Incorporation of Acid Whey Yogurt By-Product in Novel Sauces Formulation: Quality and Shelf-Life Evaluation

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Product Formulation

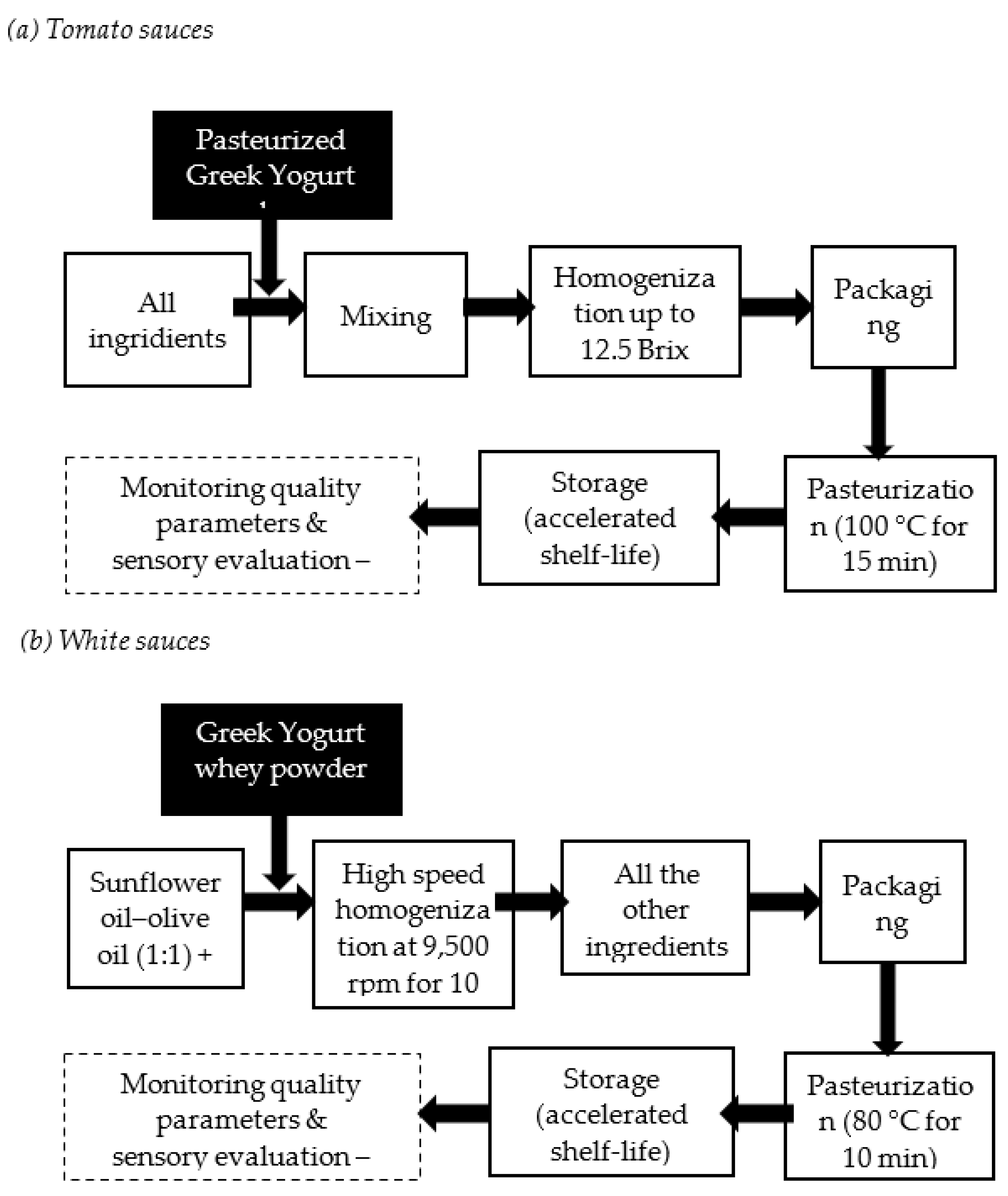

2.1.1. Novel Tomato Sauces Formulation

2.1.2. Novel White Sauces Formulation

2.1.3. Experimental Set Up

2.2. Evaluation of Quality Parameters of Sauces

