International Occupational Health and Safety Management-Systems Standards as a Frame for the Sustainability: Mapping the Territory

Abstract

:1. Introduction

2. Theoretical Background

3. Methodology

4. Results

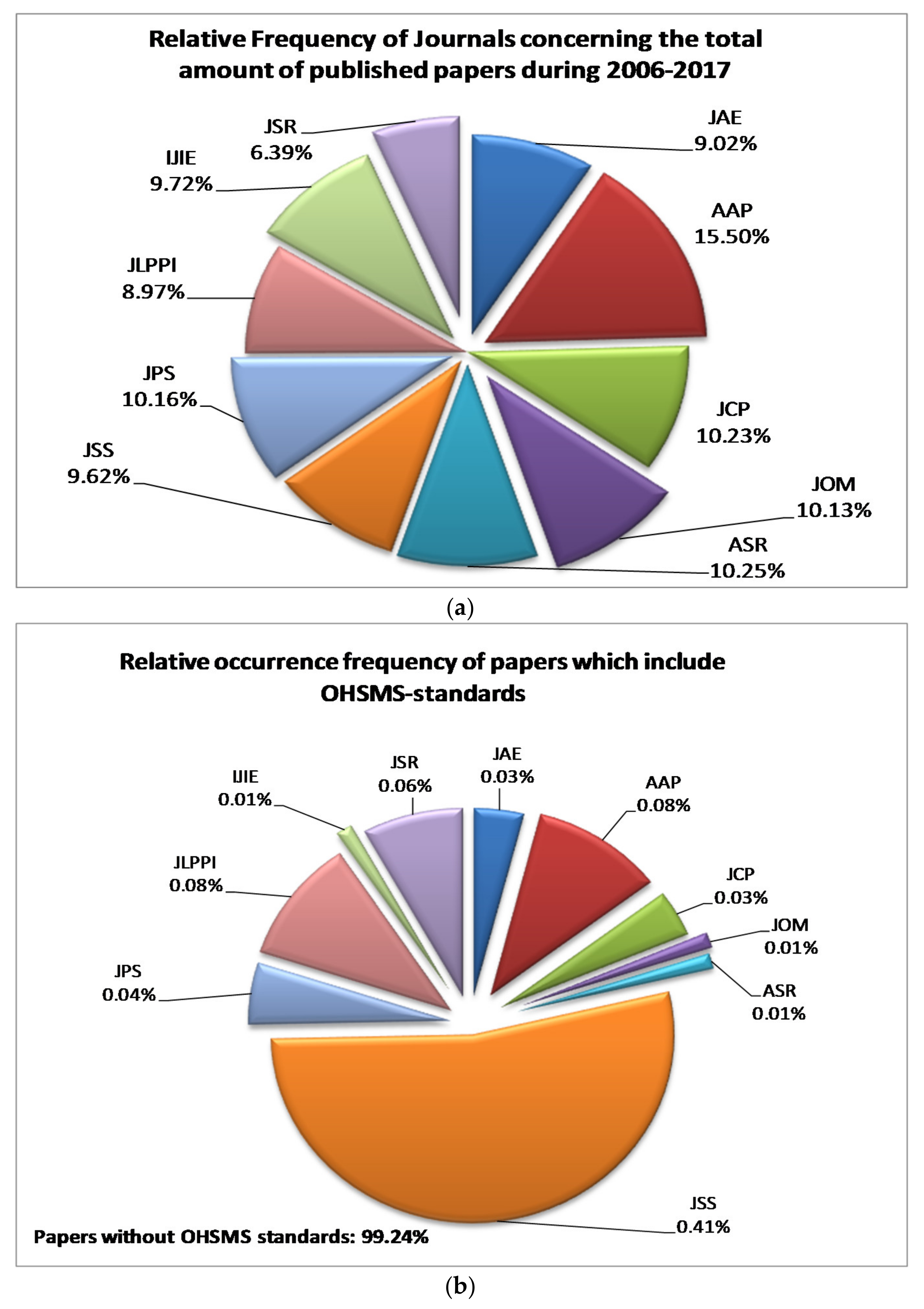

- (i)

- the absolute frequency Ni that is, the number of investigated papers per journal (col. C, that is, JAE: 886; AAP: 1522; JCP: 1005; JOM: 995; ASR: 1007; JSS: 945; JPS: 998; JLPPI: 881; IJIE: 955; JSR: 628),

- (ii)

- the relative frequency Fi = Ni/N of the ten journals, concerning the total amount of the published papers during 2006–2017 (column D, that is, JAE: 9.02%; AAP: 15.50%; JCP: 10.23%; JOM: 10.13%; ASR: 10.25%; JSS: 9.62%; JPS: 10.16%; JLPPI: 8.97%; IJIE: 9.72%; JSR: 6.39%),

- (iii)

- the number of papers nST(i) concerning OHS which include or use or refer to OHSMS standards (column E, that is, JAE: 3; AAP: 8; JCP: 3; JOM: 1; ASR: 1; JSS: 40; JPS: 4; JLPPI: 8; IJIE: 1; JSR: 6),

- (iv)

- the relative occurrence frequency of papers (referred to N) which include (or use or refer to) OHSMS-standards fST(i) = nSTS(i)/N (column F, that is, JAE: 0.03%; AAP: 0.08%; JCP: 0.03%; JOM: 0.01%; ASR: 0.01%; JSS: 0.41%; JPS: 0.04%; JLPPI: 0.08%; IJIE: 0.01%; JSR: 0.06%),

- (v)

- the normalized (per journal) occurrence frequency of papers which include OHSMS standards fi* = nST(i)/Ni(column F, that is, JAE: 0.34%; AAP: 0.53%; JCP: 0.30%; JOM: 0.10%; ASR: 0.10%; JSS: 4.23%; JPS: 0.40%; JLPPI: 0.91%; IJIE: 0.10%; JSR: 0.96%),

- (vi)

- the relative occurrence frequency of papers (referred to S) which include OHSMS standards f**ST(i) = nST(i)/S (column F, that is, JAE: 4.00%; AAP: 10.67%; JCP: 4.00%; JOM: 1.33%; ASR: 1.33%; JSS: 53.33%; JPS: 5.33%; JLPPI: 10.67%; IJIE: 1.33%; JSR: 8.00%).

5. Discussion

- (i)

- The term “systematic” in mandatory systematic OHSM is not at all the same as the term “system” in voluntary OHSM systems. This means that the UK’s HSG 65 is quite different from the other described “systems.” HSG 65 constitutes guidelines (best practice) for how to comply with the mandatory regulation of systematic OHSM (transposing of EU directive 89/391/EEC into UK legislation) while all the other listed “systems” are voluntary and more or less commercial products (which still can be very useful).

- (ii)

- Regulated mandatory systematic OHSM is not at all identical to voluntary OHSM standards. This article aims to cover both of them. In any case both mandatory OHSM (such as in all of the EU, since 1989, through 89/391/EEC but also in many other states, for example, in California since 1991) and the much more complex commercial products of voluntary OHSM systems (such as OHSAS 18001) are critically discussed and distinguished.

- (iii)

- The term “Standard” is also a term with importantly different meanings. In Anglo-saxon countries this is often the same as a regulation but a voluntary standard (such as ISO) is (by definition) not a regulation.

- There are only a few publications including OHSMS standards (during 2006–2017), which are referred to a variety of occupational fields (like construction, industry, engineering, transportation, chemistry, oil and refinery, et cetera).

- These papers address techniques that have been emerged in areas such as design/development, quality-control and maintenance, as far as occupational risk assessment is concerned.

- “Safety Science” (SS) and “Journal of Loss Prevention in the Process Industries” (JLPPI) are the scientific journals which published (during 2006–2017) the most scientific papers concerning OHSMS.

