Study on Splitting Damage Characteristics of a Rock–Shotcrete Interface Subjected to Corrosive Water

Abstract

:1. Introduction

2. Test Overview

2.1. Sample Preparation

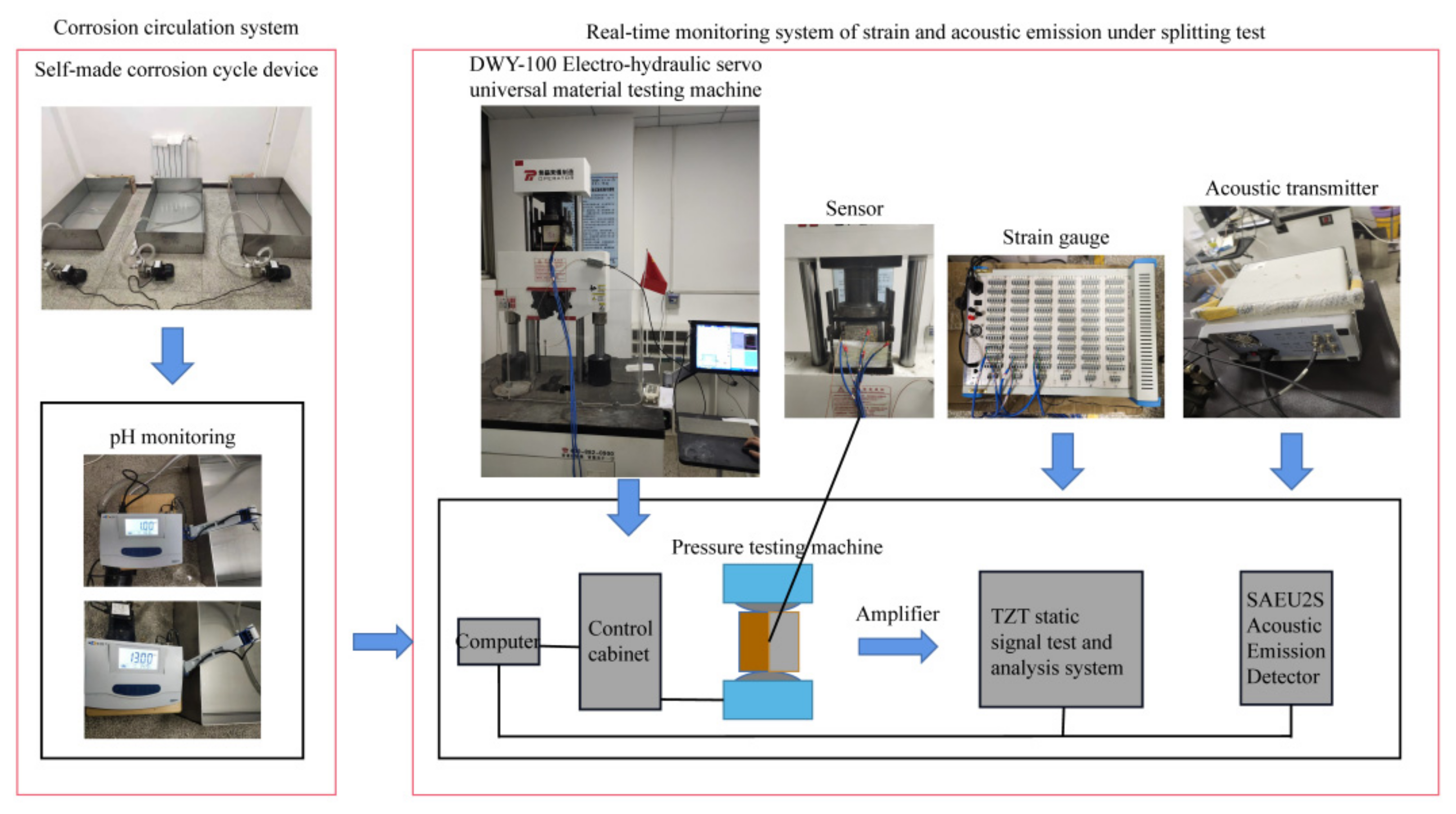

2.2. Test Equipment

2.3. Test Scheme

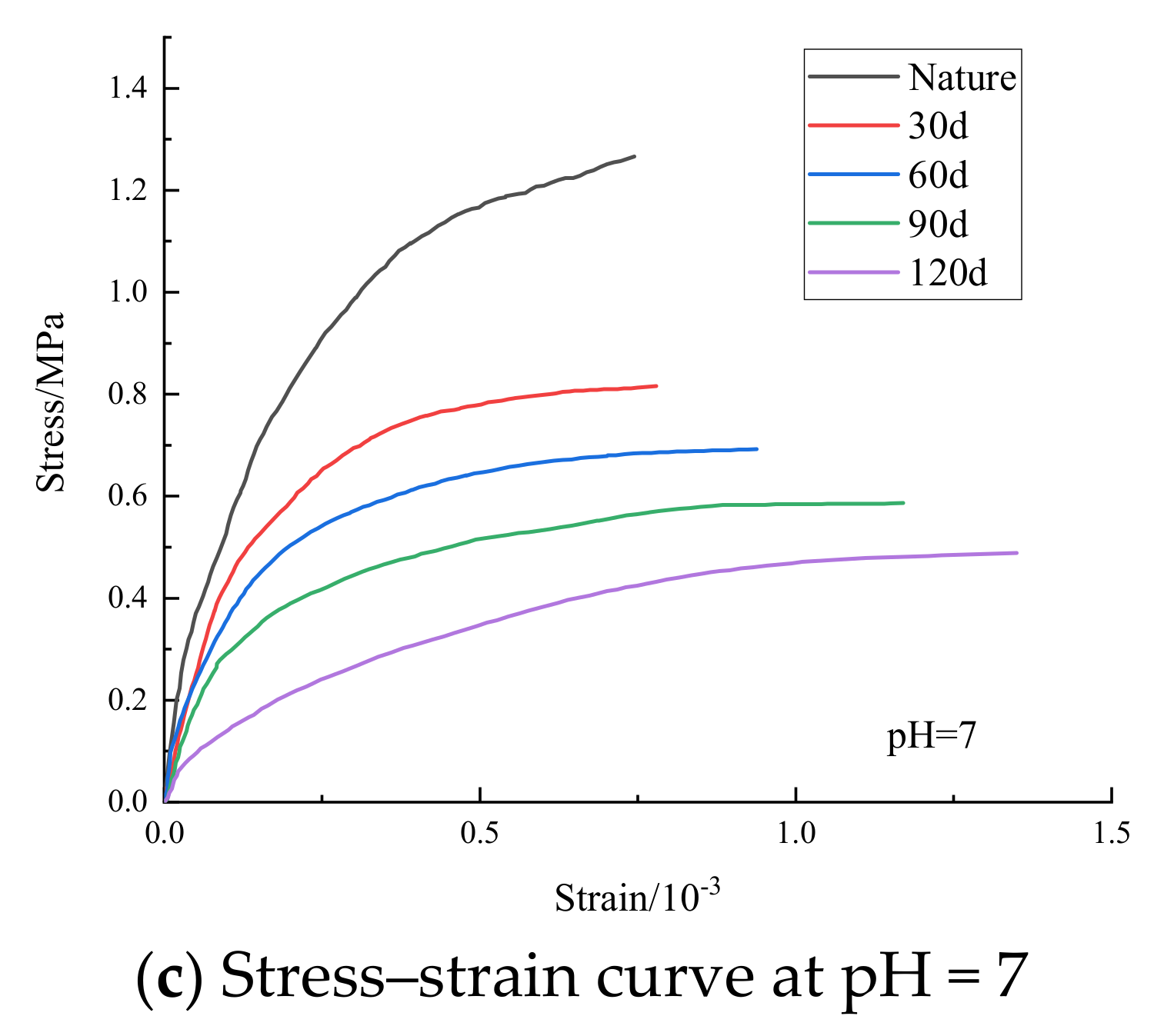

3. Results and Discussion

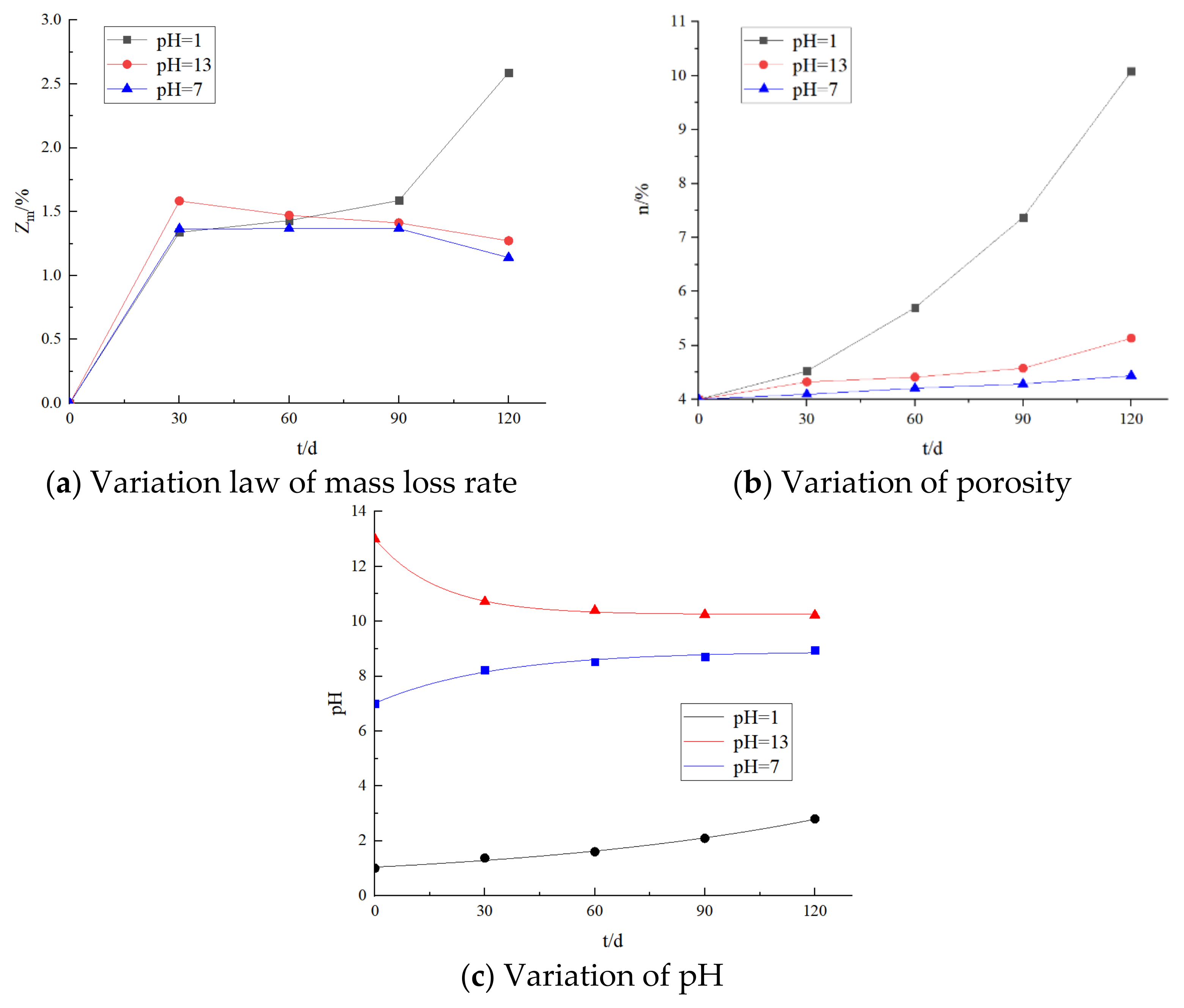

