Identifying Barriers in the Implementation of Agile Methodologies in Automotive Industry

Abstract

1. Introduction

- Do the AI companies need to implement AM?

- Are the AI companies predisposed to AM?

- What are the main barriers for implementing AM in the AI?

- What are the main enablers for implementing AM in the AI?

2. Literature Review

2.1. Agile Project Management

2.2. Agile Methodologies

2.3. Barriers and Enablers in the Implementation of Agile Methodologies

2.4. Hypotheses Formulation

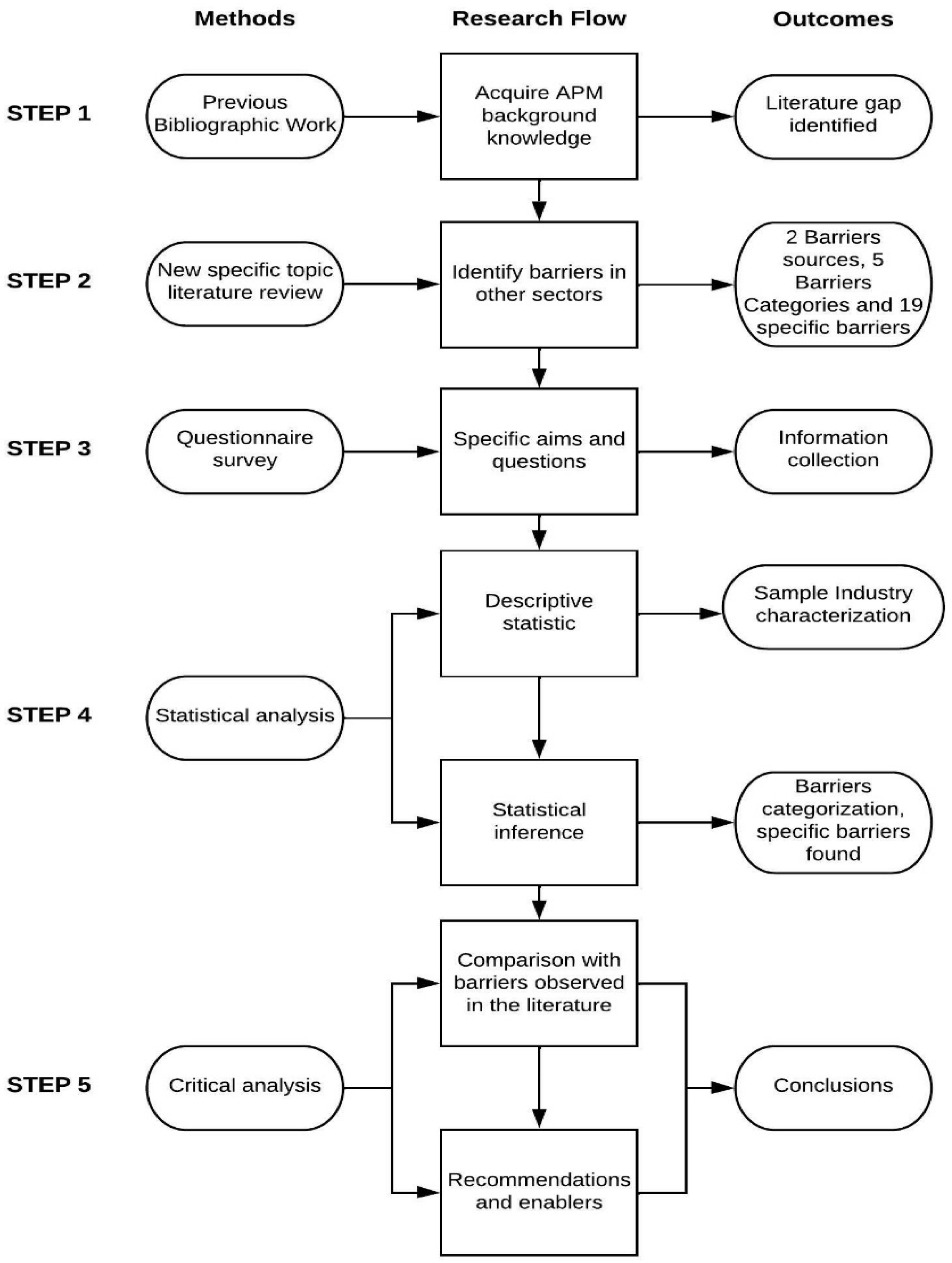

3. Methodology

3.1. Research Instrument

3.2. Survey Sample

3.3. Data Analysis

4. Results

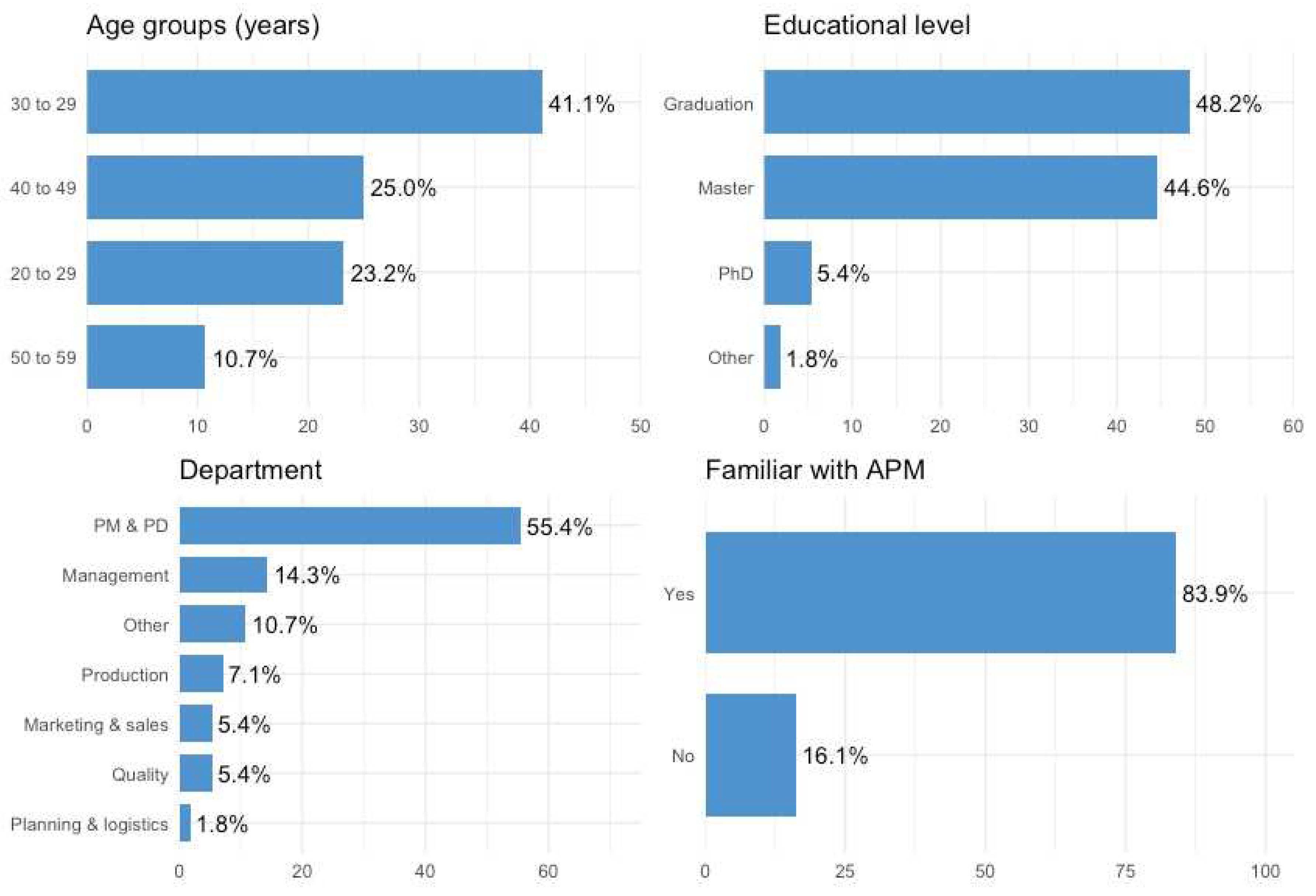

4.1. Respondents’ Characterization

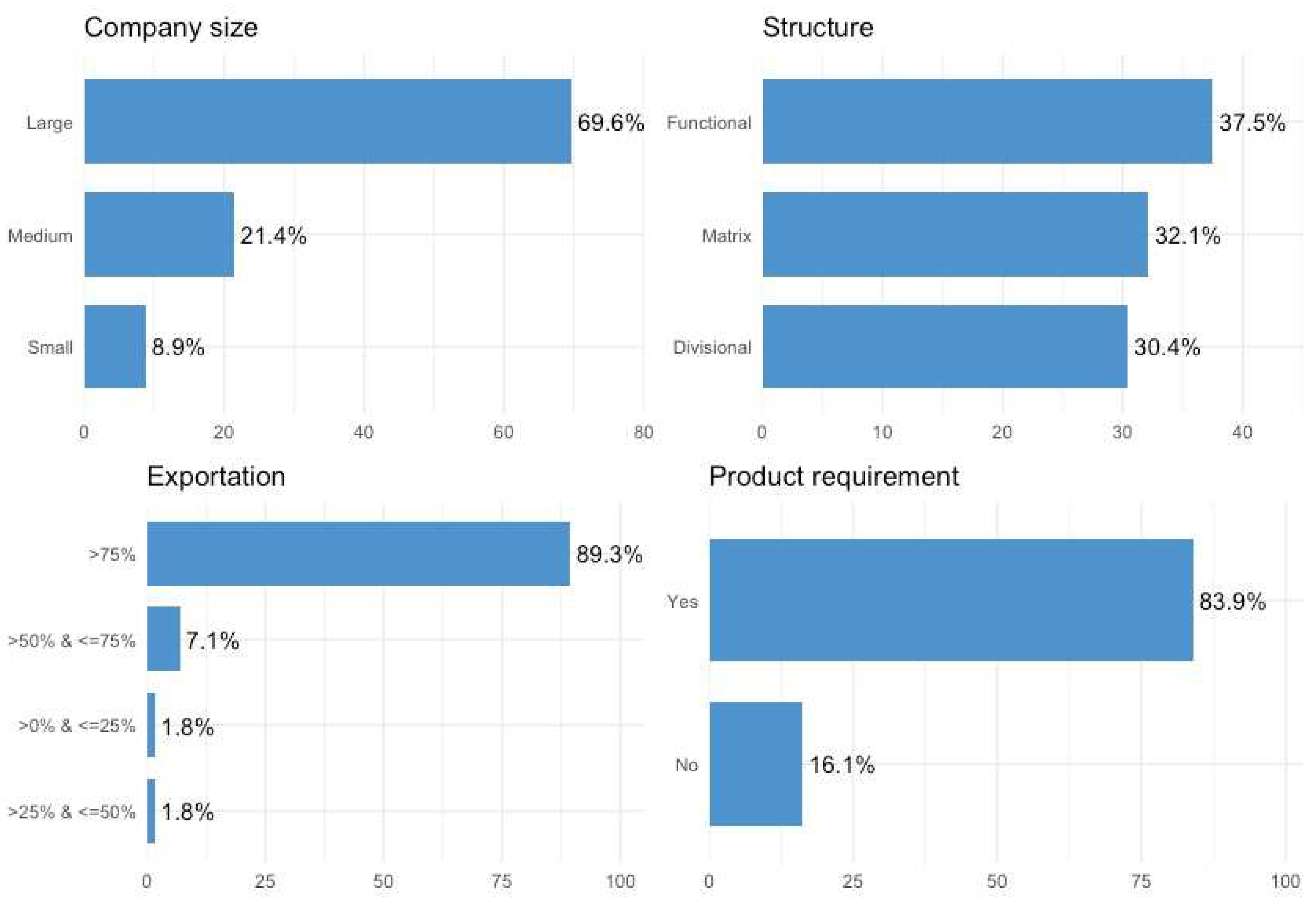

4.2. Companies’ Characterization

4.3. Manufacturing Processes’ Characterization

