Determination of Fractured Water-Conducting Zone Height Based on Microseismic Monitoring: A Case Study in Weiqiang Coalmine, Shaanxi, China

Abstract

:1. Introduction

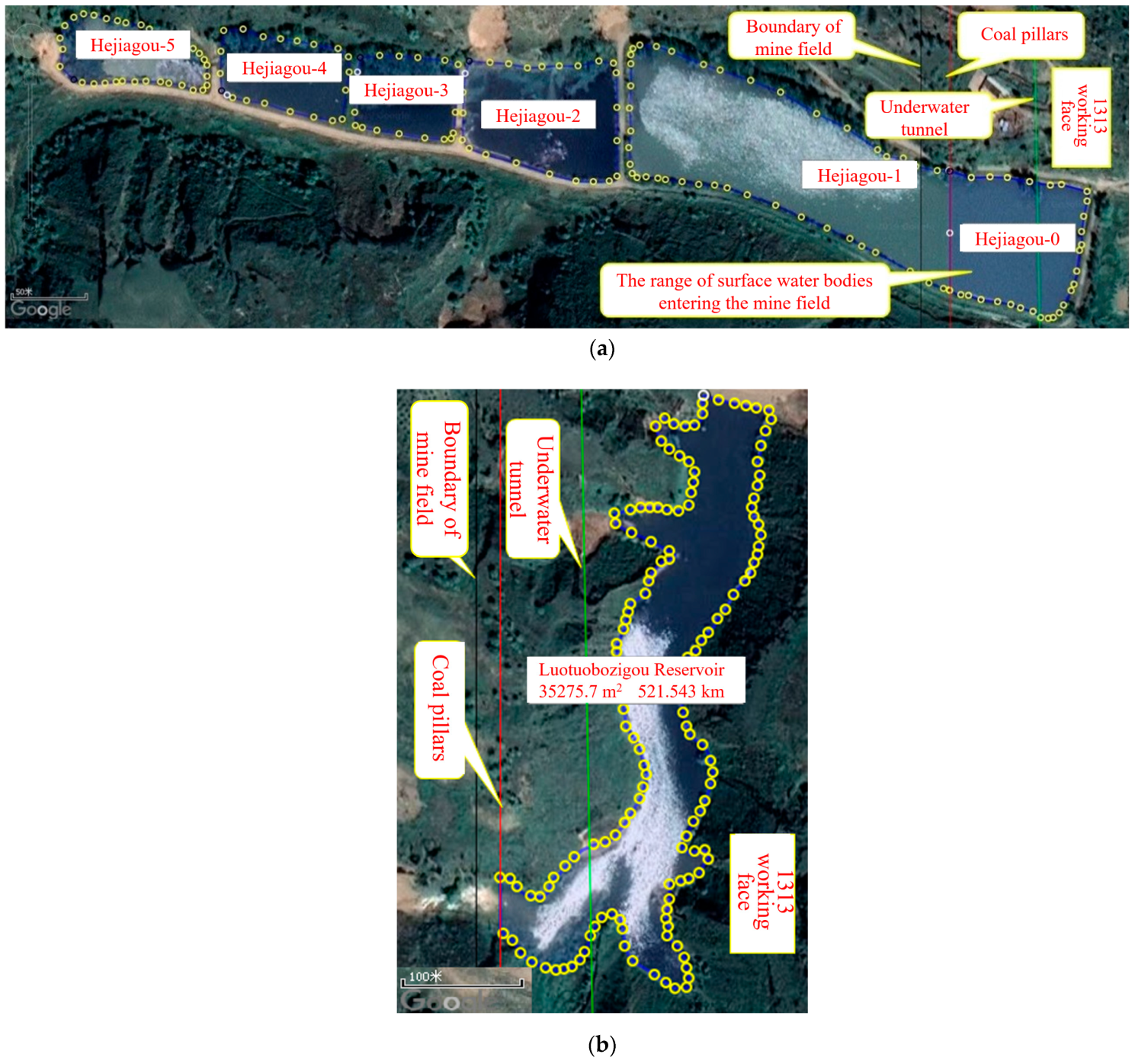

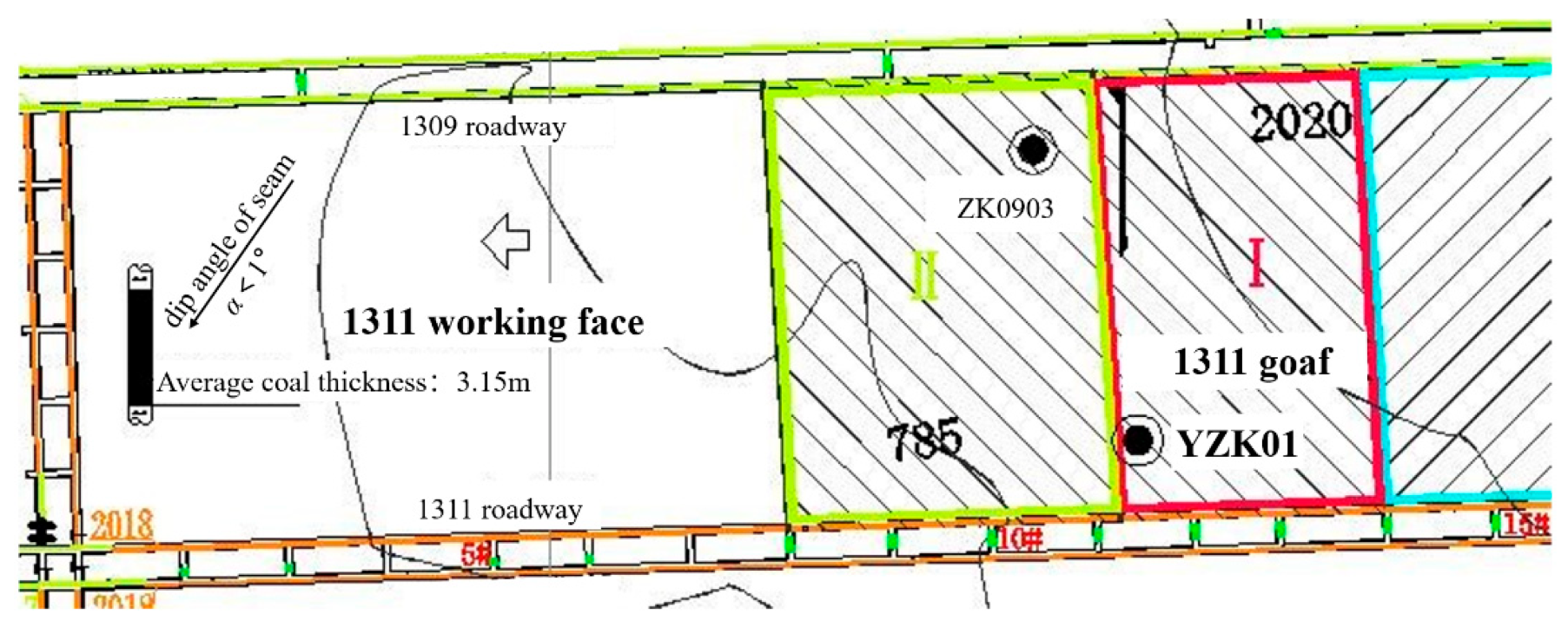

2. Weiqiang Coalmine Overview

3. Microseismic Monitoring

