Sustainable and Low-Cost Hemp FRP Composite Confinement of B-Waste Concrete

Abstract

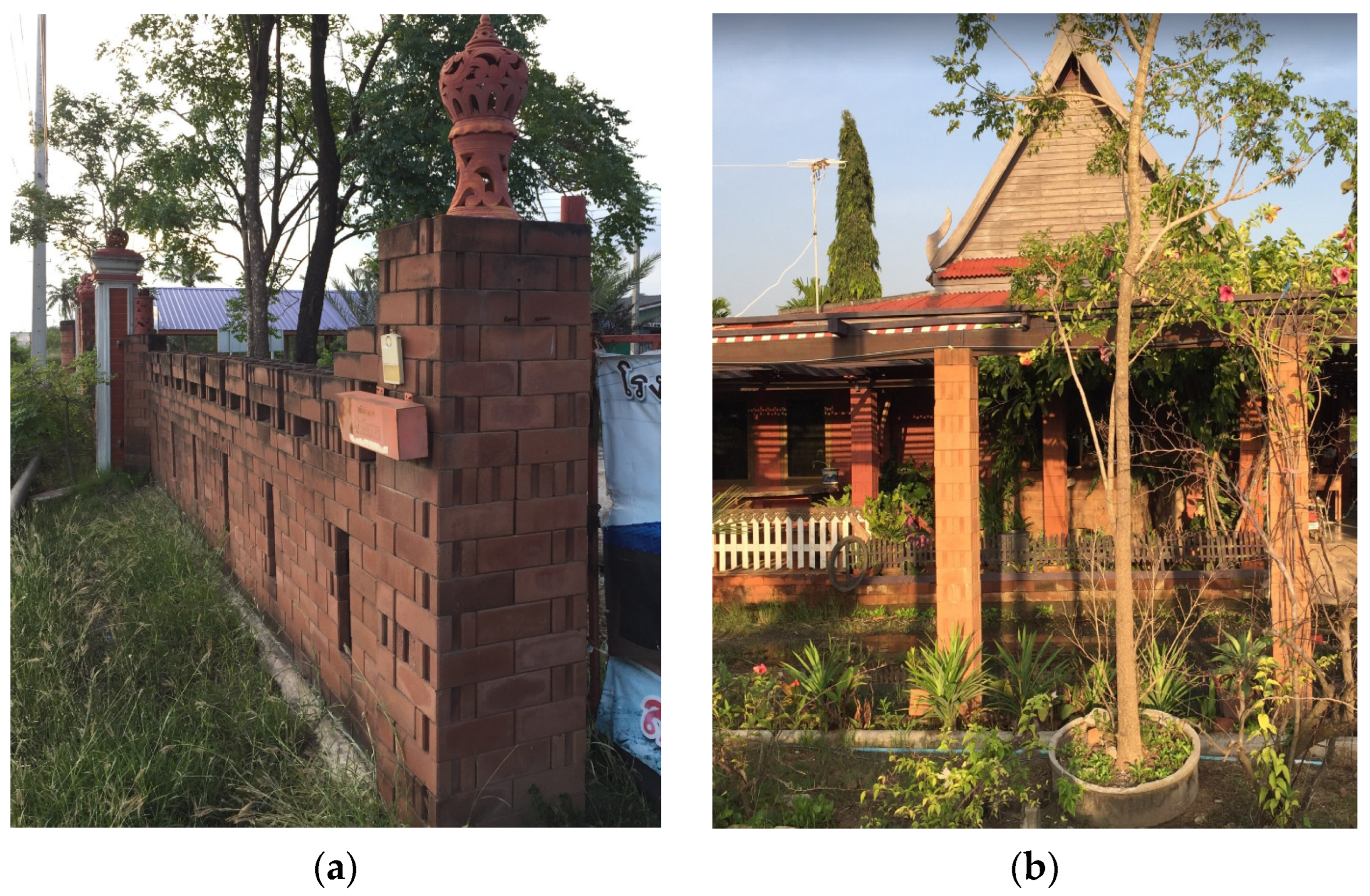

:1. Introduction

2. Experimental Program

2.1. Test Matrix

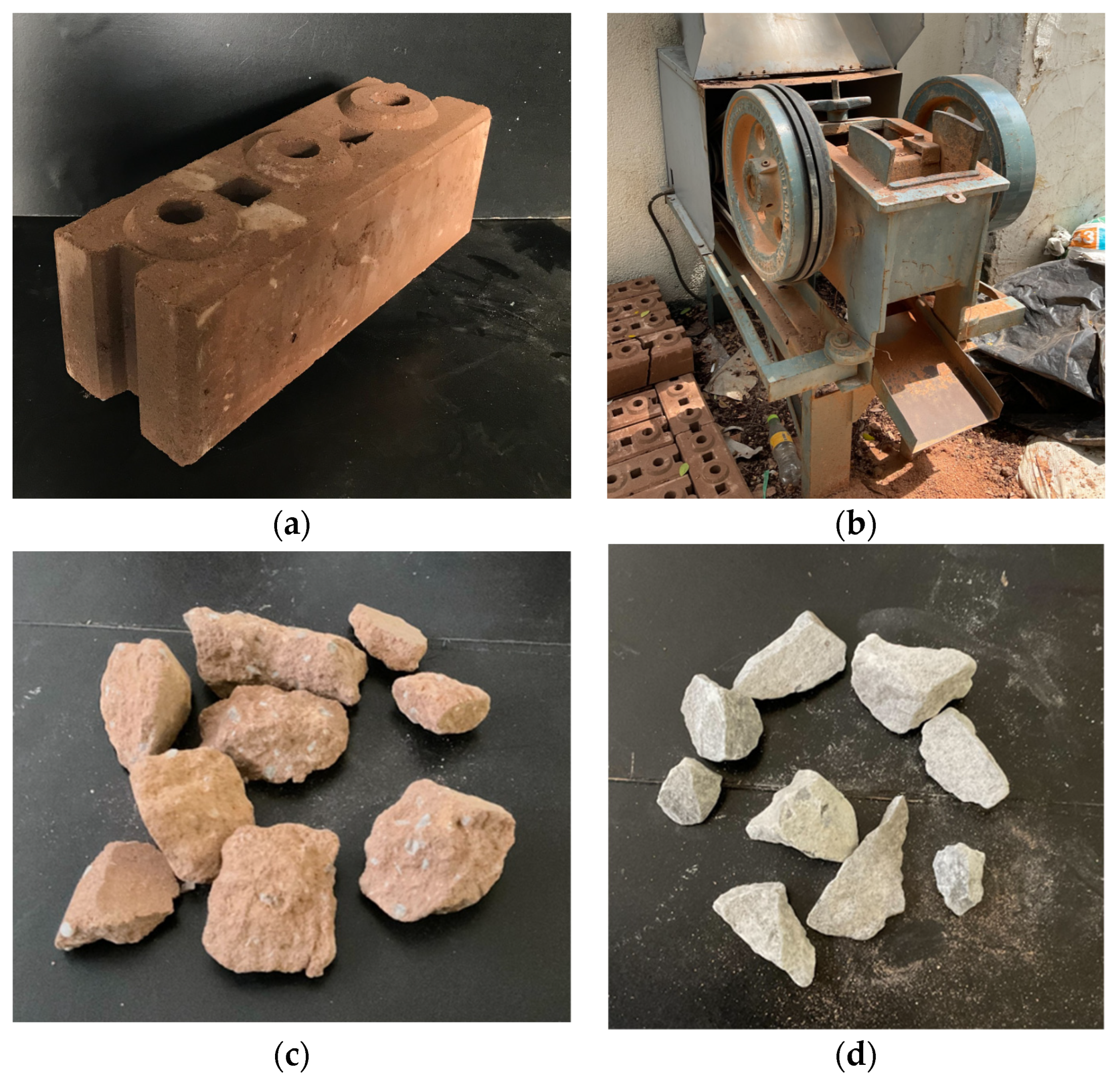

2.2. Material Properties

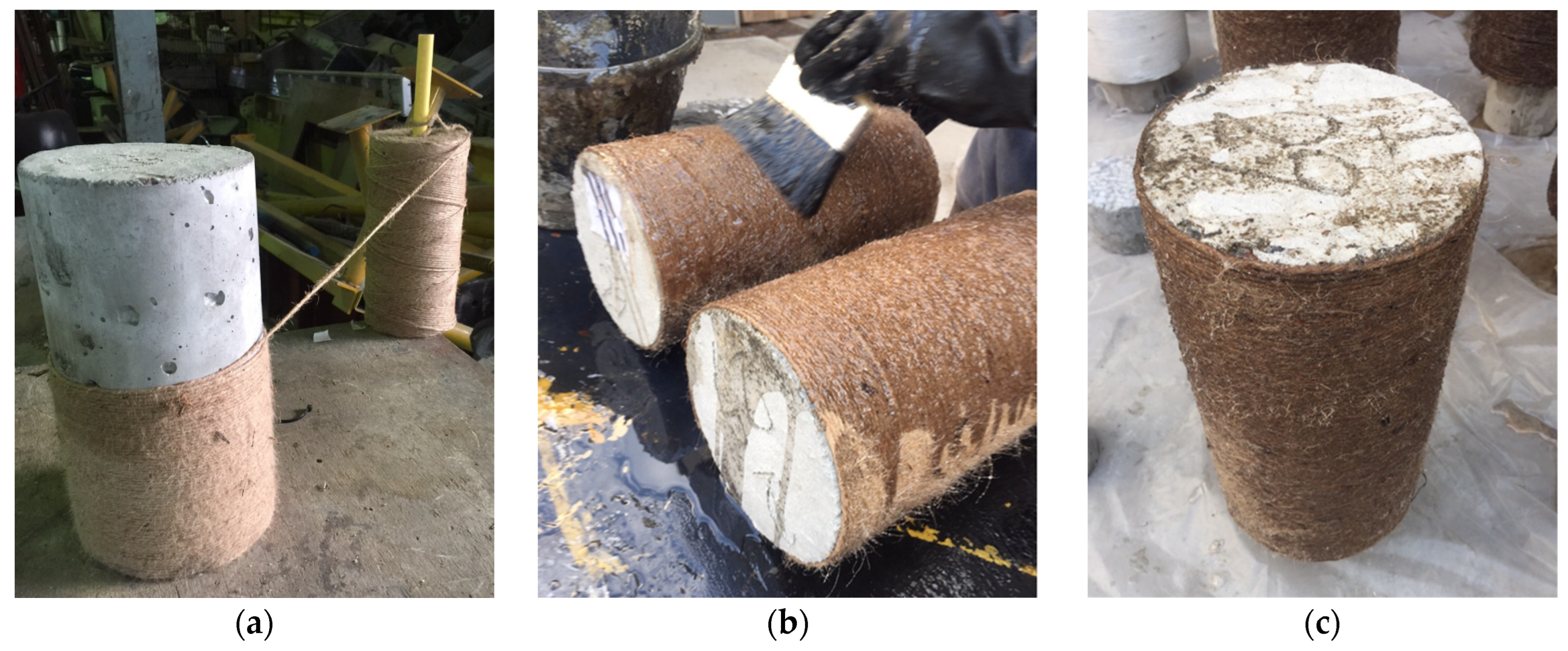

2.3. Strengthening Process

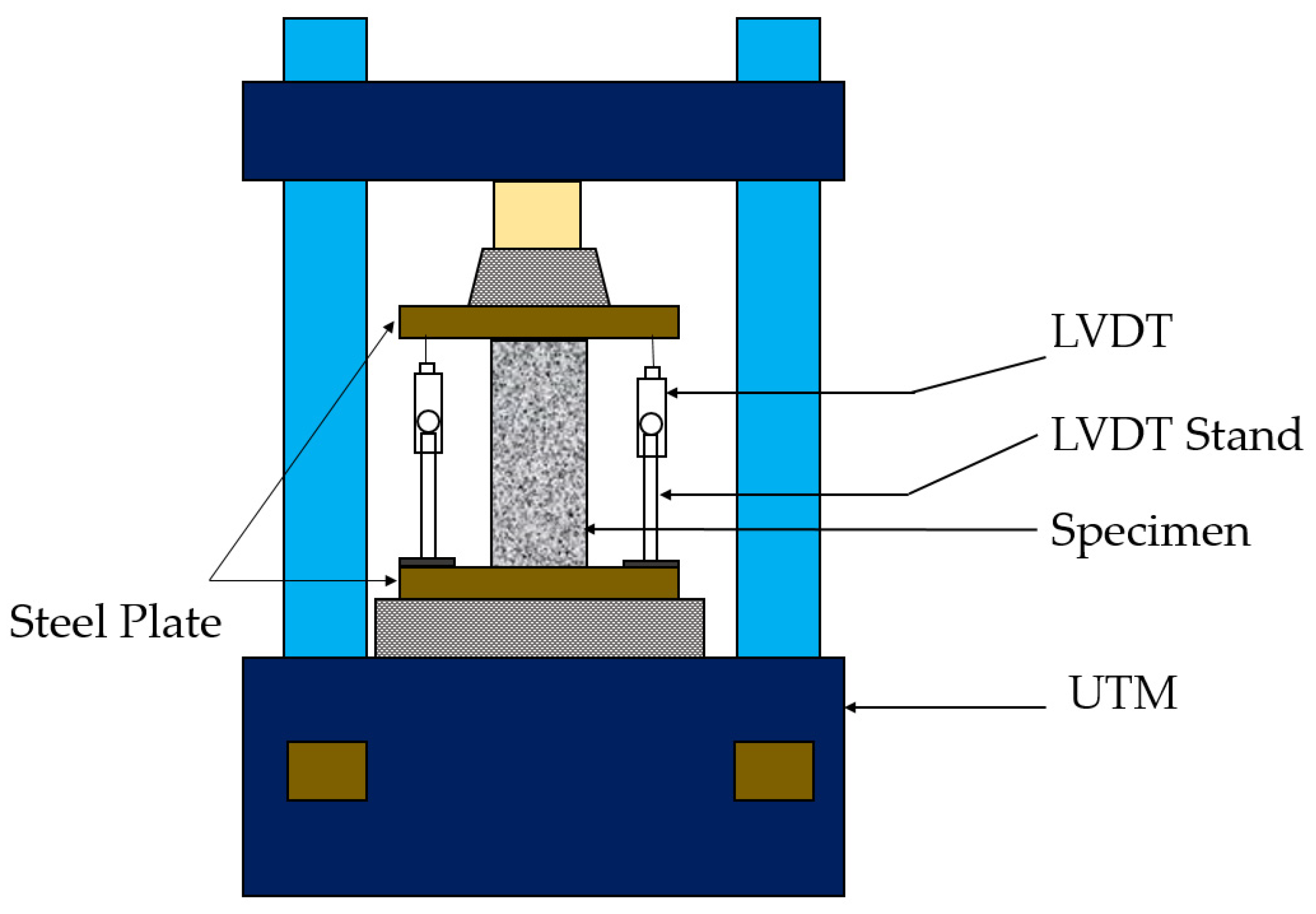

2.4. Instrumentation & Loading Setup

3. Experimental Results

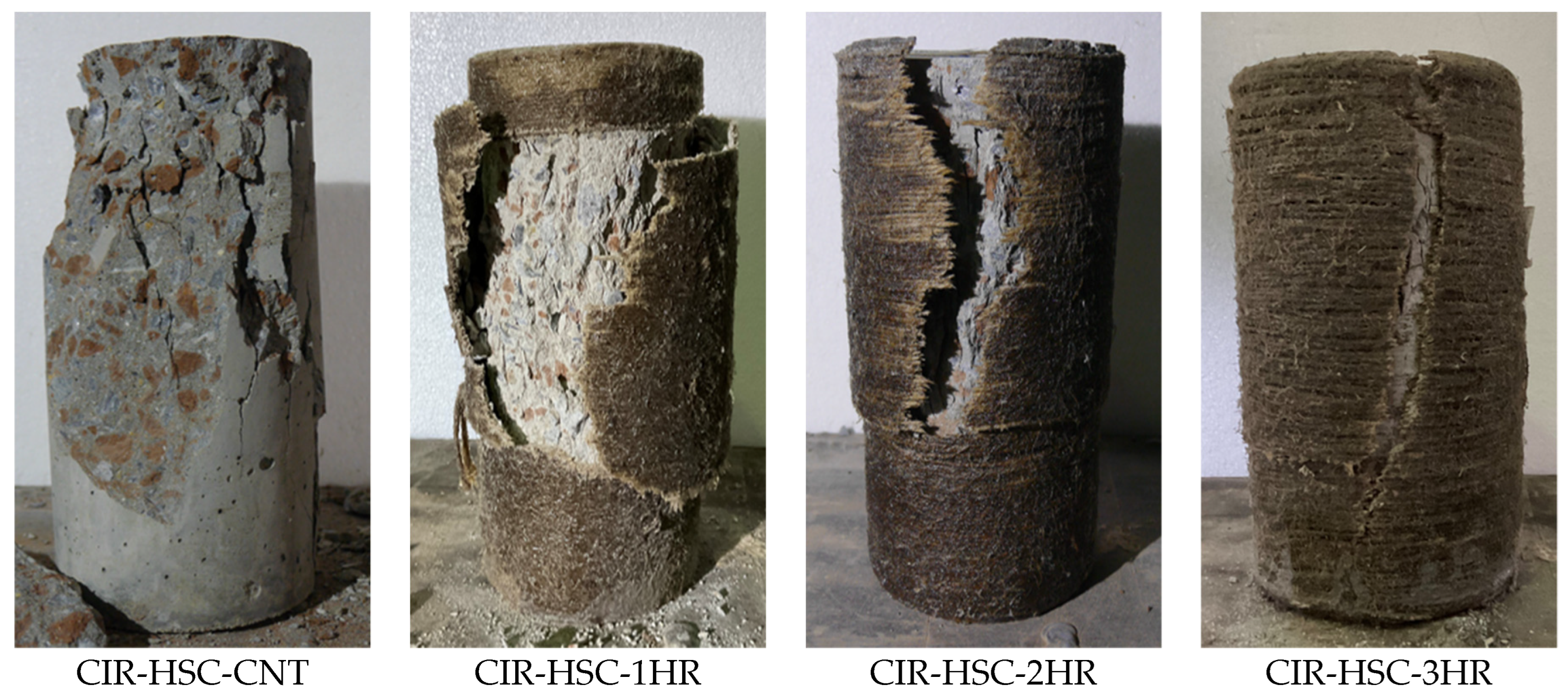

3.1. Ultimate Failure Modes

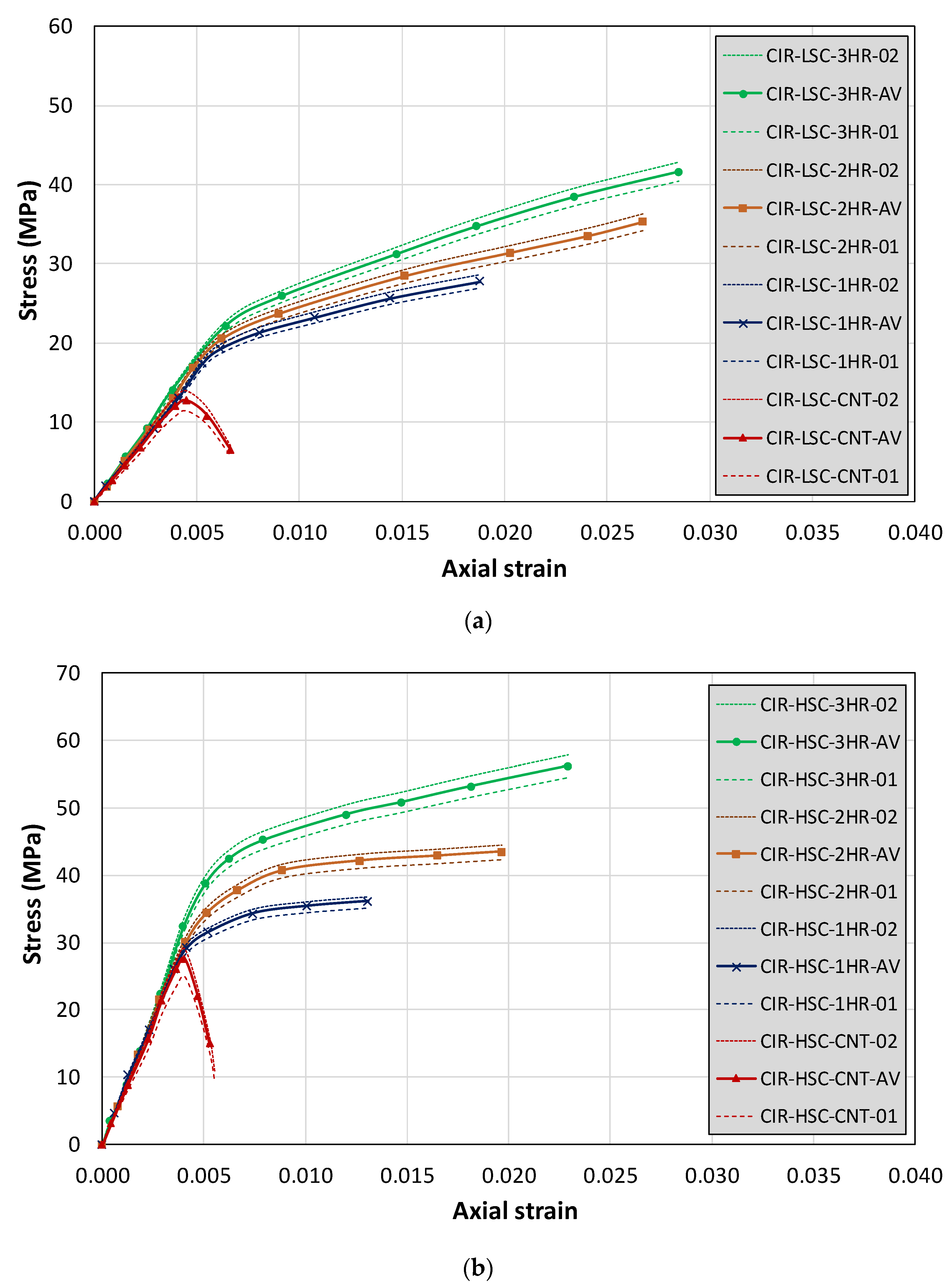

3.2. Axial Stress-Strain Response

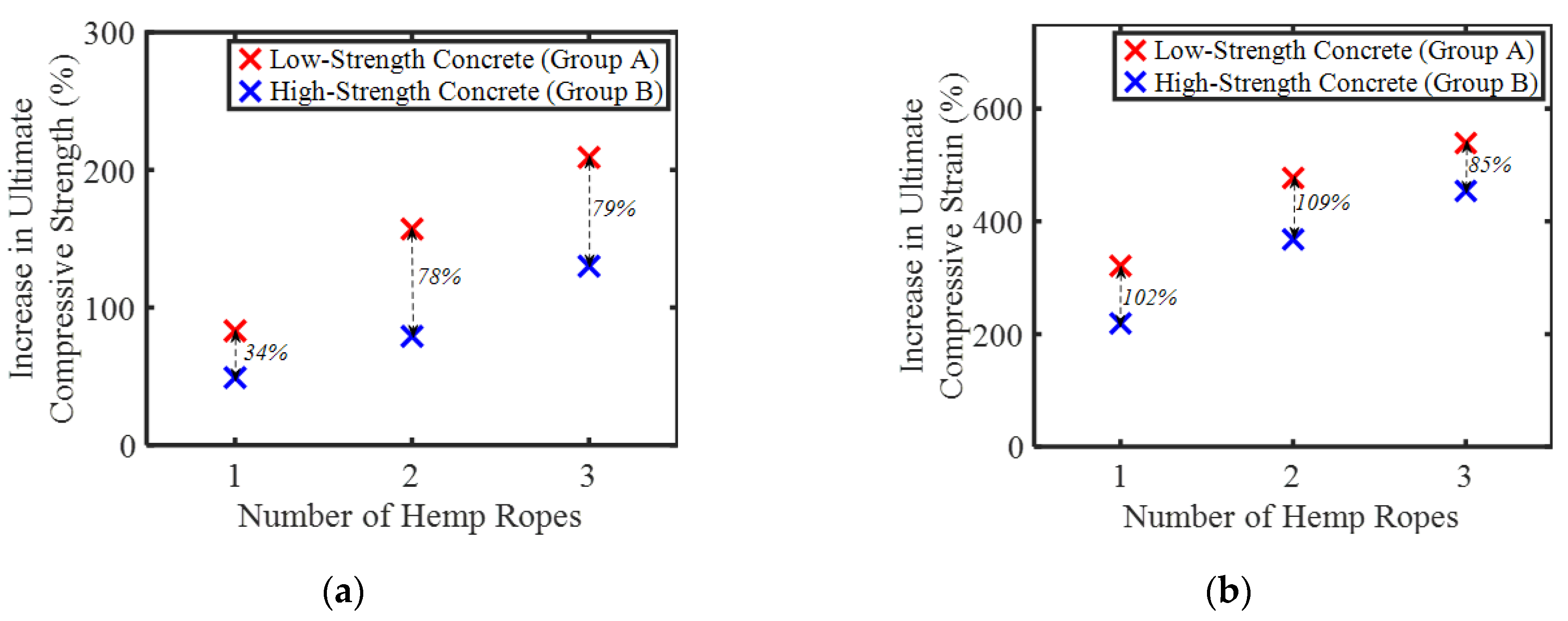

3.3. Effect of Hemp Rope Layers & Concrete Strength

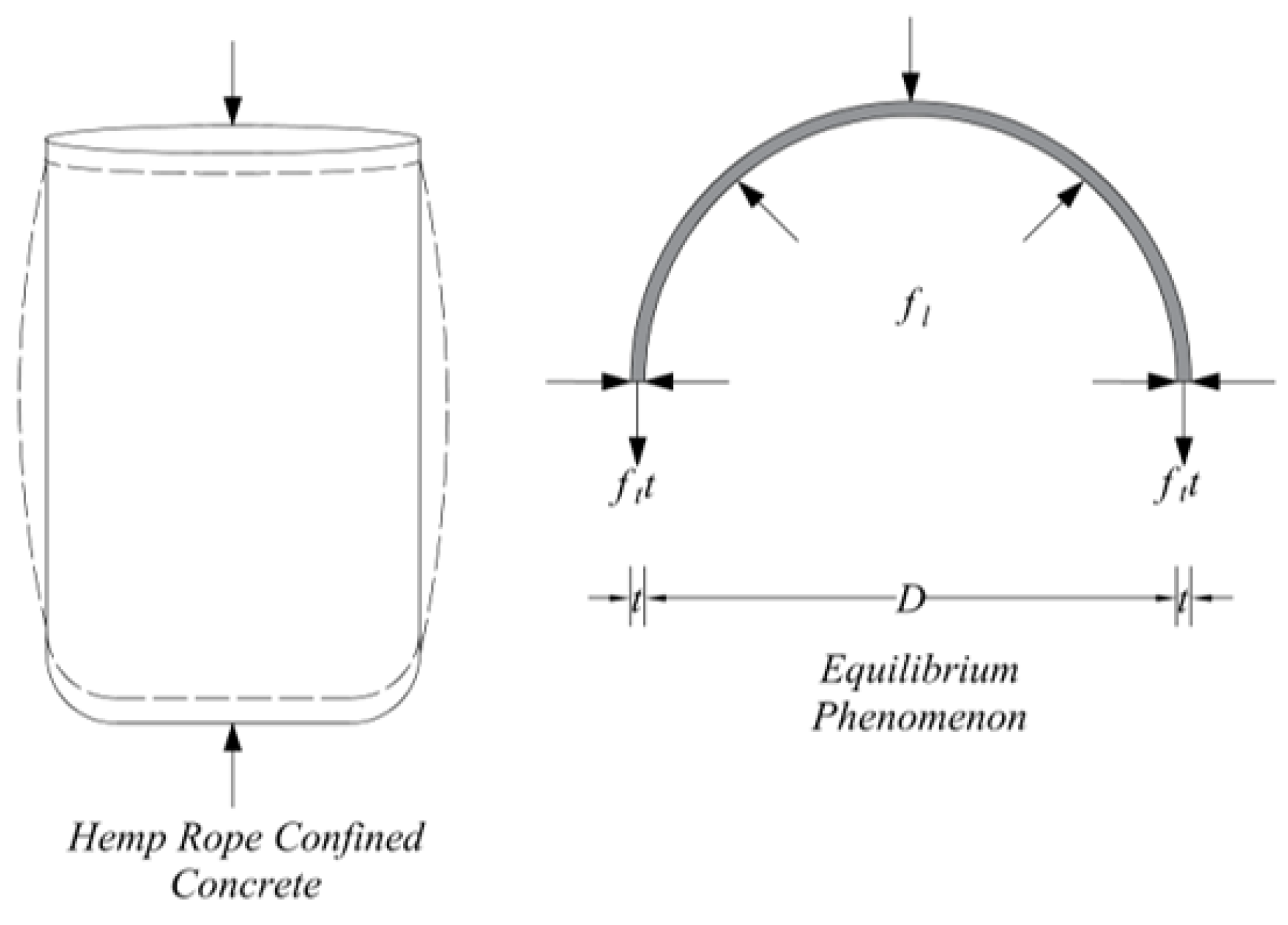

3.4. Analytical Investigations

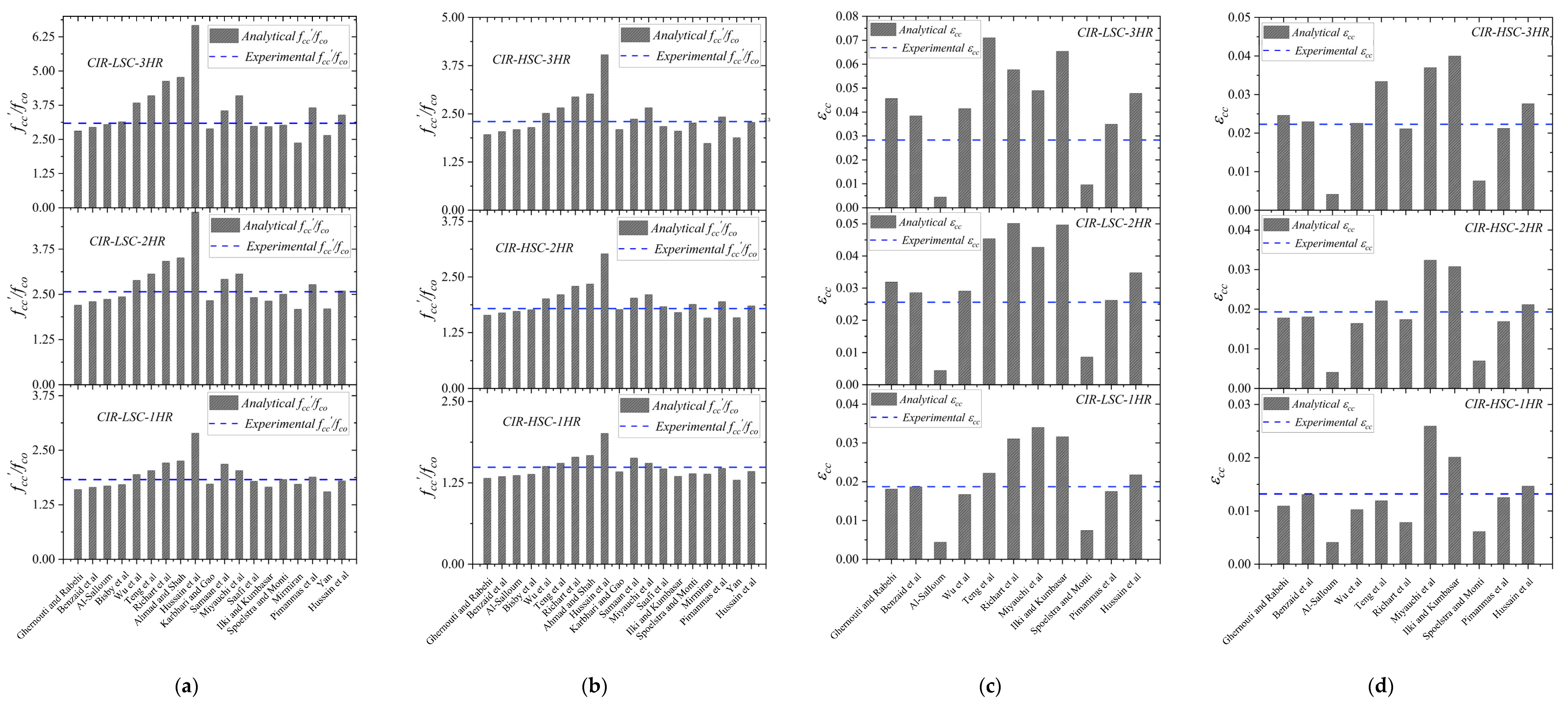

3.4.1. Peak Axial Strength Models

3.4.2. Peak Axial Strain Models

| ID | Model | ||

|---|---|---|---|

| 1 | Richart et al. [55] | ||

| 2 | Ghernouti and Rabehi [59] | ||

| 3 | Benzaid et al. [60] | ||

| 4 | Al-Salloum [61] | ||

| 5 | Bisby et al. [62] | - | |

| 6 | Wu et al. [63] | ||

| 7 | Teng et al. [64] | ||