4.4. Product Development Processes and Project Management

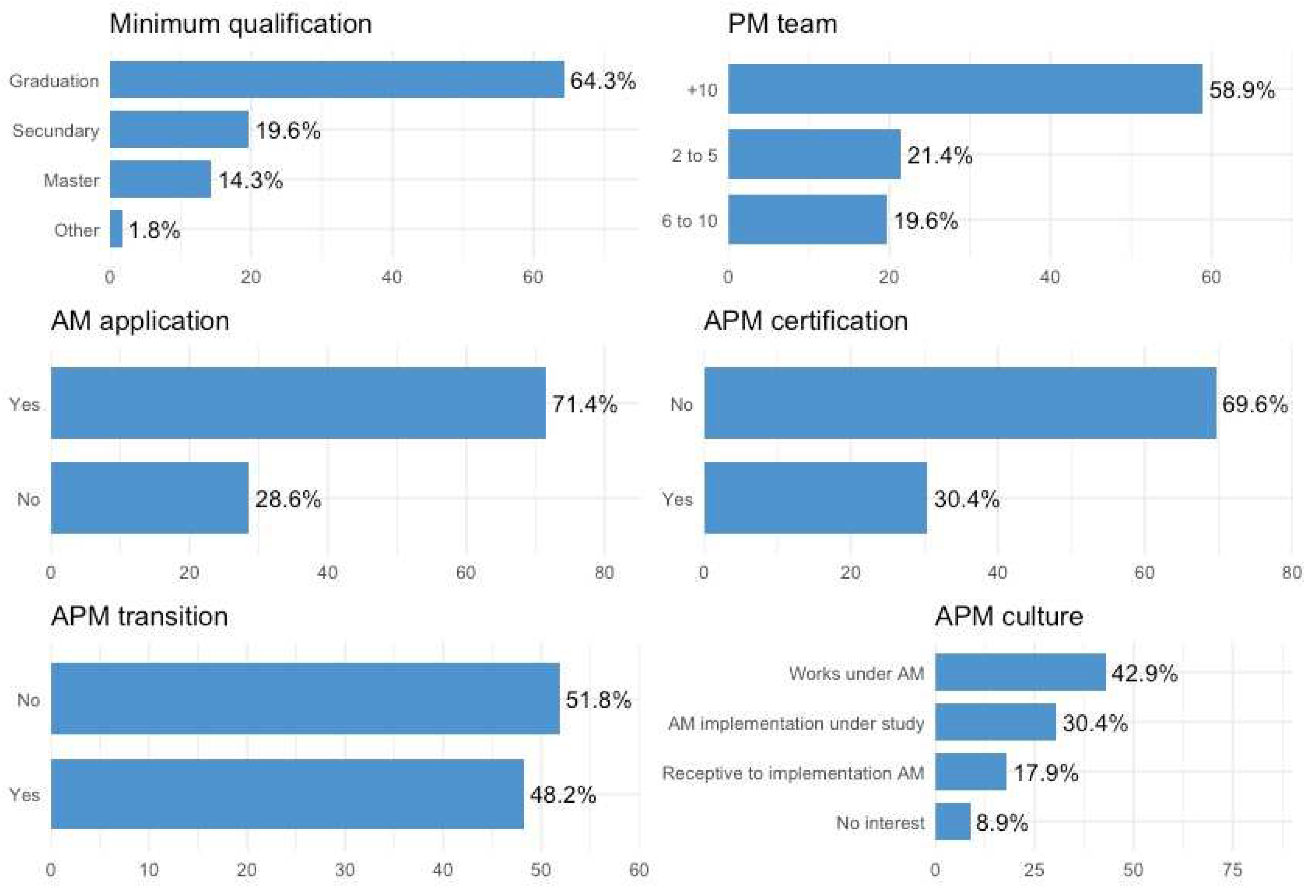

4.5. Agile Project Management Environment

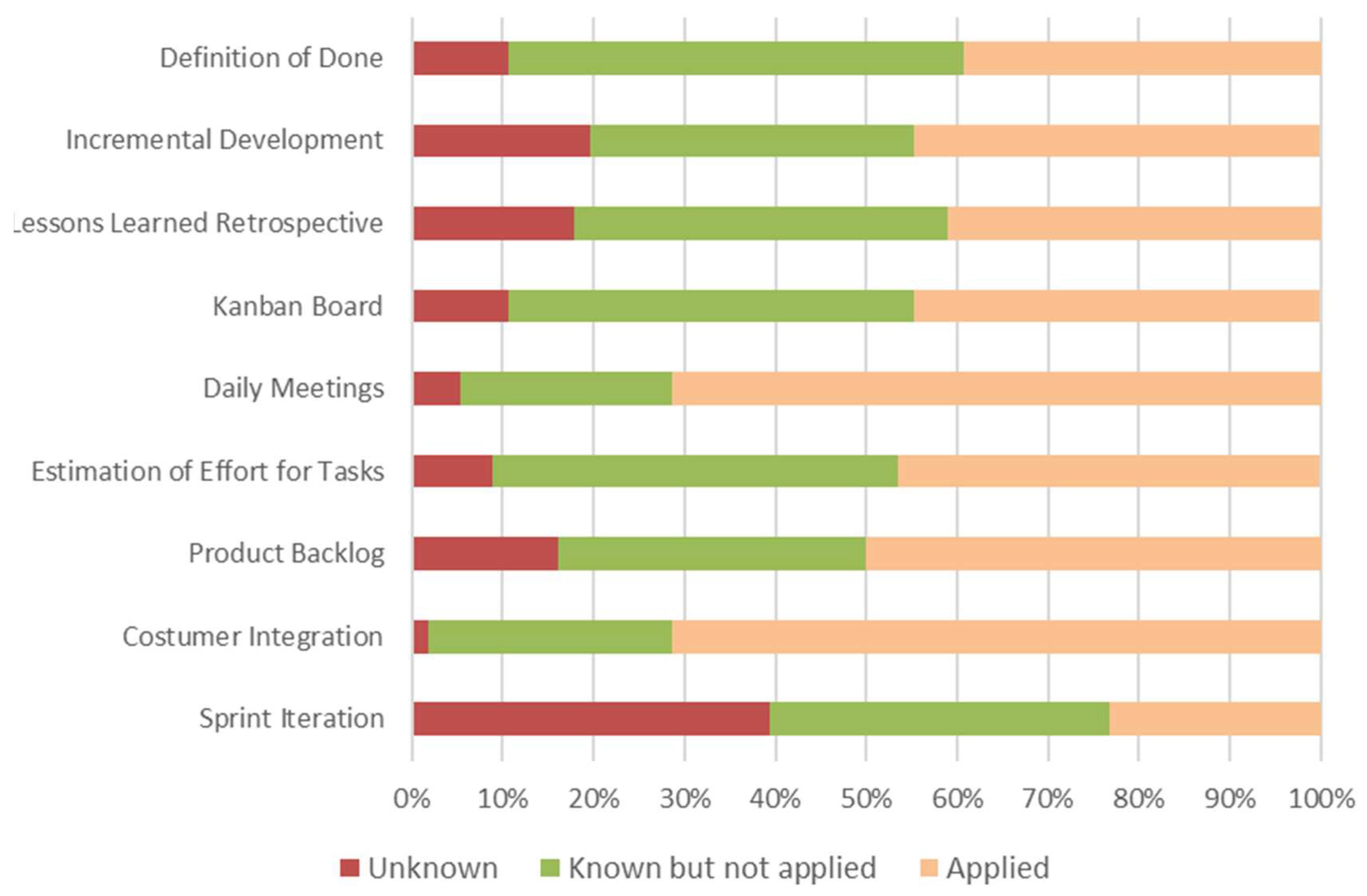

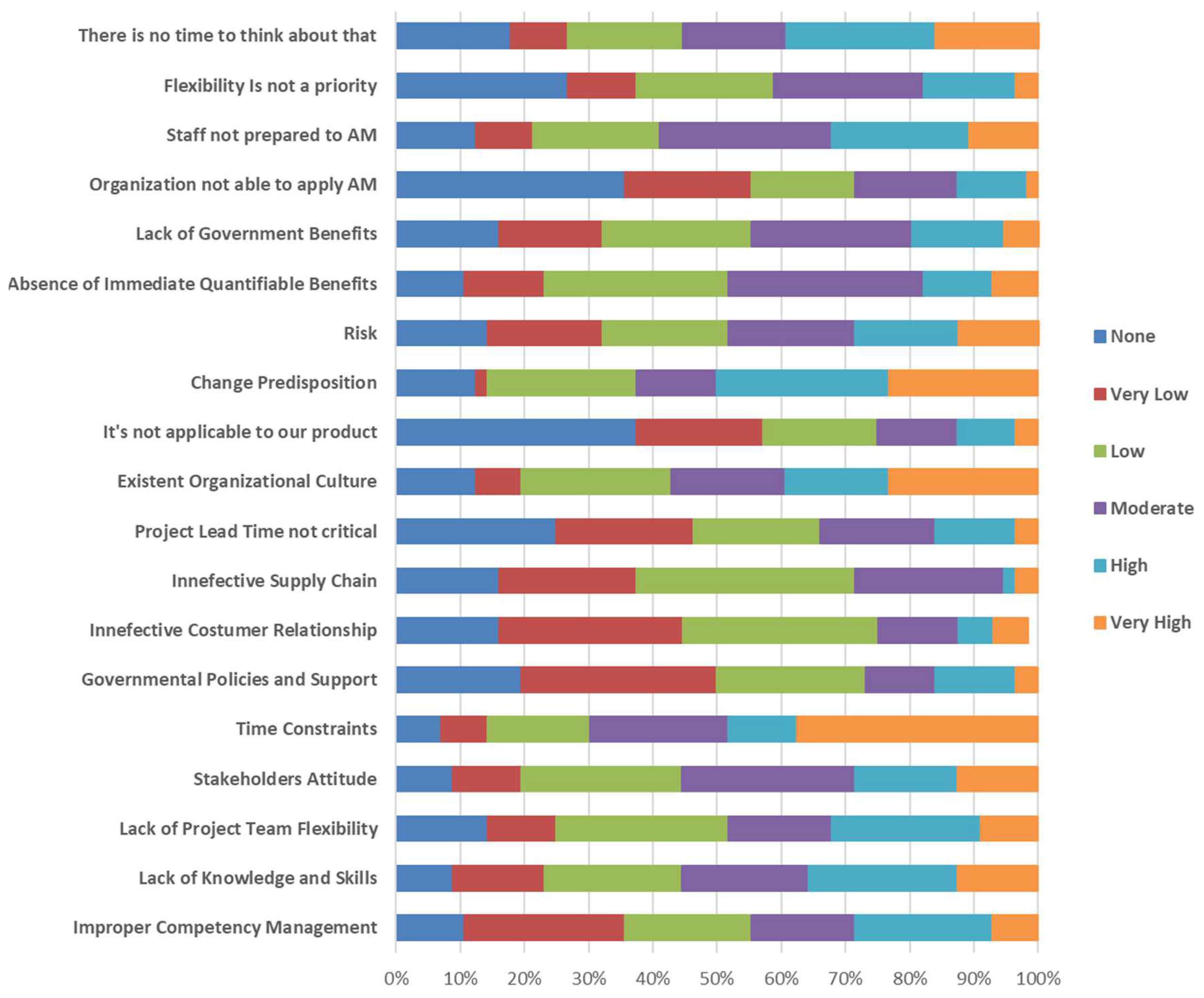

4.6. Barriers in the Implementation of Agile Methodologies

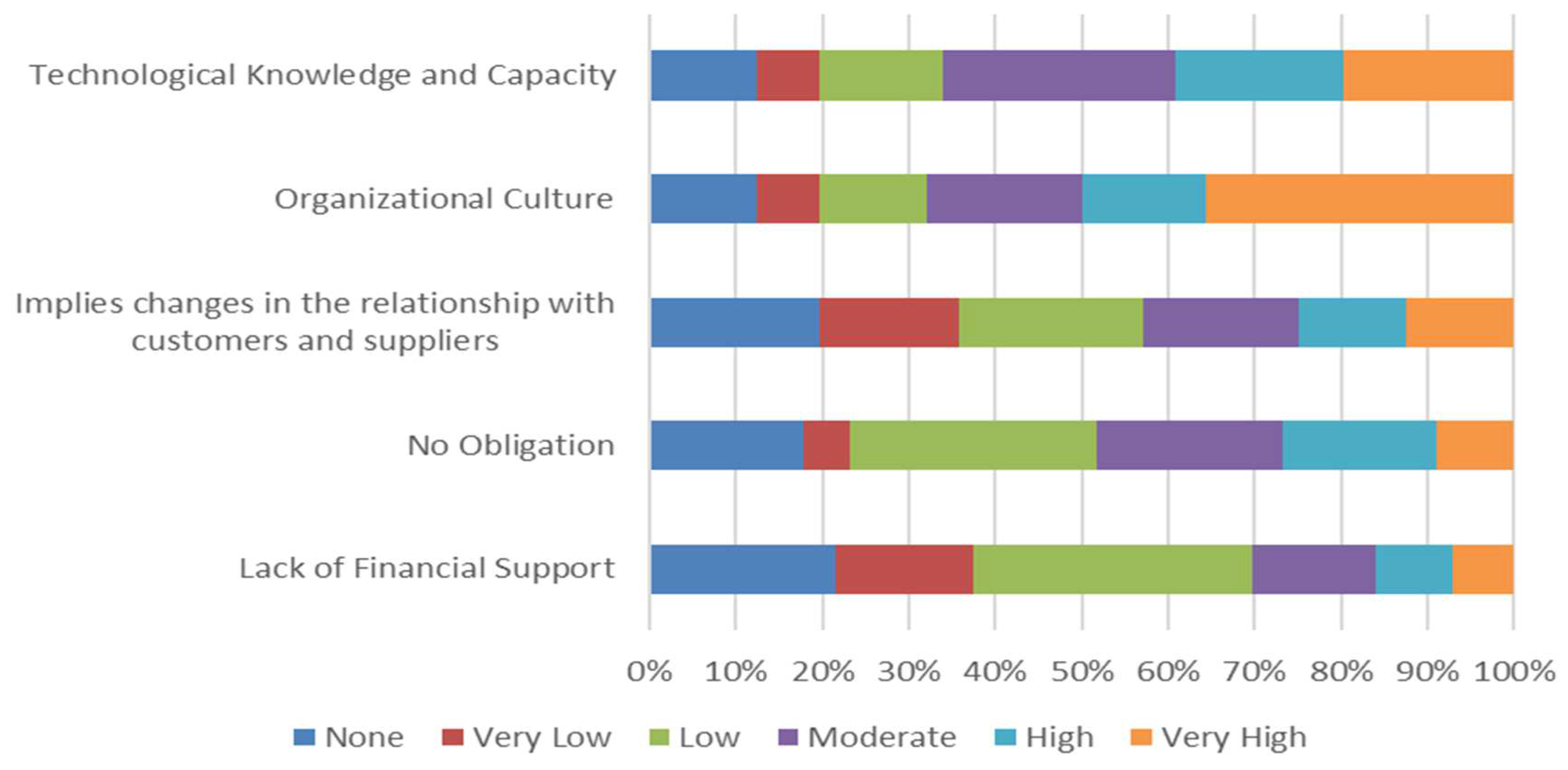

4.7. Enablers for the Implementation of Agile Methodologies

4.8. Statistical Analysis—Hypotheses’ Investigation

5. Discussion

5.1. Analysis about the Barriers Found

5.2. Analyzing Possible Enablers

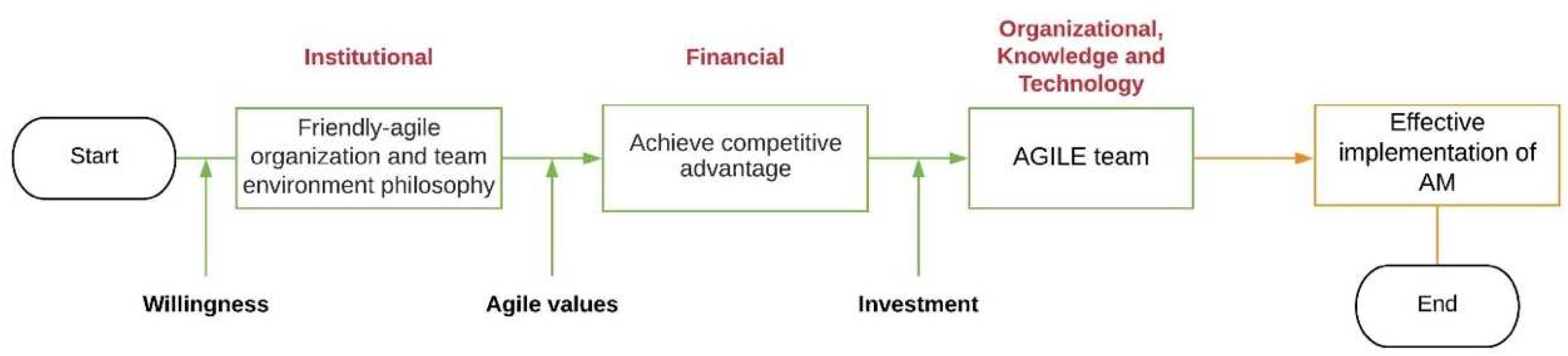

5.3. Flowchart

6. Conclusions

- ‘Companies’ degree of change’ has a direct relation to AM implementation;

- ‘High levels of change in the products’ induce the need to adopt AM;

- Just 9% of the companies have no interest in implementing APM, and 70% are already applying agile methods;