2.2.1. Physicochemical Parameters

2.2.2. Nutritional Compounds

2.2.3. Microbiological Analysis

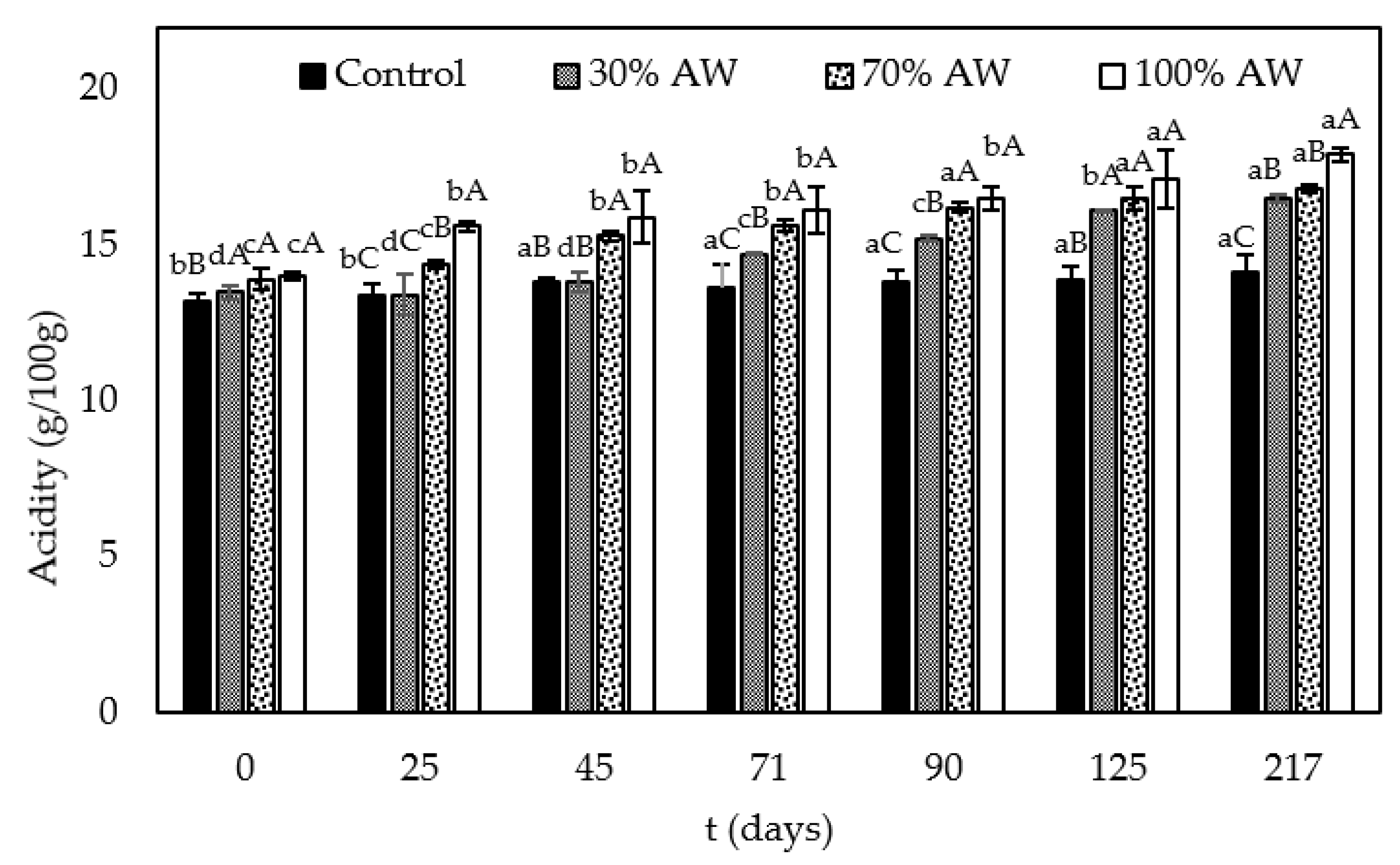

2.2.4. Determination of Acidity of Tomato Sauces

2.2.5. Determination of Lipid Oxidation of White Sauces

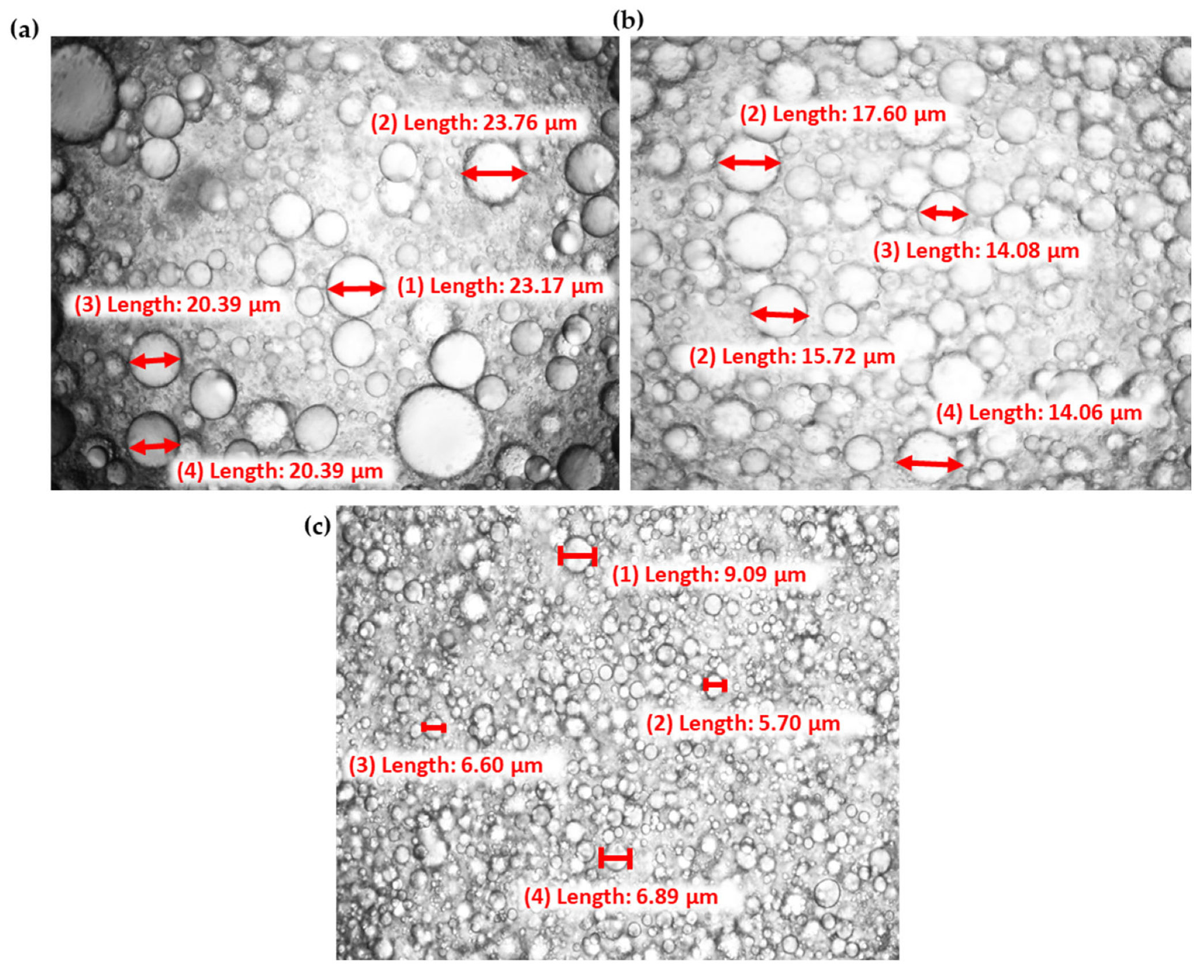

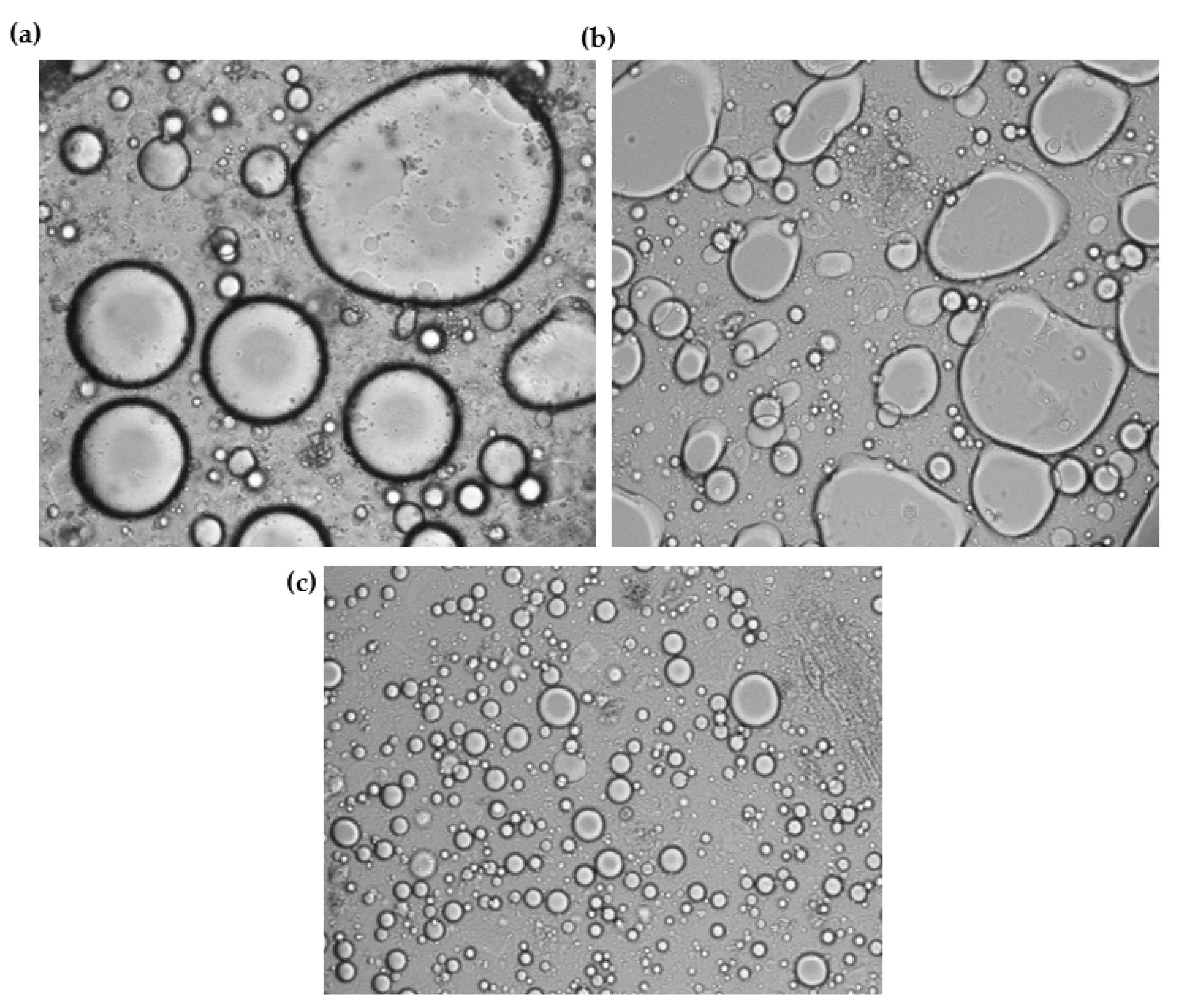

2.2.6. Optical Microscopy

