Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies

Abstract

1. Introduction

2. Background

2.1. Circular Economy

2.2. Servitized Business Models

- Product-focused BMs: In this BM type, the main purpose is to deliver tangible value to the customer [42]. Value is considered as an embedded attribute of the product being exchanged, and it mainly refers to the four P’s of the marketing mix: price, product, promotion, and place [48]. The product ownership (property rights to the product) is transferred to the customer, while the company can sell a combination of single standard products and industrial services, which are usually not customized. The aim of this kind of services is to improve or restore the functionality of the product, such as through maintenance and repair (basic field services and inspection). As the service is seen as non-core business, the company can define a network of third party service suppliers [49]. Moreover, information exchange is limited, and mostly related to technical and operational aspects. In this BM category, the company has no (or lower) responsibility for product lifecycle, and transactions are often single and independent from each other [47]. However, some extra services may be added [42]. Extended warranties, as well as repair and maintenance contracts can represent a source of value for the customer within these BMs. The main revenue stream is represented by product sales, in which is often included a pre-sales service related component. Thus, product-focused BMs do not change the incentive for companies to maximizes the product sales [7]. Therefore, through this BM type it is uncommon for companies to achieve CE objectives, since rarely do the offered solutions increase resource efficiency, extend the product lifespan, or close the loop.

- Usage-focused BMs: In this BM type, the customer does not buy the product. In fact, customers pay a fee to gain access to it [42,50]. The company also takes responsibility for providing lifecycle services such as maintenance, repair, and control [49]. Moreover, the company has also a powerful incentive to design a product in terms of which elements can be re-used after the product’s useful life. Again, the product should be easy to maintain when a maintenance contract is signed, or for the parts to be easily reused when a take-back agreement is made [18]. Because the company retains the product ownership, and users can change during the product lifetime, the product should allow upgrades, thus achieving a longer lifetime [51]. In this BM type, advanced services, such as remote monitoring and diagnosis, advanced training, consultancy on product-enabled processes, as well as predictive maintenance are crucial [18]. Internal costs for these activities have to be better quantified than in product-focused BMs—leasing or renting products instead of selling them would increase the company costs, since it would require high initial capital investments. Thus, financial resources become critical, and the payback period is often longer than for physical product sales [42]. Usage-focused BMs are more promising than product-oriented ones in achieving CE objectives, since they intensify the use of materials e.g., through sharing [7], thus increasing resource efficiency. If advanced maintenance or take-back agreements are signed, the other CE value drivers (i.e., extend product lifespan and close the loop) may also be pursued through this BM type. However, usage-focused BMs (such as sharing, leasing, pay-per-use) could bring to a less careful usage by the customer base, leading to a quicker wear and tear [7], thus questioning the pursuing of the second CE value driver.

- Result-focused BMs: In this BM type, the customer does not buy the product or system, but pays a variable fee that depends on the achievement of a contractually-set result, in terms of product/system performance or outcome of its usage [42]. Thus, the value is generated by an individualized and integrated combination of products and services to produce the expected results [47]. A field service network is a prerequisite for successful service delivery of traditional and advanced services, where field technicians interact frequently with customers, and customers tend to trust them more. In this sense, online or web-based collaboration systems serve as an additional tool [50]. Payments are generally based on outcome units, which are paid for their results [50]. The core of this concept is that the customer buys the performance, not the product and the related services. Thus, the company is responsible for all lifecycle costs [18]. This, in turn, provides a powerful incentive to design products for CE, following the design policies introduced in Section 2.1. Moreover, the company has the incentive to minimize the overall lifecycle cost, thus minimizing operating costs (for instance, by increasing resource efficiency), extending the product lifespan, and collecting back products to allow multiple lifecycles [7]. Thus, this BM type allows companies to achieve CE by the means of all the three CE value drivers. In accordance with Tukker [7], result-focused BMs may be the most effective ones to move towards CE. However, it is generally difficult to measure outcomes and results in term of product/system performance, and reach an agreement between customer and supplier in this regard.