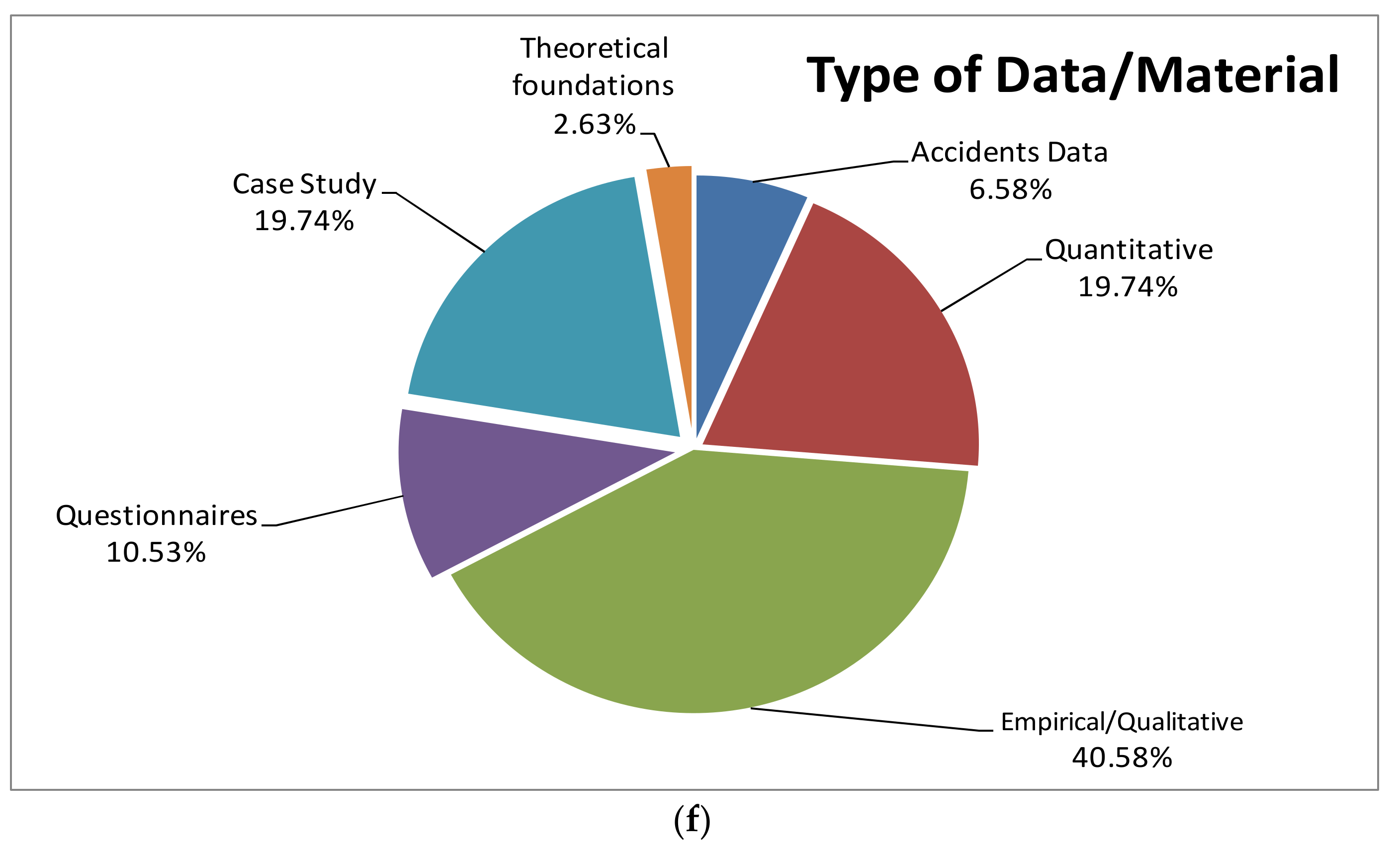

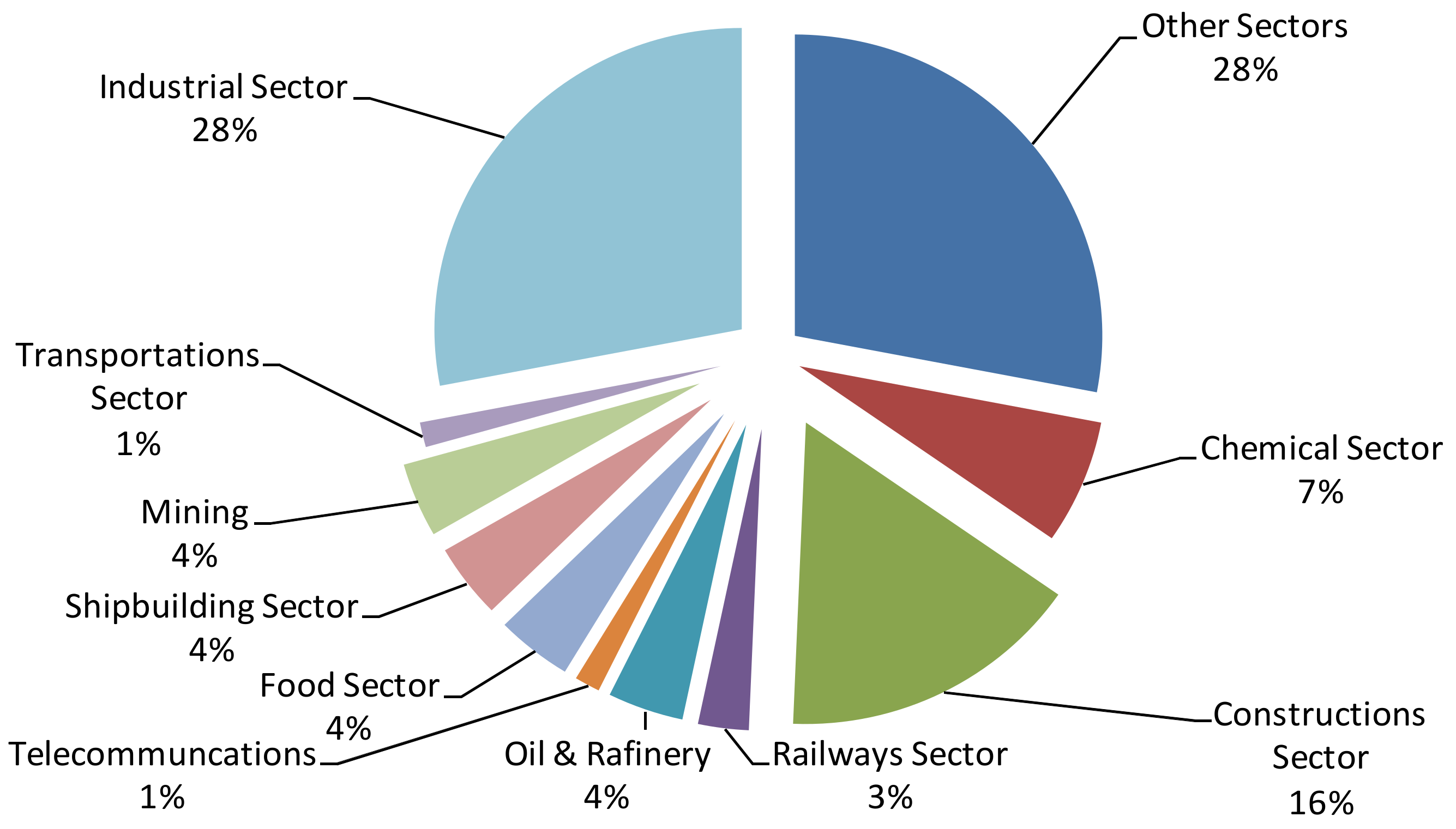

- The sector of “Industry” (with 28%) and also the “Construction” (with 16%), accounted for the highest percentage, as far as the usage of OHSMS standards is concerned, presumably because their work conditions are more unstable and dangerous in comparison with other occupational sectors (e.g., telecomunications). In addition, these sectors are very hazardous worldwide, owing to their unique dynamic nature, poor conditions and tough environment [44,50].

- The comparison between the previous presented OHSMS standards (in Table 4), depicts an overview of their features, comparatively with various developed evaluation-criteria.

- The OHSAS 18001 standard, presents the higher relative occurrence-frequency (48%) in comparison with the other OHSMS standards, due to the fact that this international standard was produced by the co-operation of 13 different international organizations which represent 80% of the certification bodies.

- The percentage distribution of the papers (with OHSMS standards) reveals that “Empirical/Qualititative” is the most frequent type compared with other types of data.

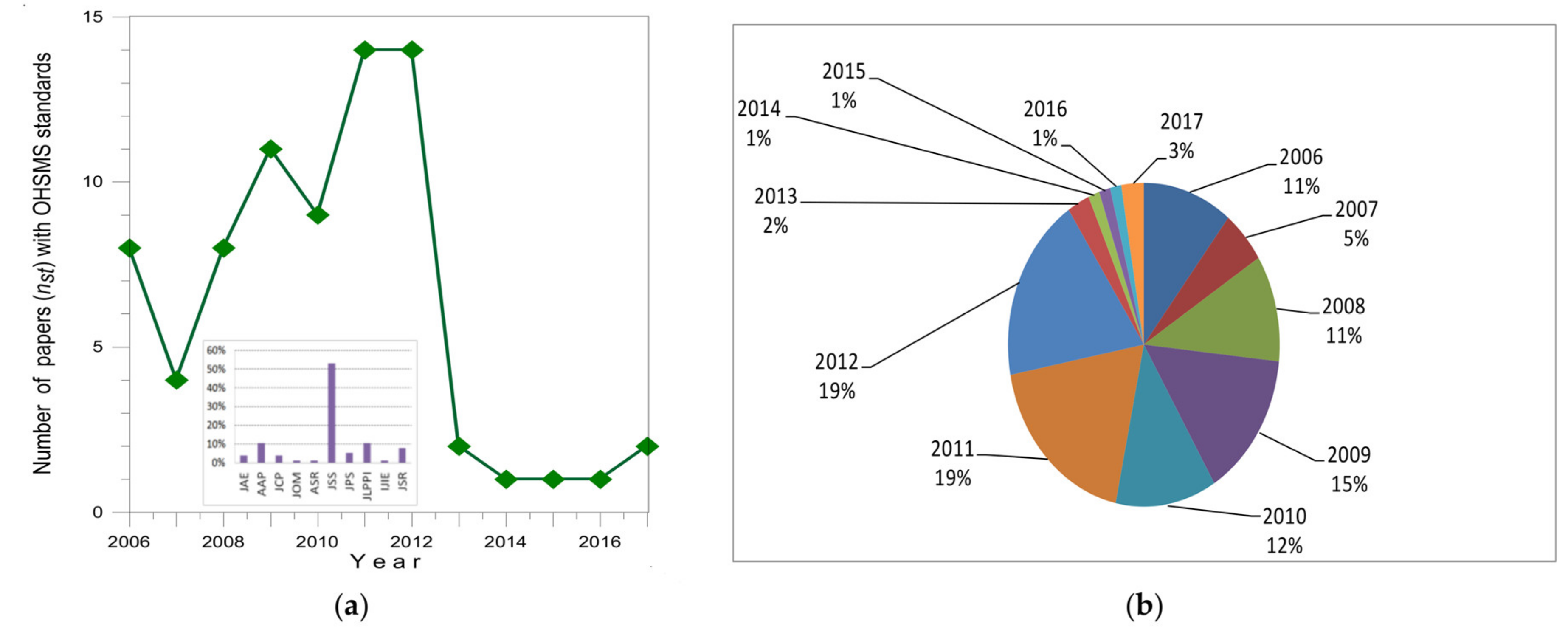

- Our selected graphs, show (for the distribution of the publications with OHSMS standards) the existence of a long-term trend factor with positive inclination (during 2007–2012), with negative inclination (during 2013–2015) and also with a positive inclination (throughout the 2016–2017).