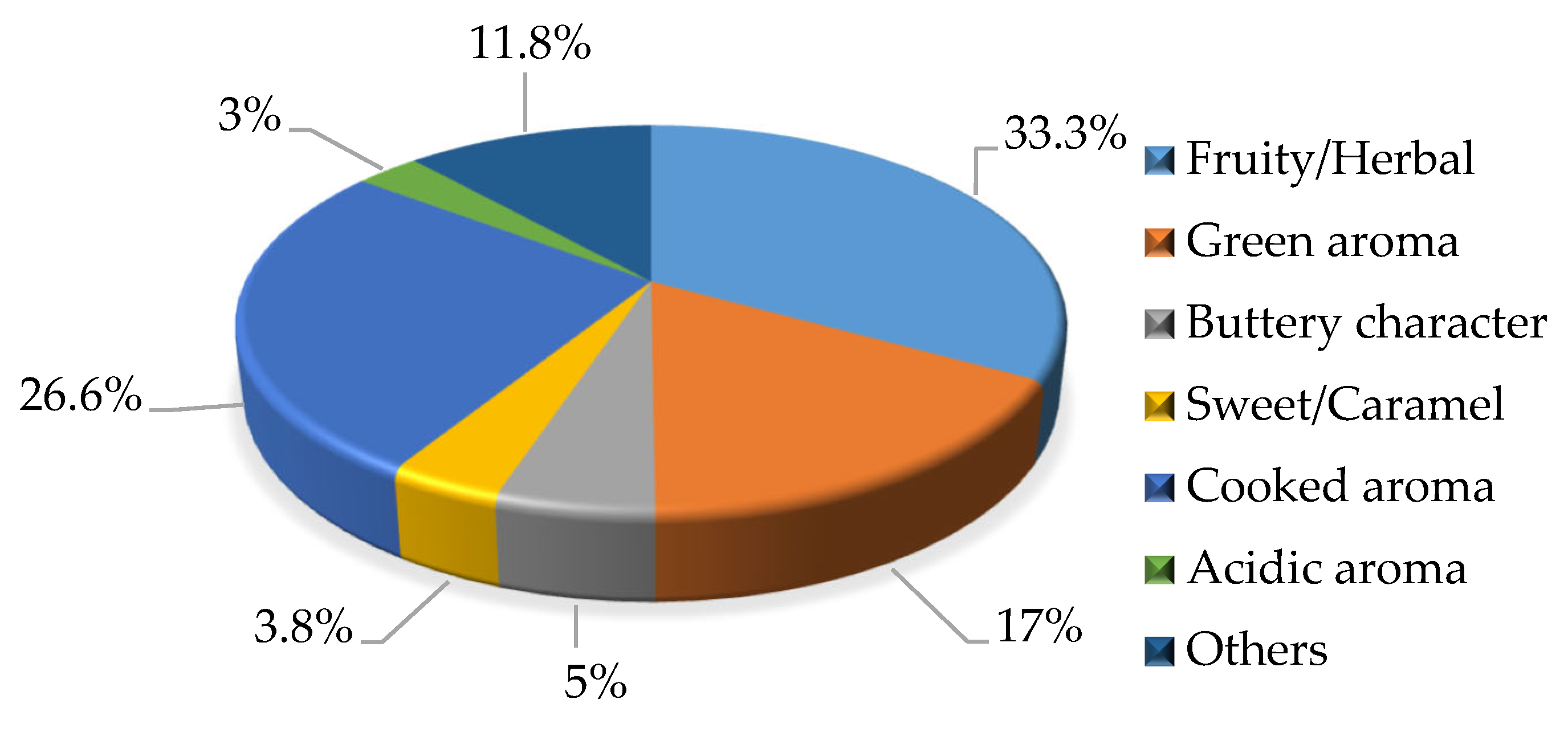

2.2.7. Determination of Volatile Compounds Using Headspace Gas Chromatography- Mass Spectrometry

2.2.8. Emulsion Stability of White Sauces

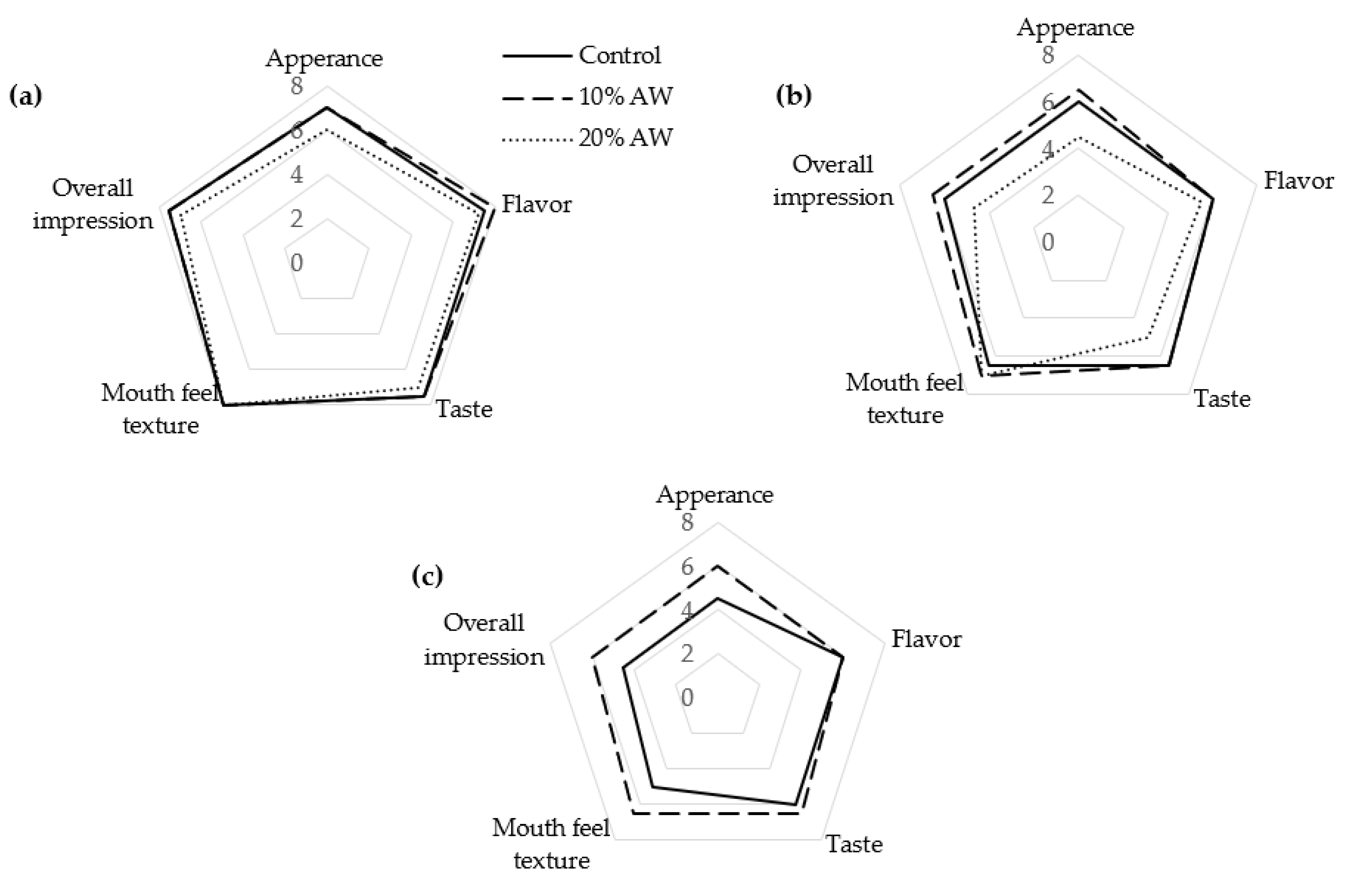

2.2.9. Sensory Evaluation

2.3. Data Analysis

2.4. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical and Nutritional Parameters of Acid Whey

