Maximizing Environmental Impact Savings Potential through Innovative Biorefinery Alternatives: An Application of the TM-LCA Framework for Regional Scale Impact Assessment

Abstract

1. Introduction

2. Materials and Methods

2.1. TM-LCA Framework Application

- (a)

- Alternative technology is defined.

- (b)

- The producer territory is defined and limited to systems interacting with the technological options being assessed within a geographical region.

- (c)

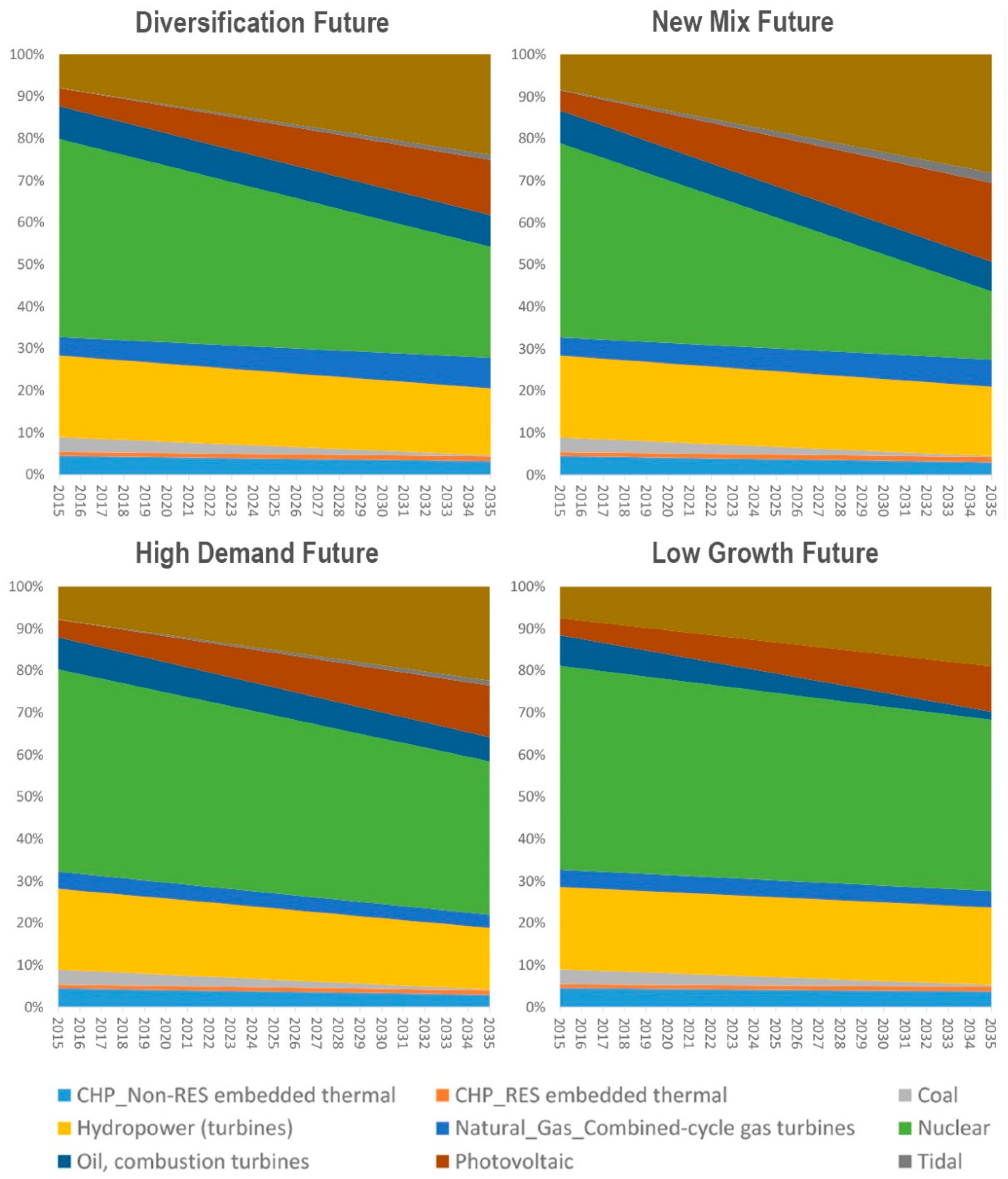

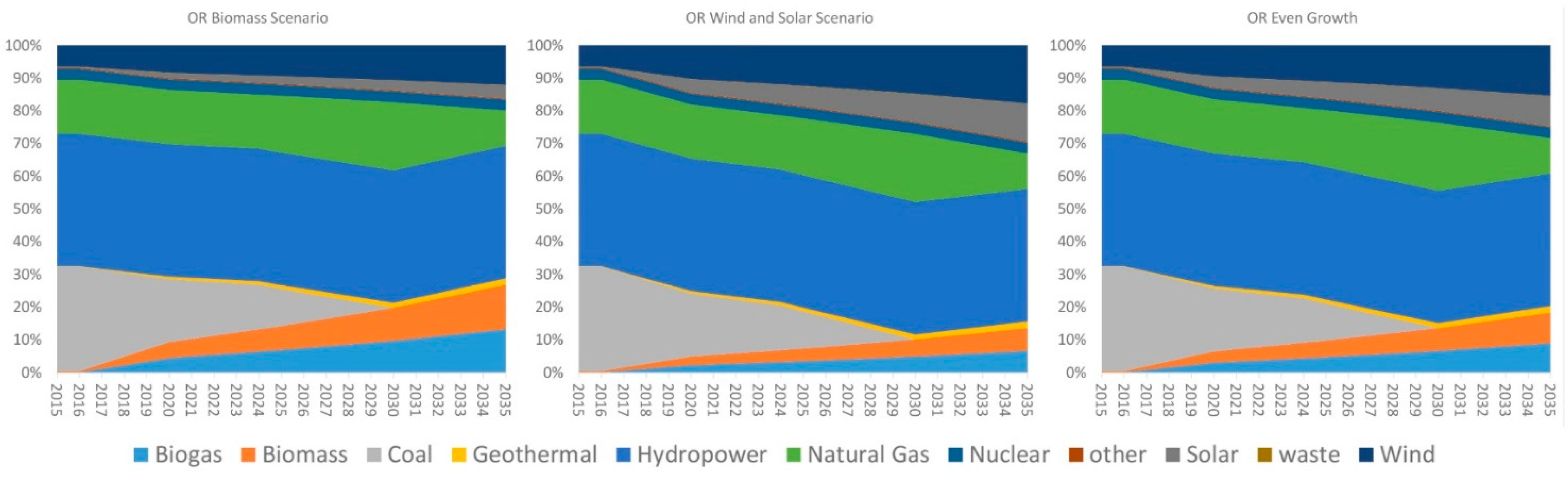

- Temporal dynamics are incorporated into the systems, e.g., in dynamic background electricity energy provision and technological efficiency improvement.

- (d)

- The assessment is scaled to encompass the whole region so that all feedstock available that may fulfill the functional unit is treated by the technological alternatives being assessed. However, only changes in systems and in the region are assessed.

