A Threshold Model of Tailings Sand Liquefaction Based on PSO-SVM

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Equipment

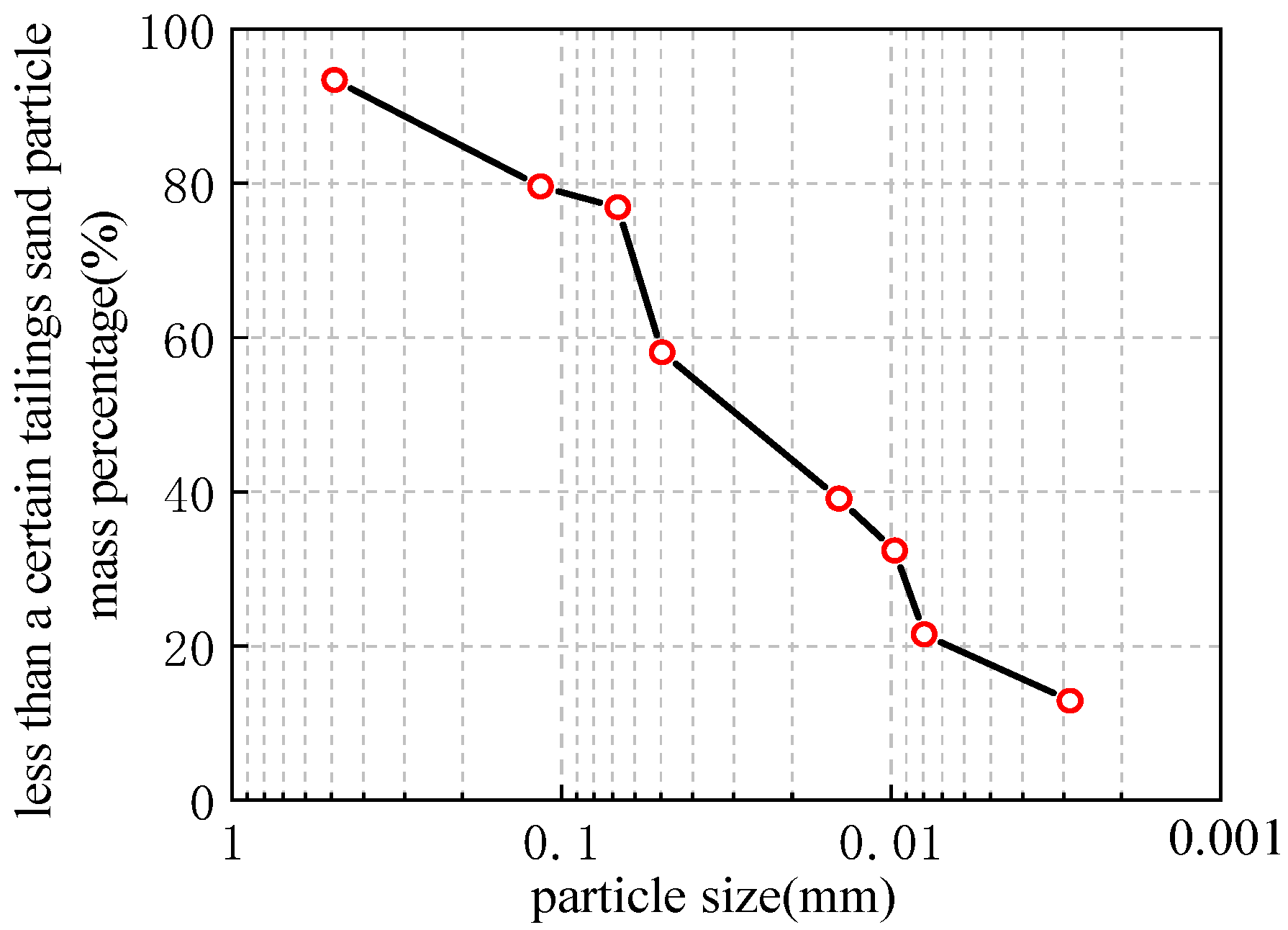

2.2. Test Material

2.3. Test Model Box

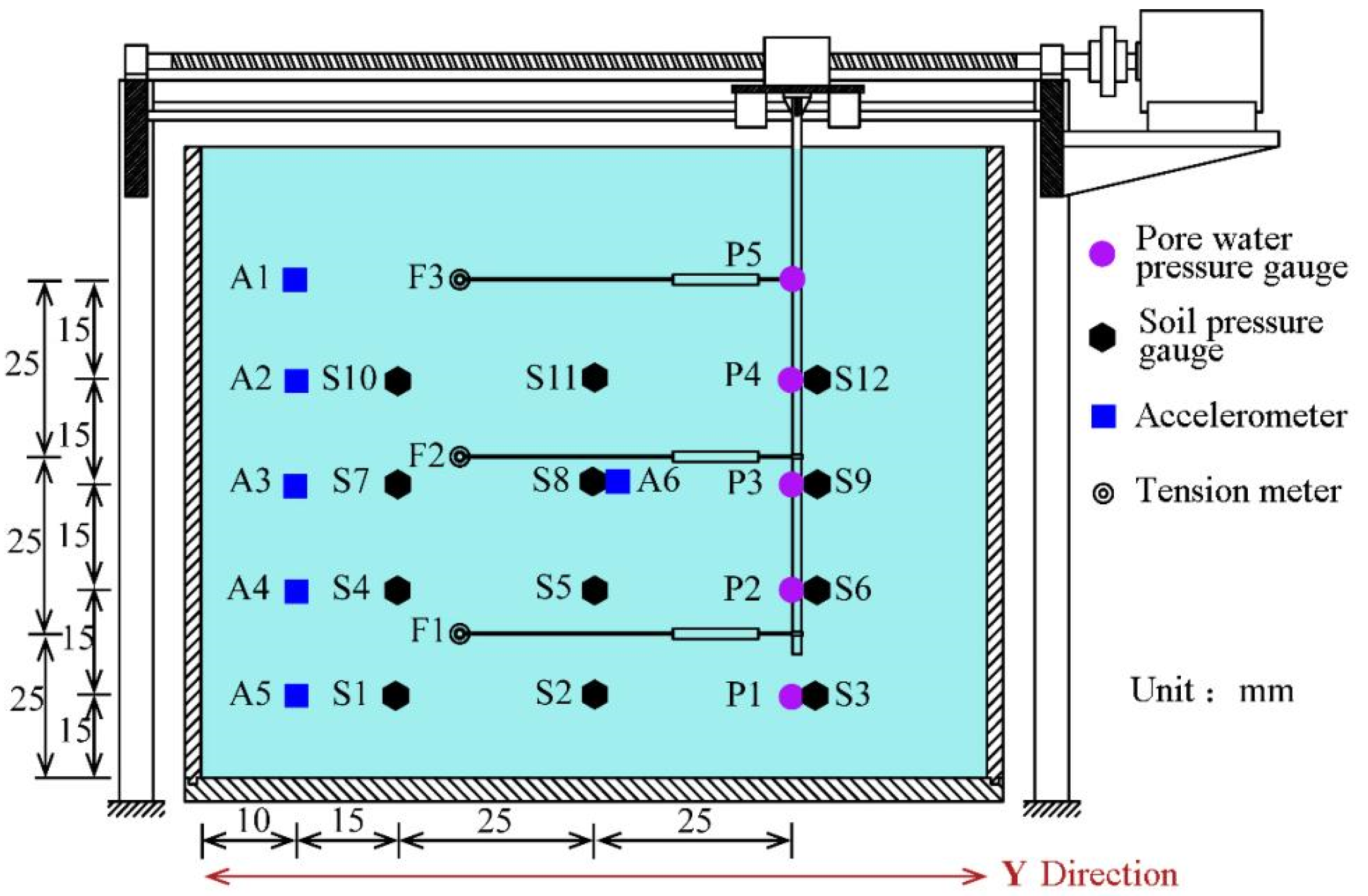

2.4. Sensor and Measuring Point Arrangement

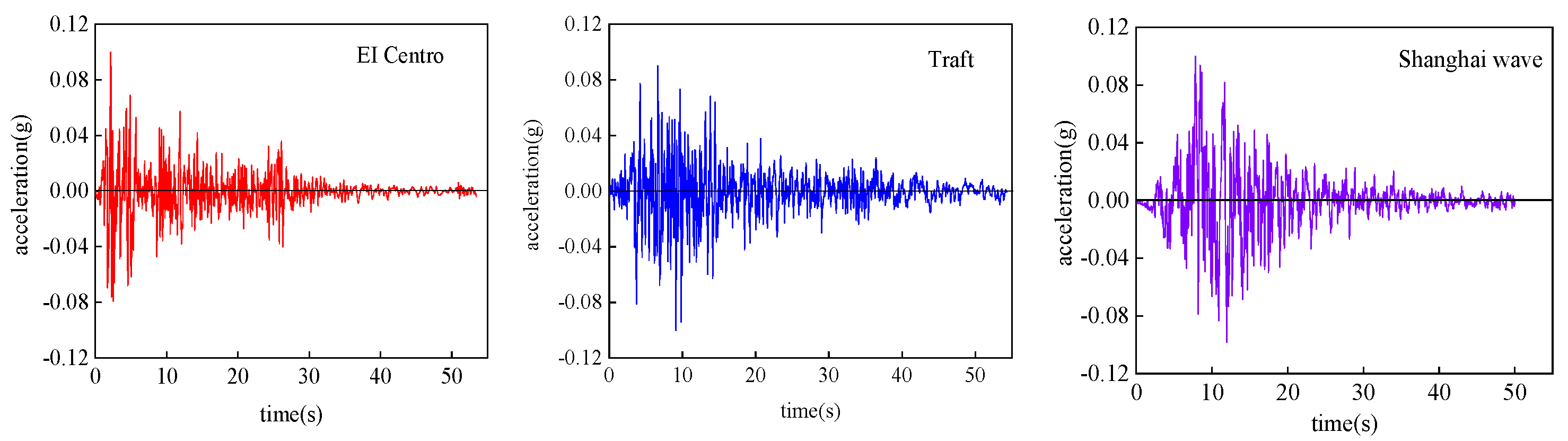

2.5. Test Loading Scheme

3. Algorithm Design Based on PSO-SVM

3.1. Particle Swarm Optimization (PSO)

3.2. Support Vector Machine (SVM)

3.3. Algorithm Design

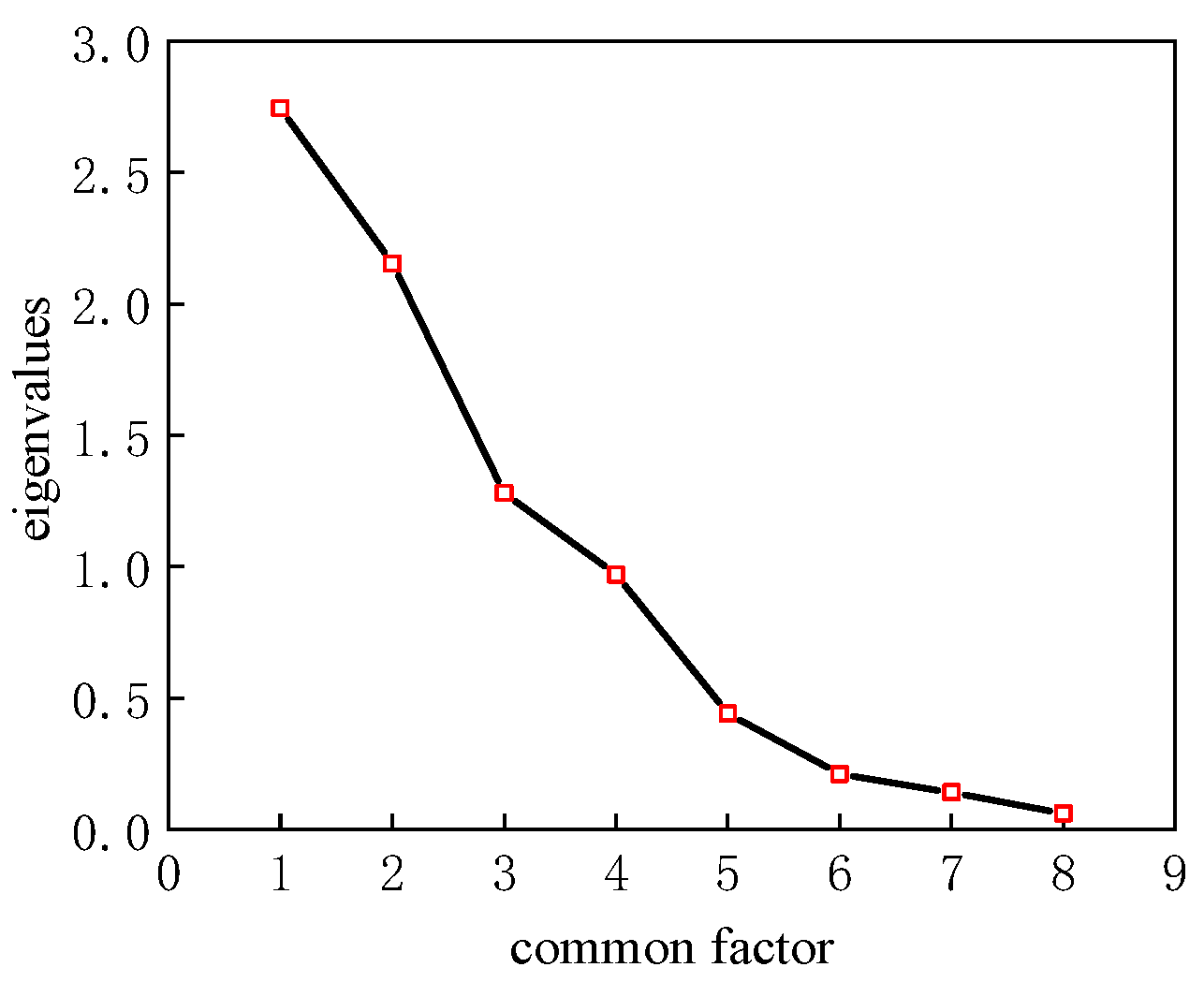

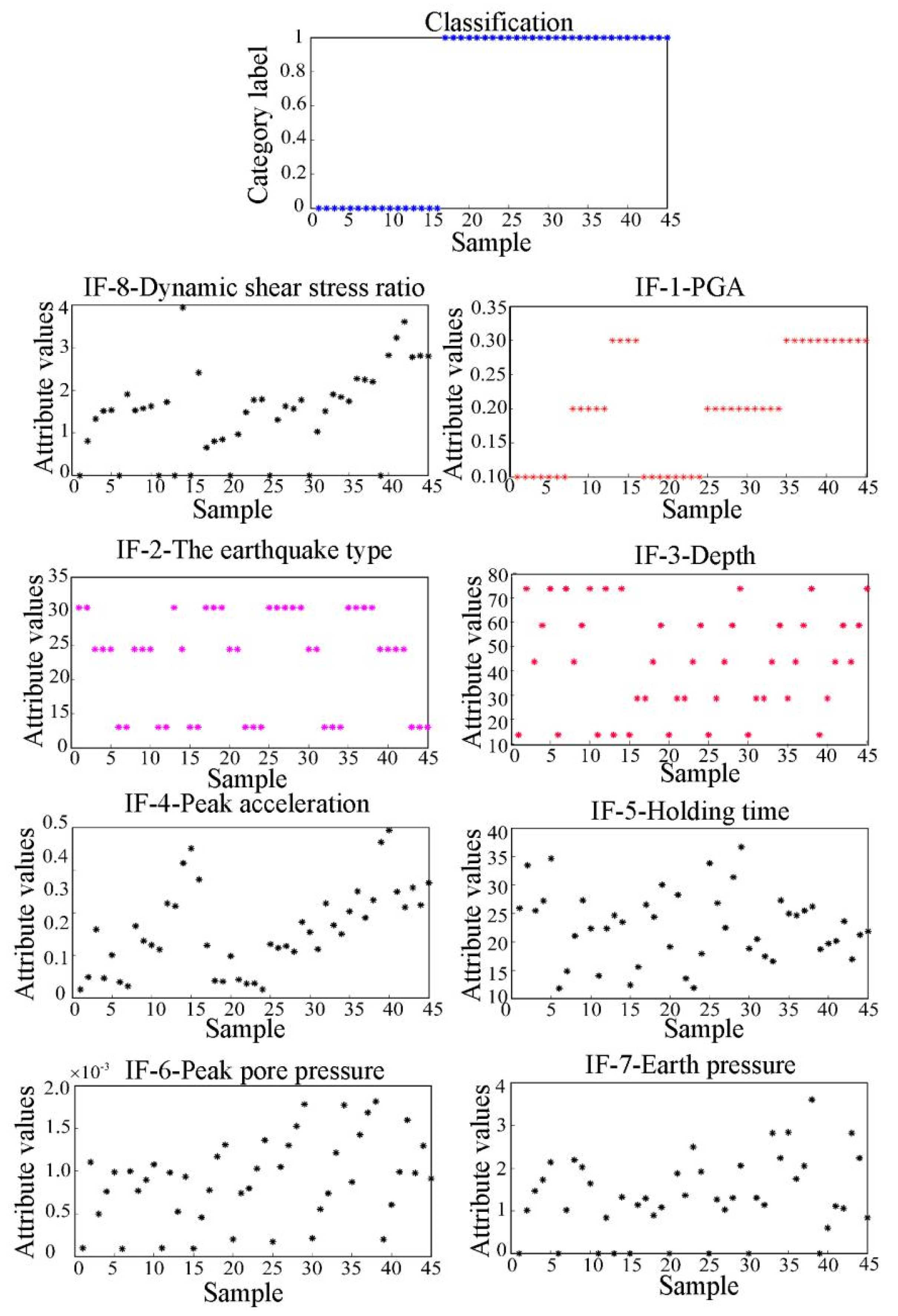

4. Factor Analysis of Influence Parameters of Tailings Sand Liquefaction

5. Tailwater Sand Liquefaction Threshold Model Based on PSO-SVM

5.1. Normalization of the Influencing Factors

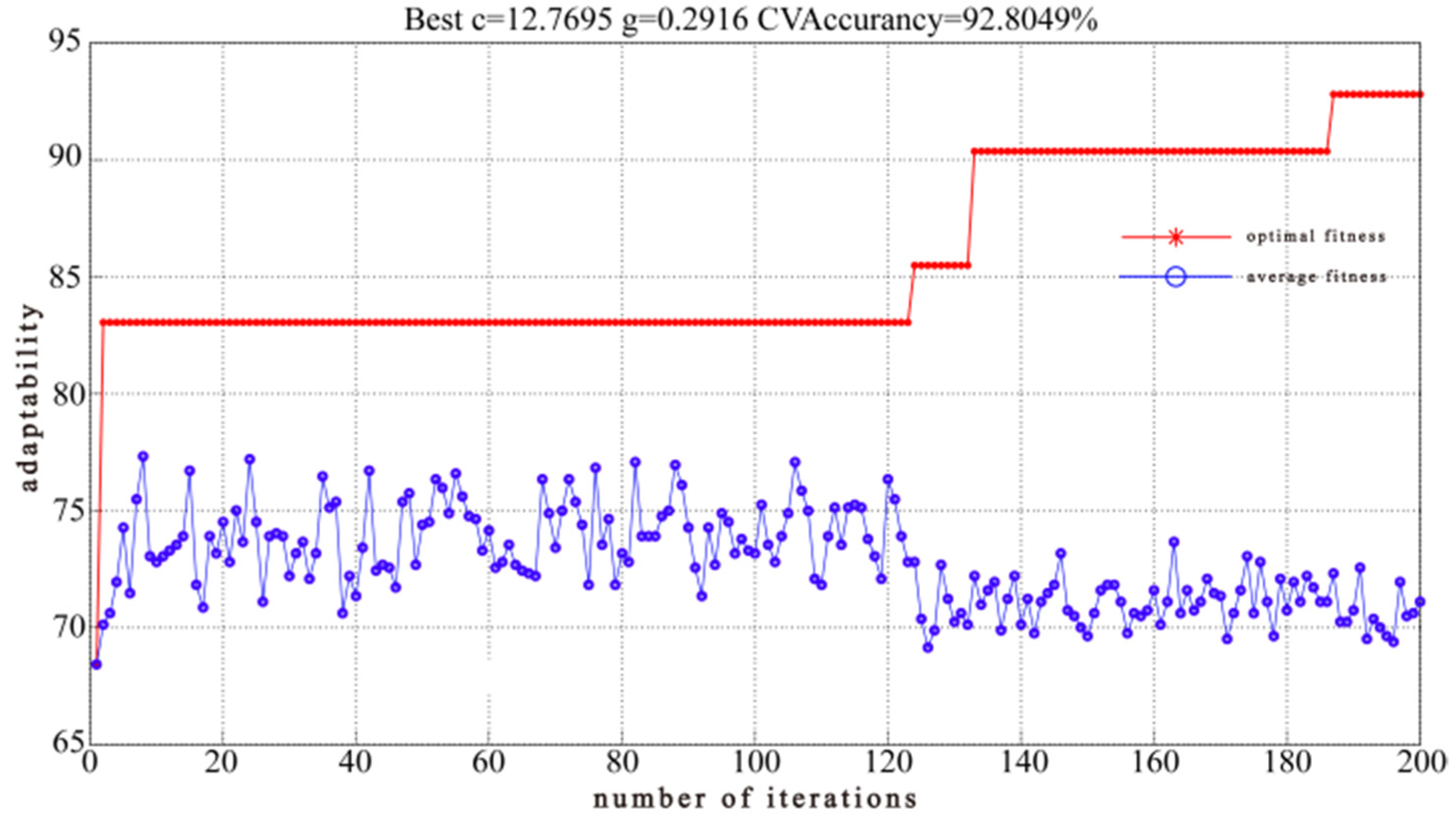

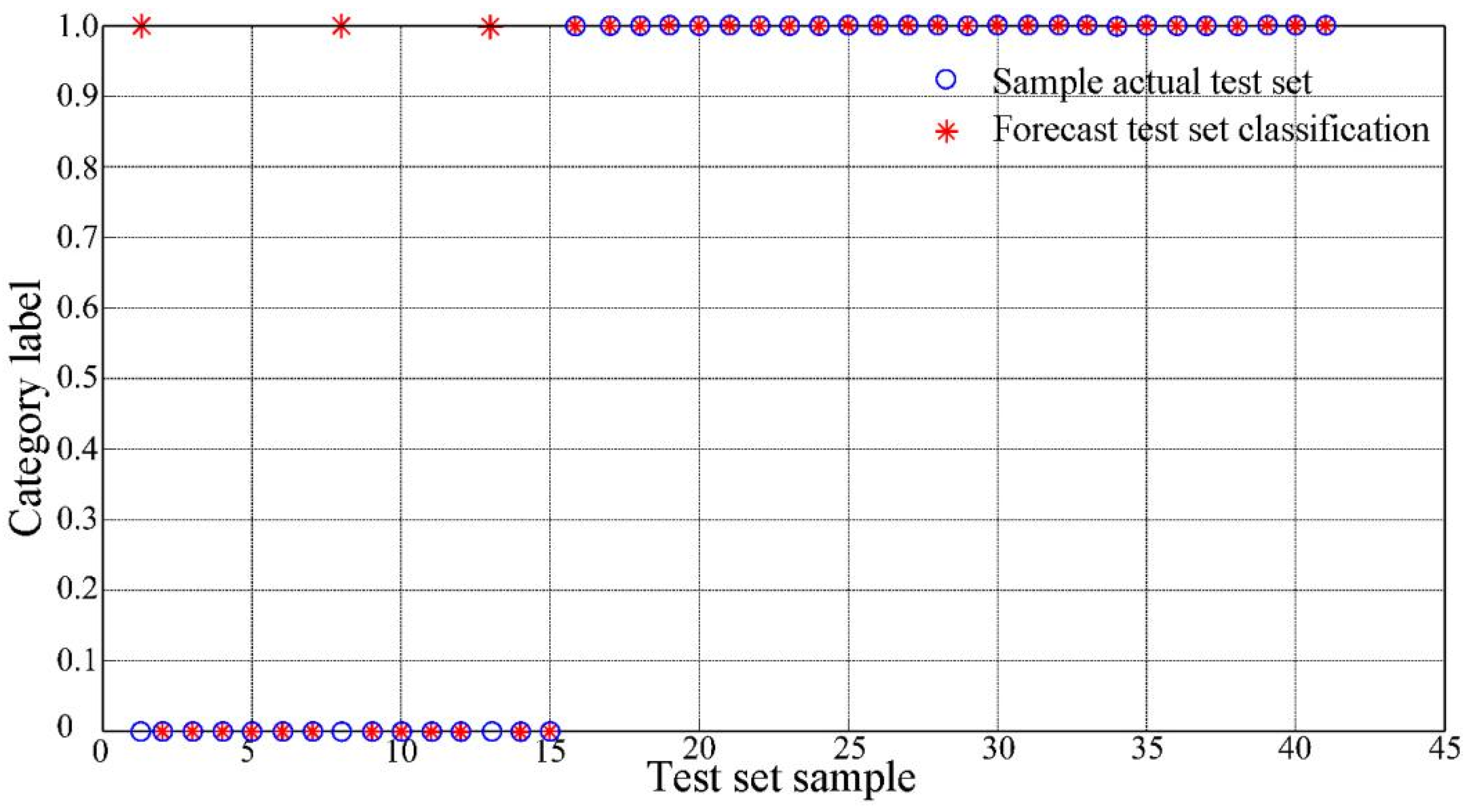

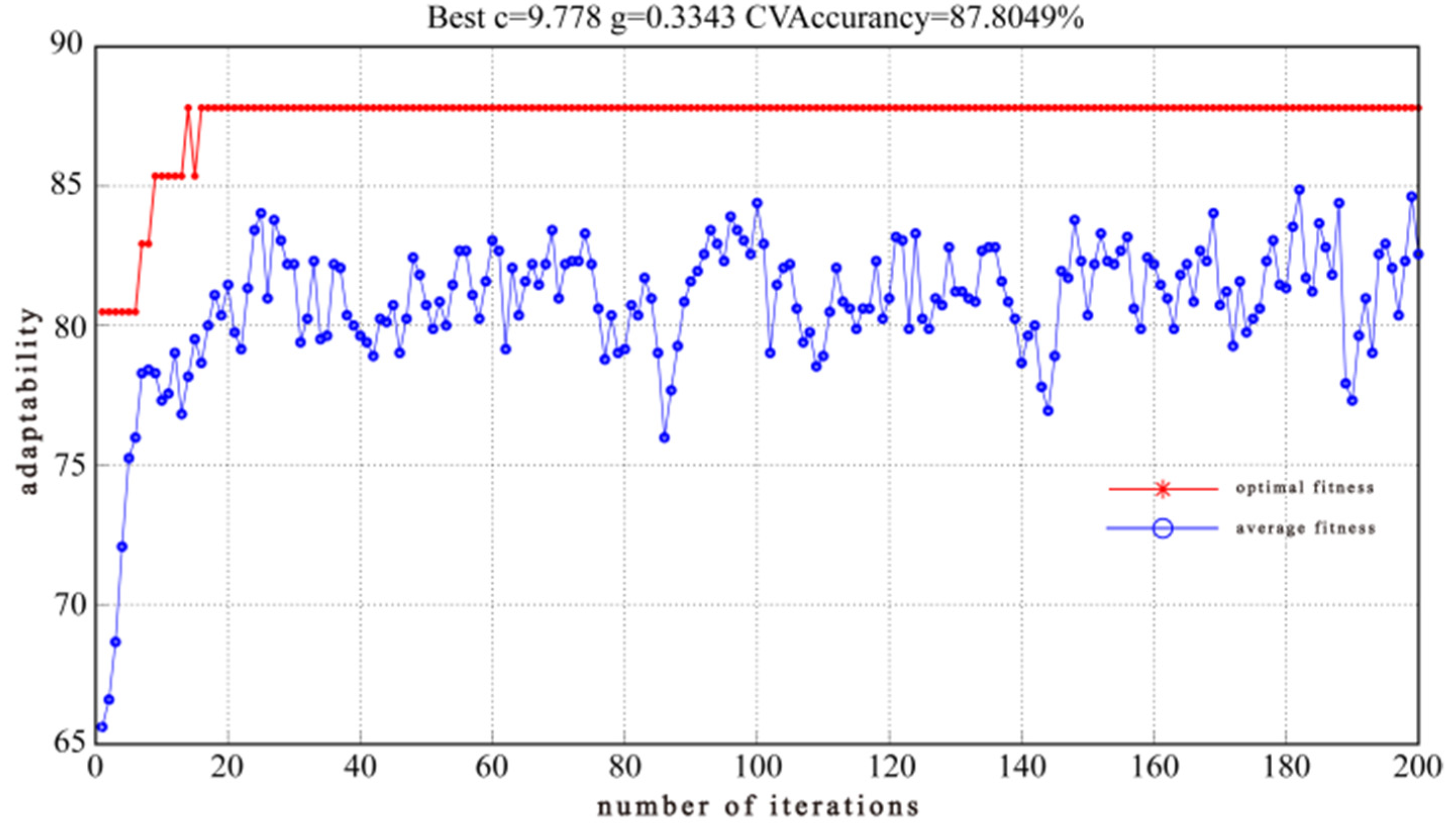

5.2. Construction of the Tailings Sand Liquefaction Threshold Model

