A Review on Fault Diagnosis Technology of Key Components in Cold Ironing System

Abstract

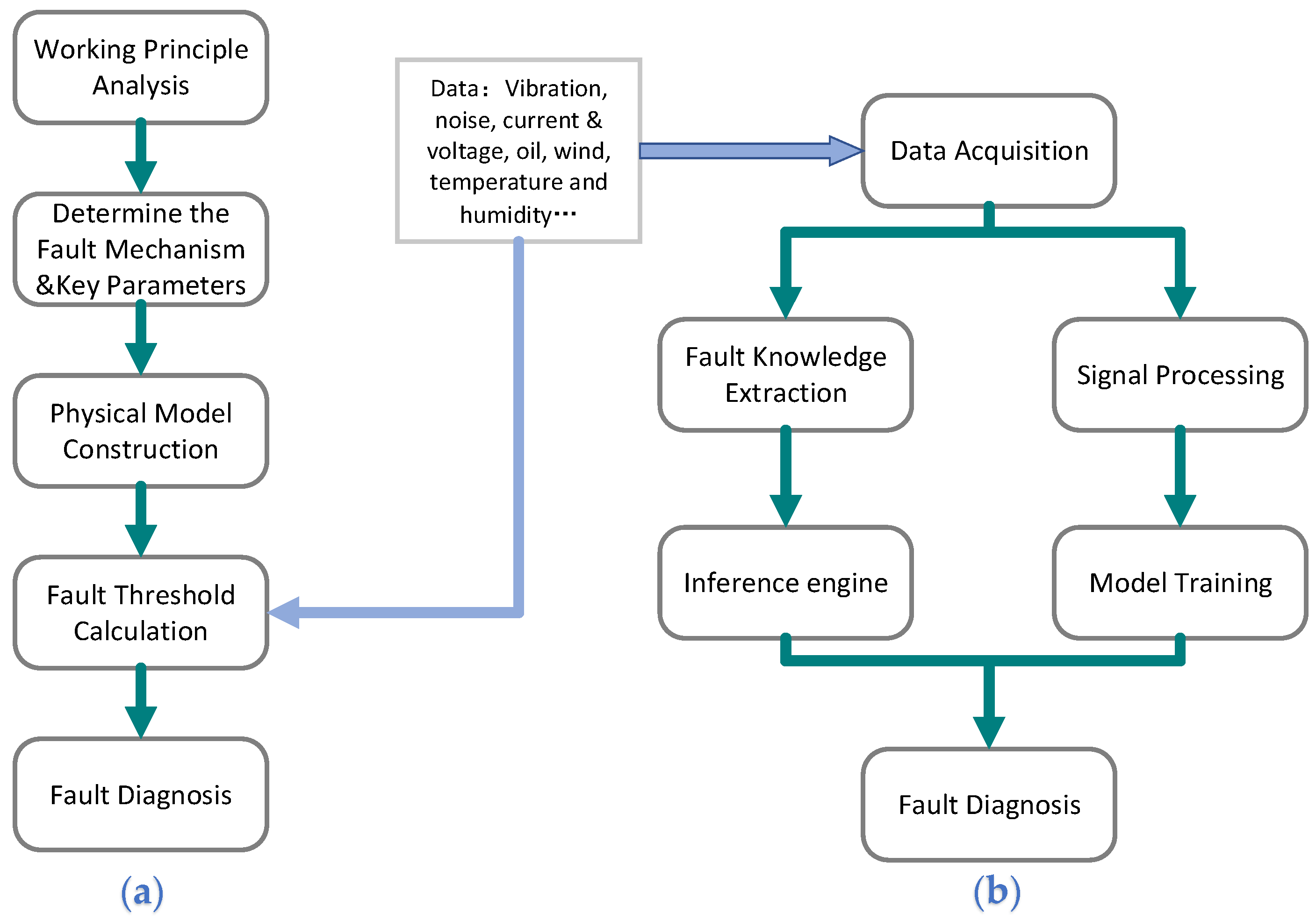

:1. Introduction

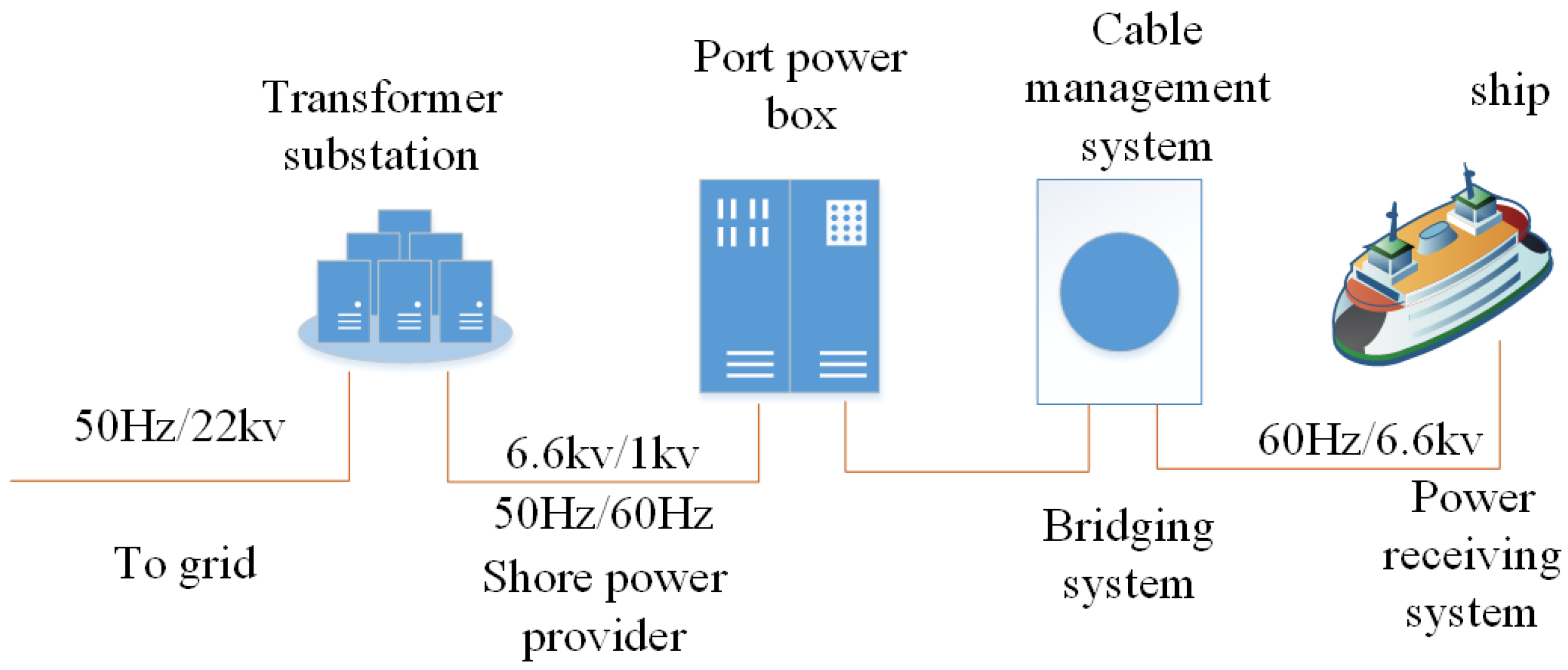

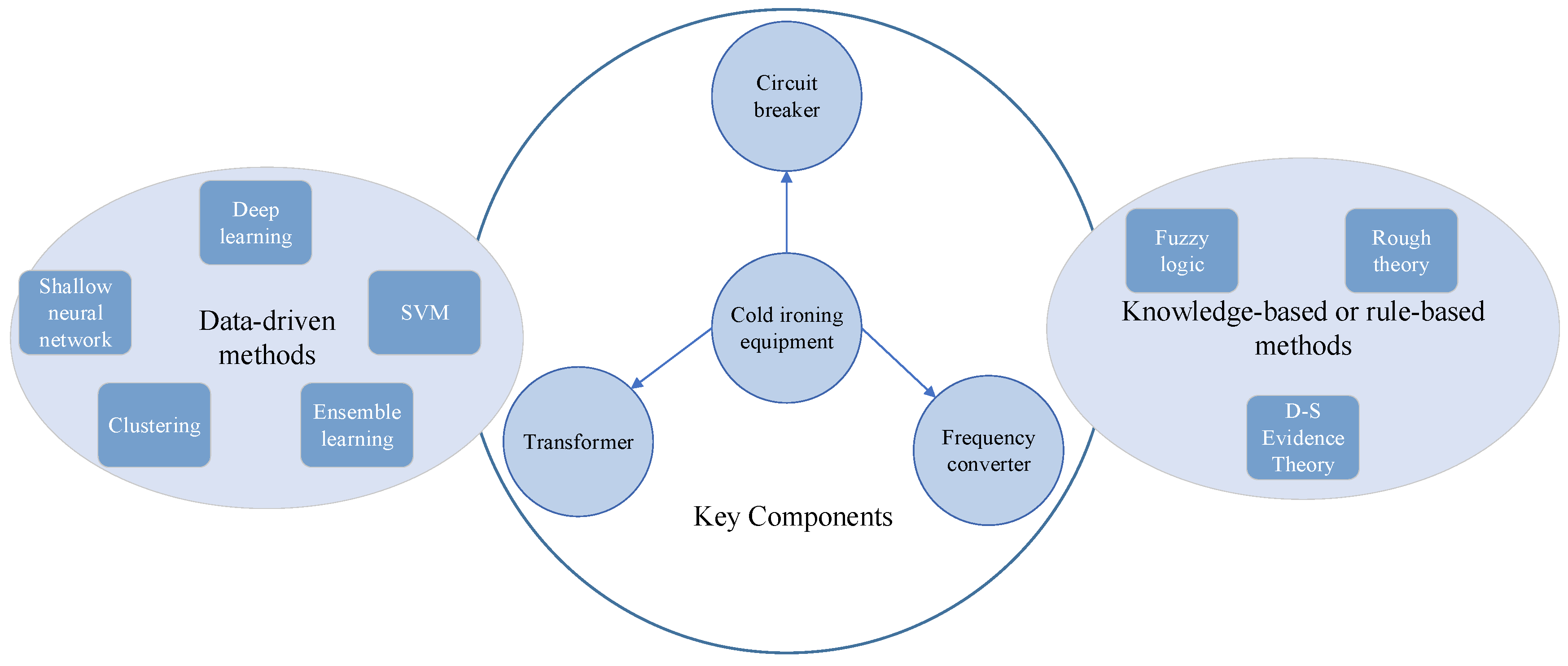

2. Introduction of Key Components in Cold Ironing System and Fault Diagnosis Technology

2.1. Key Components in Cold Ironing System