3.2. Case Study I: Incorporation of Liquid Acid Whey into Tomato Sauces

3.2.1. Physicochemical Parameters and Nutritional Compounds of Tomato Sauces in Zero Time

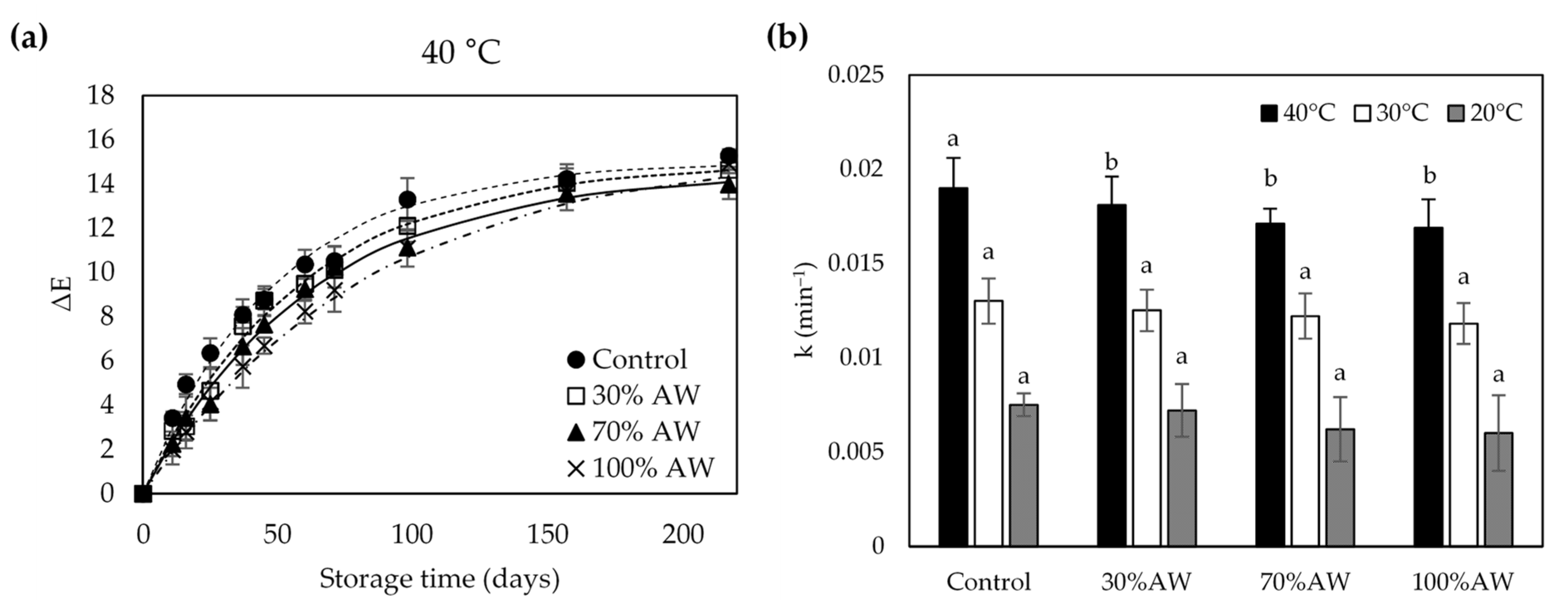

3.2.2. Shelf-Life Determination of New Tomato Sauces

3.3. Case Study II: Incorporation of Acid Whey Powder in White Sauces

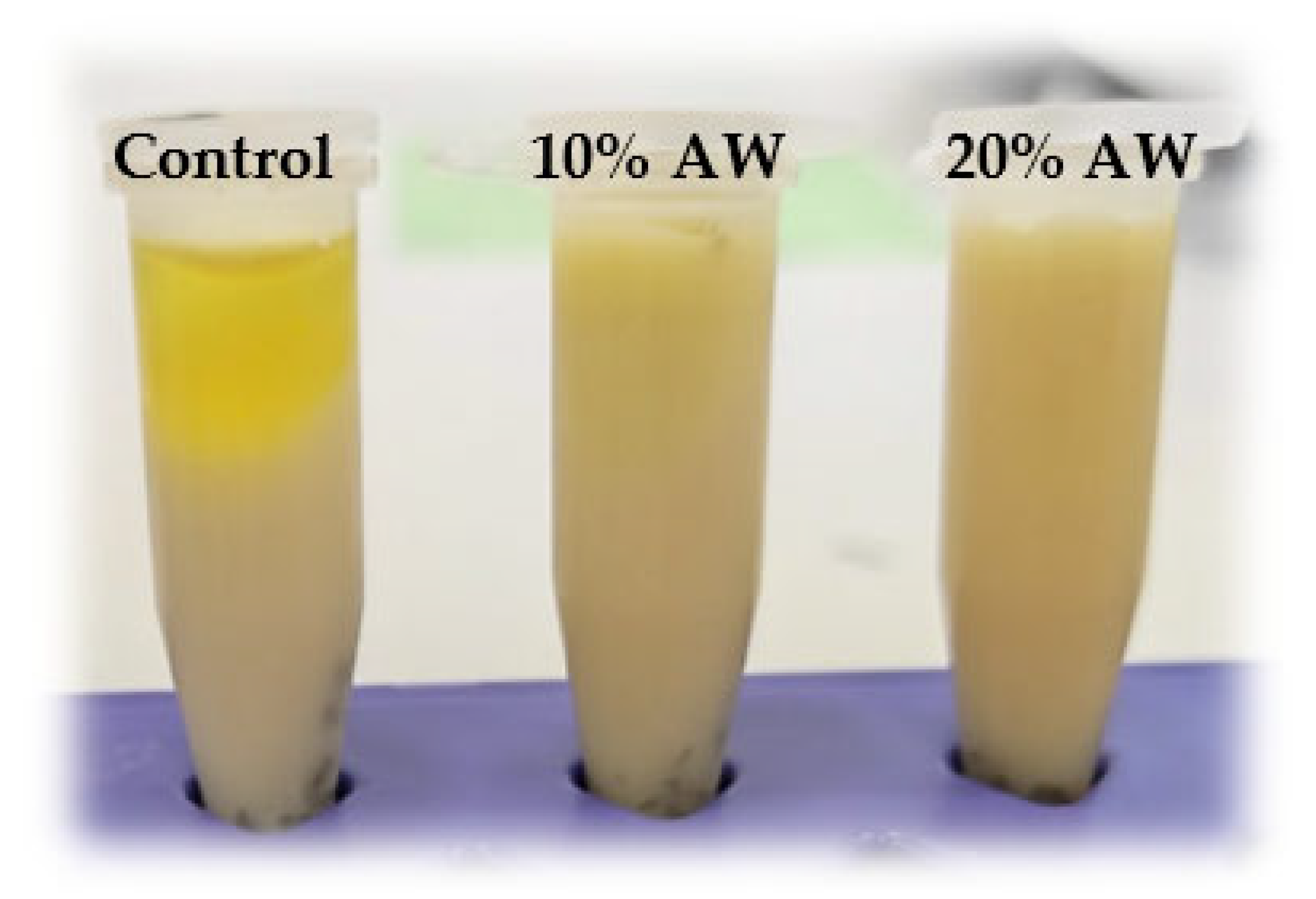

3.3.1. Physicochemical Parameters and Nutritional Compounds of White Sauces at Zero Time

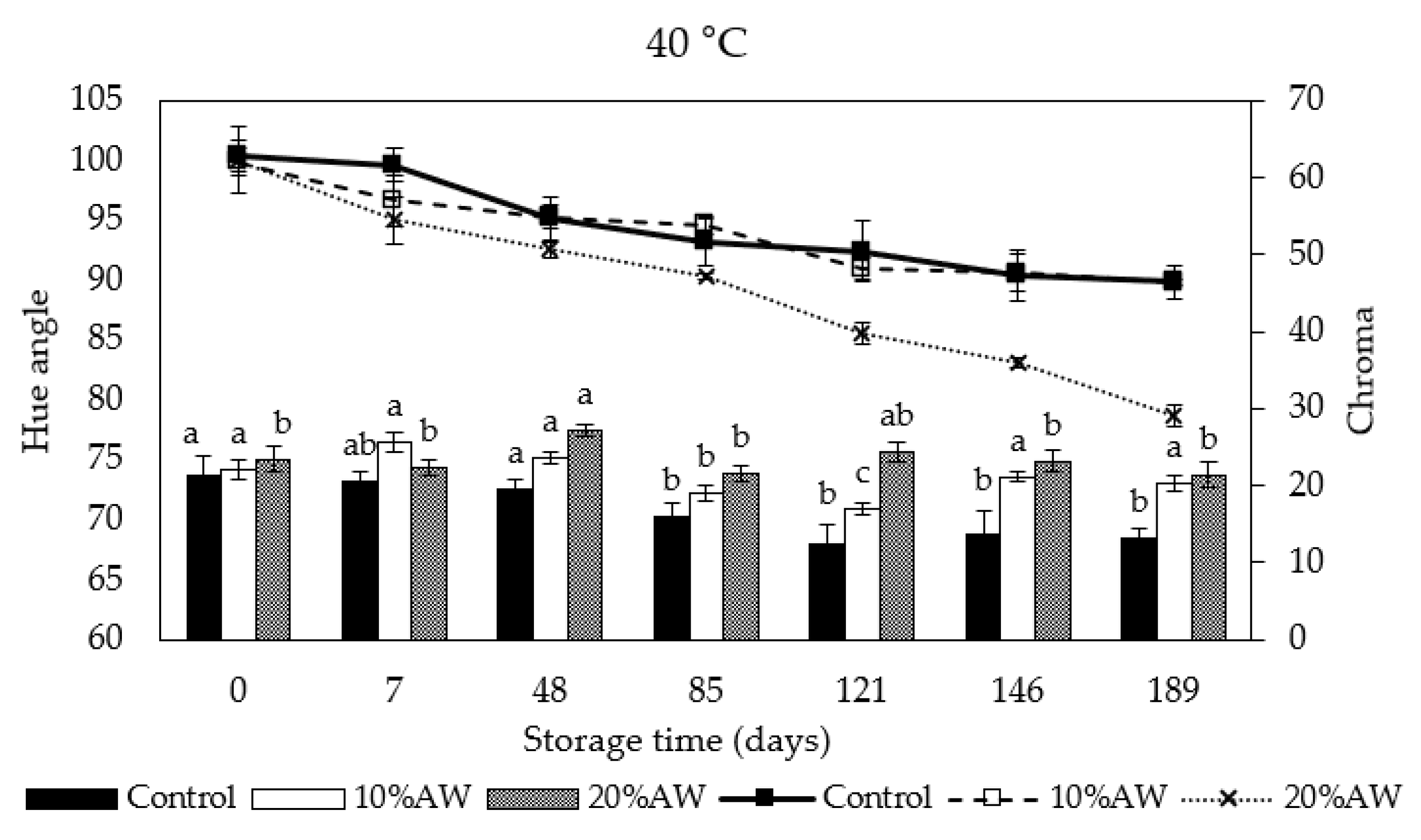

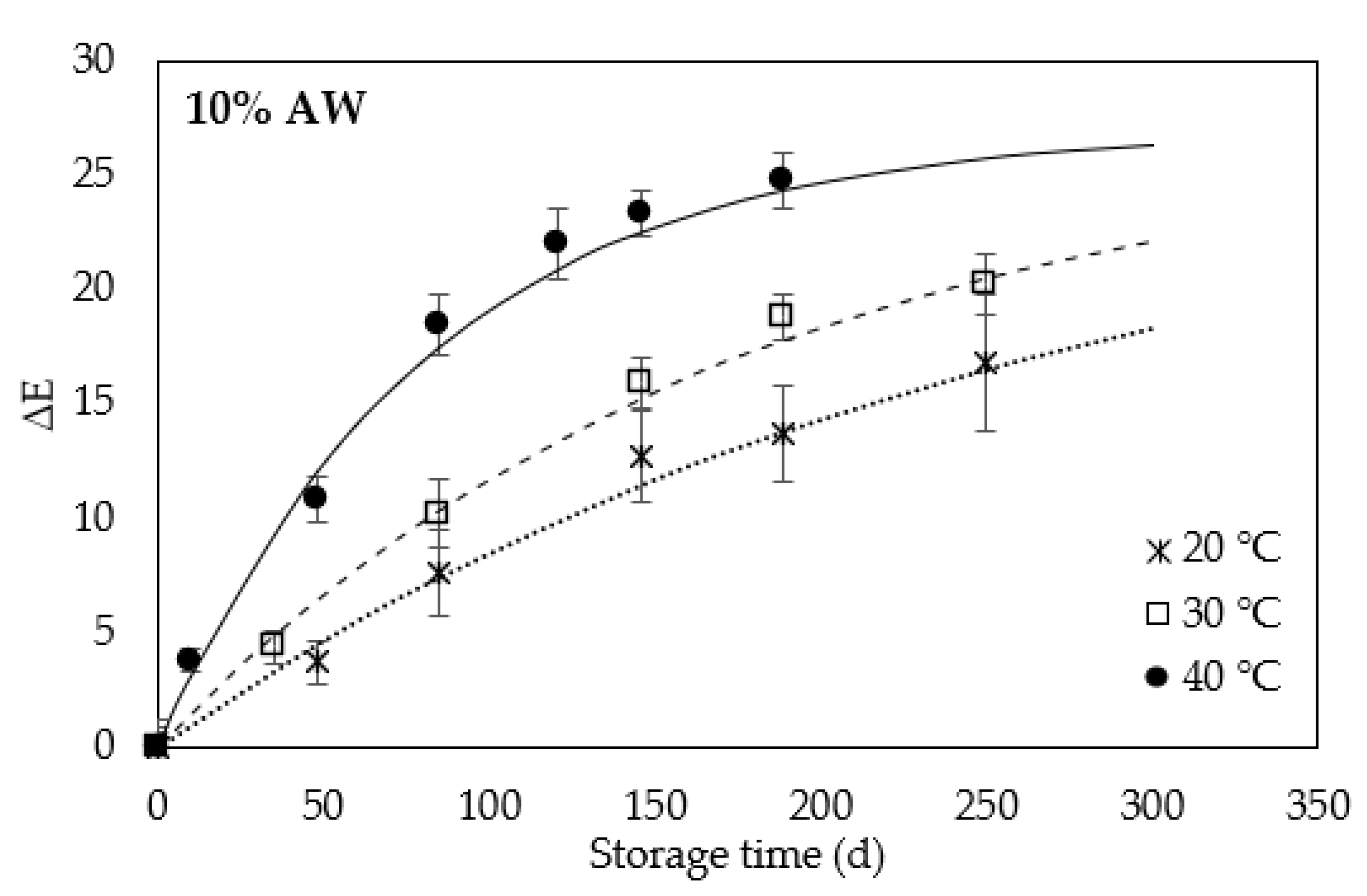

3.3.2. Shelf-Life Determination of New White Sauces

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mintel. Yogurt and Yogurt Drinks—US. 2021. Available online: https://store.mintel.com/report/us-yogurt-and-yogurt-drinks-market-report (accessed on 16 October 2022).

- Erickson, B.E. Acid whey: Is the waste product an untapped goldmine. Chem. Eng. News 2017, 95, 26–30. [Google Scholar]

- Lindsay, M.J.; Walker, T.W.; Dumesic, J.A.; Rankin, S.A.; Huber, G.W. Production of monosaccharides and whey protein from acid whey waste streams in the dairy industry. Green Chem. 2018, 20, 1824–1834. [Google Scholar] [CrossRef]

- Rocha-Mendoza, D.; Kosmerl, E.; Krentz, A.; Zhang, L.; Badiger, S.; Miyagusuku-Cruzado, G.; Mayta-Apaza, A.; Giusti, M.; Jiménez-Flores, R.; García-Cano, I. Invited review: Acid whey trends and health benefits. J. Dairy Sci. 2021, 104, 1262–1275. [Google Scholar] [CrossRef]

