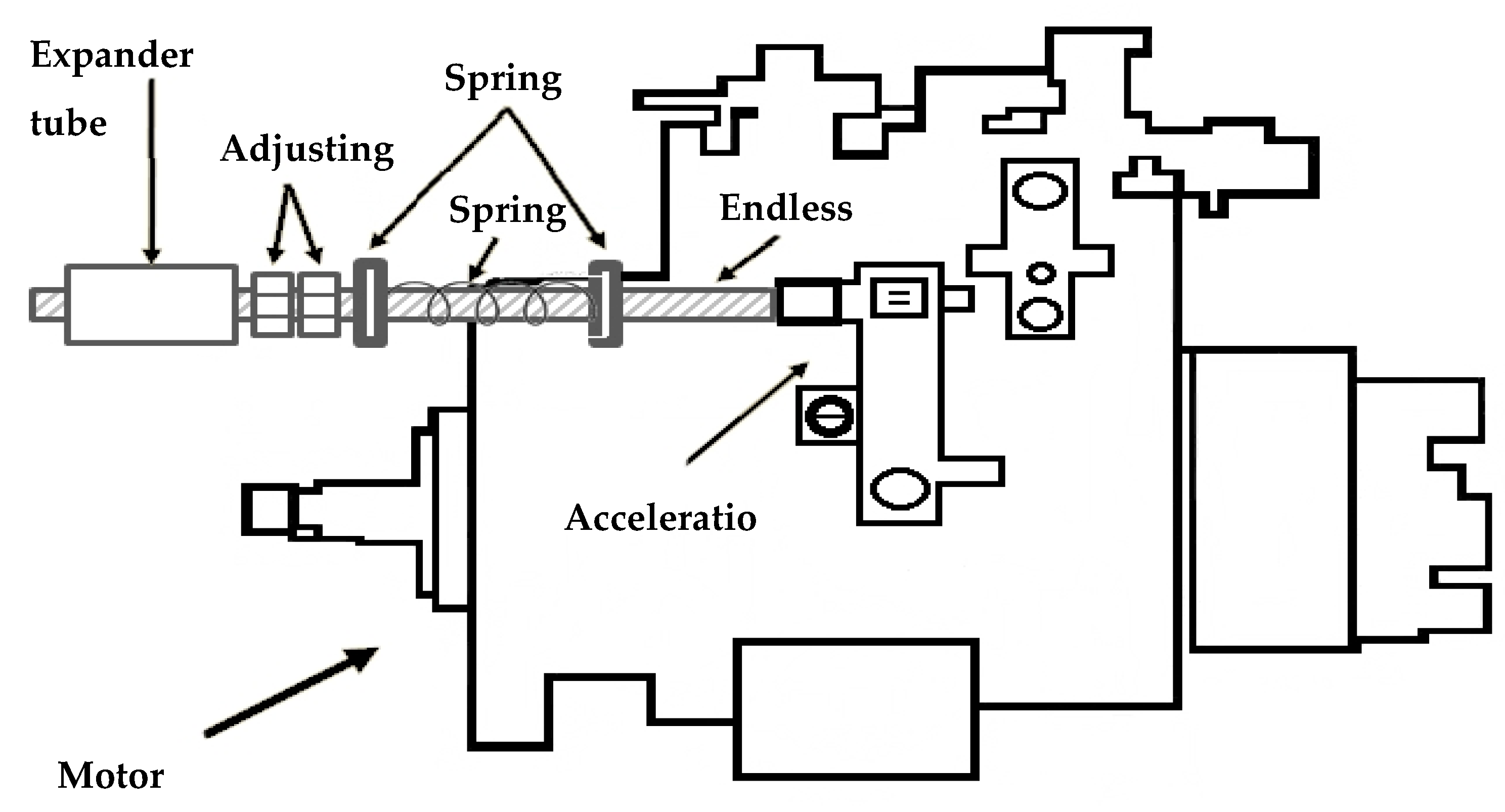

Figure 1.

Schematic diagram of experimental methodology.

Figure 1.

Schematic diagram of experimental methodology.

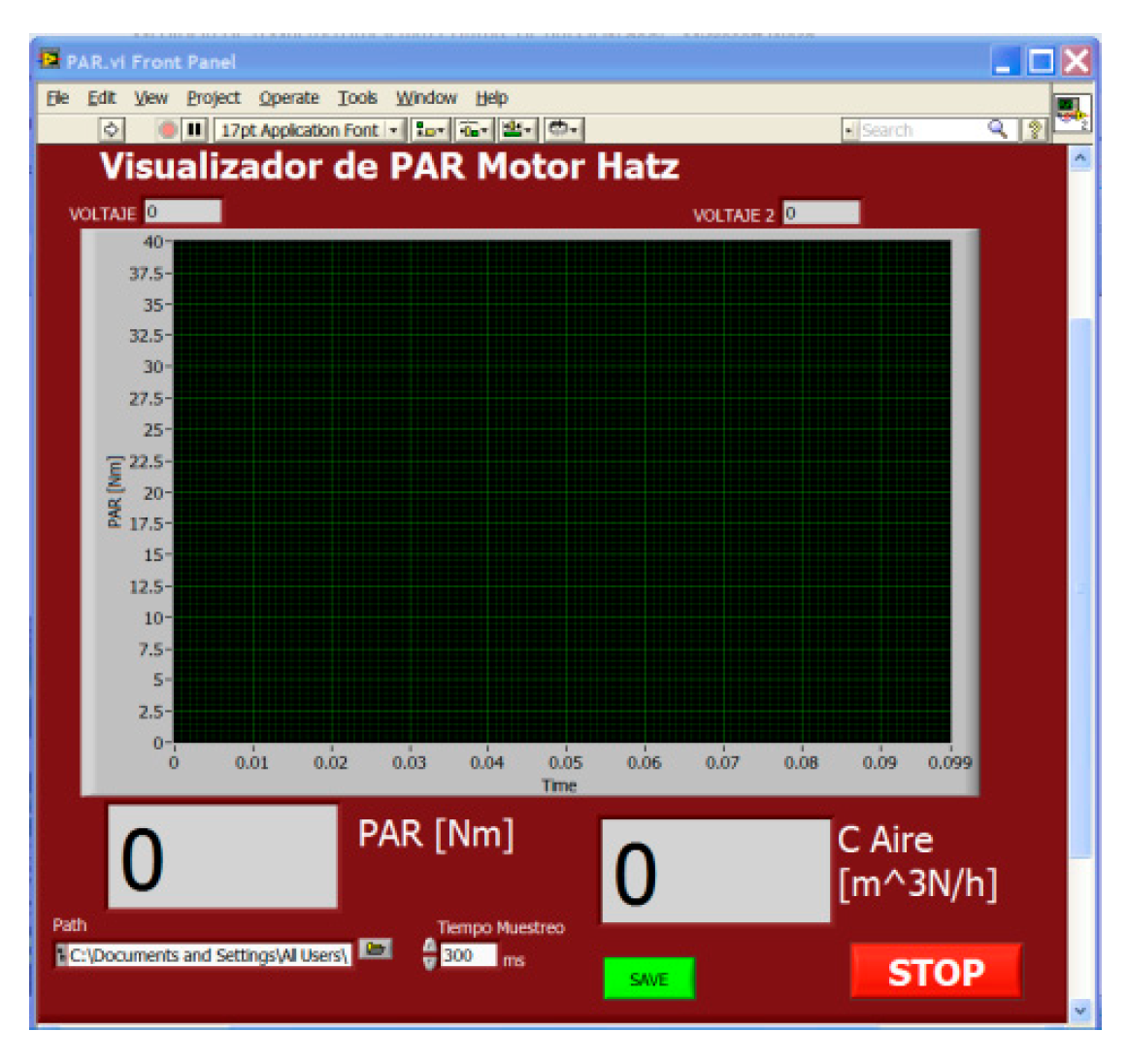

Figure 2.

Virtual instrument TONE.

Figure 2.

Virtual instrument TONE.

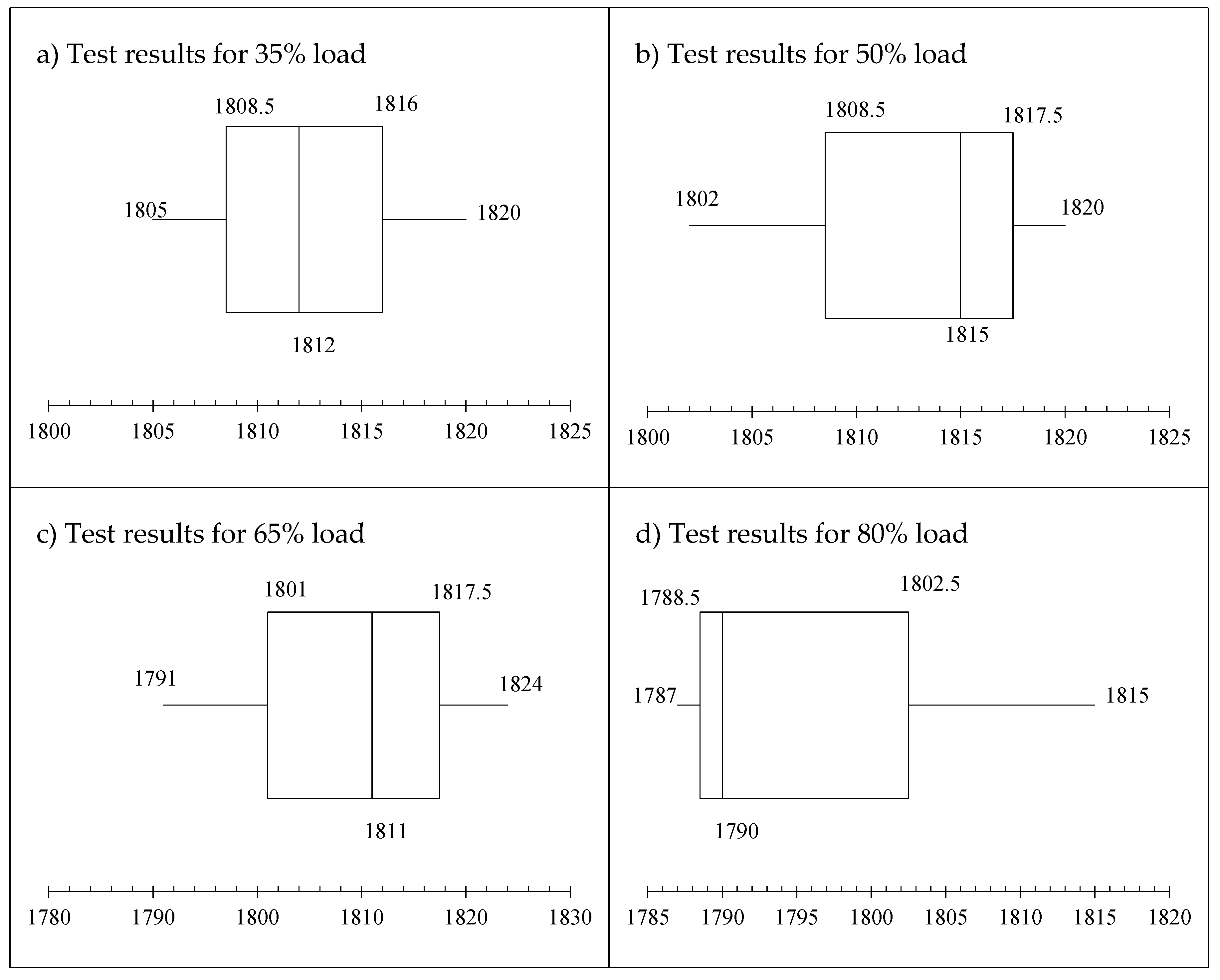

Figure 3.

Box graphs for the test results using different load percentage and RPM fixed on 1800 rpm: (a) Test results for 35% load, (b) Test results for 50% load, (c) Test results for 65% load, (d) Test results for 80% load.

Figure 3.

Box graphs for the test results using different load percentage and RPM fixed on 1800 rpm: (a) Test results for 35% load, (b) Test results for 50% load, (c) Test results for 65% load, (d) Test results for 80% load.