3.1. Principle and Composition of MMS (Mining Microseismic Monitoring)

3.2. Location Algorithms and Moment Magnitude

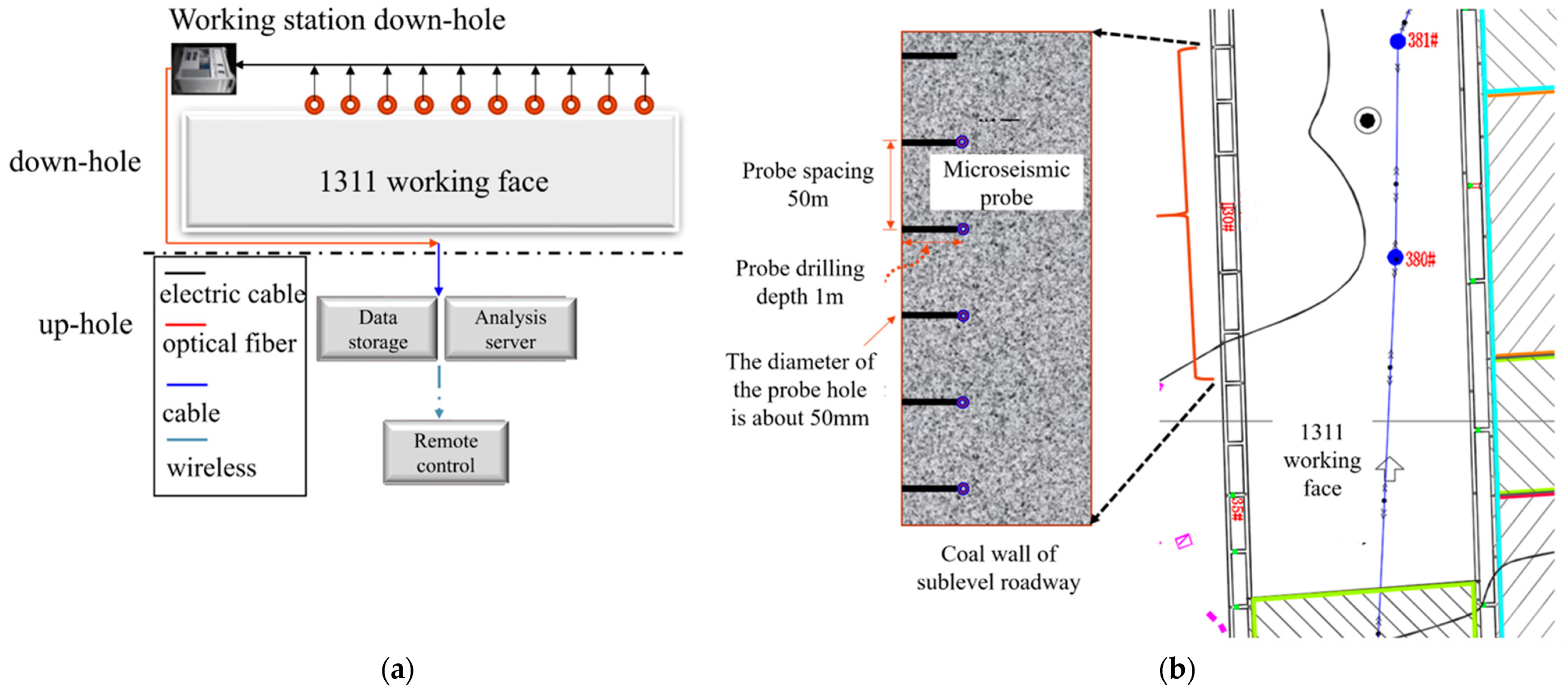

3.3. On-Site Monitoring System Layout

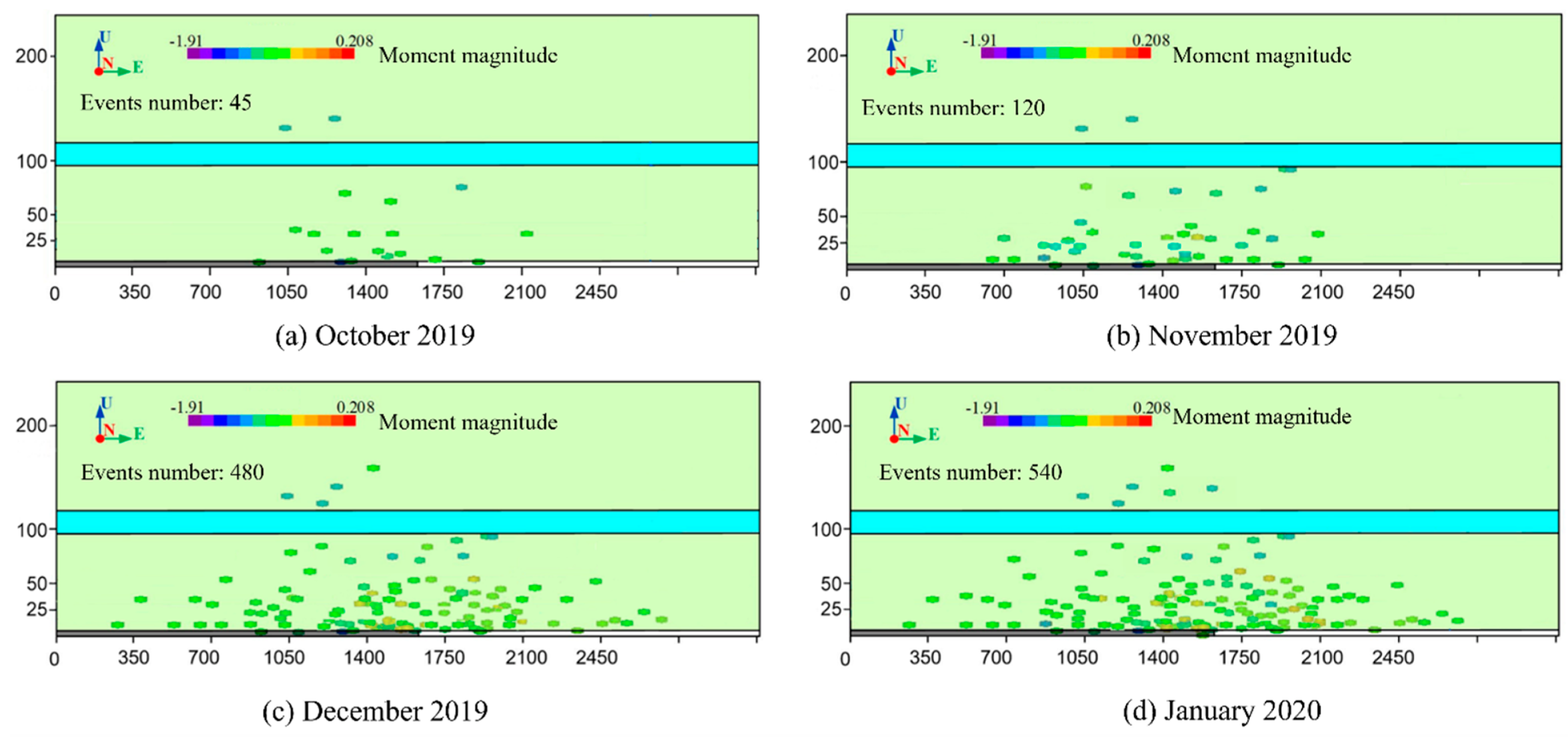

3.4. Analysis of Microseismic Monitoring Results