3.1. Variation of the Physical and Chemical Properties of Rock–Shotcrete under Corrosive Water

3.2. Analysis of Splitting Damage Evolution Based on Acoustic Emission Characteristic Parameters

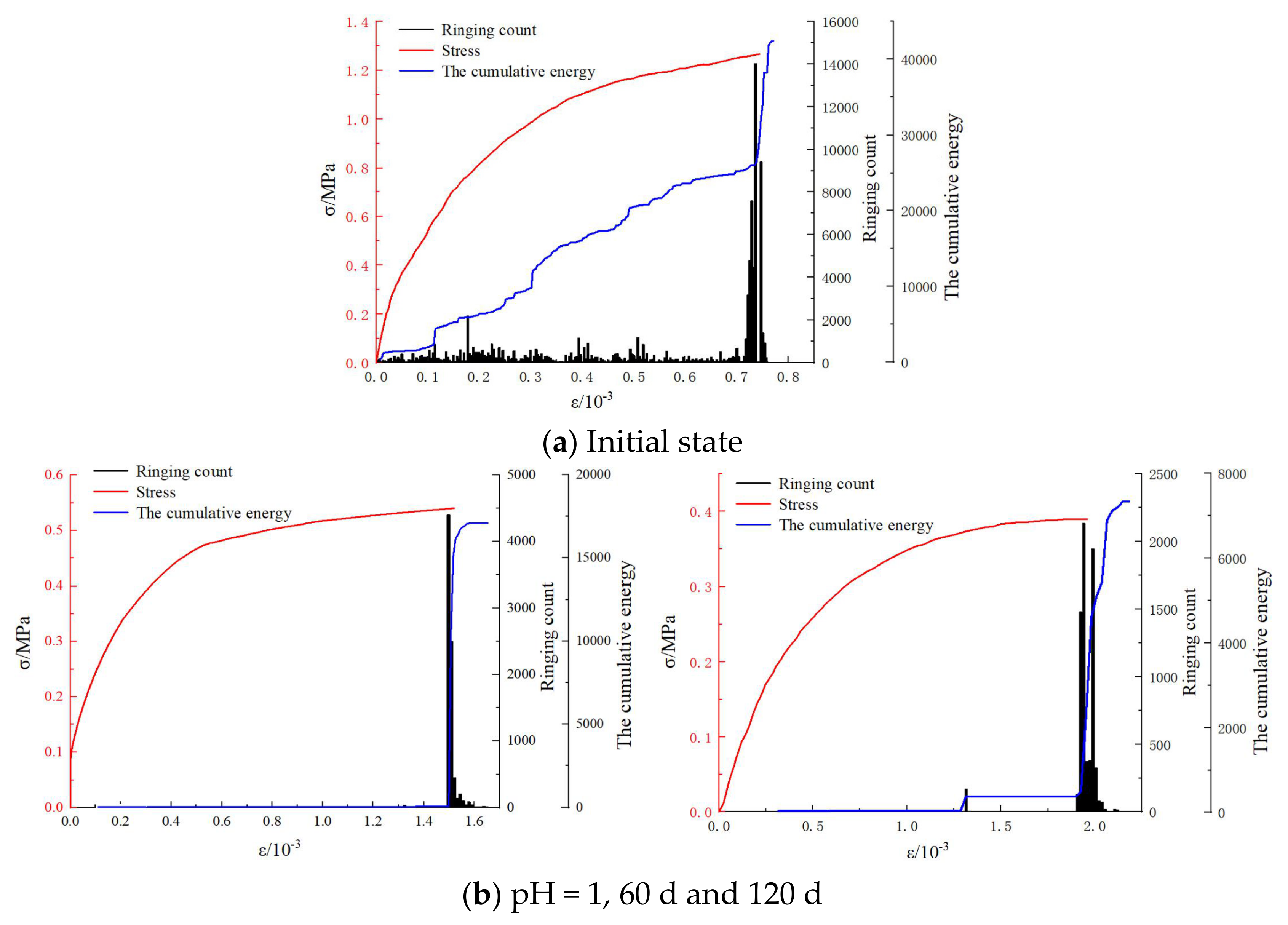

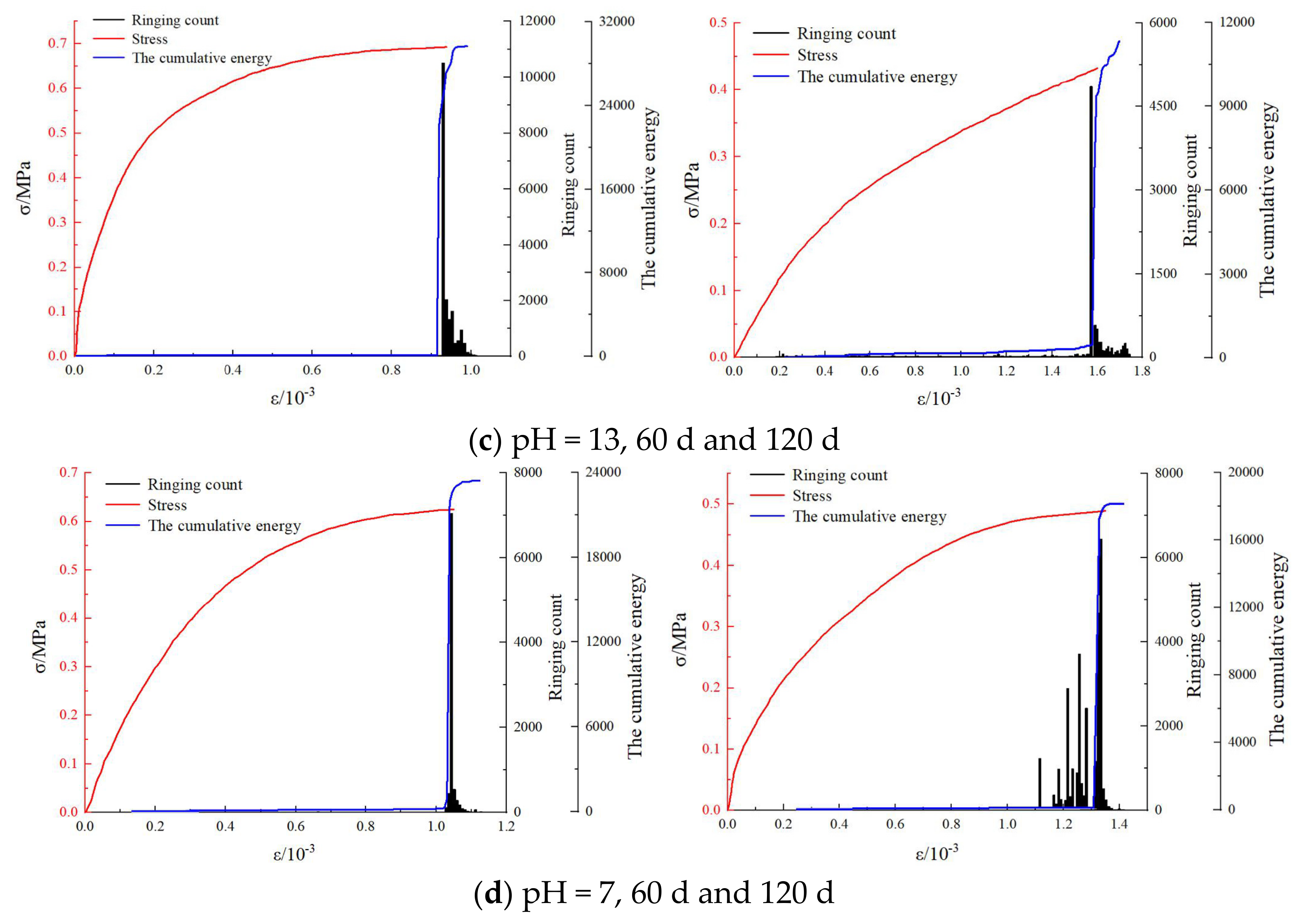

3.2.1. Variation Characteristics of the Ringing Count of Acoustic Emission

- (1).

