Abstract

Nowadays, huge amounts of refractory materials are generated around the world. The majority of them lack valorization methods. This study analyzes the ability of a doloma and two magnesia spent refractory wastes as soil stabilizers on their own, as well as when combined with Ground-Granulated Blast Furnace Slags (GGBS). These materials showed a limited ability for the soil’s plasticity modification from a plasticity index of 15.6 to a minimum of 12.7. The high pH of the additives increased the soil’s pH from 7.88 to values in the range of 10.94–11.25 before the 28 days, allowing the development of the pozzolanic reactions. Unconfined compressive strength (UCS) increased along the curing time, reaching a maximum value of 5.68 MPa after 90 days. Based on the UCS, the optimum refractory GGBS ratios oscillate between 30:70 and 50:50. The UCS values after soaking samples reduced the unsoaked results between 68.70% to 94.41%. The binders considered showed a low effect against the soil swelling and the lack of delayed expansive effects because of the MgO hydration. Finally, X Ray Diffraction (XRD) tests showed that the stabilization only slightly modified the combinations of mineralogy and the formation of Magnesium Silicate Hydrate (MSH) gels.

1. Introduction

Stabilization is an effective way to increase the bearing capacity of soft soils. The term stabilization usually refers to the addition of chemical admixtures for the geotechnical soil enhancement. Among them, calcium-based additives like lime or cement, used on their own or combined with other substances, are nowadays the most common binders [1]. Khazaei and Moayedi [2] analyzed the improvement of the properties of an expansive soil stabilized with waste from a petrochemical plant and quick lime. They observed the improvement of the bearing capacity of the treated soil samples. Okeke [3] studied the engineering behavior of an expansive soil stabilized with lime and waste ceramic dust. They observed the early strength development that occurred in the soils mixed with lime and the ceramic waste and the decrease in the soil plasticity index. Hozatlıoğlu and Yılmaz [4] stated the improvement of lime compared to fly ash and gypsum on the stabilization of swelling soils. Baldovino et al. [5] stated the improvement in the microstructure and mechanical properties of a soil treated with dolomitic lime and recycled-glass powder. Chenarboni et al. [6] investigated the effect of different percentages of cement and zeolite for the stabilization of an expansive soil. They found that the substitution of 30% of cement by zeolite reached the highest unconfined compressive strength (UCS) results.

Soil stabilization requires huge amounts of cement and lime whose manufacturing processes generate high environmental impacts in terms of raw materials consumption, energy spending and CO2 emissions [7]. A possible alternative to the calcium-based soil stabilizers are the magnesium-based ones. Magnesium-based binders have demonstrated in recent years to be effective and more sustainable alternatives to lime and to cement. Yi et al. [8] stabilized two clayey soils with binders based on reactive MgO and Ground-Granulated Blast Furnace Slag (GGBS). They found that the optimum UCS were obtained with binary MgO-GGBS binders whose ratios were generally in the range of 19:1–4:1. At the age of 28 days, these binders reached UCS values that exceeded the cement results by 1.3–4 times. Seco et al. [9] stabilized five soils containing sulfates with a low-grade MgO on its own at first, and then combined it with GGBS. They demonstrated the ability of the low-grade MgO for diminishing the soils’ swelling, and its convenience for the five soils’ stabilization and for the activation of GGBS. Li et al. [10] investigated the stabilization of a gypseous soil with binders based on high-grade and low-grade MgO products, combined with GGBS at different ratios. They stated the convenience of the MgO-GGBS binary binders for the stabilization of their gypseous soil and the better efficiency of the high-grade MgO compared to the low-grade MgO for the GGBS activation. The lower environmental impact of the magnesium-based binders is due to two main factors: (i) The lower manufacturing temperature of the MgO compared to the one of the calcium-based additives, and (ii) the use of recycled sources of reactive silicon and aluminum like GGBS or pulverized fuel ash [11]. Despite its demonstrated technical convenience and its higher sustainability compared to lime and cement, reactive MgO manufacturing shows some drawbacks: (i) Its production consumes magnesite rock, which is a scarce material [12], (ii) its manufacturing is based on the magnesite decarbonation that consumes huge amounts of energy and releases CO2 [8] and (iii) calcined magnesite is an expensive material, making the use of MgO uneconomical compared to lime or cement [13]. These reasons make the discovery of new economical and more environmentally friendly sources of reactive MgO for the soils’ stabilization necessary.

In the European Union (EU), the production of spent refractories is estimated between 1.42 and 2.66 million tons per year. Although many efforts are being conducted, these debris are an economic and environmental concern as they lack effective ways of valorizing the huge volumes generated [14,15,16]. Of these wastes, 26% are doloma and magnesia recycled refractory materials (DMRR) from the steel industry [17]. This is a potential availability of 0.43 to 0.80 million tons per year only in the EU. DMRR could become constituents for the production of MgO binders based on their high pH and their reactive MgO, free lime (CaO) and dicalcium silicate (C2S) contents [17,18].

