Reducing GHG Emissions and Improving Cost Effectiveness via Energy Efficiency Enhancements: A Case Study in a Biscuit Industry

Abstract

:1. Introduction

2. Methodology

2.1. Case Study

2.2. Research Design

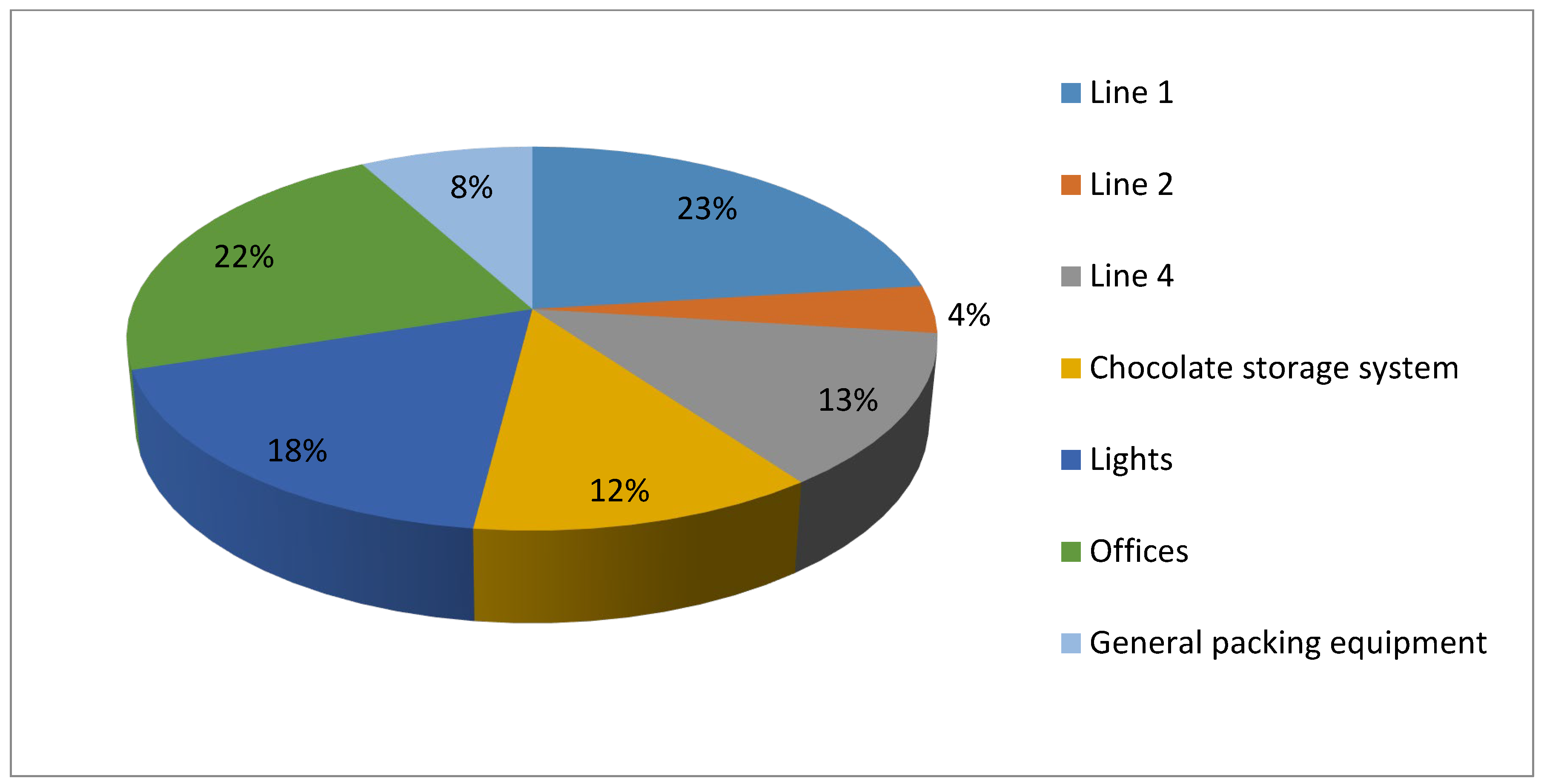

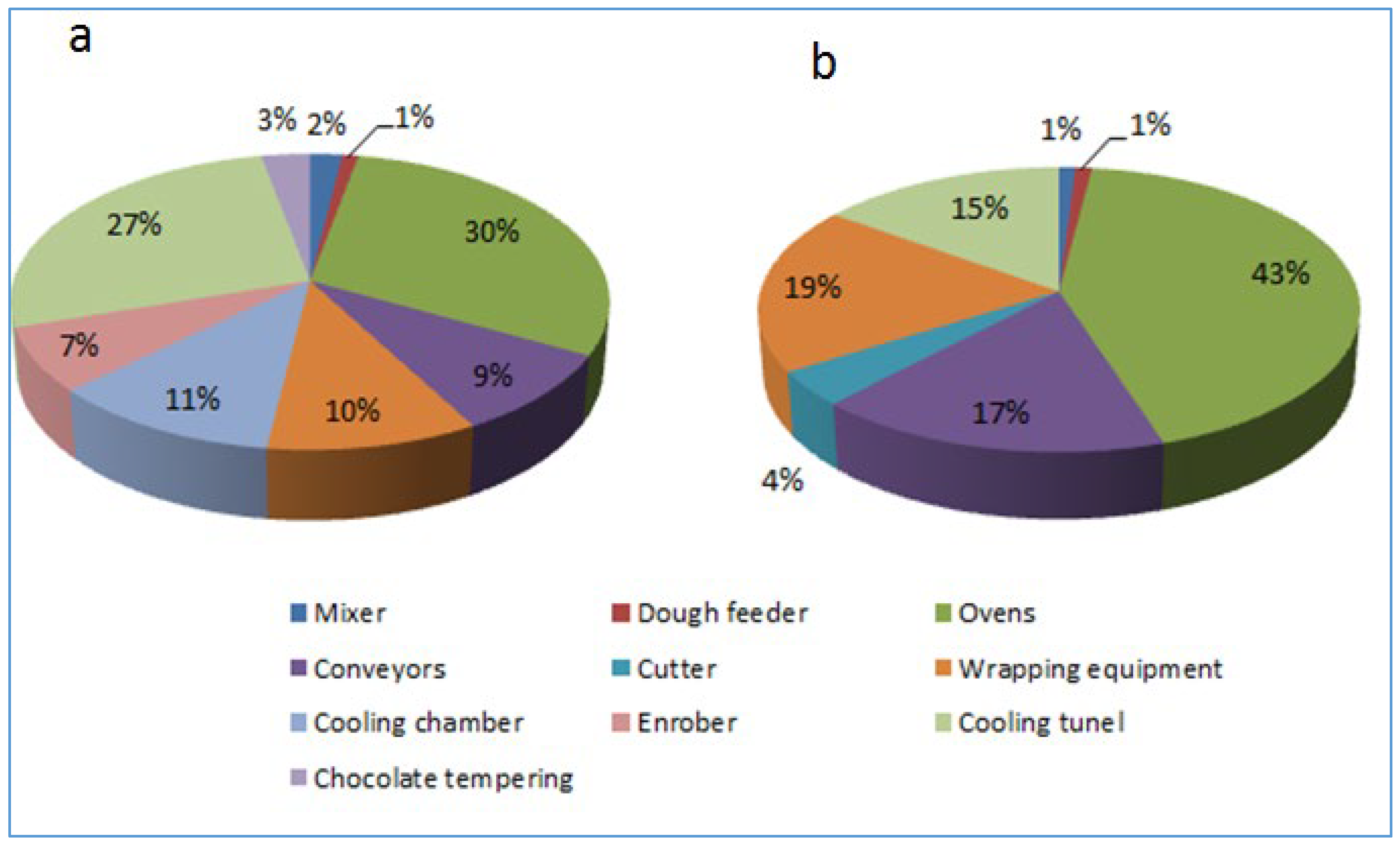