- Stationary period. The number of ringing counts is small during this period, and acoustic emission events are also rare. Even the ringing counts of specimens corroded by corrosive aqueous solutions are negligible. In the early elastic stage of the specimen being under load conditions, the energy accumulated by the external load is not enough to destroy the cohesive force between the interface and produce new microcracks. With the application of the load, energy continues to accumulate, the microcracks caused by the primary hole begin to form, and the cohesive interface force begins to resist the transverse stress. The elastic stress wave released by the mechanical occlusion is captured, and the ringing count begins to respond. From the later elastic stage to the early plastic stage, the acoustic emission events enter a relatively stable period, primarily limited to about 1000 occurrences. Compared with the initial state, due to the erosion of the corrosive solution, the initial damage inside the specimen becomes extensive. Although the cracks are interconnected, most of them are filled with the generated material. The specimen become ‘soft’. The generated stress waves are mainly concentrated below the threshold value and are not captured.

- (2).

- Development period. In the late stage of the binary specimen entering the plastic zone, with the continuous increase of stress, the primary microcracks between concrete and rock continue to expand, and secondary microcracks are constantly generated. Therefore, a significant degree of fusion and penetration is formed on the bond surface, and the damage at the interface is more and more serious. The acoustic emission signal begins to be active, and a large oscillation wave is received. The ringing count enters the development period.

- (3).

- Mutation period. When the bonding force at the interface of the rock–shotcrete binary body reaches its limit, internal cracks gather rapidly, the first debonding occurs at the edge of the interface, the acoustic emission events increase rapidly, and the ringing count continuously exceeds the previous peak. The main crack at the interface breaks through the last obstacle by increasing the load. Furthermore, the ringing count reaches its maximum value almost at the moment before the failure of the specimen. The interface loses resistance to the ‘slamming’ sound and is destroyed. Due to the small interfacial bonding force and the short time required for the formation of a failure, the occurrence time of the peak value of the ringing count is often slightly ahead of the occurrence time of the peak stress point. Moreover, this phenomenon will become more evident with the erosion of corrosive water. Therefore, the precursor information of the interfacial splitting failure of a rock–shotcrete binary body under the action of corrosive water in the time domain should be the start time of the sudden change. The ringing count begins to increase significantly by several orders of magnitude.

- (4).

- Decrease period. After the mutation period, the interface is damaged but not fully debonded. At this time, emission events are still rare. The mechanical occlusion of the interface gradually fails with the expansion of the crack. The ringing count entered the decline period until zero.