- Smithers, G.W. Whey-ing up the options—Yesterday, today and tomorrow. Int. Dairy J. 2015, 48, 2–14. [Google Scholar] [CrossRef]

- Bylund, G. Dairy Processing Handbook; Tetra Pak Processing Systems AB: Lund, Sweden, 2003. [Google Scholar]

- Menchik, P.; Zuber, T.; Zuber, A.; Moraru, C.I. Short communication: Composition of coproduct streams from dairy processing: Acid whey and milk permeate. J. Dairy Sci. 2019, 102, 3978–3984. [Google Scholar] [CrossRef]

- Lucas, A.; Rock, E.; Chamba, J.-F.; Verdier-Metz, I.; Brachet, P.; Coulon, J.-B. Respective effects of milk composition and the cheese-making process on cheese compositional variability in components of nutritional interest. Le Lait 2006, 86, 21–41. [Google Scholar] [CrossRef]

- Ketterings, Q.; Czymmek, K.; Gami, S.; Godwin, G.; Ganoe, K. Guidelines for Land Application of Acid Whey; Department of Animal Science Publication Series; Cornell University: Ithaca, NY, USA, 2017; p. 247. [Google Scholar]

- Watson, E. Greek Yogurt’s Biggest Guns Explore Creative Ways to Address Acid Whey Challenge. 2014. Available online: https://www.dairyreporter.com/Article/2014/12/05/Patent-watch-General-Mills-tackles-Greek-yogurt-acid-whey (accessed on 5 December 2014).