The objective of this work is to state the ability of spent refractory wastes as constituents of sustainable binary hydraulic binders for the stabilization of clayey soils. These materials could become recycled sources of reactive MgO and CaO that could replace commercial additives like lime or calcined magnesia. Thus, soils’ stabilization would become an effective way for the valorization of the huge amounts of spent refractories generated around the world, contributing to decrease the environmental impact of the soils’ stabilization. Thus, this article analyzes the ability of three kinds of spent refractories, on their own as well as when combined with GGBS at different ratios, for the stabilization of a clayey soil. A laboratory investigation was carried out to analyze the effect of the DMRR considered in a clayey soil as well as their ability for the activation of GGBS. The potential of these binders was evaluated by means of the analysis of the physical, mechanical and chemical properties of soil samples stabilized with these binders.

2. Materials and Methods

2.1. Materials

The soil used in this investigation was a sample of clay, collected in Pamplona (Spain). This clay soil is generated by in situ weathering processes of the local Tertiary marly rock. In order to carry out this experiment, one ton of clay was extracted, and, after homogenization of the sample, it was air-dried, crushed and sieved to a maximum particle size of 2 mm. Table 1 contains the characterization of the soil sample considered.

Table 1.

Characterization of the soil sample.

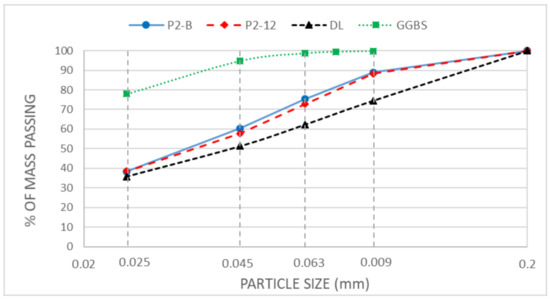

Three types of DMRR were considered in this work: Two magnesia refractory wastes named P2B and P2-12 respectively, and a doloma refractory waste named doloma lime (DL). Both P2 wastes come from the demolition of tundishes of a steel foundry: P2B is the denomination of the material recovered from the outer part of the refractory covering. This fraction is in contact with the molten metal and the slag. This fact modifies its chemical composition and sinters the refractory material that is recovered in the form of big blocks after the tundish demolition. P2-12 is the inner part of the spent magnesia refractory that is recovered in dust form. As this material is not in contact with the molten metal or the slag, it maintains a chemical composition close to that of the raw refractory. DL is made of the spent refractory of ladle furnaces. It shows higher CaO and SO3 contents than P2 wastes due to its direct contact with the ladle slag. The DMRR samples considered in this investigation were ground to reduce their granulometry and increase their surface-specific area. GGBS is a byproduct obtained during the manufacturing of pig iron. It has a large pozzolanic activity as a result of its richness in reactive calcium, silicon and aluminum oxides. GGBS is formed by rapid water cooling of molten iron slag that maintains an amorphous structure. After cooling, GGBS is dried and then ground to increase its specific surface area and thus increase its reactivity. Table 2 shows the chemical composition and reactivity parameters of these wastes. Figure 1 depicts the ground granulometric curves of the DMRRs used in this investigation.

Table 2.

Chemical composition and reactivity parameters of the doloma and magnesia recycled refractory materials (DMRRs) and the Ground-Granulated Blast Furnace Slags (GGBS) samples.

Figure 1.

Granulometric curves of the DMRRs and GGBS samples used in this investigation.

2.2. Samples’ Manufacturing and Testing

The samples’ manufacturing was carried out as follows: dried soil and additives were mixed together in a laboratory mixer for 5 min. After that, water corresponding to the optimum moisture of the soil, in accordance with the Standard Proctor (SP) test, was added slowly. An additional wet mixing was carried out for 5 min to guarantee a complete homogenization of the soil, additives and water. Once the quality of each mixture was verified visually, samples were collected for pH and Atterberg limits tests. Specimen pH values were determined according to the standard UNE-ISO 10390 by using a laboratory pH meter with an accuracy of ±0.01. Atterberg limits were stated based on the Spanish Standards UNE 103103 (Liquid Limit) and UNE 103104 (Plastic Limit). The samples’ Plasticity Index (PI) was defined as the difference between Liquid and Plastic Limits.

For the mechanical strength testing, cylindrical samples of 65 mm in diameter were prepared: 450 g of the wet mixes were pressed to 1.5 MPa into a mold, at a constant velocity of 50 mm/min. This was the pressure required to get the SP maximum density. Once compacted, samples were immediately demolded and wrapped in a polyethylene sheet in order to avoid dehydration. Specimens were cured in a wet chamber at 20 °C and 100% of relative humidity to the testing ages of 7, 28, 56 and 90 days. The mechanical properties of the samples were characterized according to the UCS test as defined in the Spanish standard UNE 103400. The UCS tests were conducted at the ages of 56 and 90 days, with two sets of samples: one without any conditioning of the curing ages, and the other after 24 h of moisture conditioning, as defined in Li et al. [10]. After testing, representative fragments of the specimens were crushed and used for the determination of the cured samples’ pH values as previously defined. At the ages of 28 and 90 days, sample fragments were crushed and dried for 1 week at 40 °C in a desiccator with silica gel and a CO2 sorbent. This conditioning was carried out to completely stop the cementation reactions. Fifty grams of each combination were ground and homogenized prior to the X-ray diffraction (XRD) analysis of these samples. A swell strain test after prolonged exposure to moisture was carried out to prevent any expansive effect of the treated soil samples. For this test, after the combinations’ mixing, samples of 63 mm in diameter and 20 mm in height were prepared at SP test maximum density and optimum moisture content, inside oedometer sample rings. The mixing as well as the sample compaction were performed manually, in accordance with the Spanish standard UNE 103601. Samples were maintained in water immersion for 15 days and linear expansion was registered daily by means of dial gauges with an accuracy of 10−5 m. Table 3 shows the 13 combinations of soil and additives considered for the experimental investigation.