| 8 | Ahmad and Shah [65] | - | |

| 9 | Hussain et al. [66] | - | |

| 10 | Karbhari and Gao [67] | - | |

| 11 | Samaan et al. [68] | - | |

| 12 | Miyauchi et al. [56] | ||

| 13 | Saafi et al. [69] | - | |

| 14 | Ilki and Kumbasar [70] | ||

| 15 | Spoelstra and Monti [71] | ||

| 16 | Mirmiran [72] | - | |

| 17 | Pimanmas et al. [73] | ||

| 18 | Yan [74] | - | |

| 19 | Hussain et al. [43] |

4. Discussion

5. Conclusions

- Reference specimens exhibited typical concrete failure under compression. Negligible axial ductility was observed in stress-strain response.

- For specimens strengthened with hemp fiber rope specimens, a bilinear axial stress-strain response was observed. This bilinear hardening behavior persisted irrespective of the number of external hemp rope layers resulting in significant improvement of axial ductility over that of the control specimens. By increasing the number of hemp rope layers, both peak axial strength and corresponding strain increased. Further, irrespective of the concrete strength, maximum peak compressive strength and strain were noticed for the case of 3-layer hemp rope confinement. Failure of hemp rope strengthened specimens was characterized by tensile rupture of hemp ropes in hoop direction. However, this was not before imparting significant ductility to the bare concrete.

- Concrete strengths of 15 and 35 MPa were considered in this study. The performance of hemp ropes in improving peak strength and corresponding strain was found superior in low-strength concrete specimens for the same configurations of hemp ropes.

- For the sake of performance-based non-linear modelling, accurate modelling at material level is necessary. For this purpose, several existing analytical stress-strain models were tested in this study to predict ultimate confined compressive strength and strain. It was found that a number of models predicted confined compressive strengths with reasonable accuracy. However, very few models were able to predict confined peak strain with good accuracy. It was established that the model of Benzaid et al. [60] and Pimanmas et al. [73] were standout among other models and consistently predicted experimental peak axial strengths and strains with reasonable accuracy.