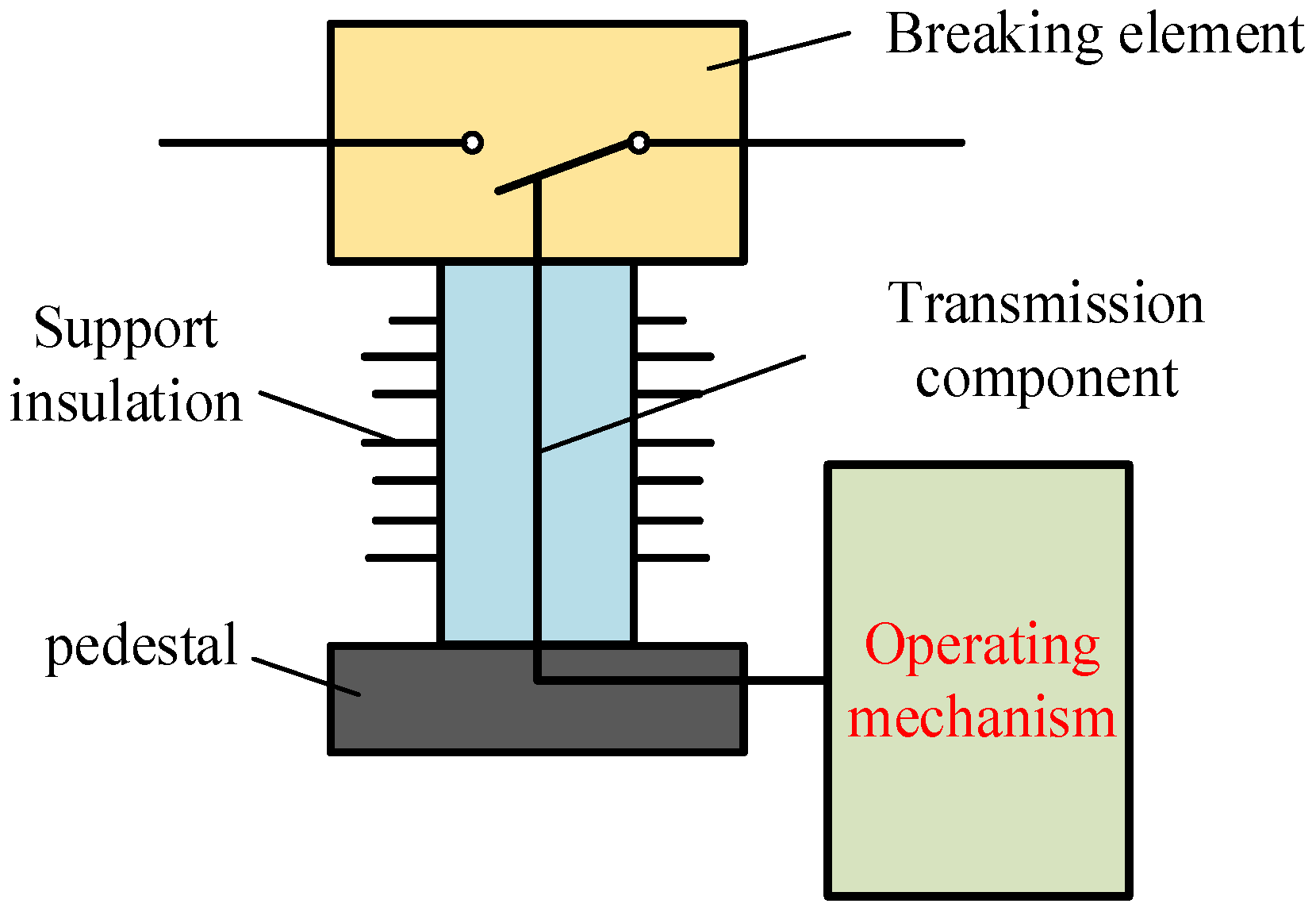

2.1.1. Circuit Breaker

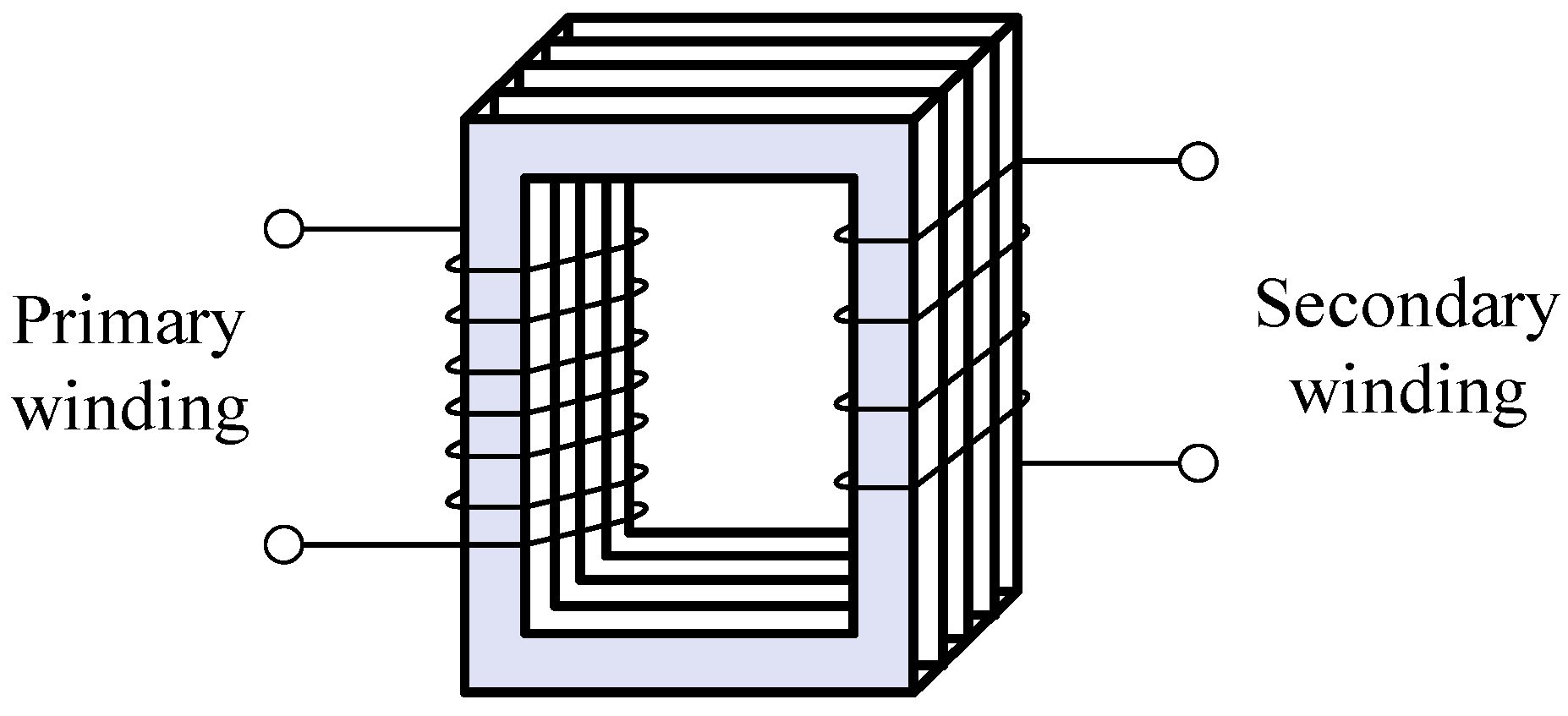

2.1.2. Transformer

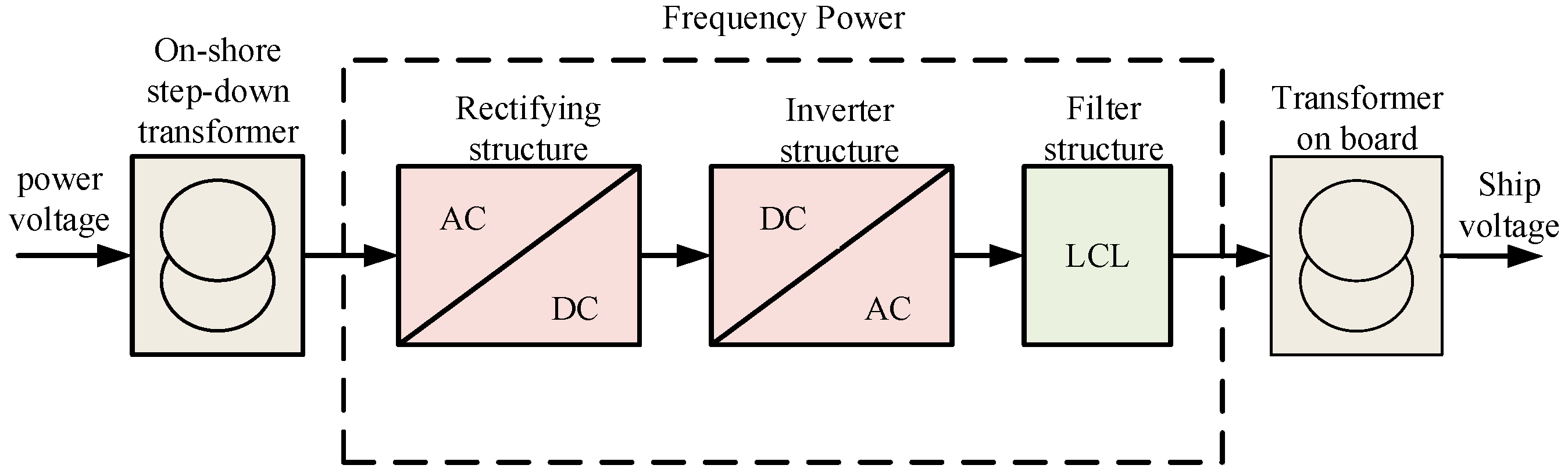

2.1.3. Frequency Converter

2.2. Fault Diagnosis Technology

2.2.1. Data-Driven Methods

- (1)

- Clustering

- (2)

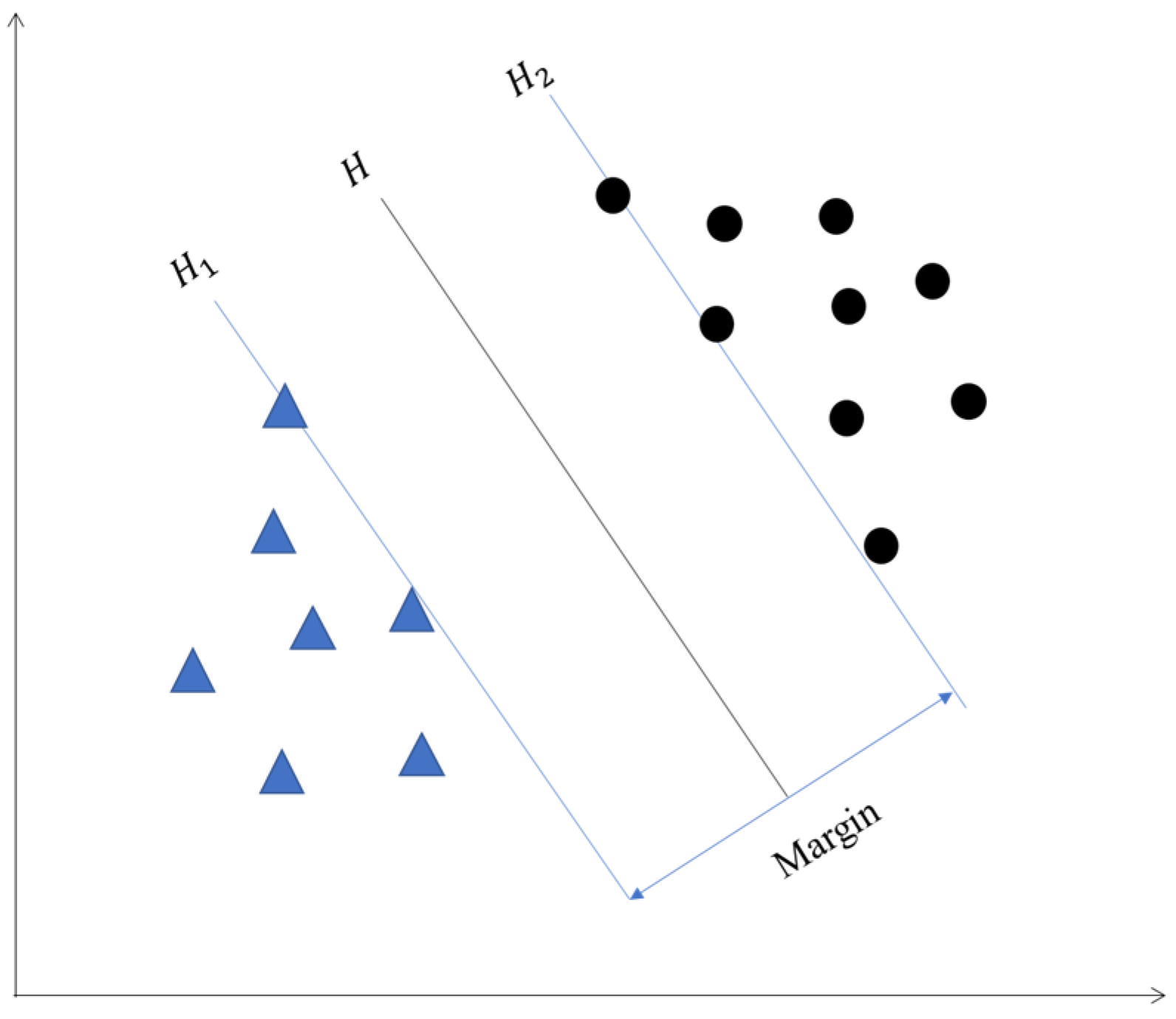

- Support vector machine (SVM)

