Effect of Corrosion in the Transverse Reinforcements in Concrete Beams: Sustainable Method to Generate and Measure Deterioration

Abstract

1. Introduction

2. Materials and Methods

2.1. Theoretical Method

Theoretical Electrochemical Method for the Induction of Deterioration in Transverse Reinforcements

- ∅t = change of diameter in time (mm);

- ∅I = initial diameter of the bar (mm);

- icorr = corrosion rate (μA/cm2);

- t = time after starting the propagation period (years);

- 0.023 = conversion factor used to convert μA/cm2 to years.

2.2. Experimental Method

2.2.1. Concrete Manufacturing

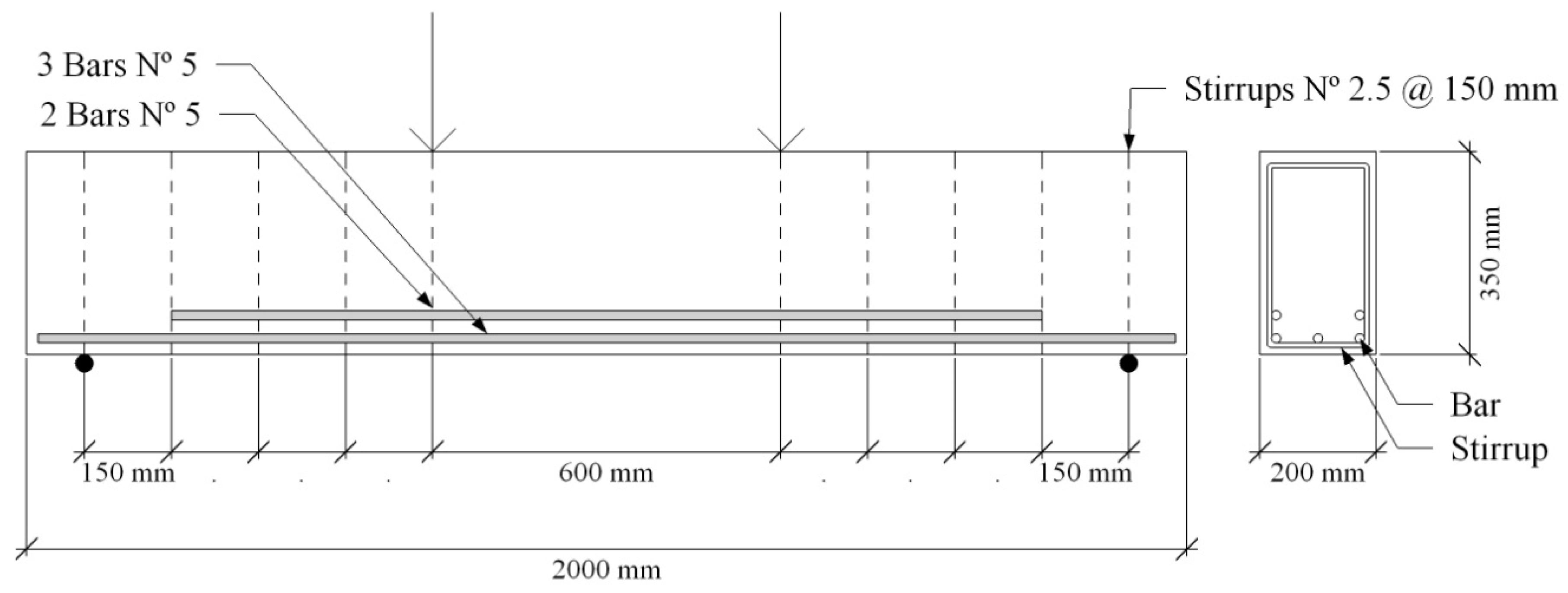

2.2.2. Manufacturing the Beams

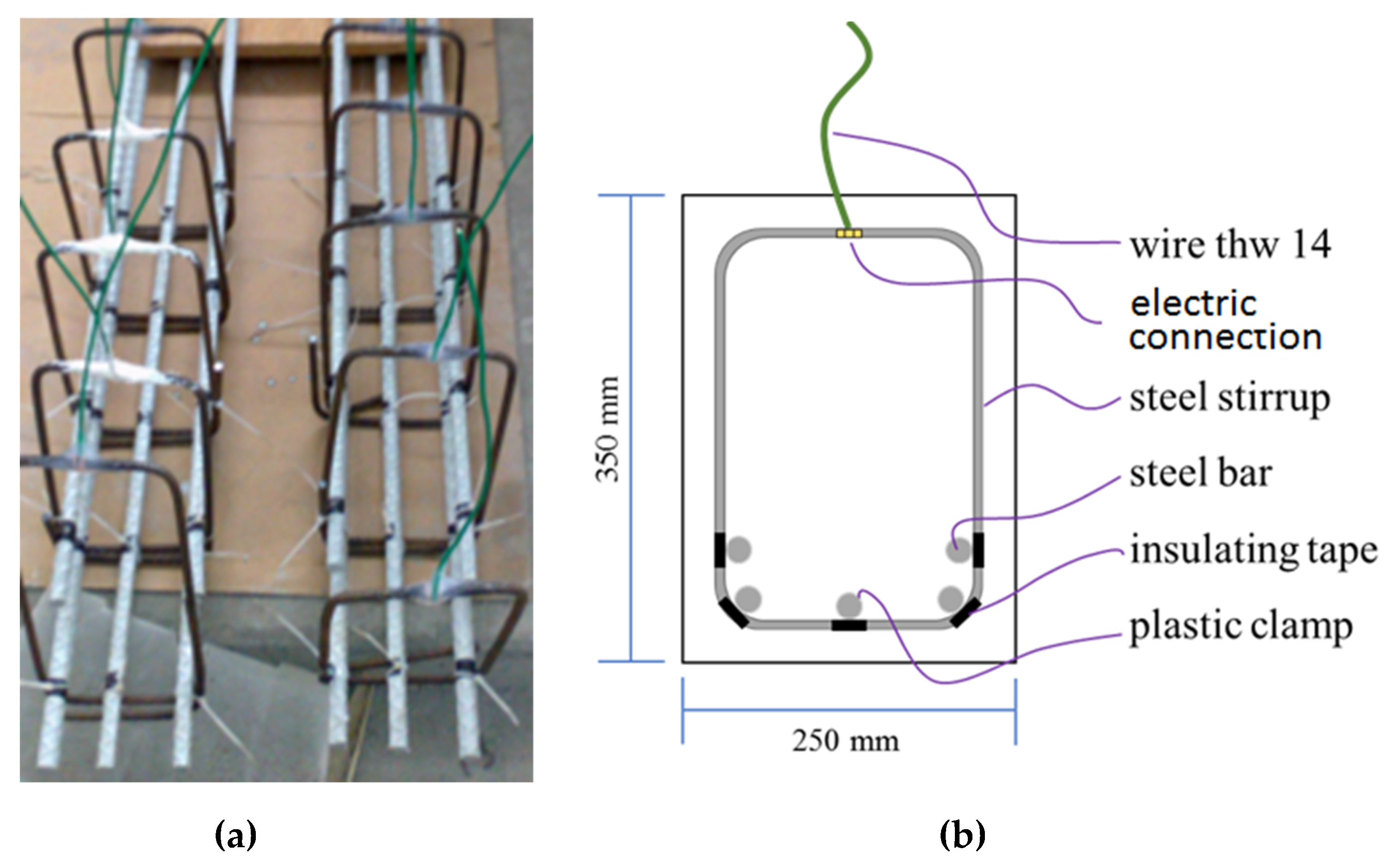

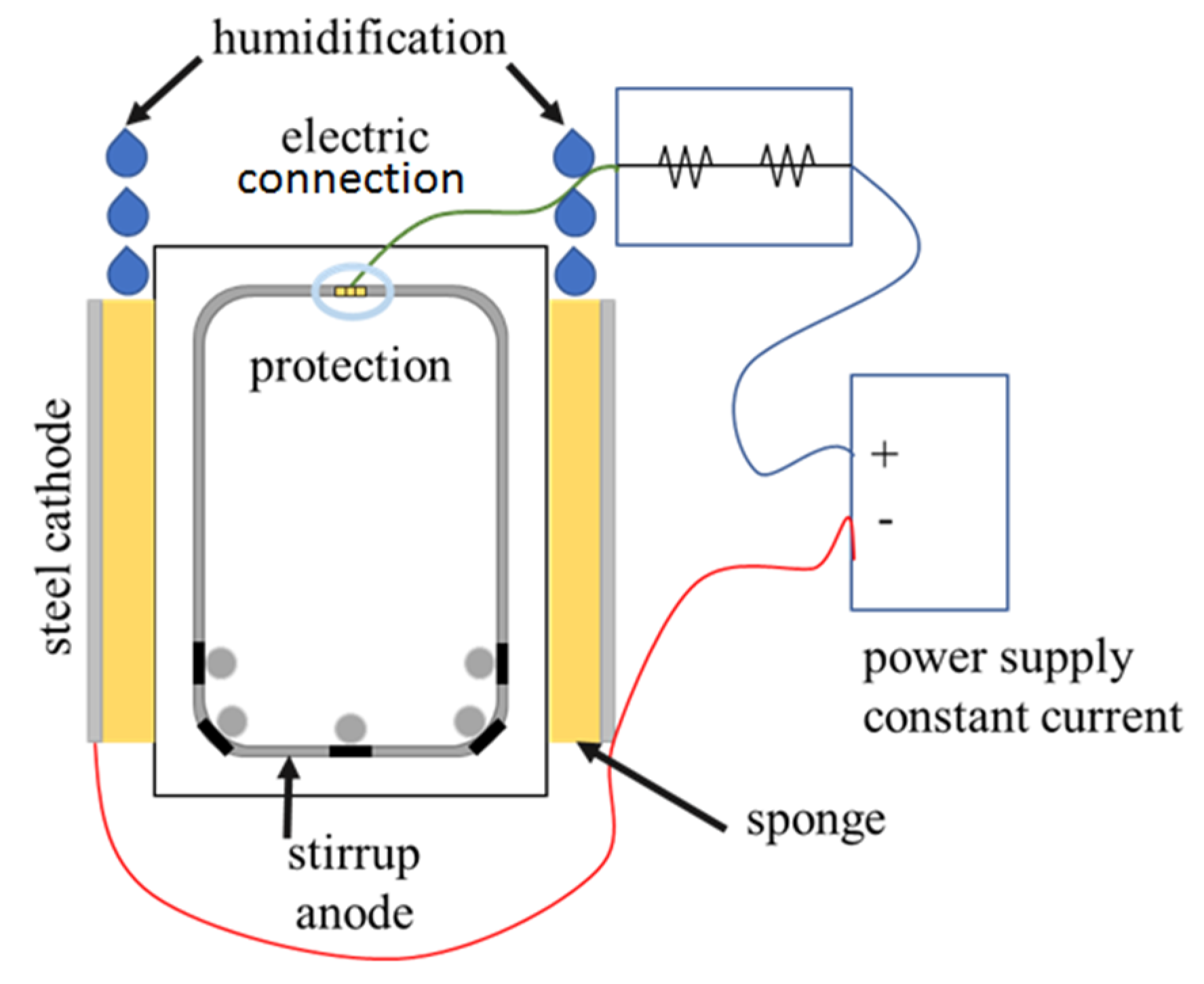

2.3. Method for Accelerated Deterioration Induction

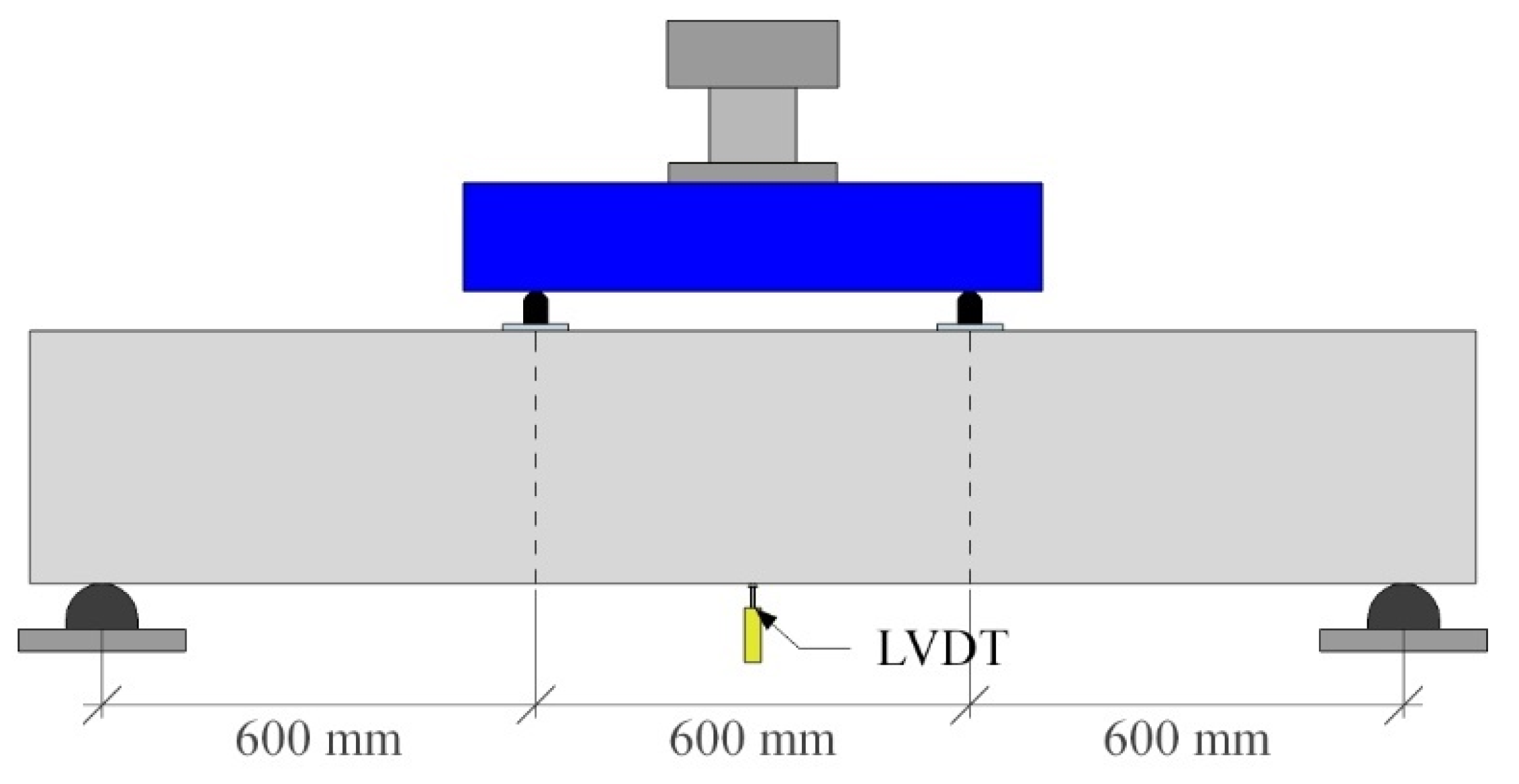

