Abstract

The present study describes the implementation of a food safety system in the dairy pilot plant “Gourmeticus Academicum,” a spin-off within the University of Agricultural Sciences and Veterinary Medicine of Cluj Napoca, Romania. In order to improve Hazard Analysis of Critical Control Points (HACCP) the preliminary programs were integrated into the quality management system (QMS) by monitoring the biological hazards. The process provides future specialists with good practice hands-on and educational tools. This study focused on hazard analysis, the determination and establishment of prerequisite programs, and the role of critical control points (CCPs) based on HACCP and the challenges found during the process as a critical thinking model on education programs. The determination of the CCPs in the processing of yogurt was made by applying the decision tree method. Besides, biological hazards are included as a by-control of the system’s implementation performance. For the successful implementation of HACCP principles, prerequisite programs (PRPs) and operational prerequisite programs (OPRPs) were initially implemented. This process could be challenging but feasible to be reached in small-scale food industries with remarkable results as educational tools.

1. Introduction

Yogurt is one of the most popular fermented dairy products, with a wide acceptance worldwide and whose nutritional and health benefits have been known for centuries [1]. As a general definition, yogurt is a fermented dairy product obtained from lactic acid fermentation by lactic acid bacteria (Streptococcus thermophilus and Lactobacillus delbrueckii ssp. bulgaricus). After fermentation, the milk acidifies and coagulates and increases the shelf life due to the low pH [2].

According to the available literature, yogurt is considered a functional food. The complexity of nutrients and digestibility gives this classification. It is a food that can be recommended for people with gastrointestinal disorders (irritable bowel disease, inflammatory bowel disease) and people with lactose intolerance. It helps increase the immune system and lose weight [3]. Yogurt and dairy products foster a significant concern to the dairy industry and public health authorities [4]. Yogurt is a good source of probiotics, but it could also be an essential source of foodborne pathogens [5]. Several authors have reported the outbreaks or incidents of foodborne diseases associated with dairy products: Brucellosis, Salmonella, Listeria, Clostridium botulinum [6,7,8,9]. In industrialized countries, milk and dairy are involved in 2–6% of outbreaks of foodborne diseases [10].

The classical methods regarding the hygienic quality of the finished products are inadequate to control hazards occurring at early stages of the process [11]. Food safety requires compliance with good manufacturing practices (GMP), sanitation standard operating procedure (SSOP), good hygiene practices (GHP), also called operation prerequisite programs (OPRPs), and the principles of Hazard Analysis of Critical Control Points (HACCP) [12].

The concept of critical control points originated in 1959, when the National Aeronautics and Space Administration (NASA), Pillsbury, and US Army laboratories collaborated to provide safe food for future space expeditions. This scientific concept is based on the assessment of food safety hazards through a control system. This system is a preventive one that analyzes the biological, chemical, and physical hazards that affect the entire food chain [11,13]. Several reports indicated the effects of implementing HACCP on the microbiological quality of food products [11,14,15,16].

Note that the implementation of HACCP is mandated for all small- and medium-sized food companies in the European Union (EU), and HACCP is recognized in the international food safety community as a worldwide guideline for controlling foodborne safety hazards [17]. Its principles, detailed in the Codex Alimentarius guidelines, are integrated with International Standard ISO 22000:2018 [18]. The application of HACCP systems does not imply the existence of a traceability system as a direct consequence of the documentation procedures. However, the implementation of such a system is of particular importance. Even if Principle 7 of the HACCP system requires established documentation and record-keeping procedures, traceability systems are not mandatory under this system [19].

ISO 22000:2018, which was introduced worldwide on 19 June, 2018, states that organizations must conduct a risk analysis to identify significant hazards [18]. ISO 22000 was not recognized by the Global Food Safety Initiative as a standardized reference for food manufacturers in the past, as it imparts no detailed PRP (prerequisite program)-related information. Hence, ISO 22000:2018 comes with improvements essentially looking to determine a PRP for and the CCP (critical control point) of the significant hazards, having as fundamental principle risk-based thinking and risk reduction [18]. In food industries, identifying the hazards was the one of the 12 application steps for the HACCP approach that were considered critical. It also agrees with the first principle of Codex HACCP and ISO 22000:2018, which calls for the execution of hazard analysis. HACCP systems aim to identify, evaluate, and control hazards [16].

This work aims to implement a food safety system (HACCP) under the ISO 22000:2018 [18] standard by conducting a hazard analysis in a small-scale dairy pilot plant and yogurt production to develop a critical thinking model as an educational tool for food engineering students (FES) as well to identify CCPs, thus setting up an effective preventive system that will lead to a safer and more efficient production of yogurt and providing an example of good practice and educational tools for FES education programs.