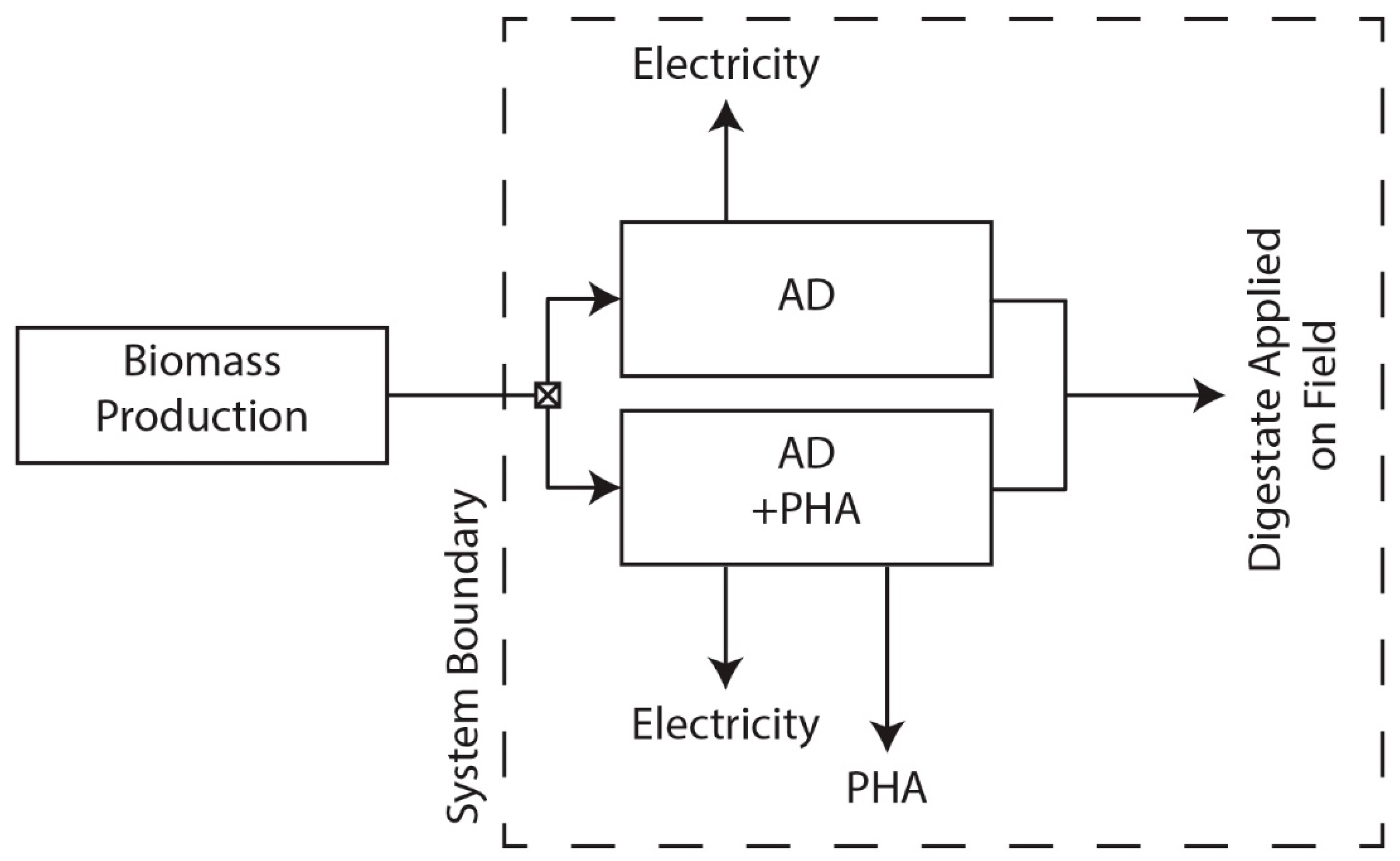

2.2. Goal and Scope

Functional Unit

2.3. Scenarios

2.3.1. Biogas Only

2.3.2. Field Application of Digestate for All Scenarios

2.3.3. PHA-Biogas

2.3.4. System Boundaries

2.4. Dynamics

PHA Process Energy Consumption

2.5. Implementation of Territorial Scale Assessment

Feedstock Provision

2.6. Impact Assessment Method

2.7. Sensitivity Analysis

2.7.1. Process Energy Consumption Related to PHA Production

2.7.2. Replacement Ratio Conventional Polymers

2.7.3. Mineralization of N in Digestate

2.7.4. Feedstock Provisioning Scenarios

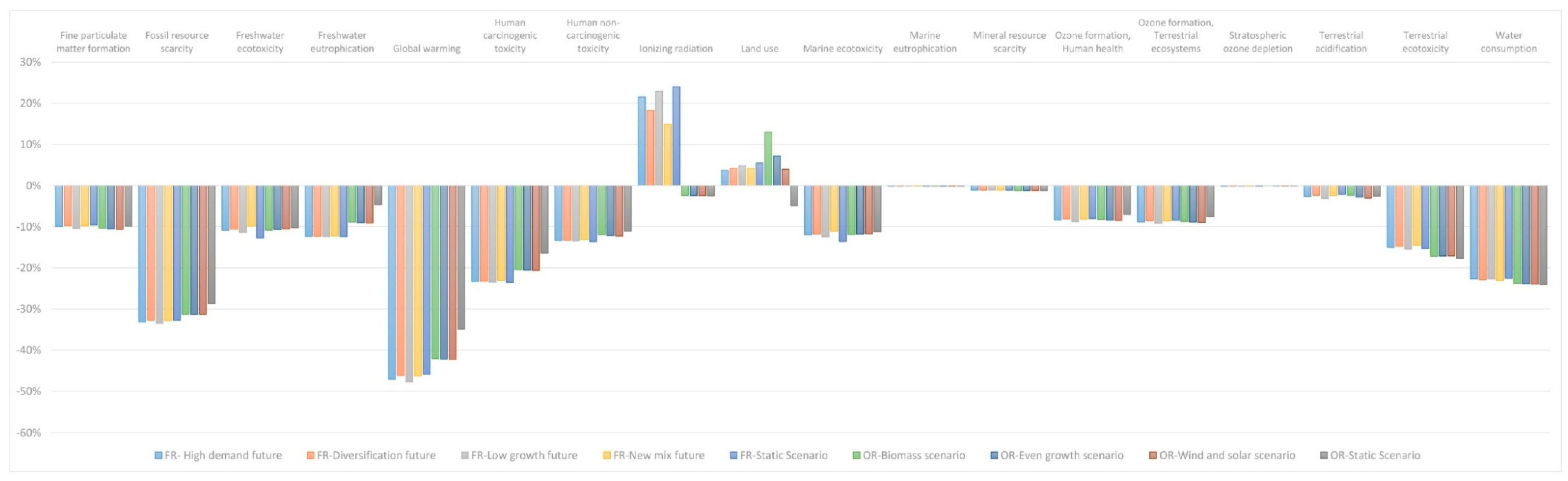

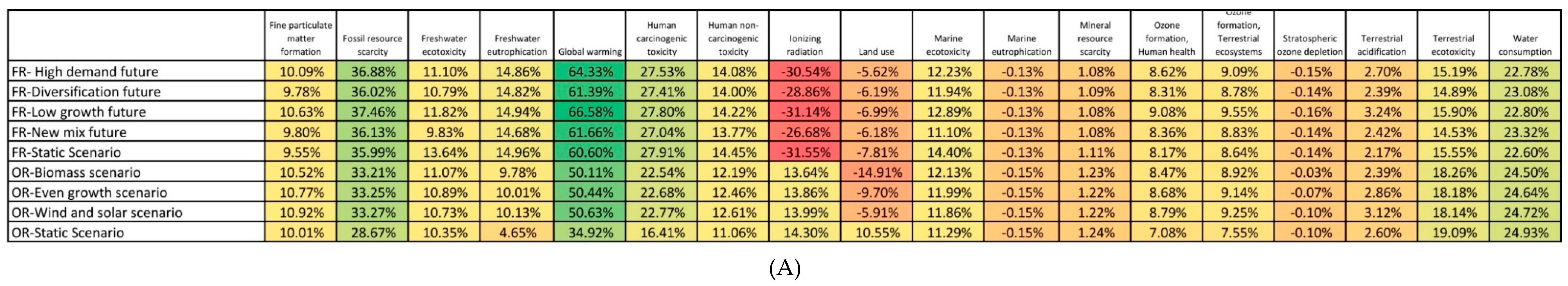

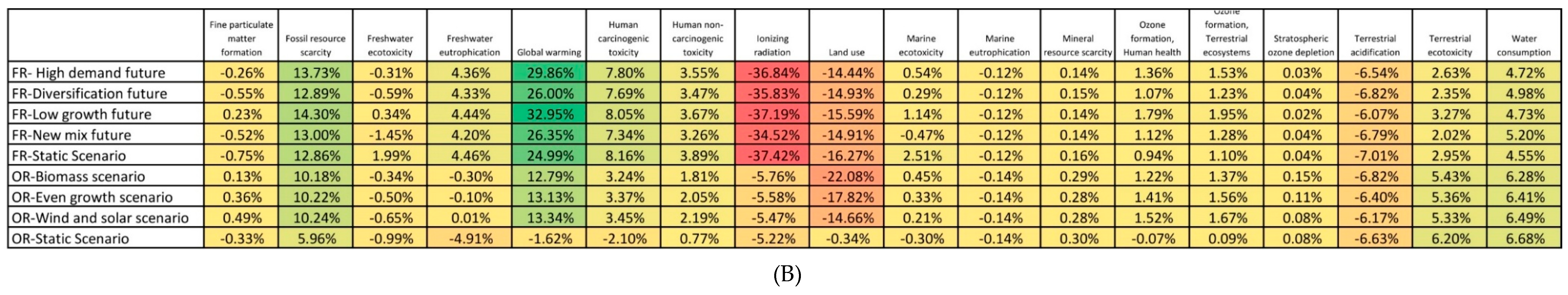

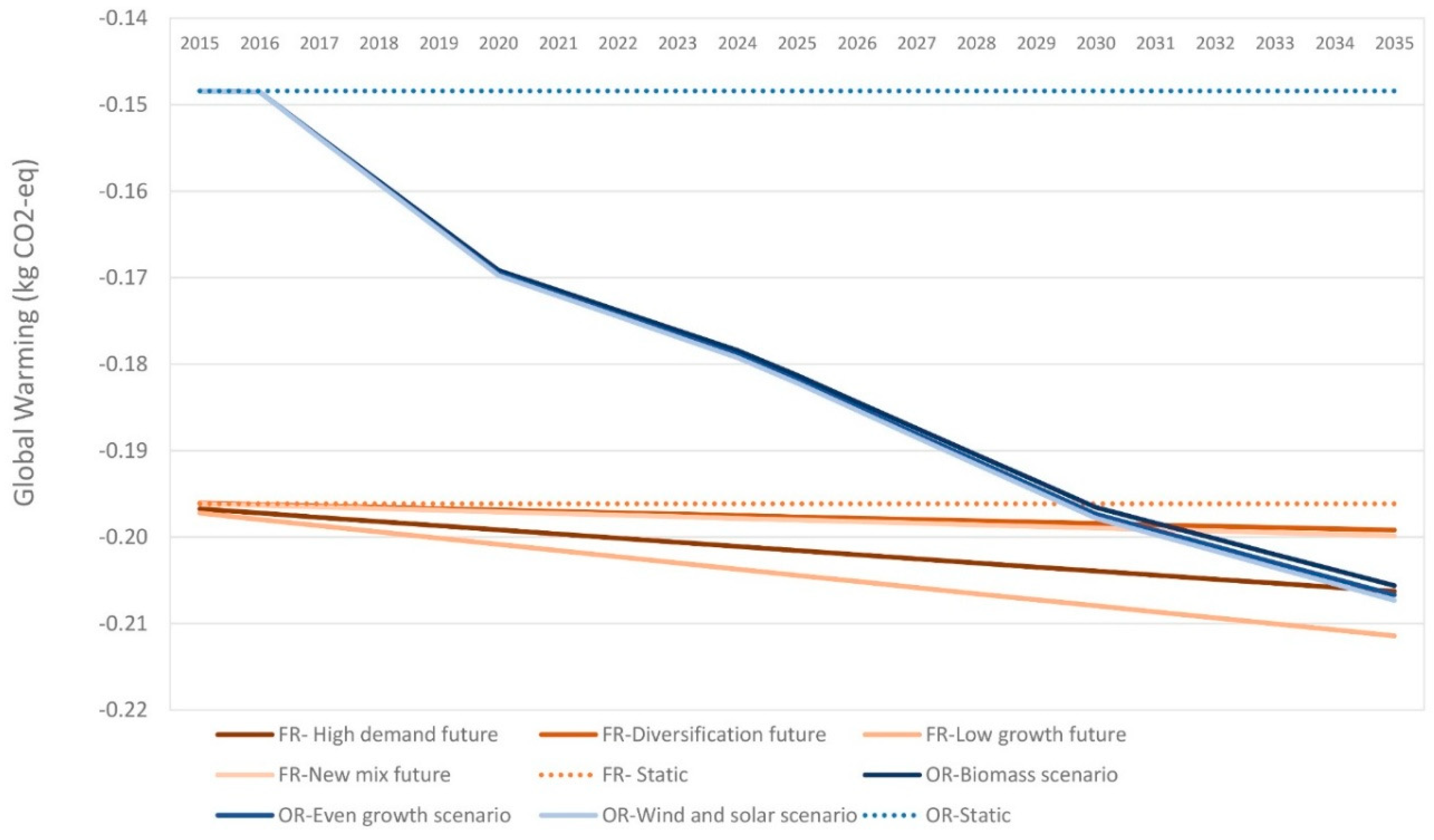

3. Results

3.1. Sensitivity Results

Sensitivity of N2O Emission Factor

3.2. Territorial Scale Application

Sensitivity Analysis of Transport at Territorial Scale

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Kluppel, H. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Sohn, J.; Kalbar, P.; Goldstein, B.; Birkved, M. Defining Temporally Dynamic Life Cycle Assessment: A Literature Review. Integr. Environ. Assess. Manag. in press.