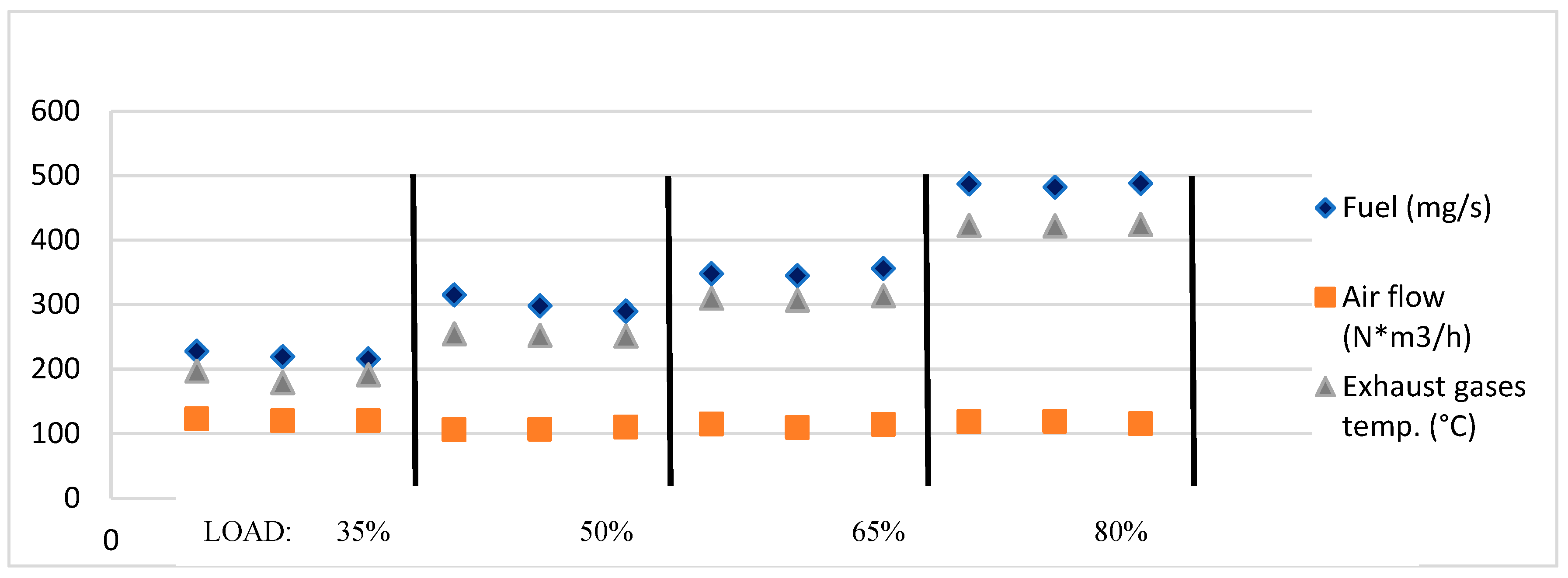

Figure 4.

Behavior for different loads of the air consumption, fuel consumption and exhaust gases temperatures.

Figure 4.

Behavior for different loads of the air consumption, fuel consumption and exhaust gases temperatures.

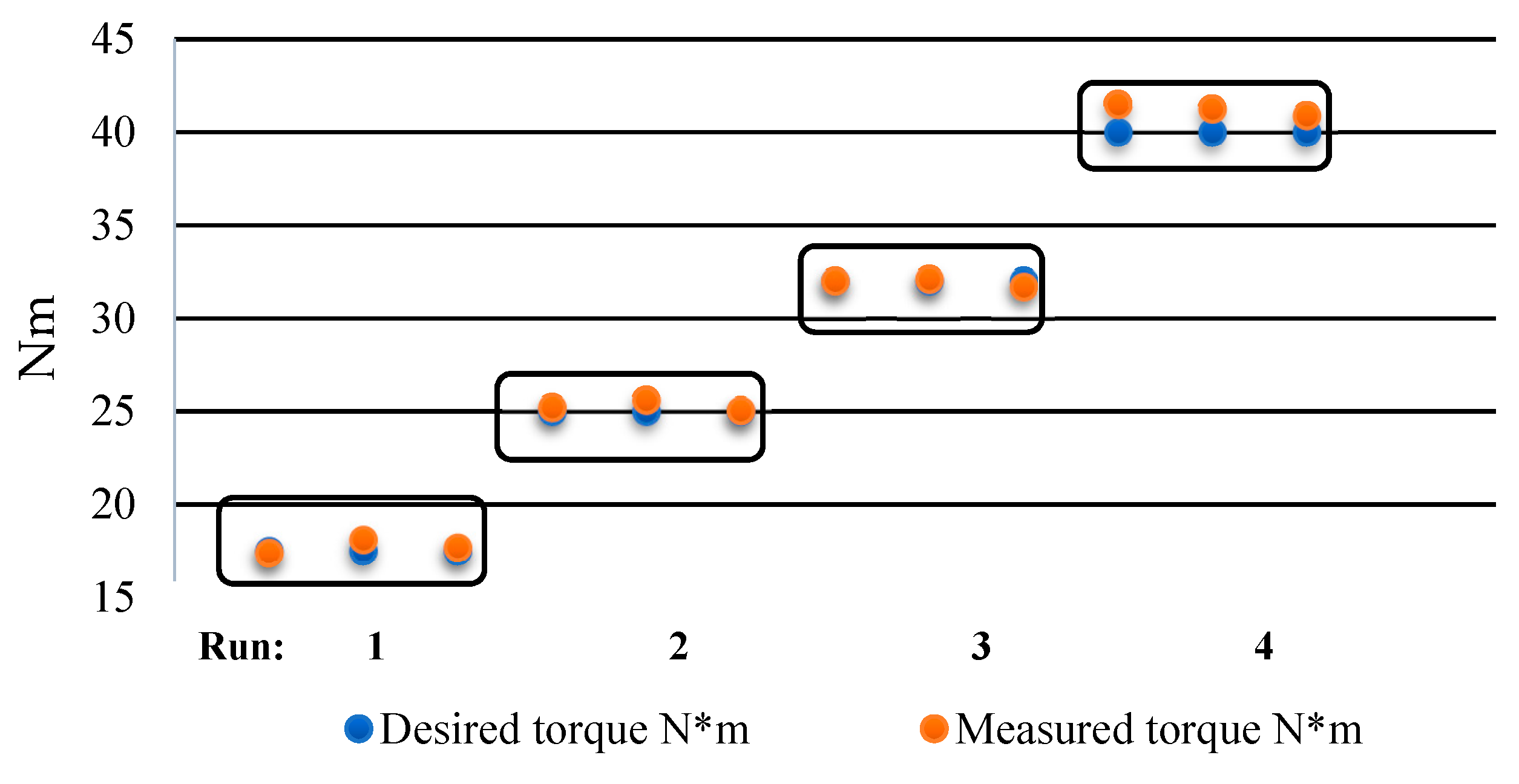

Figure 5.

Comparative between desired and measured torque.

Figure 5.

Comparative between desired and measured torque.

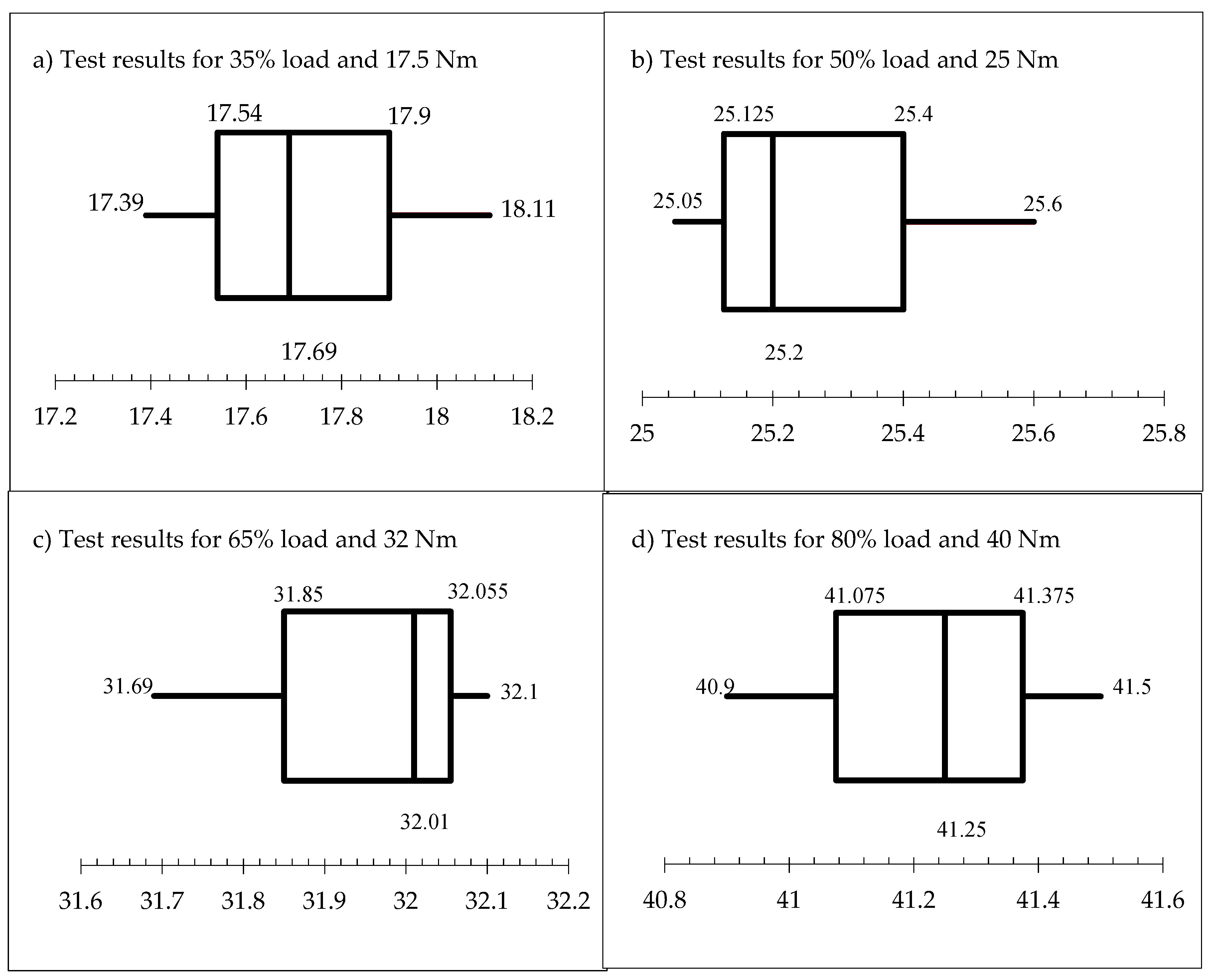

Figure 6.

Box graphs for the test results using different load percentage and Torque: (a) Test results for 35% load and 17.5 Nm, (b) Test results for 50% load and 25 Nm, (c) Test results for 65% load and 32 Nm, (d) Test results for 80% and 40 Nm.

Figure 6.

Box graphs for the test results using different load percentage and Torque: (a) Test results for 35% load and 17.5 Nm, (b) Test results for 50% load and 25 Nm, (c) Test results for 65% load and 32 Nm, (d) Test results for 80% and 40 Nm.

