Risk Mitigation in a Meat Supply Chain with Options of Redirection

Abstract

1. Introduction

1.1. Social, Environmental, and Economic Sustainability of a Supply Chain

1.2. Perishability of Items in a Supply Chain

1.3. Perishability of Food in Supply Chains

2. Description of the Repetitive Deliveries in a Supply Chain of Perishable Goods

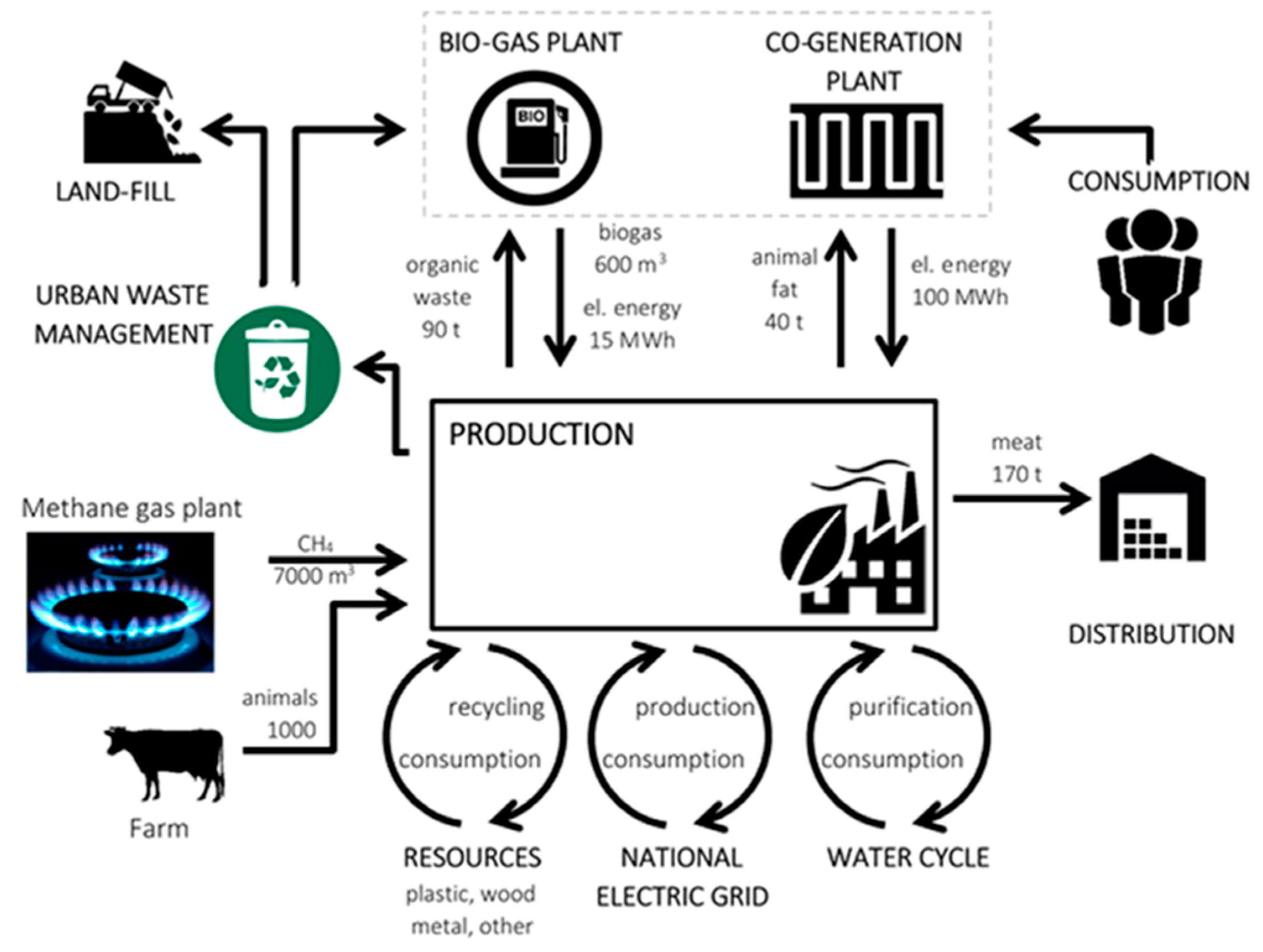

2.1. Meat Closed Loop Supply Chain

- ⚬

- Livestock farming, slaughtering, and processing with packaging of meat as part of the production chain,