- Future studies are required to further enhance the data base and to develop more accurate strength models by considering more approximate number of specimens and number of strengthening layers.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical Properties of Recycled Concrete with Demolished Waste Concrete Aggregate and Clay Brick Aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Zhu, L.; Zhu, Z. Reuse of Clay Brick Waste in Mortar and Concrete. Adv. Mater. Sci. Eng. 2020, 2020, 6326178. [Google Scholar] [CrossRef]

- Manfredi, S.; Pant, R.; Pennington, D.W.; Versmann, A. Supporting Environmentally Sound Decisions for Waste Management with LCT and LCA. Int. J. Life Cycle Assess. 2011, 16, 937–939. [Google Scholar] [CrossRef]

- Mansur, M.A.; Wee, T.H.; Cheran, L.S. Crushed Bricks as Coarse Aggregate for Concrete. Mater. J. 1999, 96, 478–484. [Google Scholar] [CrossRef]

- Khalaf, F.M. Using Crushed Clay Brick as Coarse Aggregate in Concrete. J. Mater. Civ. Eng. 2006, 18, 518–526. [Google Scholar] [CrossRef]

- Khalaf, F.M.; DeVenny, A.S. Recycling of Demolished Masonry Rubble as Coarse Aggregate in Concrete: Review. J. Mater. Civ. Eng. 2004, 16, 331–340. [Google Scholar] [CrossRef]

- Vrijders, J.; Desmyter, J. Een Hoogwaardig Gebruik van Puingranulaten Stimuleren. OVAM Mechelen 2008. [Google Scholar]

- Nováková, I.; Mikulica, K. Properties of Concrete with Partial Replacement of Natural Aggregate by Recycled Concrete Aggregates from Precast Production. Procedia Eng. 2016, 151, 360–367. [Google Scholar] [CrossRef] [Green Version]

- Debieb, F.; Kenai, S. The Use of Coarse and Fine Crushed Bricks as Aggregate in Concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with Recycled Concrete Aggregate and Crushed Clay Bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Sánchez De Rojas, M.I.; Frías, M. Influence of Mixed Recycled Aggregate on the Physical—Mechanical Properties of Recycled Concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- González, J.S.; Gayarre, F.L.; Pérez, C.L.C.; Ros, P.S.; López, M.A.S. Influence of Recycled Brick Aggregates on Properties of Structural Concrete for Manufacturing Precast Prestressed Beams. Constr. Build. Mater. 2017, 149, 507–514. [Google Scholar] [CrossRef]