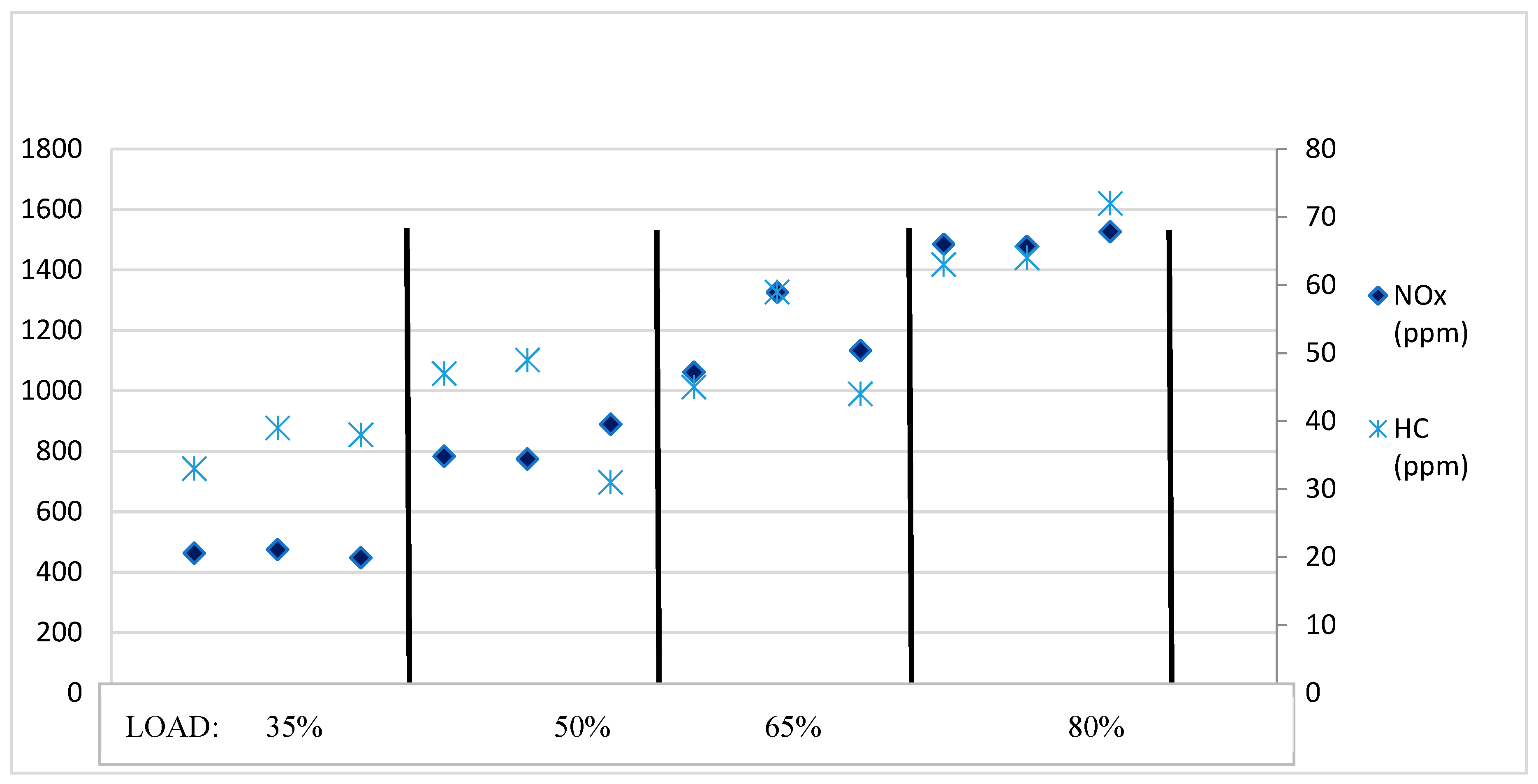

Figure 7.

Emissions NOx and HC vs load applied.

Figure 7.

Emissions NOx and HC vs load applied.

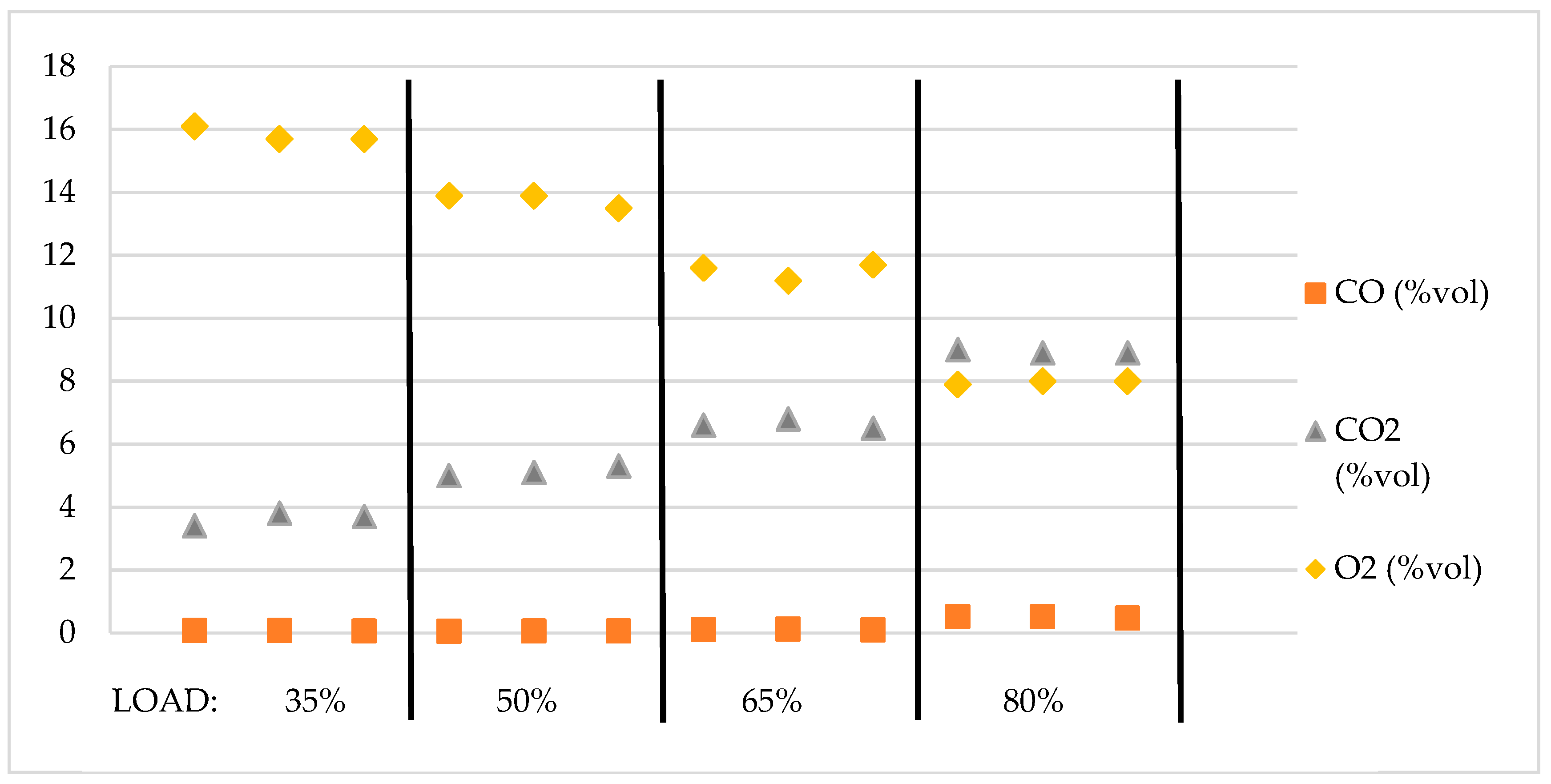

Figure 8.

Emissions CO, CO2 and O2 Vs load.

Figure 8.

Emissions CO, CO2 and O2 Vs load.

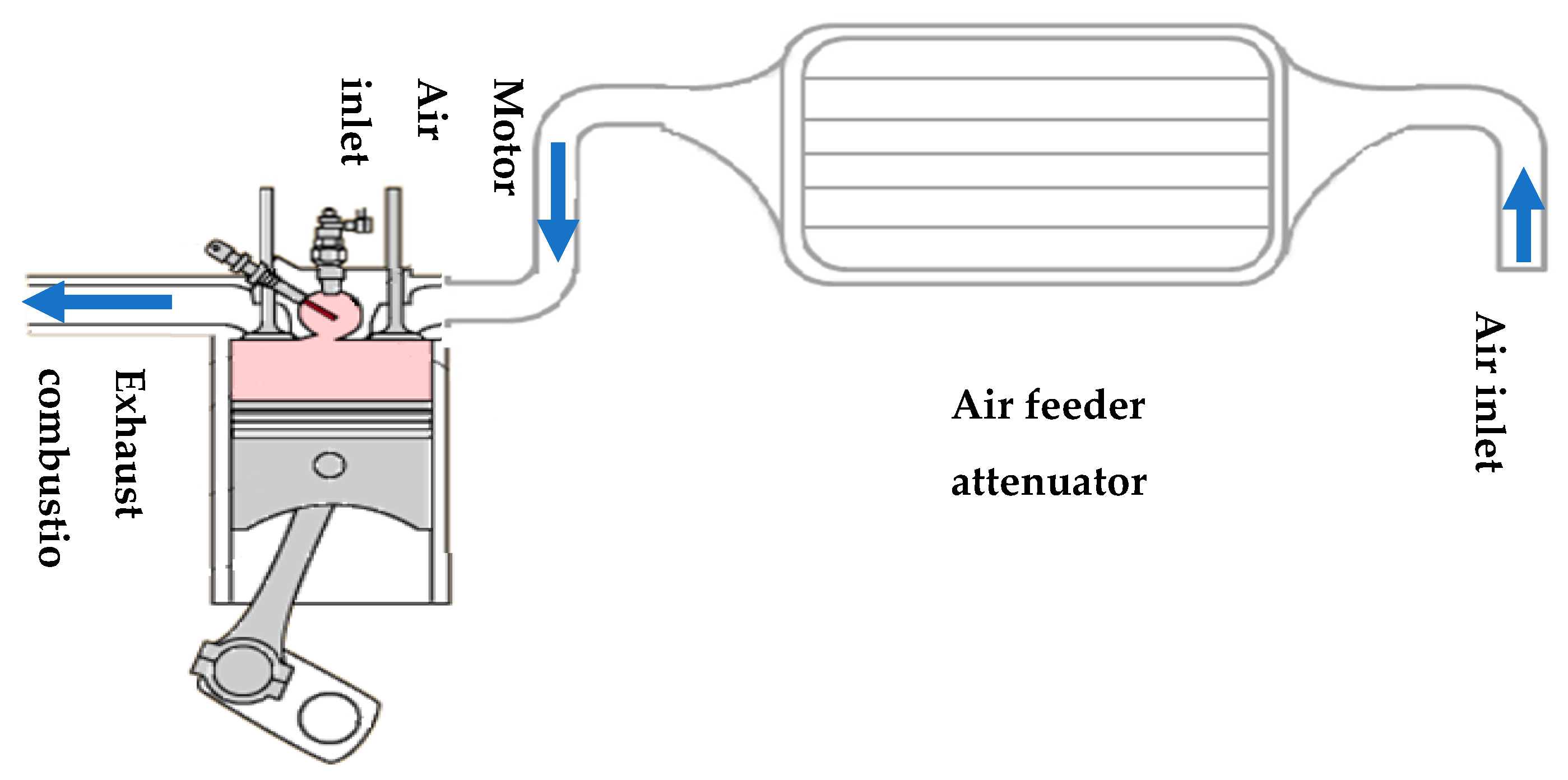

Figure 9.

Air feeder attenuator chamber for a cooling engine.

Figure 9.

Air feeder attenuator chamber for a cooling engine.

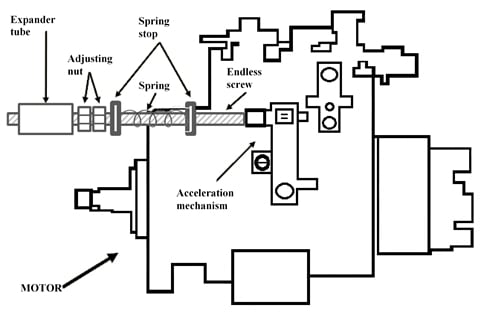

Figure 10.

Adjustment mechanism for RPM.

Figure 10.

Adjustment mechanism for RPM.

Figure 11.

Preheating air chamber for intake manifold.

Figure 11.

Preheating air chamber for intake manifold.