2. Materials and Methods

2.1. Small-Scale Dairy Pilot Plant Description

This study was conducted at the small-scale dairy pilot plant (DPP) of the Faculty of Food Science and Technology, University of Agricultural Sciences and Veterinary Medicine of Cluj Napoca, Romania. This DPP is part of the food pilot chain consisting of six pilot plants, founded in 2012. The main goal is to implement the EN ISO 22000:2018 food safety management systems [18] within the pilot plant where the practical works are carried out with the FES (as internship in traineeship programs—integrated education programs), thus setting up an effective preventive system that will lead to a safer and more efficient production of yogurt. Management commitment was realized by communicating to the organization the importance of meeting the International Standard statutory and regulatory requirements as well as customer requirements relating to food safety, and by ensuring the availability of financial, material, and human resources for the establishment of the necessary work environment, complying with the EU food standards and regulation. The products are directed exclusively to the internal market. DPP has implemented ISO 22000:2018 to improve the quality and safety of its products, customer expectations, the product image on the market, and to develop good practice as an educational tool. The identification, analysis, monitoring, and corrective actions established for CCPs and the verification of the effectiveness of the entire HACCP plan were performed according to the procedures underlying ISO 22000:2018. This standard has been implemented in production lines. However, the present study aims to integrate microbiological parameters (the total colony forming unit (CFU), somatic cell count (SCC), and Enterobacteriaceae) in the food safety system (HACCP) as quality parameters in a spin-off small-scale yogurt processing plant.

2.2. Materials

This manuscript analyzes the implementation of ISO 22000:2018 for natural yogurt with 3.6% fat made in a DPP.

Qualitative and quantitative reception of milk. Milk is transported from Cojocna farm in secured aluminum cans.

From the reception valve the milk is passed to an acid dairy products plant (IPI tank with 100 L capacity) using a pump (202 MHI type) a milk flow of 2000 L/h.

The acid dairy products plant is used for milk pasteurization and inoculation with the starter culture.

Milk pasteurization. Pasteurization is performed at high temperatures (85–90 °C) for 20–30 min. Pasteurization aims at the following:

- -

- improvement of hygienic quality of milk;

- -

- environment improvement for the development of lactic bacteria;

- -

- yogurt consistency improvement: high temperatures of pasteurization favors a softer curd that retains more whey.

From the pasteurization device the milk is continuously passed through the meanings of a pump (MHI 202 type) in a heat exchanger placed above the tank until complete pasteurization of the milk. The pasteurization is done under continuous stirring (the valve is provided with an agitator).

Milk cooling. The cooling of the milk is done in the same valve as pasteurization by recycling the milk through the heat exchanger until the yogurt reaches a temperature of 45–46 °C. The heat exchanger uses water from the regular city supplies network to cool the milk.

Milk inoculation. This is done with starter cultures of lyophilized lactic bacteria. The culture is diluted in milk and then the milk is strongly stirred until uniform distribution of the culture is reached for 10–15 min. With the help of the second pump (MHI 202 type) the inoculated milk is sent to a packaging device (ADL-ATS 200 type, 200–250 cups/h capacity for 200 mL cups).

Packaging. The dosage in sales packaging is performed in a manual device (ADL-ATS 200 type). The yogurt has to be continuously stirred in the valve during packaging. The cups are thermosealed with aluminum foil after filling.

Tempering. The packaged products are placed in a thermostatic aluminum cabinet (with a capacity of 400 cups for each 200 mL). The yogurt tempering takes place at 43–45 °C for 2.5–3 h.

Precooling at 18–20 °C for 2 h.

Cooling and storing at 2–6 °C for 12 h.

2.3. Methods

2.3.1. Elaboration of Critical Thinking Model

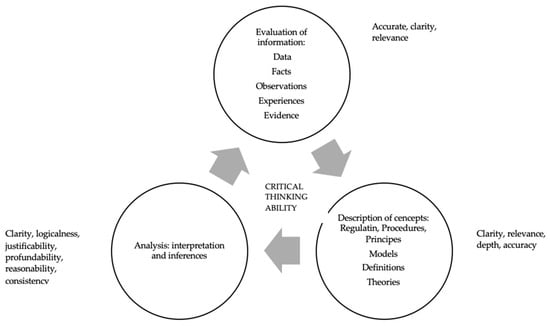

The critical thinking learning model developed and applied is described in Figure 1. Through the learning process three stages were identified: (1) Evaluation of information; (2) description/identification of problems as main concept; and (3) analysis (interpretation and inferences). The evaluation of information is based on gathering and reporting data, facts, observations, and experiences that should be clear, relevant, accurate, adequate, and consistent. The description is focused on identifying the most important concepts, theories, ideas, regulations, procedures, principles, models, and definitions that should be clear, relevant, and accurately presented. The analysis is centered on interpretation and inferences and elaborate conclusions and solutions that should be clear, logical, justifiable, and consistent. The application of the model during the learning process of FSMS (food safety management systems) to food engineering students leads to achieving the ability of critical and design thinking.