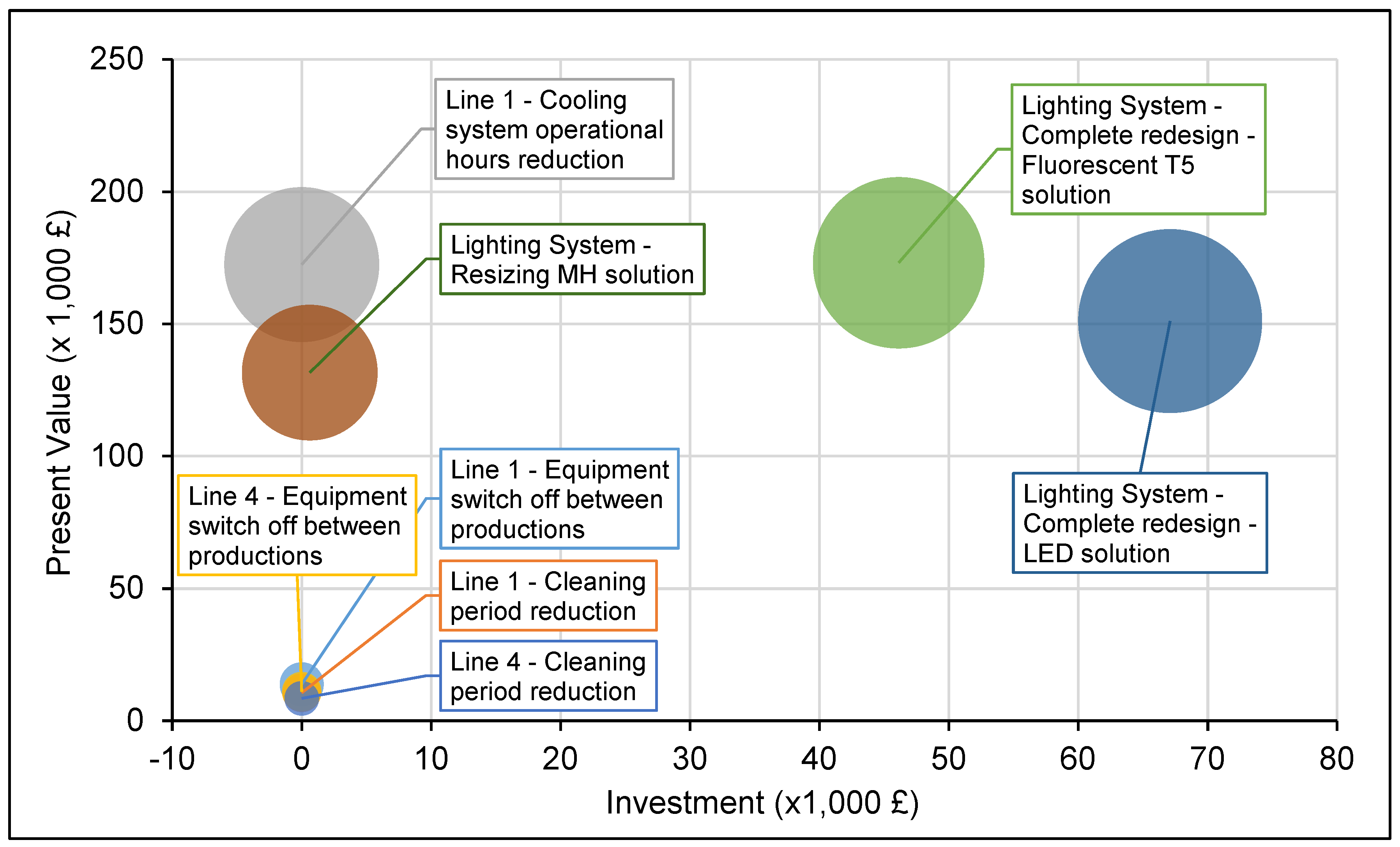

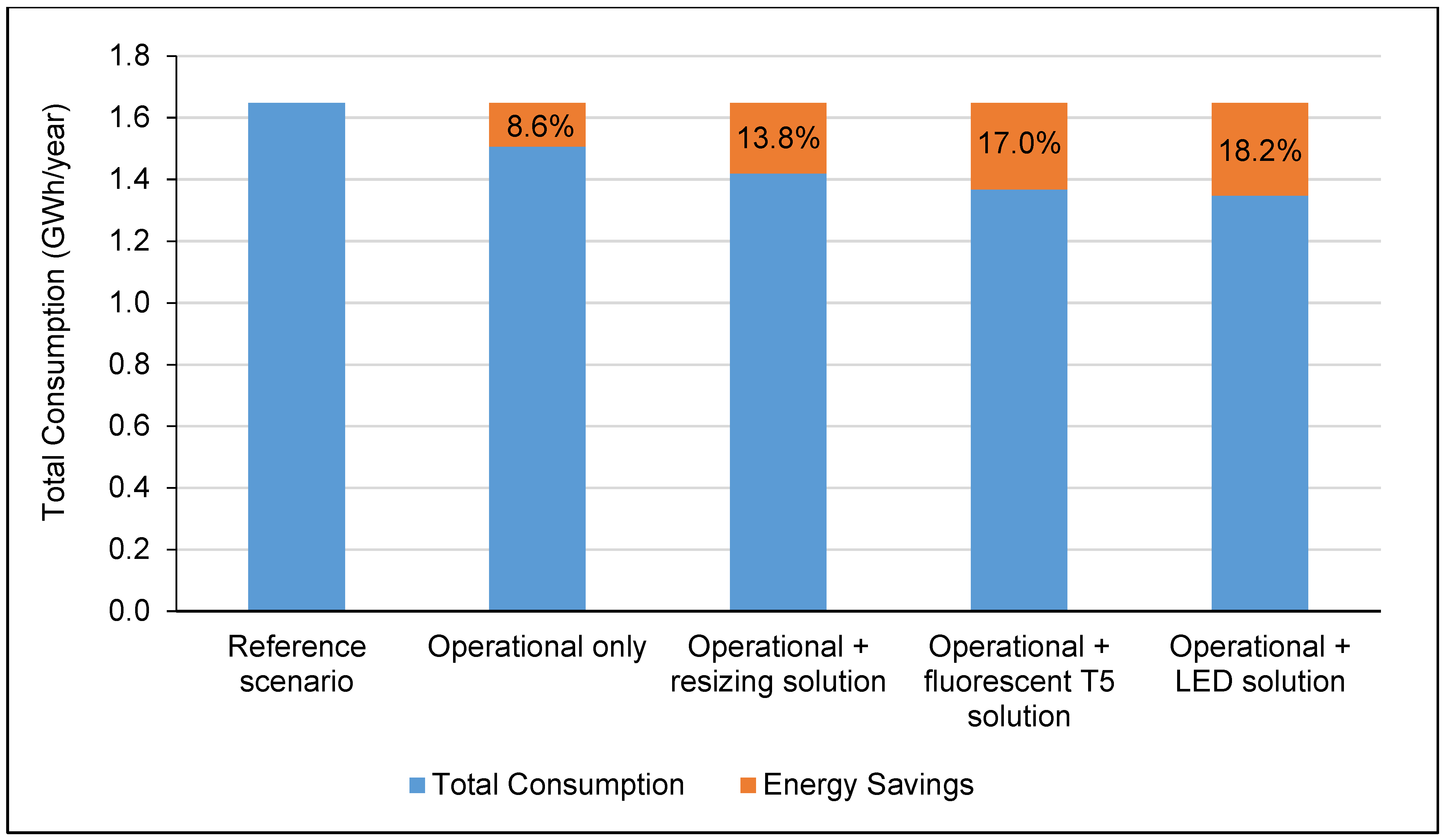

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| % | percentage |

| CO2 | Carbon Dioxide |

| CRI | Colour Rendering Index |

| DECC | Department of Energy & Climate Change |

| E | energy |

| EU | European Union |

| EU Emissions Trading System | EU ETS |

| FDF | Food and Drink Federation |

| GHG | Green House Gas |

| GW | gigawatt |

| h | hour |

| HID MH | high intensity discharge and metal halide |

| LED | Light-emitting diode |

| Lm | lumens |

| Mt | Megatonnes |

| MW | Megawatt |

| Ra | Rendering Score |

| t | tonne |

| W | Watt |

| w | week |

| y | year |

References

- European Environmental Agency (EEA). Sectoral Greenhouse Gas Emissions by IPCC Sector. 2016. Available online: https://www.eea.europa.eu/data-and-maps/daviz/change-of-co2-eq-emissions-2#tab-dashboard-01 (accessed on 1 December 2021).