2.4. Mechanical Testing of the Beams

3. Results

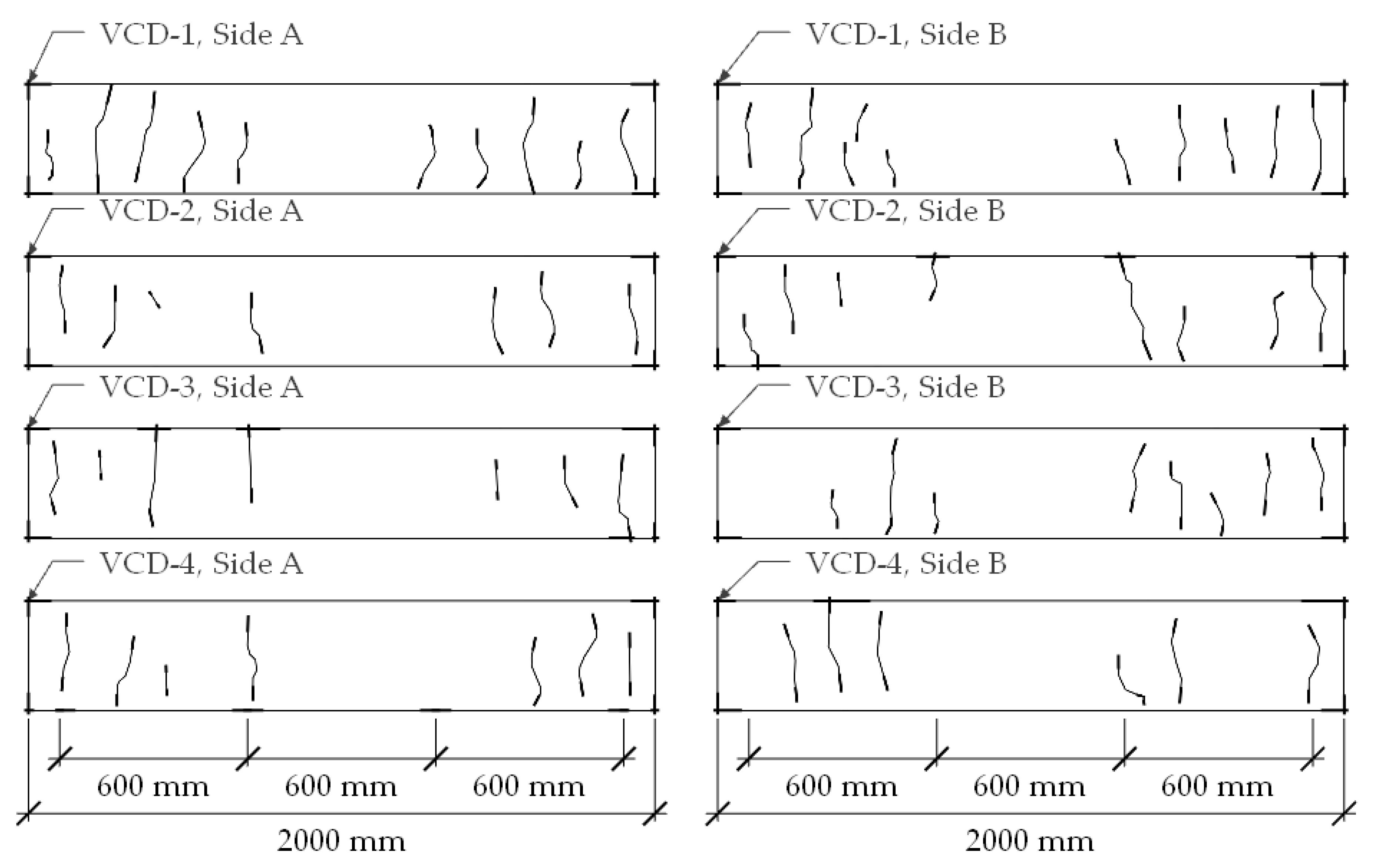

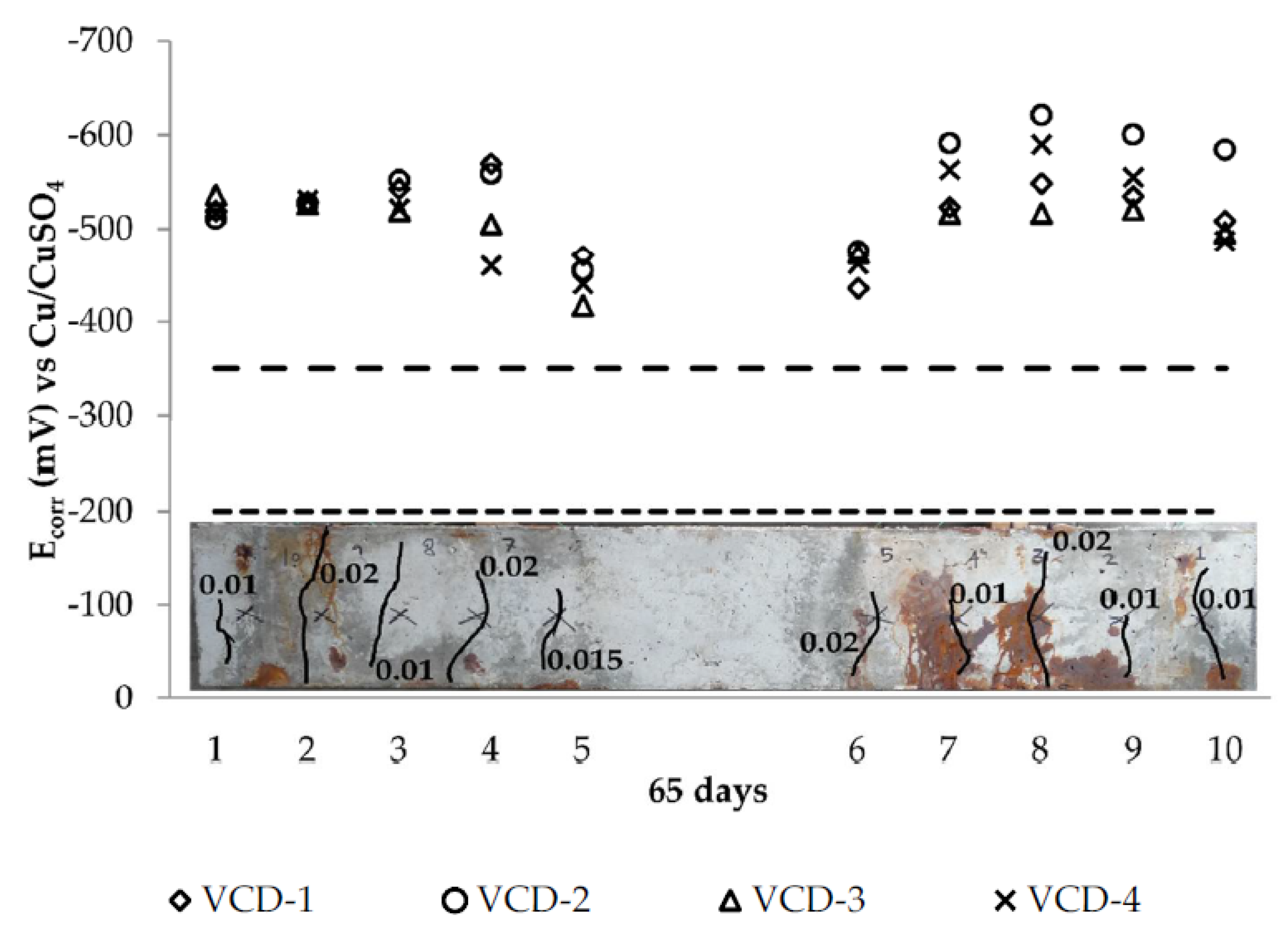

3.1. Visual Inspection

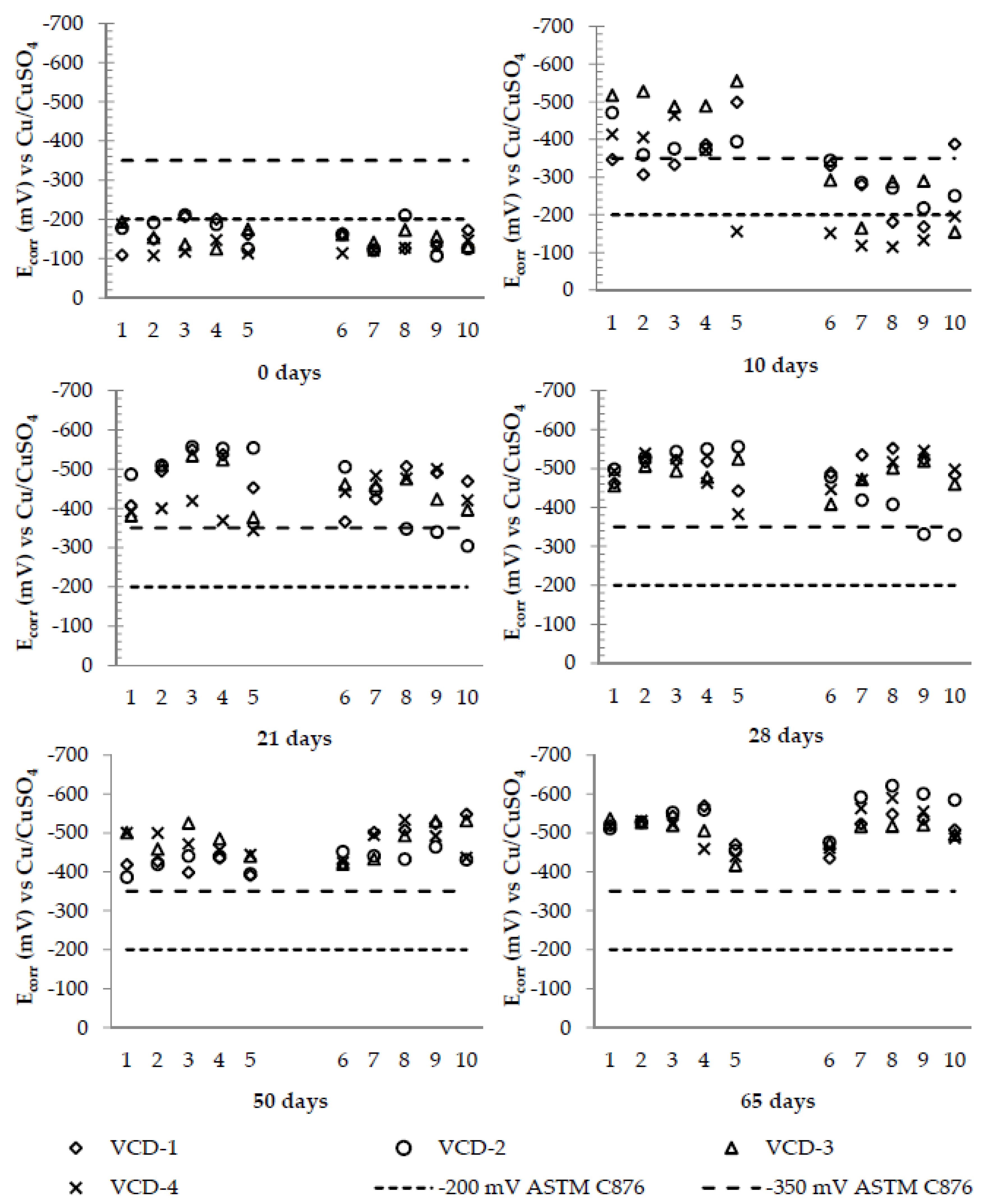

3.2. Measurement of the Corrosion Potentials

3.3. Determination of Cross-Section and Mass Losses in the Transverse Reinforcements

- W = metal weight, g, which is corroded in an aqueous solution in the time t, in s;

- I = current flux, in Amp;

- M = atomic mass of metal, in g/mol;

- n = number of consumed or produced electrons during the process;

- F = Faraday constant, 96,500 C/mol.