Figure 1.

Critical thinking model developed and applied as an educational tool to learning FSMS (food safety management systems).

2.3.2. Elaboration of PRPs

The HACCP team was responsible for coordinating and implementing the corrective measures to improve the adaptation to the PRPs (GMPs, GHPs, and SSOPs). The definition of the production chain—from the farm to final consumer; the definition of food safety and contamination; types of contamination; the importance of microbiological contamination; optimal conditions for the growth of microorganisms; contamination by microorganisms—elimination, inhibition, and prevention; the application of GMP principles (personal hygiene, environment, and equipment); habits for the correct handling of foods; benefits of GMPs (food safety, longer shelf life, reduced losses, better working environment, and consumer satisfaction); the need to change the behavior and commitment of all employees; work instructions; the importance of hygiene (how to avoid contamination); conditions for effective cleaning; phases of the hygiene process; and the presentation of work instructions as described by Cusato [20] were followed.

2.3.3. Elaboration of the HACCP Plan

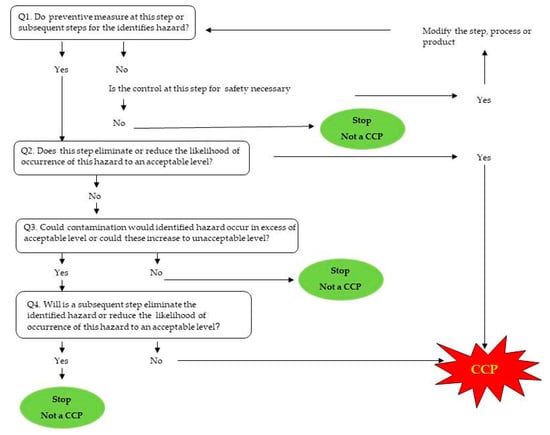

Based on ISO 22000:2018 [18] and HACCP principles, according to Codex Alimentarius, the overall technical process of yogurt production was drawn and a hazard analysis was performed following the 12 steps for developing an HACCP plan (Table 1). The identification of hazards is made according to their nature (biological, chemical, and physical). The analysis is done according to the likelihood occurrence level and its severity (Table 2) [12]. Hazard rating is calculated by multiplying likelihood by severity. The determination of CCPs is done with the help of the decision tree (DT) (Figure 2), in which only the stages with a hazard rating ≥3 are introduced [16].

Table 1.

Steps of Hazard Analysis and Critical Control Points.

Table 2.

Level of likelihood of occurrence and hazard severity.

Figure 2.

Decision tree (DT) protocol. The DT protocol was used to established CCPs.

2.3.4. Microbiological Analyses

The mandatory analyses according to Romanian legislation were performed according to Regulation No. 853/2004 as amended and supplemented by Regulation No. 1020/2008 [21] for raw material milk and pasteurized milk, and according to Regulation No. 2073/2005 as amended and supplemented by Regulation No. 365/2015 [22] for yogurt, which is in conformity with the EU Council Directive 2002/99/EC [23], Regulation (EC) No 178/2002 [24], Regulation (EC) No 852/2004 [25], Regulation (EC) No 853/2004 [26], Regulation (EC) No 854/2004 [27], and Regulation (EC) 882/2004 [28] for the public health rules and safety food trade.

The total colony forming unit (CFU) was analyzed according to the SR EN ISO 4833-1: 2014 method [29], the somatic cell count (SCC) was analyzed according to the SR EN ISO 13366-1:2008/AC:2010 method [30], and the Enterobacteriaceae were analyzed according to the ISO 21528-1: 2017 method [31].

3. Results and Discussion

3.1. Assessment and Implementation of the PRPs

The PRPs implemented in the DPP are hygiene of personnel and food hygiene, disinfection and cleaning, prevention of cross-contamination, the importance of maintaining a cold chain during food storage, hygiene premises and buildings, control pests, equipment maintenance, quality control of raw material at reception, food with water, waste and wastewater disposal, storage and transportation, product management, and supply management. A well-defined plan includes these programs. PRPs are fundamental conceptual programs for establishing security bases. There are more basic programs and assistance programs that provide foundations for HACCP [32]. The programs’ basis is GMP and GHP for products and the handling and delivery of finished products, to be provided by technology [18,33].