Table 3.

Soil and additive combinations considered in the laboratory investigation.

In Table 3, samples constituents are expressed as percentages of dry mass, considering total dosages of 5%.

3. Results and Discussion

3.1. Soil Plasticity

Table 4 shows the Atterberg limits and Plasticity Index of the combinations considered in the laboratory investigation.

Table 4.

Atterberg liquid limit (LL), plastic limit (PL) and Plasticity Index (PI) of the combinations considered in the laboratory investigation.

When P2B, P2-12, DL and GGBS were added, the LL of the soil decreased from 38.4 to 34.2, 36.1, 38.3 and 32.8, respectively. The LL decreases could be a consequence of the addition of the additive particles and their lower affinity for water compared to clay ones, in accordance with Subbarao et al. [26]. Soil PL of 22.8 decreased in the combinations with additives to 20.0 for the P2B, to 20.8 for the P2-12, to 21.7 for the DL and to 19.9 for the GGBS. The 15.6 PI of the natural soil decreased to 14.2, 15.3 and 12.9 for the P2B, P2-12 and GGBS combinations respectively, whereas it increased to 16.6 for DL. These plasticity variations were attributed to different physical and chemical processes between the soil and the additives that would overlap each other. Among them are the modification of the soil granulometry by the additive particles’ addition, the filling of voids in the soil structure, the soil flocculation or the occurrence of cementitious hydration reactions [26,27,28]. These effects were also observed in the combinations of the DMRRs with GGBS at different ratios, where the small LL and PL variations produced low plasticity variations.

3.2. pH

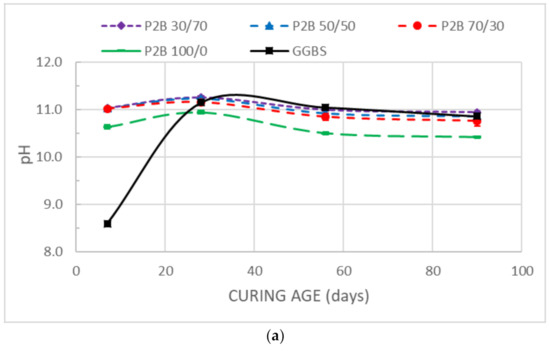

Figure 2 depicts the evolution of the samples’ pH along the 90 days of curing time.

Figure 2.

Samples’ pH variations along the curing time. (a) P2-B combinations, (b) P2-12 combinations and (c) DL combinations.

Combinations containing P2B, P2–12 and GGBS showed pH increases from day 7 to day 28. Beyond that point, there was a slight pH decrease up to day 90. On the other hand, DL combinations showed slight pH decreases all along the curing time. These observed behaviors are the consequence of the additive-free CaO and MgO contents as well as of the hydration, dissolution and precipitation mechanisms of the pozzolanic reactions [29,30]. At the earlier curing time, the pH values are explained by the presence of free CaO and MgO in the additives. These oxides hydrate in the presence of water to form portlandite and brucite respectively, that increase the combinations’ pH even for low contents of these oxides [31]. This hydration depends on the amount and availability of free CaO and MgO in the additives. In the case of the additives considered in this investigation, for P2B, P2-12 and GGBS, the pH increases were observed between day 7 and day 28. The slowness of the process and the small pH increases demonstrate low availability of free CaO and MgO. For these additives, the highest pH values reached were 11.25, 11.19 and 11.14, respectively. No pH increase was observed for DL, which after 7 days displayed the highest value of the laboratory investigation, with 11.15. This evidenced that this additive contained appreciable contents of available free lime that hydrated before 7 days. These results agree with those of other authors who observed that with high-grade MgO and CaO, the pH increases occurred between 0 and 14 days [30,32,33]. The alkaline environment is required to break the covalent Si-O and Al-O bonds in GGBS and clay particles. There is not a consensus about the pH necessary for this activation process, considering that different authors state that the required pH values are in the range of 11–12 [30]. Afterwards, Ca2+ and Mg2+ react with Si–O or Al–O to form calcium silicate hydrated (CSH), calcium aluminate hydrated (CAH), magnesium silicate hydrated (MSH) and magnesium aluminate hydrated (MAH) cementitious gels. This process consumes OH–, producing the pH decrease of the samples observed [29].