- (3)

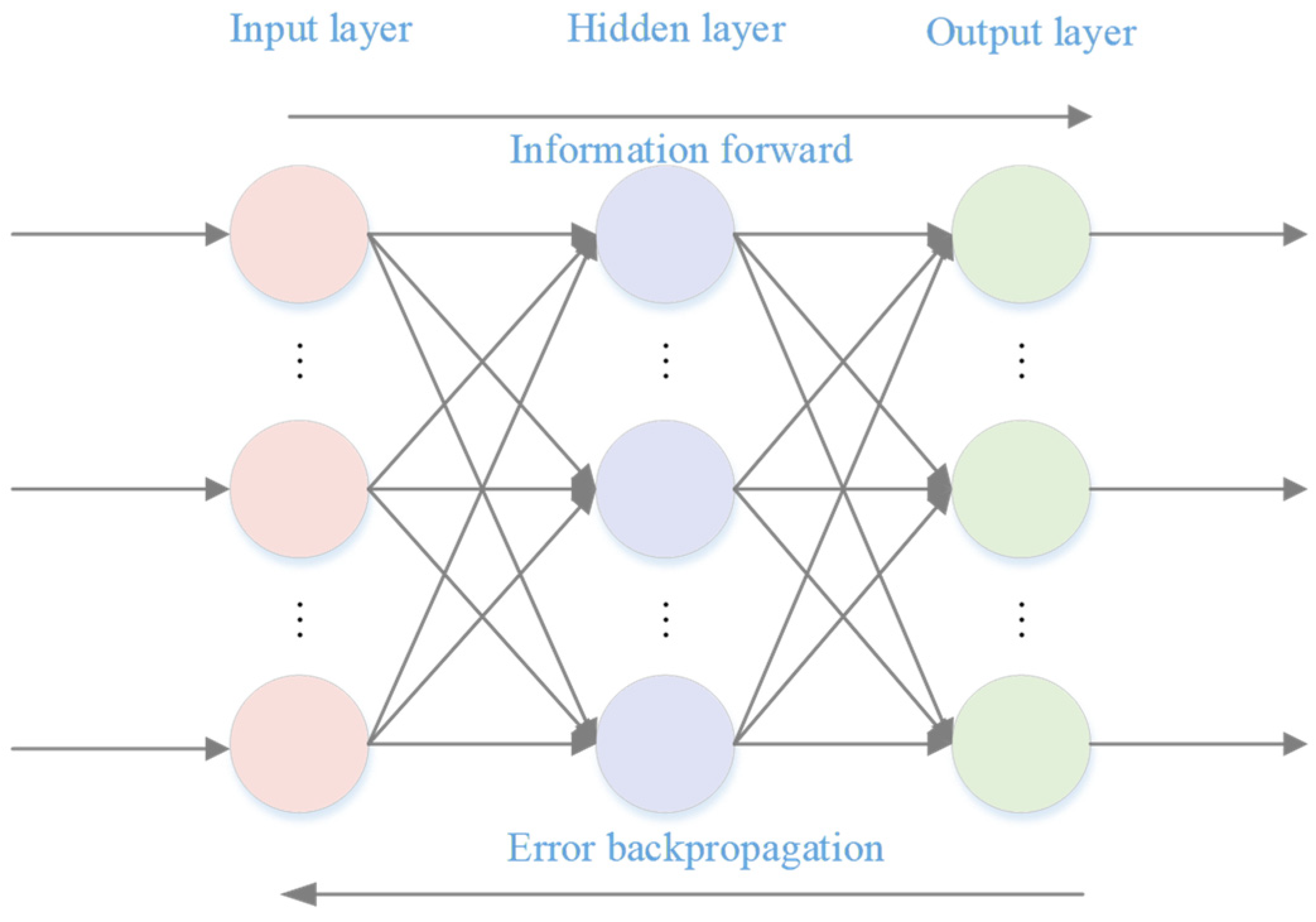

- Shallow neural network

- BP neural network

- 2.

- Extreme learning machine (ELM)

- (a)

- Determine the number of neurons in the hidden layer, the activation function and the connection weight between the input layer and the hidden layer as well as the threshold of the neurons in the hidden layer.

- (b)

- Calculate the output matrix of the hidden layer.

- (c)

- Calculate the weight of the output layer.

- (4)

- Ensemble learning (EL)

- Given a training set , together with the category label ,,…,, where , denotes the number of samples in the training set. Then, the original training set is resampled to generate new training sets {,,…,}, and the corresponding label sets are {,,…,}.

- Based on {,,…,} and {,,…,}, complete decision trees {,,…,} are generated. During the construction of each decision tree, each node performs a random selection of the feature subsets.

- Finally, the decision results of the test samples are obtained by the majority voting method.

- (5)

- Deep Learning (DL)

- (1)

- CNN

- (2)

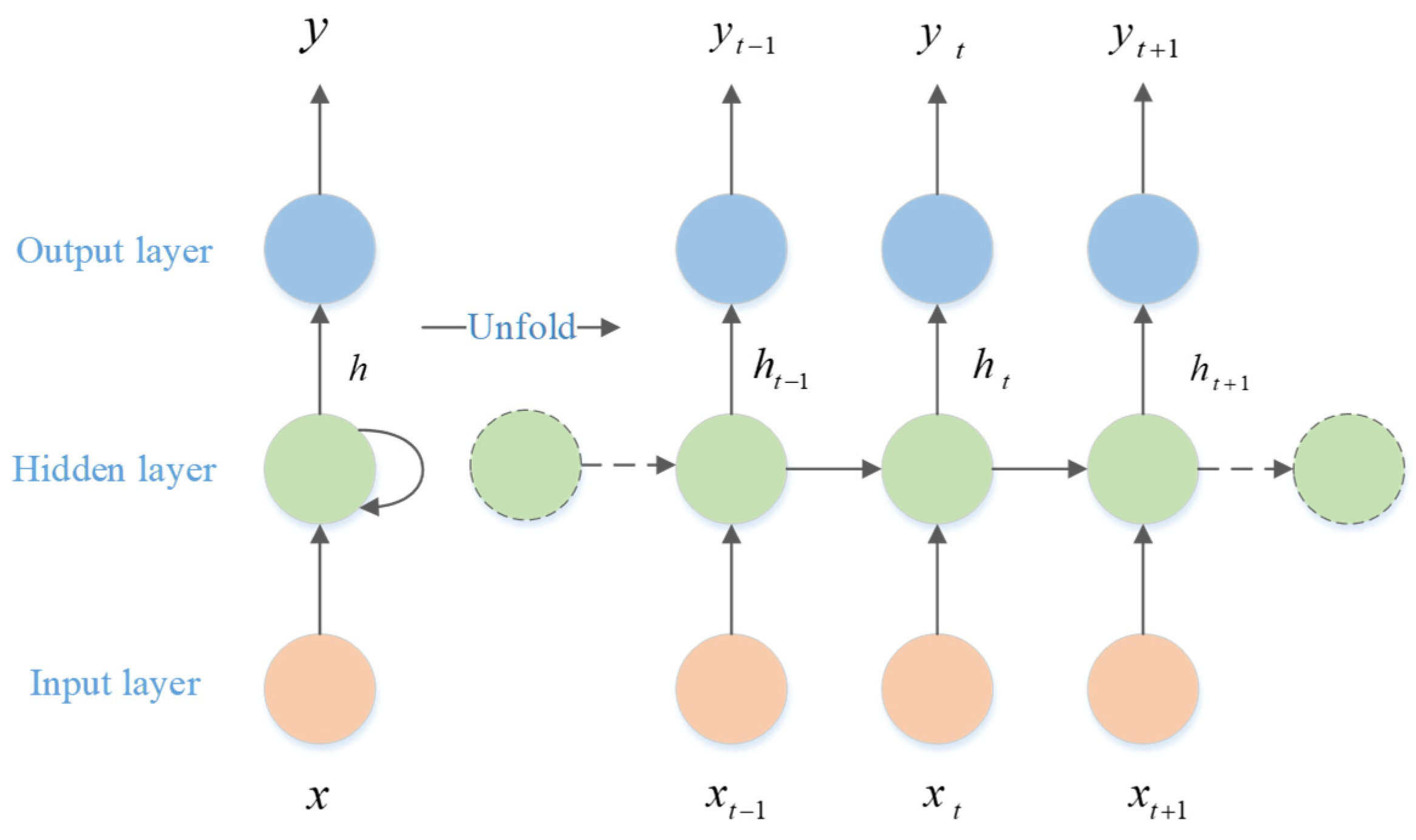

- RNN

2.2.2. Knowledge-Based or Rule-Based Methods

- (1)

- Fuzzy logic (FL)

- (2)

- Rough Set Theory (RST)

- (3)