- Most of respondents do not have skills in APM; their qualifications may be enough to apply agile tools, but insufficient to apply a fully agile approach;

- The main identified barriers are ‘Organizational culture’ and ‘Knowledge and technology’, and 61% of respondents state that the main barriers’ source is solely internal;

- ‘Organizational’, and ‘Knowledge and technology’ barriers in the AI were identified due to the ‘Improper competency management’ factor;

- ‘Lack of management involvement’ seems to be a problem. The same factor is related to the ‘Knowledge and technology’ barrier, showing a lack in managers’ skills;

- ‘Change predisposition’, and its correlation with the ‘No obligation’ barrier act as ‘Institutional’ barriers for the AM implementation;

- ‘Lack of financial support’ does not seem to be a barrier, however, a relation between the ‘Absence of immediate quantifiable benefits’ and ‘Lack of financial support’ barriers is established;

- A total of 90% of the respondents pointed out two barriers not included in the questionnaire: ‘Certification procedures’ and ‘Lack of collective motivation’;

- They also consider that the main enablers for AM implementation are ‘Organizational support’ and ‘Investment in training’.

- Do the AI companies need to implement AM? It became clear that the type of production followed by the AI requires agile methodologies to respond in due time to market requests. There is a constant modification and updating of products, requiring greater flexibility and reaction speed on the part of automotive component manufacturers. Thus, AM could significantly contribute to reducing the time needed to introduce products into the market and improve the dialogue between stakeholders. With these improvements, the efficiency of the processes improves, reducing costs and avoiding waste in terms of time and consumption of natural resources. This increases the sustainability of the processes.

- Are the AI companies predisposed to AM? Yes, companies are willing to adopt AM, but there is still some lack of preparation in both top and middle management, in order to facilitate an effective implementation of AM. However, the preparation in terms of skills still seems to be insufficient, and it is still possible to perceive that companies wait for governmental financial support (targeted support programs). This minimizes the investment necessary for the adoption of AM practices.