3.3. Mechanical Strength

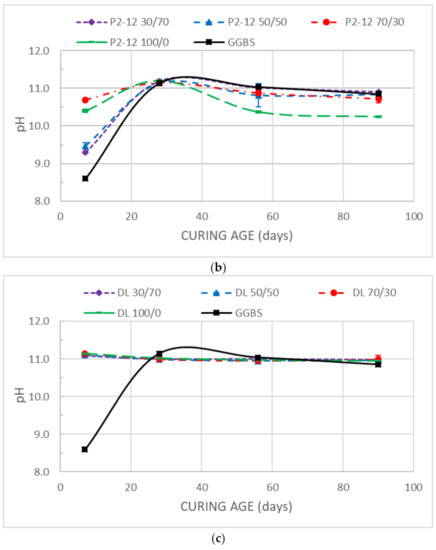

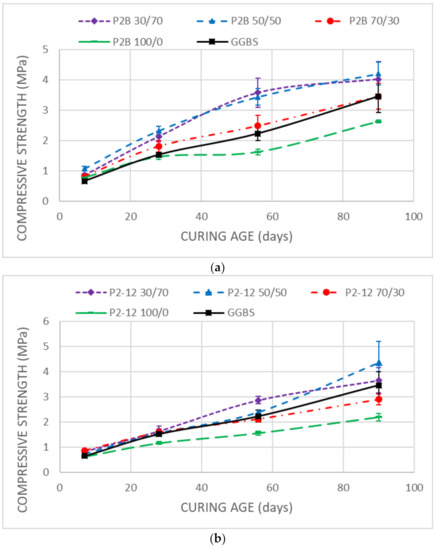

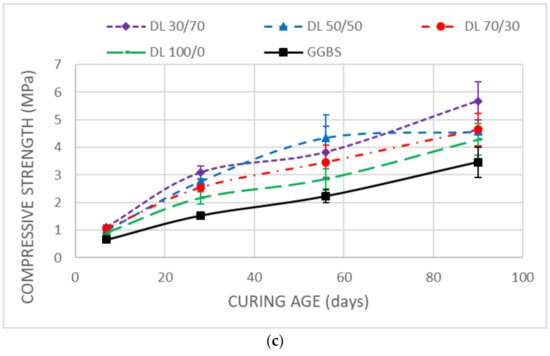

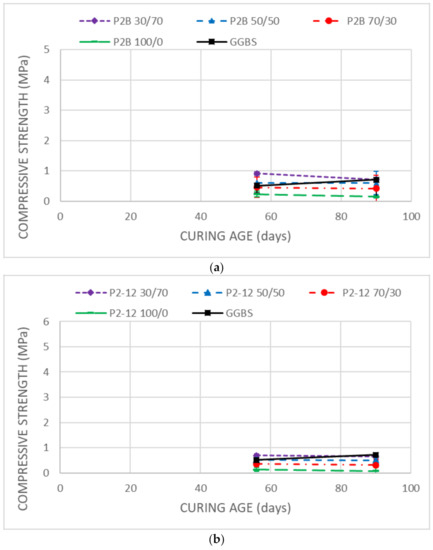

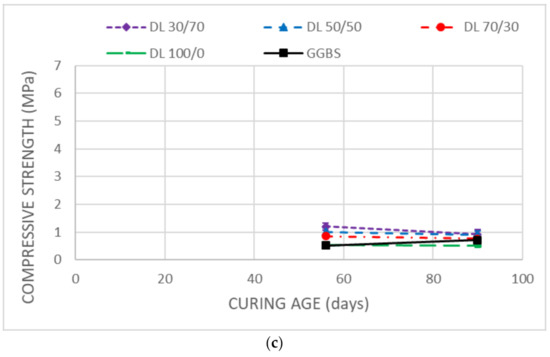

Figure 3 and Figure 4 respectively show the results of the UCS testing of the unsoaked and soaked samples.

Figure 3.

Unconfined compressive strength (UCS) test results before samples’ soaking. (a) P2-B combinations, (b) P2-12 combinations and (c) DL combinations.

Figure 4.

UCS test results after samples’ soaking. (a) P2-B combinations, (b) P2-12 combinations and (c) DL combinations.

Seven day specimen showed strength results slightly better than the 0.62 MPa achieved by the soil sample. For all the combinations, a direct correlation between the curing time and the combination strengths was observed for the above curing periods. This demonstrated that the additives used had low reactivity that developed over time. When the combinations of the unmixed additives were considered, GGBS showed a better cementitious ability compared to P2B (100/0) and P2-12 (100/0), but lower than DL (100/0), that reached the highest UCS values at all the curing ages. This fact was attributed to the higher richness of reactive CaO in the GGBS, and reactive CaO and MgO in the DL. These oxides from the additives acted as activators of the pozzolanic reactions and combined with their own silicon and aluminum, or with the clay aluminosilicates, to form cementitious compounds. The different amount and reactivity of these oxides present in the additives justify the UCS differences among the unmixed combinations.