- In general, there is an increasing scientific interest for OHSMS standards, especially in period 2009–2012.

- The entire objective of the usage of OHSMS standards is to support and promote efficient OHS practices, in balance with socio-economic requirements [2].

- The OHSMS standards are not legally binding and have not got the intention to replace national laws or regulations and/or accepted standards.

- The various OHSMS standards have common basic requirements and features but they are implemented in different processes. Besides, the different OHSMS standards follow, in general, similar paths between “start” and “finish.”

- Many organizations apply an “integrated” management system which combines the requirements of two or more management system standards simultaneously (for example OHSMS with Environmental, or OHSMS with Quality management systems standards).

6. Conclusions

- The application of OHSMS standards is not significantly extended in organizations and the knowledge about them has not been fully shared and expanded among the miscellaneous scientific fields, so we have the opinion, that the scientific community, have to transfer the similarities from one field to another.

- The implementation of a “integrated” management systems which combine the requirements of two or more management system standards simultaneously (for example OHSMS with Environmental, or OHSMS with Quality management systems standards) would enable organizations to achieve efficient results on the reduction of risks and also on productivity.

- OHSMS standards can be developed and implemented by organizations of any type and any size (large or small).

- As this study is not an empirical research but a review, the value of the article rests on clear distinctions, definitions and analysis. Moreover this exploratory study, provides a rich description for the usage of OHSMS standards in workplaces and lays the background for further research into the reliability and reinforcement of their application in any organization.

Author Contributions

Conflicts of Interest

Abbreviations and Acronyms

| ANSI | American National Standarization Institute |

| JAE | Applied Ergonomics |

| ASR | Architectural Science Review |

| AENOR | Asociación Española de Normalización/Certificación (Spanish Assoc. for Standards) |

| AS/NZS | Australian/New Zealand Standard |

| BSI | British Standards Institution |

| BSC | British Safety Council |

| CPQRA | Chemical Process Quantitative Risk Analysis |

| CCPS | left for Chemical Process Safety |

| UNI | Ente Nazionale Italiano di Unificazione (Italian National Unification) |

| EMS | Environmental Management Systems |

| HSE | Health and Safety Executive |

| IEC | International Electrotechnical Commission |

| IJIE | International Journal of Industrial Ergonomics |

| ILO | International Labour Organization |

| IMS | International Management Systems |

| ISO | International Organization for Standardization |

| JCP | Journal of Cleaner Production |

| JLPPI | Journal of Loss Prevention in the Process Industries |

| JOM | Journal of Operations Management |

| JSR | Journal of Safety Research |

| OHSAS | Occupational Health and Safety Assessment Series |

| OHSMS | Occupational health and safety management system |

| OHS | Occupational health-safety |

| JPS | Professional Safety |

| QMS | Quality Management Systems |

| RAA | Risk analysis and assessment |

| JSS | Safety Science |

| SSC | Singapore Standards Council |

| S_OHSMS | Sustainability and Occupational Health and Safety Management Systems |

| TQM | Total Quality Management |

Appendix A

| A/A | Paper Citation | Authors | Year of Publication | OHSMS Standard | Type of Paper Data or Material | Field of Application | Source |

|---|---|---|---|---|---|---|---|

| (A) | (B) | (C) | (D) | (E) | (F) | (G) | (H) |

| 1 | [53] | Jørgensen T.H. Arne Remmen M. Dolores Mellado | 2006 | ISO 14001; OHSAS 18001 | Empirical/Qualitative | All Sectors | JCP |

| 2 | [54] | J.R. Santos-Reyes and & Beard, A. N. | 2006 | BS8800 | Empirical/Qualitative | All Sectors | JPS |

| 3 | [55] | Adele Abrahms | 2006 | ANZI Z10-2005 | Empirical/Qualitative | All Sectors | JPS |

| 4 | [56] | Manuele, Fred | 2006 | ANZI Z10-2005 | Empirical/Qualitative | All Sectors | JPS |

| 5 | [57] | Wrona | 2006 | ANSI Z16.2 | Empirical/Qualitative | All Sectors | JSR |

| 6 | [58] | Nielsen et al. | 2006 | OHSAS 18001 | Empirical/Qualitative | Industrial sector | JSR |

| 7 | [59] | Cadieux et al. | 2006 | OHSAS 18001 | Empirical/Qualitative | Industrial sector | JSR |

| 8 | [60] | Paivinen | 2006 | BS 8800 | Empirical/Qualitative | Telecommunications | IJIE |

| 9 | [61] | S.X. Zeng, Jonathan J., Shi G.X. Lou | 2007 | OHSAS 18001 | Questionnaires | All Sectors | JCP |

| 10 | [62] | Fernandez-Muniz et al. | 2007 | BS 8800, OHSAS 18001 | Empirical/Qualitative | Industrial sector | JLPPI |

| 11 | [63] | Coleman and Kerkering | 2007 | ANSI Z16.1-1967 | Accidents Data | Mining | JSR |

| 12 | [3] | Robson et al. | 2007 | ANSI Z10, OHSAS 18001, BS8800, HSG 65 | Quantitative | All Sectors | JSS |

| 13 | [64] | Bevilacqua et al. | 2008 | OHSAS 18001 | Quantitative | Oil & Refinery | AAP |

| 14 | [65] | Brooks | 2008 | ANSI Z10 | Quantitative | All Sectors | JSS |

| 15 | [66] | Duijm et al. | 2008 | BS 8800, OHSAS 18000, ILO-OSH 2001, HSG 65 | Questionnaires | Industrial sector | JSS |

| 16 | [67] | Lind, Kivisto-Rahnasto | 2008 | BS 8800, ILO-OSH:2001, OHSAS 18001 | Case Study | Transportations Sector | JSS |

| 17 | [68] | Nielsen et al. | 2008 | OHSAS 18001 | Quantitative | Industrial sector | JSS |

| 18 | [69] | Schrover | 2008 | ISO-9001, ISO-14001, OHSAS-18001 | Theoretical Foundations | Chemical Sector | JSS |

| 19 | [70] | Zeng et al. | 2008 | OHSAS 18001, ISO 9001 | Accidents Data | Construction Sector | JSS |

| 20 | [71] | Komljenovic et al. | 2008 | AS/NZS: 1999, CAN/CSA Q850-97: 2002. ISO, 1999, 2000, ANSI: 2000, ASTME2205-02, 2002 | Accidents Data | Mining | JSS |

| 21 | [72] | Caroly et al. | 2009 | OHSAS 18001 | Empirical/Qualitative | Chemical Sector | JAE |

| 22 | [73] | Chang and Liang, | 2009 | OHSAS 18001, ILO-OSH-2001, BS 8800, HSG 65 | Empirical/Qualitative | Chemical Sector | JLPPI |

| 23 | [74] | Santos-Reyes, Beard | 2009 | BS 8800, ILO-OSH: 2001, HSG 65 | Empirical/Qualitative | Oil & Refinery | JLPPI |

| 24 | [75] | Crippa et al. | 2009 | OHSAS 18001 | Quantitative | Oil & Refinery | JLPPI |

| 25 | [76] | Knegtering, Pasman, | 2009 | OHSAS 18001 | Empirical/Qualitative | Industrial sector | JLPPI |

| 26 | [77] | Pasman et al. | 2009 | OHSAS 18001 | Empirical/Qualitative | Industrial sector | JLPPI |

| 27 | [78] | Moriyama, Ohtani | 2009 | ILO-OSH 2001, BS 8800 | Empirical/Qualitative | Food Sector | JSS |

| 28 | [79] | Fernandez-Muniz et al. | 2009 | BS 8800,OHSAS 18001 | Questionnaires | All Sectors | JSS |

| 29 | [80] | Celik M. | 2009 | OHSAS 18001:2007 | Quantitative | Shipbuilding Sector | JSS |

| 30 | [81] | Reniers et al. | 2009 | OHSAS 18000 | Empirical/Qualitative | All Sectors | JSS |