- What are the main barriers for implementing AM in the AI? ‘Organizational culture’ and ‘Knowledge and technology’ are identified as the main barriers. To understand this result, it is necessary to know that most Portuguese companies in the sector are of family origin, and that there is a considerable deficit of training in engineering and management in many companies. Due to international competitiveness and the need to impose themselves on the market, most companies significantly improved this aspect, but it appears that there are still some gaps.

- What are the main enablers for implementing AM in the AI? Based on the previous topic, it is not surprising that the main enablers focus on ‘Organizational support’ and ‘Investment in training’. The organizational structure of the companies still shows a lack of training in the area of management and, despite the mandatory training of employees in a certain percentage of their annual working time, this training is still not strategically programmed or directed to some aspects, such as the adoption of AM. Indeed, the implementation of AM is not yet a priority for companies.

- What are the barriers and enablers related to other important Portuguese industries, such as the cork industry and the textile industry?

- Are there similarities between the barriers and enablers found within the Portuguese AI compared to other European countries? What about other industrialized countries on other continents?

- Can the developed framework be applied in other types of Portuguese, European, or world industries?

- How will this situation evolve over time?

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OICA. Economy Contributions. Available online: http://www.oica.net/category/economic-contributions/rd/# (accessed on 7 January 2022).

- Beaume, R.; Maniak, R.; Midler, C. Crossing innovation and product projects management: A comparative analysis in the automotive industry. Int. J. Proj. Manag. 2009, 27, 166–174. [Google Scholar] [CrossRef]

- Jeffs, J.; Papillon, B.M. Globalization, the new economy and project management: A graph theory perspective. J. Mod. Proj. Manag. 2019, 7, 30–42. [Google Scholar]

- San Cristóbal, J.R.; Carral, L.; Díaz, E.; Fraguela, J.A.; Iglesias, G. Complexity and project management: A general overview. Complexity 2018, 2018, 4891286. [Google Scholar] [CrossRef]

- Sanchez, F.; Micaelli, J.P.; Bonjour, E.; Monticolo, D. A step for improving the transition between traditional project management to agile project management using a project management maturity model. J. Mod. Proj. Manag. 2019, 7, 88–105. [Google Scholar] [CrossRef]

- Conforto, E.C.; Amaral, D.C.; da Silva, S.L.; di Felippo, A.; Kamikawachi, D.S.L. The agility construct on project management theory. Int. J. Proj. Manag. 2016, 34, 660–674. [Google Scholar] [CrossRef]

- Moradlou, H.; Asadi, M. Implementation of agile manufacturing principles in small and medium enterprises (SMES). J. Mod. Process. Manuf. Prod. 2015, 4, 31–44. [Google Scholar]

- Souza Bermejo, P.H.; Zambalde, A.L.; Tonelli, A.O.; Souza, S.A.; Zuppo, L.A.; Rosa, P.L. Agile principles and achievement of success in software development: A quantitative study in Brazilian organizations. Procedia Technol. 2014, 16, 718–727. [Google Scholar] [CrossRef]

- Dingsøyr, T.; Nerur, S.; Balijepally, V.; Moe, N.B. A decade of agile methodologies: Towards explaining agile software development. J. Syst. Softw. 2012, 85, 1213–1221. [Google Scholar] [CrossRef]

- Fritzsche, A. Implications of agile manufacturing in the automotive industry for order management in the factories-evidence from the practitioner’s perspective. Procedia CIRP 2018, 72, 369–374. [Google Scholar] [CrossRef]

- Špundak, M. Mixed agile/traditional project management methodology—Reality or illusion? Procedia Soc. Behav. Sci. 2014, 119, 939–948. [Google Scholar] [CrossRef]

- Highsmith, J. Agile Project Management: Creating Innovative Products; Addison-Wesley Professional: Boston, MA, USA, 2009; ISBN-13 978-0321658395. [Google Scholar]

- Beck, K.; Beedle, M.; van Bennekum, A.; Cockburn, A.; Cunningham, W.; Fowler, M.; Martin, R.C.; Mellor, S.; Thomas, D.; Grenning, J.; et al. Agile Manifesto 2001, Agile Alliance. Available online: https://www.agilealliance.org/agile101/the-agile-manifesto/ (accessed on 19 December 2021).

- Silva, F.J.G.; Kirytopoulos, K.; Ferreira, L.P.; Sá, J.C.; Santos, G.; Nogueira, M.C. The three pillars of sustainable development and agile project management: How do they influence each other. Corp. Soc. Responsib. Environ. Manag. 2022, 29. Accepted for publication. [Google Scholar] [CrossRef]

- Obradović, V.; Todorović, M.; Bushuyev, S. Sustainability and Agility in Project Management: Contradictory or Complementary? In Advances in Intelligent Systems and Computing III (CSIT 2018); Shakhovska, N., Medykovsky, M., Eds.; Springer: Cham, Switzerland, 2019; Volume 871. [Google Scholar] [CrossRef]

- Žužek, T.; Gosar, Ž.; Kušar, J.; Berlec, T. Adopting agile project management practices in non-software SMEs: A case study of a Slovenian medium-sized manufacturing company. Sustainability 2020, 12, 9245. [Google Scholar] [CrossRef]

- Sharma, S.; Oberoi, J.S.; Gupta, R.D.; Saini, S.; Gupta, A.K.; Sharma, N. Effect of agility in different dimensions of manufacturing systems: A review. Mater. Today Proc. 2022, in press. [Google Scholar] [CrossRef]

- Malhotra, R.; Chug, A. Comparative Analysis of Agile Methods and Iterative Enhancement Model in Assessment of Software Maintenance. In Proceedings of the 3rd International Conference on Computing for Sustainable Global Development (INDIACom), New Delhi, India, 16–18 March 2016; pp. 1271–1276. [Google Scholar]

- Rising, L.; Janoff, N.S. The Scrum Software Development Process for Small Teams. IEEE Softw. 2000, 17, 26–32. [Google Scholar] [CrossRef]

- Project Management Institute; Agile Alliance. Agile Practice Guide; Project Management Institute: Campus Boulevard, PA, USA, 2017; ISBN-13 978-1628251999. [Google Scholar]

- Schwaber, K.; Sutherland, J. The Scrum Guide: The Definitive Guide to Scrum: The Rule of the Game. 2020, p. 19. Available online: http://www.scrumguides.org/docs/scrumguide/v20 (accessed on 14 December 2021).