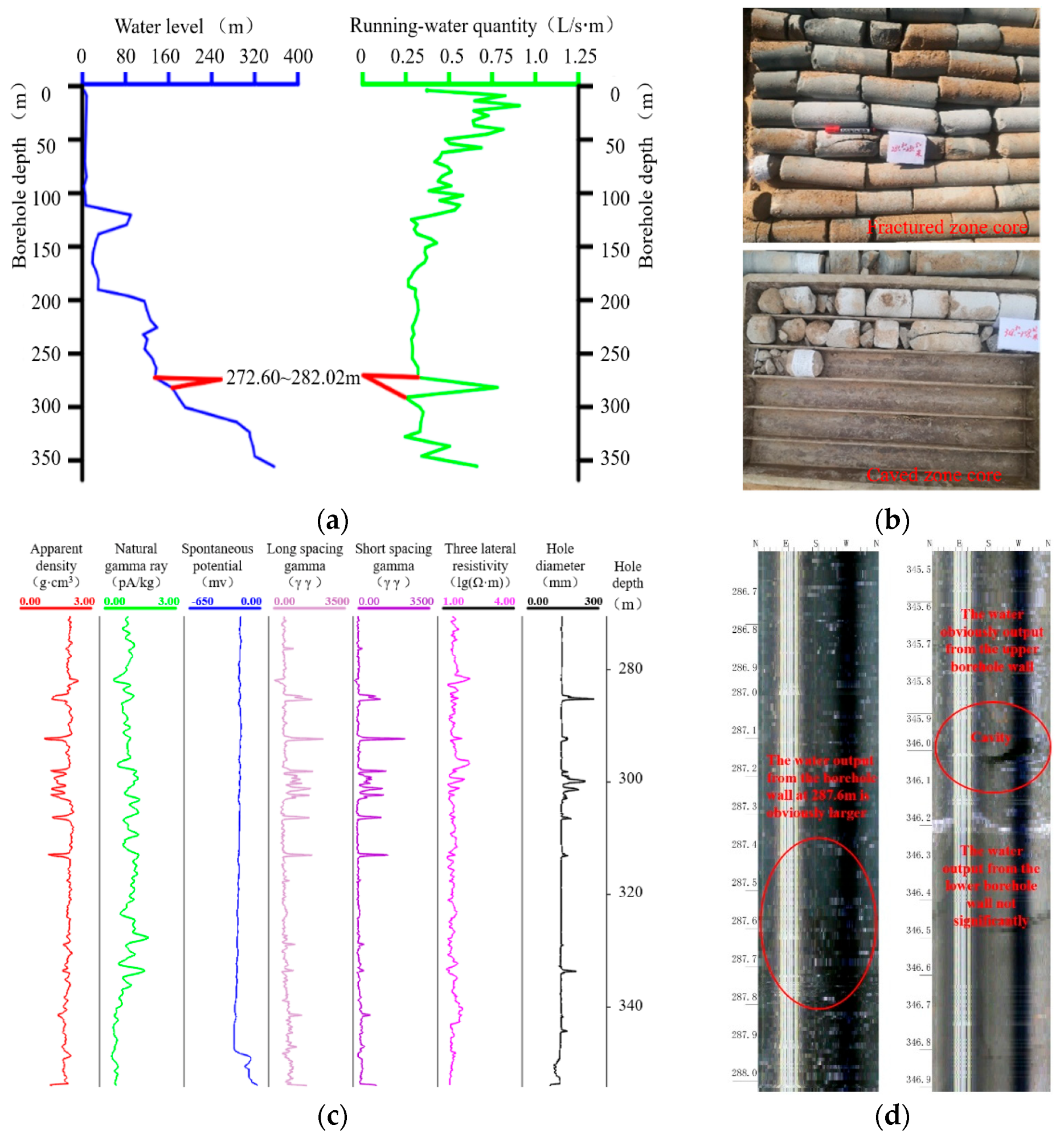

4. Field Drilling Verification

5. Mechanical Mechanism Analysis

6. Conclusions

- (1)

- The MMS is used to monitor the microseismic events of the overlying rock in the mining area of the No. 3 coal seam in real time. The results show that the water-conducting zone gradually develops upward with the advancement of the 1311 working face, and the microseismic events at 110 m from the top of the coal seam are significantly weakening. Combined with the characteristics of the “three zones”, the height of the water-conducting zone was determined to be 110 m.