3.2.2. Accumulated Energy Variation Characteristics of Acoustic Emission

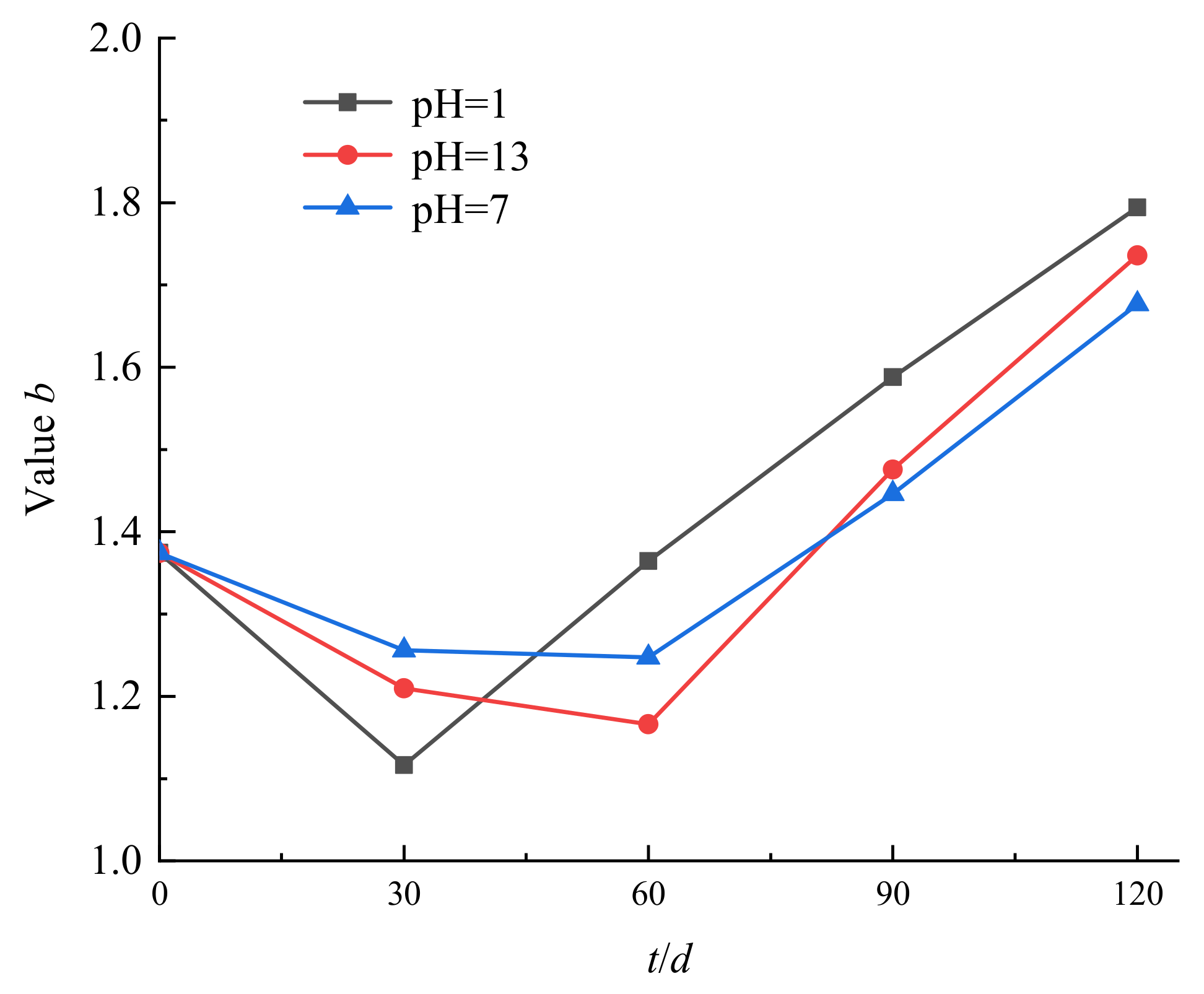

3.2.3. Variation Characteristics of Acoustic Emission b Value

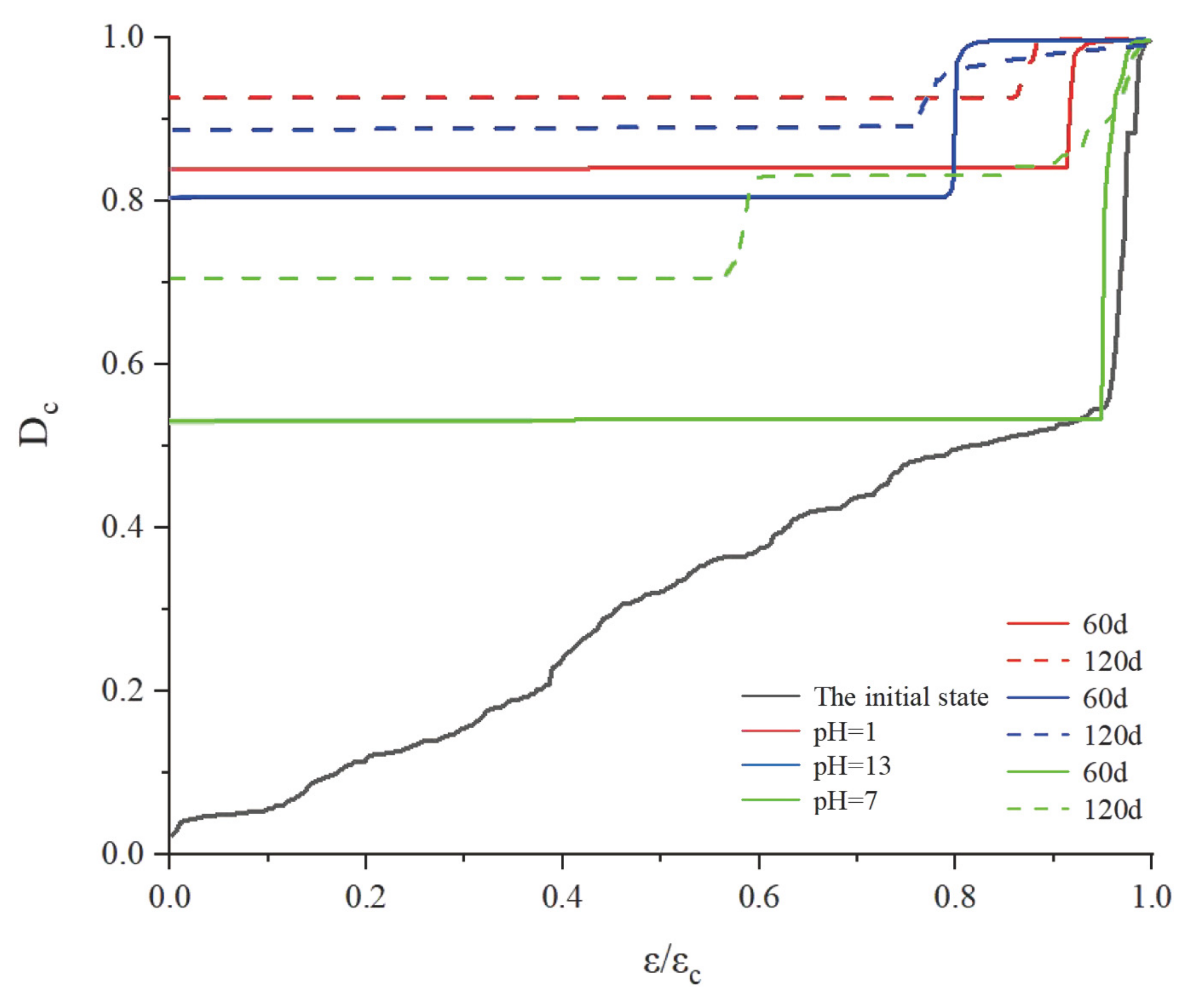

3.3. Analysis of the Deterioration Mechanism of the Rock–Shotcrete Interface Bonding Performance in Corrosive Water

4. Conclusions

- (1).

- The physical and chemical properties of rock–shotcrete binary specimens subjected to different corrosive water erosion have changed dramatically in the time domain, and the interface bonding performance decreases continuously. The H2SO4 solution with pH = 1 has a relatively significant corrosion effect.

- (2).

- The variation of the ringing count, cumulative energy, and acoustic emission b value can better characterize the quantity of rock–shotcrete interface corrosion damage and the dynamic evolution process. With the increase of corrosion, the peak point of the acoustic emission characteristic parameters of the binary specimen decreases gradually during the splitting process. Its transition time in numerical values can be used as precursor information for splitting failure. The specimen’s expansion scale of damage cracks is first large and then reduced.

- (3).

- The total evolution equation of the rock–shotcrete interface damage variable based on the acoustic emission cumulative ringing count can better reflect the coupling relationship between corrosion environment, load, and damage. Compared with the initial state specimens, the initial damage of the corroded binary specimens is more extensive, and the damage degree develops rapidly during loading.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Li, J.; Zhao, N.; Ren, X. Weak field control of rock engineering system failure. J. Liaoning Univ. Technol. (Nat. Sci. Ed.) 2005, 24, 671–673. (In Chinese) [Google Scholar]

