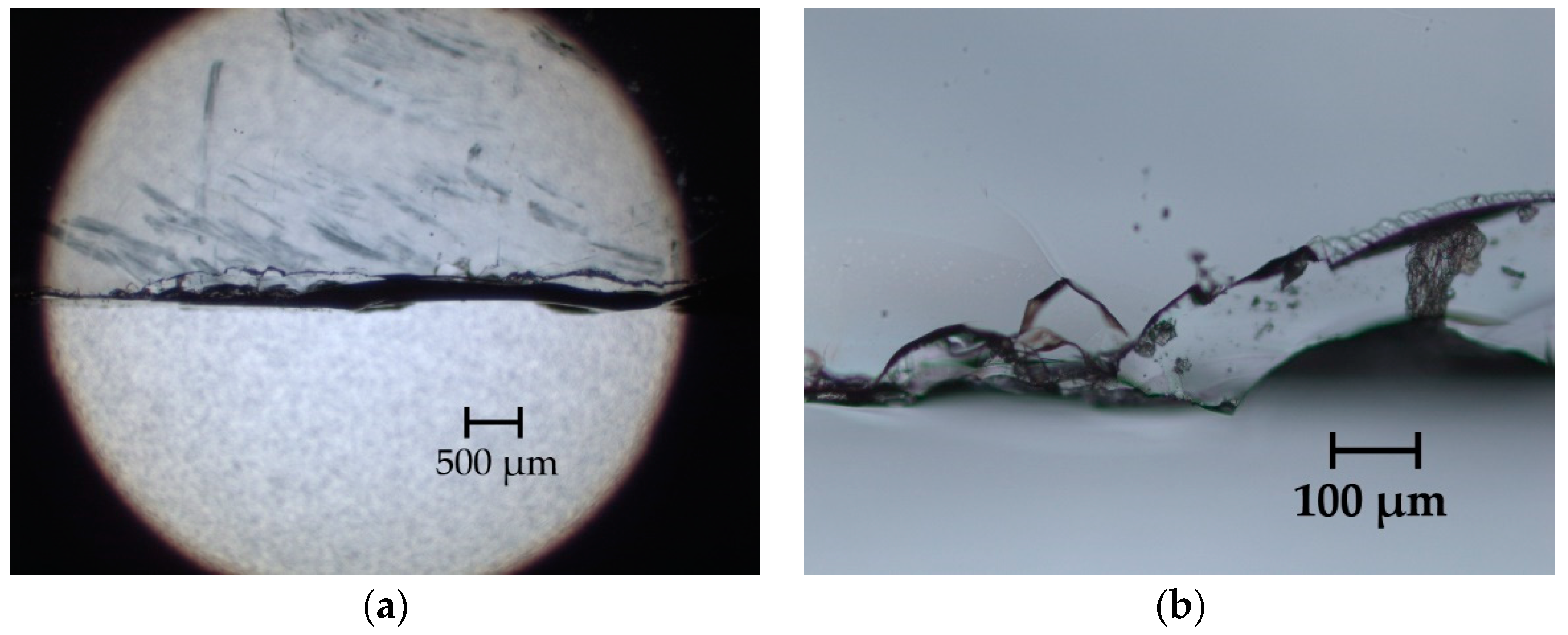

2.4. Recovering TiO2 during Remanufacturing

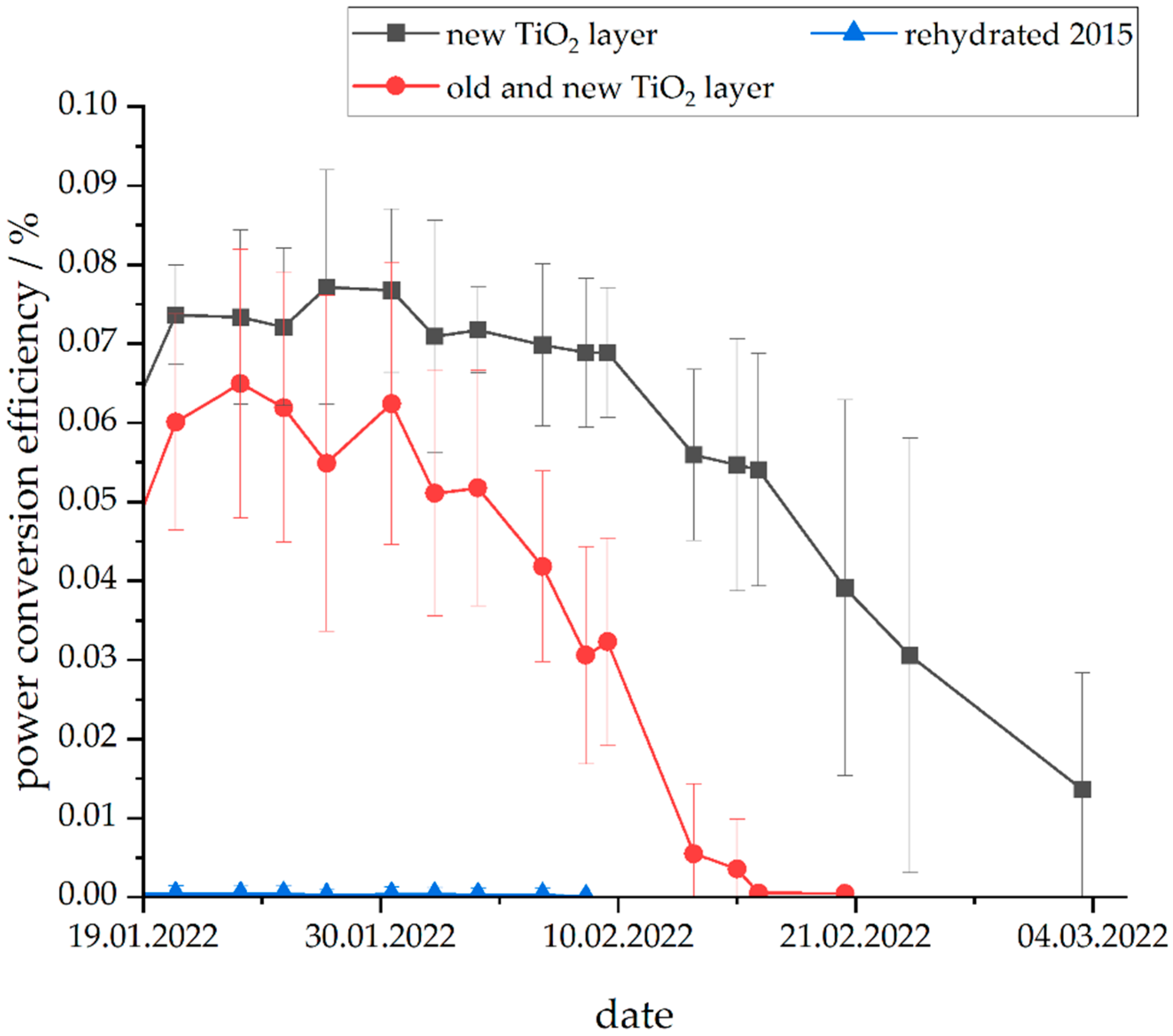