- Goldstein, B.; Birkved, M.; Quitzau, M.-B.; Hauschild, M. Quantification of urban metabolism through coupling with the life cycle assessment framework: Concept development and case study. Environ. Res. Lett. 2013, 8, 035024. [Google Scholar] [CrossRef]

- Sohn, J.; Vega, G.C.; Birkved, M. A Methodology Concept for Territorial Metabolism—Life Cycle Assessment: Challenges and Opportunities in Scaling from Urban to Territorial Assessment. Proc. CIRP 2018, 69, 89–93. [Google Scholar] [CrossRef]

- Sohn, J.L.; Kalbar, P.P.; Banta, G.T.; Birkved, M. Life-cycle based dynamic assessment of mineral wool insulation in a Danish residential building application. J. Clean. Prod. 2017, 142, 3243–3253. [Google Scholar] [CrossRef]

- Pinsonnault, A.; Lesage, P.; Levasseur, A.; Samson, R. Temporal differentiation of background systems in LCA: Relevance of adding temporal information in LCI databases. Int. J. Life Cycle Assess. 2014, 19, 1843–1853. [Google Scholar] [CrossRef]

- Beloin-Saint-Pierre, D.; Levasseur, A.; Margni, M.; Blanc, I. Implementing a Dynamic Life Cycle Assessment Methodology with a Case Study on Domestic Hot Water Production. J. Ind. Ecol. 2017, 21, 1128–1138. [Google Scholar] [CrossRef]