- D-S evidence theory

2.2.3. Comparison of Fault Diagnosis Methods

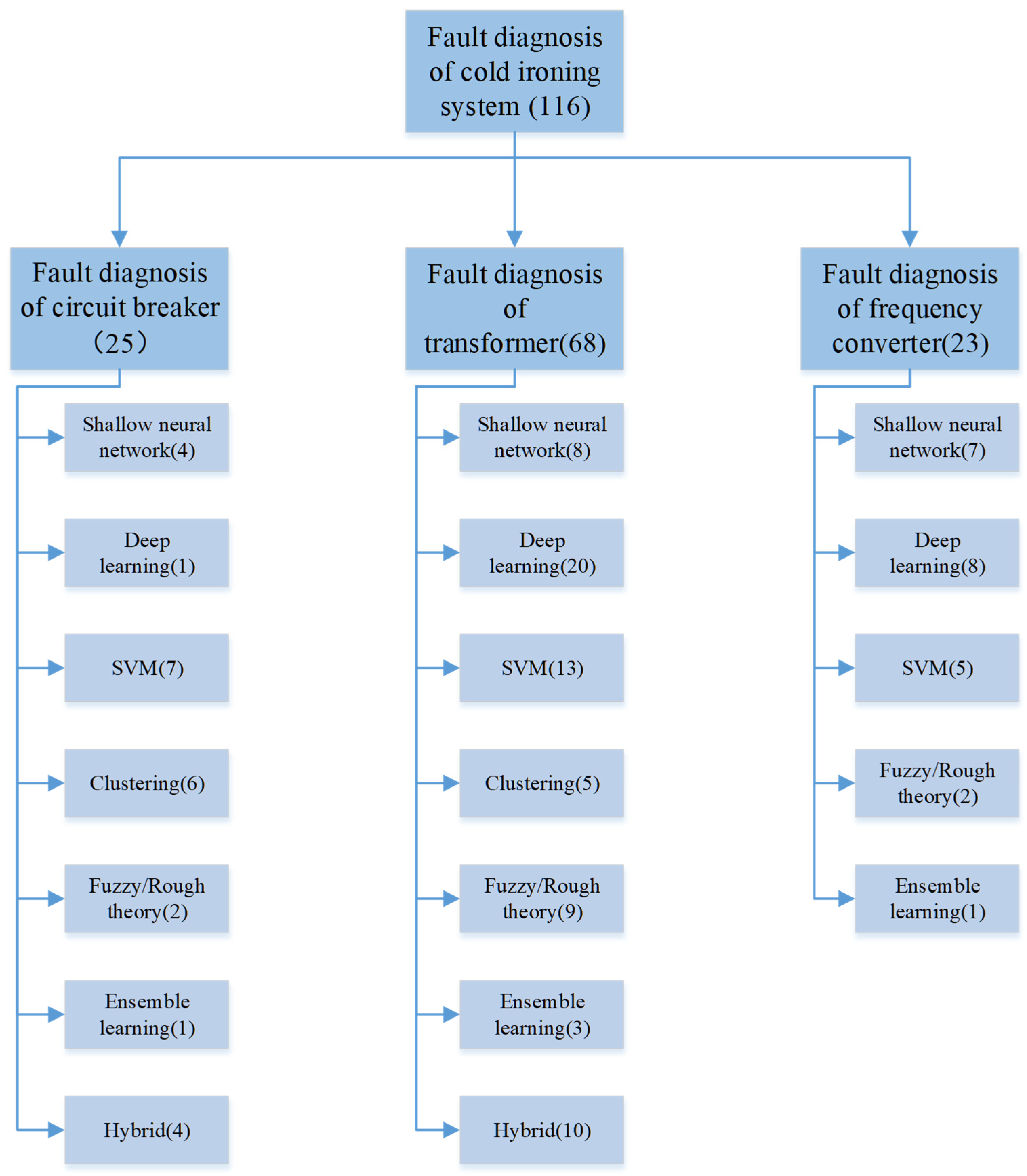

3. Fault Diagnosis of Key Components in Cold Ironing System

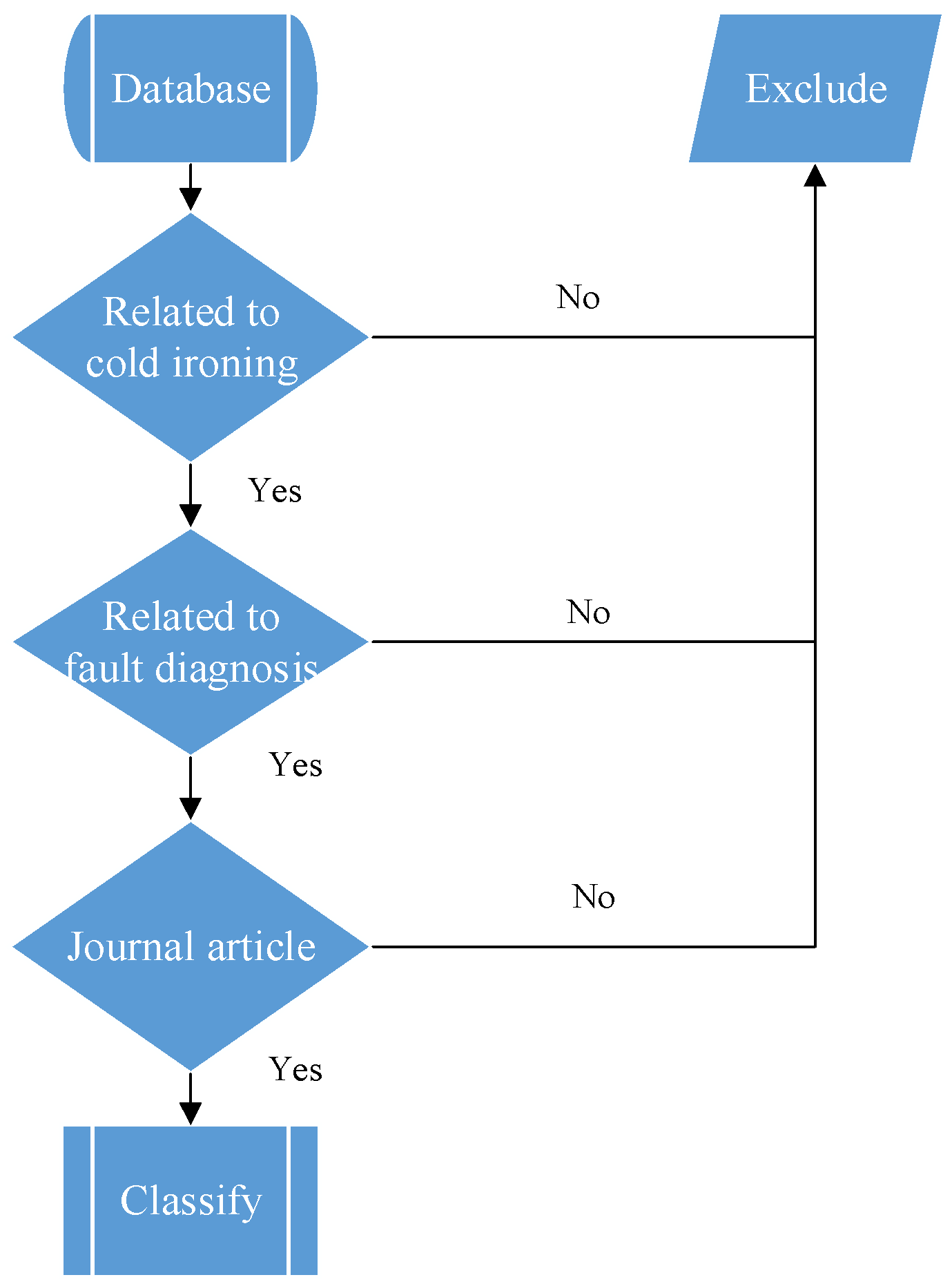

3.1. Distribution of Articles by Key Component in Cold Ironing System and Fault Diagnosis Technology

3.2. Application of Fault Diagnosis Methods to Key Components in Cold Ironing System

3.2.1. Fault Diagnosis of Circuit Breaker

3.2.2. Fault Diagnosis of Transformer

3.2.3. Fault Diagnosis of Frequency Converter

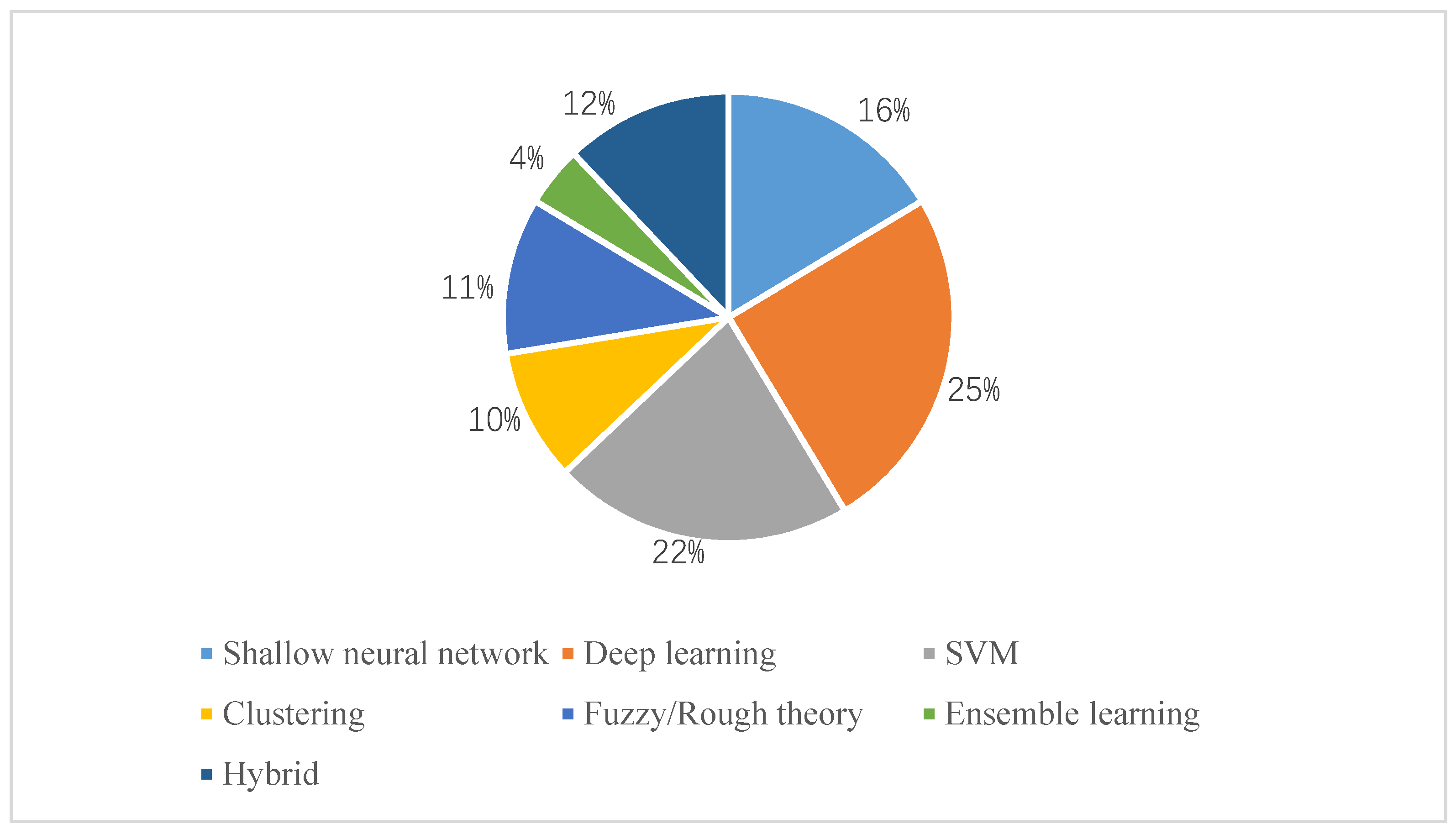

3.3. Distribution of Articles by Fault Diagnosis Technology

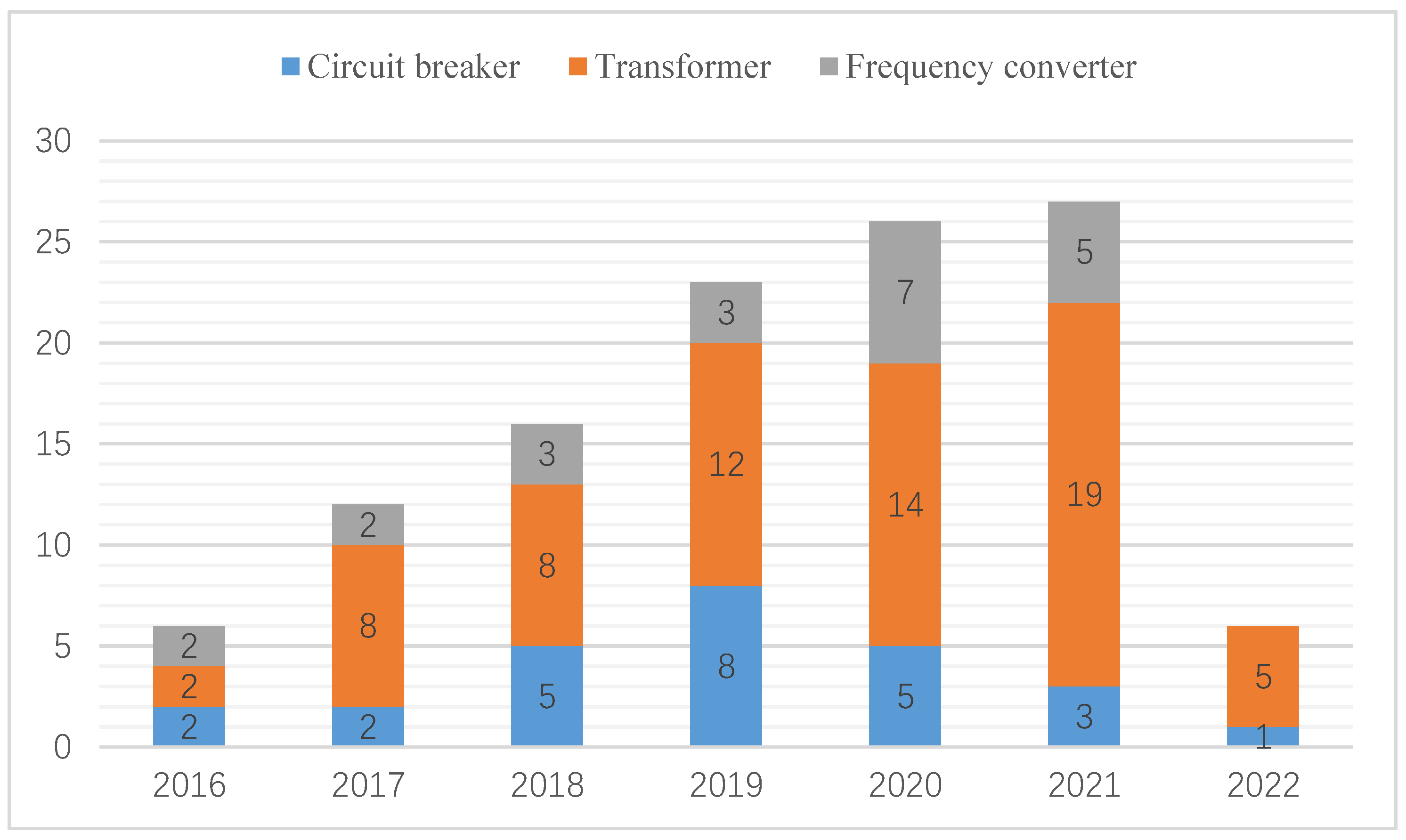

3.4. Distribution of Articles by Component Type and Publication Year

4. Conclusions

- (1)

- The fault diagnosis technology based on artificial intelligence and the real-time diagnosis of cold ironing equipment from the perspective of condition monitoring will still be the focus of future work. Although this idea can make full use of the collected data and dispense with the analysis of the complex working environment of ports to some extent, it should be noted that the complex port environment may give rise to some special types of failures, which are difficult to reveal under normal conditions. If the failure datasets cannot take these kinds of failures into account, it is highly possible that the research work may risk falling into a "false boom" of high precision results while ignoring the catastrophic consequences caused by rare failures. Therefore, the capability of distinguishing unknown faults is necessary for the intelligent fault diagnosis algorithm design with an emphasis on the key components in a cold ironing system. On this basis, improving the recognition rate of the unknown faults is also a key direction in the future.

- (2)

- As an effective way to solve the problems of imbalanced samples and label missing, deep transfer learning is worthy to be explored for the fault diagnosis of cold ironing systems. From our study, there are many research works studying the fault diagnosis of circuit breakers, transformers and frequency converters in general scenarios, while the research targeting the components used in a cold ironing system is relatively sparse. Focusing on this special application scenario, the problem of insufficient samples is nonnegligible. Transfer learning can help with taking advantage of various types of data to discover the "invariants" so as to achieve satisfactory diagnosis accuracy in the case of small samples. The combination of transfer learning and deep learning can make a more ideal fault recognizer.

- (3)

- A distributed fault diagnosis algorithm design based on deep learning is another challenging direction in the future. In the research of equipment fault diagnosis, there are various basic methods (such as DGA, FRA and vibration signal in transformer), while different methods often have their own advantages and limitations. Based on a clear understanding of the fault diagnosis equipment, we can construct distributed diagnosis models for the main components of the equipment, which can be integrated into a fault diagnosis model for the whole equipment by applying EL or hybrid methods. The distributed fault diagnosis models can make full use of the advantages of different methods so as to further improve the diagnosis effect of the equipment and give full play to the advantages of multi-source data.

Author Contributions

Funding

Conflicts of Interest

References

- Innes, A.; Monios, J. Identifying the unique challenges of installing cold ironing at small and medium ports—The case of aberdeen. Transp. Res. Part D Transp. Environ. 2018, 62, 298–313. [Google Scholar] [CrossRef]

- Adamo, F.; Andria, G.; Cavone, G.; DE Capua, C.; Lanzolla, A.M.L.; Morello, R.; Spadavecchia, M. Estimation of ship emissions in the port of Taranto. Measurement 2014, 47, 982–988. [Google Scholar] [CrossRef]

- Rolan, A.; Manteca, P.; Oktar, R.; Siano, P. Integration of Cold Ironing and Renewable Sources in the Barcelona Smart Port. IEEE Trans. Ind. Appl. 2019, 55, 7198–7206. [Google Scholar] [CrossRef]

- Ballini, F.; Bozzo, R. Air pollution from ships in ports: The socio-economic benefit of cold-ironing technology. Res. Transp. Bus. Manag. 2015, 17, 92–98. [Google Scholar] [CrossRef]