- ⚬

- physical distribution,

- ⚬

- consumption, and

- ⚬

- recycling,

2.2. Monitoring and Control of the Perishability Dynamics in Meat Supply Chains—The Literature Review

2.3. Temperature and Humidity Measurement

3. Modelling a Meat Supply Chain

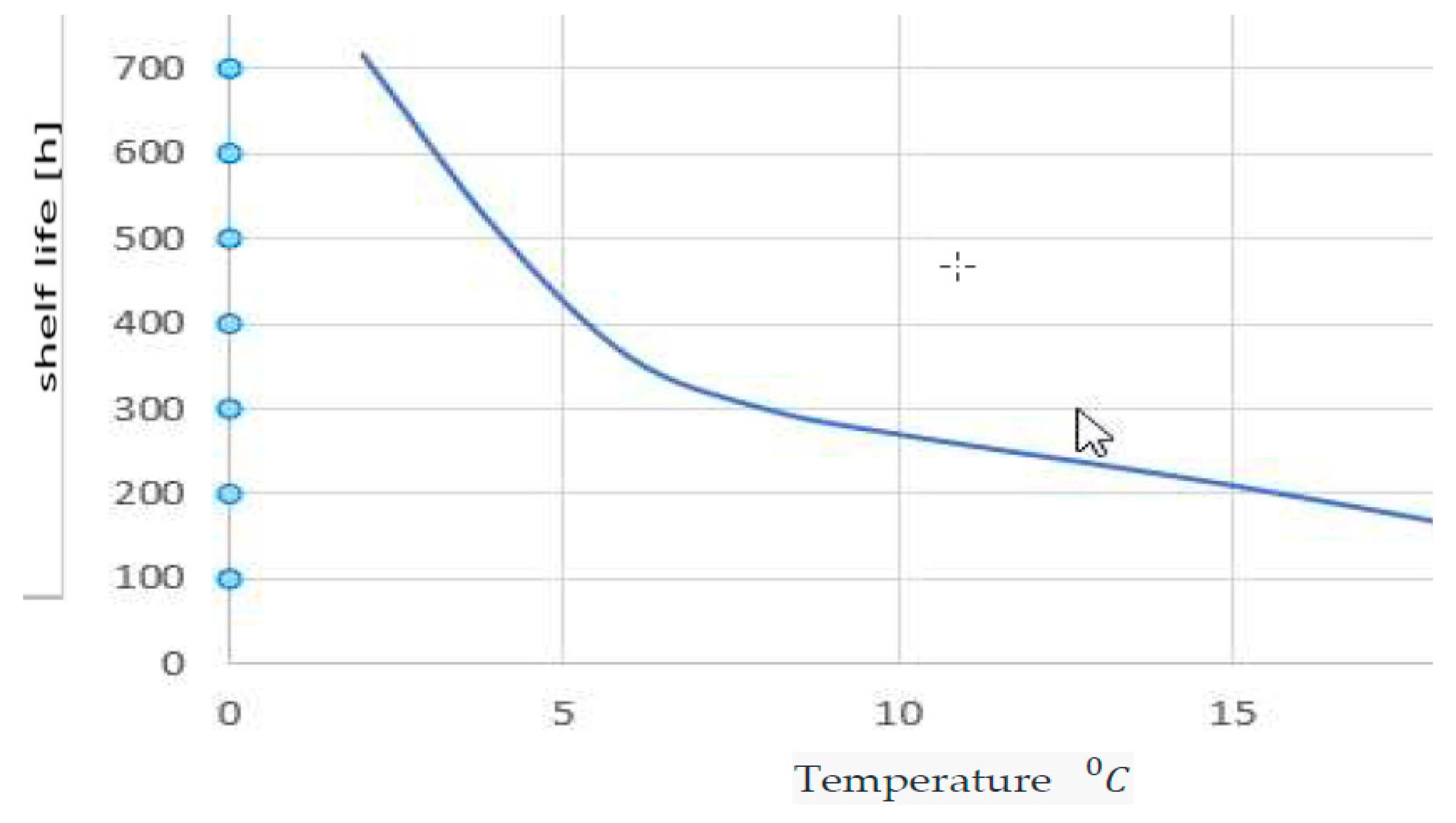

3.1. Shelf Life (SL) of Meat and the Customer Remaining Shelf Life (CRSL)

- ∙ and

- ∙………

3.2. Notation at Modification of the Extended MRP Theory and Required Data

3.3. The Skeleton Parallel to the Skeleton in the MRP Theory

3.4. The Economic Relationships of the Model

3.5. Perturbations of the Chain on the Edges or in the Nodes of a Graph

3.6. Net Present Value of the Repetitive Deliveries in a Supply Chain of Perishable Goods When the Critical Values of CRSL are Detected Earlier in the Chain

4. The Example, Where the Only Path on the Graph is a Chain

- ⚬

- Price vectors are: ]; ];

- ⚬

- the price of waste incineration in node 1 is equal to the price in the node 2:

- ⚬

- the formulation of logistic dynamics in cold chains is expressed much more simple than a general production MRP formulation, since ;

- ⚬

- ;

- ⚬

- at a given continuous interest rate and the time to disposal or earlier delivery at node 2 is 1 h from the warehouse (=1), the matrices H are:

- ⚬

- the transportation costs matrices are:

5. Conclusions and Directions to Further Research

Author Contributions

Funding

Conflicts of Interest

References

- Lambert, D.M.; Enz, M.G. Issues in Supply Chain Management: Progress and potential. Ind. Mark. Manag. 2017, 62, 1–16. [Google Scholar] [CrossRef]

- Hartmann, J.; Moeller, S. Chain liability in multitier supply chains? Responsibility attributions for unsustainable supplier behavior. J. Oper. Manag. 2014, 32, 281–294. [Google Scholar] [CrossRef]