- Garnett, T. Where are the best opportunities for reducing greenhouse gas emissions in the food system (including the food chain)? Food Policy 2011, 36, S23–S32. [Google Scholar] [CrossRef]

- WWF. Emissions from UK Food Industry Far Higher than Believed. 2017. Available online: https://www.wwf.org.uk/updates/emissions-uk-food-industry-far-higher-believed (accessed on 1 December 2021).

- DECC-Department of Energy and Climate Change. Updated Energy and Emissions Projections; Statistics; The National Archive: London, UK, 2014. [Google Scholar]

- Dorward, L.J. Where are the best opportunities for reducing greenhouse gas emissions in the food system (including the food chain)? A comment. Food Policy 2012, 37, 463–466. [Google Scholar] [CrossRef]

- Garnett, T. Three perspectives on sustainable food security: Efficiency, demand restraint, food system transformation. What role for life cycle assessment? J. Clean. Prod. 2014, 73, 10–18. [Google Scholar] [CrossRef]

- Noya, L.I.; Vasilaki, V.; Stojceska, V.; González-García, S.; Kleynhans, C.; Tassou, S.; Moreira, M.T.; Katsou, E. An environmental evaluation of food supply chain using life cycle assessment: A case study on gluten free biscuit products. J. Clean. Prod. 2018, 170, 451–461. [Google Scholar] [CrossRef]

- Wang, L. Energy efficiency technologies for sustainable food processing. Energy Effic. 2014, 7, 791–810. [Google Scholar] [CrossRef]

- Tassou, S.; Kolokotroni, M.; Gowreesunker, B.; Stojceska, V.; Azapagic, A.; Fryer, P.; Bakalis, S. Energy demand and reduction opportunities in the UK food chain. Proc. Inst. Civ. Eng. Energy 2015, 167, 162–170. [Google Scholar] [CrossRef]

- Ladha-Sabura, A.; Bakalis, S.; Peter, J.; Fryer, P.; Lopez-Quiroga, E. Review Mapping energy consumption in food manufacturing. Trends Food Sci. Technol. 2019, 86, 270–280. [Google Scholar] [CrossRef]

- Fischer, J.R.; Blackman, J.E.; Finnell, J.A. Industry and energy: Challenges and opportunities. Eng. Technol. A Sustain. World 2007, 4, 8–9. [Google Scholar]

- Muller, D.C.A.; Marechal, F.M.A.; Wolewinski, T.; Roux, P.J. An energy management method for the food industry. Appl. Therm. Eng. 2007, 27, 2677–2686. [Google Scholar] [CrossRef]

- Muster-Slawitsch, B.; Weiss, W.; Schnitzer, H.; Brunner, C. The green brewery concept-Energy efficiency and the use of renewable energy sources in breweries. Appl. Therm. Eng. 2011, 31, 2123–2134. [Google Scholar] [CrossRef] [Green Version]

- Celma, A.R.; Blázquez, F.C.; López-Rodríguez, F. Feasibility analysis of CHP in an olive processing industry. J. Clean. Prod. 2013, 42, 52–57. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Nabavi-Pelesaraei, A.; Khanali, M.; Ghahderijani MChau, K.W. Application of data envelopment analysis approach for optimization of energy use and reduction of greenhouse gas emission in peanut production of Iran. J. Clean. Prod. 2018, 172, 1327–1335. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Abdi, R.; Rafiee, S.; Bagheri, I. Determination of efficient and inefficient units for watermelon production-a case study: Guilan province of Iran. J. Saudi Soc. Agric. Sci. 2016, 15, 162–170. [Google Scholar] [CrossRef] [Green Version]

- Qasemi-Kordkheili, P.; Nabavi-Pelesaraei, A. Optimization of energy required and potential of greenhouse gas emissions reductions for nectarine production using data envelopment analysis approach. Int. J. Energy Environ. 2014, 5, 207–218. [Google Scholar]

- FeHosseinzadeh-Bandbafha, H.; Safarzadeh, D.; Ahmadi, E.; Nabavi-Pelesaraei AHosseinzadeh-Bandbafha, E. Applying data envelopment analysis to evaluation of energy efficiency and decreasing of greenhouse gas emissions of fattening farms. Energy 2017, 120, 652–662. [Google Scholar] [CrossRef]

- Meyers, S.; Schmitt, B.; Chester-Jones MSturm, B. Energy efficiency, carbon emissions, and measures towards their improvement in the food and beverage sector for six European countries. Energy 2016, 104, 266–283. [Google Scholar] [CrossRef]

- Carbon Trust. Industrial Energy Efficiency Accelerator. Guide to the Industrial Bakery Sector. 2016. Available online: www.carbontrust.com (accessed on 1 December 2021).