| 31 | [82] | Baram | 2009 | ILO-OSH 2001 | Empirical/Qualitative | Industrial sector | JSS |

| 32 | [83] | Shengli Niu, | 2010 | ILO-OSH 2001 | Empirical/Qualitative | All Sectors | JAE |

| 33 | [84] | Gangolells et al. | 2010 | OHSAS 18001 | Quantitative | Construction Sector | JSR |

| 34 | [85] | Cheng et al. | 2010 | ANSI Z10 | Quantitative | Construction Sector | JSS |

| 35 | [86] | Jacinto, Silva | 2010 | BS 8800 | Case Study | Shipbuilding Sector | JSS |

| 36 | [87] | Sgourou et al. | 2010 | BS 8800 | Quantitative | All Sectors | JSS |

| 37 | [88] | Fera, Macchiaroli | 2010 | OSHAS 18001 | Case Study | All Sectors | JSS |

| 38 | [89] | Lindhout et al. | 2010 | OHSAS 18001 | Empirical/Qualitative | Chemical Sector | JSS |

| 39 | [90] | Celik M. | 2010 | ISO 9001:2000, ISO 14001:2004, OHSAS 18001:2007 | Case Study | Shipbuilding sector | JSS |

| 40 | [91] | Dawson et al. | 2011 | AS/NZ 4360 | Empirical/Qualitative | All Sectors | AAP |

| 41 | [92] | Low Sui Phen & Goh Kim Kwang | 2011 | ISO 14001; OHSAS 18001 | Questionnaires | Construction Sector | ASR |

| 42 | [93] | Jallon et al. | 2011 | OHSAS 18001 | Quantitative | Industrial sector | JSR |

| 43 | [94] | Leka et al. | 2011 | ILO-OSH 2001, BS OHSAS and ANSI Z-10 | Empirical/Qualitative | Construction Sector | JSS |

| 44 | [95] | Blewett, O’Keeffe | 2011 | ANSI Z10, OHSAS 18001 | Quantitative | Food Sector | JSS |

| 45 | [96] | Vinodkumar, Bhasi | 2011 | OHSAS 18001, BS 8800 | Questionnaires | Chemical Sector | JSS |

| 46 | [97] | Hohnen, Hasle | 2011 | OHSAS 18001 | Case Study | All Sectors | JSS |

| 47 | [98] | Lu, Li | 2011 | OHSAS 18001 | Case Study | Mining | JSS |

| 48 | [99] | Zwetsloot et al. | 2011 | OHSAS 18001 | Case Study | Industrial sector | JSS |

| 49 | [100] | Frick | 2011 | ANSI Z-10, (2005), Australia and New Zealand (AS/NZS 4804), The Netherlands (NPR 5001), Spain (UNE 81900), UK (BS 8800), ISO 9000, ISO 14000, OHSAS:18001, ILO-OSH 2001 | Theoretical Foundations | Industrial sector | JSS |

| 50 | [101] | Granerud, Rocha | 2011 | OHSAS 18001, ISO 14000, ISO 9000 | Case Study | Industrial sector | JSS |

| 51 | [102] | Kristensen | 2011 | ISO 14001, OHSAS 18001 | Case Study | Industrial sector | JSS |

| 52 | [103] | Zwetsloot et al. | 2011 | ISO 9000, ISO 14000, OHSAS 18000 series | Case Study | Industrial sector | JSS |

| 53 | [104] | Hasle Peter, Gerard Zwetsloot | 2011 | OHSAS 18001 | Quantitative, Empirical/Qualitative | Industrial Sector | JSS |

| 54 | [105] | Beatriz Fernández-Muñiz, José Manuel Montes-Peón,, Camilo José Vázquez-Ordás | 2012 | OHSAS 18001 | Empirical/Qualitative | All Sectors | AAP |

| 55 | [106] | Goh, Y.M. et al. | 2012 | AS/NZS 4801 | Empirical/Qualitative | Construction Sector | AAP |

| 56 | [107] | Cheng et al. | 2012 | ANSI Z.16.2-1995, ILO Guidelines | Quantitative | Construction Sector | AAP |

| 57 | [108] | Pinto et al. | 2012 | BS 8800:2004 | Quantitative | Construction Sector | AAP |

| 58 | [109] | Badri et al. | 2012 | OHSAS 18000 | Case Study | Industrial sector | AAP |

| 59 | [110] | Luria Gil, Ido Morag | 2012 | OHSAS 18001 | Empirical/Qualitative | All Sectors | AAP |

| 60 | [111] | Beatriz Fernández Muñiz José Manuel Montes-Peón Camilo José Vázquez-Ordás | 2012 | OHSAS 18001 | Questionnaires | All Sectors | JCP |

| 61 | [112] | Jeremy Mawhood & Claire Dickinson | 2012 | HSG 65 | Empirical/Qualitative | Railways Sector | JPS |

| 62 | [113] | Lee et al. | 2012 | BS 8800, OHSAS 18001, ILO-OSH 2001 | Accidents data | All Sectors | JLPPI |

| 63 | [114] | Gnoni, Lettera | 2012 | OHSAS 18001 | Empirical/Qualitative | Industrial sector | JLPPI |

| 64 | [115] | Badri et al. | 2012 | ANSI Z10 | Empirical/Qualitative | Industrial sector | JSS |

| 65 | [116] | Hamidi et al. | 2012 | OHSAS-18001, ANSI z10 | Case Study | Construction Sector | JSS |

| 66 | [117] | Hsu et al. | 2012 | OHSAS: 18001, BS 8800,ILOOSH 2001 | Quantitative | Food Sector | JSS |

| 67 | [118] | Wang, Liu | 2012 | OHSAS 18001, ILO-OSH 2001, HSG 65 | Questionnaires | Railways Sector | JSS |

| 68 | [119] | Ismail et al. | 2012 | OHSAS 18001 | Empirical/Qualitative | Construction Sector | JSS |

| 69 | [120] | Jesús Abad, Esteban Lafuente, Jordi Vilajosana | 2013 | OHSAS 18001 | Accidents data | All Sectors | JSS |

| 70 | [121] | Santos G. et al. | 2013 | OHSAS 18001 | Questionnaires | Industrial Sector | JSS |

| 71 | [122] | Chris K.Y. Lo, Mark Pagell, Di Fan, Frank Wiengarten, Andy C.L. Yeung | 2014 | OHSAS 18001 | Case Study | Construction Sector | JOM |

| 72 | [123] | Yazdani A. et al. | 2015 | OHSAS18001, BS 8800:2004 | Empirical/Qualitative | Industrial Sector | JAE |

| 73 | [51] | Autenrieth D.A. et al. | 2016 | OHSAS 18001, ANZI 10 | Case Study | Industrial Sector | JSS |

| 74 | [124] | Miskeen Ali Gopang, et al. | 2017 | ILO-OSH 2001 | Empirical/Qualitative | Other Sectors | JSS |

| 75 | [125] | Segarra Cañamares M. et al. | 2017 | OHSAS 18001 | Case Study | Construction Sector | JSS |

Appendix B

| Nr | Journal | Acronym | Number of Investigated Papers (Absolute Frequency Ni) | Relative Frequency (Fi = Ni/N) (%) | Number of Papers Concerning OHS Which Include or Use OHSMS Standards (nST(i)) | Relative Occurrence Frequency of Papers (Referred to N) Which Include OHSMS-Standards (fST(i) = nST(i)/N) (%) | Normalized (Per Journal) Occurrence Frequency of Papers Which Include OHSMS Standards (fi* = nST(i)/Ni) (%) | Relative Occurrence Frequency of Papers (Referred to S) Which Include OHSMS Standards (f*ST(i) = nST(i)/S) (%) |

|---|---|---|---|---|---|---|---|---|

| (A) | (B) | (C) | (D) = (C)/N | (E) | (F) = (E)/N | (G) = (E)/(C) | (H) = (E)/S | |

| 1 | Applied Ergonomics | JAE | 886 | 9.02% | 3 | 0.03% | 0.34% | 4.00% |

| 2 | Accident Analysis and Prevention | AAP | 1522 | 15.50% | 8 | 0.08% | 0.53% | 10.67% |

| 3 | Journal of Cleaner Production | JCP | 1005 | 10.23% | 3 | 0.03% | 0.30% | 4.00% |

| 4 | Journal of Operations Management | JOM | 995 | 10.13% | 1 | 0.01% | 0.10% | 1.33% |

| 5 | Architectural Science Review | ASR | 1007 | 10.25% | 1 | 0.01% | 0.10% | 1.33% |

| 6 | Safety Science | JSS | 945 | 9.62% | 40 | 0.41% | 4.23% | 53.33% |

| 7 | Professional Safety | JPS | 998 | 10.16% | 4 | 0.04% | 0.40% | 5.33% |

| 8 | Journal of Loss Prevention in the Process Industries | JLPPI | 881 | 8.97% | 8 | 0.08% | 0.91% | 10.67% |

| 9 | International Journal of Industrial Ergonomics | IJIE | 955 | 9.72% | 1 | 0.01% | 0.10% | 1.33% |

| 10 | Journal of Safety Research | JSR | 628 | 6.39% | 6 | 0.06% | 0.96% | 8.00% |

| Totals: | 9822 | 100.00% | 75 | 0.76% | 7.96% | 100.00% |

References

- Loke, Y.; Tan Wee, J.; Pegy, H. Economic Cost of Work-Related Injuries and Health in Singapore; WSH Institute Report; WSH: Singapore, 2013; pp. 1–29. Available online: https://www.wsh-institute.sg/~/media/wshi/ past%20publications/2013/economic%20cost%20of%20work-related%20injuries%20and%20ill-health%20in%20singapore.pdf?la=en (accessed on 8 October 2018).