- Jiang, T.; Wang, X.M.; Zhang, W.P.; Chen, G.M.; Lin, Z.H. Behavior of FRP-Confined Recycled Brick Aggregate Concrete under Monotonic Compression. J. Compos. Constr. 2020, 24, 04020067. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of Fly Ash as Cement Replacement on the Properties of Recycled Aggregate Concrete. J. Mater. Civ. Eng. 2007, 19, 709–717. [Google Scholar] [CrossRef]

- Jin, C.; Wang, X.; Akinkurolere, O.O.; Jiang, C.R. Experimental Research on the Conversion Relationships. Chin. Concr. J. 2008, 11, 37–39. [Google Scholar]

- Jiabin, L.; Jianzhuang, X.; Jian, H. Influence of Recycled Coarse Aggregate Replacement Percentages on Compressive Strength of Concrete. Jianzhu Cailiao Xuebao/J. Build. Mater. 2006, 9, 297–301. [Google Scholar]

- Ameli, M.; Ronagh, H.R.; Dux, P.F. Behavior of FRP Strengthened Reinforced Concrete Beams under Torsion. J. Compos. Constr. 2007, 11, 192–200. [Google Scholar] [CrossRef]

- Attari, N.; Amziane, S.; Chemrouk, M. Flexural Strengthening of Concrete Beams Using CFRP, GFRP and Hybrid FRP Sheets. Constr. Build. Mater. 2012, 37, 746–757. [Google Scholar] [CrossRef]

- Antonopoulos, C.P.; Triantafillou, T.C. Experimental Investigation of FRP-Strengthened RC Beam-Column Joints. J. Compos. Constr. 2003, 7, 39–49. [Google Scholar] [CrossRef]

- Smith, S.T.; Hu, S.; Kim, S.J.; Seracino, R. FRP-Strengthened RC Slabs Anchored with FRP Anchors. Eng. Struct. 2011, 33, 1075–1087. [Google Scholar] [CrossRef]

- Smith, S.T.; Teng, J.G. FRP-Strengthened RC Beams. I: Review of Debonding Strength Models. Eng. Struct. 2002, 24, 385–395. [Google Scholar] [CrossRef]

- Belarbi, A.; Acun, B. FRP Systems in Shear Strengthening of Reinforced Concrete Structures. Procedia Eng. 2013, 57, 2–8. [Google Scholar] [CrossRef] [Green Version]

- Jiangfeng, D.; Shucheng, Y.; Qingyuan, W.; Wenyu, Z.; Jiangfeng, D.; Shucheng, Y.; Qingyuan, W.; Wenyu, Z. Flexural Behavior of RC Beams Made with Recycled Aggregate Concrete and Strengthened by CFRP Sheets. J. Build. Struct. 2019, 40, 71–78. [Google Scholar] [CrossRef]

- Liang, J.; Lin, S.; Ahmed, M. Axial Behavior of Carbon Fiber-Reinforced Polymer–Confined Recycled Aggregate Concrete-Filled Steel Tube Slender Square Columns. Adv. Struct. Eng. 2021, 24, 3507–3518. [Google Scholar] [CrossRef]

- Chen, G.M.; Zhang, J.J.; Jiang, T.; Lin, C.J.; He, Y.H. Compressive Behavior of CFRP-Confined Recycled Aggregate Concrete in Different-Sized Circular Sections. J. Compos. Constr. 2018, 22, 04018021. [Google Scholar] [CrossRef]

- Li, P.; Zhao, Y.; Long, X.; Zhou, Y.; Chen, Z. Ductility Evaluation of Damaged Recycled Aggregate Concrete Columns Repaired With Carbon Fiber-Reinforced Polymer and Large Rupture Strain FRP. Front. Mater. 2020, 7, 346. [Google Scholar] [CrossRef]

- Khan, A.R.; Fareed, S.; Nasir, R.; Xiao, J. Behaviour and Strength Prediction of Reinforced Recycled Aggregate Concrete Columns Confined with CFRP Wraps. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 1–13. [Google Scholar] [CrossRef]

- Chen, G.M.; He, Y.H.; Jiang, T.; Lin, C.J. Behavior of CFRP-Confined Recycled Aggregate Concrete under Axial Compression. Constr. Build. Mater. 2016, 111, 85–97. [Google Scholar] [CrossRef]

- Iskander, M.G.; Hassan, M. State of the Practice Review in FRP Composite Piling. J. Compos. Constr. 1998, 2, 116–120. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z. Evaluation of FRP and Hybrid FRP Cables for Super Long-Span Cable-Stayed Bridges. Compos. Struct. 2010, 92, 2582–2590. [Google Scholar] [CrossRef]

- Chaiyasarn, K.; Hussain, Q.; Joyklad, P.; Rodsin, K. New Hybrid Basalt/E-Glass FRP Jacketing for Enhanced Confinement of Recycled Aggregate Concrete with Clay Brick Aggregate. Case Stud. Constr. Mater. 2021, 14, e00507. [Google Scholar] [CrossRef]

- Tarvainen, K.; Jolanki, R.; Forsman-Grönholm, L.; Estlander, T.; Pfäffli, P.; Juntunen, J.; Kanerva, L. Exposure, Skin Protection and Occupational Skin Diseases in the Glass-Fibre-Reinforced Plastics Industry. Contact Dermat. 1993, 29, 119–127. [Google Scholar] [CrossRef] [PubMed]

- Tarvainen, K.; Jolanki, R.; Estlander, T. Occupational Contact Allergy to Unsaturated Polyester Resin Cements. Contact Dermat. 1993, 28, 220–224. [Google Scholar] [CrossRef] [PubMed]

- Minamoto, K.; Nagano, M.; Inaoka, T.; Kitano, T.; Ushijima, K.; Fukuda, Y.; Futatsuka, M. Skin Problems among Fiber-Glass Reinforced Plastics Factory Workers in Japan. Ind. Health 2002, 40, 42–50. [Google Scholar] [CrossRef]

- Yinh, S.; Hussain, Q.; Joyklad, P.; Chaimahawan, P.; Rattanapitikon, W.; Limkatanyu, S.; Pimanmas, A. Strengthening Effect of Natural Fiber Reinforced Polymer Composites (NFRP) on Concrete. Case Stud. Constr. Mater. 2021, 15, e00653. [Google Scholar] [CrossRef]

- Yooprasertchai, E.; Wiwatrojanagul, P.; Pimanmas, A. A Use of Natural Sisal and Jute Fiber Composites for Seismic Retrofitting of Nonductile Rectangular Reinforced Concrete Columns. J. Build. Eng. 2022, 52, 104521. [Google Scholar] [CrossRef]

- Jirawattanasomkul, T.; Likitlersuang, S.; Wuttiwannasak, N.; Ueda, T.; Zhang, D.; Shono, M. Structural Behaviour of Pre-Damaged Reinforced Concrete Beams Strengthened with Natural Fibre Reinforced Polymer Composites. Compos. Struct. 2020, 244, 112309. [Google Scholar] [CrossRef]

- Sen, T.; Jagannatha Reddy, H.N. Efficacy of Bio Derived Jute FRP Composite Based Technique for Shear Strength Retrofitting of Reinforced Concrete Beams and Its Comparative Analysis with Carbon and Glass FRP Shear Retrofitting Schemes. Sustain. Cities Soc. 2014, 13, 105–124. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.W.; Ye, L. Sisal Fibre and Its Composites: A Review of Recent Developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Joyklad, P.; Yooprasertchai, E.; Wiwatrojanagul, P.; Chaiyasarn, K.; Ali, N.; Hussain, Q. Use of Natural and Synthetic Fiber-Reinforced Composites for Punching Shear of Flat Slabs: A Comparative Study. Polymers 2022, 14, 719. [Google Scholar] [CrossRef]