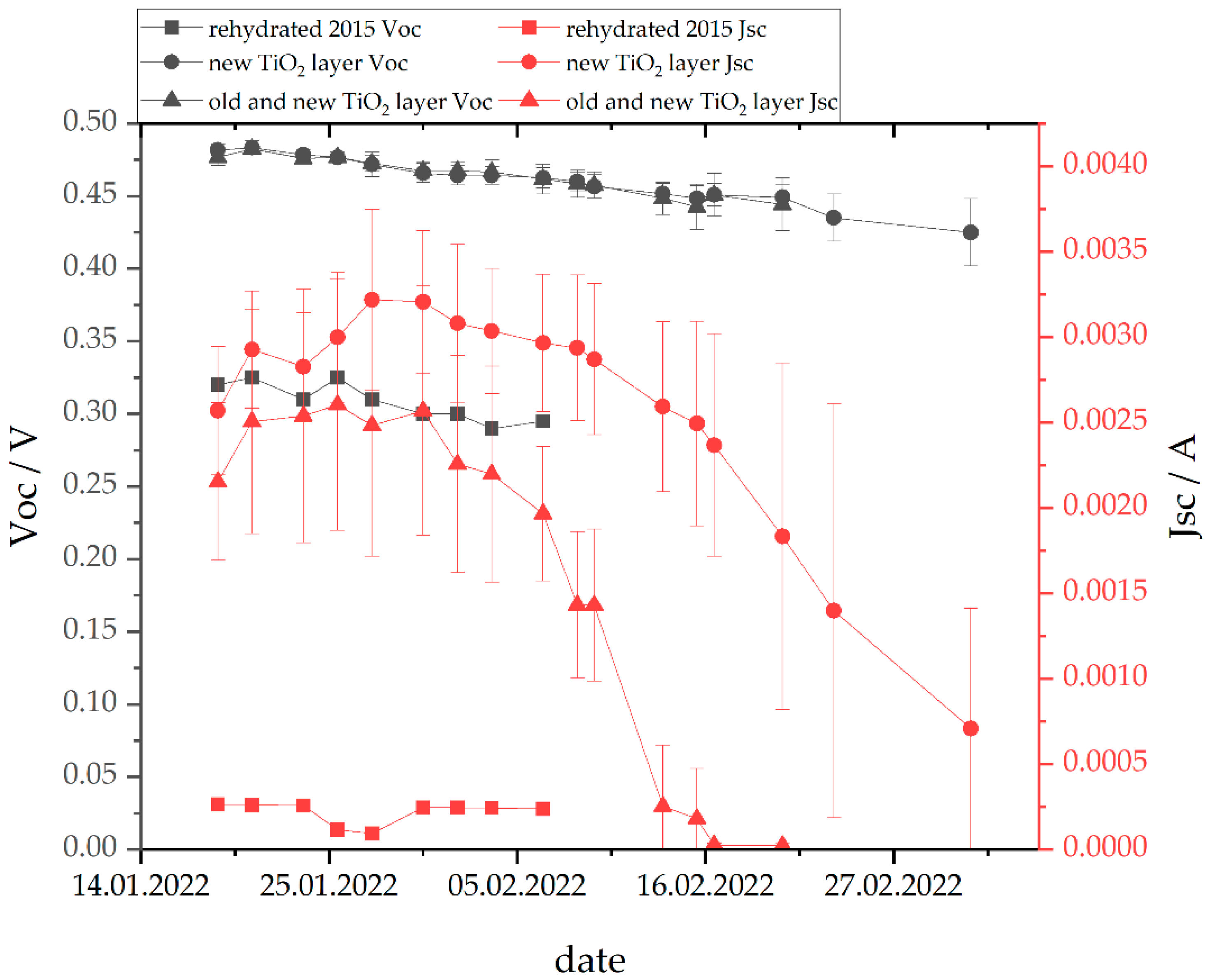

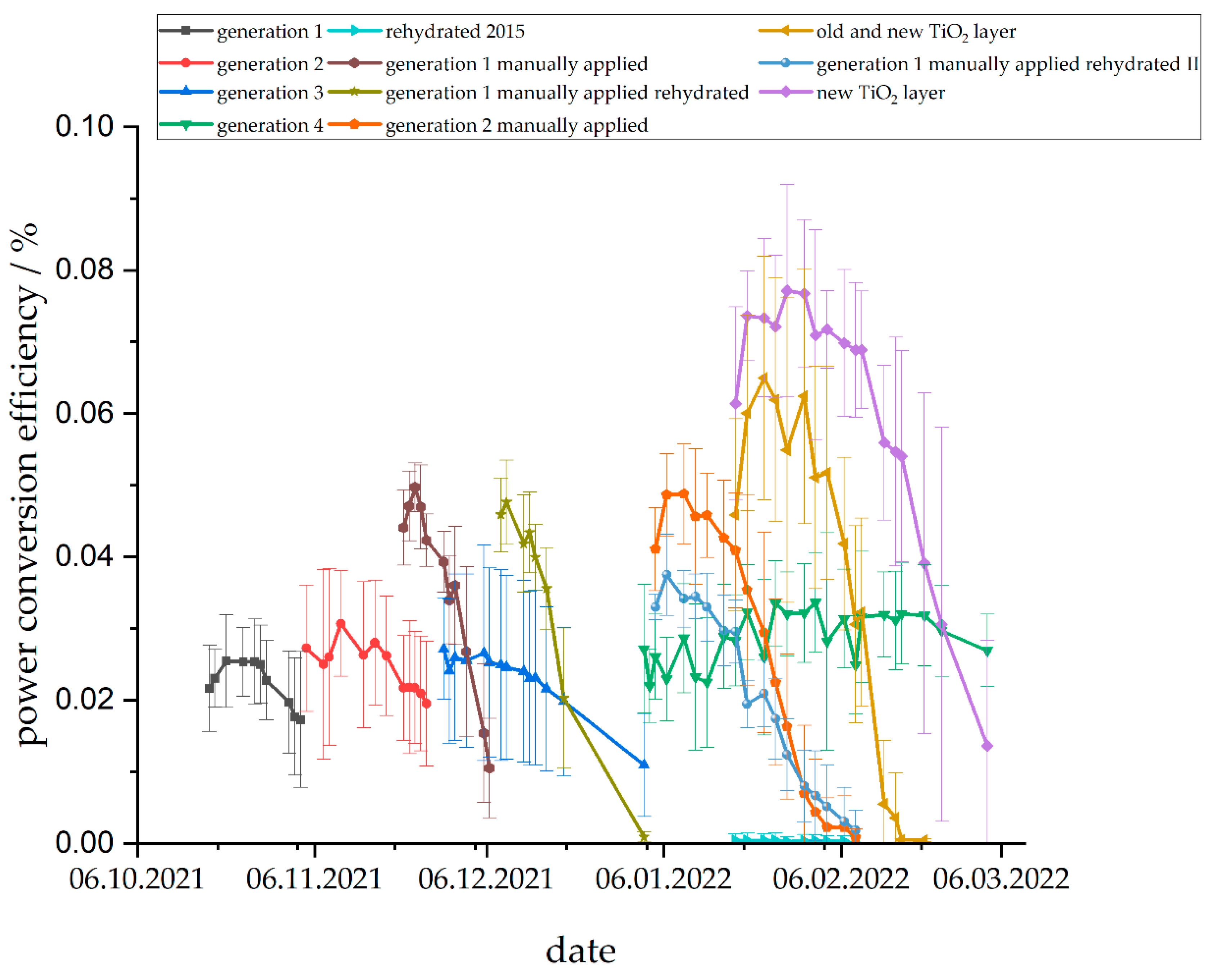

3. Results and Discussion

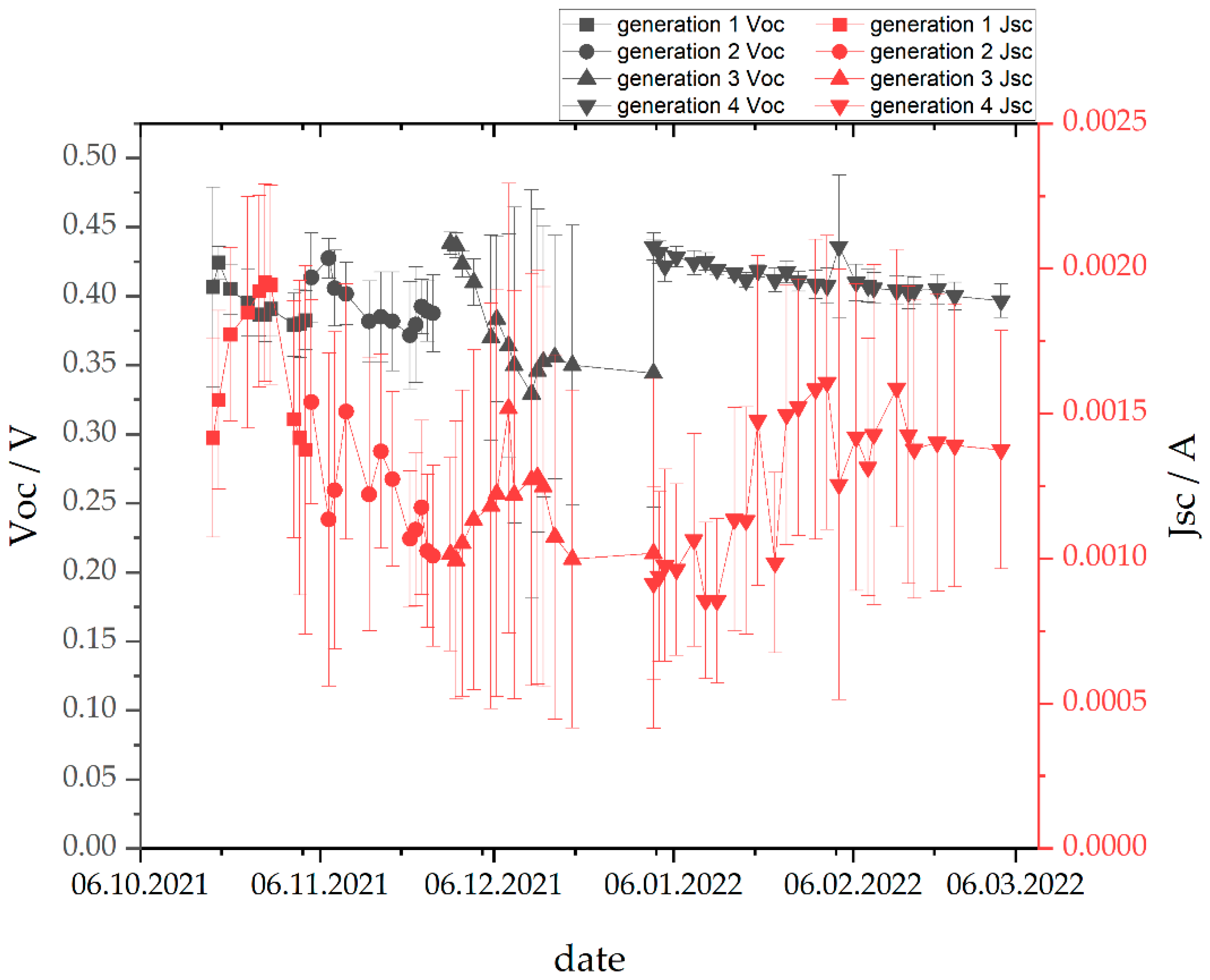

3.1. Four Generations of Commercially Applied TiO2 Layers

- In the third generation sample G3.1, the PCE goes to zero after the third measurement.

- Sample G4.2 is difficult to contact and the PCE varies between high values of 0.04% and 0%. This was probably caused by the damaging of the glass.