3.4. Determination of Chloride Content

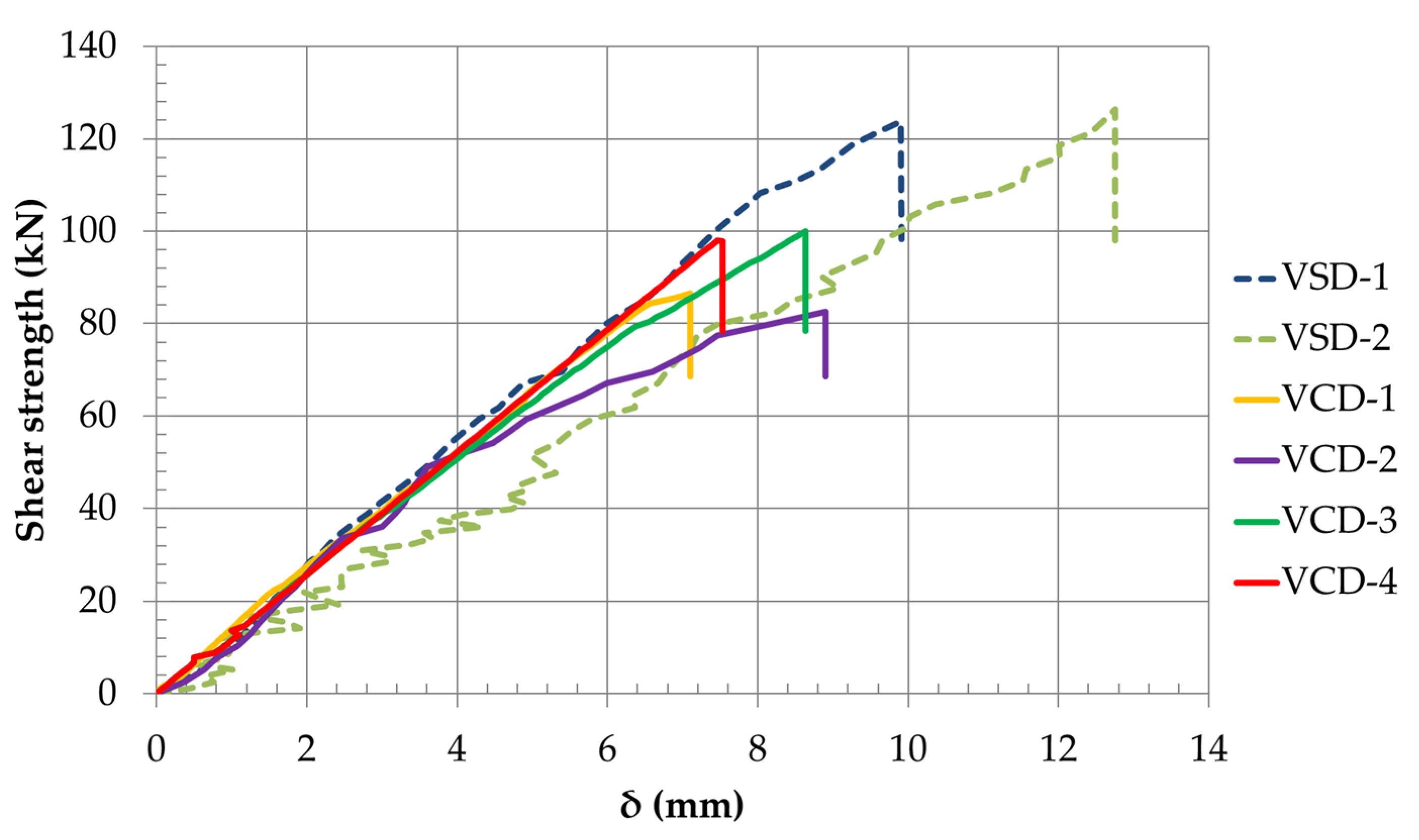

3.5. Mechanical Resistance to Shear

4. Discussion

4.1. Reliability of the Method for the Induction of Cracking in Concrete

4.2. Reliability of the Method to Generate Electrochemical Damage

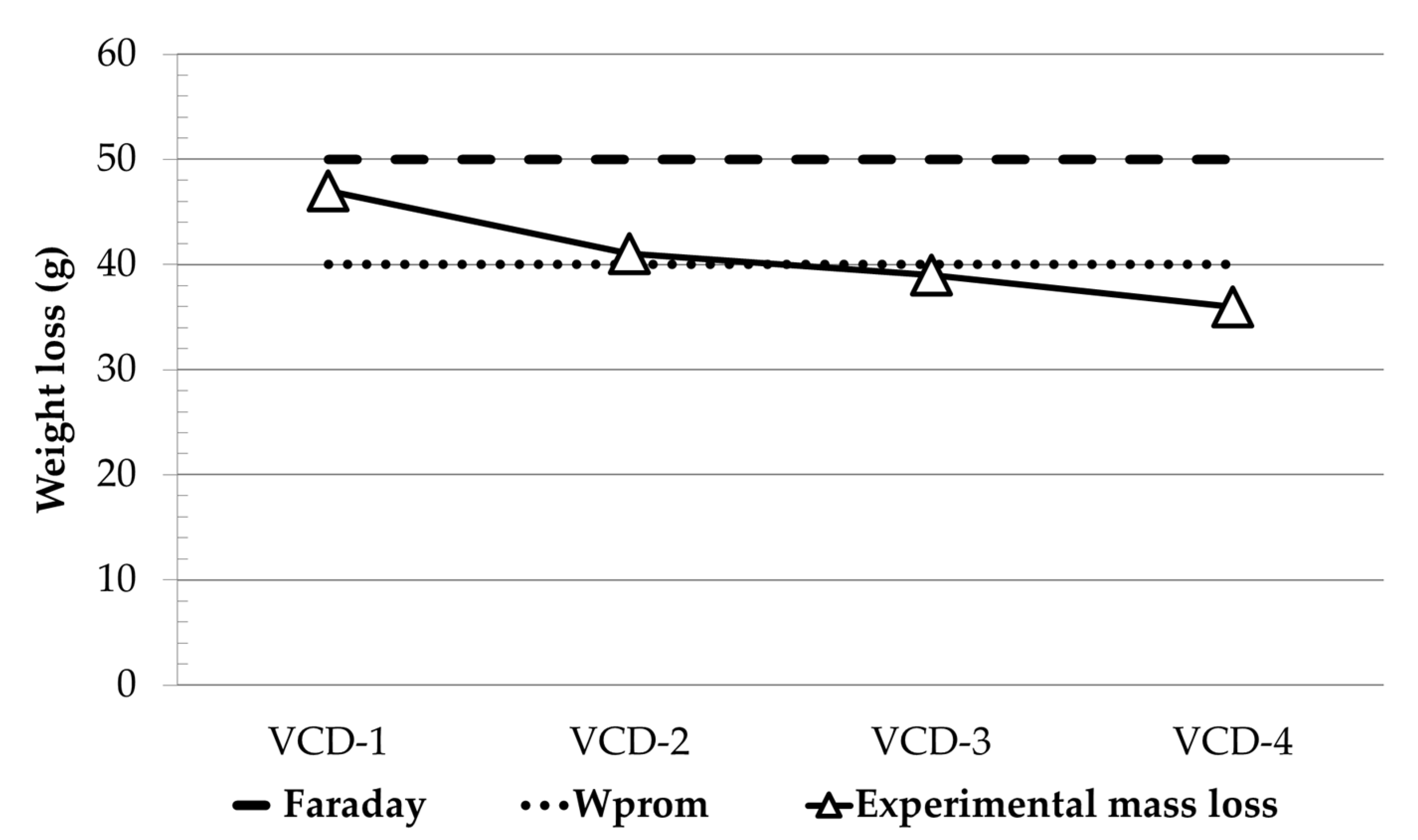

4.3. Reliability of the Calculation and the Method to Register Mass Losses in the Cross-Section

4.4. Theoretical and Experimental Comparison of the Shear Damage (Vu/Vn)

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Castro, P.; De Rincon, O.T.; Pazini, E.J. Interpretation of chloride profiles from concrete exposed to tropical marine environments. Cem. Concr. Res. 2001, 31, 529–537. [Google Scholar] [CrossRef]