- Shen, Y.; Wei, X.; Yang, G.; Wang, Y.; Jia, H.; Zhang, H.; Zhang, H. Rock-concrete interface bond strength freeze-thaw degradation model and experimental analysis. Rock Mech. Eng. 2020, 39, 480–490. [Google Scholar]

- Chen, Y. Application of acoustic emission technology in rock mechanics research. J. Geophys. 1977, 20, 312–322. [Google Scholar]

- Li, X.; Wu, X.; Gao, S.; Zhu, B. Experimental study on uniaxial compression and acoustic emission characteristics of red-bed soft rock under chemical corrosion. Railw. Sci. Eng. J. 2015, 69, 80–84. (In Chinese) [Google Scholar]

- Liu, Y.; Wang, C.; Li, X. Coupling study of acoustic emission and infrared radiation of sandstone under water-rock interaction. J. Yangtze Acad. Sci. 2022, 39, 127–133. (In Chinese) [Google Scholar]

- Zhang, G.; Li, H.; Wang, M.; Li, J.; Deng, S. Comparative study on damage characterization and evolution law of rock under uniaxial compression. Geotech. Eng. J. 2019, 41, 1074–1082. (In Chinese) [Google Scholar]

- Zhang, L.; Zhao, Y.; Jiang, A.; Ni, Q. Study on shear properties and acoustic emission characteristics of acid corroded concrete. J. Build. Mater. 2011, 14, 385–388. (In Chinese) [Google Scholar] [CrossRef]

- Sun, B.; Liu, H.; Yuan, D.; Wang, F.; Zeng, S. Research on damage characteristics of rock-concrete in two media under dry and saturated conditions. Silic. Bull. 2019, 269, 177–182. (In Chinese) [Google Scholar]

- Su, H.; Zhang, Y.; Li, Q.; Yuan, Z.; Gao, X. Acoustic emission test of the rock-concrete integrated two-medium body combined with discrete element method. Sci. Technol. Eng. 2019, 19, 206–210. (In Chinese) [Google Scholar]

- Liu, H.; Lin, J.; Yang, G.; Yun, Y.; Zhang, H.; Liang, B.; Zhang, Y. Acoustic emission test of tensile damage characteristics of sandstone under freeze-thaw cycles. J. Min. Saf. Eng. 2021, 38, 830–839. (In Chinese) [Google Scholar]

- Li, H.; Yang, C.; Liu, Y. Experimental study on acoustic and acoustic emission characteristics of salt rock under uniaxial loading. Rock Mech. Eng. 2014, 33, 2107–2116. [Google Scholar]