- McArthur, D.P.; Osland, L. Ships in a city harbour: An economic valuation of atmospheric emissions. Transp. Res. Part D Transp. Environ. 2013, 21, 47–52. [Google Scholar] [CrossRef]

- Chang, C.-C.; Wang, C.-M. Evaluating the effects of green port policy: Case study of Kaohsiung harbor in Taiwan. Transp. Res. Part D Transp. Environ. 2012, 17, 185–189. [Google Scholar] [CrossRef]

- Reusser, C.A.; Pérez, J.R. Evaluation of the Emission Impact of Cold-Ironing Power Systems, Using a Bi-Directional Power Flow Control Strategy. Sustainability 2020, 13, 334. [Google Scholar] [CrossRef]

- Cho, H.; Luck, R.; Chamra, L.M. Technical and Economical Analysis of a Micro-CHP Facility Based on Dynamic Simulation: A Case Study. In Proceedings of the ASME 2007 International Mechanical Engineering Congress and Exposition, Seattle, WA, USA, 11–15 November 2007; pp. 63–72. [Google Scholar] [CrossRef]

- Cannon, C.; Gao, Y.; Wunder, L. Port of Los Angeles—Shanghai Municipal Transportation Commission EcoPartnership on shore power. J. Renew. Sustain. Energy 2015, 7, 041507. [Google Scholar] [CrossRef]

- Men, Z.; Gu, W.; Gao, N.; Ma, L.; Wu, Y.; Xu, K.; Zhang, N.; Han, Z. Design of Cold Ironing System in Dalian Port. Electr. Appl. 2020, 39, 66–69. [Google Scholar]

- Zis, T.P. Prospects of cold ironing as an emissions reduction option. Transp. Res. Part A Policy Pract. 2018, 119, 82–95. [Google Scholar] [CrossRef] [Green Version]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.S. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Mcculloch, W.S.; Pitts, W. A Logical Calculus of the Ideas Immanent in Nervous Activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Rosenblatt, F. The perceptron: A probabilistic model for information storage and organization in the brain. Psychol. Rev. 1958, 65, 386–408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- White, B.W.; Rosenblatt, F. Principles of Neurodynamics: Perceptrons and the Theory of Brain Mechanisms. Am. J. Psychol. 1963, 76, 705–707. [Google Scholar] [CrossRef] [Green Version]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Huang, G.-B.; Zhu, Q.-Y.; Siew, C.-K. Extreme learning machine: A new learning scheme of feedforward neural networks. In Proceedings of the 2004 IEEE International Joint Conference on Neural Networks (IEEE Cat. No.04CH37541), Budapest, Hungary, 25–29 July 2004. [Google Scholar]

- Huang, G.-B.; Zhu, Q.-Y.; Siew, C.-K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Breiman, L. Bagging predictors. Mach. Learn. 1996, 24, 123–140. [Google Scholar] [CrossRef] [Green Version]

- Freund, Y.; Schapire, R.E. Experiments with a New Boosting Algorithm. In Proceedings of the Thirteenth International Conference on International Conference on Machine Learning, San Francisco, CA, USA, 3–6 July 1996; pp. 148–156. [Google Scholar]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar]

- Jerome, H.F. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar]

- Hinton, G.E.; Salakhutdinov, R.R. Reducing the Dimensionality of Data with Neural Networks. Science 2006, 313, 504–507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, K.; Jia, L.; Chen, Y.; Xu, W. Deep Learning: Yesterday, Today, and Tomorrow. J. Comp. Res. Develop. 2013, 20, 1349. [Google Scholar]

- Erhan, D.; Courville, A.; Bengio, Y.; Vincent, P. Why Does Unsupervised Pre-training Help Deep Learning? J. Mach. Learn. Res. 2010, 11, 625–660. [Google Scholar]

- Bengio, Y. Learning Deep Architectures for AI. Found. Trends Mach. Learn. 2009, 2, 1–127. [Google Scholar] [CrossRef]

- Lecun, Y.A.; Bengio, Y.O. Convolutional Networks for Images, Speech, and Time Series; MIT Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Chen, L.; Wan, S. Intelligent fault diagnosis of high-voltage circuit breakers using triangular global alignment kernel extreme learning machine. ISA Trans. 2020, 109, 368–379. [Google Scholar] [CrossRef]

- Gao, W.; Wai, R.-J.; Qiao, S.-P.; Guo, M.-F. Mechanical Faults Diagnosis of High-Voltage Circuit Breaker via Hybrid Features and Integrated Extreme Learning Machine. IEEE Access 2019, 7, 60091–60103. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, N. Fault diagnosis model of adaptive miniature circuit breaker based on fractal theory and probabilistic neural network. Mech. Syst. Signal Process. 2020, 142, 106772. [Google Scholar] [CrossRef]