- Xia, J.; Jin, W.; Li, L. Shear performance of reinforced concrete beams with corroded stirrups in chloride environment. Corros. Sci. 2011, 53, 1794–1805. [Google Scholar] [CrossRef]

- Lachemi, M.; Al-Bayati, N.; Sahmaran, M.; Anil, O. The effect of corrosion on shear behavior of reinforced self-consolidating concrete beams. Eng. Struct. 2014, 79, 1–12. [Google Scholar] [CrossRef]

- Zhu, W.; François, R.; Coronelli, D.; Cleland, D. Effect of corrosion of reinforcement on the mechanical behaviour of highly corroded RC beams. Eng. Struct. 2013, 56, 544–554. [Google Scholar] [CrossRef]

- Val, D.V. Deterioration of Strength of RC Beams due to Corrosion and Its Influence on Beam Reliability. J. Struct. Eng. 2007, 133, 1297–1306. [Google Scholar] [CrossRef]

- Zhu, W.; François, R. Corrosion of the reinforcement and its influence on the residual structural performance of a 26-year-old corroded RC beam. Constr. Build. Mater. 2014, 51, 461–472. [Google Scholar] [CrossRef]

- Zou, X.; Schmitt, T.; Perloff, D.; Wu, N.; Yu, T.Y.; Wang, X. Nondestructive corrosion detection using fiber optic photoacoustic ultrasound generator. Measurement 2015, 62, 74–80. [Google Scholar] [CrossRef]

- Dang, V.H.; François, R. Prediction of ductility factor of corroded reinforced concrete beams exposed to long term aging in chloride environment. Cem. Concr. Compos. 2014, 53, 136–147. [Google Scholar] [CrossRef]

- Almassri, B.; Kreit, A.; Al Mahmoud, F.; Francois, R. Behaviour of corroded shear-critical reinforced concrete beams repaired with NSM CFRP rods. Compos. Struct. 2015, 123, 204–215. [Google Scholar] [CrossRef]

- Sun, M.; Wen, D.-J.; Wang, H.-W. Influence of corrosion on the interface between zinc phosphate steel fiber and cement. Mater. Corros. 2012, 63, 67–72. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, X.; Zhang, J.; Ma, Y.; Liu, Y. Effects of stirrup and inclined bar corrosion on shear behavior of RC beams. Constr. Build. Mater. 2015, 98, 537–546. [Google Scholar] [CrossRef]

- Wang, L.; Li, C.; Yi, J. An experiment study on behavior of corrosion rc beams with different concrete strength. J. Coast. Res. 2015, 73, 259–264. [Google Scholar] [CrossRef]

- Juarez, C.A.; Guevara, B.; Fajardo, G.; Castro-Borges, P. Ultimate and nominal shear strength in reinforced concrete beams deteriorated by corrosion. Eng. Struct. 2011, 33, 3189–3196. [Google Scholar] [CrossRef]

- Khan, I.; François, R.; Castel, A. Prediction of reinforcement corrosion using corrosion induced cracks width in corroded reinforced concrete beams. Cem. Concr. Res. 2014, 56, 84–96. [Google Scholar] [CrossRef]

- Xue, X.; Seki, H.; Song, Y. Shear behavior of RC beams containing corroded stirrups. Adv. Struct. Eng. 2014, 17, 165–177. [Google Scholar] [CrossRef]

- Castel, A.; François, R.; Arliguie, G. Mechanical behaviour of corroded reinforced concrete beams—Part 1: Experimental study of corroded beams. Mater. Struct. Constr. 2000, 33, 539–544. [Google Scholar] [CrossRef]

- Bossio, A.; Lignola, G.P.; Fabbrocino, F.; Monetta, T.; Prota, A.; Bellucci, F.; Manfredi, G. Nondestructive assessment of corrosion of reinforcement bars through surface concrete cracks. Struct. Concr. 2017, 18, 104–117. [Google Scholar] [CrossRef]

- Andrade, C.; Alonso, C.; Gonzalez, J.A.; Rodriguez, J.O. Remaining service life of corroding structures. In Proceedings of the IABSE Symposium on Durability, Lisbon, Portugal, 6–8 September 1989; pp. 359–363. [Google Scholar]

- Andrade, C. Propagation of reinforcement corrosion: Principles, testing and modelling. Mater. Struct. 2019, 52, 1–26. [Google Scholar] [CrossRef]

- El-Maaddawy, T.; Soudki, K. Effectiveness of impressed current technique to simulate corrosion of steel reinforcement in concrete. J. Mater. Civ. Eng. 2003, 15, 41–47. [Google Scholar] [CrossRef]

- Imperatore, S.; Rinaldi, Z. Cracking in reinforced concrete structures damaged by artificial corrosion: An overview. Open Constr. Build. Technol. J. 2019, 13, 199–213. [Google Scholar] [CrossRef]

- ASTM C876-15, Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete; ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM G1-03(2017)e1, Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Zhou, H.; Lu, J.; Xv, X.; Dong, B.; Xing, F. Effects of stirrup corrosion on bond–slip performance of reinforcing steel in concrete: An experimental study. Constr. Build. Mater. 2015, 93, 257–266. [Google Scholar] [CrossRef]