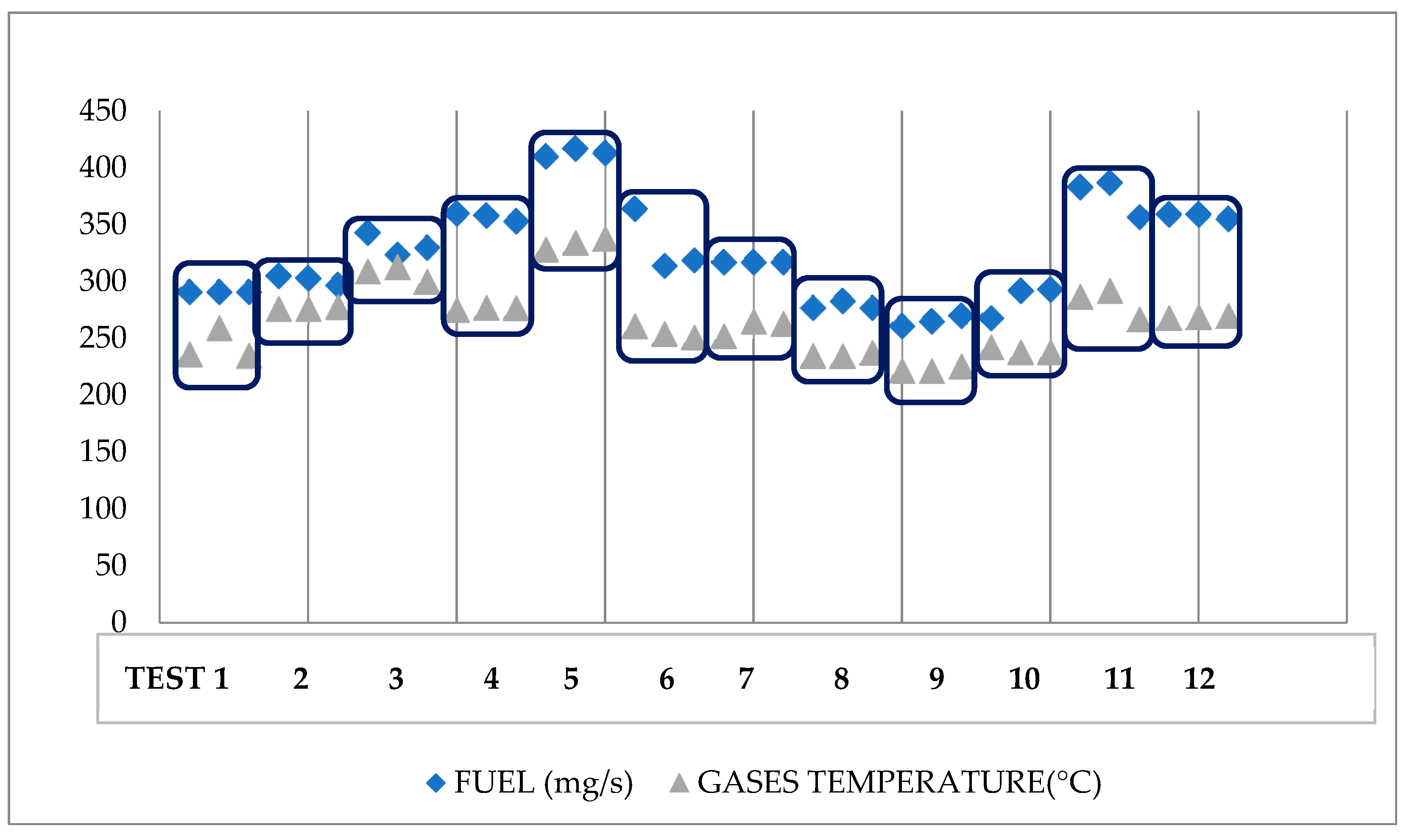

Figure 12.

Measured values of the fuel consumption and exhaust gases temperature after the improved engine set up.

Figure 12.

Measured values of the fuel consumption and exhaust gases temperature after the improved engine set up.

Figure 13.

Fuel consumption behavior. (a) Fuel consumption vs torque; (b) Fuel consumption vs RPM.

Figure 13.

Fuel consumption behavior. (a) Fuel consumption vs torque; (b) Fuel consumption vs RPM.

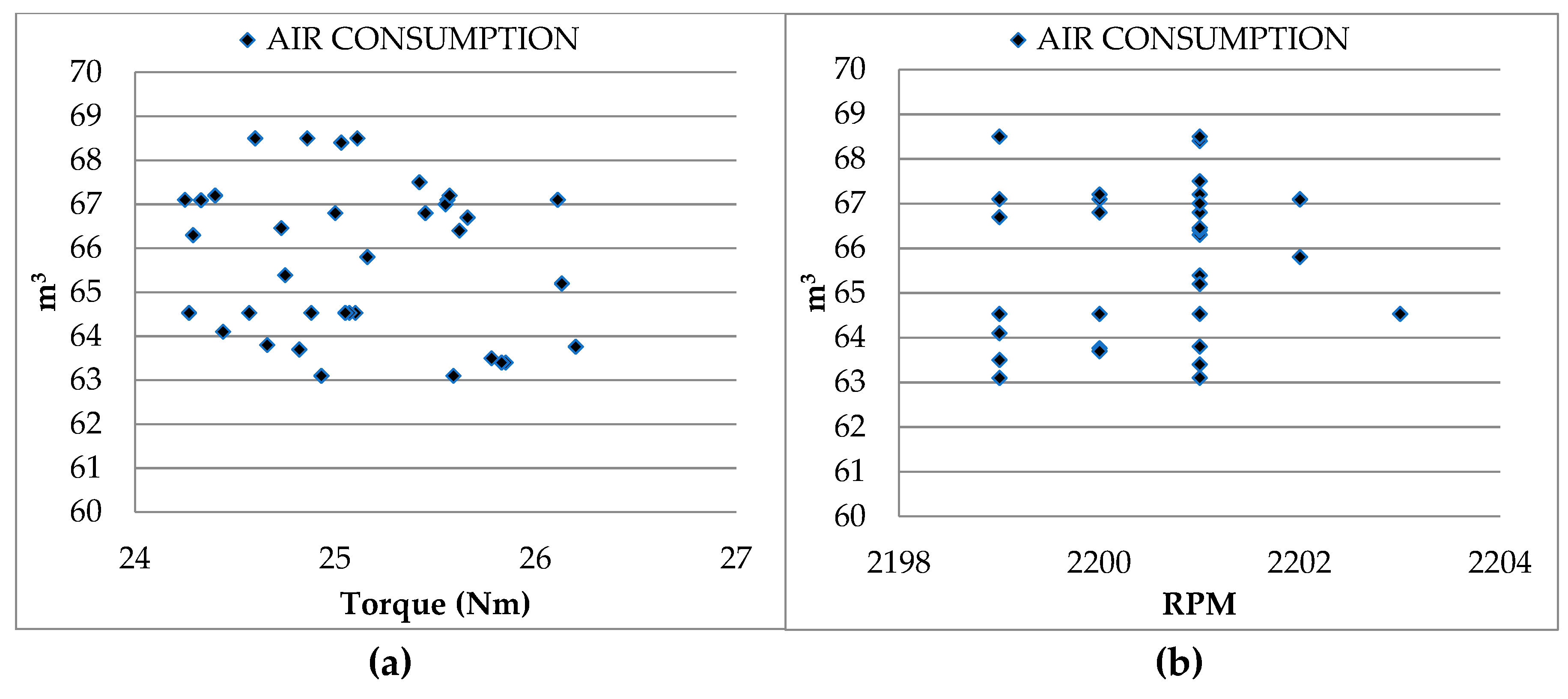

Figure 14.

Air consumption behavior. (a) Air consumption vs torque; (b) Air consumption vs RPM.

Figure 14.

Air consumption behavior. (a) Air consumption vs torque; (b) Air consumption vs RPM.

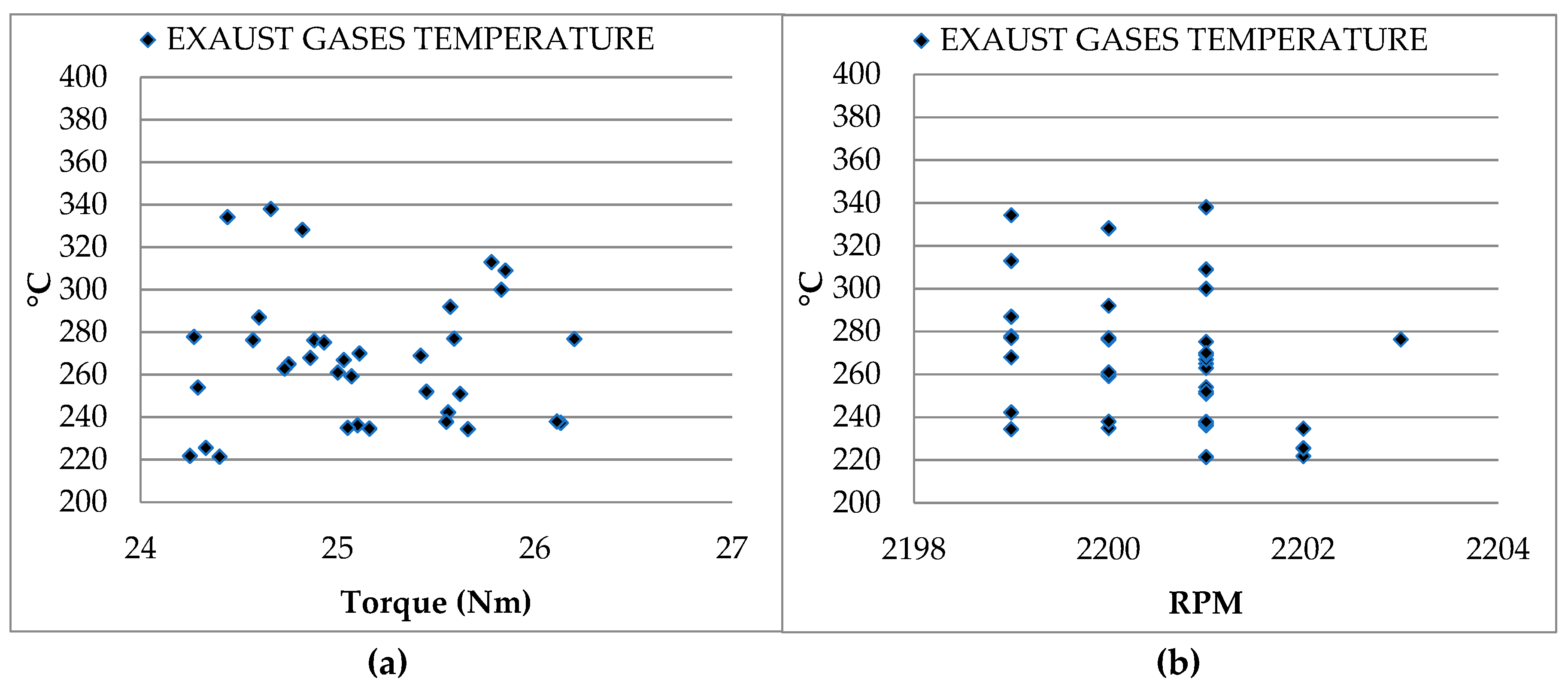

Figure 15.

Gases temperature behavior. (a) Exhaust gases temperature vs torque; (b) Exhaust gases temperature vs RPM.

Figure 15.

Gases temperature behavior. (a) Exhaust gases temperature vs torque; (b) Exhaust gases temperature vs RPM.

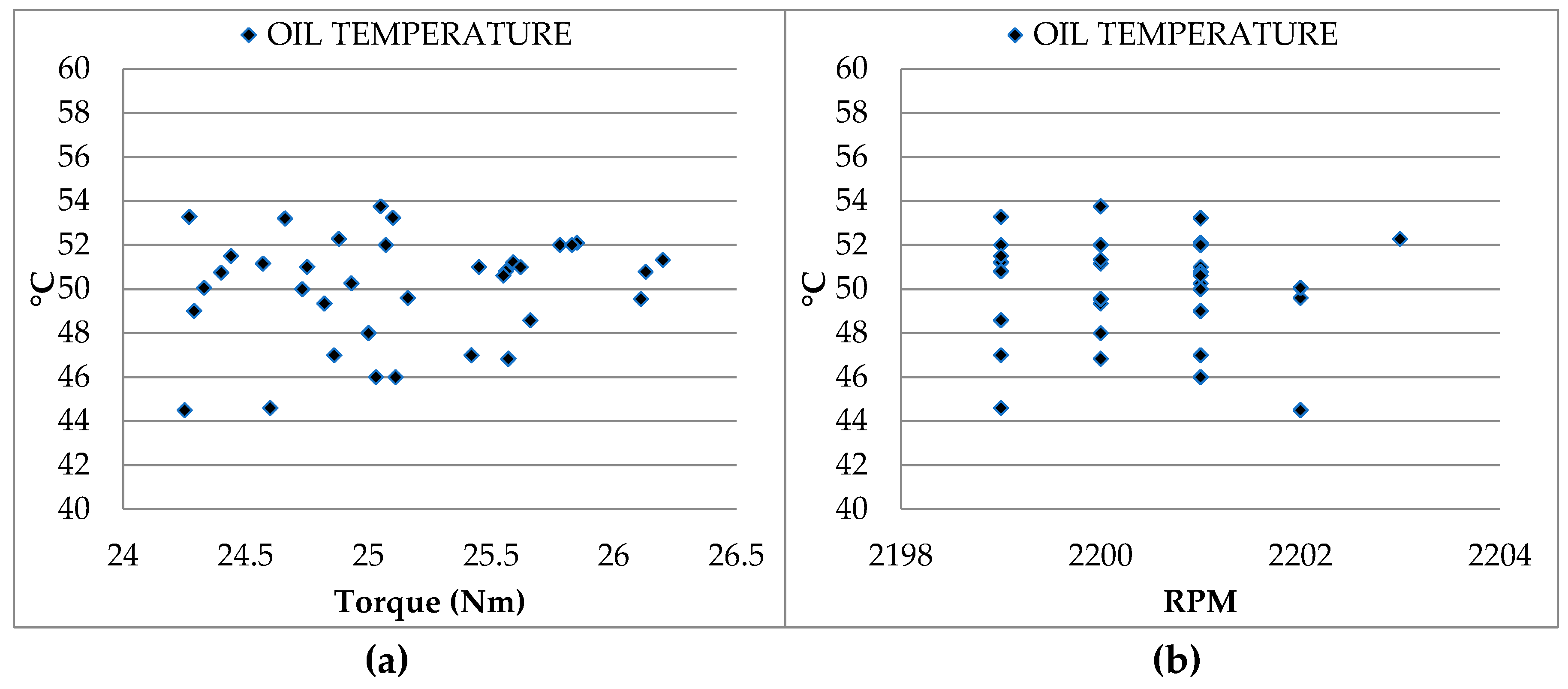

Figure 16.