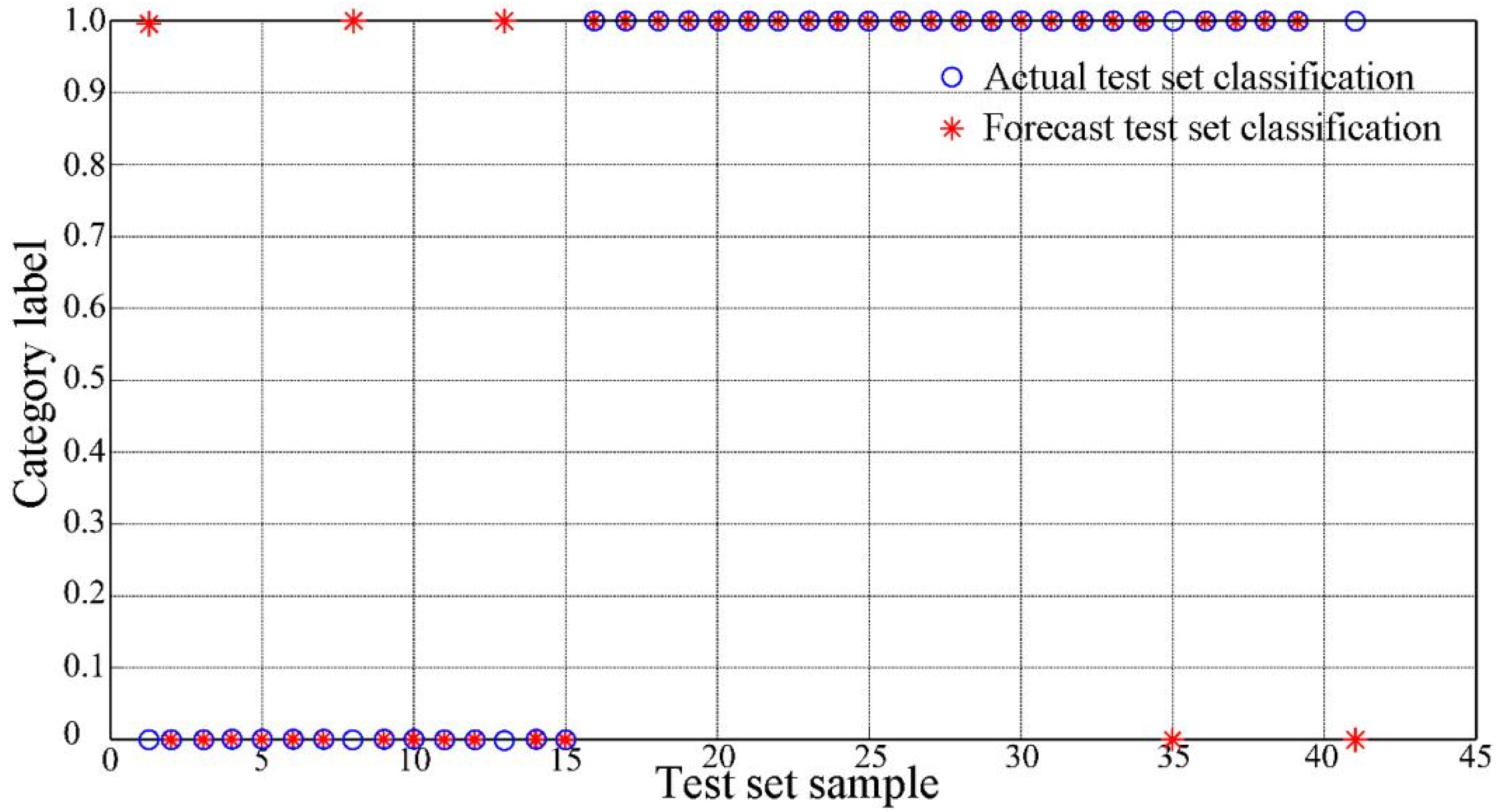

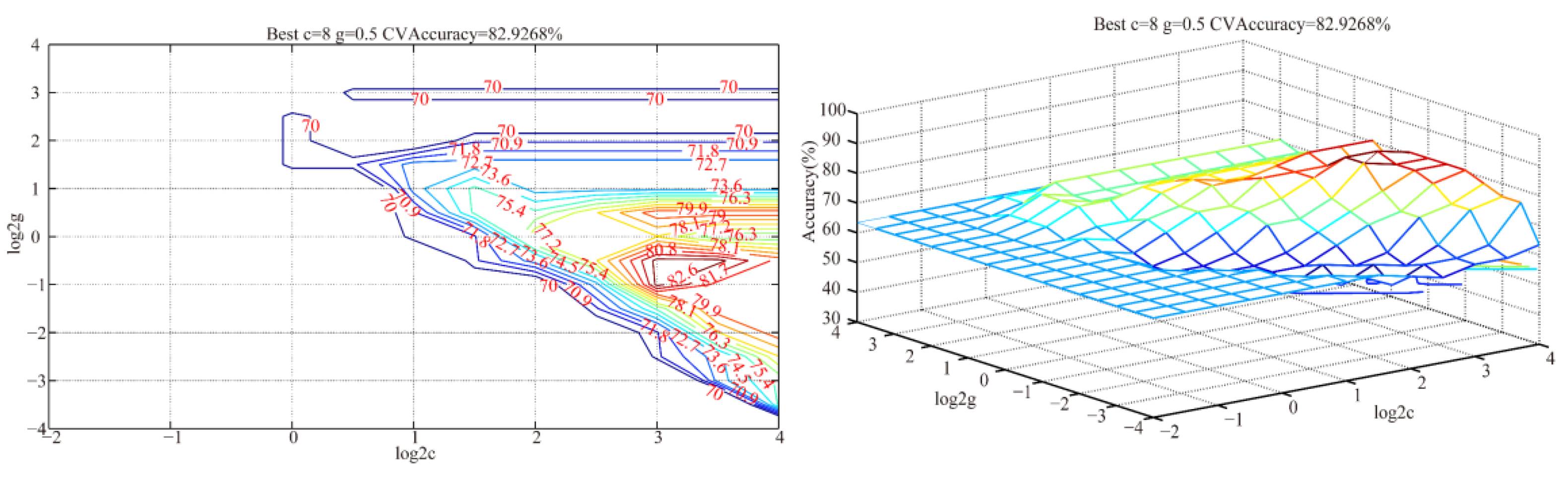

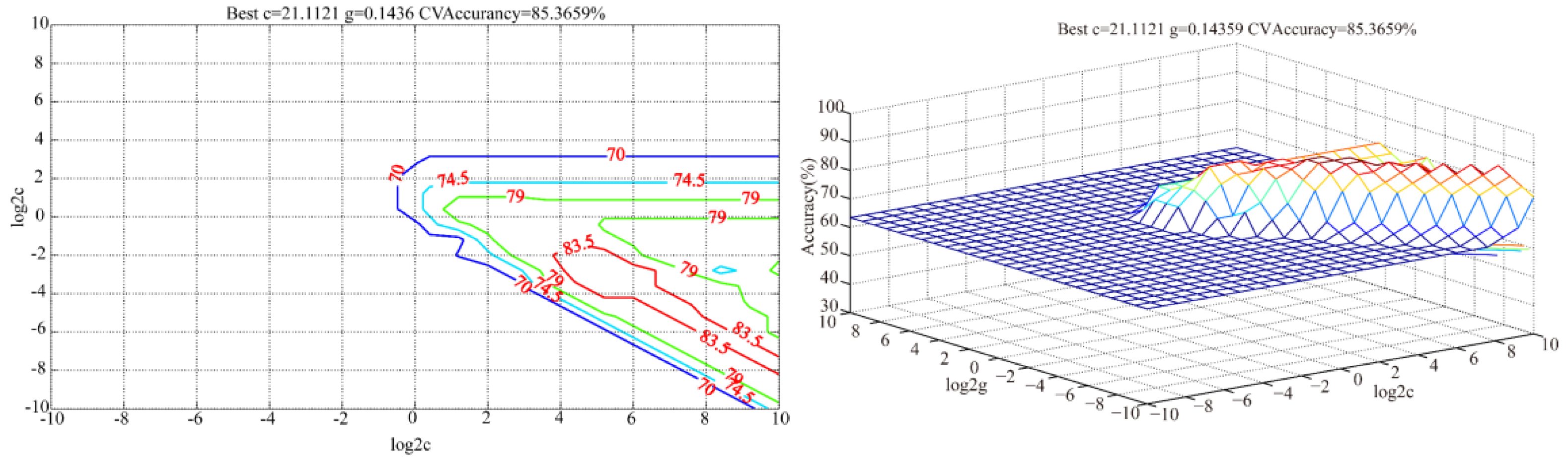

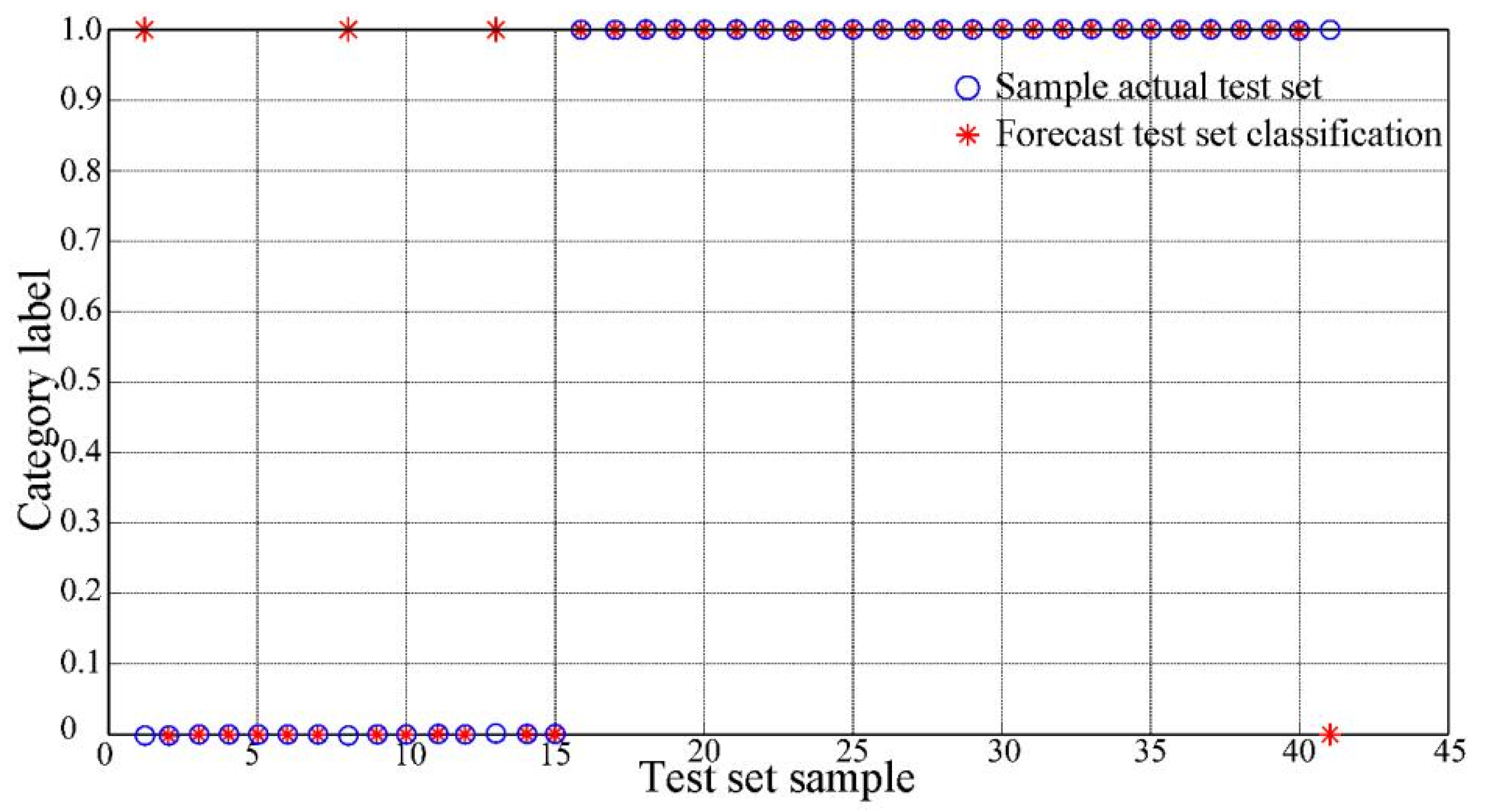

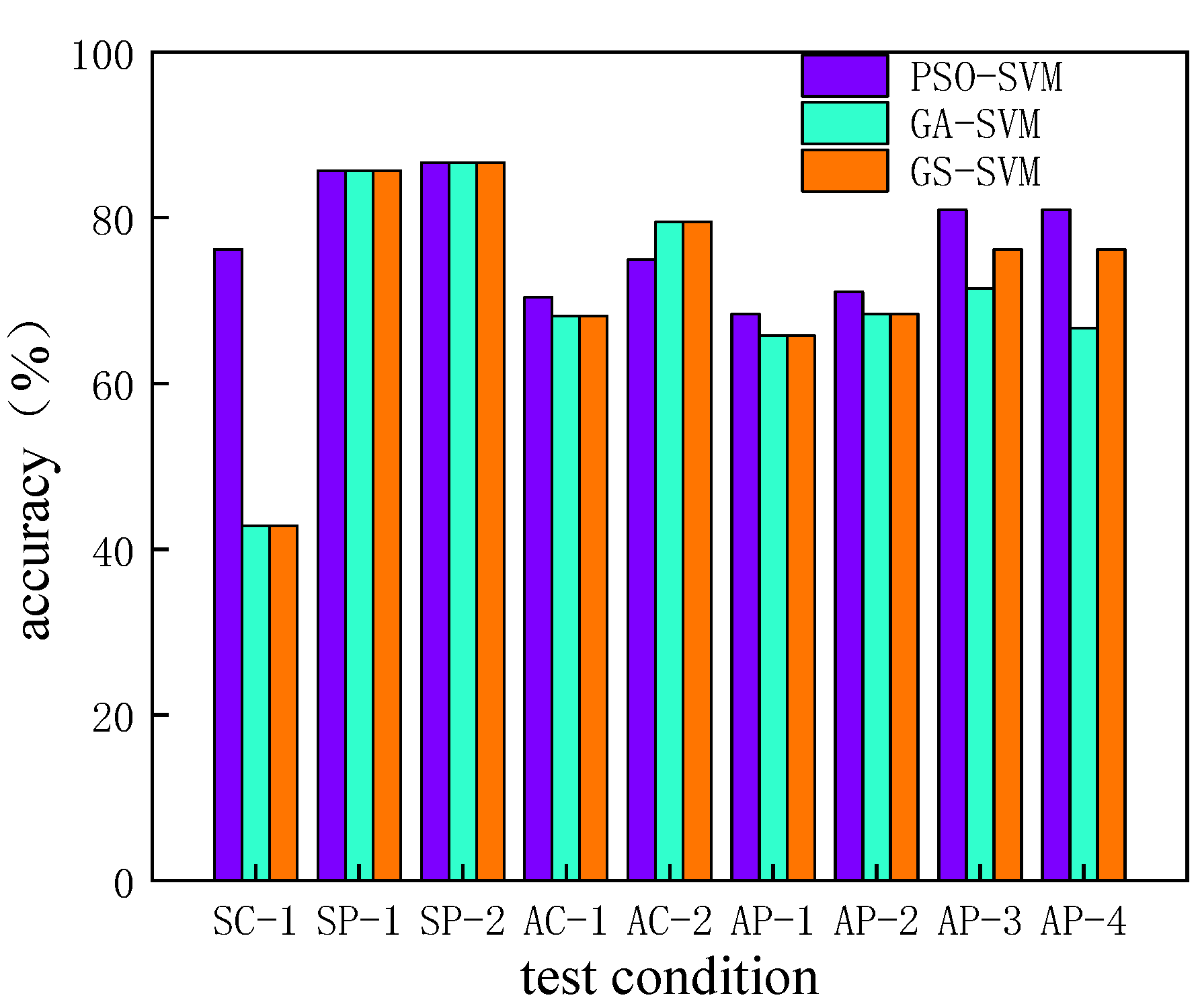

5.3. Analysis of the PSO-SVM Tailings Liquefaction Threshold Model

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Senapati, P.K.; Mishra, B.K. Feasibility Studies on Pipeline Disposal of Concentrated Copper Tailings Slurry for Waste Minimization. J. Inst. Eng. (India) Ser. C 2017, 98, 277–283. [Google Scholar] [CrossRef]

- Karaca, O.; Cameselle, C.; Reddy, K. Mine tailing disposal sites: Contamination problems, remedial options and phytocaps for sustainable remediation. Rev. Environ. Sci. Bio/Technol. 2018, 17, 205–228. [Google Scholar] [CrossRef]

- Jin, J.; Qin, Z.; Lü, X.; Liu, T.; Zhang, G.; Shi, J.; Zuo, S.; Li, D. Rheology control of self-consolidating cement-tailings grout for the feasible use in coal gangue-filled backfill. Constr. Build. Mater. 2021, 316, 125836. [Google Scholar] [CrossRef]