- Freitas, F.; Silva, F.J.G.; Campilho, R.D.S.G.; Pimentel, C.; Godina, R. Development of a suitable project management approach for projects with parallel planning and execution. Procedia Manuf. 2020, 51, 1544–1550. [Google Scholar] [CrossRef]

- Livermore, J.A. Factors that Impact Implementing an Agile Software Development Methodology. In Proceedings of the 2007 IEEE SoutheastCon, Richmond, VA, USA, 22–25 March 2007; pp. 82–86. [Google Scholar] [CrossRef]

- Boehm, B.; Turner, R. Management challenges to implementing agile processes in traditional development organizations. IEEE Softw. 2005, 22, 30–39. [Google Scholar] [CrossRef]

- Silva, F.J.G.; Gouveia, R.M. Cleaner Production: Toward a Better Future; Springer Nature Publishing: Cham, Switzerland, 2020; ISBN-13 978-3030231675. [Google Scholar]

- Rose, A.N.M.; Deros, B.M.; Ab Rahman, M.N.; Norani, N. Lean Manufacturing Best Practices in SMEs. In Proceedings of the 2011 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 22–24 January 2011; pp. 872–877. [Google Scholar]

- Bottani, E. Profile and enablers of agile companies: An empirical investigation. Int. J. Prod. Econ. 2010, 125, 251–261. [Google Scholar] [CrossRef]

- Vermunt, D.A.; Negro, S.O.; Verweij, P.A.; Kuppens, D.V.; Hekkert, M.P. Exploring barriers to implementing different circular business model. J. Clean. Prod. 2019, 222, 891–902. [Google Scholar] [CrossRef]

- Potdar, P.K.; Routroy, S.; Behera, A. Addressing the agile manufacturing impediments using interpretive structural modeling. Mater. Today Proc. 2017, 4, 1744–1751. [Google Scholar] [CrossRef]

- Sindhwani, R.; Mittal, V.K.; Singh, P.L.; Aggarwal, A. Modelling and analysis of barriers affecting the implementation of lean green agile manufacturing system (LGAMS). Benchmark. Int. J. 2019, 26, 498–529. [Google Scholar] [CrossRef]

- Ghani, I.; Bello, M. Agile adoption in IT organizations. KSII Trans. Internet Inf. Syst. 2015, 9, 3231–3248. [Google Scholar] [CrossRef][Green Version]

- Salinas, M.R.N.; Neto, A.G.S.S.; Emer, M.C.F.P. Concerns and limitations in agile software development: A survey with paraguayan companies. Commun. Comput. Inf. Sci. 2018, 802, 77–87. [Google Scholar] [CrossRef]

- Caldera, H.T.S.; Desha, C.; Dawes, L. Evaluating the enablers and barriers for successful implementation of sustainable business practice in ‘lean’ SMEs. J. Clean. Prod. 2019, 218, 575–590. [Google Scholar] [CrossRef]

- Tan, T.; Chen, K.; Xue, F.; Lu, W. Barriers to building information modeling (BIM) implementation in China’s prefabricated construction: An interpretive structural modeling (ISM) approach. J. Clean. Prod. 2019, 219, 949–959. [Google Scholar] [CrossRef]

- Kostić, D.M. Challenges of agile practices implementation in the medical device software development methodologies. Eur. Proj. Manag. J. 2017, 7, 36–44. [Google Scholar]

- Costa, M.J.R.; Gouveia, R.M.; Silva, F.J.G.; Campilho, R.D.S.G. How to solve quality problems by advanced fully-automated manufacturing systems. Int. J. Adv. Manuf. Technol. 2018, 94, 3041–3063. [Google Scholar] [CrossRef]

- Silva, F.J.G.; Soares, M.R.; Ferreira, L.P.; Alves, A.C.; Brito, M.; Campilho, R.D.S.G.; Sousa, V.F.C. A Novel automated system for the handling of car seat wires on plastic over-injection molding machines. Machines 2021, 9, 141. [Google Scholar] [CrossRef]

- Magalhães, A.J.A.; Silva, F.J.G.; Campilho, R.D.S.G. A novel concept of bent wires sorting operation between workstations in the production of automotive parts. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 25. [Google Scholar] [CrossRef]

- Costa, R.J.S.; Silva, F.J.G.; Campilho, R.D.S.G. A novel concept of agile assembly machine for sets applied in the automotive. industry. Int. J. Adv. Manuf. Technol. 2017, 91, 4043–4054. [Google Scholar] [CrossRef]

- Chen, K.-S.; Chiou, K.-C.; Yu, C.-M. Lifetime performance index of electronic products. Microelectron. Reliab. 2020, 113, 113941. [Google Scholar] [CrossRef]

- Wang, G.; Shao, M.; Lv, S.; Kong, X.; He, Z.; Vining, G. Process parameter optimization for lifetime improvement experiments considering warranty and customer satisfaction. Reliab. Eng. Syst. Saf. 2022, 221, 108369. [Google Scholar] [CrossRef]

- Monteiro, J.; Silva, F.J.G.; Ramos, S.F.; Campilho, R.D.S.G.; Fonseca, A.M. Eco-design and sustainability in packaging: A survey. Procedia Manuf. 2019, 38, 1741–1749. [Google Scholar] [CrossRef]

- Singh, A.S.; Masuku, M.B. Sampling techniques & determination of sample size in applied statistics research: An overview. International. J. Econ. Commer. Manag. 2014, 2, 1–22. [Google Scholar]

- AFIA. PORTUGAL—Auto Components Industry. 2020. Available online: https://afia.pt/en/statistics/ (accessed on 9 January 2022).

- Ciriello, R.F.; Glud, J.A.; Hansen-Schwartz, K.H. Becoming agile together: Customer influence on agile adoption within commissioned software teams. Inf. Manag. 2022, 59, 103645. [Google Scholar] [CrossRef]

- Šmite, D.; Moe, N.B.; Gonzalez-Huerta, J. Overcoming cultural barriers to being agile in distributed teams. Inf. Softw. Technol. 2021, 38, 106612. [Google Scholar] [CrossRef]

- Shashi; Centobelli, P.; Cerchione, R.; Ertz, E. Agile supply chain management: Where did it come from and where will it go in the era of digital transformation? Ind. Mark. Manag. 2020, 90, 324–345. [Google Scholar] [CrossRef]

- Brandl, F.J.; Roider, N.; Hehl, M.; Reinhart, G. Selecting practices in complex technical planning projects: A pathway for tailoring agile project management into the manufacturing industry. CIRP J. Manuf. Sci. 2021, 33, 293–305. [Google Scholar] [CrossRef]