Oil temperature behavior. (a) Oil temperature vs torque; (b) Oil temperature vs RPM.

Figure 16.

Oil temperature behavior. (a) Oil temperature vs torque; (b) Oil temperature vs RPM.

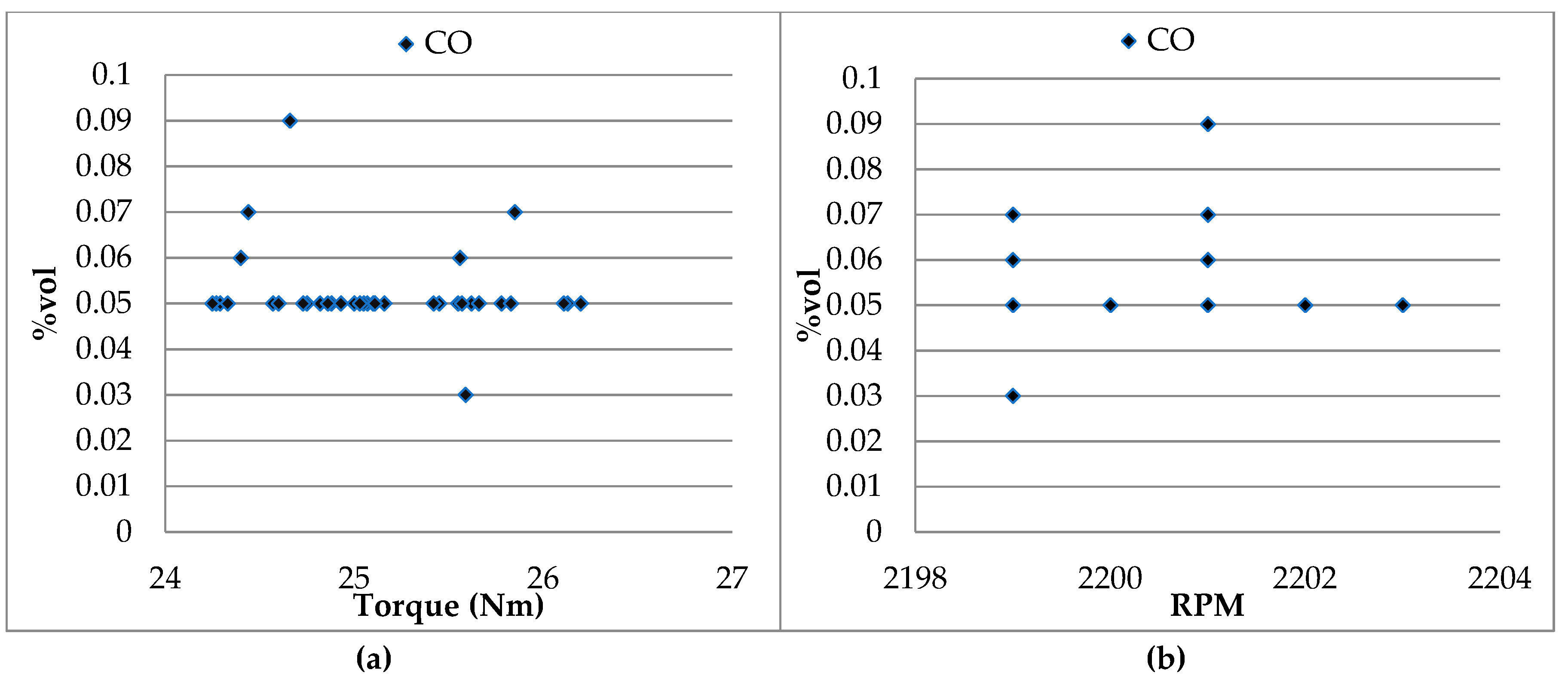

Figure 17.

CO emissions behavior. (a) Dispersion data torque vs CO; (b) Dispersion data RPM vs CO.

Figure 17.

CO emissions behavior. (a) Dispersion data torque vs CO; (b) Dispersion data RPM vs CO.

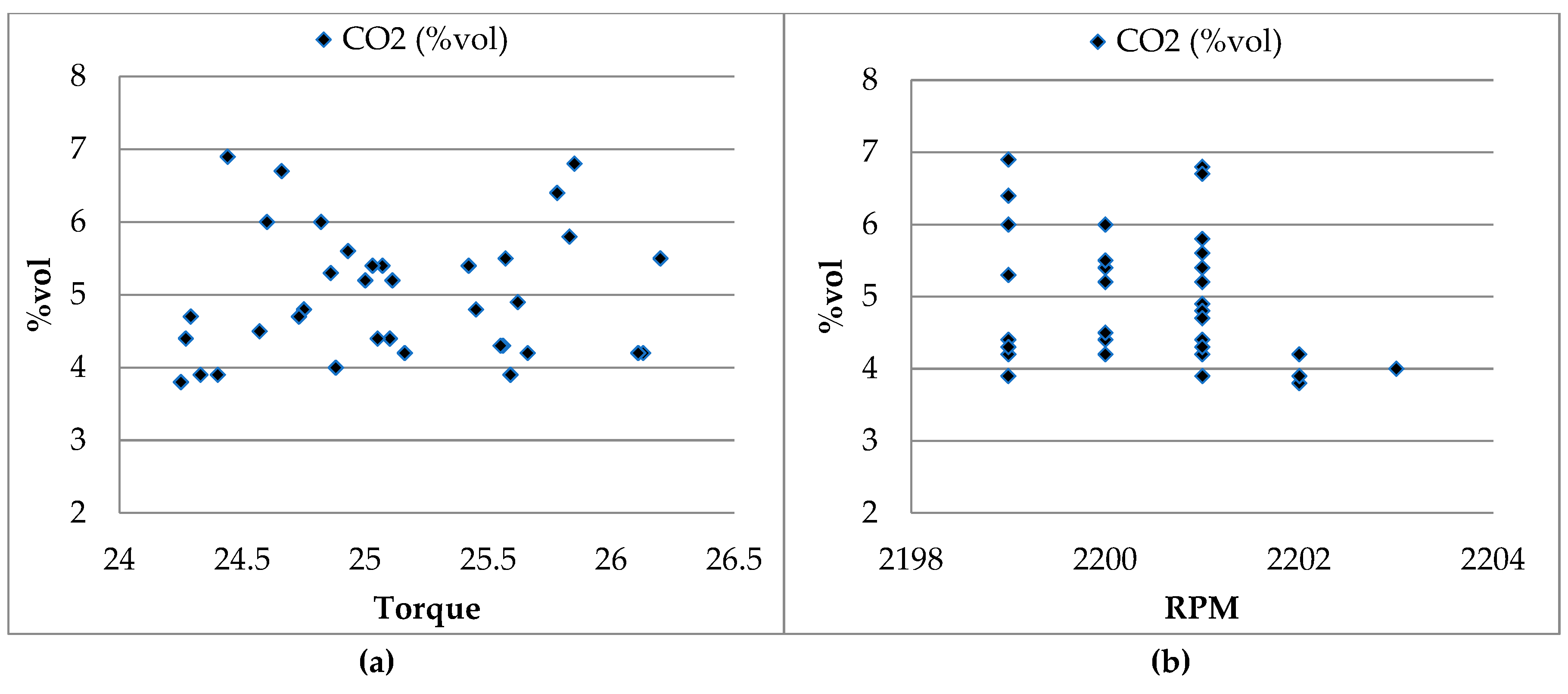

Figure 18.

CO2 emissions behavior. (a) Dispersion data of the torque vs CO2; (b) Dispersion data of the RPM vs CO2.

Figure 18.

CO2 emissions behavior. (a) Dispersion data of the torque vs CO2; (b) Dispersion data of the RPM vs CO2.

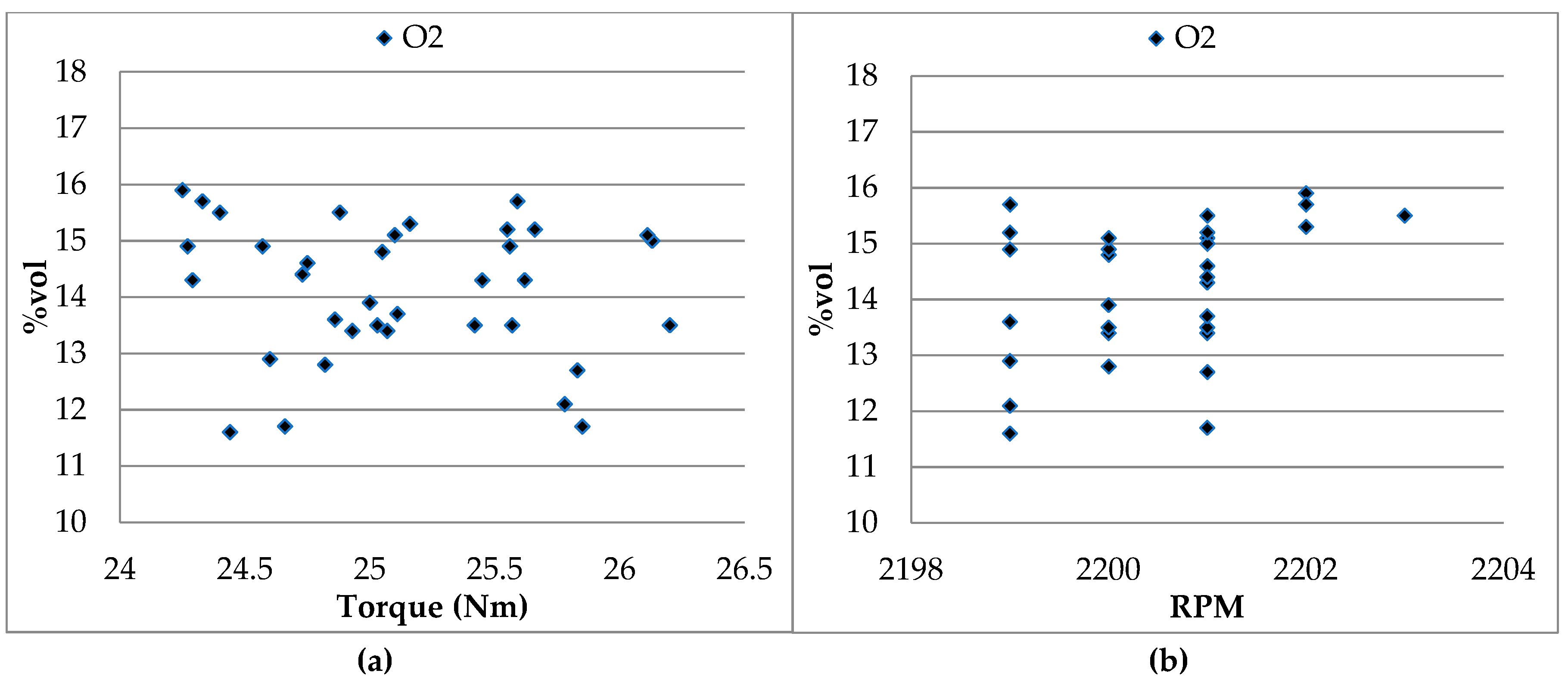

Figure 19.