For the implementation of PRPs, buildings, facilities, equipment, utensils, food handlers, production, transportation of food, and documentation were evaluated. Following the evaluation and the observed non-conformities, operational procedures were performed. As an educational tool, the essential stage of the implementation of FSMS is the training. Although most people involved, especially interns, know about food contamination, theoretical training is not sufficient to implement FSMS in practice. The theoretical and practical training applied was observed by changing habits and behavior regarding GMPs and GHPs (by applying the principles of GMP (personal hygiene, environment, and equipment), habits for the correct handling of foods, how to avoid contamination, types of surfaces to be cleaned and cleaning agents, conditions for effective cleaning (solution concentration, water temperature, exposure time, and mechanical action), phases of the hygiene process (pre-rinsing, detergent solution, rinsing, and sanitizing), and the presentation of work instructions). Another aspect that encounters difficulties in DPP is the large rotation of the interns, delaying a team’s consolidation with the desired standard work and resulting in improvements taking longer than expected. To improve this aspect, a technological engineer (a university assistant responsible for student practice) was delegated to do theoretical and practical training and verify the activity on PRPs and the necessary monitoring. A similar approach was noted by Cusato [20] in a small dairy factory and by Karaman [34] in a dairy factory in Turkey.

3.2. Implementation of HACCP Plan

Preliminary steps to enable hazard analysis (Step 1–6).

3.2.1. Food Safety Team

A multidisciplinary team composed of nine people was created to implement the requirements of the system. The team members were trained thoroughly on the HACCP system and ISO 22000:2018 standard [18]. The food safety team members are an HACCP team leader, dairy technological engineer, technological engineer (university assistant responsible for student practice), testing laboratory manager, hygiene manager (responsible), maintenance manager, supply manager, sales manager, and HACCP team secretary.

3.2.2. Product Characteristics and Intended Use

The food safety team preceded a complete description of the yogurt, identifying its composition; chemical, biological, and physical characteristics; treatments; durability; storage conditions; and distribution methods. Table 3 summarizes the yogurt’s characteristics, and its use is recommended for all segments of the population, except sensitive people (people with a milk allergy or intolerance).

Table 3.

Gourmeticus yogurt product description.

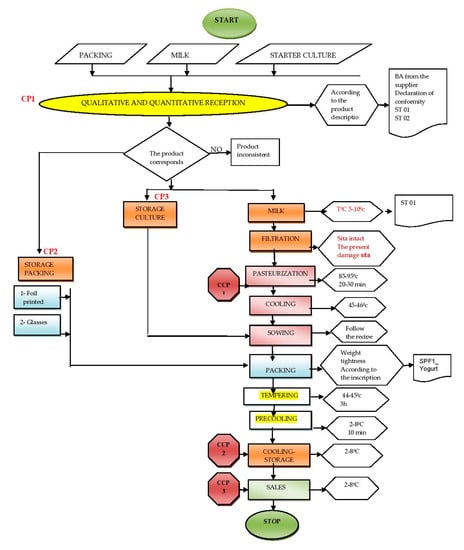

3.2.3. Flow Diagram

The flow diagram includes all the technological process stages for making Gourmeticus yogurt (Figure 3). In addition to the technological process stages, the diagram shows the stages until delivery to consumers (storage on the market). This detail is essential for a better presentation of the environmental conditions that could affect the product’s quality and safety. These aspects must be taken into account due to their importance for consumer health [35]. The flow diagrams were checked on-site by the food safety team.

Figure 3.

Flow diagram describing the technological steps of the Gourmeticus yogurt process.

3.2.4. HACCP Plan Principles (Steps 7–12): Hazard Identification and Determination of Acceptable Levels

The identification and assessment of hazards is a crucial principle for all HACCP systems [36] and a prerequisite to protecting public health. To achieve this step, the food safety team established a procedure specifying the methodology for hazard analysis, described in Table 4. Hazard analysis is applied from the receipt of raw materials to the delivery of the finished product. The dangers can have a direct or indirect impact on yogurt. They are based on the implementation of PRPs and aim to identify CCPs.

Table 4.

Hazard analysis and assessment. The table presents the hazard analysis of each steps of the technological flow diagram.

The identified hazards are classified according to pathogens (biological hazards), toxic substances (chemical hazards), and external particles (physical hazards) and are due to contamination, multiplication, and persistence. The HACCP team’s identification and analysis of the dangers of yogurt were performed for all stages of the production process.

Assessment of hazards based on the severity (S) of known effects on consumer health and the likelihood of these hazards occurring in DPP. The probability (P) is established according to the history and expertise of the DPP. Each hazard is evaluated and receives a score between 1 and 3. A hazard is considered significant if the resulting hazard rating (HR) score from the multiplication of the probability by the severity is above 3 [12,16,37,38]. A significant hazard is one of such a nature that its elimination or reduction to an acceptable level is essential to the production of safe food.

Following the hazard analysis, an HR is established. For hazards of HR ≤ 2, which are considered low or almost non-existent hazards, control measures are made using PRPs, with no CP (control point) or CCP required [39].