- Moharrami, A.; Hassanzadeh, Y.; Salmasi, F.; Moradi, G.; Moharrami, G. Performance of the horizontal drains in upstream shell of earth dams on the upstream slope stability during rapid drawdown conditions. Arab. J. Geosci. 2013, 7, 1957–1964. [Google Scholar] [CrossRef]

- Fourie, A.B.; Blight, G.E.; Papageorgiou, G. Static liquefaction as a possible explanation for the Merriespruit tailings dam failure. Can. Geotech. J. 2001, 38, 707–719. [Google Scholar] [CrossRef]

- Wanatowski, D.; Chu, J. Static liquefaction of sand in plane strain. Can. Geotech. J. 2007, 44, 299–313. [Google Scholar] [CrossRef]

- Verdugo, R.; González, J. Liquefaction-induced ground damages during the 2010 Chile earthquake. Soil Dyn. Earthq. Eng. 2015, 79, 280–295. [Google Scholar] [CrossRef]

- Seed, H.B.; Idriss, I.M. Simplified procedure for evaluating soil liquefaction potential. J. Soil Mech. Found. Div. 1971, 197, 71–78. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.; Qin, S.; Zhao, N.; Chu, Z. An improved non-linear creep model for rock applied to tunnel displacement prediction. Int. J. Appl. Mech. 2021, 13, 2150094. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.; Sharifzadeh, M.; Chu, Z.; Qin, S. Analytical approach to estimating the influence of shotcrete hardening property on tunnel response. J. Eng. Mech. 2022, 148, 04021127. [Google Scholar] [CrossRef]

- Du, G.; Gao, C.; Liu, S.; Guo, Q.; Luo, T. Evaluation Method for the Liquefaction Potential Using the Standard Penetration Test Value Based on the CPTU Soil Behavior Type Index. Adv. Civ. Eng. 2019, 2019, 5612857. [Google Scholar] [CrossRef]

- Chu, Z.; Wu, Z.; Wang, Z.; Weng, L.; Liu, Q.; Fan, L. Micro-mechanism of brittle creep in saturated sandstone and its mechanical behavior after creep damage. Int. J. Rock Mech. Min. Sci. 2021, 149, 104994. [Google Scholar] [CrossRef]