2.3. The Role of the Internet of Things, Big Data, and Analytics for Servitized Business Models and Circular Economy

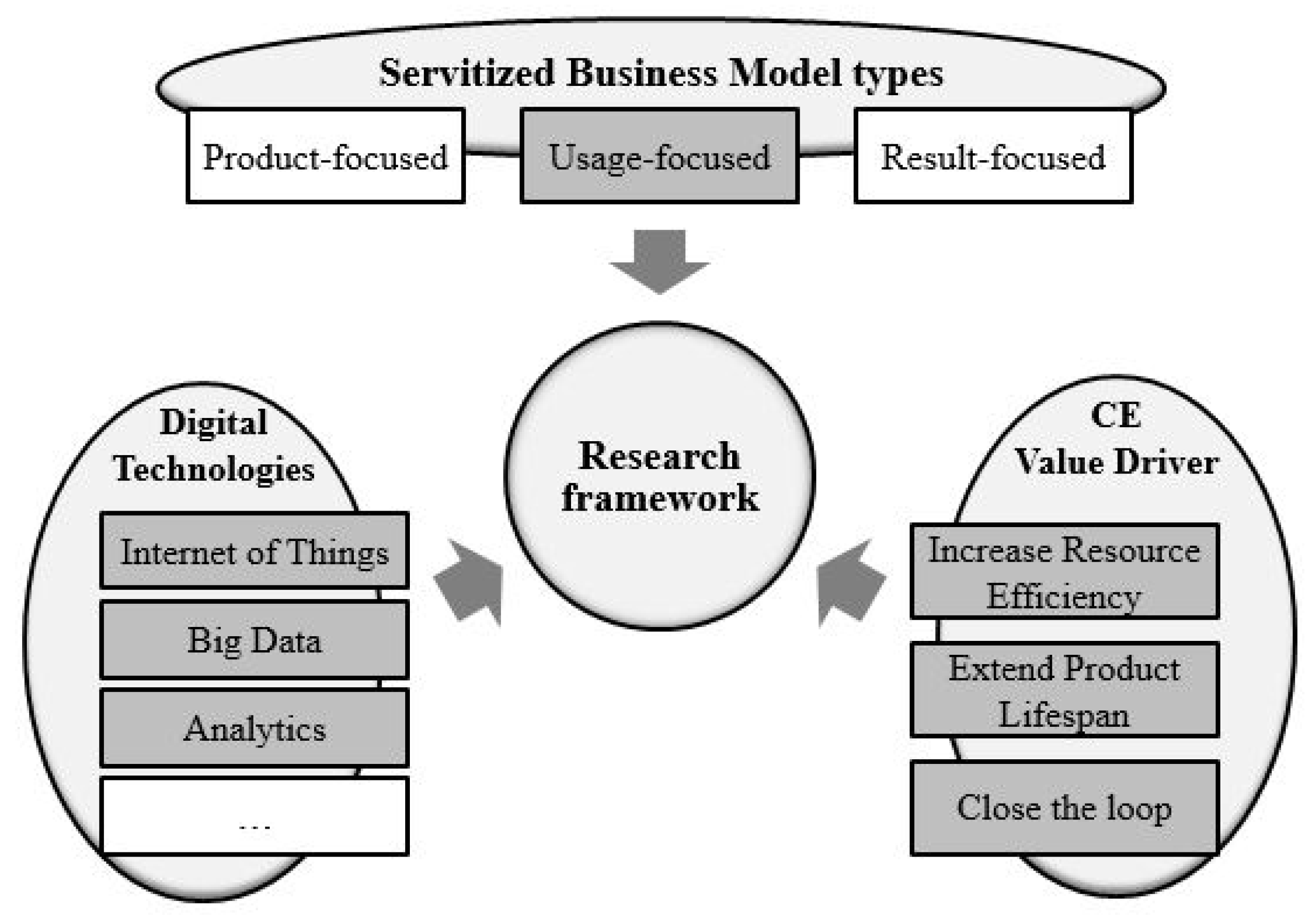

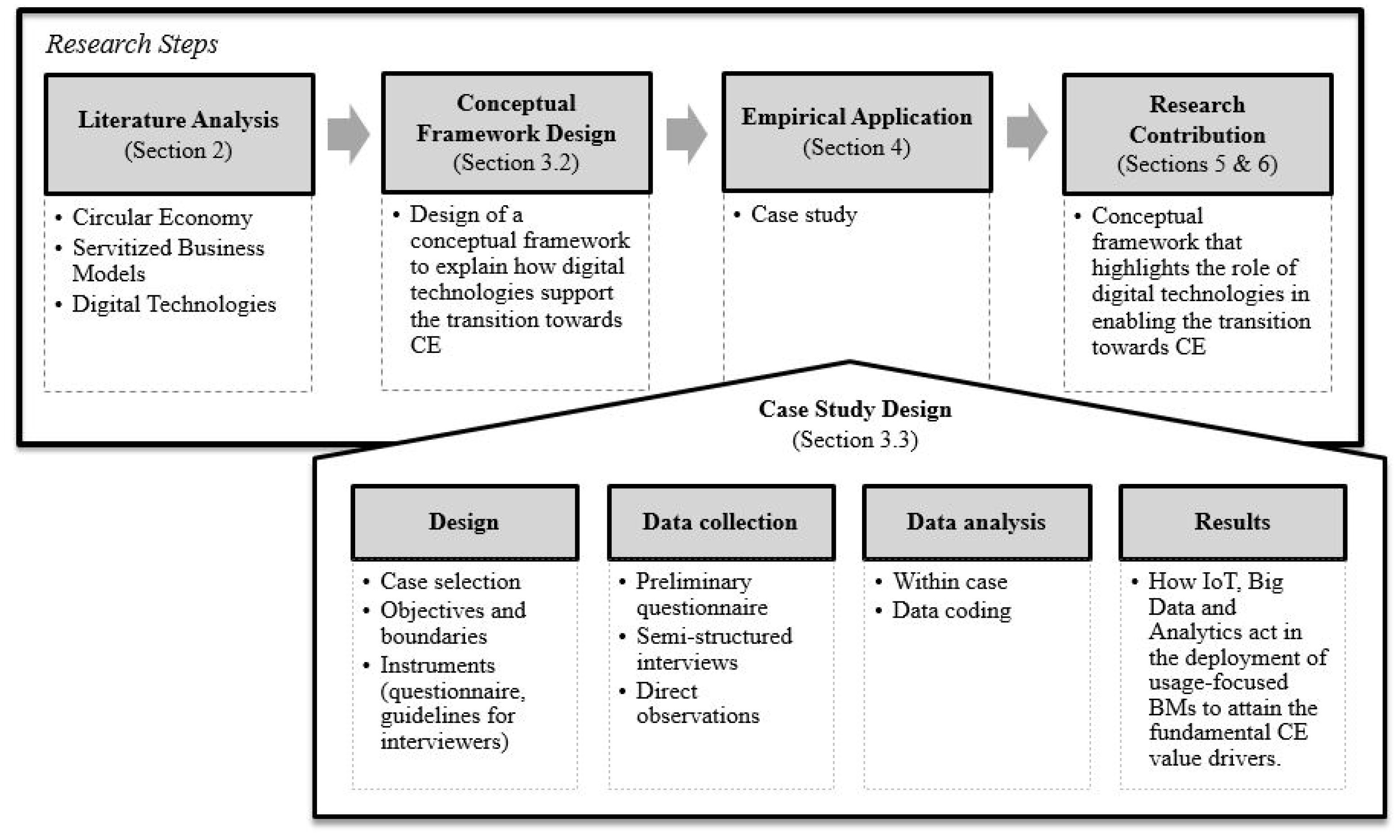

3. Research Design, Framework, and Methods

3.1. Research Design

3.2. The Conceptual Framework: The Functionalities of Digital Technologies in Servitized Business Models

3.3. Case Study Research

4. The Alpha Case

4.1. Company Overview and Usage-Focused Business Models

4.2. Digital Technologies in the Alpha Case

5. Discussion

6. Conclusions

6.1. Contribution to Research

- Enhancing product design, thus extending product lifespan and closing the loop.

- Enhancing marketing activities by attracting target customer segments, thus reaching a wider diffusion of the CE offering and therefore creating value through all the three CE value drivers.

- Allowing the monitoring and tracking of product activity, thus preventing incorrect usage behavior and enabling the sharing of products among multiple users, extending product lifespan and increasing resource efficiency.

- Enhancing the provision of technical support, thus extending product lifespan.

- Allowing the provision of preventive and predictive maintenance, thus extending product lifespan.

- Optimizing the usage of the product, thus increasing resource efficiency.