The PRPs control the potential chemical hazards associated with milk, such as veterinary drug residues, food additives, residue of migration of substances from packaging materials, heavy metals, and oil-free air compressors or potential biological hazards in order to reduce the probability of occurrence [40].

Even if greater importance is given to chemical and biological hazards, physical hazards in dairy products are just as significant [40]. Physical hazards can easily occur through non-compliance with PRPs or accidental contamination [41], and are related to contact with various objects, packaging, or incorrect labelling [40].

Milk cleaning is not considered in our unit, with HR ≥ 3 (CCP or CP), but is periodically checked for the presence of external particles (glass, plastic, wood, metal, etc.) [39].

When significant hazards are identified as having HR ≥ 3, a 4Q (Questions) decision tree is used to decide whether a particular hazard is a CCP or control point (CP), analyzed in Table 5. Although it is not mandatory to use the CCP decision tree method of ISO 22000:2018, the decision tree, a clear, well-organized, and understandable visual analysis tool, should be used to determine [41] and to prioritize [42] the CCPs.

Table 5.

CCP 1/CP 2 identification.

The first CCP identified was pasteurization, because non-compliance with the parameters of this stage could lead to the survival of pathogenic bacteria, which has the consequence of causing health problems to consumers. Several publications have been identified that describe the effect of term treatment on the inactivation of toxins and bacteria [43,44,45].

The second CCP is considered cooling, followed by storage. At this stage of the technological process, the temperature is reduced from 85 °C to 2–8 °C in 1 h. This CCP is considered essential because keeping it under control prevents the growth of potentially present thermotolerant bacteria. After pasteurization, product cross-contamination can be controlled by applying strict cleaning and disinfection rules [11].

The growth of bacteria can be controlled by strict time–temperature control. Consequently, time and temperature must be carefully monitored during the storage process [46]. The same strict conditions must be observed for the delivery and sales stages—CCP 3.

After the correct performance of the CCPs, the critical limits are established for each, monitoring procedures and actions to be taken if critical limits or action limits or action criteria are exceeded, as illustrated in Table 6.

Table 6.

Identifying critical limits, monitoring procedures, and corrective actions.

To check whether the HACCP plan is functioning as envisaged, the food safety team established a verification plan in Table 7, which specifies the application domain, frequencies, and responsibilities for the verification activities.

Table 7.

Establishing verification procedures.

In this study, to achieve the last principle of the HACCP plan, the documents and records prepared during the implementation of the plan are used. These documents represent evidence regarding the realization of the HACCP principles, the monitoring of the parameters of the CCPs, and the proposed corrective actions. These documents are divided into instructions and procedures and consist of the documents elaborated for the educational tool [11]. Their structural elements are title, purpose, application/scope, definitions, abbreviations, authorities, responsibilities, description of activities, records, related documents, references, and annexes.

3.3. Microbiological Analysis Results of Yogurt

The microbiological characteristics of raw milk, pasteurized milk, and yogurt samples are shown in Table 8. The samples were analyzed before and after the implementation of ISO 22000:2018 to verify the advantages of FSMS.

Table 8.

Microbiological characteristics of raw milk, pasteurized milk, and yogurt samples quantified before and after the HACCP implementation.

Following the HACCP plan’s implementation, a decrease in the specific microbiological load is observed, as shown in Table 8. In the case of raw milk, CFU decreases from 250,000 cfu/mL to 80,182 cfu/mL. In the case of pasteurized milk it decreases from 754 cfu/mL to 97 cfu/mL. These values are within the maximum allowed [21] of 300,000 cfu/mL for raw milk and 100,000 cfu/mL for pasteurized milk. In the case of NCS there is a decrease in raw milk from 345,000 NCS/mL to 14,000 NCS/mL, with the maximum allowed [21] being 400,000 NCS/mL. Spectacular decreases are also observed in the case of Enterobacteriaceae: In the case of pasteurized milk it decreases from 6 cfu/mL to 0 cfu/mL, and in the case of yogurt it decreases from 3 cfu/mL to 0 cfu/mL, within the maximum allowed values [22] of 10 cfu/mL. In the literature, the HACCP system application in dairy establishments has improved the microbial quality of the dairy product [14,20]. A study by Cusato [20] show similar results and showed the reduction of total coliform, mold, and yeast count in yogurt after the application of the HACCP plan in a dairy factory.

4. Limitation of the Study

The study integrates the microbiological parameters as a quality control (QC) tool of FSMS (Food Safety Management Systems) (HACCP) concerning good hands-on practice for FES implemented on-site in a small-scale yogurt pilot plant as educational programs. The model is adapted to a small-scale yogurt pilot plant, implementing only a simple FSMS (Food Safety Management System) involving HACCP principles and PRPs. These limitations help define new good practice and thinking models for teaching and learning FSMS in food-scale yogurt plant production.