- Panigrahi, S.S.; Bahinipati, B.; Jain, V. Sustainable supply chain management. Manag. Environ. Qual. 2019, 30, 1001–1049. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. The constructs of sustainable supply chain management—A content analysis based on published case studies. Prog. Ind. Ecol. Int. J. 2010, 7, 114. [Google Scholar] [CrossRef]

- Seuring, S.; Sarkis, J.; Müller, M.; Rao, P. Sustainability and supply chain management—An introduction to the special issue. J. Clean. Prod. 2008, 16, 1545–1551. [Google Scholar] [CrossRef]

- Grimm, J.H.; Hofstetter, J.S.; Sarkis, J. Exploring sub-suppliers’ compliance with corporate sustainability standards. J. Clean. Prod. 2016, 112, 1971–1984. [Google Scholar] [CrossRef]

- Venkatesh, V.; Kang, K.; Wang, B.; Zhong, R.Y.; Zhang, A. System architecture for blockchain based transparency of supply chain social sustainability. Robot. Comput. Manuf. 2020, 63, 101896. [Google Scholar] [CrossRef]

- Bansal, P. Evolving sustainably: A longitudinal study of corporate sustainable development. Strat. Manag. J. 2005, 26, 197–218. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Green, K.W.; Inman, R.A.; Sower, V.E.; Zelbst, P.J. Impact of JIT, TQM and green supply chain practices on environmental sustainability. J. Manuf. Technol. Manag. 2019, 30, 26–47. [Google Scholar] [CrossRef]

- Florida, R.; Davison, D. Gaining from Green Management: Environmental Management Systems inside and outside the Factory. Calif. Manag. Rev. 2001, 43, 64–84. [Google Scholar] [CrossRef]

- Vachon, S.; Mao, Z. Linking supply chain strength to sustainable development: A country-level analysis. J. Clean. Prod. 2008, 16, 1552–1560. [Google Scholar] [CrossRef]

- Deng, X.; Yang, X.; Zhang, Y.; Li, Y.; Lu, Z. Risk propagation mechanisms and risk management strategies for a sustainable perishable products supply chain. Comput. Ind. Eng. 2019, 135, 1175–1187. [Google Scholar] [CrossRef]