Among P2B combinations, P2B (30/70) and P2B (50/50) showed very close UCS results at all the curing ages, overcoming those obtained in P2B (70/30), P2B (100/0) and GGBS combinations. These achieved final UCS values of 4.02, 4.20, 3.46, 2.62 and 3.46 MPa, respectively. This demonstrated the ability of P2B for the activation of the GGBS in the treated soil and the existence of an optimum beneficial effect of the substitution of GGBS by P2B in the range of 30% to 50%. These results agree with the behavior observed between a high-grade MgO and GGBS by Yi et al. [34] and Yi et al. [8]. They found that the optimum content of MgO in the MgO-GGBS binder was close to 20%. The optimum content of P2B in the P2B-GGBS binder obtained in this investigation was between 30% and 50%, highlighting the lower reactivity of P2B compared to a high-grade MgO. P2-12 combinations showed a similar behavior to P2B ones. In this case, all the combinations containing any P2-12-GGBS binders showed close UCS values to those of the GGBS ones at the ages of 7 and 28 days, reaching UCS values in the range of 0.66 to 0.87 MPa and 1.53 to 1.65 MPa, respectively. At 56 days, P2-12 (30/70) had the highest P2-12 UCS result at that stage, with 2.89 MPa. At 90 days, P2-12 (50/50) reached the highest strength among the P2-12 combinations, with 4.36 MPa. This would show a lower reactivity of the P2-12 compared to the P2B, in accordance with its lower effect for the soil plasticity modification. DL (100/0) combination showed improved UCS results compared to GGBS at all the curing ages, demonstrating its higher reactivity and its ability to form cementitious compounds with the soil aluminosilicates. DL (30/70), DL (50/50) and DL (70/30) improved the GGBS and the DL (100/0) UCS results at all the curing ages, evidencing the ability of DL to activate the GGBS. At 90 days, UCS results were 5.68 MPa for the combination DL (30/70), 4.57 MPa for the DL (50/50), 4.64 MPa for the DL (70/30) and 4.28 MPa for the DL (100/0). All of them improved the GGBS result of 3.46 MPa at 90 days. Considering the final UCS results, the optimum DL ratio in a DL-GGBS binder is 30%. This result was the highest UCS of all the combinations considered.

After soaking, UCS results showed strength losses in all the combinations at 56 days as at 90 days, in the range of 68.70% to 94.41%. These losses of strength were attributed mainly to the additive dosages considered in the laboratory investigation and probably to the low UCS results obtained for the unsoaked samples [10]. In spite of the loss of strength, GGBS was the only combination that increased its soaked UCS results at 90 days compared to those at 56 days from 0.04 to 0.05 MPa. On the other hand, the samples containing DMRR reduced their strength after soaking between these curing ages. These results demonstrated that, as expected, water plays a significant role in the loss of strength of the stabilized soils. This behavior is attributed to factors like the change in the soil’s pore water pressure, the affinity and the ability to hold water of the cementitious gels, or the soil’s plasticity reduction produced by the clay flocculation [35,36,37].

3.4. Swell Stress

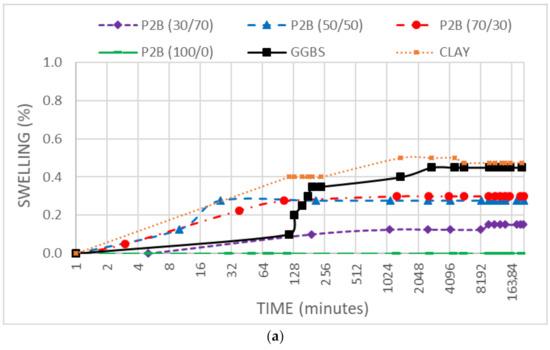

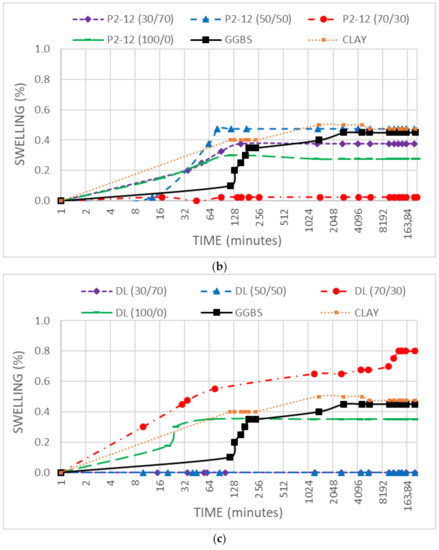

Figure 5 depicts the swell stress results after prolonged exposure to moisture of the soil and the stabilized combinations.

Figure 5.

Swell stress test results. (a) P2-B combinations, (b) P2-12 combinations and (c) DL combinations.

The maximum free swelling index of the un-stabilized clay was 0.48%. Three days of testing were required to reach this value. GGBS combination reached a total swelling of 0.45% that stabilized at 2 days of testing. This additive showed a very low effect against the clay swelling that was attributed to its low free lime content. P2B (30/70), P2B (50/50), P2B (70/30) and P2B (100/0) reduced the soil swelling to 0.15%, 0.28%, 0.30% and 0.00%, respectively. These swelling reductions did not show any correlation with the ratio P2B: GGBS of the binder, probably due to experimental uncertainties and the low swell index of the soil and the stabilized combinations. In all of them, the maximum swelling was reached before 3 days of testing, remaining stable afterwards. This demonstrated the nonexistence of possible delayed swelling cases due to the hydration of any P2B constituents. P2-12 (30/70), P2-12 (50/50), P2-12 (70/30) and P2-12 (100/0) combinations reached their final swellings of 0.38%, 0.48%, 0.03% and 0.28% respectively, during the first 3 days of testing. As in the P2B combinations, the swell index obtained in P2-12 combinations did not show any correlation with the ratio P2-12:GGBS. DL (30/70), DL (50/50), DL (70/30) and DL (100/0) combinations respectively obtained final swellings of 0.00%, 0.00%, 0.80% and 0.35%. The general behavior of these combinations was similar to those of the other DMRRs. Among them, only DL (70/30) increased the natural soil’s swelling (9 days of testing were required to reach its maximum value). The good results obtained by the combinations DL (30/70) and DL (50/50) were attributed to their close to optimal proportions between the binder constituents. This generated cementitious compounds, preventing any swell. The existence of a delayed hydration processes in binary MgO-GGBS binders was observed by Li et al. [10], but in this case, considering the low swelling values of the DL combinations and the low swelling increase (0.1%) between days 6 and 9, this fact was attributed to experimental uncertainties.