5. Conclusions

The implementation of PRPs has a significant impact on the implementation of the HACCP system. The decision tree application shows that pasteurization, cooling/storage, and distribution processes are the selected hazard control measures, classified as CCP. The results of microbiological analysis of packed yogurt showed that the implementation of HACCP could improve the microbial quality of yogurt. The implementation of the HACCP plan in a small-scale yogurt pilot plant has brought benefits to food security. This system allows immediate action to be taken when safety issues are reported from the receipt of the raw milk to the delivery of the yogurt and the basis of educational tools for practice and learning the implementation of FSMS.

The results obtained following the implementation of ISO 22000:2018 regarding the processing of yogurt in a small-scale yogurt pilot plant have implications for the yogurt industry and education programs. The HACCP approach in DPP and the results obtained can be easily applied in pilot stations or food industry factories at a food scale-up, assessing the advantages and drawbacks of implementing FSMS in the food industry. This study’s conclusions underlie future research regarding the development of FSMS by applying predictive microbiology models and risk-assessment schemes, being an integrated model of good practice and education tools.

Author Contributions

Conceptualization, C.C.M. and R.A.M.; methodology, C.C.M. and M.J.; software, R.S.; validation, C.C.M., R.A.M. and A.C.; formal analysis, A.M. and A.N.; investigation, A.C.; resources, R.S.; data curation, C.C.M. and M.J.; writing—original draft preparation, C.C.M. and I.R.; writing—review and editing, C.C.M., R.A.M. and R.S.; visualization, C.C.M. and R.A.M.; supervision, C.C.M. and R.S.; project administration, R.A.M.; funding acquisition, R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by FDI 0252.

Acknowledgments

The authors give thanks to the anonymous reviewers and all the editors in the process of manuscript revision.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| DPP | Dairy pilot plant |

| CCP | Critical control point |

| CP | Control point |

| PRPs | Prerequisite programs |

| OPRPs | Operational prerequisite programs |

| GMP | Good manufacturing practices |

| SSOP | Sanitation standard operating procedure |

| GMP | Good manufacturing practices |

| GHP | Good hygiene practices |

| HACCP | Hazard Analysis Critical Control Points |

| FSMS | Food safety management system |

| QMS | Quality management system |

| QS | Quality system |

| CFU | Colony forming units |

| SCC | Somatic cell count |

| FES | Food engineering students |

References

- Zhang, S.S.; Xu, Z.S.; Qin, L.H.; Kong, J. Low-sugar yogurt making by the co-cultivation of Lactobacillus plantarum WCFS1 with yogurt starter cultures. J. Dairy Sci. 2020. [Google Scholar] [CrossRef]

- Corrieu, G.; Béal, C. Yogurt: The Product and its Manufacture. Encycl. Food Health 2016, 617–624. [Google Scholar] [CrossRef]

- Aryana, K.J.; Olson, D.W. A 100-Year Review: Yogurt and other cultured dairy products. J. Dairy Sci. 2017, 100, 9987–10013. [Google Scholar] [CrossRef]

- Melo, J.; Andrew, P.W.; Faleiro, M.L. Listeria monocytogenes in cheese and the dairy environment remains a food safety challenge: The role of stress re-sponses. Food Res. Int. 2015, 67, 75–90. [Google Scholar] [CrossRef]

- Soni, R.; Jain, N.K.; Shah, V.; Soni, J.; Suthar, D.; Gohel, P. Development of probiotic yogurt: Effect of strain combination on nutritional, rheological, organoleptic and probiotic properties. J. Food Sci. Technol. 2020, 1–13. [Google Scholar] [CrossRef]

- Garcell, H.G.; Garcia, E.G.; Pueyo, P.V.; Martín, I.R.; Arias, A.V.; Serrano, R.N.A. Outbreaks of brucellosis related to the consumption of unpasteurized camel milk. J. Infect. Public Health 2016, 9, 523–527. [Google Scholar] [CrossRef]

- Gould, L.H.; Mungai, E.; Barton Behravesh, C. Outbreaks attributed to Cheese: Differences between outbreaks caused by unpasteurized and pasteurized dairy products, United States, 1998-2011. Foodborne Pathog. Dis. 2014, 11, 545–551. [Google Scholar] [CrossRef]

- Lindstrom, M.; Myllykoski, J.; Sivela, S.; Korkeala, H. Clostridium botulinum in cattle and dairy products. Crit. Rev. Food Sci. Nutr. 2010, 50, 281–304. [Google Scholar] [CrossRef]

- Motarjemi, Y.; Moy, G.G.; Jooste, P.J.; Anelich, L.E. Milk and dairy products. In Food Safety Management—A Practical Guide for the Food Industry; Motarjemi, Y., Lelieveld, H., Eds.; Academic Press: New York, NY, USA, 2014; pp. 83–117. [Google Scholar]