- Diop, N.; Jaffee, S.M. Fruits and vegetables: Global trade and competition in fresh and processed product markets. In Global Agricultural Trade & Developing Countries; Aksoy, M., Ed.; World Bank: Washingtion, DC, USA, 2005; pp. 237–257. [Google Scholar]

- Noya, I.; Aldea, X.; Gasol, C.M.; González-García, S.; Amores, M.J.; Colón, J.; Ponsá, S.; Roman, I.; Rubio, M.A.; Casas, E.; et al. Carbon and water footprint of pork supply chain in Catalonia: From feed to final products. J. Environ. Manag. 2016, 171, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, S.; Su, J. Identifying vulnerable nodes in supply chain based on the risk transmission model. In Proceedings of the 6th International Conference on Industrial Technology and Management, Cambridge, UK, 7–10 March 2017. [Google Scholar]

- Sprong, J.; Lin, X.; Maestre, J.; Negenborn, R. Quality-Aware Control for Optimizing Meat Supply Chains. In Proceedings of the 18th European Control Conference, Naples, Italy, 25–28 June 2019. [Google Scholar]

- Food and Agriculture Organization (FAO). Per Capita Egg Consumption. 2017. Available online: https://ourworldindata.org/meat-production#per-capita-egg-consumption (accessed on 3 April 2020).

- Raab, V.; Petersen, B.; Kreyenschmidt, J. Temperature monitoring in meat supply chains. Br. Food J. 2011, 113, 1267–1289. [Google Scholar] [CrossRef]

- Arason, S.; Asgeirsson, E.I.; Margeirsson, B.; Margeirsson, I.; Olsen, P.; Stefansson, H. Decision support systems for the food industry. In Handbook of Decision Making; Jain, L.C., Lim, C.P., Eds.; Springer: Berlin, Heidelberg, 2010; pp. 295–315. [Google Scholar] [CrossRef]

- Andriolo, A.; Battini, D.; Calzavara, M.; Gamberi, M.; Peretti, U.; Persona, A.; Pilati, F.; Sgarbossa, F. New RFID pick-to-light system: Operating characteristics and future potential. Int. J. RF Technol. Res. Appl. 2016, 7, 43–63. [Google Scholar] [CrossRef]

- Azzi, A.; Battini, D.; Persona, A.; Sgarbossa, F. Packaging Design: General Framework and Research Agenda. Packag. Technol. Sci. 2012, 25, 435–456. [Google Scholar] [CrossRef]

- Battini, D.; Bortolini, M.; Faccio, M.; Regattieri, A. Energy and cost optimization in multi-modal fresh food distribution network. In Proceedings of the 22nd International Conference on Production Research, Parana, Brazil, 28 June–1 August 2013. [Google Scholar]

- Battini, D.; Calzavara, M.; Persona, A.; Sgarbossa, F. Sustainable Packaging Development for Fresh Food Supply Chains. Packag. Technol. Sci. 2015, 29, 25–43. [Google Scholar] [CrossRef]

- Yang, S.; Xiao, Y.; Kuo, Y.-H. The Supply Chain Design for Perishable Food with Stochastic Demand. Sustainability 2017, 9, 1995. [Google Scholar] [CrossRef]

- Grubbström, R.W.; Tang, O. An Overview of Input-Output Analysis Applied to Production-Inventory Systems. Econ. Syst. Res. 2000, 12, 3–25. [Google Scholar] [CrossRef]

- Grubbström, R.W. Transform methodology applied to some inventory problems. J. Bus. Econ. 2007, 12, 3–25. [Google Scholar] [CrossRef]

- Grubbström, R.W.; Bogataj, L.; Bogataj, M. A Compact Representation and Optimisation of Distribution and Reverse Logistics in the Value Chain. In Mathematical Economics, Operational Research and Logistics; Bogataj, L., Ros Mcdonell, L., Eds.; Faculty of Economics: Ljubljana, Slovenia, 2007. [Google Scholar]

- Bogataj, M.; Grubbström, R.W. On the representation of timing for different structures within MRP theory. Int. J. Prod. Econ. 2012, 140, 749–755. [Google Scholar] [CrossRef][Green Version]