- Liu, M.; Li, B.; Zhang, J.; Wang, K. An application of ensemble empirical mode decomposition and correlation dimension for the HV circuit breaker diagnosis. Automatika 2019, 60, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Ruan, J.; Zhuang, Z.; Huang, D. Condition Evaluation for Opening Damper of Spring Operated High-Voltage Circuit Breaker Using Vibration Time-Frequency Image. IEEE Sens. J. 2019, 19, 8116–8126. [Google Scholar] [CrossRef]

- Rudsari, F.N.; Kazemi, A.A.R.; Shoorehdeli, M.A. Fault Analysis of High-Voltage Circuit Breakers Based on Coil Current and Contact Travel Waveforms Through Modified SVM Classifier. IEEE Trans. Power Deliv. 2019, 34, 1608–1618. [Google Scholar] [CrossRef]

- Huang, N.; Chen, H.; Cai, G.; Fang, L.; Wang, Y. Mechanical Fault Diagnosis of High Voltage Circuit Breakers Based on Variational Mode Decomposition and Multi-Layer Classifier. Sensors 2016, 16, 1887. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, S.; Wang, E. Fault Diagnosis of Circuit Breaker Energy Storage Mechanism Based on Current-Vibration Entropy Weight Characteristic and Grey Wolf Optimization–Support Vector Machine. IEEE Access 2019, 7, 86798–86809. [Google Scholar] [CrossRef]

- Miao, D. Research on Fault Diagnosis of High-Voltage Circuit Breaker Based on Support Vector Machine. Int. J. Pattern Recognit. Artif. Intell. 2019, 33, 1959019. [Google Scholar] [CrossRef]

- Dou, L.; Wan, S.; Zhan, C. Application of Multiscale Entropy in Mechanical Fault Diagnosis of High Voltage Circuit Breaker. Entropy 2018, 20, 325. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, L.; Wang, B.; Qi, J.; Chen, L.; Huang, N. A Novel Mechanical Fault Feature Selection and Diagnosis Approach for High-Voltage Circuit Breakers Using Features Extracted without Signal Processing. Sensors 2019, 19, 288. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Li, Y. A novel data-driven method for maintenance prioritization of circuit breakers based on the ranking SVM. Int. J. Electr. Power Energy Syst. 2021, 129, 106779. [Google Scholar] [CrossRef]

- Zhu, K.; Mei, F.; Zheng, J. Adaptive fault diagnosis of HVCBs based on P-SVDD and P-KFCM. Neurocomputing 2017, 240, 127–136. [Google Scholar] [CrossRef]

- Ji, T.; Ye, X.; Shi, M.; Li, M.; Wu, Q. Typical current modelling and feature extraction of high voltage circuit breaker towards condition analysis and fault diagnosis. IET Gener. Transm. Distrib. 2020, 14, 1521–1527. [Google Scholar] [CrossRef]

- Lu, Y.; Li, Y. A novel fault diagnosis method for circuit breakers based on optimized affinity propagation clustering. Int. J. Electr. Power Energy Syst. 2020, 118, 105651. [Google Scholar] [CrossRef]

- He, M.Y.; Ding, Q.; Zhao, S.; Yao, W. Research of circuit breaker intelligent fault diagnosis method based on double clustering. IEICE Electron. Express 2017, 14, 20170463. [Google Scholar]

- Xia, X.F.; Lu, Y.F.; Su, Y.; Yang, J. Research on the Mechanical Fault Diagnosis Method for Circuit Breakers Based on KFCM. In Proceedings of the 2020 6th International Conference on Energy Materials and Environment Engineering, Dali, China, 17–19 July 2020. [Google Scholar]

- Wan, S.; Dou, L.; Li, C.; Ma, X. Fault diagnosis for high voltage circuit breaker based on timing parameters and FCM. IEICE Electron. Express 2018, 15, 20180227. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Yue, S.; Zha, X. Method of power grid fault diagnosis using intuitionistic fuzzy Petri nets. IET Gener. Transm. Distrib. 2018, 12, 295–302. [Google Scholar] [CrossRef]

- Kaluđer, S.; Fekete, K.; Jozsa, L.; Klaić, Z. Fault diagnosis and identification in the distribution network using the fuzzy expert system. Eksploat. Niezawodn. Maint. Reliab. 2018, 20, 621–629. [Google Scholar] [CrossRef]

- Ma, S.; Chen, M.; Wu, J.; Wang, Y.; Jia, B.; Jiang, Y. High-Voltage Circuit Breaker Fault Diagnosis Using a Hybrid Feature Transformation Approach Based on Random Forest and Stacked Autoencoder. IEEE Trans. Ind. Electron. 2018, 66, 9777–9788. [Google Scholar] [CrossRef]

- Wan, S.; Chen, L. Fault Diagnosis of High-Voltage Circuit Breakers Using Mechanism Action Time and Hybrid Classifier. IEEE Access 2019, 7, 85146–85157. [Google Scholar] [CrossRef]

- Huang, N.; Fang, L.; Cai, G.; Xu, D.; Chen, H.; Nie, Y. Mechanical Fault Diagnosis of High Voltage Circuit Breakers with Unknown Fault Type Using Hybrid Classifier Based on LMD and Time Segmentation Energy Entropy. Entropy 2016, 18, 322. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Wu, Y.; Xu, Z.; Din, Z.; Chen, H. Fault diagnosis of high voltage circuit breaker based on multi-sensor information fusion with training weights. Measurement 2022, 192, 110894. [Google Scholar] [CrossRef]

- Petrović, I.; Glavaš, H.; Noskov, R.; Blažević, D. Real-Time Circuit Breaker Availability Assessment in the Transmission Network. Appl. Sci. 2021, 11, 9635. [Google Scholar] [CrossRef]

- Li, J.; Hai, C.; Feng, Z.; Li, G. A Transformer Fault Diagnosis Method Based on Parameters Optimization of Hybrid Kernel Extreme Learning Machine. IEEE Access 2021, 9, 126891–126902. [Google Scholar] [CrossRef]

- Lu, S.; Gao, W.; Hong, C.; Sun, Y. A newly-designed fault diagnostic method for transformers via improved empirical wavelet transform and kernel extreme learning machine. Adv. Eng. Inform. 2021, 49, 101320. [Google Scholar] [CrossRef]

- Yang, X.; Chen, W.; Li, A.; Yang, C.; Xie, Z.; Dong, H. BA-PNN-based methods for power transformer fault diagnosis. Adv. Eng. Inform. 2019, 39, 178–185. [Google Scholar] [CrossRef]

- Equbal, D.; Khan, S.A.; Islam, T. Transformer incipient fault diagnosis on the basis of energy-weighted DGA using an artificial neural network. Turk. J. Electr. Eng. Comput. Sci. 2018, 26, 77–88. [Google Scholar] [CrossRef]

- Wang, F.; Bi, J.G.; Zhang, B.W.; Yuan, S. Research of Transformer Intelligent Evaluation and Diagnosis Method Based on DGA. In Proceedings of the 2016 3rd International Conference on Mechanics and Mechatronics Research, Chongqing, China, 15–17 June 2016. [Google Scholar]

- Yan, C.; Li, M.; Liu, W. Transformer Fault Diagnosis Based on BP-Adaboost and PNN Series Connection. Math. Probl. Eng. 2019, 2019, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.; Wei, Y.; Xiao, H. Fault diagnosis of neural network classified signal fractal feature based on SVM. Clust. Comput. J. Netw. Softw. Tools Appl. 2019, 22, 4249–4254. [Google Scholar] [CrossRef]

- Naganathan, G.; Senthilkumar, M.; Aiswariya, S.; Muthulakshmi, S.; Riyasen, G.S.; Priyadharshini, M.M. Internal fault diagnosis of power transformer using artificial neural network. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Chen, S.; Ge, H.; Li, H.; Sun, Y.; Qian, X. Hierarchical deep convolution neural networks based on transfer learning for transformer rectifier unit fault diagnosis. Measurement 2021, 167, 108257. [Google Scholar] [CrossRef]

- Wei, D.; Wang, B.; Lin, G.; Liu, D.; Dong, Z.; Liu, H.; Liu, Y. Research on Unstructured Text Data Mining and Fault Classification Based on RNN-LSTM with Malfunction Inspection Report. Energies 2017, 10, 406. [Google Scholar] [CrossRef] [Green Version]

- Luo, Z.; Zhang, Z.; Yan, X.; Qin, J.; Zhu, Z.; Wang, H.; Gao, Z. Dissolved Gas Analysis of Insulating Oil in Electric Power Transformers: A Case Study Using SDAE-LSTM. Math. Probl. Eng. 2020, 2020, 2420456. [Google Scholar] [CrossRef]

- Zollanvari, A.; Kunanbayev, K.; Bitaghsir, S.A.; Bagheri, M. Transformer Fault Prognosis Using Deep Recurrent Neural Network Over Vibration Signals. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar] [CrossRef]

- Ma, X.; Hu, H.; Shang, Y. A New Method for Transformer Fault Prediction Based on Multifeature Enhancement and Refined Long Short-Term Memory. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar] [CrossRef]

- Dai, J.; Song, H.; Sheng, G.; Jiang, X. Dissolved gas analysis of insulating oil for power transformer fault diagnosis with deep belief network. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2828–2835. [Google Scholar] [CrossRef]

- Chen, R.; Yuan, Y.; Zhang, Z.; Chen, X.; He, F. Fault Diagnosis for Transformers Based on FRVM and DBN. In Proceedings of the 4th International Conference on Advances in Energy Resources and Environment Engineering, Chengdu, China, 7–9 December 2019. [Google Scholar]

- Duan, L.; Hu, J.; Zhao, G.; Chen, K.; Wang, S.X.; He, J. Method of inter-turn fault detection for next-generation smart transformers based on deep learning algorithm. High Volt. 2019, 4, 282–291. [Google Scholar] [CrossRef]

- Zhang, L.J.; Sheng, G.H.; Hou, H.J.; Jiang, X.C. A Fault Diagnosis Method of Power Transformer Based on Cost Sensitive One-Dimensional Convolution Neural Network. In Proceedings of the 2020 5th Asia Conference on Power and Electrical Engineering, Chengdu, China, 9–12 April 2020. [Google Scholar]

- Afrasiabi, S.; Afrasiabi, M.; Parang, B.; Mohammadi, M. Integration of Accelerated Deep Neural Network into Power Transformer Differential Protection. IEEE Trans. Ind. Inform. 2020, 16, 865–876. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Afrasiabi, S.; Parang, B.; Mohammadi, M. Power transformers internal fault diagnosis based on deep convolutional neural networks. J. Intell. Fuzzy Syst. 2019, 37, 1165–1179. [Google Scholar] [CrossRef]

- Do, T.-D.; Tuyet-Doan, V.-N.; Cho, Y.-S.; Sun, J.-H.; Kim, Y.-H. Convolutional-Neural-Network-Based Partial Discharge Diagnosis for Power Transformer Using UHF Sensor. IEEE Access 2020, 8, 207377–207388. [Google Scholar] [CrossRef]

- Dey, D.; Chatterjee, B.; Dalai, S.; Munshi, S.; Chakravorti, S. A deep learning framework using convolution neural network for classification of impulse fault patterns in transformers with increased accuracy. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3894–3897. [Google Scholar] [CrossRef]

- Yang, K.; Chu, R.; Zhang, R.; Xiao, J.; Tu, R. A Novel Methodology for Series Arc Fault Detection by Temporal Domain Visualization and Convolutional Neural Network. Sensors 2020, 20, 162. [Google Scholar] [CrossRef] [Green Version]