- Rousakis, T.C. Inherent Seismic Resilience of RC Columns Externally Confined with Nonbonded Composite Ropes. Compos. Part B Eng. 2018, 135, 142–148. [Google Scholar] [CrossRef]

- Rousakis, T.C. Reusable and Recyclable Nonbonded Composite Tapes and Ropes for Concrete Columns Confinement. Compos. Part B Eng. 2016, 103, 15–22. [Google Scholar] [CrossRef]

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P. Behavior of Concrete Confined with Epoxy Bonded Fiber Ropes under Axial Load. Constr. Build. Mater. 2020, 263, 120093. [Google Scholar] [CrossRef]

- Fragoudakis, R.; Gallagher, J.A.; Kim, V. A Computational Analysis of the Energy Harvested by Gfrp and Nfrp Laminated Beams Under Cyclic Loading. Procedia Eng. 2017, 200, 221–228. [Google Scholar] [CrossRef]

- Ghalieh, L.; Awwad, E.; Saad, G.; Khatib, H.; Mabsout, M. Concrete Columns Wrapped with Hemp Fiber Reinforced Polymer—An Experimental Study. Procedia Eng. 2017, 200, 440–447. [Google Scholar] [CrossRef]

- ASTM C1314-21; Standard Test Method for Compressive Strength of Masonry Prisms. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C140/C140M-22a; Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM A931-18; Standard Test Method for Tension Testing of Wire Ropes and Strand. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM E8/E8M-13; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- Deng, J.; Zheng, Y.; Wang, Y.; Liu, T.; Li, H. Study on Axial Compressive Capacity of Frp-Confined Concrete-Filled Steel Tubes and Its Comparisons with Other Composite Structural Systems. Int. J. Polym. Sci. 2017, 2017, 6272754. [Google Scholar] [CrossRef] [Green Version]

- Qi, Y.; Xie, L.; Bai, Y.; Liu, W.; Fang, H. Axial Compression Behaviours of Pultruded GFRP–Wood Composite Columns. Sensors 2019, 19, 755. [Google Scholar] [CrossRef] [Green Version]

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P.; Wijeyewickrema, A.C. Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings 2021, 11, 355. [Google Scholar] [CrossRef]

- Shehata, I.A.E.M.; Carneiro, L.A.V.; Shehata, L.C.D. Strength of Short Concrete Columns Confined with CFRP Sheets. Mater. Struct. 2002, 35, 50–58. [Google Scholar] [CrossRef]

- Rodsin, K.; Hussain, Q.; Suparp, S.; Nawaz, A. Compressive behavior of extremely low strength concrete confined with low-cost glass FRP composites. Case Stud. Constr. Mater. 2020, 13, e00452. [Google Scholar] [CrossRef]

- Richart, F.E.; Brandtzæg, A.; Brown, R.L. A Study of the Failure of Concrete under Combined Compressive Stresses. Bull. Eng. Exp. Stn. 1928, 26, 12. [Google Scholar]

- Miyauchi, K. Estimation of Strengthening Effects with Crbon Feber Sheet for Concrete Column. In Proceedings of the 3rd International Symposium on Non-Metallic (FRP) Reinforcement for Concrete Structures, Sapporo, Japan, 14–16 October 1997; pp. 217–224. [Google Scholar]

- Suparp, S.; Ali, N.; Al Zand, A.W.; Chaiyasarn, K.; Rashid, M.U.; Yooprasertchai, E.; Joyklad, P. Axial Load Enhancement of Lightweight Aggregate Concrete (LAC) Using Environmentally Sustainable Composites. Buildings 2022, 12, 851. [Google Scholar] [CrossRef]

- Lam, L.; Hussain, Q.; Joyklad, P.; Pimanmas, A. Behavior of RC Deep Beams Strengthened in Shear Using Glass Fiber Reinforced Polymer with Mechanical Anchors. In Proceedings of the International Conference on Environment and Civil Engineering (ICEACE’2015), Pattaya, Thailand, 24 April 2015. [Google Scholar]

- Ghernouti, Y.; Rabehi, B. FRP-Confined Short Concrete Columns under Compressive Loading: Experimental and Modeling Investigation. J. Reinf. Plast. Compos. 2010, 30, 241–255. [Google Scholar] [CrossRef]

- Benzaid, R.; Mesbah, H. Nasr Eddine Chikh FRP-Confined Concrete Cylinders: Axial Compression Experiments and Strength Model. J. Reinf. Plast. Compos. 2010, 29, 2469–2488. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A. Compressive Strength Models of FRP-Confined Concrete. In Proceedings of the 1st Asia-Pacific Conference on FRP in Structures, APFIS 2007, Hong Kong, China, 12–14 December 2007; Volume 1, pp. 175–180. [Google Scholar]

- Bisby, L.A.; Dent, A.J.S.; Green, M.F. Comparison of Confinement Models for Fiber-Reinforced Polymer-Wrapped Concrete. ACI Struct. J. 2005, 102, 62–72. [Google Scholar] [CrossRef]

- Wu, H.-L.; Wang, Y.-F.; Yu, L.; Li, X.-R. Experimental and Computational Studies on High-Strength Concrete Circular Columns Confined by Aramid Fiber-Reinforced Polymer Sheets. J. Compos. Constr. 2009, 13, 125–134. [Google Scholar] [CrossRef]

- Teng, J.G.; Huang, Y.L.; Lam, L.; Ye, L.P. Theoretical Model for Fiber-Reinforced Polymer-Confined Concrete. J. Compos. Constr. 2007, 11, 201–210. [Google Scholar] [CrossRef]

- Ahmad, S.H.; Shah, S.P. Complete Triaxial Stress-Strain Curves for Concrete. J. Struct. Div. 1982, 108, 728–742. [Google Scholar] [CrossRef]

- Hussain, Q.; Rattanapitikon, W.; Pimanmas, A. Axial Load Behavior of Circular and Square Concrete Columns Confined with Sprayed Fiber-Reinforced Polymer Composites. Polym. Compos. 2016, 37, 2557–2567. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Gao, Y. Composite Jacketed Concrete under Uniaxial Compression—Verification of Simple Design Equations. J. Mater. Civ. Eng. 1997, 9, 185–193. [Google Scholar] [CrossRef]

- Samaan, M.; Mirmiran, A.; Shahawy, M. Model of Concrete Confined by Fiber Composites. J. Struct. Eng. 1998, 124, 1025–1031. [Google Scholar] [CrossRef]

- Saafi, M.; Toutanji, H.A.; Li, Z. Behavior of Concrete Columns Confined with Fiber Reinforced Polymer Tubes. ACI Mater. J. 1999, 96, 500–509. [Google Scholar] [CrossRef]

- Ilki, A.; Kumbasar, N. Behavior of Damaged and Un-Damaged Concrete Strengthened by Carbon Fiber Composite Sheets. Int. J. Struct. Eng. Mech. 2002, 13, 75–90. [Google Scholar] [CrossRef]

- Spoelstra, M.R.; Monti, G. FRP-Confined Concrete Model. J. Compos. Constr. 1999, 3, 143–150. [Google Scholar] [CrossRef]

- Mirmiran, A.; Shahawy, M. Behavior of Concrete Columns Confined by Fiber Composites. J. Struct. Eng. 1997, 123, 583–590. [Google Scholar] [CrossRef]

- Pimanmas, A.; Hussain, Q.; Panyasirikhunawut, A.; Rattanapitikon, W. Axial Strength and Deformability of Concrete Confined with Natural Fibre-Reinforced Polymers. Mag. Concr. Res. 2018, 71, 55–70. [Google Scholar] [CrossRef]