- Tiruta-Barna, L.; Pigné, Y.; Navarrete Gutiérrez, T.; Benetto, E. Framework and computational tool for the consideration of time dependency in Life Cycle Inventory: Proof of concept. J. Clean. Prod. 2016, 116, 198–206. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Samson, R. Biogenic carbon and temporary storage addressed with dynamic life cycle assessment. J. Ind. Ecol. 2013, 17, 117–128. [Google Scholar] [CrossRef]

- Vega, G.C.; Sohn, J.; Birkved, M. Innovative method to optimize territorial organic waste resources. In Proceedings of the SETAC Europe 28 th Annual Meeting, Rome, Italy, 13–17 May 2018. [Google Scholar]

- Almeida, J.; Degerickx, J.; Achten, W.M.; Muys, B. Greenhouse gas emission timing in life cycle assessment and the global warming potential of perennial energy crops warming potential of perennial energy crops. Carbon Manag. 2015, 6, 185–195. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications A State-of-the-Art Survey; Springer: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Sohn, J.L.; Kalbar, P.P.; Birkved, M. Life cycle based dynamic assessment coupled with multiple criteria decision analysis: A case study of determining an optimal building insulation level. J. Clean. Prod. 2017, 162, 449–457. [Google Scholar] [CrossRef]

- Laurent, A.; Olsen, S.I.; Hauschild, M.Z. Limitations of carbon footprint as indicator of environmental sustainability. Environ. Sci. Technol. 2012, 46, 4100–4108. [Google Scholar] [CrossRef] [PubMed]

- Cavinato, C.; Da Ros, C.; Pavan, P.; Bolzonella, D. Influence of temperature and hydraulic retention on the production of volatile fatty acids during anaerobic fermentation of cow manure and maize silage. Bioresour. Technol. 2017, 223, 59–64. [Google Scholar] [CrossRef] [PubMed]

- GreenDelta. OpenLCA 1.8.0. 2019. Available online: www.greendelta.com (accessed on 30 May 2019).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 3, 1218–1230. [Google Scholar] [CrossRef]

- Hamelin, L.; Wesnaes, M.; Wenzel, H.; Petersen, B.M. Life Cycle Assessment of Biogas from Separated slurry. Odense. 2010. Available online: https://www2.mst.dk/udgiv/publications/2010/978-87-92668-03-5/pdf/978-87-92668-04-2.pdf (accessed on 30 May 2019).