- Enhancing product upgrading, therefore increasing resource efficiency and extending product lifespan.

- Enhancing the execution of renovation and end-of-life activities such as refurbishment, remanufacturing, and recycling, thus closing the loop.

6.2. Managerial Implications

6.3. Limitations and Future Research Directions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards a Circular Economy, Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2012. [Google Scholar]

- Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Sarkis, J.; Filho, M.G. Unlocking the circular economy through new business models based on large-scale data: An integrative framework and research agenda. Technol. Forecast. Soc. Chang. 2017. [Google Scholar] [CrossRef]

- Nobre, G.C.; Tavares, E. Scientific literature analysis on big data and Internet of Things applications on circular economy: A bibliometric study. Scientometrics 2017, 111, 463–492. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Cohen, B.; Kietzmann, J. Ride On! Mobility Business Models for the Sharing Economy. Organ. Environ. 2014, 27, 279–296. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Firnkorn, J.; Müller, M. What will be the environmental effects of new free-floating car-sharing systems? The case of car2go in Ulm. Ecol. Econ. 2011, 70, 1519–1528. [Google Scholar] [CrossRef]

- Mont, O.; Dalhammar, C.; Jacobsson, N. A new business model for baby prams based on leasing and product remanufacturing. J. Clean. Prod. 2006, 14, 1509–1518. [Google Scholar] [CrossRef]

- Baines, T.; Lightfoot, H.W. Servitization of the manufacturing firm. Exploring the operations practices and technologies that deliver advanced services. Int. J. Oper. Prod. Manag. 2013, 34, 2–35. [Google Scholar] [CrossRef]

- Spring, M.; Araujo, L. Product biographies in servitization and the circular economy. Ind. Mark. Manag. 2017, 60, 126–137. [Google Scholar] [CrossRef]

- Kamp, B.; Parry, G. Servitization and advanced business services as levers for competitiveness. Ind. Mark. Manag. 2017, 60, 11–16. [Google Scholar] [CrossRef]

- Turunen, T.; Finne, M. The organisational environment’s impact on the servitization of manufacturers. Eur. Manag. J. 2014. [Google Scholar] [CrossRef]

- Alghisi, A.; Saccani, N. Internal and external alignment in the servitization journey—Overcoming the challenges. Prod. Plan. Control 2015. [Google Scholar] [CrossRef]

- Neely, A. Exploring the financial consequences of the servitization of manufacturing. Oper. Manag. Res. 2008, 1, 103–118. [Google Scholar] [CrossRef]

- Adrodegari, F.; Saccani, N. Business models for the service transformation of industrial firms. Serv. Ind. J. 2017, 37, 57–83. [Google Scholar] [CrossRef]

- Lenka, S.; Parida, V.; Wincent, J. Digitalization Capabilities as Enablers of Value Co-Creation in Servitizing Firms. Psychol. Mark. 2017, 34, 92–100. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Intelligent Assets: Unlocking the Circular Economy Potential; Ellen MacArthur Foundation: Cowes, UK, 2016. [Google Scholar]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Parida, V.; Sjödin, D.R.; Wincent, J.; Kohtamäki, M. Mastering the transition to product-service provision: Insights into business models, Learning activities, and capabilities. Res. Technol. Manag. 2014, 57, 44–52. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Pigosso, D.C.A.; McAloone, T.C. The Emergent Role of Digital Technologies in the Circular Economy: A Review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving “leapfrog development”. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Tecchio, P.; McAlister, C.; Mathieux, F.; Ardente, F. In search of standards to support circularity in product policies: A systematic approach. J. Clean. Prod. 2017, 168, 1533–1546. [Google Scholar] [CrossRef] [PubMed]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Franco, M.A. Circular economy at the micro level: A dynamic view of incumbents’ struggles and challenges in the textile industry. J. Clean. Prod. 2017, 168, 833–845. [Google Scholar] [CrossRef]

- Van Loon, P.; Van Wassenhove, L.N. Assessing the economic and environmental impact of remanufacturing: A decision support tool for OEM suppliers. Int. J. Prod. Res. 2017, 1–13. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions—A strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- Kumar, S.; Putnam, V. Cradle to cradle: Reverse logistics strategies and opportunities across three industry sectors. Int. J. Prod. Econ. 2008, 115, 305–315. [Google Scholar] [CrossRef]