- Yan, L. Plain Concrete Cylinders and Beams Externally Strengthened with Natural Flax Fabric Reinforced Epoxy Composites. Mater. Struct./Mater. Et Constr. 2016, 49, 2083–2095. [Google Scholar] [CrossRef]

- Pimanmas, A.; Saleem, S. Evaluation of Existing Stress–Strain Models and Modeling of PET FRP–Confined Concrete. J. Mater. Civ. Eng. 2019, 31, 04019303. [Google Scholar] [CrossRef]

| Group | Specimen | Strength (MPa) | Layers of Hemp RFRP |

|---|---|---|---|

| A | CIR-LSC-CNT-01 | Low strength concrete | - |

| CIR-LSC-CNT-02 | Low strength concrete | - | |

| CIR-LSC-1HR-01 | Low strength concrete | 1 | |

| CIR-LSC-1HR-02 | Low strength concrete | 1 | |

| CIR-LSC-2HR-01 | Low strength concrete | 2 | |

| CIR-LSC-2HR-02 | Low strength concrete | 2 | |

| CIR-LSC-3HR-01 | Low strength concrete | 3 | |

| CIR-LSC-3HR-02 | Low strength concrete | 3 | |

| B | CIR-HSC-CNT-01 | High strength concrete | - |

| CIR-HSC-CNT-02 | High strength concrete | - | |

| CIR-HSC-1HR-01 | High strength concrete | 1 | |

| CIR-HSC-1HR-02 | High strength concrete | 1 | |

| CIR-HSC-2HR-01 | High strength concrete | 2 | |

| CIR-HSC-2HR-02 | High strength concrete | 2 | |

| CIR-HSC-3HR-01 | High strength concrete | 3 | |

| CIR-HSC-3HR-02 | High strength concrete | 3 |

| Low Strength Concrete (15 MPa) | High Strength Concrete (35 MPa) | |

|---|---|---|

| Cement | 242 | 444 |

| Fine aggregates | 726 | 605 |

| Natural coarse aggregates | 605 | 504 |

| Clay brick aggregates | 605 | 504 |

| Property | Value |

|---|---|

| Ultimate Elongation (%) | 2.5 |

| Flexural Strength (MPa) | 75 |

| Tensile Strength (MPa) | 50 |

| Curing Time (hours) | 6–10 |

| Group | Specimen | Ultimate Stress (MPa) | Increase in Ultimate Stress (%) | Ultimate Strain | Increase in Ultimate Strain (%) |

|---|---|---|---|---|---|

| A | CIR-LSC-CNT | 13.02 | - | 0.0044 | - |

| CIR-LSC-1HR | 23.77 | 83 | 0.0187 | 321 | |

| CIR-LSC-2HR | 33.39 | 157 | 0.0256 | 477 | |

| CIR-LSC-3HR | 40.18 | 209 | 0.0283 | 539 | |

| B | CIR-HSC-CNT | 24.34 | - | 0.0041 | - |

| CIR-HSC-1HR | 36.22 | 49 | 0.0132 | 219 | |

| CIR-HSC-2HR | 43.58 | 79 | 0.0193 | 368 | |

| CIR-HSC-3HR | 56.03 | 130 | 0.0229 | 454 |

| Model | ||||||||

|---|---|---|---|---|---|---|---|---|

| Group #1 | Group #2 | Group #1 | Group #2 | |||||

| AAR (%) | AR | AAR (%) | AR | AAR (%) | AR | AAR (%) | AR | |

| Richart et al. [55] | 34.93 | 0.90 | 22.30 | 0.75 | 88.66 | 2.83 | 18.54 | 1.88 |

| Ghernouti and Rabehi [59] | 11.78 | 0.88 | 11.30 | 0.89 | 29.53 | 1.27 | 11.81 | 0.95 |

| Benzaid et al. [60] | 8.11 | 0.92 | 8.66 | 0.91 | 15.84 | 1.16 | 3.37 | 0.98 |

| Al-Salloum [61] | 5.58 | 0.94 | 6.83 | 0.93 | 81.00 | 0.19 | 76.27 | 0.24 |

| Bisby et al. [62] | 4.39 | 0.97 | 6.83 | 0.95 | - | - | - | - |

| Wu et al. [63] | 14.55 | 1.14 | 7.63 | 1.07 | 23.53 | 1.17 | 12.84 | 0.88 |

| Teng et al. [64] | 21.34 | 1.21 | 12.52 | 1.12 | 82.35 | 1.83 | 24.66 | 1.18 |

| Ahmad and Shah [65] | 38.45 | 1.38 | 24.83 | 1.24 | - | - | - | - |

| Hussain et al. [66] | 87.03 | 1.87 | 59.77 | 1.59 | - | - | - | - |

| Karbhari and Gao [67] | 6.97 | 0.93 | 4.81 | 0.95 | - | - | - | - |

| Samaan et al. [68] | 16.23 | 1.16 | 8.60 | 1.08 | - | - | - | - |

| Miyauchi et al. [56] | 21.34 | 1.21 | 12.52 | 1.12 | 73.95 | 1.74 | 76.77 | 1.77 |

| Saafi et al. [69] | 3.66 | 0.96 | 3.15 | 0.98 | - | - | - | - |

| Ilki and Kumbasar [70] | 7.50 | 0.92 | 8.22 | 0.92 | 98.09 | 1.98 | 63.68 | 1.64 |

| Spoelstra and Monti [71] | 1.51 | 0.99 | 4.45 | 0.99 | 64.31 | 0.36 | 61.03 | 0.39 |

| Mirmiran [72] | 15.73 | 0.84 | 14.35 | 0.86 | - | - | - | - |

| Pimanmas et al. [73] | 10.01 | 1.10 | 4.99 | 1.04 | 10.74 | 1.06 | 7.42 | 0.93 |

| Yan [74] | 15.81 | 0.84 | 14.35 | 0.86 | - | - | - | - |

| Hussain et al. [43] | 4.23 | 1.03 | 2.86 | 0.99 | 40.48 | 1.40 | 14.95 | 1.15 |

| [41,58,59,60,65,67,68,69] | [41,58,59,60,61,65,66,67,68,69,71] | N/A | [58,71] | |||||

| [41,58,59,60,65,67,68,69] | [41,58,59,60,61,65,66,67,68,69,71] | [71] | [57,58,71] | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joyklad, P.; Yooprasertchai, E.; Rahim, A.; Ali, N.; Chaiyasarn, K.; Hussain, Q. Sustainable and Low-Cost Hemp FRP Composite Confinement of B-Waste Concrete. Sustainability 2022, 14, 7673. https://doi.org/10.3390/su14137673

Joyklad P, Yooprasertchai E, Rahim A, Ali N, Chaiyasarn K, Hussain Q. Sustainable and Low-Cost Hemp FRP Composite Confinement of B-Waste Concrete. Sustainability. 2022; 14(13):7673. https://doi.org/10.3390/su14137673

Chicago/Turabian StyleJoyklad, Panuwat, Ekkachai Yooprasertchai, Abdur Rahim, Nazam Ali, Krisada Chaiyasarn, and Qudeer Hussain. 2022. "Sustainable and Low-Cost Hemp FRP Composite Confinement of B-Waste Concrete" Sustainability 14, no. 13: 7673. https://doi.org/10.3390/su14137673

APA StyleJoyklad, P., Yooprasertchai, E., Rahim, A., Ali, N., Chaiyasarn, K., & Hussain, Q. (2022). Sustainable and Low-Cost Hemp FRP Composite Confinement of B-Waste Concrete. Sustainability, 14(13), 7673. https://doi.org/10.3390/su14137673