- Brockmann, D.; Pradel, M.; Hélias, A. Agricultural use of organic residues in life cycle assessment: Current practices and proposal for the computation of field emissions and of the nitrogen mineral fertilizer equivalent. Resour. Conserv. Recycl. 2018, 133, 50–62. [Google Scholar] [CrossRef]

- Bruun, S.; Yoshida, H.; Nielsen, M.P.; Jensen, L.S.; Christensen, T.H.; Scheutz, C. Estimation of long-term environmental inventory factors associated with land application of sewage sludge. J. Clean. Prod. 2016, 126, 440–450. [Google Scholar] [CrossRef]

- Hansen, S.S.; Abrahamsen, P.P.; Petersen, C.T.; Styczen, M.M. Daisy: Model Use, Calibration, and Validation. Trans. ASABE 2012, 55, 1317–1335. [Google Scholar] [CrossRef]

- Yoshida, H.; Nielsen, M.P.; Scheutz, C.; Jensen, L.S.; Bruun, S.; Christensen, T.H. Long-Term Emission Factors for Land Application of Treated Organic Municipal Waste. Environ. Model. Assess. 2016, 21, 111–124. [Google Scholar] [CrossRef]

- 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Eggleston, S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Strategies: Hayama, Japan, 2006; Volume 5. [Google Scholar]

- Intelligen Inc. SuperPro Designer v.10 (R). 2018. Available online: Intelligen.com (accessed on 30 May 2019).

- Royer, S.J.; Ferrón, S.; Wilson, S.T.; Karl, D.M. Production of methane and ethylene from plastic in the environment. PLoS ONE 2018, 13, e0200574. [Google Scholar] [CrossRef]

- Browne, M.A.; Underwood, A.J.; Chapman, M.G.; Williams, R.; Thompson, R.C.; van Franeker, J.A. Linking effects of anthropogenic debris to ecological impacts. Proc. R. Soc. B Biol. Sci. 2015, 282, 20142929. [Google Scholar] [CrossRef]

- Réseau de Transport d’Électricité. 2014 Edition Generation Adequacy Report on the Electricity Supply-Demand Balance in France; Réseau de Transport d’Électricité: Paris, France, 2014; Available online: https://www.rte-france.com/sites/default/files/2014_generation_adequacy_report.pdf (accessed on 30 May 2019).

- Oregon State. Chapter 469a—Renewable Portfolio Standards. 2017, Volume 11. Available online: https://www.oregonlaws.org/ors/chapter/469A (accessed on 30 May 2019).

- Dietrich, K.; Dumont, M.; Del, L.F.; Orsat, V. Producing PHAs in the bioeconomy—Towards a sustainable bioplastic. Sustain. Prod. Consum. 2017, 9, 58–70. [Google Scholar] [CrossRef]

- Morgan-Sagastume, F.; Heimersson, S.; Laera, G.; Werker, A.; Svanström, M. Techno-environmental assessment of integrating polyhydroxyalkanoate (PHA) production with services of municipal wastewater treatment. J. Clean. Prod. 2016, 137, 1368–1381. [Google Scholar] [CrossRef]

- Frison, N.; Katsou, E.; Malamis, S.; Bolzonella, D.; Fatone, F. Biological nutrients removal via nitrite from the supernatant of anaerobic co-digestion using a pilot-scale sequencing batch reactor operating under transient conditions. Chem. Eng. J. 2013, 230, 595–604. [Google Scholar] [CrossRef]

- Bugge, J.; Kjær, S.; Blum, R. High-efficiency coal-fired power plants development and perspectives. Energy 2006, 31, 1437–1445. [Google Scholar] [CrossRef]

- Torres, J.L.; Varela, B.; García, M.T.; Carilla, J.; Matito, C.; Centelles, J.J.; Cascante, M.; Sort, X.; Bobet, R. Valorization of grape (Vitis vinifera) byproducts. Antioxidant and biological properties of polyphenolic fractions differing in procyanidin composition and flavonol content. J. Agric. Food Chem. 2002, 50, 7548–7555. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.; Harding, J. The Oxford Companion to Wine, 4th ed.; Oxford University Press: Oxford, UK, 2015. [Google Scholar]

- NW Natural. Cow Pie—Or Renewable Energy? What is Biogas? 2017. Available online: https://www.nwnatural.com/Residential/SmartEnergy/BattlingClimateChange/CarbonOffsets/Biogas (accessed on 30 May 2019).

- France AgriMer. Région Languedoc-Roussillon: Les Services de FranceAgriMer au sein de la Direction Régionale de l’Alimentation, de l’Agriculture et de la Forêt du Languedoc-Roussillon. 2014. Available online: https://www.franceagrimer.fr/content/download/38160/document/Languedoc-Roussillon.pdf (accessed on 30 May 2019).

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollabder, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Average PET. Available online: http://www.matweb.com/search/datasheet.aspx?MatGUID=a696bdcdff6f41dd98f8eec3599eaa20 (accessed on 15 January 2019).

- NatureWorks® IngeoTM. 3001D Injection Grade PLA. Available online: http://www.matweb.com/search/datasheet.aspx?MatGUID=a696bdcdff6f41dd98f8eec3599eaa20 (accessed on 1 February 2019).