3.2. Two Generations of Manually Applied TiO2 Layers

3.3. Remanufactured DSSCs from 2015

3.4. Comparison of the DSSC PCEs

3.5. Recovering TiO2 during Remanufacturing

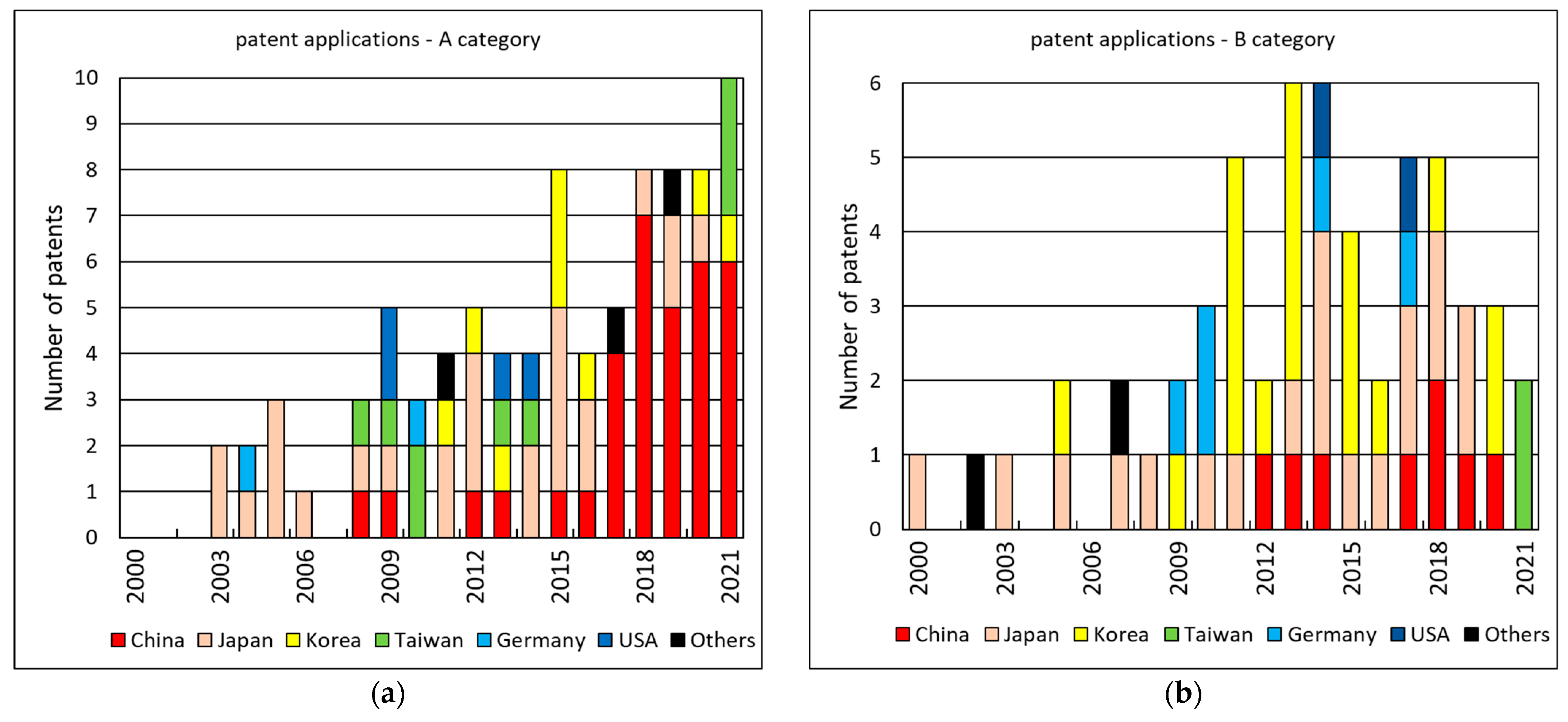

3.6. Remanufacturing Strategies and Technologies for c-SI and Thin-Film PV

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Erickson, L.E.; Brase, G. Paris Agreement on Climate Change. In Reducing Greenhouse Gas Emissions and Improving Air Quality; CRC Press: Boca Raton, FL, USA, 2019; pp. 11–22. [Google Scholar] [CrossRef]

- Lambert, L. Why Lumber Prices Are Suddenly Rising again|Fortune. Available online: https://fortune.com/2021/09/27/lumber-prices-rising-2021-covid/ (accessed on 6 January 2022).

- Choudhury, S.R. JPMorgan on Semiconductor Shortage and Outlook for 2022, 2023. Available online: https://www.cnbc.com/2021/11/19/jpmorgan-on-semiconductor-shortage-and-outlook-for-2022-2023.html (accessed on 6 January 2022).

- The Ellen MacArthur Foundation. Towards the Circular Economy: An Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013; Volume 1, p. 96. [Google Scholar]

- The Ellen MacArthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015; p. 100. [Google Scholar]

- United Nations. Leveraging Energy Action for Advancing the Sustainable Development Goals; United Nations: New York, NY, USA, 2021.

- Pohl, R.; Heitmann, B. Aufarbeitung von Altmodulen Und Rückführung von Wertstoffen in Den Stoffkreislauf; TIB: Hannover, Germany, 2019. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; van der Heide, A.; Radavičius, T.; Denafas, J.; Lemaire, E.; Wang, K.; Poortmans, J.; Voroshazi, E. Towards a Circular Supply Chain for PV Modules: Review of Today’s Challenges in PV Recycling, Refurbishment and Re-Certification. Prog. Photovolt. Res. Appl. 2020, 28, 454–464. [Google Scholar] [CrossRef]

- pvXchnage. Available online: https://www.pvxchange.com/ (accessed on 14 February 2022).