- Occupational Health and Safety Assessment Series (OHSAS) Project Group. OHSAS 18001:2007—Occupational Health and Safety Management Systems—Requirements; OHSAS: Sydney, Australia, 2007; ISBN 978 0 580 50802 8. [Google Scholar]

- Robson, L.S.; Clarke, J.A.; Cullen, K.L.; Amber, B.; Colette, S.; Bigelow, P.L.; Irvin, E.; Culyer, A.; Quenby, M. The effectiveness of occupational health and safety management system interventions: A systematic review. Saf. Sci. 2007, 45, 329–353. [Google Scholar] [CrossRef]

- Sinelnikov, S.; Inouye, J.; Kerper, S. Using leading indicators to measure occupational health and safety performance. Saf. Sci. 2015, 72, 240–248. [Google Scholar] [CrossRef]

- Høj, N.P.; Kröger, W. Risk analyses of transportation on road and railway from a European Perspective. Saf. Sci. 2002, 40, 337–357. [Google Scholar]

- Woodruff, J.M. Consequence and likelihood in risk estimation: A matter of balance in UK health and safety risk assessment practice. Saf. Sci. 2005, 43, 345–353. [Google Scholar] [CrossRef]

- Reniers, G.L.L.; Dullaert, W.; Ale, B.J.M.; Soudan, K. Developing an external domino accident prevention framework: Hazwim. J. Loss Prev. Process Ind. 2005, 18, 127–138. [Google Scholar] [CrossRef]

- Haimes, Y.Y. Risk Modeling, Assessment, and Management, 3rd ed.; John Wiley & Sons Inc.: New York, NY, USA, 2009; pp. 154–196. [Google Scholar]

- Marhavilas, P.K. Risk Assessment Techniques in the Worksites of Occupational Health-Safety Systems with Emphasis on Industries and Constructions. Ph.D. Thesis, Department of Production and Management Engineering, Democritus University of Thrace, Xanthi, Greece, March 2015. [Google Scholar]

- Cliff, D. The Management of Occupational Health and Safety in the Australian Mining Industry; International Mining for Development Centre, Mining for Development, Guide to Australian Practice: Melbourne, Australia, 2012; pp. 100–200. [Google Scholar]

- International Labour Organization (ILO). Occupational Safety and Health: Synergies between Security and Productivity; ILO’s Governing Body Paper GB.295/ESP/3, GB; ILO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO/IEC. Guide 51: Safety Aspects—Guidelines for Their Inclusion in Standards, 2nd ed.; ISO/IEC: Geneva, Switzerland, 1999. [Google Scholar]

- Lee, M. How Does Climate Change Affect the Assessment of Landslide Risk? 2006. Available online: http://cliffs.lboro.ac.uk/downloads/ML2006.pdf (accessed on 15 July 2017).

- Olsson, F. Tolerable Fire Risk Criteria for Hospitals; Report 3101; Department of Fire Safety Engineering, Lund University: Lund, Sweden, 1999; ISSN 1402-3504. [Google Scholar]

- IEC (International Electrotechnical Commission). Risk Analysis of Technological Systems; International Standard 60300-3-9, Dependability Management—Part 3: Application Guide—Section 9; IEC: Geneva, Switzerland, 1995. [Google Scholar]

- Marhavilas, P.K.; Koulouriotis, D.E.; Gemeni, V. Risk Analysis and Assessment Methodologies in the Work Sites: On a Review, Classification and Comparative Study of the Scientific Literature of the Period 2000–2009. J. Loss Prev. Process Ind. 2011, 24, 477–523. [Google Scholar] [CrossRef]

- Jonkman, S.N.; van Gelder, P.H.A.J.M.; Vrijling, J.K. An overview of quantitative risk measures for loss of life and economic damage. J. Hazard. Mater. 2003, 99, 1–30. [Google Scholar]

- Vrouwenvelder, A.C.W.M.; Lovegrove, R.; Holicky, M.; Tanner, P.; Canisius, G. Risk Assessment and Risk Communication in Civil Engineering, 1st ed.; CIB General Secretariat: Rotterdam, The Netherlands, 2001; pp. 1–62. ISBN 90-6363-026-3. [Google Scholar]

- CCPS. Guidelines for Chemical Process Quantitative Risk Analysis, 2nd ed.; Center for Chemical Process Safety (CCPS) of American Institute of Chemical Engineers: New York, NY, USA, 1989; pp. 1–748. ISBN 978-0-8169-0720-5. [Google Scholar]

- International Organization for Standardization (ISO). Standards in Action. 2017. Available online: https://www.iso.org/standards-in-action.html (accessed on 15 July 2017).

- Gallagher, C. Occupational Health and Safety Management Systems: System Types and Effectiveness. Ph.D. Thesis, Deakin University, Melbourne, Australia, 2000. [Google Scholar]

- British Standards Institution (BSI). BS 8800:1996—Guide to Occupational Health and Safety Management Systems; BSI: London, UK, 1996; pp. 1–70. ISBN 0-580-25859-9. [Google Scholar]

- British Standards Institution (BSI). BS 18004:2008—Guide to Achieving Effective Occupational Health and Safety Performance; BSI: London, UK, 2008; pp. 1–78. ISBN 978 0 580 52910 8. [Google Scholar]

- British Standards Institution (BSI). BS 8800:2004—Occupational Health and Safety Management Systems-Guide; BSI: London, UK, 2004; pp. 1–87. ISBN 0 580 43987 9. [Google Scholar]

- Health and Safety Executive (HSE). Successful Health and Safety Management; HSE: London, UK, 1997; pp. 1–80. ISBN 978-0-7176-1276-5. [Google Scholar]

- Health and Safety Executive (HSE). Managing for Health and Safety; HSE: London, UK, 2013; pp. 1–66. ISBN 978-0-7176-6456-6. [Google Scholar]

- International Labour Organization (ILO). Guidelines on Occupational Safety and Health Management Systems—ILO-OSH 2001; ILO: London, UK, 2009; ISBN 92-2-111634-4. [Google Scholar]

- Australian/New Zealand Standard (AS/NZS). AS/NZS 4801:2001-Occupational Health and Safety Management Systems-Specification with Guidance for Use; AS/NZS: Melbourne, Australia, 2001; ISBN 0-7337-4092-8. [Google Scholar]

- American Industrial Hygiene Association (AIHA). ANSI/AIHA Z10-2005 Occupational Health and Safety Management Systems; AIHA: New York, NY, USA, 2005; ISBN1 10:1931504644. ISBN2 13:978-1931504645. [Google Scholar]

- SAI Global. ANSI/AIHA Z10-2005. Available online: https://www.saiglobal.com/assurance/ohs/Z10.htm (accessed on 15 July 2017).

- Singapore Standards Council (SSC). SS 506—Occupational Safety and Health (OSH) Management Systems—Part 1: Requirements; SSC: Singapore, 2009; ISBN 978-981-4278-15-7. [Google Scholar]

- Singapore Standards Council (SSC). SS 506—Occupational Safety and Health (OSH) Management Systems—Part 2: Guidelines for the Implementation of SS 506: Part 1; SSC: Singapore, 2009; ISBN 978-981-4278-16-4. [Google Scholar]

- Romero, J.C.R. Security Management Systems and Health at Work—Certified Or UNS Certified? ILO GuIdelines OHSAS 18001 Standard; Industrial Security of the E.T.S.I.I. Malaga University: Malaga, Spain, 2001; pp. 4–13. [Google Scholar]

- Barone, D.; Milano, Italy. Le nuove norme UNI 10617-2012 e UNI 10616-2012 relative ai Sistemi di Gestione della Sicurezza negli impianti a rischio di incidente rilevante. Personal communication, 2012. [Google Scholar]

- International Organization for Standardization (ISO). ISO Survey. Available online: https://www.iso.org/the-iso-survey.html (accessed on 19 September 2018).

- International Organization for Standardization (ISO). ISO 45001 Occupational Health and Safety—Briefing Notes. 2015. Available online: https://www.iso.org/iso-45001-occupational-health-and-safety.html (accessed on 19 September 2018).

- International Organization for Standardization (ISO). ISO 45001—Occupational Health and Safety. Available online: https://www.iso.org/iso-45001-occupational-health-and-safety.html (accessed on 19 September 2018).

- Gallagher, C. Health and Safety Management Systems: An Analysis of System Types and Effectiveness; National Key Centre in Industrial Relations, Monash University: Melbourne, Austrialia, 1997. [Google Scholar]

- European Commission. Communication from the Commission Concerning Corporate Social Responsibility: A Business Contribution to Sustainable Development. 2002. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2002:0347:FIN:EN:PDF (accessed on 26 September 2018).