- Tondolo, F. Bond behaviour with reinforcement corrosion. Constr. Build. Mater. 2015, 93, 926–932. [Google Scholar] [CrossRef]

- Al-Saidy, A.H.; Al-Jabri, K.S. Effect of damaged concrete cover on the behavior of corroded concrete beams repaired with CFRP sheets. Compos. Struct. 2011, 93, 1775–1786. [Google Scholar] [CrossRef]

- ACI Committee. ACI 318-19: Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2014; p. 520. [Google Scholar]

- ASTM C1218/C1218M-20 Standard Test Method for Water-Soluble Chloride in Mortar and Concrete; ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Alonso, C.; Castellote, M.; Andrade, C. Chloride threshold dependence of pitting potential of reinforcements. Electrochim. Acta 2002, 47, 3469–3481. [Google Scholar] [CrossRef]

- Angst, U.; Elsener, B.; Larsen, C.K.; Vennesland, Ø. Critical chloride content in reinforced concrete—A review. Cem. Concr. Res. 2009, 39, 1122–1138. [Google Scholar] [CrossRef]

- Pedrosa, F.; Andrade, C. Corrosion induced cracking: Effect of different corrosion rates on crack width evolution. Constr. Build. Mater. 2017, 133, 525–533. [Google Scholar] [CrossRef]

- Castro, P.; Véleva, L.; Balancán, M. Corrosion of reinforced concrete in a tropical marine environment and in accelerated tests. Constr. Build. Mater. 1997, 11, 75–81. [Google Scholar] [CrossRef]

- Suffern, C.; El-Sayed, A.; Soudki, K. Shear strength of disturbed regions with corroded stirrups in reinforced concrete beams. Can. J. Civ. Eng. 2010, 37, 1045–1056. [Google Scholar] [CrossRef]

| Cement | Water | Aggregate | f’c | Slump | |

|---|---|---|---|---|---|

| Coarse | Fine | ||||

| 393 kg | 216 kg | 960 kg | 768 kg | 26 MPa | 150 mm |

| Beam | Experimental Mass Loss | Theoretical Mass Loss by Equation (2) | Relation /Equation (2) | ||

|---|---|---|---|---|---|

| Stirrup | Percentage | Stirrup | Percentage | ||

| VCD-1 | 43.0 g | 11.4% | 50 g | 12.50% | 0.86 |

| VCD-2 | 30.0 g | 8.0% | 50 g | 12.50% | 0.60 |

| VCD-3 | 40.0 g | 10.0% | 50 g | 12.50% | 0.80 |

| VCD-4 | 37.0 g | 10.0% | 50 g | 12.50% | 0.74 |

| Beam | % Chloride by Weight of Cement |

|---|---|

| VCD-1 | 2.15 |

| VCD-2 | 3.00 |

| VCD-3 | 2.30 |

| VCD-4 | 2.75 |

| VSD-1 | VSD-2 | VCD-1 | VCD-2 | VCD-3 | VCD-4 |

|---|---|---|---|---|---|

| 124 kN 9.9 mm | 126 kN 12.8 mm | 88 kN 6.9 mm | 84 kN 8.9 mm | 100 kN 8.6 mm | 98 kN 7.5 mm |

| Beam | Diameter (mm) | Shear Strength (kN) | ||||||

|---|---|---|---|---|---|---|---|---|

| Theor. | exp. | Critical | Vs | Vc | Vn | Vu | Vu/Vn | |

| VSD-1 | 8.00 | 7.90 | 8.00 | 87 | 46 | 133 | 124 | 0.93 |

| VSD-2 | 8.00 | 7.90 | 8.00 | 87 | 46 | 133 | 126 | 0.95 |

| VCD-1 | 7.20 | 7.20 | 6.05 | 51 | 46 | 97 | 88 | 0.91 |

| VCD-2 | 7.20 | 7.20 | 5.90 | 49 | 46 | 95 | 84 | 0.88 |

| VCD-3 | 7.20 | 7.26 | 5.38 | 39 | 46 | 85 | 100 | 1.18 |

| VCD-4 | 7.20 | 7.30 | 5.40 | 41 | 46 | 87 | 98 | 1.12 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castro-Borges, P.; Juárez-Alvarado, C.A.; Soto-Ibarra, R.I.; Briceño-Mena, J.A.; Miguel, G.F.-S.; Valdez-Tamez, P. Effect of Corrosion in the Transverse Reinforcements in Concrete Beams: Sustainable Method to Generate and Measure Deterioration. Sustainability 2020, 12, 8105. https://doi.org/10.3390/su12198105

Castro-Borges P, Juárez-Alvarado CA, Soto-Ibarra RI, Briceño-Mena JA, Miguel GF-S, Valdez-Tamez P. Effect of Corrosion in the Transverse Reinforcements in Concrete Beams: Sustainable Method to Generate and Measure Deterioration. Sustainability. 2020; 12(19):8105. https://doi.org/10.3390/su12198105

Chicago/Turabian StyleCastro-Borges, P., C. A. Juárez-Alvarado, R. I. Soto-Ibarra, J. A. Briceño-Mena, G. Fajardo-San Miguel, and P. Valdez-Tamez. 2020. "Effect of Corrosion in the Transverse Reinforcements in Concrete Beams: Sustainable Method to Generate and Measure Deterioration" Sustainability 12, no. 19: 8105. https://doi.org/10.3390/su12198105

APA StyleCastro-Borges, P., Juárez-Alvarado, C. A., Soto-Ibarra, R. I., Briceño-Mena, J. A., Miguel, G. F.-S., & Valdez-Tamez, P. (2020). Effect of Corrosion in the Transverse Reinforcements in Concrete Beams: Sustainable Method to Generate and Measure Deterioration. Sustainability, 12(19), 8105. https://doi.org/10.3390/su12198105