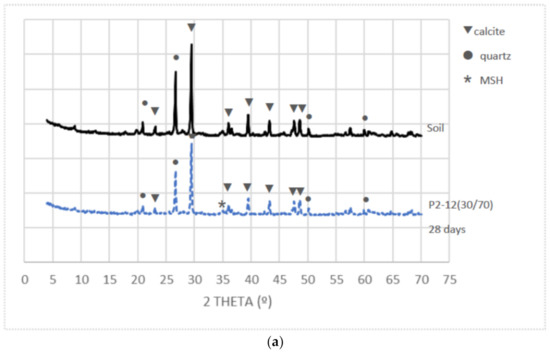

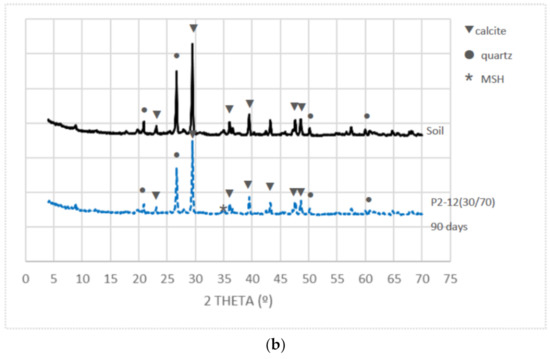

3.5. X-ray Diffraction

XRD tests were carried out in all the treated soil combinations at the ages of 28 and 90 days to identify mineralogy differences among them. The existence of peaks in the stabilized samples that do not appear in the soil diffractogram would be due to the different additive compositions or to chemical changes in the samples because of the cementation process. The intensity of the peaks would be related to the additive dosages or to the formation or destruction of minerals. At the age of 28 days as well as at 90 days, only small differences between the treated samples’ mineralogy and the soil were observed. Figure 6 shows the diffractograms of the soil and the P2-12 (30/70) combination at the ages of 28 and 90 days, as an example of the results obtained in these tests.

Figure 6.

Diffractograms of the soil and the P2-12 (30/70) samples: (a) at the age of 28 days and (b) at the age of 90 days.

In all the cases, the crystalline phases of the samples showed the soil mineralogy, which was composed mainly of calcite, quartz, halloysite and albite. The more intense peaks corresponded to calcite and quartz [38]. P2-12 (30/70) samples showed these main peaks, but their intensity decreased slightly due to the presence of the additives that reduced the soil’s content in the samples. No minerals from DMRR or GGBS were observed as a result of the low degree of crystallinity of these materials, the low dosage considered and the overlapping of their peak with those of the soil minerals [8,39]. The only hydration product was observed as a peak at 2 theta (35°) that was attributed to the formation of MSH gels based on Reference [38].

4. Conclusions

The goal of this study was to analyze the ability of the DMRR as a source of reactive magnesium for the stabilization of soils, by means of the characterization of physical and chemical properties of samples of clay treated with these products alone and combined with GGBS. Based on the results obtained, the following conclusions were drawn:

- DMRR and GGBS showed a low effect against the soil’s swelling because of their low free CaO and free MgO. The modification of the plasticity observed was attributed to the soil particles’ substitution and to a lesser extent to flocculation and cementation processes because of the low reactivity of the additives.

- The pH values at earlier ages of the stabilized samples are related to the free CaO and MgO provided by DMRR and GGBS, reaching values adequate for the occurrence of pozzolanic reactions. The pH evolution is consistent with hydration and cementation processes.

- Unsoaked samples increased the UCS results during all the curing time. DMRR demonstrated their ability to stabilize the soil as well as to activate GGBS. The optimum DMRR:GGBS ratio oscillates between 30:70 and 50:50. Based on its chemical composition, DL was the more effective DMRR, as expected.

- The UCS decreases observed in the stabilized samples after soaking demonstrated that the soil, after the treatment, keeps high affinity and water-holding capacity that diminishes its bearing capacity.

- The binders considered have demonstrated a low effect against the soil swelling, depending mainly on the DMRR free CaO content. No swelling processes related to delayed MgO hydration were observed.

- XRD showed that the mineralogy changes in the stabilized samples were mainly due to the particles’ soil substitution and the MSH cementitious products’ formation.

This work has demonstrated the ability of spent refractory wastes to act as a source of low-grade reactive MgO for the soil stabilization. Although the findings of this investigation are promising, more studies with other refractory materials and other soils are required to increase the knowledge available to date. This way, many of these wastes that so far lack effective valorization methods would become a recycled source of MgO for the manufacturing of low-impact construction binders.