- Second Sol. Available online: https://www.secondsol.com/ (accessed on 14 February 2022).

- Glatthaar, J.; Kamdje, E.; Ricklefs, U.; Stadlbauer, E.A.; Glatthaar, J.; Kamdje, E.; Barnickel, J.B.; Dax, M.; Schaub, V.; Stevens, H.G.; et al. Development of a Modular Cradle to Cradle Process-Chain for c-Si-PV Panel Recycling. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 1528–1532. [Google Scholar] [CrossRef]

- Grand View Research. Dye Sensitized Solar Cell Market Size, Share & Trends Analysis Report by Application; Grand View Research: San Francisco, CA, USA, 2020. [Google Scholar]

- Pandey, A.K.; Ahmad, M.S.; Shahabuddin, S. Dye-Sensitized Solar Cells: Emerging Trends and Advanced Applications; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Kohn, S.; Großerhode, C.; Storck, J.L.; Grötsch, G.; Cornelißen, C.; Streitenberger, A.; Grassmann, C.; Schwarz-Pfeiffer, A.; Ehrmann, A. Commercially Available Teas as Possible Dyes for Dye-Sensitized Solar Cells. Optik 2019, 185, 178–182. [Google Scholar] [CrossRef]

- Gossen, K.; Storck, J.L.; Ehrmann, A. Influence of Solvents on Aloe Vera Gel Performance in Dye-Sensitized Solar Cells. Optik 2019, 180, 615–618. [Google Scholar] [CrossRef]

- Storck, J.L.; Grothe, T.; Dotter, M.; Adabra, S.; Surjawidjaja, M.; Brockhagen, B. Long-Term Stability Improvement of Non-Toxic Dye-Sensitized Solar Cells via Poly(Ethylene Oxide) Gel Electrolytes for Future Textile-Based Solar Cells. Polymers 2020, 12, 3035. [Google Scholar] [CrossRef] [PubMed]

- Juhász Junger, I.; Großerhode, C.; Storck, J.L.; Kohn, S.; Grethe, T.; Grassmann, C.; Schwarz-Pfeiffer, A.; Grimmelsmann, N.; Meissner, H.; Blachowicz, T.; et al. Influence of Graphite-Coating Methods on the DSSC Performance. Optik 2018, 174, 40–45. [Google Scholar] [CrossRef]

- Schoden, F.; Siebert, A.; Keskin, A.; Herzig, K.; Straus, M.; Schwenzfeier-Hellkamp, E. Building a Wind Power Plant from Scrap and Raising Public Awareness for Renewable Energy Technology in a Circular Economy. Sustainability 2020, 12, 90. [Google Scholar] [CrossRef] [Green Version]

- Kawakita, J. Trends of Research and Development of Dye-Sensitized Solar Cells. Sci. Technol. Trends 2010, 35, 70–82. [Google Scholar]

- Mariotti, N.; Bonomo, M.; Fagiolari, L.; Barbero, N.; Gerbaldi, C.; Bella, F.; Barolo, C. Recent Advances in Eco-Friendly and Cost-Effective Materials towards Sustainable Dye-Sensitized Solar Cells. Green Chem. 2020, 22, 7168–7218. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, W.; Xu, D.; Xu, Q.; Xie, J.; Chen, X.; Zhang, T.; Xiong, C.; He, Y.; Zhang, Y.; et al. Outdoor Testing and Ageing of Dye-Sensitized Solar Cells for Building Integrated Photovoltaics. Sol. Energy 2018, 165, 233–239. [Google Scholar] [CrossRef]

- O’Regan, B.; Grätzel, M. A Low-Cost, High-Efficiency Solar Cell Based on Dye-Sensitized Colloidal TiO2 Films. Nature 1991, 354, 737–740. [Google Scholar] [CrossRef]

- Schoden, F.; Schnatmann, A.K.; Davies, E.; Diederich, D.; Storck, J.L.; Knefelkamp, D.; Blachowicz, T.; Schwenzfeier-Hellkamp, E. Investigating the Recycling Potential of Glass Based Dye-Sensitized Solar Cells—Melting Experiment. Materials 2021, 14, 6622. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.; Liang, J.; Sumathy, K. Review on Dye-Sensitized Solar Cells (DSSCs): Fundamental Concepts and Novel Materials. Renew. Sustain. Energy Rev. 2012, 16, 5848–5860. [Google Scholar] [CrossRef]

- Ehrmann, A.; Błachowicz, T. Solarstrom Aus Früchtetee. Phys. Unserer Zeit 2020, 51, 196–200. [Google Scholar] [CrossRef]

- Richhariya, G.; Meikap, B.C.; Kumar, A. Review on Fabrication Methodologies and Its Impacts on Performance of Dye-Sensitized Solar Cells. Environ. Sci. Pollut. Res. 2022, 29, 15233–15251. [Google Scholar] [CrossRef] [PubMed]

- Pawlus, K.; Jarosz, T. Transition Metal Coordination Compounds as Novel Materials for Dye-Sensitized Solar Cells. Appl. Sci. 2022, 12, 3442. [Google Scholar] [CrossRef]