- Kalverkamp, M.; Pehlken, A.; Wuest, T. Cascade Use and the Management of Product Lifecycles. Sustainability 2017, 9, 1540. [Google Scholar] [CrossRef]

- Park, J.Y.; Chertow, M.R. Establishing and testing the “reuse potential” indicator for managing wastes as resources. J. Environ. Manag. 2014, 137, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Go, T.F.; Wahab, D.A.; Hishamuddin, H. Multiple generation life-cycles for product sustainability: The way forward. J. Clean. Prod. 2015, 95, 16–29. [Google Scholar] [CrossRef]

- Mont, O. Innovative approaches to optimising design and use of durable consumer goods. Int. J. Prod. Dev. 2008, 6, 227. [Google Scholar] [CrossRef]

- Bakker, C.; Wang, F.; Huisman, J.; den Hollander, M. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strateg. Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Dimache, A.; Roche, T. A decision methodology to support servitisation of manufacturing. Int. J. Oper. Prod. Manag. 2013. [Google Scholar] [CrossRef]

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strateg. Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Baden-Fuller, C.; Morgan, M.S. Business Models as Models. Bus. Model. 2010. [Google Scholar] [CrossRef]

- Wise, R.; Baumgartner, P. Go Downstream: The New Profit Imperative in Manufacturing. Harv. Bus. Rev. 1999. Available online: https://hbr.org/1999/09/go-downstream-the-new-profit-imperative-in-manufacturing (accessed on 13 February 2018).

- Michelini, R.C.; Razzoli, R.P. Product-service for environmental safeguard: A metrics to sustainability. Resour. Conserv. Recycl. 2004, 42, 83–98. [Google Scholar] [CrossRef]

- Tukker, A.; Tischner, U. Product-services as a research field: Past, present and future. Reflections from a decade of research. J. Clean. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- Barquet, A.P.B.; de Oliveira, M.G.; Amigo, C.R.; Cunha, V.P.; Rozenfeld, H. Employing the business model concept to support the adoption of product–service systems (PSS). Ind. Mark. Manag. 2013, 42, 693–704. [Google Scholar] [CrossRef]

- Mccarthy, E.J. Basic Marketing: A Managerial Approach. Acad. Mark. Sci. 1964. Available online: http://www.worldcat.org/title/basic-marketing-a-managerial-approach/oclc/242331 (accessed on 13 February 2018).

- Kujala, S.; Artto, K.; Aaltonen, P.; Turkulainen, V. Business models in project-based firms—Towards a typology of solution-specific business models. Int. J. Proj. Manag. 2010. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Örtqvist, D. Product–Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Pialot, O.; Millet, D.; Bisiaux, J. “Upgradable PSS”: Clarifying a new concept of sustainable consumption/production based on upgradablility. J. Clean. Prod. 2017, 141, 538–550. [Google Scholar] [CrossRef]

- Rymaszewska, A.; Helo, P.; Gunasekaran, A. IoT powered servitization of manufacturing—An exploratory case study. Int. J. Prod. Econ. 2017, 192, 92–105. [Google Scholar] [CrossRef]

- Ardolino, M.; Rapaccini, M.; Saccani, N.; Gaiardelli, P.; Crespi, G.; Ruggeri, C. The role of digital technologies for the service transformation of industrial companies. Int. J. Prod. Res. 2017, 7543, 1–17. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How Smart, Connected Product Are Transforming Competition. Harv. Bus. Rev. 2014, 92, 64–89. [Google Scholar]

- Allmendinger, G.; Lombreglia, R. Four strategies for the age of smart services. Harv. Bus. Rev. 2005, 83, 131–145. [Google Scholar] [PubMed]

- Rust, R.T.; Huang, M.-H. The Service Revolution and the Transformation of Marketing Science. Mark. Sci. 2014. [Google Scholar] [CrossRef]

- Cheng, C.-Y.; Barton, D.; Prabhu, V. The servicisation of the cutting tool supply chain. Int. J. Prod. Res. 2010, 48, 1–19. [Google Scholar] [CrossRef]

- Cenamor, J.; Rönnberg Sjödin, D.; Parida, V. Adopting a platform approach in servitization: Leveraging the value of digitalization. Int. J. Prod. Econ. 2017, 192, 54–65. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; SAGE: Newcastle upon Tyne, UK, 2009; ISBN 978-1-4129-6099-1. [Google Scholar]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