- Therkelsen, P.; Masanet EWorrell, E. Energy efficiency opportunities in the U.S. commercial baking industry. J. Food Eng. 2014, 130, 14–22. [Google Scholar] [CrossRef]

- Khatir, Z.; Paton, J.; Thompson, H.; Kapur, N.; Toropov, V. Optimisation of the energy efficiency of bread-baking ovens using a combined experimental and computational approach. Appl. Energy 2013, 112, 918–927. [Google Scholar] [CrossRef]

- Paton, J.; Khatir, Z.; Thompson, H.; Kapur, N.; Toropov, V. Thermal energy management in the bread baking industry using a system modelling approach. Appl. Therm. Eng. 2013, 53, 340–347. [Google Scholar] [CrossRef]

- Dora, M.; Gellynck, X. House of lean for food processing SMEs. Trends Food Sci. Technol. 2015, 44, 272–281. [Google Scholar] [CrossRef]

- European Commission. 2020 Climate & Energy Package. 2017. Available online: https://ec.europa.eu/clima/eu-action/climate-strategies-targets/2020-climate-energy-package_en#:~:text=The%202020%20package%20is%20a%20set%20of%20laws,1990%20levels%29%2020%25%20of%20EU%20energy%20from%20renewables (accessed on 1 December 2021).

- Environment Agency. Umbrella Climate Change Agreement for the Food and Drink Sector; Agreement; The Government Digital Service: London, UK, 2013. [Google Scholar]

- DEFRA-Department for Environment, Food & Rural Afairs. Guidelines to Defra/DECC’s GHG Conversion Factors for Company Reporting; Guideline; AEA: London, UK, 2012. [Google Scholar]

- The Society of Light and Lighting. Lighting Guide 1: The Industrial Environment; Guideline; CIBSE: London, UK, 2012. [Google Scholar]

- The Society of Light and Lighting. The SLL Lighting Handbook; Handbook; CIBSE: London, UK, 2009. [Google Scholar]

- The Society of Light and Lighting. The SLL Code for Lighting; Code; IBSE: London, UK, 2012. [Google Scholar]

- Kannan, R.; Boie, W. Energy management practices in SME—Case study of a bakery in Germany. Energy Convers. Manag. 2003, 44, 945–959. [Google Scholar] [CrossRef]

- Wang, Y.; Li, K.; Gan, S.; Cameron, C. Analysis of energy saving potentials in intelligent manufacturing: A case study of bakery plants. Energy 2019, 172, 477–486. [Google Scholar] [CrossRef]

- De Almeida, A.; Santos, B.; Paolo, B.; Quicheron, M. Solid state lighting review–Potential and challenges in Europe. Renew. Sustain. Energy Rev. 2014, 34, 30–48. [Google Scholar] [CrossRef]

- Sabzevari, A.; Nabavi-Pelesaraei, A. Prognostication of total greenhouse gas emissions and economic indices for hazelnut production in Guilan province, Iran. J. Biodivers. Environ. Sci. 2015, 6, 132–140. [Google Scholar]

- Ruonan, Li.; Mahalec, V. Greenhouse gas emissions reduction by cross-sector integration of energy systems: Optimal sizing of integrated entities. Energy Convers. Manag. 2021, 248, 114788. [Google Scholar]