- (2)

- By comprehensively using four methods—the simple hydrological observation method, engineering geological catalogue, geophysical detection, and downhole television—the range of the water-conducting zone is about 105.4–120.4 m.

- (3)

- Based on the key strata theory, the mechanical mechanism of the development of the water-conducting zone was analyzed. The KSPB was used to determine the position of the key strata, and the height of the water-conducting zone was determined to be developed to the bottom of the 15.5 m thick siltstone layer, and the height was 112 m.

- (4)

- The microseismic monitoring is consistent with the theoretical results of on-site drilling detection and key strata theory, and can accurately determine the time, location, and nature of rock mass micro-ruptures. Compared with traditional prediction methods, it has the advantages of safety, high efficiency, accurate prediction, and easy studying of the law of overlying rock movement. Therefore, the promotion of microseismic monitoring technology is conducive to the safe production of mines, and has good social and economic benefits.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| xi, yi, zi | The spatial coordinate of the ith sensor |

| x, y, z | The spatial coordinate of the test point |

| ti | The time when the sensor i captures the elastic wave P wave |

| t | The time when the microseismic event occurs |

| vp | Velocity of P wave |

| tc,i | The time that the P wave obtained from the spatial coordinates |

| of the test point is transmitted to the sensor i | |

| ρ0 | The density of the source medium |

| c0 | The seismic wave velocity |

| R | Distance between the source position and the measuring point |

| Fc | The seismic wave radiation coefficient |

| Rc | The seismic wave free surface amplification coefficient |

| Sc | The seismic wave field correction coefficient |

| MW | The moment magnitude |

| M0 | The seismic moment |

References

- Qian, M.; Xu, J.; Wang, J. Further on the sustainable mining of coal. J. China Coal Soc. 2018, 43, 1–13. [Google Scholar]

- Qian, M.; Xu, J. Behaviors of strata movement in coal mining. J. China Coal Soc. 2019, 44, 973–984. [Google Scholar]

- Qian, M.; Mou, X.; Xu, J. Green mining of coal resources harmonizing with environment. J. China Coal Soc. 2007, 32, 1–7. [Google Scholar]

- Yang, T.; Tang, C.; Tan, Z.; Zhu, W.; Feng, Q. State of the art of inrush models in rock mass failure and developing trend for prediction and forecast of groundwater inrush. Chin. J. Rock Mech. Eng. 2007, 26, 268–277. [Google Scholar]

- Wang, X.; Xu, J.; Zhu, W. Influence of primary key stratum structure stability on evolution of water flowing fracture. J. China Coal Soc. 2012, 37, 606–612. [Google Scholar]

- Qian, M.; Mou, X.; Xu, J. Theoretical study of key stratum in ground control. J. China Coal Soc. 1996, 21, 2–7. [Google Scholar]

- Xu, J.; Qian, M. Study on the influence of key strata movement on subsidence. J. China Coal Soc. 2000, 25, 122–126. [Google Scholar]

- Jiang, F. View point of spatial structures of overlying strata and its application in coalmine. J. Min. Saf. Eng. 2006, 23, 30–33. [Google Scholar]

- Xu, J.; Lian, G.; Zhu, W.; Qian, M.-G. Influence of the key strata in deep mining to mining subsidence. J. China Coal Soc. 2007, 32, 686–690. [Google Scholar]

- Xu, J.; Zhu, W.; Wang, X.; Ti, M.-S. Classification of key strata structure of overlying strata in shallow coal seam. J. China Coal Soc. 2009, 34, 865–870. [Google Scholar]

- Qin, W.; Xu, J. Discussion on Key stratum distinguishing method of overlying strata based on the thin slab theory. J. China Coal Soc. 2010, 35, 194–197. [Google Scholar]

- Huang, B.; Liu, Z.; Xu, J. Effect of little fault in working face on water conducted fissure height. J. China Coal Soc. 2009, 34, 1316–1321. [Google Scholar]

- Hu, X.; Li, W.; Cao, D.-T.; Liu, M.-C. Index of multiple factors and expected height of fully mechanized water flowing fractured zone. J. China Coal Soc. 2012, 37, 613–620. [Google Scholar]

- Xu, J.; Zhu, W.; Wang, X. New method to predict the height of fractured water-conducting zone by location of key strata. J. China Coal Soc. 2012, 37, 762–769. [Google Scholar]

- Cao, Z.; Ju, J.; Xu, J. Distribution model of water-conducted fracture main channel and its flow characteristics. J. China Coal Soc. 2019, 44, 3719–3728. [Google Scholar]

- Wang, X.; Xu, J.; Han, H.K.; Ju, J.F.; Xing, Y.T. Stepped development characteristic of water flowing fracture height with variation of mining thickness. J. China Coal Soc. 2019, 44, 3740–3749. [Google Scholar]