- Henry, G.T. Practical Sampling. In SAGE Handbook of Applied Social Research Methods; SAGE: Newcastle upon Tyne, UK, 2009. [Google Scholar]

- Adrodegari, F.; Saccani, N.; Kowalkowski, C.; Vilo, J. PSS business model conceptualization and application. Prod. Plan. Control 2017, 28, 1251–1263. [Google Scholar] [CrossRef]

- Saccani, N.; Perona, M.; Bacchetti, A. The total cost of ownership of durable consumer goods: A conceptual model and an empirical application. Int. J. Prod. Econ. 2017, 183, 1–13. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

| Servitized BM Type | Circular Economy Value Driver | Main Drawback with Respect to CE Adoption | ||

|---|---|---|---|---|

| Increase Resource Efficiency | Extend Lifespan | Close the Loop | ||

| Product-focused (customers have the product ownership) | +: After-sales services such as repair, extended warranties, maintenance contracts | This BM type incentives companies to maximize product sales, alongside the negative environmental impact of more products that probably will become waste | ||

| Usage-focused (customers pay a fee to gain access to a product) | +: Product sharing among users | +: Extra-Services such as extended warranties, predictive maintenance, repair +: Design-to-last products +: Upgrade −: Quicker wear and tear due to less careful usage by customers | +: Take-back agreement +: Design for closing the loop | This BM type could bring a less careful usage by the customers base, leading to a quicker wear and tear |

| Result-focused (customers pay a variable fee depending on the achievement of agreed results) | +: Product sharing among users | +: Extra-Services such as extended warranties, predictive maintenance, repair +: Design-to-last products +: Upgrade | +: Take-back agreement +: Design for closing the loop | It may be difficult to measure results in terms of product/system performance and reach an agreement between customer and supplier |

| ID | Functionality | Digital Technologies | Ref. | Description | CE Value Driver | |||

|---|---|---|---|---|---|---|---|---|

| IoT | Big Data & Analytics | Increase Resource Efficiency | Extend Lifespan | Close the Loop | ||||

| 1 | Improving product design | X | X | [12,54] | By collecting usage data through IoT and by analyzing them through appropriate analytics, companies may improve the design of their products to better respond to customers’ needs. | |||

| 2 | Attracting target customers | X | X | [12,13,19,22,50,52,54] | An elaboration of the information gathered from the products installed base (through IoT) regarding how customers are using products allows companies to improve marketing activities, with the aim to attract new and targeted customers. | |||

| 3 | Monitoring and tracking products activity | X | [4,5,12,13,19,22,52,54] | Through IoT, companies monitor product condition, status, location and usage. To enable product sharing between multiple users, this information must be collected and easily made available to each single users. | ||||

| 4 | Providing technical support | X | X | [12,13,52] | Information collected through IoT helps companies and their field network to provide technical support and other services such as spare parts management, repair, etc. | |||

| 5 | Providing preventive and predictive maintenance | X | X | [12,13,52,54] | The analysis of Big Data collected through IoT by appropriate analytics entails the provision of preventive and predictive maintenance. | |||

| 6 | Optimizing the product usage | X | X | [12,50,52,54] | By analyzing with appropriate analytics the Big Data collected through IoT, companies may provide to their customers personalized advice with the aim to optimize the usage phase, e.g., how product should be used to reduce energy consumption. | |||

| 7 | Upgrading the product | X | [52] | When the product offered becomes smart [ 54], companies may upgrade only its digital elements, e.g., the product firmware, thus enhancing the feasibility of upgrade. | ||||

| 8 | Enhancing renovation and end-of-life activities | X | X | [12,23] | Through the IoT technology, companies can access in real-time product location and condition. This information may be used for a better execution of end-of-life collection, refurbishment, remanufacturing, and recycling activities. | |||

| ID | Functionality | Product Life Cycle Stage | Empirical Evidences from Alpha Case and Role for CE | CE Value Driver [20] | ||

|---|---|---|---|---|---|---|

| Increase Resource Efficiency | Extend Lifespan | Close the Loop | ||||

| 1 | Improving product design | Begin of life | This functionality has not been encountered in Alpha case, since the company does not perform this activity internally. | |||