- Ataee, O.; Moghaddas, N.H.; Lashkaripour, G.R. Estimating shear wave velocity of soil using standard penetration test (SPT) blow counts in Mashhad city. J. Earth Syst. Sci. 2019, 128, 66–91. [Google Scholar] [CrossRef] [Green Version]

- Abdi, Y.; Taheri-Garavand, A.; Sahamieh, R.Z. Prediction of strength parameters of sedimentary rocks using artificial neural networks and regression analysis. Arab. J. Geosci. 2018, 11, 587. [Google Scholar] [CrossRef]

- Sahu, S.P.; Patra, A.K. Development and assessment of multiple regression and neural network models for prediction of respirable PM in the vicinity of a surface coal mine in India. Arab. J. Geosci. 2020, 13, 890. [Google Scholar] [CrossRef]

- Chakraborty, A.; Goswami, D. Prediction of slope stability using multiple linear regression (MLR) and artificial neural network (ANN). Arab. J. Geosci. 2017, 10, 385. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.; Qin, S.; Wei, W.; Chu, Z. A critical review on the performance of yielding supports in squeezing tunnels. Tunn. Undergr. Space Technol. 2021, 115, 103815. [Google Scholar] [CrossRef]

- Hu, B.; Sharifzadeh, M.; Feng, X.-T.; Guo, W.; Talebi, R. Role of stress, slenderness and foliation on large anisotropic deformations at deep underground excavations. Int. J. Min. Sci. Technol. 2021, 31, 577–590. [Google Scholar] [CrossRef]

- Zahmatkesh, A.; Noorzad, R. Investigation of monotonic and cyclic behavior of sand using a bounding surface plasticity model. Arab. J. Geosci. 2018, 11, 40. [Google Scholar] [CrossRef]

- Kimiaefar, R.; Siahkoohi, H.R.; Hajian, A.R.; Kalhor, A. Seismic random noise attenuation using artificial neural network and wavelet packet analysis. Arab. J. Geosci. 2016, 9, 234. [Google Scholar] [CrossRef]