- Frick, K.; Wren, J. Reviewing occupational health and safety management: Multiple roots, diverse perspectives and ambiguous outcomes. In Systematic Occupational Health and Safety Management: Perspectives on an International Development; Frick, K., Jensen, P.L., Quinlan, M., Wilthagen, T., Eds.; Pergamon: Amsterdam, The Netherlands, 2000; pp. 17–42. ISBN 9780080434131. [Google Scholar]

- Walters, D. (Ed.) Regulating Health and Safety Management in the European Union: A Study of the Dynamics of Change; Presses Interuniversitaires Europeenes: Brussels, Belgium, 2002; ISBN 90-5201-998-3. [Google Scholar] [CrossRef]

- Gallagher, C.; Underhill, E.; Rimmer, M. Occupational safety and health management systems in Australia: Barriers to success. Policy Pract. Health Saf. 2003, 1, 67–81. [Google Scholar] [CrossRef]

- Saksvik, P.O.; Quinlan, M. Regulating systematic occupational health and safety management: Comparing the Norwegian and Australian experience. Relat. Ind./Ind. Relat. 2003, 58, 33–59. [Google Scholar] [CrossRef]

- Marhavilas, P.K.; Koulouriotis, D.E.; Spartalis, S.H. Harmonic Analysis of Occupational-Accident Time-Series as a Part of the Quantified Risk Evaluation in Worksites: Application on Electric Power Industry and Construction Sector. Reliab. Eng. Syst. Saf. 2013, 112, 8–25. [Google Scholar] [CrossRef]

- International Labour Organization (ILO). Emerging Risks and New Patterns of Prevention in Changing World of Work, 1st ed.; ILO: Geneva, Switzerland, 2010; pp. 1–22, ISBN 978-92-2-123342-8 (print), ISBN 978-92-2-123343-5 (web pdf). [Google Scholar]

- Jordan, J.R.; Letti, G.; Pinto, T.L. A proposal for the use of serious games in occupational safety. In Occupational Safety and Hygiene II; Arezes, P., Baptista, J.S., Barroso, M.P., Carneiro, P., Cordeiro, P., Costa, N., Melo, R.B., Miguel, S.A., Perestrelo, G., Eds.; Taylor and Francis Group: London, UK, 2014; ISBN 978-1-138-00144-2. [Google Scholar]

- Gallagher, C.; Underhill, E.; Rimmer, M. Occupational Health and Safety Management Systems: A Review of their Effectiveness in Securing Healthy and Safe Workplaces; National Occupational Health and Safety Commission: Sydney, Australia, 2001; ISBN 0 642 70981 5. [Google Scholar]

- Robson, L.S.; Macdonald, S.; Gray, G.C.; Van Eerd, D.L.; Bigelow, P.L. A descriptive study of the OHS management auditing methods used by public sector organizations conducting audits of workplaces: Implications for audit reliability and validity. Saf. Sci. 2012, 50, 181–189. [Google Scholar] [CrossRef]

- Li, Y.; Guldenmund, F.W. Safety management systems: A broad overview of the literature. Saf. Sci. 2018, 103, 94–123. [Google Scholar] [CrossRef]

- Aneziris, O.N.; Topali, E.; Papazoglou, I.A. Occupational risk of building construction. Reliab. Eng. Syst. Saf. 2012, 105, 36–46. [Google Scholar] [CrossRef]

- Autenrieth, D.A.; Brazile, W.J.; Sandfort, D.R.; Douphrate, D.I.; Román-Muñiz, I.N.; Reynolds, S.J. The associations between occupational health and safety management system programming level and prior injury and illness rates in the U.S. dairy industry. Saf. Sci. 2016, 84, 108–116. [Google Scholar] [CrossRef]

- Tsalis, T.A.; Stylianou, M.S.; Nikolaou, I.E. Evaluating the quality of corporate social responsibility reports: The case of occupational health and safety disclosures. Saf. Sci. 2018, 109, 313–323. [Google Scholar] [CrossRef]

- Jørgensen, T.H.; Remmen, A.; Mellado, M.D. Integrated management systems—Three different levels of integration. J. Clean. Prod. 2006, 14, 713–722. [Google Scholar] [CrossRef]

- Santos-Reyes, J.; Beard, A.N. Viability of a systemic safety management system. In Proceedings of the Safety and Reliability Conference, ESREL-2006, Estoril, Portugal, 18–22 September 2006. [Google Scholar]

- Adele, A.L. Legal Perpspectives of ANZI Z10-2005. Prof. Saf. 2006, 41–43. Available online: www.xprolegal.com/expertarticles/359-1312558749_ASSE%20Z10%20Article.pdf (accessed on 26 September 2018).

- Fred, M. ANSI/AIHA Z10-2005: The new benchmark for safety management systems. Prof. Saf. 2006, 51, 25–33. Available online: https://aeasseincludes.assp.org/professionalsafety/pastissues/051/02/ 020206as.pdf (accessed on 26 September 2018).

- Wrona, R.M. The use of state workers’ compensation administrative data to identify injury scenarios and quantify costs of work-related traumatic brain injuries. J. Saf. Res. 2006, 37, 75–81. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, K.J.; Carstensen, O.; Rasmussen, K. The prevention of occupational injuries in two industrial plants using an incident reporting scheme. J. Saf. Res. 2006, 37, 479–486. [Google Scholar] [CrossRef] [PubMed]

- Cadieux, J.; Roy, M.; Desmarais, L. A preliminary validation of a new measure of occupational health and safety. J. Saf. Res. 2006, 37, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Päivinen, M. Electricians’ perception of work-related risks in cold climate when working on high places. Int. J. Ind. Ergon. 2006, 36, 661–670. [Google Scholar] [CrossRef]

- Zeng, S.X.; Shi, J.J.; Lou, G.X. A synergetic model for implementing an integrated management system: An empirical study in China. J. Clean. Prod. 2007, 15, 1760–1767. [Google Scholar] [CrossRef]

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Safety management system: Development and validation of a multidimensional scale. J. Loss Prev. Process Ind. 2007, 20, 52–68. [Google Scholar] [CrossRef]

- Coleman, P.J.; Kerkering, J.C. Measuring mining safety with injury statistics: Lost workdays as indicators of risk. J. Saf. Res. 2007, 38, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Bevilacqua, M.; Ciarapica, F.E.; Giacchetta, G. Industrial and occupational ergonomics in the petrochemical process industry: A regression trees approach. Accid. Anal. Prev. 2008, 40, 1468–1479. [Google Scholar] [CrossRef]

- Brooks, B. Shifting the focus of strategic occupational injury prevention: Mining free-text, workers compensation claims data. Saf. Sci. 2008, 46, 1–21. [Google Scholar] [CrossRef]

- Duijm, N.J.; Fiévez, C.; Gerbec, M.; Hauptmanns, U.; Konstandinidou, M. Management of health, safety and environment in process industry. Saf. Sci. 2008, 46, 908–920. [Google Scholar] [CrossRef] [Green Version]

- Salla, L.; Kivistö-Rahnasto, J. Utilization of external accident information in companies’ safety promotion—Case: Finnish metal and transportation industry. Saf. Sci. 2008, 46, 802–814. [Google Scholar] [CrossRef]

- Nielsen, K.J.; Rasmussen, K.; Glasscock, D.; Spangenberg, S. Changes in safety climate and accidents at two identical manufacturing plants. Saf. Sci. 2008, 46, 440–449. [Google Scholar] [CrossRef]

- Schrover, A.J.M. Ten years SHE-improvements on a chemical and nuclear research-site—Learning drivers. Saf. Sci. 2008, 46, 551–563. [Google Scholar] [CrossRef]

- Zeng, S.X.; Vivian, W.Y.; Tam, C.M. Towards occupational health and safety systems in the construction industry of China. Saf. Sci. 2008, 46, 1155–1168. [Google Scholar] [CrossRef]

- Komljenovic, D.; Groves, W.A.; Kecojevic, V.J. Injuries in U.S. mining operations—A preliminary risk analysis. Saf. Sci. 2008, 46, 792–801. [Google Scholar] [CrossRef]

- Caroly, S.; Coutarel, F.; Landry, A.; Mary-Cheray, I. Sustainable MSD prevention: Management for continuous improvement between prevention and production-Ergonomic intervention in two assembly line companies. Appl. Ergon. 2009, 41, 591–599. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.I.; Liang, C.-L. Performance evaluation of process safety management systems of paint manufacturing facilities. J. Loss Prev. Process Ind. 2009, 22, 398–402. [Google Scholar] [CrossRef]

- Santos-Reyes, J.; Beard, A.N. A SSMS model with application to the oil and gas industry. J. Loss Prev. Process Ind. 2009, 22, 958–970. [Google Scholar] [CrossRef]

- Crippa, C.; Fiorentini, L.; Rossini, V.; Stefanelli, R.; Tafaro, S.; Marchi, M. Fire risk management system for safe operation of large atmospheric storage tanks. J. Loss Prev. Process Ind. 2009, 22, 574–581. [Google Scholar] [CrossRef]

- Knegtering, B.; Pasman, H.J. Safety of the process industries in the 21st century: A changing need of process safety management for a changing industry. J. Loss Prev. Process Ind. 2009, 22, 162–168. [Google Scholar] [CrossRef]