- Li, S.; Yin, X.; Wang, Y.; Tang, H. Research on acoustic emission characteristics of rock failure process under uniaxial compression. Rock Mech. Eng. 2004, 15, 2499–2503. (In Chinese) [Google Scholar]

- Yao, Q.; Li, X.; He, L.; Zhou, J. The strength damage and acoustic emission characteristics of water-bearing sandstone under uniaxial compression. J. Min. Saf. Eng. 2013, 30, 717–722. (In Chinese) [Google Scholar]

- Su, C.; Zhai, X.; Li, B.; Li, H.Q. Experimental study on acoustic emission characteristics of sandstone during uniaxial and triaxial compression. J. Min. Saf. Eng. 2011, 28, 225–230. [Google Scholar]

- Ji, H.; Lu, X. Acoustic emission characteristics of granite and its main fracture precursor information under conventional triaxial compression. J. Rock Mech. Eng. 2015, 34, 694–702. [Google Scholar]

- Wu, K.; Shao, Z.; Qin, S.; Zhao, N.; Chu, Z. An improved non-linear creep model for rock applied to tunnel displacement prediction. Int. J. Appl. Mech. 2021, 13, 2150094. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.; Sharifzadeh, M.; Chu, Z.; Qin, S. Analytical approach to estimating the influence of shotcrete hardening property on tunnel response. J. Eng. Mech. 2022, 148, 04021127. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.; Sharifzadeh, M.; Hong, S.; Qin, S. Analytical computation of support characteristic curve for circumferential yielding lining in tunnel design. J. Rock Mech. Geotech. Eng. 2022, 14, 144–152. [Google Scholar] [CrossRef]

- Wu, X.; Liu, J.; Liu, X.; Zhao, K.; Zhang, Y. Exploring the coupling relationship between cumulative counts of rock acoustic emission ringing and damage constitutive model. J. Min. Saf. Eng. 2015, 32, 28–34. (In Chinese) [Google Scholar] [CrossRef]

- Qin, S.; Li, Z. Fractal distribution of rock acoustic emission events in space. Appl. Acoust. 1992, 11, 19–21. [Google Scholar]

- Han, J.; Yao, L. Crustal stress evaluation method based on seismic activity parameter b-value. Rly. Std. Desg. 2015, 59, 36–39+127. (In Chinese) [Google Scholar] [CrossRef]

- Kachanov, M. On the time to failure under creep conditions. Izv. Akad. Nauk. USSR Otd. Tekhn. Nauk. 1958, 8, 26–31. [Google Scholar]

- Liu, J.; Zhao, L.; Song, S.; Ji, H. Acoustic and acoustic emission characteristics and mechanism of concrete sulfate corrosion damage. J. Eng. Sci. 2016, 38, 1075–1081. (In Chinese) [Google Scholar] [CrossRef]

| Petrographic Composition | SiO2 | Al2O3 | CaO | K2O | Na2O | Fe2O3 |

|---|---|---|---|---|---|---|

| mass fraction % | 70 | 15 | 0.9 | 1.1 | 0.3 | 0.4 |

| Name | Taking Values | Name | Taking Values |

|---|---|---|---|

| cement | 398 | water-cement ratio | 0.44 |

| water | 175 | percentage of sand | 31% |

| river sand | 566 | rapid setting admixture | 23.88 |

| crushed stone | 1261 | Water reducing admixture | 3.98 |

| Material | Density (kg/m3) | Poisson Ratio | Elastic Modulus(GPa) | Compressive Strength (MPa) |

|---|---|---|---|---|

| concrete | 2400 | 0.20 | 30.27 | 38.13 |

| rock | 2590 | 0.24 | 50.34 | 85.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, S.; Shen, Y.; Li, S.; Ma, W.; Lv, Y.; Li, X. Study on Splitting Damage Characteristics of a Rock–Shotcrete Interface Subjected to Corrosive Water. Sustainability 2022, 14, 4987. https://doi.org/10.3390/su14094987

Tian S, Shen Y, Li S, Ma W, Lv Y, Li X. Study on Splitting Damage Characteristics of a Rock–Shotcrete Interface Subjected to Corrosive Water. Sustainability. 2022; 14(9):4987. https://doi.org/10.3390/su14094987

Chicago/Turabian StyleTian, Sisi, Yanjun Shen, Shuguang Li, Wen Ma, You Lv, and Xueting Li. 2022. "Study on Splitting Damage Characteristics of a Rock–Shotcrete Interface Subjected to Corrosive Water" Sustainability 14, no. 9: 4987. https://doi.org/10.3390/su14094987

APA StyleTian, S., Shen, Y., Li, S., Ma, W., Lv, Y., & Li, X. (2022). Study on Splitting Damage Characteristics of a Rock–Shotcrete Interface Subjected to Corrosive Water. Sustainability, 14(9), 4987. https://doi.org/10.3390/su14094987