- Wu, Y.-C.; Feng, J.-W. Development and Application of Artificial Neural Network. Wirel. Pers. Commun. 2017, 102, 1645–1656. [Google Scholar] [CrossRef]

- Farrokhi, F.; Firoozfar, A.; Maghsoudi, M.S. Evaluation of liquefaction-induced lateral displacement using a GMDH-type neural network optimized by genetic algorithm. Arab. J. Geosci. 2020, 13, 4. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.; Sharifzadeh, M.; Hong, S.; Qin, S. Analytical computation of support characteristic curve for circumferential yielding lining in tunnel design. J. Rock Mech. Geotech. Eng. 2022, 14, 144–152. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.; Qin, S.; Zhao, N.; Hu, H. Analytical-based assessment of effect of highly deformable elements on tunnel lining within viscoelastic rocks. Int. J. Appl. Mech. 2020, 12, 2050030. [Google Scholar] [CrossRef]

- Goh, A. Neural network modeling of CPT seismic liquefaction data. J. Geotech. Eng. 1996, 122, 70–73. [Google Scholar] [CrossRef]

- Goh, A. Probabilistic neural network for evaluating seismic liquefaction potential. Can. Geotech. J. 2002, 39, 219–232. [Google Scholar] [CrossRef]

- Goh, A. Seismic liquefaction potential assessed by neural networks. J. Geotech. Eng. 1994, 120, 1467–1480. [Google Scholar] [CrossRef]

- Juang, C.H.; Chen, C.J. CPT-based liquefaction evaluation using artificial neural networks. Comput. Civ. Infrastruct. Eng. 1999, 14, 221–229. [Google Scholar] [CrossRef]

- Rahman, M.; Wang, J. Fuzzy neural network models for liquefaction prediction. Soil Dyn. Earthq. Eng. 2002, 22, 685–694. [Google Scholar] [CrossRef]

- Baziar, M.; Nilipour, N. Evaluation of liquefaction potential using neural-networks and CPT results. Soil Dyn. Earthq. Eng. 2003, 23, 631–636. [Google Scholar] [CrossRef]

- Hanna, A.M.; Ural, D.; Saygili, G. Neural network model for liquefaction potential in soil deposits using Turkey and Taiwan earthquake data. Soil Dyn. Earthq. Eng. 2007, 27, 521–540. [Google Scholar] [CrossRef]

- Chern, S.-G.; Lee, C.-Y.; Wang, C.-C. CPT-based liquefaction assessment by using fuzzy-neural network. J. Mar. Sci. Technol. 2008, 16, 139–148. [Google Scholar] [CrossRef]

- Erzin, Y.; Ecemis, N. Thhe use of neural networks for CPT-based liquefaction screening. Bull. Eng. Geol. Environ. 2015, 74, 103–116. [Google Scholar] [CrossRef] [Green Version]

- Xue, X.; Xiao, M. Application of genetic algorithm-based support vector machines for prediction of soil liquefaction. Environ. Earth Sci. 2016, 75, 874. [Google Scholar] [CrossRef]

- Xue, X.; Liu, E. Seismic liquefaction potential assessed by neural networks. Environ. Earth Sci. 2017, 76, 192. [Google Scholar] [CrossRef]

- Hoang, N.-D.; Bui, D.T. Predicting earthquake-induced soil liquefaction based on a hybridization of kernel Fisher discriminant analysis and a least squares support vector machine: A multi-dataset study. Bull. Eng. Geol. Environ. 2018, 77, 191–204. [Google Scholar] [CrossRef]

- Jin, J.; Ding, Q.; Cui, H.; Zhang, P.; Xiao, X.; Lv, X. Dynamic response characteristics of a tailing dam determined by shaking-table tests. Arab. J. Geosci. 2020, 13, 897. [Google Scholar] [CrossRef]

- Jin, J.X. Study on Dynamic Characteristics of Upstream Tailings Pond under Seismic Load; Northeastern University: Shenyang, China, 2014. [Google Scholar]

- Liu, X.; Ji, Y.C.; Zhao, J.B.; Hou, S.W.; Hao, Z. Experimental study on liquefaction characteristics of tailing sand. Eng. Surv. Investig. 2015, 43, 15–18+24. [Google Scholar]

- Liu, X.K. Research on Damage Identification of Civil Structures Based on PSO-SVM; Jilin Jianzhu University: Jilin, China, 2021. [Google Scholar]

| Plasticity | Liquid Limit | Plasticity Index | Optimum Moisture Content | Void Ratio | Specific Gravity | Maximum Dry Density |

|---|---|---|---|---|---|---|

| ωp/% | ωl/% | Ip/% | ωop/% | e/% | G/g/cm3 | Ρdmax/g/cm3 |

| 13.1% | 20.5 | 7.4 | 14.2 | 0.892 | 2.84 | 1.92 |

| Working Condition | Seismic Wave | Peak Acceleration /m/s2 | Reference Point Acceleration /m/s2 | Comparing Point Acceleration /m/s2 | Boundary Norm Index /% |

|---|---|---|---|---|---|

| 1 | II (El Centro) | 0.2 | 0.246 | 0.250 | 1.868 |

| 2 | 0.4 | 0.457 | 0.465 | 1.965 | |

| 3 | 0.6 | 0.665 | 0.670 | 0.755 | |

| 4 | III (Traft) | 0.1 | 0.157 | 0.158 | 1.061 |

| 5 | 0.3 | 0.317 | 0.340 | 7.652 | |

| 6 | 0.5 | 0.560 | 0.566 | 1.245 | |

| 7 | IV (Shanghai wave) | 0.4 | 0.453 | 0.453 | 0.011 |

| 8 | 0.2 | 0.289 | 0.284 | 1.653 | |

| 9 | 0.4 | 0.415 | 0.454 | 9.282 | |

| 10 | 0.5 | 0.578 | 0.580 | 0.335 |

| Site Type | Seismic Wave | Earthquake Intensity (PGA) | Working Condition |

|---|---|---|---|

| III | Traft | 0.1 g | 1 |

| 0.2 g | 2 | ||

| 0.3 g | 3 | ||

| II | El Centro | 0.1 g | 4 |

| 0.2 g | 5 | ||

| 0.3 g | 6 | ||

| IV | Shanghai wave | 0.1 g | 7 |

| 0.2 g | 8 | ||

| 0.3 g | 9 |

| PGA (g) | Type of Earthquake | Buried Depth (cm) | Peak Acceleration (g) | Holding Time (s) | Peak Pore Pressure (MPa) | Peak Earth Pressure (MPa) | Dynamic Shear Stress Ratio | Liquefaction State | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.1 | Traft | −75 | 0.12 | 30.9 | 0.0001 | —— | —— | Unliquefied |

| 2 | 0.1 | Traft | −60 | 0.224 | 31.52 | 0.0008 | 1.2932 | 0.6578 | liquefied |

| 3 | 0.1 | Traft | −45 | 0.141 | 29.38 | 0.0012 | 0.8931 | 0.8068 | liquefied |

| 4 | 0.1 | Traft | −30 | 0.139 | 35.02 | 0.0013 | 1.0849 | 0.84a91 | liquefied |

| 5 | 0.1 | Traft | −15 | 0.149 | 38.46 | 0.0011 | 1.0104 | 0.8117 | Unliquefied |

| 6 | 0.1 | El Centro | −75 | 0.199 | 24.12 | 0.0002 | —— | —— | liquefied |

| 7 | 0.1 | El Centro | −60 | 0.143 | 33.26 | 0.0007 | 1.8774 | 0.9701 | liquefied |

| 8 | 0.1 | El Centro | −45 | 0.261 | 30.46 | 0.0005 | 1.4663 | 1.3297 | Unliquefied |

| 9 | 0.1 | El Centro | −30 | 0.147 | 32.22 | 0.0008 | 1.7283 | 1.5168 | Unliquefied |

| 10 | 0.1 | El Centro | −15 | 0.201 | 39.66 | 0.001 | 2.139 | 1.5355 | Unliquefied |

| 11 | 0.1 | Shanghai wave | −75 | 0.138 | 16.82 | 0.0001 | —— | —— | Unliquefied |

| 12 | 0.1 | Shanghai wave | −60 | 0.134 | 18.56 | 0.0008 | 1.3646 | 1.4841 | liquefied |

| 13 | 0.1 | Shanghai wave | −45 | 0.135 | 16.88 | 0.001 | 2.4964 | 1.7746 | liquefied |

| 14 | 0.1 | Shanghai wave | −30 | 0.12 | 22.92 | 0.0014 | 1.9191 | 1.7892 | liquefied |