O2 Emissions behavior. (a) Dispersion data of the torque vs O2; (b) Dispersion data of the RPM vs O2.

Figure 19.

O2 Emissions behavior. (a) Dispersion data of the torque vs O2; (b) Dispersion data of the RPM vs O2.

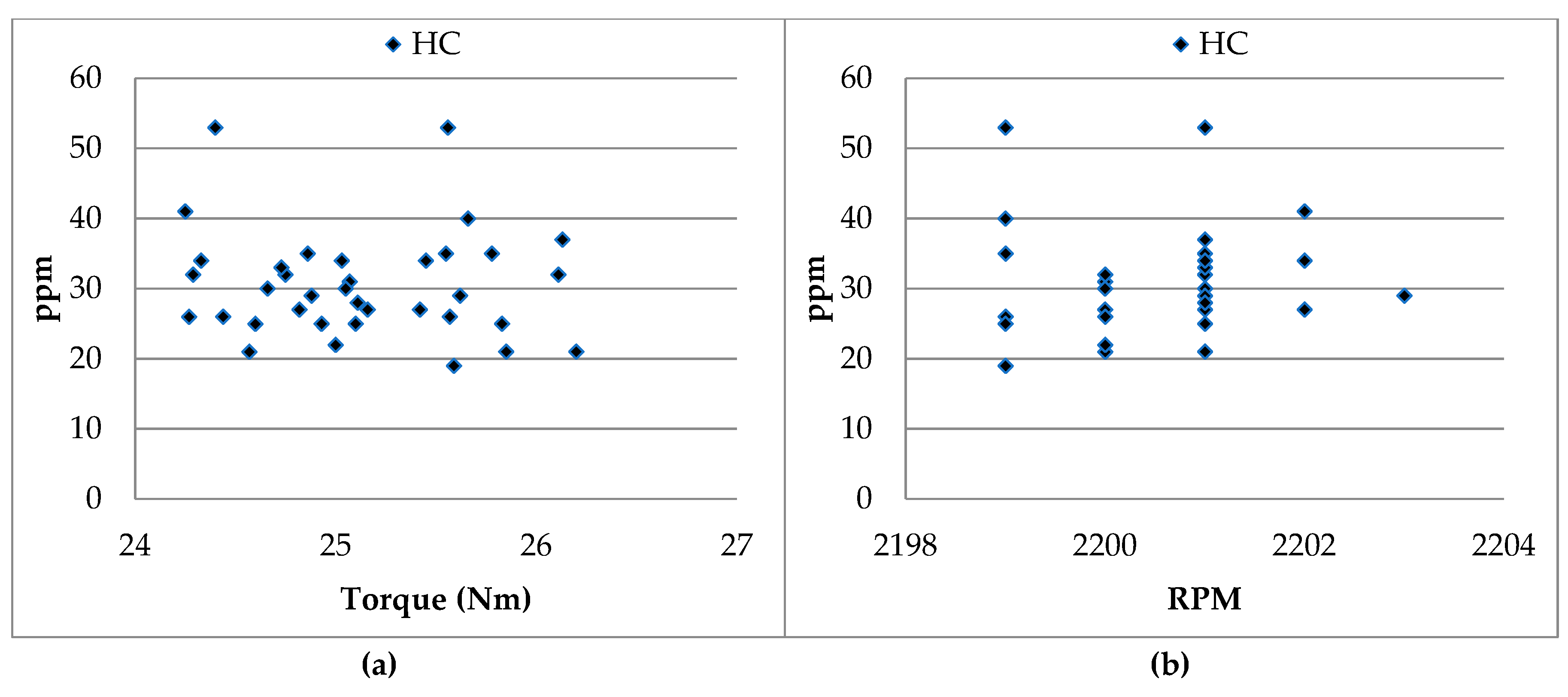

Figure 20.

HC emissions behavior. (a) Dispersion data of the torque vs HC; (b) Dispersion data of the RPM vs HC.

Figure 20.

HC emissions behavior. (a) Dispersion data of the torque vs HC; (b) Dispersion data of the RPM vs HC.

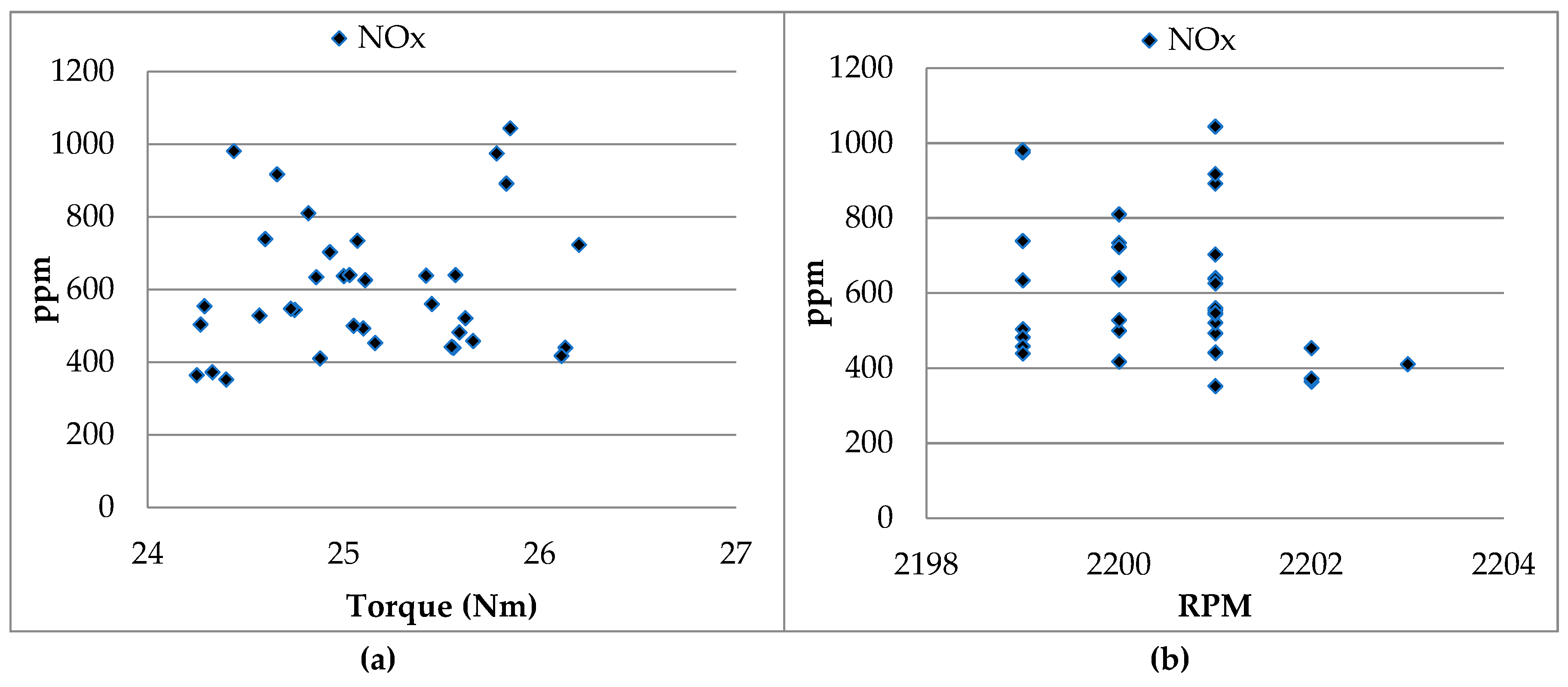

Figure 21.

NOx emissions behavior. (a) Dispersion data of the torque vs NOX; (b) Dispersion data of the RPM vs NOX.

Figure 21.

NOx emissions behavior. (a) Dispersion data of the torque vs NOX; (b) Dispersion data of the RPM vs NOX.

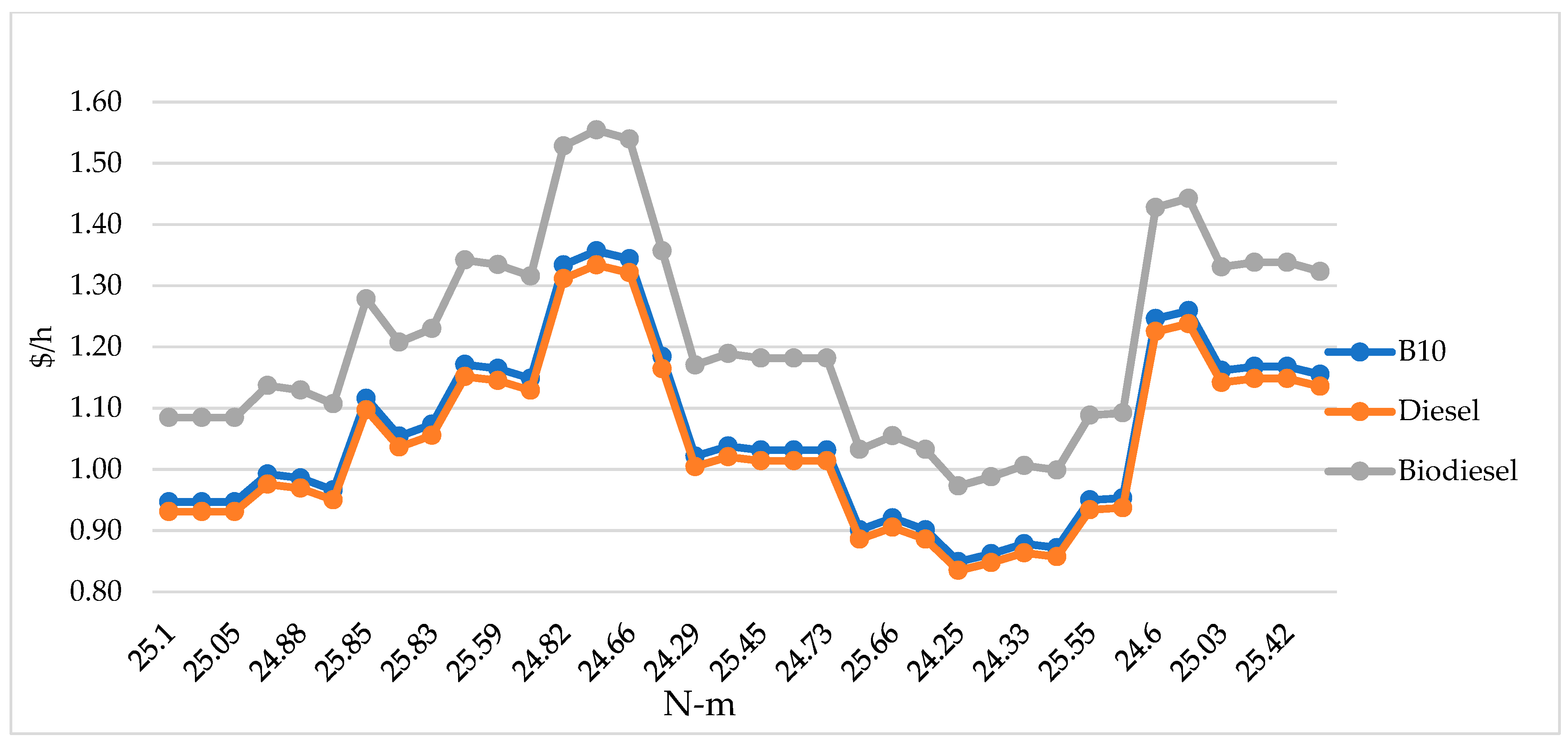

Figure 22.

Actuals fuels costs vs power obtain.

Figure 22.

Actuals fuels costs vs power obtain.