- Bogataj, M.; Grubbström, R.W. Transportation delays in reverse logistics. Int. J. Prod. Econ. 2013, 143, 395–402. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Bogataj, D.; Bogataj, M.; Hudoklin, D. Mitigating risks of perishable products in the cyber-physical systems based on the extended MRP model. Int. J. Prod. Econ. 2017, 193, 51–62. [Google Scholar] [CrossRef]

- Mexis, S.F.; Kontominas, M.G. PACKAGING: Active Food Packaging. Encyclopedia of Food Microbiology, 2nd ed.; University of Ioannina: Ioannina, Greece, 2014; pp. 999–1005. [Google Scholar]

- DHL Parcel Delivery Boxes Now in Apartment Buildings. Available online: https://www.dhl.com/en/press/releases/releases_2015/group/dhl_parcel_delivery_boxes_now_in_apartment_buildings.html (accessed on 10 September 2020).

- Commission Directive 92/2/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:31992L0002 (accessed on 2 September 2020).

- Agreement on the International Carriage of Perishable Foodstuffs and Special Equipment to be Used for such Carriage. Available online: https://www.unece.org/fileadmin/DAM/trans/main/wp11/ATP_publication/ATP-2016e_-def-web.pdf (accessed on 5 September 2020).

- Hudoklin, D.; Bojkovski, J.; Nielsen, J.; Drnovsek, J. Design and validation of a new primary standard for calibration of the top-end humidity sensors. Measurement 2008, 41, 950–959. [Google Scholar] [CrossRef]

- Beges, G.; Rudman, M.; Drnovsek, J. Evaluation of Flat Surface Temperature Probes. Int. J. Thermophys. 2010, 32, 396–406. [Google Scholar] [CrossRef]

- Pušnik, I.; Drnovšek, J. Infrared ear thermometers—Parameters influencing their reading and accuracy. Physiol. Meas. 2005, 26, 1075–1084. [Google Scholar] [CrossRef]

- Bogataj, D.; Bogataj, M. The role of free economic zones in global supply chains—A case of reverselogistics. Int. J. Prod. Econ. 2011, 131, 365–371. [Google Scholar] [CrossRef]

- Internet of Things in Logistics. DHL Trend Research. Available online: http://www.dhl.com/en/about_us/logistics_insights/dhl_trend_research.html (accessed on 6 September 2020).

- Net present value evaluation of energy production and consumption in repeated reverse logistics. Technol. Econ. Dev. Econ. 2015, 23, 877–894. [CrossRef]

- Mack, M.; Dittmer, P.; Veigt, M.; Kus, M.; Nehmiz, U.; Kreyenschmidt, J. Quality tracing in meat supply chains. Philos. Trans. R. Soc. 2014, 372, 999–1005. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Sgarbossa, F.; Russo, I. A proactive model in sustainable food supply chain: Insight from a case study. Int. J. Prod. Econ. 2017, 183, 596–606. [Google Scholar] [CrossRef]

- Animal Production and Health. Good Practices for the Meat Industry. Available online: http://www.fao.org/docrep/004/t0279e/T0279E00.htm#TOC (accessed on 5 September 2020).

- Berkel, B.M.; Boogard, B.V.; Heijnen, C. Preservation of fish and meat. Agromisa Found. 2004, 8, 78–80. [Google Scholar]

- Mutwakil; Dave, D.; Ghaly, A.E. Meat Spoilage Mechanisms and Preservation Techniques: A Critical Review. Am. J. Agric. Biol. Sci. 2011, 6, 486–510. [Google Scholar] [CrossRef]

- Smiddy, M.; Papkovsky, D.; Kerry, J. Evaluation of oxygen content in commercial modified atmosphere packs (MAP) of processed cooked meats. Food Res. Int. 2002, 35, 571–575. [Google Scholar] [CrossRef]

- Kuswandi, B.; Jayus; Oktaviana, R.; Abdullah, A.; Heng, L.Y. A Novel On-Package Sticker Sensor Based on Methyl Red for Real-Time Monitoring of Broiler Chicken Cut Freshness. Packag. Technol. Sci. 2014, 27, 69–81. [Google Scholar] [CrossRef]