- González, T.; Smith, E.B. Soluble fiber from yogurt whey. U.S. Patent No. 20140348979, 27 November 2014. [Google Scholar]

- De La Cruz, L.; Saint-Denis, T. Acid whey with stable lactose content. U.S. Patent No. WO 2016/177701 Al, 31 December 2020. [Google Scholar]

- Smith, E.; Wang, W.; Ghosh, V. Food products with yogurt whey. U.S. Patent No. 20140348981, 27 November 2014. [Google Scholar]

- Skryplonek, K.; Dmytrów, I.; Mituniewicz-Małek, A. Probiotic fermented beverages based on acid whey. J. Dairy Sci. 2019, 102, 7773–7780. [Google Scholar] [CrossRef] [PubMed]

- Žolnere, K.; Ciproviča, I. The study of physical properties of spray dried whey and milk permeates lactose. Agron. Res. 2019, 17, 1501–1510. [Google Scholar] [CrossRef]

- Chandrapala, J.; Vasiljevic, T. Feasibility of Spray Drying Concentrated Acid Whey After Nanofiltration. Food Bioprocess Technol. 2018, 11, 1505–1515. [Google Scholar] [CrossRef]

- Flinois, J.C.; Dando, R.; Padilla-Zakour, O.I. Effects of replacing buttermilk with yogurt acid whey in ranch dressing. J. Dairy Sci. 2019, 102, 7874–7883. [Google Scholar] [CrossRef]

- El-Kadi, S. Effect of some Organic Acids on Some Fungal Growth and Their Effect of Some Organic Acids on Some Fungal. Int. J. Adv. Biol. 2015, 2, 1–11. [Google Scholar] [CrossRef]

- Lievore, P.; Simões, D.R.S.; Silva, K.M.; Drunkler, N.L.; Barana, A.C.; Nogueira, A.; Demiate, I.M. Chemical characterisation and application of acid whey in fermented milk. J. Food Sci. Technol. 2013, 52, 2083–2092. [Google Scholar] [CrossRef]

- Jeličić, I.; Božanić, R.; Tratnik, L. Whey-based beverages-a new generation of dairy products. Mljekarstvo 2008, 58, 257–274. [Google Scholar]

- Chavan, R.S.; Shraddha, R.C.; Kumar, A.; Nalawade, T. Whey Based Beverage: Its Functionality, Formulations, Health Benefits and Applications. J. Food Process. Technol. 2015, 6, 1. [Google Scholar] [CrossRef]

- Sady, M.; Jaworska, G.; Grega, T.; Bernas, E.; Domagala, J. Application of acid whey in orange drink production. Food Technol. Biotechnol. 2013, 51, 266. [Google Scholar]

- Villarreal, M. Value Added Products Utilizing Acid Whey: Development of a Fruit Yogurt Beverage and a Sports Drink. Ph.D. Thesis, Cornell University, Ithaca, NY, USA, 2017. [Google Scholar]

- Flinois, J.C.; Dando, R.; Padilla-Zakour, O.I. Yogurt Acid Whey Utilization for Production of Baked Goods: Pancakes and Pizza Crust. Foods 2019, 8, 615. [Google Scholar] [CrossRef]

- Sikora, M.; Badrie, N.; Deisingh, A.K.; Kowalski, S. Sauces and Dressings: A Review of Properties and Applications. Crit. Rev. Food Sci. Nutr. 2008, 48, 50–77. [Google Scholar] [CrossRef]

- Mirzanajafi-Zanjani, M.; Yousefi, M.; Ehsani, A. Challenges and approaches for production of a healthy and functional mayonnaise sauce. Food Sci. Nutr. 2019, 7, 2471–2484. [Google Scholar] [CrossRef]

- Yusof, N.; Jaswir, I.; Jamal, P.; Jami, M.S. Texture Profile Analysis (TPA) of the jelly dessert prepared from halal gelatin extracted using High Pressure Processing (HPP). Malays. J. Fundam. Appl. Sci. 2019, 15, 604–608. [Google Scholar] [CrossRef]

- International Standard Organisation (ISO) ISO 11261:1995; Soil Quality—Determination of Total Nitrogen—Modified Kjeldahl Method. ISO: Geneva, Switzerland, 1995.

- DuBois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric method for determination of sugars and related substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Andreou, V.; Thanou, I.; Giannoglou, M.; Giannakourou, M.C.; Katsaros, G. Dried Figs Quality Improvement and Process Energy Savings by Combinatory Application of Osmotic Pretreatment and Conventional Air Drying. Foods 2021, 10, 1846. [Google Scholar] [CrossRef]

- Official Methods of Analysis, 16th ed.; AOAC International: Arlington, VA, USA, 1995.

- Stadtman, F.H.; Buhlert, J.E.; Marsh, G.L. TITRATABLE ACIDITY OF TOMATO JUICE AS AFFECTED BY BREAK PROCEDURE. J. Food Sci. 1977, 42, 379–382. [Google Scholar] [CrossRef]

- Li, J.; Di, T.; Bai, J. Distribution of Volatile Compounds in Different Fruit Structures in Four Tomato Cultivars. Molecules 2019, 24, 2594. [Google Scholar] [CrossRef]

- Mcclements, D.J.; Decker, E.A. Lipid Oxidation in Oil-in-Water Emulsions: Impact of Molecular Environment on Chemical Reactions in Heterogeneous Food Systems. J. Food Sci. 2000, 65, 1270–1282. [Google Scholar] [CrossRef]

- Dec, B.; Chojnowski, W. Characteristics of acid whey powder partially demineralised by nanofiltration. Pol. J. Food Nutr. Sci. 2006, 15, 87. [Google Scholar]

- Huppertz, T.; Kanning, M.W.; Akkerman, C. Unravelling acid whey processing by understanding lactose crystallisation. New Food Mag. 2016, 19, 10. [Google Scholar]

- Yasmin, A.; Butt, M.S.; Sameen, A.; Shahid, M. Physicochemical and Amino Acid Profiling of Cheese Whey. Pak. J. Nutr. 2013, 12, 455–459. [Google Scholar] [CrossRef][Green Version]

- Ward, L.S. Whey Protein Provides an Ideal Dietary Source of Essential Amino Acids; Dairy for Global Nutrition: Boise, ID, USA, 2010; p. 1. [Google Scholar]

- Martins, S.I.; Jongen, W.M.; van Boekel, M.A. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Ashoor, S.H.; Zent, J.B. Maillard Browning of Common Amino Acids and Sugars. J. Food Sci. 1984, 49, 1206–1207. [Google Scholar] [CrossRef]

- Frelichowska, J.; Bolzinger, M.-A.; Chevalier, Y. Effects of solid particle content on properties of o/w Pickering emulsions. J. Colloid Interface Sci. 2010, 351, 348–356. [Google Scholar] [CrossRef]

- Katsaros, G.; Tsoukala, M.; Giannoglou, M.; Taoukis, P. Effect of storage on the rheological and viscoelastic properties of mayonnaise emulsions of different oil droplet size. Heliyon 2020, 6, e05788. [Google Scholar] [CrossRef]

- Lee, M.N.; Chan, H.K.; Mohraz, A. Characteristics of Pickering Emulsion Gels Formed by Droplet Bridging. Langmuir 2011, 28, 3085–3091. [Google Scholar] [CrossRef]

- Karwowska, M.; Dolatowski, Z.J. Effect of acid whey and freeze-dried cranberries on lipid oxidation and fatty acid composition of nitrite-/nitrate-free fermented sausage made from deer meat. Asian-Australas. J. Anim. Sci. 2016, 30, 85–93. [Google Scholar] [CrossRef]

- Halliwell, B. Lipid peroxidation, antioxidants and cardiovascular disease: How should we move forward? Cardiovasc. Res. 2000, 47, 410–418. [Google Scholar] [CrossRef]

- Andreou, V.; Chanioti, S.; Stergiou, P.; Katsaros, G. Valorization of the Olive Oil Production Residue: Healthy Ingredient for Developing High Value-Added Spread. Sustainability 2021, 13, 13984. [Google Scholar] [CrossRef]

- Gohtani, S.; Sirendi, M.; Yamamoto, N.; Kajikawa, K.; Yamano, Y. Effect of Droplet Size on Oxidation of Docosahexaenoic Acid in Emulsion System. J. Dispers. Sci. Technol. 1999, 20, 1319–1325. [Google Scholar] [CrossRef]