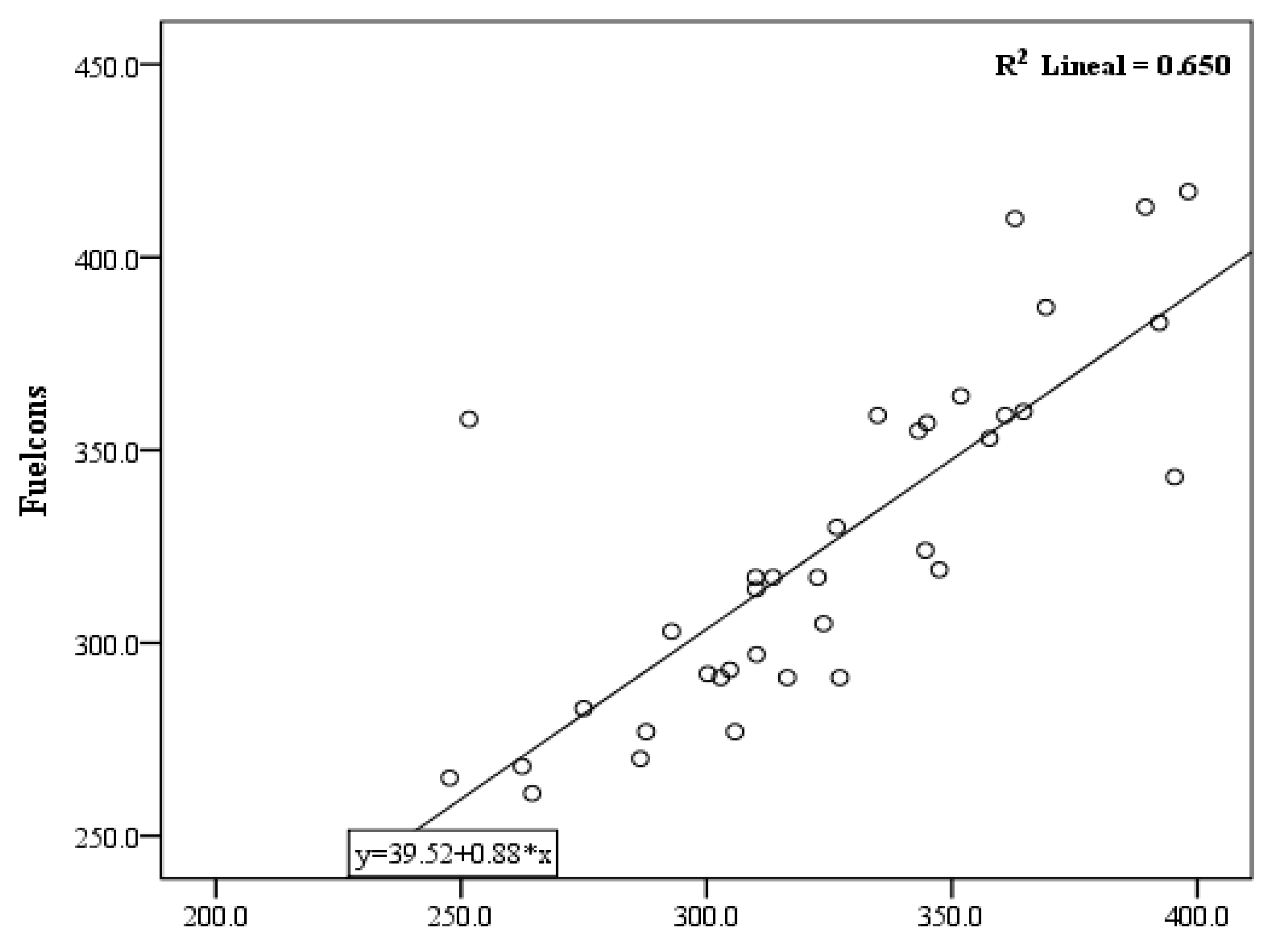

Figure 23.

Scatter diagram, dependent variable: Fuelcons.

Figure 23.

Scatter diagram, dependent variable: Fuelcons.

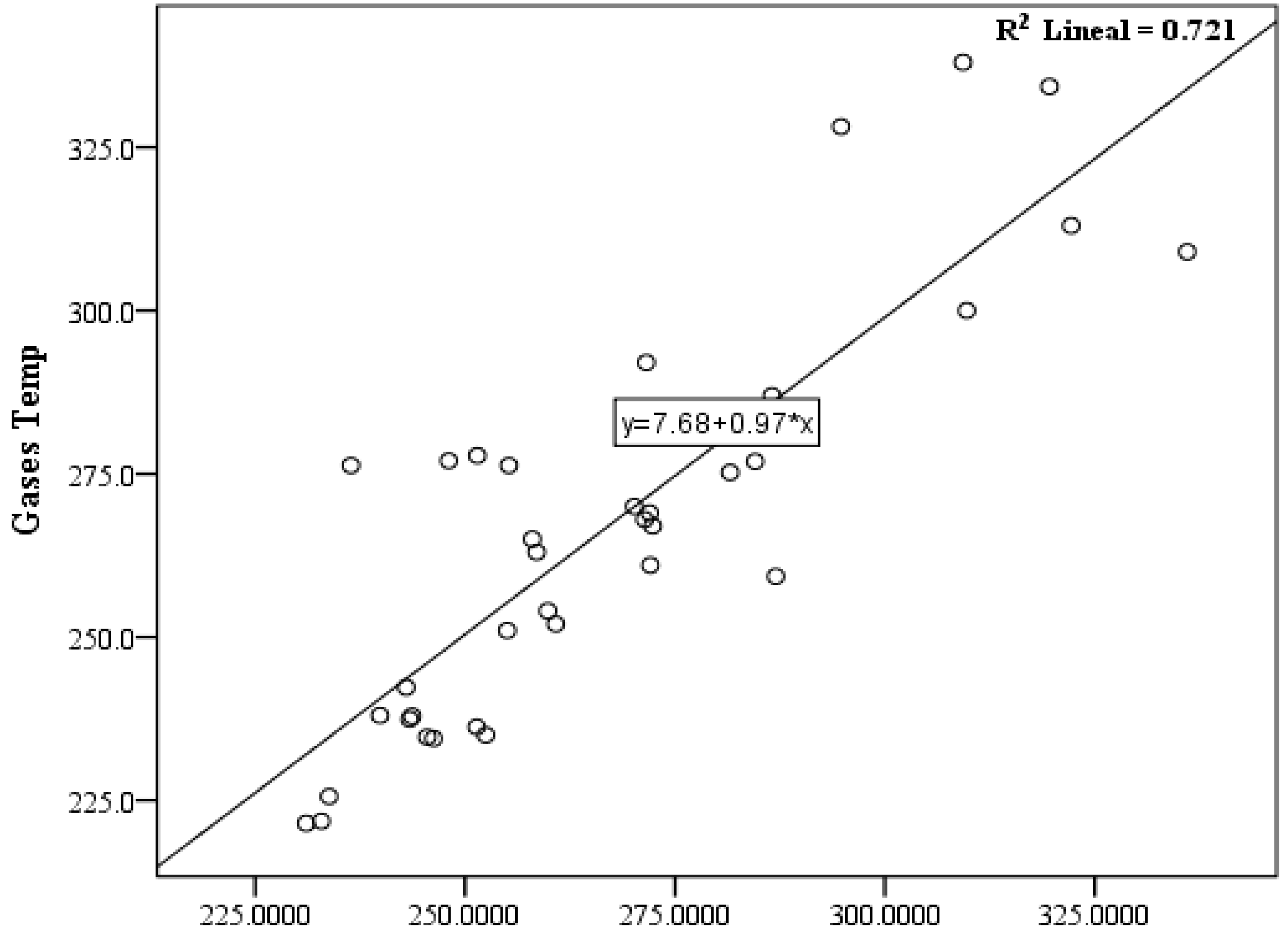

Figure 24.

Scatter diagram, dependent variable: Gases Temp.

Figure 24.

Scatter diagram, dependent variable: Gases Temp.

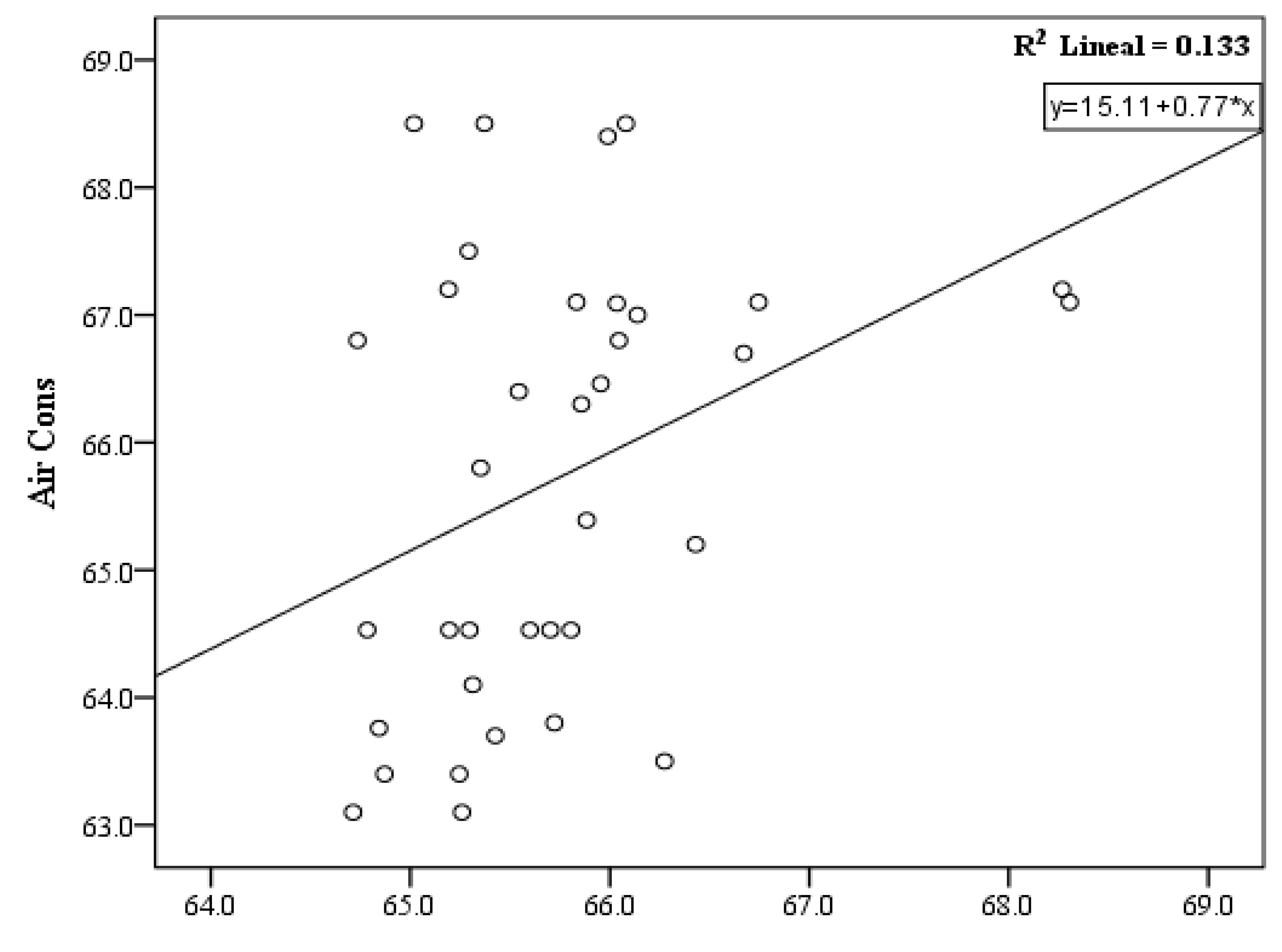

Figure 25.

Scatter diagram, dependent variable: Aircons.

Figure 25.

Scatter diagram, dependent variable: Aircons.

Table 1.

Properties of B100 and palm oil.

Table 1.

Properties of B100 and palm oil.

| Properties | Density at 15 °C gm/ml | Kinematic Viscosity at 40 °C mm2/s | Flash Point, °C | Heating Value MJ/kg |

|---|

| Method | ASTM D1298 | ASTM D445 | ASTM D92 | ASTM D270 |

| B100 | 0.877 | 4.56 | 196 | 40.56 |

| Palm oil | 0.925 | 41 | 260 | 39.849 |

Table 2.

Biodiesel B10 properties.

Table 2.

Biodiesel B10 properties.

| Properties | B10 |

|---|

| Higher calorific power (MJ/kg) | 45.4 |

| Lower calorific power (MJ/kg) | 42.9 |

| Specific gravity (a 20 °C) | 0.87 |

| Flash point (°C) | 60 |

| Freezing point (°C) | 23 |

| Cloud point (°C) | 45 |

| Soot (%) | 0.001 |

| Cetane number (Cst) | 45-50 |

| Viscosity (20 °C) (Cst) | 4.1 |

| Viscosity (40 °C) (Cst) | 2.6 |

| Viscosity (60 °C) (Cst) | 2.046 |

| Viscosity (100 °C) (Cst) | 1.1 |

Table 3.