- Handbook of Biodegradable Polymers, 2nd ed.; Bastioli, C., Ed.; Smithers Rapra Technology Ltd.: Shrewbury, UK, 2014. [Google Scholar]

- Bjørn, A.; Hauschild, M.Z. Introducing carrying capacity-based normalisation in LCA: Framework and development of references at midpoint level. Int. J. Life Cycle Assess. 2015, 20, 1005–1018. [Google Scholar] [CrossRef]

- Croxatto Vega, G.C.; ten Hoeve, M.; Birkved, M.; Sommer, S.G.; Bruun, S. Choosing co-substrates to supplement biogas production from animal—A life cycle assessment of the environmental consequences. Bioresour. Technol. 2014, 171, 410–420. [Google Scholar] [CrossRef]

- Ten Hoeve, M.; Hutchings, N.J.; Peters, G.M.; Svanström, M.; Jensen, L.S.; Bruun, S. Life cycle assessment of pig slurry treatment technologies for nutrient redistribution in Denmark. J. Environ. Manag. 2014, 132, 60–70. [Google Scholar] [CrossRef]

- Ten Hoeve, M.; Nyord, T.; Peters, G.M.; Hutchings, N.J.; Jensen, L.S.; Bruun, S. A life cycle perspective of slurry acidification strategies under different nitrogen regulations. J. Clean. Prod. 2016, 127, 591–599. [Google Scholar] [CrossRef]

| Languedoc-Roussillon | Oregon | |

|---|---|---|

| Annual Grape Marc Production (tons at crush) | 212,940 | 8,009 |

| Annual Cow Waste Production (tons) | 372,300 | 2,389,091 |

| Max. Co-digestion Feedstock Availability at 35% Grape Marc (tons/day) | 1569 | 62 |

| Cow Waste Demand at 100% Grape Marc Utilization (tons) | 395,460 | 14,875 |

| Grape Marc Demand at 100% Cow Waste Utilization (tons) | 200,469 | 1,286,433 |

| Cow Waste Demand at 100% Grape Marc Utilization (% of available cow waste) | 106% | 0.62% |

| Grape Marc Demand at 100% Cow Waste Utilization (% of available grape marc) | 94% | 16,061% |

| PET [38] | PLA [39] | PHB [40] | |

|---|---|---|---|

| Yield strength, σ (Mpa) | 2410.0 | 3830.0 | 2200.0 |

| Tensile strength (Mpa) | 38.8 | 48.0 | 32.0 |

| Density (kg/m3) | 1.3 | 1.2 | 1.2 |

| Performance index (YS) | 1882.8 | 3088.7 | 1833.3 |

| Performance index (TS) | 30.3 | 38.7 | 26.7 |

| Average performance | 956.6 | 1563.7 | 930.0 |

| Replacement Ratio (RR), YS | 0.97 | 0.59 | |

| RR, TS | 0.88 | 0.69 | |

| RR, AVG | 0.93 | 0.64 |

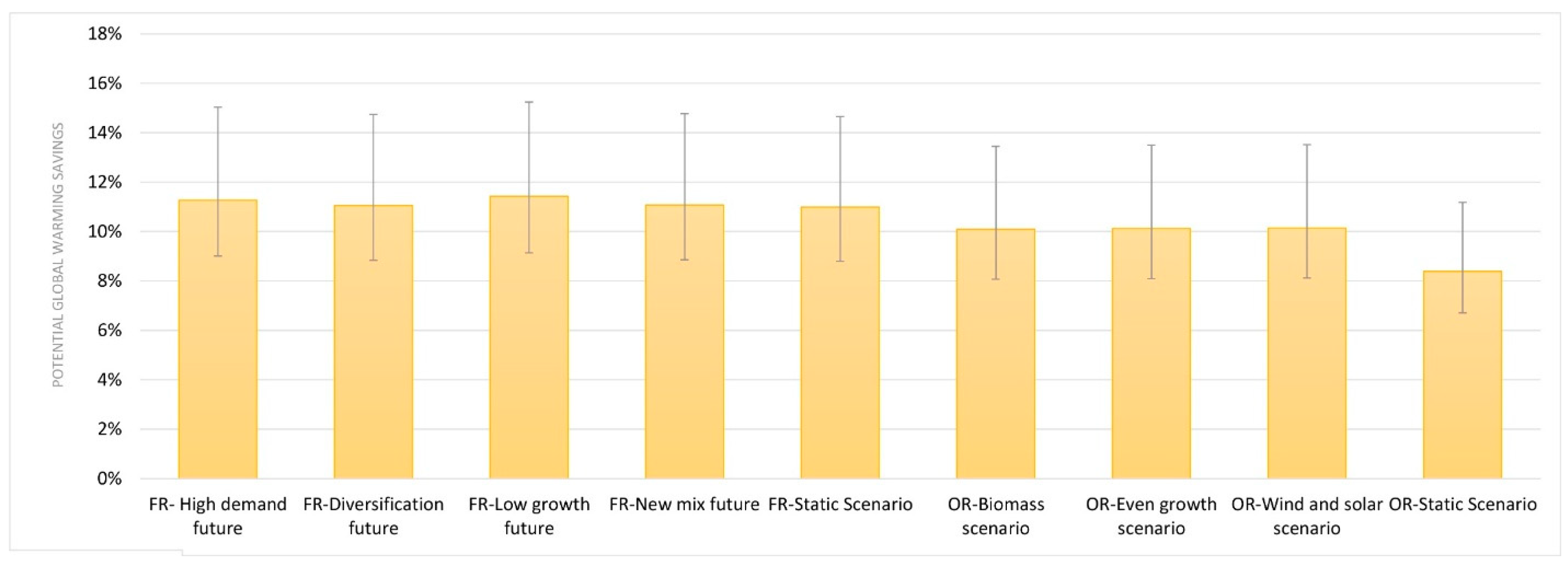

| GWP (Kg CO2e) Reduction/Fu | Person Years (PY) of Carrying Capacity (C.Cap) Reduction Daily | PY of C.Cap Reduction Annually | |