Highlights

- Spent refractories showed low effect against soil plasticity and swelling

- Spent refractories show some reactivity due to their pH and free lime and MgO contents

- Spent refractories stabilized the soil and activated GGBS

- Stabilized soil keeps high affinity and water-holding capacity

- No delayed swelling processes related to MgO hydration were observed

Author Contributions

Conceptualization, A.S. and S.E.; methodology, J.M.d.C. and S.E.; validation, J.M.d.C. and S.M.-S.; formal analysis, J.M.d.C. and A.S.; investigation, B.G. and S.M.-S.; resources, S.M.-S. and B.G.; data curation, J.M.d.C. and S.E.; writing—original draft preparation, J.M.d.C.; writing—review and editing, A.S.; visualization, B.G.; supervision, A.S.; project administration, S.M.-S.; funding acquisition, B.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by Gobierno de Navarra and Fondo Europeo de Desarrollo Regional (FEDER) by the Fomento de la economía circular en la valorización de materiales refractarios (Reference: 0011-1365-2019-000100) research project.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data required to reproduce these findings are available from the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Behnood, A. Soil and clay stabilization with calcium- and non-calcium-based additives: A state-of-the-art review of challenges, approaches and techniques. Transp. Geotech. 2018, 17, 14–32. [Google Scholar] [CrossRef]

- Khazaei, J.; Moayedi, H. Soft Expansive Soil Improvement by Eco-Friendly Waste and Quick Lime. Arab. J. Sci. Eng. 2019, 44, 8337–8346. [Google Scholar] [CrossRef]

- Okeke, C.A.U. Engineering behaviour of lime- and waste ceramic dust-stabilized expansive soil under continuous leaching. Bull. Eng. Geol. Environ. 2020, 79, 2169–2185. [Google Scholar] [CrossRef]

- Hozatlıoğlu, D.T.; Yılmaz, I. Shallow mixing and column performances of lime, fly ash and gypsum on the stabilization of swelling soils. Eng. Geol. 2021, 280, 105931. [Google Scholar] [CrossRef]

- Baldovino, J.J.A.; Izzo, R.L.S.; Rose, J.L.; Domingos, M.D.I. Strength, durability, and microstructure of geopolymers based on recycled-glass powder waste and dolomitic lime for soil stabilization. Constr. Build. Mater. 2021, 271, 121874. [Google Scholar] [CrossRef]

- Chenarboni, H.A.; Lajevardi, S.H.; MolaAbasi, H.; Zeighami, E. The effect of zeolite and cement stabilization on the mechanical behavior of expansive soils. Constr. Build. Mater. 2021, 272, 121630. [Google Scholar] [CrossRef]

- Zhang, X.; Li, W.; Tang, Z.; Wang, X.; Sheng, D. Sustainable regenerated binding materials (RBM) utilizing industrial solid wastes for soil and aggregate stabilization. J. Clean. Prod. 2020, 275, 122991. [Google Scholar] [CrossRef]

- Yi, Y.; Zheng, X.; Liu, S.; Al-Tabbaa, A. Comparison of reactive magnesia- and carbide slag-activated ground granulated blastfurnace slag and Portland cement for stabilisation of a natural soil. Appl. Clay Sci. 2015, 111, 21–26. [Google Scholar] [CrossRef]

- Seco, A.; Miqueleiz, L.; Prieto, E.; Marcelino, S.; García, B.; Urmeneta, P. Sulfate soils stabilization with magnesium-based binders. Appl. Clay Sci. 2017, 135, 457–464. [Google Scholar] [CrossRef]

- Li, W.; Yi, Y.; Puppala, A.J. Suppressing Ettringite-Inducen Swelling of Gypseous Soil Using Magnesia-Activated Ground Granulated Blast-Furnace Slag. J. Geotech. Geoenviron. Eng. 2020, 146, 6020008. [Google Scholar] [CrossRef]

- Zhang, F. Magnesium Oxide Based Binders as Low-Carbon Cements; Imperial College: London, UK, 2012. [Google Scholar]

- Ruan, S.; Unluer, C. Comparative life cycle assessment of reactive MgO and Portland cement production. J. Clean. Prod. 2016, 137, 258–273. [Google Scholar] [CrossRef]

- Gu, K.; Jin, F.; Al-Tabbaa, A.; Shi, B.; Liu, C.; Gao, L. Incorporation of reactive magnesia and quicklime in sustainable binders for soil stabilisation. Eng. Geol. 2015, 195, 53–62. [Google Scholar] [CrossRef]

- Conejo, A.N.; Lule, R.G.; Lopéz, F.; Rodriguez, R. Recycling MgO-C refractory in electric arc furnaces. Resour. Conserv. Recycl. 2006, 49, 14–31. [Google Scholar] [CrossRef]

- Arianpour, F.; Kazemi, F.; Fard, F.G. Characterization, microstructure and corrosion behavior of magnesia refractories produced from recycled refractory aggregates. Miner. Eng. 2010, 23, 273–276. [Google Scholar] [CrossRef]

- Silva, A.P.; Segadães, A.M.; Lopes, R.A. Castable systems designed with powders reclaimed from dismantled steel induction furnace refractory linings. Ceram. Int. 2017, 43, 5020–5031. [Google Scholar] [CrossRef]