- Freitag, M.; Teuscher, J.; Saygili, Y.; Zhang, X.; Giordano, F.; Liska, P.; Hua, J.; Zakeeruddin, S.M.; Moser, J.E.; Grätzel, M.; et al. Dye-Sensitized Solar Cells for Efficient Power Generation under Ambient Lighting. Nat. Photonics 2017, 11, 372–378. [Google Scholar] [CrossRef]

- Udomrungkhajornchai, S.; Junger, I.J.; Ehrmann, A. Optimization of the TiO2 Layer in DSSCs by a Nonionic Surfactant. Optik 2020, 203, 163945. [Google Scholar] [CrossRef]

- Hölscher, F.; Trümper, P.R.; Juhász Junger, I.; Schwenzfeier-Hellkamp, E.; Ehrmann, A. Raising Reproducibility in Dye-Sensitized Solar Cells under Laboratory Conditions. J. Renew. Sustain. Energy 2018, 10, 013506. [Google Scholar] [CrossRef]

- Sánchez-García, M.A.; Bokhimi, X.; Velázquez Martínez, S.; Jiménez-González, A.E. Dye-Sensitized Solar Cells Prepared with Mexican Pre-Hispanic Dyes. J. Nanotechnol. 2018, 2018, 1236878. [Google Scholar] [CrossRef] [Green Version]

- Juhász Junger, I.; Tellioglu, A.; Ehrmann, A. Refilling DSSCs as a Method to Ensure Longevity. Optik 2018, 160, 255–258. [Google Scholar] [CrossRef]

- Kang, M.S.; Kim, J.H.; Won, J.; Kang, Y.S. Oligomer Approaches for Solid-State Dye-Sensitized Solar Cells Employing Polymer Electrolytes. J. Phys. Chem. C 2007, 111, 5222–5228. [Google Scholar] [CrossRef]

- Dotter, M.; Storck, J.L.; Surjawidjaja, M.; Adabra, S.; Grothe, T. Investigation of the Long-Term Stability of Different Polymers and Their Blends with Peo to Produce Gel Polymer Electrolytes for Non-Toxic Dye-Sensitized Solar Cells. Appl. Sci. 2021, 11, 5834. [Google Scholar] [CrossRef]

- Gossen, K.; Ehrmann, A. Glycerin-Based Electrolyte for Reduced Drying of Dye-Sensitized Solar Cells. Optik 2020, 207, 163772. [Google Scholar] [CrossRef]

- Baxter, J.B. Commercialization of Dye Sensitized Solar Cells: Present Status and Future Research Needs to Improve Efficiency, Stability, and Manufacturing. J. Vac. Sci. Technol. A Vac. Surf. Films 2012, 30, 020801. [Google Scholar] [CrossRef]

- Parisi, M.L.; Maranghi, S.; Vesce, L.; Sinicropi, A.; Di Carlo, A.; Basosi, R. Prospective Life Cycle Assessment of Third-Generation Photovoltaics at the Pre-Industrial Scale: A Long-Term Scenario Approach. Renew. Sustain. Energy Rev. 2020, 121, 109703. [Google Scholar] [CrossRef]

- Wu, X.; Wu, B.; Zhu, Z.; Tayyab, M.; Gao, D. Importance and Advancement of Modification Engineering in Perovskite Solar Cells. Sol. RRL 2022, 2200171. [Google Scholar] [CrossRef]

- Paula, T.; de Fatima Marques, M. Recent Advances in Polymer Structures for Organic Solar Cells: A Review. AIMS Energy 2022, 10, 149–176. [Google Scholar] [CrossRef]

- Parashar, M.; Sharma, M.; Kaul, A.B. Solution-Processed Perovskite Photoabsorbers with Mixed Cations for Improved Stability in Solar Cells. Miner. Met. Mater. Ser. 2022, 1377–1384. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, C.; Xiao, L. Bi-Based Lead-Free Perovskite Solar Cells. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 14–19 June 2020; pp. 77–78. [Google Scholar] [CrossRef]

- Anctil, A.; Babbitt, C.; Landi, B.; Rafaelle, P.R. Life-Cycle Assessment of Organic Solar Cell Technologies. In Proceedings of the 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 742–747. [Google Scholar]

- Parisi, M.L.; Maranghi, S.; Basosi, R. The Evolution of the Dye Sensitized Solar Cells from Grätzel Prototype to Up-Scaled Solar Applications: A Life Cycle Assessment Approach. Renew. Sustain. Energy Rev. 2014, 39, 124–138. [Google Scholar] [CrossRef]

- Mozaffari, S.; Nateghi, M.R.; Zarandi, M.B. An Overview of the Challenges in the Commercialization of Dye Sensitized Solar Cells. Renew. Sustain. Energy Rev. 2017, 71, 675–686. [Google Scholar] [CrossRef]