- Claeys, W.L.; Cardoen, S.; Daube, G.; De Block, J.; Dewettinck, K.; Dierick, K.; De Zutter, L.; Huyghebaert, A.; Imberechts, H.; Thiange, P.; et al. Raw or heated cow milk consumption: Review of risks and benefits. Food Control 2013, 31, 251–262. [Google Scholar] [CrossRef]

- Allata, S.; Valero, A.; Benhadja, L. Implementation of traceability and food safety systems (HACCP) under the ISO 22000:2005 standard in North Africa: The case study of an ice cream company in Algeria. Food Control 2017, 79, 239–253. [Google Scholar] [CrossRef]

- Kamboj, S.; Gupta, N.; Bandral, J.D.; Gandotra, G.; Anjum, N. Food safety and hygiene: A review. Int. J. Chem. Stud. 2020, 8, 358–368. [Google Scholar] [CrossRef]

- Manley, D. Quality management systems and hazard analysis critical control point (HACCP) in biscuit manufacture. Manley’s Technol. Biscuitscrackers Cookies 2011, 23–28. [Google Scholar] [CrossRef]

- El-Hofi, M.; El-Tanboly, E.S.; Ismail, A. Implementation of the hazard analysis critical control point (HACCP) system to UF white cheese production line. Acta Sci. Pol. Technol. Aliment. 2010, 9, 331–342. [Google Scholar]

- Nada, S.; Ilija, D.; Igor, T.; Jelena, M.; Ruzica, G. Implication of food safety measures on microbiological quality of raw and pasteurized milk. Food Control 2012, 25, 728–731. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Y.; Liu, S.; Yang, H.; Chen, C.; Chen, Y. Establishment the critical control point methodologies of seven major food processes in the catering industry to meet the core concepts of ISO 22000:2018 based on the Taiwanese experience. J. Food Saf. 2019, 1–10. [Google Scholar] [CrossRef]

- Panghal, A.; Chhikara, N.; Sindhu, N.; Jaglan, S. Role of Food Safety Management Systems in safe food production: A review. J. Food Saf. 2018, 38. [Google Scholar] [CrossRef]

- ISO 22000:2018. ISO 22000-Food Safety Management Systems Requirements for Any Organization in the Food Chain; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Chhikara, N.; Jaglan, S.; Sindhu, N.; Anshid, V.; Veera, M.; Charan, S.; Panghal, A. Importance of traceability in food supply chain for brand protection and food safety systems implementation. Ann. Biol. 2018, 34, 111–118. [Google Scholar]

- Cusato, S.; Gameiro, A.H.; Corassin, C.H.; Sant’Ana, A.S.; Cruz, A.G.; Faria, J.d.A.F.; de Oliveira, C. AF Food Safety Systems in a Small Dairy Factory: Implementation, Major Challenges, and Assessment of Systems’ Performances. Foodborne Pathog. Dis. 2013, 10, 6–12. [Google Scholar] [CrossRef]

- Regulation (EC) No 853/2004 of the European Parliament and of the Council of 29 April 2004 Laying Down Specific Hygiene Rules for Food of Animal Origin as Amended and Supplemented by Reg. Nr. 1020/2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32004R0853&from=en (accessed on 11 May 2020).

- Regulation (EU) No. 365/2010 of the Commission of 28 April 2010 Amending Regulation (EC) No Regulation (EC) No 2073/2005 on Microbiological Criteria for Food as Regards Enterobacteria in Pasteurized Milk and Other Liquid Pasteurized Milk Products and Listeria Monocytogenes in Food Salt. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32010R0365&from=EN (accessed on 11 May 2020).

- EU Council Directive 2002/99/EC. Council Directive 2002/99/EC of 16 December 2002 Laying Down the Animal Health Rules Governing the Production, Processing, Distribution and Introduction of Products of Animal Origin for Human Consumption. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32002L0099&from=DE (accessed on 11 May 2020).

- Regulation (EC) No 178/2002. Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 Laying Down the General Principles and Requirements of Food Law, Establishing the European Food Safety Authority and Laying Down Procedures in Matters of Food Safety. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32002R0178&from=EN (accessed on 11 May 2020).

- Regulation (EC) No 852/2004. Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29 April 2004 on the Hygiene of Foodstuffs. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32004R0852&from=EN (accessed on 11 May 2020).

- Regulation (EC) No 854/2004. Regulation (EC) No 854/2004 of the European Parliament and of the Council of 29 April 2004 Laying Down Specific Rules for the Organisation of Official Controls on Products of Animal Origin Intended for Human Consumption. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32004R0854&from=EN (accessed on 11 May 2020).