- Zhang, C.; Zhao, Y.; Han, P.; Bai, Q. Coal pillar failure analysis and instability evaluation methods: A short review and prospect. Eng. Fail. Anal. 2022, 138, 106344. [Google Scholar] [CrossRef]

- Chen, J.; Liu, P.; Liu, L.; Zheng, B.; Zhao, H.; Zhang, C.; Zhang, J.; Li, D. Anchorage performance of a modified cable anchor subjected to different joint opening conditions. Constr. Build. Mater. 2022, 336, 127558. [Google Scholar] [CrossRef]

- Miao, X.; Cui, X.; Wang, J.; Xu, J. The height of fractured water-conducting zone in undermined rock strata. Eng. Geol. 2011, 120, 32–39. [Google Scholar] [CrossRef]

- Li, P.; Wang, X.; Cao, W.; Zhang, D.; Qin, D.; Wang, H. Influence of Spatial Relationships between Key Strata on the Height of Mining-Induced Fracture Zone: A Case Study of Thick Coal Seam Mining. Energies 2018, 11, 102. [Google Scholar] [CrossRef] [Green Version]

- Gui, H.; Zhou, Q.; Liao, D.; Kang, Q.; Fan, Z.; Zou, H. Prediction of maximum height of the fractured zone by stressing method for sub-level caving mining. J. China Coal Soc. 1997, 22, 41–45. [Google Scholar]

- Chen, R.; Bai, H.; Feng, M. Determination of the height of water flowing fractured zone in overburden strata above fully-mechanized top-coal caving face. J. Min. Saf. Eng. 2006, 23, 220–223. [Google Scholar]

- Lu, W. Measure and simulation for development height of water conducted crack zone in overburden roof. J. Xi’an Univ. Sci. Technol. 2014, 34, 309–313. [Google Scholar]

- Yi, W.; Weifeng, Y.; Ming, L.; Liu, X. Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int. J. Rock Mech. Min. Sci. 2012, 52, 50–55. [Google Scholar]

- Zhang, J. Investigations of water inrushes from aquifers under coal seams. Int. J. Rock Mech. Min. Sci. 2005, 42, 350–360. [Google Scholar] [CrossRef]

- Li, T.; Mei, T.; Sun, X.; Lv, Y.; Sheng, J.; Cai, M. A study on a water-inrush incident at Laohutai coalmine. Int. J. Rock Mech. Min. Sci. 2013, 59, 151–159. [Google Scholar] [CrossRef]

- Huang, Z.; Jiang, Z.; Zhu, S.; Qian, Z.; Cao, D. Characterizing the hydraulic conductivity of rock formations between deep coal and aquifers using injection tests. Int. J. Rock Mech. Min. Sci. 2014, 71, 12–18. [Google Scholar] [CrossRef]

- D’Angiò, D.; Lenti, L.; Martino, S. Microseismic monitoring to assess rock mass damaging through a novel damping ratio-based approach. Int. J. Rock Mech. Min. Sci. 2021, 146, 104883. [Google Scholar] [CrossRef]

- Ma, K.; Sun, X.Y.; Tang, C.A.; Yuan, F.Z.; Wang, S.J.; Chen, T. Floor water inrush analysis based on mechanical failure characters and microseismic monitoring. Tunn. Undergr. Space Technol. 2021, 108, 103698. [Google Scholar] [CrossRef]

- Wamriew, D.; Charara, M.; Pissarenko, D. Joint event location and velocity model update in real-time for downhole microseismic monitoring: A deep learning approach. Comput. Geosci. 2022, 158, 104965. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, G.; Liu, C.; Li, S.; Xue, J.; Cheng, R.; Wnag, X.; Zheng, X. Prediction of rockbursts in a typical island working face of a coal mine through microseismic monitoring technology. Tunn. Undergr. Space Technol. 2021, 113, 103972. [Google Scholar] [CrossRef]

- Yi, D.; Xun, L.; Si, G.; Canbulat, I. Seismic source location using the shortest path method based on boundary discretisation scheme for microseismic monitoring in underground mines. Int. J. Rock Mech. Min. Sci. 2022, 149, 104982. [Google Scholar]

- Srinivasan, C.; Arora, S.K.; Benady, S. Precursory monitoring of impending rockbursts in Kolar gold mines from microseismic emissions at deeper levels. Int. J. Rock Mech. Min. Sci. 1999, 36, 941–948. [Google Scholar] [CrossRef]

- Simser, B.P.; Andrieux, P.P.; Peterson, D.A.; Macdonald, T.A.; Alcott, J.M. Advanced monitoring and analysis of microseismic activity as an aid to mining at Brunswick Mines. Int. J. Rock Mech. Min. Sci. 1998, 35, 389. [Google Scholar] [CrossRef]