- Schoden, F.; Dotter, M.; Knefelkamp, D.; Blachowicz, T.; Schwenzfeier Hellkamp, E. Review of State of the Art Recycling Methods in the Context of Dye Sensitized Solar Cells. Energies 2021, 14, 3741. [Google Scholar] [CrossRef]

- Remanufacturing Industries Council. Ansi/Ric001.1-2016; Remanufacturing Industries Council: West Henrietta, NY, USA, 2017; p. 7. [Google Scholar]

- Collaborative Project. Refurbished Parts: Busting Myths Surrounding Their Impact on New Product Sales; Ellen MacArthur Foundation: Cowes, UK, 2013; pp. 1–10. [Google Scholar]

- Yao, J.; Zhu, S.; Cui, P. Design for Remanufacturing and Remanufacturability Based on Process. Adv. Mater. Res. 2011, 338, 18–21. [Google Scholar] [CrossRef]

- Fofou, R.F.; Jiang, Z.; Wang, Y. A Review on the Lifecycle Strategies Enhancing Remanufacturing. Appl. Sci. 2021, 11, 5937. [Google Scholar] [CrossRef]

- Rebitzer, G. Integrating Life Cycle Costing and Life Cycle Assessment for Managing Costs and Environmental Impacts in Supply Chains. In Cost Management in Supply Chains; Physica: Heidelberg, Germany, 2002; pp. 127–146. [Google Scholar] [CrossRef]

- De Wild-Scholten, M.J.; Veltkamp, A.C. Environmental Life Cycle Analysis of Large Area Dye Sensitized Solar Modules, Status and Outlook. In Proceedings of the 22nd European Photovoltaic Solar Energy Conference and Exhibition, Milan, Italy, 3–7 September 2007; pp. 3–7. [Google Scholar]

- Chiang, Y.F.; Chen, R.T.; Shen, P.S.; Chen, P.; Guo, T.F. Extension Lifetime for Dye-Sensitized Solar Cells through Multiple Dye Adsorption/Desorption Process. J. Power Sources 2013, 225, 257–262. [Google Scholar] [CrossRef]

- Rinovasol. Available online: https://www.rinovasol.de/ (accessed on 14 February 2022).

- Solar-pur GmbH. Available online: https://www.solar-pur.de/ (accessed on 14 February 2022).

- ReProSolar. Available online: https://eitrawmaterials.eu/project/reprosolar/ (accessed on 14 February 2022).

- Krueger, L. Overview of First Solar’s Module Collection and Recycling Program. Available online: https://www.bnl.gov/pv/files/prs_agenda/2_krueger_ieee-presentation-final.pdf (accessed on 14 February 2022).

- Fthenakis, V.; Athias, C.; Blumenthal, A.; Kulur, A.; Magliozzo, J.; Ng, D. Sustainability Evaluation of CdTe PV: An Update. Renew. Sustain. Energy Rev. 2020, 123, 109776. [Google Scholar] [CrossRef]

- Sinha, P.; Raju, S.; Drozdiak, K.; Wade, A. Life Cycle Management and Recycling of PV Systems. Available online: www.pv-tech.org (accessed on 14 February 2022).

- Saint-Sernin, E.; Einhaus, R.; Bamberg, K.; Panno, P. Industrialisation of Apollon Solar’s Nice Module Technology. In Proceedings of the 23rd EU PVSEC, Valencia, Spain, 1–4 September 2008. [Google Scholar]

| Solar Cells | DSSC Solar Cells | Solar Cell Materials | Titanium Dioxide TiO2 | |

|---|---|---|---|---|

| remanufacturing | 0 | 0 | 0 | 0 |

| recyclable | 5 | 0 | 1 | 0 |

| recycling | 143 | 0 | 30 | 0 |

| reusing | 25 | 0 | 1 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schoden, F.; Detzmeier, J.; Schnatmann, A.K.; Blachowicz, T.; Schwenzfeier-Hellkamp, E. Investigating the Remanufacturing Potential of Dye-Sensitized Solar Cells. Sustainability 2022, 14, 5670. https://doi.org/10.3390/su14095670

Schoden F, Detzmeier J, Schnatmann AK, Blachowicz T, Schwenzfeier-Hellkamp E. Investigating the Remanufacturing Potential of Dye-Sensitized Solar Cells. Sustainability. 2022; 14(9):5670. https://doi.org/10.3390/su14095670

Chicago/Turabian StyleSchoden, Fabian, Joscha Detzmeier, Anna Katharina Schnatmann, Tomasz Blachowicz, and Eva Schwenzfeier-Hellkamp. 2022. "Investigating the Remanufacturing Potential of Dye-Sensitized Solar Cells" Sustainability 14, no. 9: 5670. https://doi.org/10.3390/su14095670

APA StyleSchoden, F., Detzmeier, J., Schnatmann, A. K., Blachowicz, T., & Schwenzfeier-Hellkamp, E. (2022). Investigating the Remanufacturing Potential of Dye-Sensitized Solar Cells. Sustainability, 14(9), 5670. https://doi.org/10.3390/su14095670