- Pasman, H.J.; Jung, S.; Prem, K.; Rogers, W.J.; Yang, X. Is risk analysis a useful tool for improving process safety? J. Loss Prev. Process Ind. 2009, 22, 769–777. [Google Scholar] [CrossRef]

- Moriyama, T.; Ohtani, H. Risk assessment tools incorporating human error probabilities in the Japanese small-sized establishment. Saf. Sci. 2009, 47, 1379–1397. [Google Scholar] [CrossRef]

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Relation between occupational safety management and firm performance. Saf. Sci. 2009, 47, 980–991. [Google Scholar] [CrossRef]

- Celik, M. Designing of integrated quality and safety management system (IQSMS) for shipping operations. Saf. Sci. 2009, 47, 569–577. [Google Scholar] [CrossRef]

- Reniers, G.L.L.; Ale, B.J.M.; Dullaert, W.; Soudan, K. Designing continuous safety improvement within chemical industrial areas. Saf. Sci. 2009, 47, 578–590. [Google Scholar] [CrossRef]

- Baram, M. Globalization and workplace hazards in developing nations. Saf. Sci. 2009, 47, 756–766. [Google Scholar] [CrossRef]

- Shengli, N. Ergonomics and occupational safety and health: An ILO perspective. Appl. Ergon. 2010, 41, 744–753. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Roca, X.; Fuertes, A. Mitigating construction safety risks using prevention through design. J. Saf. Res. 2010, 41, 107–122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, C.-W.; Leu, S.-S.; Lin, C.-C.; Fan, C. Characteristic analysis of occupational accidents at small construction enterprises. Saf. Sci. 2010, 48, 698–707. [Google Scholar] [CrossRef]

- Celeste, J.; Silva, C. A semi-quantitative assessment of occupational risks using bow-tie representation. Saf. Sci. 2010, 48, 973–979. [Google Scholar] [CrossRef]

- Sgourou, E.; Katsakiori, P.; Goutsos, S.; Manatakis, E. Assessment of selected safety performance evaluation methods in regards to their conceptual, methodological and practical characteristics. Saf. Sci. 2010, 48, 1019–1025. [Google Scholar] [CrossRef]

- Fera, M.; Macchiaroli, R. Appraisal of a new risk assessment model for SME. Saf. Sci. 2010, 48, 1361–1368. [Google Scholar] [CrossRef]

- Lindhout, P.; Kingston-Howlett, J.C.; Ale, B.J.M. Controlled readability of Seveso II company safety documents, the design of a new KPI. Saf. Sci. 2010, 48, 734–746. [Google Scholar] [CrossRef]

- Celik, M. Enhancement of occupational health and safety requirements in chemical tanker operations: The case of cargo explosion. Saf. Sci. 2010, 48, 195–203. [Google Scholar] [CrossRef]

- Dawson, D.; Ian Noy, Y.; Härmä, M.; Åkerstedt, T.; Belenky, G. Modelling fatigue and the use of fatigue models in work settings. Accid. Anal. Prev. 2011, 43, 549–564. [Google Scholar] [CrossRef]

- Pheng, L.S.; Kwang, G.K. ISO 9001, ISO 14001 and OHSAS 18001 Management Systems: Integration, Costs and Benefits for Construction Companies. Arch. Sci. Rev. 2005, 48, 145–152. [Google Scholar] [CrossRef]

- Romain, J.; Imbeau, D.; de Marcellis-Warin, N. Development of an indirect-cost calculation model suitable for workplace use. J. Saf. Res. 2011, 42, 149–164. [Google Scholar] [CrossRef]

- Leka, S.; Aditya, J.; Widerszal-Bazyl, M.; Żołnierczyk-Zreda, D.; Zwetsloot, G. Developing a standard for psychosocial risk management: PAS 1010. Saf. Sci. 2011, 49, 1047–1057. [Google Scholar] [CrossRef]

- Verna, B.; O’Keeffe, V. Weighing the pig never made it heavier: Auditing OHS, social auditing as verification of process in Australia. Saf. Sci. 2011, 49, 1014–1021. [Google Scholar] [CrossRef]

- Vinodkumar, M.N.; Bhasi, M. A study on the impact of management system certification on safety management. Saf. Sci. 2011, 49, 498–507. [Google Scholar] [CrossRef]

- Pernille, H.; Hasle, P. Making work environment auditable—A ‘critical case’ study of certified occupational health and safety management systems in Denmark. Saf. Sci. 2011, 49, 1022–1029. [Google Scholar] [CrossRef]

- Ying, L.; Xingdong, L. A study on a new hazard detecting and controlling method: The case of coal mining companies in China. Saf. Sci. 2011, 49, 279–285. [Google Scholar] [CrossRef]

- Zwetsloot, G.I.J.M.; Zwanikken, S.; Hale, A. Policy expectations and the use of market mechanisms for regulatory OSH certification and testing regimes. Saf. Sci. 2011, 49, 1007–1013. [Google Scholar] [CrossRef]

- Frick, K. Worker influence on voluntary OHS management systems—A review of its ends and means. Saf. Sci. 2011, 49, 974–987. [Google Scholar] [CrossRef]

- Granerud, R.L.; Sø Rocha, R. Organisational learning and continuous improvement of health and safety in certified manufacturers. Saf. Sci. 2011, 49, 1030–1039. [Google Scholar] [CrossRef]

- Kristensen, P.H. Managing OHS: A route to a new negotiating order in high-performance work organizations? Saf. Sci. 2011, 49, 964–973. [Google Scholar] [CrossRef]

- Zwetsloot, G.I.J.M.; Hale, A.; Zwanikken, S. Regulatory risk control through mandatory occupational safety and health (OSH) certification and testing regimes (CTRs). Saf. Sci. 2011, 49, 995–1006. [Google Scholar] [CrossRef]

- Hasle, P.; Zwetsloot, G. Editorial: Occupational Health and Safety Management Systems: Issues and challenges. Saf. Sci. 2011, 49, 961–963. [Google Scholar] [CrossRef]

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Safety climate in OHSAS 18001-certified organisations: Antecedents and consequences of safety behavior. Accid. Anal. Prev. 2012, 45, 745–758. [Google Scholar] [CrossRef] [PubMed]

- Goh, Y.M.; Love, P.E.D.; Stagbouer, G.; Annesley, C. Dynamics of safety performance and culture: A group model building approach. Accid. Anal. Prev. 2012, 48, 118–125. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.-W.; Leu, S.-S.; Cheng, Y.M.; Wu, T.C.; Lin, C.C. Applying data mining techniques to explore factors contributing to occupational injuries in Taiwan’s construction industry. Accid. Anal. Prev. 2012, 48, 214–222. [Google Scholar] [CrossRef]

- Pinto, A.; Ribeiro, R.A.; Nunes, I.L. Fuzzy approach for reducing subjectivity in estimating occupational accident severity. Accid. Anal. Prev. 2012, 45, 281–290. [Google Scholar] [CrossRef] [PubMed]

- Badri, A.; Nadeau, S.; Gbodossou, A. Proposal of a risk-factor-based analytical approach for integrating occupational health and safety into project risk evaluation. Accid. Anal. Prev. 2012, 48, 223–234. [Google Scholar] [CrossRef]

- Luria, G.; Morag, I. Safety management by walking around (SMBWA): A safety intervention program based on both peer and manager participation. Accid. Anal. Prev. 2012, 45, 248–257. [Google Scholar] [CrossRef]

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Occupational risk management under the OHSAS 18001 standard: Analysis of perceptions and attitudes of certified firms. J. Clean. Prod. 2012, 24, 36–47. [Google Scholar] [CrossRef]

- Mawhood, J.; Dickinson, C. Rail Staff Fatigue—The GB Regulators Perspective on Managing the Risks; Dadashi, N., Scott, A., Wilson, J.R., Mills, A., Eds.; Taylor & Francis: New York, NY, USA, 2012; pp. 337–346, Print ISBN 978-1-138-00037-7, eBook ISBN 978-0-203-75972-1. [Google Scholar]

- Lee, S.-W.; Kim, K.-H.; Kim, T.-G. Current situation of certification system and future improvements of the occupational health and safety management system for loss prevention in Korea—Focused on KOSHA 18001. J. Loss Prev. Process Ind. 2012, 25, 1085–1089. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Lettera, G. Near-miss management systems: A methodological comparison. J. Loss Prev. Process Ind. 2012, 25, 609–616. [Google Scholar] [CrossRef]

- Badri, A.; Gbodossou, A.; Nadeau, S. Occupational health and safety risks: Towards the integration into project management. Saf. Sci. 2012, 50, 190–198. [Google Scholar] [CrossRef]

- Hamidi, N.; Omidvari, M.; Meftahi, M. The effect of integrated management system on safety and productivity indices: Case study; Iranian cement industries. Saf. Sci. 2012, 50, 1180–1189. [Google Scholar] [CrossRef]

- Hsu, I.-Y.; Su, T.-S.; Kao, C.-S.; Shu, Y.-L.; Lin, P.-R.; Tseng, J.-M. Analysis of business safety performance by structural equation models. Saf. Sci. 2012, 50, 1–11. [Google Scholar] [CrossRef]