- DECC-Department of Energy and Climate Change. Climate Change Agreements: 2013 Technical Annex; DECC-Department of Energy and Climate Change: London, UK, 2013; p. 10. [Google Scholar]

| (a) | |||

| Parameter | Equipment Switched Off between Productions | Cleaning Period Reduction | Cooling System Operational Hours Reduction |

| Energy Savings (MWh/y) | 9.0 | 6.9 | 112.7 |

| Energy Savings Impact on Total Consumption (%) | 0.50 | 0.40 | 6.80 |

| Cost Savings (base year) (EUR) | 990.00 | 750.00 | 12,320.00 |

| Cost Savings (projected 20 years) (EUR) | 27,762.00 | 21,304.00 | 347,208.00 |

| Present energy value (EUR) | 16,431.00 | 12,606.00 | 205,465.00 |

| Carbon reduction (base year) (tCO2) | 4.54 | 3.48 | 56.7 |

| Carbon reduction (projected 20 years) (tCO2) | 34.3 | 26.3 | 429 |

| (b) | |||

| Parameter | Equipment Switched off between Productions | Cleaning Period Reduction | |

| Energy Savings (MWh/y) | 7.2 | 5.5 | |

| Energy Savings Impact on Total Consumption (%) | 0.4 | 0.3 | |

| Cost Savings (base year) (EUR) | 786.40 | 607.07 | |

| Cost Savings (projected 20 years) (EUR) | 222,209.00 | 17,040.00 | |

| Present energy value (EUR) | 13,142.00 | 10,080.00 | |

| Carbon reduction (base year) (tCO2) | 3.63 | 2.79 | |

| Carbon reduction (projected 20 years) (tCO2) | 27.4 | 21.1 | |

| Technical Details | Complete Redesign | Resizing of the Existing System | |

|---|---|---|---|

| Fluorescent T5 Solution | LED Solution | LED Solution | |

| Distributed annual failure rate (%) | 12 | 8 | 21 |

| Life expectancy (h) | 25,000 | 40,000 | 15,000 |

| Investment (EUR) | 48,932.8 | 79,843.05 | 737.80 |

| Fixtures (enclosed, 2 tubes) (EUR) | 34,718.25 | 40,430.25 | 0 |

| T5 tube (35 W, highly efficient, 1500 mm) (EUR) | 2314.55 | 21,562.80 | 737.80 |

| Others (design, cables, control system, installation) (EUR) | 17,850 | 17,850 | 0 |

| Operational Costs (average) (EUR) | 821.10 | 4188.80 | 1237.60 |

| Annual maintenance cost (EUR) | 289.17 | 1677.90 | 595 |

| 25,000 h replacement cost (EUR) | 1157.50 | 10,781.40 | 1356.60 |

| Energy Savings (MWh/y) | 138.1 | 159.0 | 86.4 |

| Energy Savings Impact on Total Consumption (%) | 8.40 | 9.60 | 5.20 |

| Cost Savings (base year) (EUR) | 15,362.90 | 16,255.40 | 9424.80 |

| Cost Savings (projected 20 years) (EUR) | 436,289.70 | 427,055.30 | 265,834.10 |

| Present Value (EUR) | 206,012.80 | 179,797.10 | 156,615.90 |

| Internal Rate of Return (%) | 45.20 | 29.50 | 1380 |

| Payback Period (years) | 3.3 | 4.5 | <1.0 |

| Carbon Savings (base year) (tCO2) | 69.5 | 80.0 | 43.5 |

| Carbon Savings (projected 20 years) (tCO2) | 525 | 605 | 329 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stojceska, V.; Parker, N.; Tassou, S.A. Reducing GHG Emissions and Improving Cost Effectiveness via Energy Efficiency Enhancements: A Case Study in a Biscuit Industry. Sustainability 2022, 14, 69. https://doi.org/10.3390/su14010069

Stojceska V, Parker N, Tassou SA. Reducing GHG Emissions and Improving Cost Effectiveness via Energy Efficiency Enhancements: A Case Study in a Biscuit Industry. Sustainability. 2022; 14(1):69. https://doi.org/10.3390/su14010069

Chicago/Turabian StyleStojceska, Valentina, Nicholas Parker, and Savvas A. Tassou. 2022. "Reducing GHG Emissions and Improving Cost Effectiveness via Energy Efficiency Enhancements: A Case Study in a Biscuit Industry" Sustainability 14, no. 1: 69. https://doi.org/10.3390/su14010069

APA StyleStojceska, V., Parker, N., & Tassou, S. A. (2022). Reducing GHG Emissions and Improving Cost Effectiveness via Energy Efficiency Enhancements: A Case Study in a Biscuit Industry. Sustainability, 14(1), 69. https://doi.org/10.3390/su14010069