- Donnelly, J.L.; Decker, E.A.; McClements, D.J. Iron-Catalyzed Oxidation of Menhaden Oil as Affected by Emulsifiers. J. Food Sci. 2006, 63, 997–1000. [Google Scholar] [CrossRef]

- Shao, P.; Feng, J.; Sun, P.; Xiang, N.; Lu, B.; Qiu, D. Recent advances in improving stability of food emulsion by plant polysaccharides. Food Res. Int. 2020, 137, 109376. [Google Scholar] [CrossRef]

- Rousseau, D. Fat crystals and emulsion stability—A review. Food Res. Int. 2000, 33, 3–14. [Google Scholar] [CrossRef]

- Meybodi, N.M.; Mohammadifar, M.A.; Naseri, A.R. Effective factors on the stability of oil-in-water emulsion based beverage: A review. J. Food Qual. Hazards Control. 2014, 1, 67–71. [Google Scholar]

- Degner, B.M.; Chung, C.; Schlegel, V.; Hutkins, R.; McClements, D. Factors Influencing the Freeze-Thaw Stability of Emulsion-Based Foods. Compr. Rev. Food Sci. Food Saf. 2014, 13, 98–113. [Google Scholar] [CrossRef]

- Ghosh, S.; Rousseau, D. Fat crystals and water-in-oil emulsion stability. Curr. Opin. Colloid Interface Sci. 2011, 16, 421–431. [Google Scholar] [CrossRef]

- McClements, D.J. Critical Review of Techniques and Methodologies for Characterization of Emulsion Stability. Crit. Rev. Food Sci. Nutr. 2007, 47, 611–649. [Google Scholar] [CrossRef]

- Wijaya, W.; Patel, A.R.; Setiowati, A.D.; Van der Meeren, P. Functional colloids from proteins and polysaccharides for food applications. Trends Food Sci. Technol. 2017, 68, 56–69. [Google Scholar] [CrossRef]

- Zamani, S.; Malchione, N.; Selig, M.J.; Abbaspourrad, A. Formation of shelf stable Pickering high internal phase emulsions (HIPE) through the inclusion of whey protein microgels. Food Funct. 2017, 9, 982–990. [Google Scholar] [CrossRef]

- Chen, L.; Ao, F.; Ge, X.; Shen, W. Food-Grade Pickering Emulsions: Preparation, Stabilization and Applications. Molecules 2020, 25, 3202. [Google Scholar] [CrossRef]

- Azfaralariff, A.; Farahfaiqah, F.; Joe, L.S.; Fazry, S.; Mohamed, M.; Nazar, M.F.; Lazim, A.M. Sago starch nanocrystal-stabilized Pickering emulsions: Stability and rheological behavior. Int. J. Biol. Macromol. 2021, 182, 197–206. [Google Scholar] [CrossRef]

- Ghirro, L.C.; Rezende, S.; Ribeiro, A.S.; Rodrigues, N.; Carocho, M.; Pereira, J.A.; Barros, L.; Demczuk, B.; Barreiro, M.-F.; Santamaria-Echart, A. Pickering Emulsions Stabilized with Curcumin-Based Solid Dispersion Particles as Mayonnaise-like Food Sauce Alternatives. Molecules 2022, 27, 1250. [Google Scholar] [CrossRef]

- Huang, Z.-X.; Lin, W.-F.; Zhang, Y.; Tang, C.-H. Outstanding Freeze-Thaw Stability of Mayonnaise Stabilized Solely by a Heated Soy Protein Isolate. Food Biophys. 2022, 17, 335–343. [Google Scholar] [CrossRef]

- Chung, C.; McClements, D.J. Controlling microstructure and physical properties of biopolymer hydrogel particles through modulation of electrostatic interactions. J. Food Eng. 2015, 158, 13–21. [Google Scholar] [CrossRef]

- Marafon, A.P.; Sumi, A.; Alcântara, M.R.; Tamime, A.Y.; de Oliveira, M.N. Optimization of the rheological properties of probiotic yoghurts supplemented with milk proteins. LWT Food Sci. Technol. 2011, 44, 511–519. [Google Scholar] [CrossRef]

- de Castro, F.P.; Cunha, T.M.; Ogliari, P.J.; Teófilo, R.F.; Ferreira, M.M.; Prudêncio, E.S. Influence of different content of cheese whey and oligofructose on the properties of fermented lactic beverages: Study using response surface methodology. LWT Food Sci. Technol. 2009, 42, 993–997. [Google Scholar] [CrossRef]

- González-Martínez, C.; Becerra, M.; Cháfer, M.; Albors, A.; Carot, J.M.; Chiralt, A. Influence of substituting milk powder for whey powder on yoghurt quality. Trends Food Sci. Technol. 2002, 13, 334–340. [Google Scholar] [CrossRef]