- Regulation (EC) 882/2004. Regulation (EC) No 882/2004 of the European Parliament and of the Council of 29 April 2004 on Official Controls Performed to Ensure the Verification of Compliance with Feed and Food Law, Animal Health and Animal Welfare Rules. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32004R0882&from=EN (accessed on 11 May 2020).

- SR EN ISO 4833-1:2014 Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 Degrees c by the Pour Plate Technique. Available online: https://www.iso.org/standard/53728.html (accessed on 11 May 2020).

- SR EN ISO 13366-1:2008/AC:2010 Milk—Enumeration of Somatic Cells—Part 1: Microscopic Method (Reference Method). Available online: https://www.iso.org/standard/40259.html (accessed on 11 May 2020).

- ISO 21528-1:2017 Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae—Part 1: Detection of Enterobacteriaceae; ISO: Geneva, Switzerland, 2017.

- Da Cruz, A.G.; Cenci, S.A.; Maia, M.C. Quality assurance requirements in produce processing. Trends Food Sci. Technol. 2006, 8, 406–411. [Google Scholar] [CrossRef]

- Gaaloul, I.; Riabi, S.; Ghorbel, R.E. Implementation of ISO 22000 in cereal food industry “SMID” in Tunisia. Food Control 2011, 22, 59–66. [Google Scholar] [CrossRef]

- Karaman, A.D.; Cobanoglu, F.; Tunalioglu, R.; Ova, G. Barriers and benefits of the implementation of food safety management systems among the Turkish dairy industry: A case study. Food Control 2012, 25, 732–739. [Google Scholar] [CrossRef]

- Martínez-Rodríguez, A.J.; Carrascosa, A.V. HACCP to control microbial safety hazards during winemaking: Ochratoxin A. Food Control 2009, 20, 469–475. [Google Scholar] [CrossRef]

- Mortimore, S. How to make HACCP really work in practice. Food Control 2001, 12, 209–215. [Google Scholar] [CrossRef]

- Fernandez-Segovia, I.; Perez-LIacer, A.; Peidro, B.; Fuentes, A. Implementation of a food safety management system according to ISO 22000 in the food supplement industry: A case study. Food Control 2014, 43, 28–34. [Google Scholar] [CrossRef]

- McSwane, D.; Rue, N.; Linton, R. Essentials of Food Safety and Sanitation, 3rd ed.; Pearson Education: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Arvanitoyannis, I.S.; Varzakas, T.H.; Koukaliaroglou-van Houwelingen, M. Implementing HACCP and ISO 22000 for Foods of Animal Origin—Dairy Products. In HACCP and ISO 22000-Application to Foods of Animal Origin; Arvanitoyiannis, I.S., Ed.; Wiley-Blackwell: Oxford, UK, 2009; pp. 91–180. [Google Scholar]

- Papademas, P.; Bintsis, T. Food safety management systems (FSMS) in the dairy industry: A review. Int. J. Dairy Technol. 2010, 63, 489–503. [Google Scholar] [CrossRef]

- MacSwane, D.; Rue, N.; Linton, R. Food safety. In Essentials of Food Safety and Sanitation, 2nd ed.; McSwane, D., Rue, N., Linton, R., Eds.; Prentice Hall: Upper Saddle River, NJ, USA, 2000; pp. 1–75. [Google Scholar]

- Van Asselt, E.D.; Noordam, M.Y.; Pikkemaat, M.G.; Dorgelo, F.O. Risk-based monitoring of chemical substances in food: Prioritization by decision trees. Food Control 2018, 93, 112–120. [Google Scholar] [CrossRef]

- Trevisani, M.; Mancusi, R.; Valero, A. Thermal inactivation kinetics of Shiga toxin-producing Escherichia coli in buffalo mozzarella curd. J. Dairy Sci. 2014, 97, 642–650. [Google Scholar] [CrossRef]

- Valero, A.; Cejudo, M.; García-Gimeno, R.M. Inactivation kinetics for Salmonella Enteritidis in potato omelet using microwave heating treatments. Food Control 2014, 43, 175–182. [Google Scholar] [CrossRef]

- Van Lieverloo, J.H.M.; de Roode, M.; Fox, M.B.; Zwietering, M.H.; Wells- Bennik, M.H. Multiple regression model for thermal inactivation of Listeria monocytogenes in liquid food products. Food Control 2013, 29, 394–400. [Google Scholar] [CrossRef]

- Lu, J.; Pua, X.H.; Liu, C.T.; Chang, C.L.; Cheng, K.C. The implementation of HACCP management system in a chocolate ice cream plant. J. Food Drug Anal. 2014, 22, 391–398. [Google Scholar] [CrossRef]

- Kassem, M.; Salem, E.; Ahwal, A.M.; Saddik, M.; Gomaa, N.F. Application of hazard analysis and critical control point in dairy industry. Rev. Sante Mediterr. Orient. 2002, 8, 114–128. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).