- Occhiena, C.; Pirulli, M.; Scavia, C. A microseismic-based procedure for the detection of rock slope instabilities. Int. J. Rock Mech. Min. Sci. 2014, 69, 67–79. [Google Scholar] [CrossRef]

- Hassani, H.; Hloušek, F.; Alexandrakis, C.; Buske, S. Migration-based microseismic event location in the Schlema-Alberoda mining area. Int. J. Rock Mech. Min. Sci. 2018, 110, 161–167. [Google Scholar] [CrossRef]

- Mngadi, S.B.; Durrheim, R.J.; Manzi, M.S.D.; Ogasawara, H.; Yabe, Y.; Yilmaz, H.; Wechsler, N.; van Aswegen, G.; Roberts, D.; Ward, A.K.; et al. Integration of underground mapping, petrology, and high-resolution microseismicity analysis to characterise weak geotechnical zones in deep South African gold mines. Int. J. Rock Mech. Min. Sci. 2019, 114, 79–91. [Google Scholar] [CrossRef]

- Fuxing, J. Application of microseismic monitoring technology of strata fracturing in underground coalmine. Chin. J. Geotech. Eng. 2002, 24, 147–149. [Google Scholar]

- Fuxing, J.; Xun, L.; Shuhua, Y. Study on microseismic monitoring for spatial structure of overlying strata and mining pressure field in longwall face. Chin. J. Geotech. Eng. 2003, 25, 23–25. [Google Scholar]

- Cheng, Y.; Jiang, F.; Zhang, X. C-shaped strata spatial structure and stress field in longwall face monitored by microseismic monitoring. Chin. J. Rock Mech. Eng. 2007, 26, 102–107. [Google Scholar]

- Yang, Z.; Yu, R.; Guo, R. Application of microseismic monitoring to deep mines. Chin. J. Rock Mech. Eng. 2008, 27, 1066–1073. [Google Scholar]

- Wang, S.; Mao, D.; Pan, J. Measurement on the whole process of abutment pressure evolution and microseismic activities at the lateral strata of goaf. J. China Coal Soc. 2015, 40, 2772–2779. [Google Scholar]

- Liu, H.; Yang, T.; Zhang, B. Influence factors of overlying coal strata falling and mine pressure behaviours in western coalmines. J. China Coal Soc. 2017, 42, 460–469. [Google Scholar]

- Tang, G.; Zhu, Z.; Han, Y. Relationship between overburden strata movement and strata behavior during dual system seam mining based on microseismic monitoring technology. J. China Coal Soc. 2017, 42, 212–218. [Google Scholar]

- Wang, H.; Jiang, F.; Cheng, Y. Research on microseismic (MS) monitoring of the height of fractured water-conducting zone in overlying rock. Eng. Geol. 2006, 120, 74–76. [Google Scholar]

- Jiang, F.; Ye, G.; Wang, C. Application of high-precision microseismic monitoring technique to water inrush monitoring in coalmine. Chin. J. Rock Mech. Eng. 2008, 27, 1932–1938. [Google Scholar]

- Liu, C.; Li, S.; Xue, J. Identification method of high fractured body for overlying strata in goaf based on microseismic monitoring technology. J. China Univ. Min. Technol. 2016, 45, 709–716. [Google Scholar]

- Han, J.; Zhang, H.; Gao, Z. Failure height of weak overburden by layered fully-mechanized mining in extremely thick coal seam. J. Min. Saf. Eng. 2016, 33, 226–230. [Google Scholar]

| Sensor Number | N | E | Elevation (M) |

|---|---|---|---|

| 1 | 037:59:55.915306 | 109:15:12.732641 | 788.218 |

| 2 | 037:59:57.532875 | 109:15:12.694932 | 787.749 |

| 3 | 037:59:59.157386 | 109:15:12.657013 | 788.916 |

| 4 | 038:00:00.510342 | 109:15:12.622709 | 786.871 |

| 5 | 038:00:02.140542 | 109:15:12.589681 | 786.828 |

| 6 | 038:00:03.759413 | 109:15:12.560642 | 785.881 |

| Method | Height of Water-Conducting Zone (m) | The Ratio of the Height of the Fractured Zone to the Mining Height |

|---|---|---|

| Simple hydrological observation method | 120.4 | 36.27 |

| Engineering geological catalogue | 111.7 | 33.64 |

| Geophysical logging | 108 | 32.53 |

| Downhole television | 105.4 | 31.75 |

| Strata | No. | Depth (m) | Thickness (m) | Name | Key Strata | Hard Rock Formation | Three Zones |