Variables for the study.

Table 3.

Variables for the study.

| Variable | Units |

|---|

| Engine speed | Revolutions per minute (rpm) |

| Torque | N-m |

| Fuel consumption | mg/s |

| Air consumption | /h |

| Exhaust gases temperature | °C |

| Motor oil temperature | °C |

| Carbon monoxide | CO |

| Carbon dioxide | CO2 |

| Hydrocarbons | HC |

| Nitrogen oxides | NOX |

| Oxygen | O2 |

Table 4.

The regression ANOVA.

Table 4.

The regression ANOVA.

| Source of Variance | Sum of Squares | Degrees of Freedom (df) | Mean Squares (SS/df) | F-ratio (F statistic) | Sig. |

|---|

| Regression | Regression SS | 1 | Regression MS | F | Pr(F>Fobs) |

| Residual | Residual SS | N-k | Residual MS | | |

| Total | SST | N-1 | | | |

Table 5.

Air flowmeter characteristics.

Table 5.

Air flowmeter characteristics.

| Parameter | Measurement Interval (normalized) |

|---|

| Maximum flow range | 0.05 to 200 Nm/s air velocity at standard conditions 100 psi |

| Minimum flow range | 0.05 to 2.5 Nm/s air velocity at standard conditions 100 psi |

| Precision | +/−1% Reading |

| Repeatability | +/−0.5% Reading |

| Working temperature | 70 to 40 °C |

Table 6.

Characteristics of the equipment EXSA 240 cl.

Table 6.

Characteristics of the equipment EXSA 240 cl.

| Measurement Range | 0–2500 ppm |

|---|

| Operating temperature | 5 to 45 °C |

| Response time | T90 in 30 s |

| Linearity | +/−2% of full scale |

| Reproducibility | +/−0.5% of full scale |

| Warm-up time | 30 min |

| Analog out | 0–1 V |

Table 7.

Characteristics of the equipment VL Dicom 400.

Table 7.

Characteristics of the equipment VL Dicom 400.

| Measurement Parameters | Unit | Range | Resolution |

|---|

| Turning rate | rpm | 250 to 800 | 10 |

| Oil temperature | °C | 1 to 120 | 1 |

| CO | % vol. | 0 to 10 | 0.01 |

| CO2 | % vol. | 0 to 20 | 0.1 |

| HC | **ppm in vol. | 0 to 20000 | 1 |

| O2 | % vol. | 0 to 4 and 4 to 22 | 0.01 0.1 |

| NO | **ppm in vol. | 0 to 9000 | 1 |

| Spark advance angle * | ° of the crankshaft | −10 to 100 | 0.1 |

Table 8.

Equipment operation range.

Table 8.

Equipment operation range.

| Parameter | Units | Measurement Range | Resolution |

|---|

| Rotation | rpm | 250 to 800 * | 10 |

| Oil temperature | °C | 1 to 120 * | 1 |

Table 9.

Data of the run test for controls adjustment.

Table 9.

Data of the run test for controls adjustment.

| Load | Regime (rpm) | Torque (Nm) | Fuel | Air | Exhaust Gases Temp | Oil Temp | NOx | CO | CO2 | O2 | HC |

|---|

| Load | Desired | Measured | Desired | Measured | mg/s | N*m3/h | °C | °C | ppm | % Vol | % Vol | % Vol | ppm |

| 35% | 1800 | 1805 | 17.5 | 17.39 | 228 | 123.1 | 197.26 | 79 | 463 | 0.07 | 3.4 | 16.1 | 33 |

| 1800 | 1820 | 17.5 | 18.11 | 219 | 120.13 | 179.27 | 83 | 475 | 0.07 | 3.8 | 15.7 | 39 |

| 1800 | 1812 | 17.5 | 17.69 | 216 | 120.08 | 191.46 | 98 | 448 | 0.06 | 3.7 | 15.7 | 38 |

| 50% | 1800 | 1815 | 25 | 25.20 | 315 | 106.24 | 254.80 | 93 | 784 | 0.05 | 5.0 | 13.9 | 47 |

| 1800 | 1802 | 25 | 25.60 | 298 | 107.12 | 252.50 | 93 | 774 | 0.06 | 5.1 | 13.9 | 49 |

| 1800 | 1820 | 25 | 25.05 | 290 | 110.51 | 251.50 | 106 | 890 | 0.06 | 5.3 | 13.5 | 31 |

| 65% | 1800 | 1811 | 32 | 32.01 | 348 | 115.08 | 310.00 | 104 | 1061 | 0.10 | 6.6 | 11.6 | 45 |

| 1800 | 1791 | 32 | 32.10 | 345 | 109.66 | 307.00 | 104 | 1326 | 0.12 | 6.8 | 11.2 | 59 |

| 1800 | 1824 | 32 | 31.69 | 356 | 114.41 | 313.56 | 114 | 1133 | 0.09 | 6.5 | 11.7 | 44 |

| 80% | 1800 | 1787 | 40 | 41.50 | 487 | 118.87 | 422.69 | 111 | 1485 | 0.52 | 9.0 | 7.9 | 63 |

| 1800 | 1790 | 40 | 41.25 | 482 | 119.32 | 422.11 | 112 | 1478 | 0.52 | 8.9 | 8.0 | 64 |

| 1800 | 1815 | 40 | 40.90 | 488 | 115.42 | 424.00 | 114 | 1526 | 0.47 | 8.9 | 8.0 | 72 |

Table 10.

One factor ANOVA results.

Table 10.

One factor ANOVA results.

| | F value | P value | Fcrit |

|---|

| CO (%vol) | 2.016 | 0.073 | 2.216 |

| CO2 (%vol) | 12.749 | 1.687 × 10 −7 | 2. 216 |

| O2 (%vol) | 13.336 | 1.091 × 10 −7 | 2. 216 |

| HC (ppm) | 3.063 | 0.010 | 2. 216 |

| NOx (ppm) | 19.325 | 2.607 × 10 −9 | 2. 216 |

| TORQUE (N.m) | 4.655 | 7.988 × 10 −4 | 2. 216 |

| RPM | 0.632 | 0.784 | 2. 216 |

| GAS TEMP (°C) | 68.026 | 2.430× 10 −15 | 2. 216 |

| AIR CONSUM (m3/h) | 48.692 | 1.102× 10 −13 | 2. 216 |

| EXHAUST GASES TEMP (°C) | 50.680 | 7.009× 10 −14 | 2. 216 |

| OIL TEMP (°C) | 7.316 | 2.531× 10 −5 | 2. 216 |

Table 11.

Pearson Correlation of FC.

Table 11.

Pearson Correlation of FC.

| | Fuelcons | CO | CO2 | O2 | HC | NOx |

|---|

| Fuelcons | 1.000 | 0.278 | 0.791 | −0.768 | −0.542 | 0.720 |

| CO | 0.278 | 1.000 | 0.532 | −0.538 | 0.155 | 0.466 |

| CO2 | 0.791 | 0.532 | 1.000 | −0.994 | −0.392 | 0.972 |

| O2 | −0.768 | −0.538 | −0.994 | 1.000 | 0.351 | −0.972 |

| HC | −0.542 | 0.155 | −0.392 | 0.351 | 1.000 | −0.437 |

| NOx | 0.720 | 0.466 | 0.972 | −0.972 | −0.437 | 1.000 |

Table 12.

FC statistic change.

Table 12.

FC statistic change.

| Model | R | R Square | R Adjusted Square | Standard Error of the Estimate | Statistic change |

|---|

| Change in R Square | Change in F | df1 | df2 | Sig. change in F |

|---|

| 1 | 0.791a | 0.625 | 0.614 | 27.341 | 0.625 | 56.662 | 1 | 34 | 0.000 |

| 2 | 0.830b | 0.689 | 0.670 | 25.275 | 0.064 | 6.786 | 1 | 33 | 0.014 |

| 3 | 0.876c | 0.768 | 0.746 | 22.188 | 0.079 | 10.819 | 1 | 32 | 0.002 |

Table 13.

Regression ANOVA for FC.

Table 13.

Regression ANOVA for FC.

| Model | Sum of square | df | Mean squares | F | Sig. |

|---|

| 1 | Regression | 42357.948 | 1 | 42357.948 | 56.662 | 0.000b |

| Residue | 25416.940 | 34 | 747.557 | | |

| Total | 67774.889 | 35 | | | |

| 2 | Regression | 46693.167 | 2 | 23346.583 | 36.545 | 0.000c |

| Residue | 21081.722 | 33 | 638.840 | | |

| Total | 67774.889 | 35 | | | |

| 3 | Regression | 52019.993 | 3 | 17339.998 | 35.220 | 0.000d |

| Residue | 15754.896 | 32 | 492.340 | | |

| Total | 67774.889 | 35 | | | |

| b: CO2, c: CO2, HC, d: CO2, HC, NOx |

Table 14.

Correlations for temperature of combustion gases.

Table 14.

Correlations for temperature of combustion gases.

| | TempGases | CO | CO2 | O2 | HC | NOx |

|---|

| Pearson correlation | TempGases | 1.000 | 0.424 | 0.857 | −0.847 | −0.497 | 0.870 |

| CO | 0.424 | 1.000 | 0.532 | −0.538 | 0.155 | 0.466 |

| CO2 | 0.857 | 0.532 | 1.000 | −0.994 | −0.392 | 0.972 |

| O2 | −0.847 | −0.538 | −0.994 | 1.000 | 0.351 | −0.972 |

| HC | −0.497 | 0.155 | −0.392 | 0.351 | 1.000 | −0.437 |

| NOx | 0.870 | 0.466 | 0.972 | −0.972 | −0.437 | 1.000 |

Table 15.

Statistic change of gas temperatures.

Table 15.

Statistic change of gas temperatures.

| Model | R | R Square | R Adjusted Square | Standard Error of the Estimate | Statistic Change |

|---|

| Change in R Square | Change in F | df1 | df2 | Sig. Change in F |

|---|

| 1 | 0.870a | 0.756 | 0.749 | 15.553 | 0.756 | 105.365 | 1 | 34 | 0.000 |

Table 16.

Regression ANOVA of gas temperature.

Table 16.

Regression ANOVA of gas temperature.

| Model | Sum of Square | df | Mean Squares | F | Sig. |

|---|

| 1 | Regression | 25489.332 | 1 | 25489.332 | 105.365 | 0.000b |

| Residue | 8225.135 | 34 | 241.916 | | |

| Total | 33714.467 | 35 | | | |

| | b: NOx | | | | | |

Table 17.

Pearson correlations air consume.

Table 17.

Pearson correlations air consume.

| | Aircons | CO | CO2 | O2 | HC | NOx |

|---|

| Aircons | 1.000 | −0.138 | −0.294 | 0.284 | 0.447 | −0.441 |

| CO | −0.138 | 1.000 | 0.532 | −0.538 | 0.155 | 0.466 |

| CO2 | −0.294 | 0.532 | 1.000 | −0.994 | −0.392 | 0.972 |

| O2 | 0.284 | −0.538 | −0.994 | 1.000 | 0.351 | −0.972 |

| HC | 0.447 | 0.155 | −0.392 | 0.351 | 1.000 | −0.437 |

| NOx | −0.441 | 0.466 | 0.972 | −0.972 | −0.437 | 1.000 |

Table 18.

Statistic of change of air consumption.

Table 18.

Statistic of change of air consumption.

| Model | R | R Square | R Sum of Square | Standard Error of the Estimate | Statistic Change |

|---|

| Change in R Square | Change in F | df1 | df2 | Sig. Change in F |

|---|

| 1 | 0.447a | 0.200 | 0.177 | 1.566 | 0.200 | 8.509 | 1 | 34 | 0.006 |

Table 19.

Regression of ANOVA of air consumption.

Table 19.

Regression of ANOVA of air consumption.

| Model | Sum of Square | df | Mean Squares | F | Sig. |

|---|

| 1 | Regression | 20.882 | 1 | 20.882 | 8.509 | 0.006b |

| Residue | 83.440 | 34 | 2.454 | | |

| Total | 104.321 | 35 | | | |

| | b: HC | | | | | |