- Taha, I.B.M.; Ibrahim, S.; Mansour, D.-E.A. Power Transformer Fault Diagnosis Based on DGA Using a Convolutional Neural Network with Noise in Measurements. IEEE Access 2021, 9, 111162–111170. [Google Scholar] [CrossRef]

- Hong, K.; Jin, M.; Huang, H. Transformer Winding Fault Diagnosis Using Vibration Image and Deep Learning. IEEE Trans. Power Deliv. 2020, 36, 676–685. [Google Scholar] [CrossRef]

- Elsisi, M.; Tran, M.Q.; Mahmoud, K.; Mansour, D.E.A.; Lehtonen, M.; Darwish, M.M. Effective IoT-based Deep Learning Platform for Online Fault Diagnosis of Power Transformers Against Cyberattack and Data Uncertainties. Measurement 2022, 190, 110686. [Google Scholar] [CrossRef]

- Lopes, S.M.D.A.; Flauzino, R.A.; Altafim, R.A.C. Incipient fault diagnosis in power transformers by data-driven models with over-sampled dataset. Electr. Power Syst. Res. 2021, 201, 107519. [Google Scholar] [CrossRef]

- Duan, J.; He, Y.; Wu, X. Serial transfer learning (STL) theory for processing data insufficiency: Fault diagnosis of transformer windings. Int. J. Electr. Power Energy Syst. 2021, 130, 106965. [Google Scholar] [CrossRef]

- Rucconi, V.; De Maria, L.; Garatti, S.; Bartalesi, D.; Valecillos, B.; Bittanti, S. Deep Learning for Fault Detection In Transformers Using Vibration Data. IFAC-PapersOnLine 2021, 54, 262–267. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Z.; Tang, C.; Yao, C.; Li, C.; Islam, S. Classifying Transformer Winding Deformation Fault Types and Degrees Using FRA Based on Support Vector Machine. IEEE Access 2019, 7, 112494–112504. [Google Scholar] [CrossRef]

- Wu, J.; Li, K.; Sun, J.; Xie, L. A Novel Integrated Method to Diagnose Faults in Power Transformers. Energies 2018, 11, 3041. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhang, L. A Combined Fault Diagnosis Method for Power Transformer in Big Data Environment. Math. Probl. Eng. 2017, 2017, 9670290. [Google Scholar] [CrossRef]

- Ma, H.Z.; Zhang, W.; Wu, R.R.; Yang, C.Y.; IOP. A Power Transformers Fault Diagnosis Model Based on Three DGA Ratios and PSO Optimization SVM. In Proceedings of the 2017 2nd International Conference on Mechatronics and Electrical Systems, Wuhan, China, 15–17 December 2018. [Google Scholar]

- Zhang, C.; He, Y.; Jiang, S.; Wang, T.; Yuan, L.; Li, B. Transformer Fault Diagnosis Method Based on Self-Powered RFID Sensor Tag, DBN, and MKSVM. IEEE Sens. J. 2019, 19, 8202–8214. [Google Scholar] [CrossRef]

- Yuan, F.; Guo, J.; Xiao, Z.; Zeng, B.; Zhu, W.; Huang, S. A Transformer Fault Diagnosis Model Based on Chemical Reaction Optimization and Twin Support Vector Machine. Energies 2019, 12, 960. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Zhao, Z.; Pang, K.; Wang, D.; Tang, C.; Yao, C. Improved Winding Mechanical Fault Type Classification Methods Based on Polar Plots and Multiple Support Vector Machines. IEEE Access 2020, 8, 216271–216282. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, H.; Liao, R.; Wang, Y.; Yang, L.; Yan, C. A New Support Vector Machine Model Based on Improved Imperialist Competitive Algorithm for Fault Diagnosis of Oil-immersed Transformers. J. Electr. Eng. Technol. 2017, 12, 830–839. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, Q.; Wang, K.; Wang, J.; Zhou, T.; Zhang, Y. Optimal dissolved gas ratios selected by genetic algorithm for power transformer fault diagnosis based on support vector machine. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1198–1206. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Zheng, H.; Yao, H.; Liu, J.; Zhang, C.; Peng, H.; Jiao, J. A Fault Diagnosis Model of Power Transformers Based on Dissolved Gas Analysis Features Selection and Improved Krill Herd Algorithm Optimized Support Vector Machine. IEEE Access 2019, 7, 102803–102811. [Google Scholar] [CrossRef]

- Li, J.; Li, G.; Hai, C.; Guo, M. Transformer Fault Diagnosis Based on Multi-Class AdaBoost Algorithm. IEEE Access 2021, 10, 1522–1532. [Google Scholar] [CrossRef]

- Wu, Y.; Sun, X.; Zhang, Y.; Zhong, X.; Cheng, L. A Power Transformer Fault Diagnosis Method-Based Hybrid Improved Seagull Optimization Algorithm and Support Vector Machine. IEEE Access 2021, 10, 17268–17286. [Google Scholar] [CrossRef]

- Huerta-Rosales, J.R.; Granados-Lieberman, D.; Garcia-Perez, A.; Camarena-Martinez, D.; Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M. Short-circuited turn fault diagnosis in transformers by using vibration signals, statistical time features, and support vector machines on FPGA. Sensors 2021, 21, 3598. [Google Scholar] [CrossRef]

- Abbasi, A.R.; Mahmoudi, M.R.; Avazzadeh, Z. Diagnosis and clustering of power transformer winding fault types by cross-correlation and clustering analysis of FRA results. IET Gener. Transm. Distrib. 2018, 12, 4301–4309. [Google Scholar] [CrossRef]

- Islam, M.; Lee, G.; Hettiwatte, S.N. A nearest neighbour clustering approach for incipient fault diagnosis of power transformers. Electr. Eng. 2017, 99, 1109–1119. [Google Scholar] [CrossRef]

- Zhu, J.; Li, S.; Dong, H. Running Status Diagnosis of Onboard Traction Transformers Based on Kernel Principal Component Analysis and Fuzzy Clustering. IEEE Access 2021, 9, 121835–121844. [Google Scholar] [CrossRef]

- Zhao, Z.; Tang, C.; Chen, Y.; Zhou, Q.; Yao, C.; Islam, S. Interpretation of transformer winding deformation fault by the spectral clustering of FRA signature. Int. J. Electr. Power Energy Syst. 2021, 130, 106933. [Google Scholar] [CrossRef]

- Bigdeli, M.; Abu-Siada, A. Clustering of transformer condition using frequency response analysis based on k-means and GOA. Electr. Power Syst. Res. 2022, 202, 107619. [Google Scholar] [CrossRef]

- Lu, P.; Li, W.; Huang, D. Transformer fault diagnosis method based on graph theory and rough set. J. Intell. Fuzzy Syst. 2018, 35, 223–230. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Y.; Wang, Y.; Wang, C.; Zhang, G. Integrated decision-making method for power transformer fault diagnosis via rough set and DS evidence theories. IET Gener. Transm. Distrib. 2020, 14, 5774–5781. [Google Scholar] [CrossRef]

- Peng, W.; Li, H.; Bian, G.; Zhang, E. Fault Diagnosis and Maintenance Decision Method of Marine Transformer: A Rough Set Theory Based Study. J. Coast. Res. 2020, 106, 562. [Google Scholar] [CrossRef]

- Zhou, L.; Hu, T. Multifactorial condition assessment for power transformers. IET Gener. Transm. Distrib. 2020, 14, 1607–1615. [Google Scholar] [CrossRef]

- Liu, Y.Z. Applied Research on Fault Diagnosis of Power Transformers Based on Rough Set Theory. Agro Food Ind. Hi-Tech 2017, 28, 2712–2715. [Google Scholar]

- Hoballah, A.; Mansour, D.-E.A.; Taha, I.B.M. Hybrid Grey Wolf Optimizer for Transformer Fault Diagnosis Using Dissolved Gases Considering Uncertainty in Measurements. IEEE Access 2020, 8, 139176–139187. [Google Scholar] [CrossRef]

- Ghoneim, S.S. Intelligent prediction of transformer faults and severities based on dissolved gas analysis integrated with thermodynamics theory. IET Sci. Meas. Technol. 2018, 12, 388–394. [Google Scholar] [CrossRef]

- Huerta-Rosales, J.R.; Granados-Lieberman, D.; Amezquita-Sanchez, J.P.; Camarena-Martinez, D.; Valtierra-Rodriguez, M. Vibration Signal Processing-Based Detection of Short-Circuited Turns in Transformers: A Nonlinear Mode Decomposition Approach. Mathematics 2020, 8, 575. [Google Scholar] [CrossRef]

- Soni, R.; Mehta, B. Graphical examination of dissolved gas analysis by ratio methods and Duval triangle method to investigate internal faults of power transformer. Mater. Today Proc. 2022, in press. [Google Scholar] [CrossRef]

- Zhang, C.; He, Y.; Du, B.; Yuan, L.; Li, B.; Jiang, S. Transformer fault diagnosis method using IoT based monitoring system and ensemble machine learning. Future Gener. Comput. Syst. Int. J. ESci. 2020, 108, 533–545. [Google Scholar] [CrossRef]

- Shang, H.; Xu, J.; Zheng, Z.; Qi, B.; Zhang, L. A Novel Fault Diagnosis Method for Power Transformer Based on Dissolved Gas Analysis Using Hypersphere Multiclass Support Vector Machine and Improved D–S Evidence Theory. Energies 2019, 12, 4017. [Google Scholar] [CrossRef] [Green Version]

- Taha, I.B.; Mansour, D.-E.A. Novel Power Transformer Fault Diagnosis Using Optimized Machine Learning Methods. Intell. Autom. Soft Comput. 2021, 28, 739–752. [Google Scholar] [CrossRef]

- Wani, S.A.; Gupta, D.; Farooque, U.; Khan, S.A. Multiple incipient fault classification approach for enhancing the accuracy of dissolved gas analysis (DGA). IET Sci. Meas. Technol. 2019, 13, 959–967. [Google Scholar] [CrossRef]

- Kari, T.; Gao, W.; Zhao, D.; Zhang, Z.; Mo, W.; Wang, Y.; Luan, L. An integrated method of ANFIS and Dempster-Shafer theory for fault diagnosis of power transformer. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 360–371. [Google Scholar] [CrossRef]

- Fan, J.; Wang, F.; Sun, Q.; Bin, F.; Liang, F.; Xiao, X. Hybrid RVM–ANFIS algorithm for transformer fault diagnosis. IET Gener. Transm. Distrib. 2017, 11, 3637–3643. [Google Scholar] [CrossRef]

- Wu, X.; He, Y.; Duan, J. A Deep Parallel Diagnostic Method for Transformer Dissolved Gas Analysis. Appl. Sci. 2020, 10, 1329. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Su, L.; Yan, Y.; Sheng, G.; Xie, D.; Jiang, X. Prediction Method for Power Transformer Running State Based on LSTM_DBN Network. Energies 2018, 11, 1880. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Wu, X.; Ding, P.; Li, X.; He, N.; Zhang, G.; Zhang, X. Research on Transformer Partial Discharge UHF Pattern Recognition Based on Cnn-lstm. Energies 2020, 13, 61. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Park, J.; Kim, W.; Jo, S.-H.; Youn, B.D. Learning from even a weak teacher: Bridging rule-based Duval method and a deep neural network for power transformer fault diagnosis. Int. J. Electr. Power Energy Syst. 2022, 136, 107619. [Google Scholar] [CrossRef]