- Shameem, M.; Kumar, R.R.; Nadeem, M.; Khan, A.A. Taxonomical classification of barriers for scaling agile methods in global software development environment using fuzzy analytic hierarchy process. Appl. Soft Comput. 2020, 90, 106122. [Google Scholar] [CrossRef]

- Stettina, C.J.; Hörz, J. Agile portfolio management: An empirical perspective on the practice in use. Int. J. Proj. Manag. 2015, 33, 140–152. [Google Scholar] [CrossRef]

- Araújo, W.; Silva, F.J.G.; Campilho, R. Manufacturing cushions and suspension mats for vehicle seats: A novel cell concept. Int. J. Adv. Manuf. Technol. 2017, 90, 1539–1545. [Google Scholar] [CrossRef]

- Moreira, B.M.D.N.; Gouveia, R.M.; Silva, F.J.G.; Campilho, R.D.S.G. A novel concept of production and assembly processes integration. Procedia Manuf. 2017, 11, 1385–1395. [Google Scholar] [CrossRef]

- Hariyani, D.; Mishra, S. Organizational enablers for sustainable manufacturing and industrial ecology. Clean. Eng. Technol. 2022, 9, 100375. [Google Scholar] [CrossRef]

- Ahmed, A.; Bhatti, S.H.; Gölgecic, I.; Arslan, A. Digital platform capability and organizational agility of emerging market manufacturing SMEs: The mediating role of intellectual capital and the moderating role of environmental dynamism. Technol. Forecast. Soc. Chang. 2022, 177, 121513. [Google Scholar] [CrossRef]

- Sarangee, K.; Schmidt, J.B.; Srinath, P.B.; Wallace, A. Agile transformation in dynamic, high-technology markets: Drivers, inhibitors, and execution. Ind. Mark. Manag. 2022, 102, 24–34. [Google Scholar] [CrossRef]

- Loiro, C.; Castro, H.; Ávila, P.; Cruz-Cunha, M.M.; Putnik, G.D.; Ferreira, L. Agile project management: A communicational workflow proposal. Procedia Comput. Sci. 2019, 164, 485–490. [Google Scholar] [CrossRef]

- Gonçalves, D.; Bergquist, M.; Alänge, S.; Bunk, R. How digital tools align with organizational agility and strengthen digital innovation in automotive startups. Procedia Comput. Sci. 2022, 196, 107–116. [Google Scholar] [CrossRef]

- Sandberg, J.; Alvesson, M. Ways of constructing research questions: Gap-spotting or problematization? Organization 2011, 18, 23–44. [Google Scholar] [CrossRef]

| Literature Reference | Barrier(s) |

|---|---|

| Vermunt et al. [28] | Internal; external; financial; organizational; knowledge and technology; supply chain and market; institutional. |

| Potdar et al. [29] | Improper competency management. |

| Silva and Gouveia [25]; Potdar et al. [29]; Sindhwani et al. [30] | Governmental policies and support. |

| Ghani and Bello [31]; Salinas et al. [32]; Potdar et al. [29]; Sindhwani et al. [30] | Ineffective customer relationship. |

| Vermunt et al. [28]; Caldera et al. [33]; Ghani and Bello [31] | Lack of knowledge and skills. |

| Silva and Gouveia [25]; Vermunt et al. [28]; Potdar et al. [29] | Ineffective supply chain. |

| Ghani and Bello [31]; Caldera et al. [33] | Existent organizational culture. |

| Caldera et al. [33]; Tan et al. [34] | Time constraints. |

| Caldera et al. [33]; Kostić [35] | Risk. |

| Ghani and Bello [31]; Potdar et al. [29] | Stakeholders’ attitude. |

| Added through the authors’ personal experience and industrial knowledge | Absence of immediate quantifiable benefits; lack of project team flexibility; project lead time not critical; not applicable to our product; organization not able to apply AM; flexibility is not a priority; there is no time to think about that; staff not prepared to AM; lack of government benefits; change predisposition. |

| Literature Reference | Enablers, Possible Solutions or Recommendations |

|---|---|

| Ghani and Bello [31]; Vermunt et al. [28] | Organizational support |

| Ghani and Bello [31]; Silva and Gouveia [25] | Stakeholder collaboration |

| Ghani and Bello [31] | Investment in training; lean relationship |

| Groups | Questions | Variables |

|---|---|---|

| Respondent characterization | 1–5 | Familiar with APM; age; department; job function. |

| Company characterization | 6–11 | Region; employees (company size), organizational structure; exportation volume; product requirements. |

| Manufacturing process characterization | 12–19 | Production type; production changes and purposes influence; improve flexibility; management involvement; manufacturing system; influence factors; quality criteria. |

| Product development process and PM | 20–23 | Product development process; PM approach; project and product development criteria; project changes. |

| APM environment | 24–32 | APM transition; APM culture; AM application; departments applying AM; APM certification; PM team; minimum qualification; agile techniques and tools; agile techniques; tools contribution. |

| Barriers in the implementation of AM | 33–37 | Barriers category; barriers source; specific barriers; other impediments; AM implementation difficulty. |

| Enablers for the implementation of AM | 38 | AM implementation enablers. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soares, D.; da Silva, F.J.G.; Ramos, S.C.F.; Kirytopoulos, K.; Sá, J.C.; Ferreira, L.P. Identifying Barriers in the Implementation of Agile Methodologies in Automotive Industry. Sustainability 2022, 14, 5453. https://doi.org/10.3390/su14095453

Soares D, da Silva FJG, Ramos SCF, Kirytopoulos K, Sá JC, Ferreira LP. Identifying Barriers in the Implementation of Agile Methodologies in Automotive Industry. Sustainability. 2022; 14(9):5453. https://doi.org/10.3390/su14095453

Chicago/Turabian StyleSoares, Daniel, Francisco José Gomes da Silva, Sandra Cristina Faria Ramos, Konstantinos Kirytopoulos, José Carlos Sá, and Luís Pinto Ferreira. 2022. "Identifying Barriers in the Implementation of Agile Methodologies in Automotive Industry" Sustainability 14, no. 9: 5453. https://doi.org/10.3390/su14095453

APA StyleSoares, D., da Silva, F. J. G., Ramos, S. C. F., Kirytopoulos, K., Sá, J. C., & Ferreira, L. P. (2022). Identifying Barriers in the Implementation of Agile Methodologies in Automotive Industry. Sustainability, 14(9), 5453. https://doi.org/10.3390/su14095453