- Horckmans, L.; Nielsen, P.; Dierckx, P.; Ducastel, A. Recycling of refractory bricks used in basic steelmaking: A review. Resour. Conserv. Recycl. 2019, 140, 297–304. [Google Scholar] [CrossRef]

- Fang, H.; Smith, J.D.; Peaslee, K.D. Study of spent refractory waste recycling from metal manufacturers in Missouri. Resour. Conserv. Recycl. 1999, 25, 111–124. [Google Scholar] [CrossRef]

- AENOR. UNE-EN ISO 17892-12:2019. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 12: Determination of Liquid and Plastic Limits; ISO: Geneva, Swithzerland, 2019. [Google Scholar]

- AENOR. UNE 103204:2019. Organic Matter Content of a Soil by the Potassium Permanganate Method; UNE: Madrid, Spain, 2019. [Google Scholar]

- AENOR. UNE-EN 1744-1:2010+A1:2013. Tests for Chemical Properties of Aggregates—Part 1: Chemical Analysis; UNE: Madrid, Spain, 2013. [Google Scholar]

- AENOR. UNE 103500:1994. Geotechnic. Compactation Standard Test. Standard Proctor; UNE: Madrid, Spain, 1994. [Google Scholar]

- AENOR. UNE-EN ISO 17892-7:2019. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 7: Unconfined Compression Test; ISO: Geneva, Swithzerland, 2019. [Google Scholar]

- AENOR. UNE 103601:1996. Test for Free Swelling of Soils in Oedometer Device; UNE: Madrid, Spain, 1996. [Google Scholar]

- AENOR. UNE 103502:1995. Test Laboratory Method for Determining in a Soil the C.B.R Index; UNE: Madrid, Spain, 1995. [Google Scholar]

- Subbarao, G.V.R.; Siddartha, D.; Muralikrishna, T.; Sailaja, K.S.; Sowmya, T. Industrial Wastes in Soil Improvement. ISRN Civ. Eng. 2011, 2011. [Google Scholar] [CrossRef]

- Deepak, M.S.; Rohini, S.; Harini, B.S.; Ananthi, G.B.G. Influence of fly-ash on the engineering characteristics of stabilised clay soil. Mater. Today Proc. 2020, 37, 2014–2018. [Google Scholar] [CrossRef]

- Sharma, V.; Singh, S. Modeling for the use of waste materials (Bottom ash and fly ash) in soil stabilization. Mater. Today Proc. 2020, 33, 1610–1614. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, T.; Hu, J.; Tang, Y.; Niu, Y.; Wei, J.; Yu, Q. Characterization of reaction products and reaction process of MgO-SiO2-H2O system at room temperature. Constr. Build. Mater. 2014, 61, 252–259. [Google Scholar] [CrossRef]

- Zheng, J.; Sun, X.; Guo, L.; Zhang, S.; Chen, J. Strength and hydration products of cemented paste backfill from sulphide-rich tailings using reactive MgO-activated slag as a binder. Constr. Build. Mater. 2019, 203, 111–119. [Google Scholar] [CrossRef]

- Jin, F.; Al-Tabbaa, A. Strength and hydration products of reactive MgO-silica pastes. Cem. Concr. Compos. 2014, 52, 27–33. [Google Scholar] [CrossRef]

- Zhang, T.; Cheeseman, C.R.; Vandeperre, L.J. Development of low pH cement systems forming magnesium silicate hydrate (M-S-H). Cem. Concr. Res. 2011, 41, 439–442. [Google Scholar] [CrossRef]

- Jin, F.; Al-Tabbaa, A. Thermogravimetric study on the hydration of reactive magnesia and silica mixture at room temperature. Thermochim. Acta 2013, 566, 162–168. [Google Scholar] [CrossRef]

- Yi, Y.; Liska, M.; Al-Tabbaa, A. Properties of Two Model Soils Stabilized with Different Blends and Contents of GGBS. Mgo, Lime, and PC. J. Mater. Civ. Eng. 2014, 26, 267–274. [Google Scholar] [CrossRef]

- Seco, A.; Ramírez, F.; Miqueleiz, L.; Garci, B.; Prieto, E. The use of non-conventional additives in Marls stabilization. Appl. Clay Sci. 2011, 51, 419–423. [Google Scholar] [CrossRef]

- Miqueleiz, L.; Ramírez, F.; Seco, A.; Nidzam, R.M.; Kinuthia, J.M.; Tair, A.A.; Garcia, R. The use of stabilised Spanish clay soil for sustainable construction materials. Eng. Geol. 2012, 133–134, 9–15. [Google Scholar] [CrossRef]

- Chakraborty, S.; Nair, S. Impact of curing time on moisture-induced damage in lime-treated soils. Int. J. Pavement Eng. 2020, 21, 215–227. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, C.; Xi, P.; Chen, K.; Zhang, F.; Wang, S. Study on flexural properties of active magnesia carbonation concrete with fly ash content. Constr. Build. Mater. 2018, 187, 884–891. [Google Scholar] [CrossRef]

- Gomes, C.M.; de Oliveira, A.D.S. Chemical phases and microstructural analysis of pastes based on magnesia cement. Constr. Build. Mater. 2018, 188, 615–620. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).