- Salinas, Y.; Ros-Lis, J.V.; Vivancos, J.-L.; Martínez-Máñez, R.; Marcos, M.D.; Aucejo, S.; Herranz, N.; Lorente, I. Monitoring of chicken meat freshness by means of a colorimetric sensor array. Analyst 2012, 137, 3635–3643. [Google Scholar] [CrossRef]

- Salinas, Y.; Ros-Lis, J.V.; Vivancos, J.-L.; Martínez-Máñez, R.; Marcos, M.D.; Aucejo, S.; Herranz, N.; Lorente, I.; Garcia, E. A novel colorimetric sensor array for monitoring fresh pork sausages spoilage. Food Control. 2014, 35, 166–176. [Google Scholar] [CrossRef]

- Paull, R. Effect of temperature and relative humidity on fresh commodity quality. Postharvest Biol. Technol. 1999, 15, 263–277. [Google Scholar] [CrossRef]

- Kentved, A.B.; Heinonen, M.; Hudoklin, D. Practical Study of Psychrometer Calibrations. Int. J. Thermophys. 2012, 33, 1408–1421. [Google Scholar] [CrossRef]

- Regulation (EU) No 1169/2011. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32011R1169 (accessed on 3 September 2020).

- Kiermeier, A.; Tamplin, M.; May, D.; Holds, G.; Williams, M.; Dann, A. Microbial growth, communities and sensory characteristics of vacuum and modified atmosphere packaged lamb shoulders. Food Microbiol. 2013, 36, 305–315. [Google Scholar] [CrossRef] [PubMed]

- Bruckner, S.; Albrecht, A.; Petersen, B.; Kreyenschmidt, J. Influence of cold chain interruptions on the shelf life of fresh pork and poultry. Int. J. Food Sci. Technol. 2012, 47, 1639–1646. [Google Scholar] [CrossRef]

- Raab, V.; Bruckner, S.; Beierle, E.; Kampmann, Y.; Petersen, B.; Kreyenschmidt, J. Generic model for the prediction of remaining shelf life in support of cold chain management in pork and poultry supply chains. J. Chain Netw. Sci. 2008, 8, 59–73. [Google Scholar] [CrossRef]

- Bogataj, L. Preface. In Input-Output Analysis and Laplace Transforms in Material Requirements Planning; Bogataj, L., Grubbström, R.W., Eds.; FPP: Portorož, Slovenia, 1998. [Google Scholar]

- Bogataj, D.; Battini, D.; Calzavara, M.; Persona, A. The Response Latency in Global Production and Logistics: A Trade-off Between Robotization and Globalization of a Chain. Procedia Manuf. 2019, 39, 1428–1437. [Google Scholar] [CrossRef]

- Marín, F.; Alhama, F.; Moreno, J. Modelling of stick-slip behaviour with different hypotheses on friction forces. Int. J. Eng. Sci. 2012, 60, 13–24. [Google Scholar] [CrossRef]

- Marín, F.; Alhama, F.; Meroño, P.A.; Moreno, J.A. Modelling of stick–slip behaviour in a Girling brake using network simulation method. Nonlinear Dyn. 2016, 84, 153–162. [Google Scholar] [CrossRef]

- Alhama, F.; Marín, F.; Moreno, J. An efficient and reliable model to simulate microscopic mechanical friction in the Frenkel–Kontorova–Tomlinson model. Comput. Phys. Commun. 2011, 182, 2314–2325. [Google Scholar] [CrossRef]

| Commodity | Shelf Life/Days | Relative Humidity/% at the Optimal Temperature |

|---|---|---|

| Asparagus | 14–28 | 90–100 |

| Carrots | 28–180 | 90–100 |

| Cucumbers | 10–14 | 95 |

| Banana | 7–28 | 85–95 |

| Strawberries | 2–7 | 90–95 |

| Beef | 21–35 | 90 |

| Lamb | 10–15 | 90–95 |

| Pork | 7–14 | 90–95 |

| Veal | 7–21 | 90 |

| Chicken | 7–10 | >95 |

| Rabbit | max. 5 | 90–95 |

| Temperature [°C] | 2 | 8 | 17 | 20 |

| Shelf life (days) | 30 | 18 | 7 | 6 |

| H ·H | Input matrix describing how many items ( from is needed to produce or to package one item in activity cell (no. of items) in the input matrix | The complex frequency in the Laplace transformed domain (h−1) | |