|---|---|---|---|---|---|---|---|

| Q21 | 1 | 68.00 | 68.00 | Loess | bending zone | ||

| K1zh | 2 | 69.20 | 1.20 | medium-grained sandstone | |||

| 3 | 120.65 | 51.45 | coarse-grained sandstone | NO. 5 | |||

| J2a | 4 | 127.90 | 7.25 | sandy mudstone | |||

| 5 | 132.40 | 4.50 | fine-grained sandstone | ||||

| 6 | 136.80 | 4.40 | sandy mudstone | ||||

| 7 | 140.00 | 3.20 | coarse-grained sandstone | ||||

| 8 | 143.90 | 3.90 | sandy mudstone | ||||

| 9 | 149.80 | 5.90 | siltstone | ||||

| 10 | 153.50 | 3.70 | sandy mudstone | ||||

| 11 | 157.10 | 3.60 | siltstone | ||||

| 12 | 162.00 | 4.90 | fine-grained sandstone | ||||

| 13 | 166.30 | 4.30 | medium-grained sandstone | ||||

| 14 | 170.00 | 3.70 | siltstone | ||||

| 15 | 173.50 | 3.50 | sandy mudstone | ||||

| 16 | 175.00 | 1.50 | medium-grained sandstone | ||||

| 17 | 180.40 | 5.40 | sandy mudstone | ||||

| 18 | 182.00 | 1.60 | medium-grained sandstone | ||||

| J2z | 19 | 186.60 | 4.60 | siltstone | |||

| 20 | 191.30 | 4.70 | medium-grained sandstone | ||||

| 21 | 196.50 | 5.20 | siltstone | ||||

| 22 | 207.50 | 11.00 | coarse-grained sandstone | ||||

| 23 | 220.00 | 12.50 | siltstone | ||||

| 24 | 221.80 | 1.80 | medium-grained sandstone | ||||

| 25 | 243.30 | 21.50 | siltstone | NO. 4 | |||

| 26 | 245.90 | 2.60 | fine-grained sandstone | ||||

| 27 | 248.30 | 2.40 | siltstone | ||||

| 28 | 252.00 | 3.70 | medium-grained sandstone | ||||

| 29 | 259.40 | 7.40 | fine-grained sandstone | ||||

| 30 | 264.10 | 4.70 | siltstone | ||||

| 31 | 265.50 | 1.40 | coarse-grained sandstone | ||||

| 32 | 281.00 | 15.50 | siltstone | main key strata | NO. 3 | ||

| 33 | 282.80 | 1.80 | medium-grained sandstone | fractured zone | |||

| 34 | 295.80 | 13.00 | siltstone | ||||

| 35 | 298.10 | 2.30 | medium-grained sandstone | ||||

| 36 | 305.80 | 7.70 | sandy mudstone | ||||

| 37 | 310.00 | 4.20 | siltstone | ||||

| 38 | 313.10 | 3.10 | medium-grained sandstone | ||||

| 39 | 319.60 | 6.50 | siltstone | ||||

| 40 | 321.30 | 1.70 | sandy mudstone | ||||

| 41 | 324.90 | 3.60 | medium-grained sandstone | ||||

| 42 | 329.60 | 4.70 | siltstone | ||||

| 43 | 336.00 | 6.40 | medium-grained sandstone | ||||

| 44 | 341.00 | 5.00 | fine-grained sandstone | ||||

| 45 | 358.28 | 17.28 | coarse-grained sandstone | NO. 2 | |||

| J2y | 46 | 360.13 | 1.85 | siltstone | |||

| 47 | 361.90 | 1.77 | mudstone | ||||

| 48 | 365.79 | 3.89 | siltstone | ||||

| 49 | 366.67 | 0.88 | mudstone | ||||

| 50 | 370.37 | 3.70 | siltstone | ||||

| 51 | 393.00 | 22.63 | feldspar sandstone | sub-key strata | NO. 1 | caving zone | |

| J2y3 | 52 | 396.32 | 3.32 | coal |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, W.; Li, Y.; He, Q. Determination of Fractured Water-Conducting Zone Height Based on Microseismic Monitoring: A Case Study in Weiqiang Coalmine, Shaanxi, China. Sustainability 2022, 14, 8385. https://doi.org/10.3390/su14148385

Gao W, Li Y, He Q. Determination of Fractured Water-Conducting Zone Height Based on Microseismic Monitoring: A Case Study in Weiqiang Coalmine, Shaanxi, China. Sustainability. 2022; 14(14):8385. https://doi.org/10.3390/su14148385

Chicago/Turabian StyleGao, Wei, Yingchun Li, and Qingyuan He. 2022. "Determination of Fractured Water-Conducting Zone Height Based on Microseismic Monitoring: A Case Study in Weiqiang Coalmine, Shaanxi, China" Sustainability 14, no. 14: 8385. https://doi.org/10.3390/su14148385

APA StyleGao, W., Li, Y., & He, Q. (2022). Determination of Fractured Water-Conducting Zone Height Based on Microseismic Monitoring: A Case Study in Weiqiang Coalmine, Shaanxi, China. Sustainability, 14(14), 8385. https://doi.org/10.3390/su14148385