|---|---|---|---|

| FR-HIGH DEMAND FUTURE | 4.23 | 6.74 | 2460.75 |

| FR-DIVERSIFICATION FUTURE | 4.15 | 6.61 | 2413.15 |

| FR-LOW GROWTH FUTURE | 4.29 | 6.84 | 2495.46 |

| FR-NEW MIX FUTURE | 4.16 | 6.62 | 2417.67 |

| FR-STATIC SCENARIO | 4.13 | 6.57 | 2399.86 |

| OR-BIOMASS SCENARIO | 3.79 | 0.24 | 86.98 |

| OR-EVEN GROWTH SCENARIO | 3.80 | 0.24 | 87.25 |

| OR-WIND AND SOLAR SCENARIO | 3.80 | 0.24 | 87.41 |

| OR-STATIC SCENARIO | 3.14 | 0.20 | 72.14 |

| 50 km | 100 km | 200 km | 500 km | |

|---|---|---|---|---|

| AVERAGE CHANGE AMONGST ALL IMPACT CATEGORIES | 11% | 21% | 43% | 106% |

| AVERAGE CHANGE IN GWP | 36% | 73% | 145% | 363% |

| MAX. CHANGE IN GWP | 71% | 142% | 284% | 710% |

| FR- High Demand Future | FR-Diversification Future | FR-Low Growth Future | FR-New Mix Future | FR-Static Scenario | OR-Biomass Scenario | OR-Even Growth Scenario | OR-Wind and Solar Scenario | OR-Static Scenario | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Energy Demand for PHA Production (kWh/FU) | ||||||||||

| 70.70 | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA |

| TOPSIS Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | |

| 77.70 | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA |

| TOPSIS Preference | PHA | PHA | PHA | PHA | Biogas | PHA | PHA | PHA | PHA | |

| 84.84 | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA |

| TOPSIS Preference | Biogas | Biogas | Biogas | PHA | Biogas | Biogas | PHA | PHA | PHA | |

| 98.98 | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | PHA | PHA | PHA | |

| 106.10 | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | PHA | PHA | |

| 113.12 | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | Biogas |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | PHA | PHA | |

| 127.26 | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | Biogas |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | PHA | |

| 226.34 | GWP Preference | PHA | PHA | PHA | PHA | PHA | Biogas | Biogas | Biogas | Biogas |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | |

| 388.85 | GWP Preference | PHA | PHA | PHA | PHA | Biogas | Biogas | Biogas | Biogas | Biogas |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | |

| 537.32 | GWP Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | |

| Polymer replacement ratio (PHB:PET) | ||||||||||

| 42% | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA |

| TOPSIS Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | |

| 32% | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA |

| TOPSIS Preference | PHA | PHA | PHA | PHA | Biogas | Biogas | Biogas | Biogas | PHA | |

| 22% | GWP Preference | PHA | PHA | PHA | PHA | PHA | PHA | PHA | PHA | Biogas |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | |

| 12% | GWP Preference | PHA | Biogas | PHA | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas |

| TOPSIS Preference | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | Biogas | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Croxatto Vega, G.; Sohn, J.; Bruun, S.; Olsen, S.I.; Birkved, M. Maximizing Environmental Impact Savings Potential through Innovative Biorefinery Alternatives: An Application of the TM-LCA Framework for Regional Scale Impact Assessment. Sustainability 2019, 11, 3836. https://doi.org/10.3390/su11143836

Croxatto Vega G, Sohn J, Bruun S, Olsen SI, Birkved M. Maximizing Environmental Impact Savings Potential through Innovative Biorefinery Alternatives: An Application of the TM-LCA Framework for Regional Scale Impact Assessment. Sustainability. 2019; 11(14):3836. https://doi.org/10.3390/su11143836

Chicago/Turabian StyleCroxatto Vega, Giovanna, Joshua Sohn, Sander Bruun, Stig Irving Olsen, and Morten Birkved. 2019. "Maximizing Environmental Impact Savings Potential through Innovative Biorefinery Alternatives: An Application of the TM-LCA Framework for Regional Scale Impact Assessment" Sustainability 11, no. 14: 3836. https://doi.org/10.3390/su11143836

APA StyleCroxatto Vega, G., Sohn, J., Bruun, S., Olsen, S. I., & Birkved, M. (2019). Maximizing Environmental Impact Savings Potential through Innovative Biorefinery Alternatives: An Application of the TM-LCA Framework for Regional Scale Impact Assessment. Sustainability, 11(14), 3836. https://doi.org/10.3390/su11143836