| Risk taking measure of a decision maker | |||

| G;G | Output matrix; no. of items from i-th node to j-th node | Generalised matrix (in frequency) | |

| Indexes of activity cells(nodes) in a supply chain | Shelf life (SL); the remaining shelf life (RSL) at the node j (hours) | ||

| Intensity of activities no/cycle in j-th activity cell | ; | Power of decrease of RSL per time unit between nodes and in the node | |

| Intensity of flow from to ; intensity of reverse flow from to | Decrease of RSL in transportation from to | ||

| Lead time for the manipulation of item inside activity cell (hours) | Decrease of RSL | ||

| Lead time for transportation of items from to (hours) | Generalized basic transportation input–output matrix | ||

| Lead time matrix with element in its diagonal position, or 0 | c | Price vector | |

| Costs of transportation one unit of from to (eur) | c* | perturbed price vector; | |

| (Continuous) interest rate | K | Setup and other fix costs in the cycle (see [59]) (Eur) |

| Interpretation | Comment | |

|---|---|---|

| Net production and distribution of items used in and delivered from the production | “Standard” net production, to which recycled usable items are added. Some items go directly to recycling: | |

| Net “production and distribution” of items distributed | Items from the output of distribution (less those redistributed), reallocated geographically (and temporally), compared to inputs, some goes to recycling: | |

| Net “production and distribution” of items consumed | Used items and “new” in the sense that they did not exist before as used. are energy and gas returned to city consumption (cogeneration) | |

| Net production of recycled items | Outputs from recycling activities possible to use later as components in production. The landfill is assumed as an unit inside the recycling |

| Stipulated in the Contract: CRSL ≥ 230 h → | (a.) Optimal Temperature, Which Is Constant | (b.) Perturbations of Temperatures on the Route | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Node or Arc i-j or i | Phase in a Lamb Cold Chain | Time [h] | Temp. [°C] | Shelf Life Reduction [h] | Perisha- Bility Dynamics | Temp. [°C] | Shelf Life [h] Reduc-Tion |

Perisha- Bility Dyna- mics | |

| I | II | III | IV | V | VI | VII | VIII | IX | X |

| 4–3 | transport | 10 | 2 | 10 | 0.975369 | 0.002494 | 7 | 19 | 0.004793 |

| 3 | Distribu- tion center | 48 | 2 | 58 | 0.878788 | 0.002692 | 6 | 99 | 0.006156 |

| 3–2 | transport | 6 | 2 | 64 | 0.982759 | 0.002899 | 4 | 107 | 0.077411 |

| 2 | wholesaler | 24 | 2 | 88 | 0.929825 | 0.003032 | 5 | 142 | - |

| 2–1 | transport | 8 | 2 | 96 | 0.974843 | 0.003185 | 6 | 156 | - |

| 1 | retailer | 72 | 2 | 168 | 0.767742 | 0.003671 | 7 | 292 | - |

| total | 168 | 292 | |||||||

| CRSL | 238 | 108 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogataj, D.; Hudoklin, D.; Bogataj, M.; Dimovski, V.; Colnar, S. Risk Mitigation in a Meat Supply Chain with Options of Redirection. Sustainability 2020, 12, 8690. https://doi.org/10.3390/su12208690

Bogataj D, Hudoklin D, Bogataj M, Dimovski V, Colnar S. Risk Mitigation in a Meat Supply Chain with Options of Redirection. Sustainability. 2020; 12(20):8690. https://doi.org/10.3390/su12208690

Chicago/Turabian StyleBogataj, David, Domen Hudoklin, Marija Bogataj, Vlado Dimovski, and Simon Colnar. 2020. "Risk Mitigation in a Meat Supply Chain with Options of Redirection" Sustainability 12, no. 20: 8690. https://doi.org/10.3390/su12208690

APA StyleBogataj, D., Hudoklin, D., Bogataj, M., Dimovski, V., & Colnar, S. (2020). Risk Mitigation in a Meat Supply Chain with Options of Redirection. Sustainability, 12(20), 8690. https://doi.org/10.3390/su12208690