- Hua, Y.; Sun, Y.; Xu, G.; Sun, S.; Wang, E.; Pang, Y. A fault diagnostic method for oil-immersed transformer based on multiple probabilistic output algorithms and improved DS evidence theory. Int. J. Electr. Power Energy Syst. 2022, 137, 107828. [Google Scholar] [CrossRef]

- Abdo, A.; Liu, H.; Zhang, H.; Guo, J.; Li, Q. A new model of faults classification in power transformers based on data optimization method. Electr. Power Syst. Res. 2021, 200, 107446. [Google Scholar] [CrossRef]

- Yu, S.; Tan, W.; Zhang, C.; Fang, Y.; Tang, C.; Hu, D. Research on hybrid feature selection method of power transformer based on fuzzy information entropy. Adv. Eng. Inform. 2021, 50, 101433. [Google Scholar] [CrossRef]

- Wang, L.; Lyu, F.; Su, Y.; Yue, J. Kernel Entropy-Based Classification Approach for Superbuck Converter Circuit Fault Diagnosis. IEEE Access 2018, 6, 45504–45514. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Y. A Transferrable Data-Driven Method for IGBT Open-Circuit Fault Diagnosis in Three-Phase Inverters. IEEE Trans. Power Electron. 2021, 36, 13478–13488. [Google Scholar] [CrossRef]

- Talha, M.; Asghar, F.; Kim, S.H. A Novel Three-Phase Inverter Fault Diagnosis System Using Three-dimensional Feature Extraction and Neural Network. Arab. J. Sci. Eng. 2019, 44, 1809–1822. [Google Scholar] [CrossRef]

- Talha, M.; Asghar, F.; Kim, S.H. A Matlab and Simulink Based Three-Phase Inverter Fault Diagnosis Method Using Three-Dimensional Features. Int. J. Fuzzy Log. Intell. Syst. 2016, 16, 173–180. [Google Scholar] [CrossRef]

- Yang, G.H.; Wan, P.Z.; Li, B.X.; Lei, B.; Tang, H.; Li, R. Fault Diagnosis Method of Ningxia Photovoltaic Inverter Based on Wavelet Neural Network. In Proceedings of the Advanced Computational Methods in Energy, Power, Electric Vehicles, and Their Integration, Lsms 2017, Nanjing, China, 22–24 September 2017. [Google Scholar]

- Huang, Z.; Wang, Z.; Zhang, H. Multiple Open-Circuit Fault Diagnosis Based on Multistate Data Processing and Subsection Fluctuation Analysis for Photovoltaic Inverter. IEEE Trans. Instrum. Meas. 2018, 67, 516–526. [Google Scholar] [CrossRef]

- Hu, H.; Feng, F.; Wang, T. Open-circuit fault diagnosis of NPC inverter IGBT based on independent component analysis and neural network. Energy Rep. 2020, 6, 134–143. [Google Scholar] [CrossRef]

- Xue, Z.Y.; XiaHou, K.S.; Li, M.S.; Ji, T.Y.; Wu, Q.H. Diagnosis of Multiple Open-Circuit Switch Faults Based on Long Short-Term Memory Network for DFIG-Based Wind Turbine Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 2600–2610. [Google Scholar] [CrossRef]

- Ye, S.; Jiang, J.; Li, J.; Liu, Y.; Zhou, Z.; Liu, C. Fault Diagnosis and Tolerance Control of Five-Level Nested NPP Converter Using Wavelet Packet and LSTM. IEEE Trans. Power Electron. 2020, 35, 1907–1921. [Google Scholar] [CrossRef]

- Gong, W.; Chen, H.; Zhang, Z.; Zhang, M.; Gao, H. A Data-Driven-Based Fault Diagnosis Approach for Electrical Power DC-DC Inverter by Using Modified Convolutional Neural Network with Global Average Pooling and 2-D Feature Image. IEEE Access 2020, 8, 73677–73697. [Google Scholar] [CrossRef]

- Sun, Q.; Yu, X.; Li, H.; Fan, J. Adaptive feature extraction and fault diagnosis for three-phase inverter based on hybrid-CNN models under variable operating conditions. Complex Intell. Syst. 2021, 8, 29–42. [Google Scholar] [CrossRef]

- Kim, S.-H.; Yoo, D.-Y.; An, S.-W.; Park, Y.-S.; Lee, J.-W.; Lee, K.-B. Fault Detection Method Using a Convolution Neural Network for Hybrid Active Neutral-Point Clamped Inverters. IEEE Access 2020, 8, 140632–140642. [Google Scholar] [CrossRef]

- Skowron, M.; Orlowska-Kowalska, T.; Wolkiewicz, M.; Kowalski, C.T. Convolutional Neural Network-Based Stator Current Data-Driven Incipient Stator Fault Diagnosis of Inverter-Fed Induction Motor. Energies 2020, 13, 1475. [Google Scholar] [CrossRef] [Green Version]

- Ke, L.; Zhang, Y.; Yang, B.; Luo, Z.; Liu, Z. Fault diagnosis with synchrosqueezing transform and optimized deep convolutional neural network: An application in modular multilevel converters. Neurocomputing 2021, 430, 24–33. [Google Scholar] [CrossRef]

- Xiao, C.; Liu, Z.; Zhang, T.; Zhang, X. Deep Learning Method for Fault Detection of Wind Turbine Converter. Appl. Sci. 2021, 11, 1280. [Google Scholar] [CrossRef]

- Yuan, W.Y.; Wang, T.; Diallo, D. A Secondary Classification Fault Diagnosis Strategy Based on PCA-SVM for Cascaded Photovoltaic Grid-connected Inverter. In Proceedings of the 45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 5986–5991. [Google Scholar]

- Wang, T.; Qi, J.; Xu, H.; Wang, Y.; Liu, L.; Gao, D. Fault diagnosis method based on FFT-RPCA-SVM for Cascaded-Multilevel Inverter. ISA Trans. 2016, 60, 156–163. [Google Scholar] [CrossRef]

- Yu, Y.; Pei, S. Open-Circuit Fault Diagnosis of Neutral Point Clamped Three-Level Inverter Based on Sparse Representation. IEEE Access 2018, 6, 73499–73508. [Google Scholar] [CrossRef]

- Leon-Ruiz, Y.; Gonzalez-Garcia, M.; Alvarez-Salas, R.; Cuevas-Tello, J.; Cardenas, V. Fault Diagnosis Based on Machine Learning for the High Frequency Link of a Grid-Tied Photovoltaic Converter for a Wide Range of Irradiance Conditions. IEEE Access 2021, 9, 151209–151220. [Google Scholar] [CrossRef]

- Sarita, K.; Kumar, S.; Saket, R. OC fault diagnosis of multilevel inverter using SVM technique and detection algorithm. Comput. Electr. Eng. 2021, 96, 107481. [Google Scholar] [CrossRef]

- Oliveira, A.B.M.; Moreno, R.L.; Ribeiro, E.R. Digital short-circuit diagnosis and reconfiguration of a fault tolerant VSI. In Proceedings of the 2017 IEEE Southern Power Electronics Conference, Puerto Varas, Chile, 4–7 December 2017. [Google Scholar]

- Oliveira, A.B.D.M.; Moreno, R.L.; Ribeiro, E.R. Short-Circuit Fault Diagnosis Based on Rough Sets Theory for a Single-Phase Inverter. IEEE Trans. Power Electron. 2019, 34, 4747–4764. [Google Scholar] [CrossRef]

- Kou, L.; Liu, C.; Cai, G.W.; Zhou, J.N.; Yuan, Q.D.; Pang, S.M. Fault diagnosis for open-circuit faults in NPC inverter based on knowledge-driven and data-driven approaches. IET Power Electron. 2020, 13, 1236–1245. [Google Scholar] [CrossRef]

| Method | Advantages | Disadvantages | ||

|---|---|---|---|---|

| Data-driven | Clustering | K-means |

|

|

| DBSCAN |

|

| ||

| Hierarchical clustering |

|

| ||

| SVM | Construction of multi-classification SVM by direct method |

|

| |

| Construction of multi-classification SVM by indirect method |

|

| ||

| BP Neural Network | Does not require much calculation, simple to implement;Powerful parallel capability;Automatic adjustment capability. |

| ||

| ELM | The weight and threshold of neural network do not need to be adjusted. |

| ||

| EL | Random Forest |

| For the data of attributes with different values, the attributes with more values will have a greater impact on the random forest, so the attribute weight produced by the random forest on this data is not credible. | |

| Adaboost |

|

| ||

| GBDT |

|

| ||

| CNN |

|

| ||

| RNN |

|

| ||

| Knowledge-based | FL |

| Difficult to obtain fuzzy rules and membership functions. | |

| RST | Difficult to deal with continuous data. | |||

| D-S evidence theory |

| |||

| Key Component in Cold Ironing System | Fault Diagnosis Method | References | |

|---|---|---|---|

| Circuit Breaker | Shallow Neural Network | ELM | [30,31] |

| Probabilistic Neural network (PNN) | [32] | ||

| BP | [33] | ||

| Deep Learning | CNN | [34] | |

| SVM | [35,36,37,38,39,40,41] | ||

| Clustering | [42,43,44,45,46,47] | ||

| FL/RST | [48,49] | ||

| EL | [50] | ||

| Hybrid Model | [51,52,53,54] | ||

| Transformer | Shallow Neural Network | ELM | [55,56] |

| PNN | [57] | ||

| BP | [58,59,60,61,62] | ||

| Deep Learning | RNN | [63,64,65,66,67] | |

| Deep Belief Network (DBN) | [68,69] | ||

| Auto-encoder | [70] | ||

| CNN | [63,71,72,73,74,75,76,77,78,79,80,81,82] | ||

| SVM | [83,84,85,86,87,88,89,90,91,92,93,94,95] | ||

| Clustering | [96,97,98,99,100] | ||

| FL/RST | [101,102,103,104,105,106,107,108,109] | ||

| EL | [110,111,112] | ||

| Hybrid Model | [113,114,115,116,117,118,119,120,121,122] | ||

| Frequency Converter | Shallow Neural Network | ELM | [123,124] |

| BP | [125,126,127,128,129] | ||

| Deep Learning | RNN | [130,131] | |

| CNN | [132,133,134,135,136,137] | ||

| SVM | [138,139,140,141,142] | ||

| FL/RST | [143,144] | ||

| EL | [145] | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, K.; Yao, C.; Li, Y.; Hao, Q.; Lv, Y.; Huang, Z. A Review on Fault Diagnosis Technology of Key Components in Cold Ironing System. Sustainability 2022, 14, 6197. https://doi.org/10.3390/su14106197

Ding K, Yao C, Li Y, Hao Q, Lv Y, Huang Z. A Review on Fault Diagnosis Technology of Key Components in Cold Ironing System. Sustainability. 2022; 14(10):6197. https://doi.org/10.3390/su14106197

Chicago/Turabian StyleDing, Kai, Chen Yao, Yifan Li, Qinglong Hao, Yaqiong Lv, and Zengrui Huang. 2022. "A Review on Fault Diagnosis Technology of Key Components in Cold Ironing System" Sustainability 14, no. 10: 6197. https://doi.org/10.3390/su14106197

APA StyleDing, K., Yao, C., Li, Y., Hao, Q., Lv, Y., & Huang, Z. (2022). A Review on Fault Diagnosis Technology of Key Components in Cold Ironing System. Sustainability, 14(10), 6197. https://doi.org/10.3390/su14106197