| 2 | Attracting target customers | Begin of life | Thanks to an elaboration of the information gathered from the Alpha installed base, the company may improve its marketing activity. This, in turn, increases the number of users that access the Alpha sustainable offering, thus enhancing resource efficiency, extending lifespan and closing the loop. | X | X | X |

| 3 | Monitoring and tracking products activity | Middle of life | Through IoT, Alpha monitors the appliances condition, location and usage. This is an essential requirement for enabling appliances sharing between multiple households. Therefore, it increases the product utilization, resulting in an improvement in resource efficiency. Moreover, product monitoring prevent wrong users’ behavior in product usage, which may lead to a quicker wear and tear. Thus, this functionality extend product lifespan. | X | X | |

| 4 | Providing technical support | Middle of life | Information collected through IoT helps Alpha and its field network to provide technical support and other services such as spare parts management, repair, etc. This, in turn, extends the product lifespan. | X | ||

| 5 | Providing preventive and predictive maintenance | Middle of life | The analysis of Big Data by appropriate analytics entails the provision of preventive and predictive maintenance. For instance, Alpha knows the expected life of appliances components that fail most frequently while working in an operational field (i.e., the households’ houses). This information may be utilized for the execution of preventive and predictive maintenance. Thus, the lifespan of the product is extended. | X | ||

| 6 | Optimizing the product usage | Middle of life | By analyzing with appropriate analytics the data collected through IoT, Alpha knows the best operational way that reduces the consumption of appliances consumables. Thus, by comparing it with each user’s habits, Alpha provides personal advice to its customers (by the means of the Mobile App) in order to reduce the consumption of consumables. This feature contributes to increase resource efficiency. | X | ||

| 7 | Upgrading the product | End of life | Thanks to the provision of smart products, Alpha may upgrade only the digital part of the appliances, i.e., the software that controls the appliances usage phase. The aim is to upgrade the appliance firmware, in order to incorporate the most up-to-date programs, which allows achieving a reduction of consumables. Therefore, resource efficiency may be achieved, by the means of a reduction in the appliances consumables. Moreover, also the lifespan of the appliances is extended, since old appliances remain competitive, and their replacement is postponed over time. | X | X | |

| 8 | Enhancing renovation and end-of-life activities | End of life | Through the IoT technology, Alpha knows in real-time the product location and condition. Thus, Alpha may use the information regarding product location for a better organization of the collection activities when subscription ends. Moreover, the information regarding products and components status may be used for a better performance of other CE end-of-life activities such as refurbishment, remanufacturing, recycling. This, in turn, enhances closing the loop. | X | ||

| ID | Usage-Focused BMs Functionality | Digital Technologies | Product Life Cycle Stage | CE Value Driver [20] | |||

|---|---|---|---|---|---|---|---|

| IoT | Big Data & Analytics | Increase Resource Efficiency | Extend Lifespan | Close the Loop | |||

| 1 | Improving product design | X | X | Begin of life | X | X | |

| X | |||||||

| 2 | Attracting target customers | X | X | Begin of life | X | X | X |

| X | |||||||

| 3 | Monitoring and tracking products activity | X | Middle of life | X | X | ||

| 4 | Providing technical support | X | X | Middle of life | X | ||

| X | |||||||

| 5 | Providing preventive and predictive maintenance | X | X | Middle of life | X | ||

| X | |||||||

| 6 | Optimizing the product usage | X | X | Middle of life | X | ||

| X | |||||||

| 7 | Upgrading the product | X | End of life | X | X | ||

| 8 | Enhancing renovation and end-of-life activities | X | X | End of life | X | ||

| X | |||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. https://doi.org/10.3390/su10030639

Bressanelli G, Adrodegari F, Perona M, Saccani N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability. 2018; 10(3):639. https://doi.org/10.3390/su10030639

Chicago/Turabian StyleBressanelli, Gianmarco, Federico Adrodegari, Marco Perona, and Nicola Saccani. 2018. "Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies" Sustainability 10, no. 3: 639. https://doi.org/10.3390/su10030639

APA StyleBressanelli, G., Adrodegari, F., Perona, M., & Saccani, N. (2018). Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability, 10(3), 639. https://doi.org/10.3390/su10030639