| Quality Characteristics | Liquid Acid Whey | Acid Whey Powder |

|---|---|---|

| pH | 4.26 ± 0.01 | 4.55 ± 0.03 |

| Acidity (%) | 0.28 ± 0.13 | 0.35 ± 0.22 |

| Total soluble solids (°Brix) | 8.72 ± 0.25 | - |

| Water activity | - | 0.215 ± 0.025 |

| Total protein (%) | 0.24 ± 0.02 | 3.87 ± 0.65 |

| Total fat (%) | 0.00 ± 0.00 | 0.00 ± 0.00 |

| Moisture (%) | 92.50 ± 0.98 | 3.01 ± 0.02 |

| Ash (%) | 0.78 ± 0.02 | 11.57 ± 0.12 |

| Individual sugars | g/100 mL | g/100 g |

| Lactose (%) | 3.72 ± 0.25 | 45.67 ± 2.65 |

| Galactose (%) | 0.82 ± 0.08 | 8.06 ± 1.57 |

| Glucose (%) | 0.04 ± 0.01 | 0.24 ± 0.02 |

| Individual organic acids | g/100 mL | g/100 g |

| Citric acid (%) | 0.26 ± 0.00 | 6.17 ± 0.56 |

| Lactic acid (%) | 1.00 ± 0.08 | 11.88 ± 1.45 |

| Minerals | g/100 mL | g/100 g |

| Calcium | 95.38 ± 2.25 | 1.22 ± 0.06 |

| Potassium | 159.1 ± 3.98 | 2.59 ± 0.36 |

| Phosphorus | 95.38 ± 4.22 | 1.22 ± 0.04 |

| Magnesium | 13.28 ± 0.25 | 0.27 ± 0.08 |

| Sodium | 58.47 ± 1.25 | 0.73 ± 0.04 |

| Free Amino Acids (mg/100 g) | Liquid Acid Whey | Acid Whey Powder |

|---|---|---|

| Aspartic acid | 2.94 ± 0.01 | 106.29 ± 2.35 |

| Glutamic acid | 4.29 ± 0.07 | 145.38 ± 3.65 |

| Serine | 1.00 ± 0.09 | 40.08 ± 4.20 |

| Histidine | 0.54 ± 0.10 | 28.83 ± 2.65 |

| Glycine | 0.57 ± 0.15 | 28.98 ± 1.95 |

| Threonine | 1.26 ± 0.12 | 44.06 ± 3.65 |

| Arginine | 3.14 ± 0.35 | 81.11 ± 2.22 |

| Alanine | 0.50 ± 0.11 | 19.78 ± 0.98 |

| Tyrosine | 0.57 ± 0.01 | 18.77 ± 1.22 |

| Cysteine | 0.77 ± 0.03 | 22.72 ± 1.55 |

| Valine | 1.99 ± 0.22 | 62.37 ± 1.69 |

| Methionine | 0.78 ± 0.15 | 27.54 ± 2.47 |

| Phenylalaline | 1.27 ± 0.10 | 39.23 ± 3.85 |

| Isoleucine | 1.58 ± 0.07 | 46.41 ± 3.96 |

| Leucine | 3.87 ± 0.42 | 74.05 ± 4.12 |

| Lysine | 0.26 ± 0.08 | 42.11 ± 0.89 |

| Essentials AA | 58.6% | 49.2% |

| Non-essentials AA | 41.4% | 50.8% |

| 0% AW | 30% AW | 70% AW | 100% AW | |

|---|---|---|---|---|

| Physicochemical Characteristics of Tomato Sauces | ||||

| pH | 4.07 ± 0.00 a | 4.08 ± 0.01 a | 4.07 ± 0.01 a | 4.05 ± 0.01 a |

| Brix | 13.8 ± 0.1 c | 14.5 ± 0.1 b | 15.0 ± 0.1 a | 15.1 ± 0.1 a |

| Color Parameters | ||||

| L | 25.7 ± 0.4 a | 28.3 ± 1.6 a | 26.8 ± 1.5 a | 28.4 ± 1.3 a |

| a | 14.4 ± 0.2 a | 14.0 ± 2.4 a | 13.7 ± 2.4 a | 14.3 ± 1.9 a |

| b | 13.5 ± 0.9 a | 15.1 ± 1.5 a | 14.4 ± 1.9 a | 14.9 ± 2.2 a |

| a/b | 1.06 ± 0.22 a | 0.92 ± 0.15 a | 0.95 ± 0.21 a | 0.96 ± 0.17 a |

| Hue angle | 0.55 ± 0.05 a | 0.75 ± 0.15 a | 0.71 ± 0.17 a | 0.70 ± 0.06 a |

| Chroma | 19.74 ± 1.95 a | 20.59 ± 1.22 a | 19.87 ± 1.32 a | 20.65 ± 1.41 a |

| Texture Properties | ||||

| Hardness (kg) | 0.196 ± 0.032 a | 0.216 ± 0.025 a | 0.195 ± 0.036 a | 0.186 ± 0.018 a |

| Cohesiveness (kg/s) | 2.403 ± 0.032 a | 2.241 ± 0.035 a | 2.173 ± 0.022 a | 1.979 ± 0.025 a |

| Adhesiveness (kg/s) | −0.032 ± 0.022 a | −0.035 ± 0.005 a | −0.036 ± 0.015 a | −0.038 ± 0.036 a |

| Chewiness | 1.187 ± 0.122 a | 1.193 ± 0.116 a | 1.093 ± 0.114 a | 1.181 ± 0.128 a |

| Gumminess | 0.434 ± 0.216 a | 0.533 ± 0.124 a | 0.425 ± 0.116 a | 0.491 ± 0.124 a |

| Nutritional Compounds of Tomato Sauces | ||||

| Moisture (g/100 g) | 84.32 ± 0.13 a | 85.01 ± 0.11 a | 84.75 ± 0.08 a | 83.92 ± 0.09 a |

| Ash (g/100 g) | 2.32 ± 0.05 a | 2.27 ± 0.04 a | 2.35 ± 0.01 a | 2.40 ± 0.06 a |

| Total proteins (g/100 g) | 11.37 ± 0.05 c | 12.72 ± 0.07 b | 12.98 ± 0.10 a | 13.15 ± 0.02 a |

| Total carbohydrates (g lactose/100 g dm) | 7.3 ± 0.1 d | 7.6 ± 0.9 c | 8.0 ± 0.6 b | 8.3 ± 0.5 a |

| Minerals (mg/100 g) | ||||

| Ca2+ | 9.04 ± 0.12 d | 16.19 ± 2.51 c | 25.73 ± 3.41 b | 32.88 ± 2.98 a |

| Mg2+ | 29.00 ± 0.35 a | 30.00 ± 0.09 a | 31.32 ± 0.11 a | 32.32 ± 0.12 a |

| K+ | 893.27 ± 1.52 d | 905.20 ± 2.22 c | 921.11 ± 1.47 b | 933.05 ± 3.65 a |

| Na+ | 403.04 ± 0.98 d | 410.20 ± 1.32 c | 419.29 ± 2.65 b | 429.86 ± 1.25 a |

| kSE (d−1) | ||||

|---|---|---|---|---|

| T (°C) | Control | 30% AW | 70% AW | 100% AW |

| 40 | 0.0112 ± 0.0008 b | 0.0111 ± 0.0004 b | 0.0114 ± 0.0006 b | 0.0133 ± 0.0005 a |

| 30 | 0.0049 ± 0.0004 b | 0.0049 ± 0.0006 b | 0.0050 ± 0.0007 b | 0.0075 ± 0.0010 a |

| 20 | 0.0030 ± 0.0006 b | 0.0032 ± 0.0003 b | 0.0038 ± 0.0004 b | 0.0045 ± 0.0007 a |

| Shelf life at ambient temperature (d) | 670 ± 15 a | 646 ± 16 a | 629 ± 11 a | 509 ± 14 b |

| Physicochemical Properties | 0% AW | 10% AW | 20% AW |

|---|---|---|---|

| pH value | 3.68 ± 0.01 b | 4.05 ± 0.02 a | 4.10 ± 0.00 a |

| Brix | 12.46 ± 0.31 c | 23.5 ± 1.91 b | 30.32 ± 2.01 a |

| Conductivity (μS/cm) | 8.57 ± 0.01 c | 13.79 ± 0.22 b | 16.65 ± 0.81 a |

| L | 57.65 ± 0.20 b | 61.44 ± 0.28 a | 63.52 ± 1.43 a |

| a | −3.79 ± 0.05 a | −3.78 ± 0.04 a | −4.07 ± 0.30 a |

| b | 20.82 ± 0.35 c | 21.76 ± 0.17 b | 23.04 ± 0.68 a |

| Hue angle | 100.34 ± 1.25 a | 99.88 ± 0.15 a | 100.02 ± 2.17 a |

| Chroma | 21.16 ± 0.95 a | 22.09 ± 0.22 a | 23.4 ± 0.32 a |

| Viscosity (cp) | 2800 ± 200 a | 3000 ± 100 a | 1950 ± 50 b |

| Nutrients (g/100 g) | |||

| Moisture | 58.08 ± 0.13 a | 57.43 ± 0.11 a | 58.41 ± 0.08 a |

| Ash | 0.75 ± 0.05 c | 1.85 ± 0.04 b | 2.99 ± 0.03 a |

| Proteins | 0.63 ± 0.03 c | 1.18 ± 0.02 b | 1.52 ± 0.06 a |

| Lactose | 1.12 ± 0.25 c | 5.47 ± 0.32 b | 7.66 ± 0.61 a |

| Minerals (mg/100 g) | |||

| Ca2+ | 18.7 ± 5.5 c | 103.5 ± 2.51 b | 149.6 ± 3.41 a |

| Mg2+ | 4.9 ± 0.35 c | 36.3 ± 0.09 b | 42.3 ± 0.11 a |

| K+ | 87.6 ± 8.5 c | 504.4 ± 2.22 b | 855.7 ± 1.47 a |

| k∆Ε (d−1) | |||

|---|---|---|---|

| T (°C) | Control | 10% AW | 20% AW |

| 40 | 0.0123 ± 0.0011 b | 0.0125 ± 0.0005 b | 0.0151 ± 0.0009 a |

| 30 | 0.0053 ± 0.0009 b | 0.0056 ± 0.0010 b | 0.0074 ± 0.0004 a |

| 20 | 0.0041 ± 0.0008 b | 0.0043 ± 0.0007 b | 0.0063 ± 0.0009 a |

| Shelf Life at Ambient Temperature (d) | 405 ± 14 a | 384 ± 16 a | 239 ± 10 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andreou, V.; Chanioti, S.; Xanthou, M.-Z.; Katsaros, G. Incorporation of Acid Whey Yogurt By-Product in Novel Sauces Formulation: Quality and Shelf-Life Evaluation. Sustainability 2022, 14, 15722. https://doi.org/10.3390/su142315722

Andreou V, Chanioti S, Xanthou M-Z, Katsaros G. Incorporation of Acid Whey Yogurt By-Product in Novel Sauces Formulation: Quality and Shelf-Life Evaluation. Sustainability. 2022; 14(23):15722. https://doi.org/10.3390/su142315722

Chicago/Turabian StyleAndreou, Varvara, Sofia Chanioti, Maria-Zaharoula Xanthou, and George Katsaros. 2022. "Incorporation of Acid Whey Yogurt By-Product in Novel Sauces Formulation: Quality and Shelf-Life Evaluation" Sustainability 14, no. 23: 15722. https://doi.org/10.3390/su142315722

APA StyleAndreou, V., Chanioti, S., Xanthou, M.-Z., & Katsaros, G. (2022). Incorporation of Acid Whey Yogurt By-Product in Novel Sauces Formulation: Quality and Shelf-Life Evaluation. Sustainability, 14(23), 15722. https://doi.org/10.3390/su142315722