| 15 | 0.1 | Shanghai wave | −15 | 0.128 | 19.84 | 0.001 | 1.018 | 1.9084 | Unliquefied |

| 16 | 0.2 | Traft | −75 | 0.226 | 38.82 | 0.0002 | —— | —— | liquefied |

| 17 | 0.2 | Traft | −60 | 0.218 | 31.82 | 0.001 | 1.2664 | 1.3091 | liquefied |

| 18 | 0.2 | Traft | −45 | 0.222 | 27.48 | 0.0013 | 1.026 | 1.6283 | liquefied |

| 19 | 0.2 | Traft | −30 | 0.209 | 36.38 | 0.0015 | 1.3019 | 1.5671 | liquefied |

| 20 | 0.2 | Traft | −15 | 0.278 | 41.68 | 0.0018 | 2.0589 | 1.7761 | liquefied |

| 21 | 0.2 | El Centro | −75 | 0.255 | 23.84 | 0.0002 | —— | —— | liquefied |

| 22 | 0.2 | El Centro | −60 | 0.215 | 25.48 | 0.0006 | 1.3066 | 1.0313 | liquefied |

| 23 | 0.2 | El Centro | −45 | 0.269 | 26.04 | 0.0008 | 2.1932 | 1.53 | Unliquefied |

| 24 | 0.2 | El Centro | −30 | 0.234 | 32.3 | 0.0009 | 2.0239 | 1.5746 | Unliquefied |

| 25 | 0.2 | El Centro | −15 | 0.225 | 27.34 | 0.0011 | 1.6395 | 1.627 | Unliquefied |

| 26 | 0.2 | Shanghai wave | −75 | 0.214 | 19.04 | 0.0001 | —— | —— | Unliquefied |

| 27 | 0.2 | Shanghai wave | −60 | 0.322 | 22.44 | 0.0007 | 1.1371 | 1.5094 | liquefied |

| 28 | 0.2 | Shanghai wave | −45 | 0.271 | 21.58 | 0.0012 | 2.8246 | 1.9063 | liquefied |

| 29 | 0.2 | Shanghai wave | −30 | 0.25 | 32.3 | 0.0018 | 2.2371 | 1.843 | liquefied |

| 30 | 0.2 | Shanghai wave | −15 | 0.322 | 27.34 | 0.001 | 0.8388 | 1.7258 | Unliquefied |

| 31 | 0.3 | Traft | −75 | 0.316 | 29.64 | 0.0005 | —— | —— | Unliquefied |

| 32 | 0.3 | Traft | −60 | 0.303 | 29.96 | 0.0009 | 2.8406 | 1.7432 | liquefied |

| 33 | 0.3 | Traft | −45 | 0.35 | 29.64 | 0.0014 | 1.7487 | 2.2737 | liquefied |

| 34 | 0.3 | Traft | −30 | 0.289 | 30.48 | 0.0017 | 2.0538 | 2.2511 | liquefied |

| 35 | 0.3 | Traft | −15 | 0.33 | 31.2 | 0.0018 | 3.6069 | 2.2024 | liquefied |

| 36 | 0.3 | El Centro | −75 | 0.466 | 23.7 | 0.0002 | —— | —— | liquefied |

| 37 | 0.3 | El Centro | −60 | 0.493 | 24.7 | 0.0006 | 0.5975 | 2.8199 | liquefied |

| 38 | 0.3 | El Centro | −45 | 0.349 | 25.16 | 0.001 | 1.1091 | 3.2321 | liquefied |

| 39 | 0.3 | El Centro | −30 | 0.313 | 28.62 | 0.0016 | 1.0587 | 3.6079 | liquefied |

| 40 | 0.3 | El Centro | −15 | 0.416 | 28.46 | 0.0009 | 1.323 | 3.9402 | Unliquefied |

| 41 | 0.3 | Shanghai wave | −75 | 0.451 | 17.4 | 0.0001 | —— | —— | Unliquefied |

| 42 | 0.3 | Shanghai wave | −60 | 0.378 | 20.58 | 0.0005 | 1.1371 | 2.4138 | Unliquefied |

| 43 | 0.3 | Shanghai wave | −45 | 0.359 | 21.94 | 0.001 | 2.8246 | 2.779 | liquefied |

| 44 | 0.3 | Shanghai wave | −30 | 0.318 | 26.22 | 0.0013 | 2.2371 | 2.8106 | liquefied |

| 45 | 0.3 | Shanghai wave | −15 | 0.37 | 26.86 | 0.0009 | 0.8388 | 2.8 | Unliquefied |

| Influencing Factor | PGA | Type of Earthquake | Buried Depth | Peak Acceleration | Holding Time | Pore Pressure | Earth Pressure | Dynamic Shear Stress Ratio | |

|---|---|---|---|---|---|---|---|---|---|

| Correlation | PGA | 1.000 | —— | —— | —— | —— | —— | —— | —— |

| Type of earthquake | 0.000 | 1.000 | —— | —— | —— | —— | —— | —— | |

| Buried depth | 0.000 | 0.000 | 1.000 | —— | —— | —— | —— | —— | |

| Peak acceleration | 0.873 | −0.083 | −0.055 | 1.000 | —— | —— | —— | —— | |

| Holding time | −0.113 | 0.719 | 0.388 | −0.156 | 1.000 | —— | —— | —— | |

| Pore pressure | 0.139 | 0.168 | 0.760 | −0.045 | 0.394 | 1.000 | —— | —— | |

| Earth pressure | 0.153 | −0.054 | 0.073 | −0.005 | 0.021 | 0.337 | 1.000 | —— | |

| Dynamic shear stress ratio | 0.773 | −0.270 | 0.222 | 0.727 | −0.301 | 0.163 | 0.041 | 1.000 | |

| Significant | PGA | —— | 0.500 | 0.500 | 0.000 | 0.201 | 0.135 | 0.187 | 0.000 |

| Type of earthquake | 0.500 | —— | 0.500 | 0.338 | 0.000 | 0.091 | 0.377 | 0.056 | |

| Buried depth | 0.500 | 0.500 | —— | 0.385 | 0.011 | 0.001 | 0.337 | 0.097 | |

| Peak acceleration | 0.000 | 0.338 | 0.385 | —— | 0.217 | 0.349 | 0.488 | 0.000 | |

| Holding time | 0.201 | 0.000 | 0.011 | 0.217 | —— | 0.015 | 0.452 | 0.037 | |

| Pore pressure | 0.135 | 0.091 | 0.001 | 0.349 | 0.015 | —— | 0.021 | 0.182 | |

| Earth pressure | 0.187 | 0.377 | 0.337 | 0.488 | 0.452 | 0.021 | —— | 0.407 | |

| Dynamic shear stress ratio | 0.000 | 0.056 | 0.097 | 0.000 | 0.037 | 0.182 | 0.407 | —— |

| KMO Sampling Suitability | Bartlett Sphericity Test | ||

|---|---|---|---|

| 0.523 | Approximate chi square | Degree of freedom | Significant |

| 155.182 | 28 | 0.000 | |

| Initial Parameter | Sizepop | Maxgen | Learning Factor | Learning Factor | Inertia Weight | Penalty Factor C Optimization Range | Kernel Parameter g Optimization Range |

|---|---|---|---|---|---|---|---|

| Value | 20 | 200 | 1.5 | 1.7 | 0.5 | [0, 200] | [0, 1] |

| SVM Parameters | Coarse Grid Range | Fine Mesh Range |

|---|---|---|

| C | (2−5, 25) | (2−2, 24) |

| g | (2−10, 210) | (2−4, 24) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.; Yuan, S.; Cui, H.; Xiao, X.; Jia, B. A Threshold Model of Tailings Sand Liquefaction Based on PSO-SVM. Sustainability 2022, 14, 2720. https://doi.org/10.3390/su14052720

Jin J, Yuan S, Cui H, Xiao X, Jia B. A Threshold Model of Tailings Sand Liquefaction Based on PSO-SVM. Sustainability. 2022; 14(5):2720. https://doi.org/10.3390/su14052720

Chicago/Turabian StyleJin, Jiaxu, Shihao Yuan, Hongzhi Cui, Xiaochun Xiao, and Baoxin Jia. 2022. "A Threshold Model of Tailings Sand Liquefaction Based on PSO-SVM" Sustainability 14, no. 5: 2720. https://doi.org/10.3390/su14052720

APA StyleJin, J., Yuan, S., Cui, H., Xiao, X., & Jia, B. (2022). A Threshold Model of Tailings Sand Liquefaction Based on PSO-SVM. Sustainability, 14(5), 2720. https://doi.org/10.3390/su14052720