- Wang, C.-H.; Liu, Y.-J. Omnidirectional safety culture analysis and discussion for railway industry. Saf. Sci. 2012, 50, 1196–1204. [Google Scholar] [CrossRef]

- Zubaidah, I.; Doostdar, S.; Harun, Z. Factors influencing the implementation of a safety management system for construction sites. Saf. Sci. 2012, 50, 418–423. [Google Scholar] [CrossRef]

- Abad, J.; Esteban, L.; Jordi, V. An assessment of the OHSAS 18001 certification process: Objective drivers and consequences on safety performance and labour productivity. Saf. Sci. 2013, 60, 47–56. [Google Scholar] [CrossRef]

- Santos, G.; Barros, S.; Mendes, F.; Lopes, N. The main benefits associated with health and safety management systems certification in Portuguese small and medium enterprises post quality management system certification. Saf. Sci. 2013, 51, 29–36. [Google Scholar] [CrossRef]

- Lo, C.K.Y.; Pagell, M.; Fan, D.; Wiengarten, F.; Yeung, A.C.L. OHSAS 18001 certification and operating performance: The role of complexity and coupling. J. Oper. Manag. 2014, 32, 268–280. [Google Scholar] [CrossRef]

- Yazdani, A.; Neumann, W.P.; Imbeau, D.; Bigelow, P.; Pagell, M.; Wells, R. Prevention of musculoskeletal disorders within management systems: A scoping review of practices, approaches, and techniques. Appl. Ergon. 2015, 51, 255–262. [Google Scholar] [CrossRef] [PubMed]

- Gopang, M.A.; Nebhwani, M.; Khatri, A.; Marri, H.B. An assessment of occupational health and safety measures and performance of SMEs: An empirical investigation. Saf. Sci. 2017, 93, 127–133. [Google Scholar] [CrossRef]

- Cañamares, S.M.; Escribano, B.M.V.; González-García, M.N.; Barriuso, A.R.; Rodríguez-Sáiz, A. Occupational risk-prevention diagnosis: A study of construction SMEs in Spain. Saf. Sci. 2017, 92, 104–115. [Google Scholar] [CrossRef]

| Codes | Edition Year | Institutions | Description | Focus | Reference |

|---|---|---|---|---|---|

| BS 8800 | 1996 (as BS 8800:1996) and revised in 2004 (as BS 8800:2004) and in 2008 (as BS 18004:2008). | BSI | “It gives guidance on OHS management systems for assisting compliance with stated OHS policies and objectives and on how OHS should be integrated within the organization’s overall management system” | Social dimension | [22,23,24] |

| HSG 65 | 1991 and revised in the years 1997 and 2013. | HSE | “A useful guide for directors, managers, health/safety professionals and employee representatives who wanted to improve health and safety in their organizations” | Social dimension | [25,26] |

| OHSAS 18001 | The first edition (OHSAS 18001:1999) has been technically revised and replaced by the OHSAS 18001:2007 edition (second one). | 44 cooperating organizations (constituting OHSAS Project Group) | “It is based on (i) “Plan”: establish the aims and processes which are essential for the achievement in accordance with the organization’s OHS policy, (ii) “Do”: implement the processes, (iii) “Check”: monitor and measure processes against OHS policy, objectives, legal and other requirements and report the results, (iii) “Act”: take actions to continually improve OHS performance” | Social dimension | [2] |

| ILO-OSH 2001 | 2001 and revised in 2009. | ILO | “It provides a unique and powerful instrument for the development of a sustainable safety culture within organizations. The practical recommendations of these guidelines are intended for use by all those who have responsibility for occupational safety and health management” | Social dimension | [27] |

| AS/NZS 4801:2001 | 2001 | AS/NZS | “The scope of this standard is to set auditable criteria for an OHSMS. It is a specification that aims to cover the best elements of such systems already widely used in New Zealand and Australia. It incorporates guidance on how those criteria may be accomplished” | Social dimension | [28] |

| ANSI/AIHA Z10-2005 | 2005 and revised in 2012 | ANSI | “Significant features that define Z10 include focus on management leadership roles, efficient employee participation, design review and change. It provides a tool to help organizations create and develop OHS performance” | Social dimension | [29,30] |

| SS 506 | 2004 (as SS 506:2004) and revised in 2009 (as SS 506:2009). | SSC | “It is consisted of three parts: (i) Requirements, (ii) Guidelines for the implementation of SS 506, (iii) Requirements for the chemical industry. It designates requirements for an OSH management system to activate a company to develop and implement a strategy and scopes which take into account legal requirements and information about OSH risks” | Social dimension | [31,32] |

| Une 81900:1996 EX | 1996 | AENOR | “- UNE 81900:1996 EX: Prevention of Occupational Hazards. Rules for the implementation of a SGPRL. - UNE 81901:1996 EX: Prevention of Occupational Hazards. General Rules for the Evaluation of SGPRLs. - UNE 81902:1996 EX: Prevention of Occupational Hazards. Vocabulary. - BUNE 81903:1997 EX: Prevention of Occupational Hazards. General Rules for the Evaluation of a SGPRL. Criteria for the qualification of the Auditors of Prevention. - UNE 81904:1997 EX: Prevention of Occupational Hazards. General Rules for the Evaluation of SGPRLs. Management of audit programs. - UNE 81905:1997 EX: Prevention of Occupational Hazards. Guide for the implementation of a SGPRL” | Social dimension | [33] |

| Uni 10616 | 1997 (and withdrawn in 2012 | UNI | “Some of the major qualifying points are: (i) Espousal of inherent safety principles. (ii) Espousal of matrices or risk charts for assessing the acceptability/tolerability of risks. (iii) Definition of inspection activities and periodic checks of critical lines and equipment. (iv) The assessment of the external domino effect between neighbouring plants, (v) The adoption of a work-permission system, (vi) Selection of suppliers of goods and services such as companies, companies, builders, consortia, (vii) Adopting procedures for periodic internal auditing with internal or external auditors” | Social dimension | [34] |

| ISO 14000 | ISO 14001:2004 | ISO | “The ISO 14000 family of standards emphasize on manage their environmental responsibilities. In particular, ISO 14001:2015 and its accompanying standards such as ISO 14006:2011 concentrate on environmental systems to achieve this” | Environmental dimension | [35] |

| ISO 45001 | 2018 | ISO | “ISO 45001 is intended for use by any organization, regardless of its size or the nature of its work and can be integrated into other health and safety programmes such as worker wellness and wellbeing. It can assist an organization to conform its legal requirements” | Social dimension | [36,37] |

| Year | ISO 14001 | ILOOSH 2001 | BS 8800 | OHSAS 18001 | HSG65 | ANSI/AIHA Z10 | AS/NZS 4801 | SS 506 | Une 81900 | Uni 10616 | ISO 45001 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1990 | − | − | − | − | − | − | − | − | − | − | − |

| 1991 | − | − | − | − | + | − | − | − | − | − | − |

| 1992 | + | − | − | − | + | − | − | − | − | − | − |

| 1993 | + | − | − | − | + | − | − | − | − | − | − |

| 1994 | + | − | − | − | + | − | − | − | − | − | − |

| 1995 | ++ | − | − | − | + | − | − | − | − | − | − |

| 1996 | +++ | − | + | − | + | − | − | − | + | − | − |

| 1997 | +++ | − | + | − | ++ | − | − | − | + | + | − |

| 1998 | +++ | − | + | − | ++ | − | − | − | + | + | − |

| 1999 | +++ | − | + | + | ++ | − | + | − | + | + | − |

| 2000 | +++ | − | + | + | ++ | − | ++ | − | + | + | − |

| 2001 | +++ | + | + | + | ++ | − | +++ | − | + | + | − |

| 2002 | +++ | + | + | + | ++ | − | +++ | − | − | + | − |

| 2003 | +++ | + | + | + | ++ | − | +++ | − | − | + | − |

| 2004 | ++++ | + | ++ | + | ++ | − | +++ | + | − | + | − |

| 2005 | ++++ | + | ++ | + | ++ | + | +++ | + | − | + | − |

| 2006 | ++++ | + | ++ | + | ++ | + | +++ | + | − | + | − |

| 2007 | ++++ | + | ++ | ++ | ++ | + | +++ | + | − | + | − |

| 2008 | ++++ | + | +++ | ++ | ++ | + | +++ | + | − | + | − |

| 2009 | ++++ | ++ | +++ | ++ | ++ | + | +++ | ++ | − | + | − |

| 2010 | ++++ | ++ | +++ | ++ | ++ | + | +++ | ++ | − | + | − |

| 2011 | ++++ | ++ | +++ | ++ | ++ | + | +++ | ++ | − | + | − |

| 2012 | ++++ | ++ | +++ | ++ | ++ | ++ | +++ | ++ | − | − | − |

| 2013 | ++++ | ++ | +++ | ++ | +++ | ++ | +++ | ++ | − | − | − |

| 2014 | ++++ | ++ | +++ | ++ | +++ | ++ | +++ | ++ | − | − | − |

| 2015 | +++++ | ++ | +++ | ++ | +++ | ++ | +++ | ++ | − | − | − |

| 2016 | +++++ | ++ | +++ | ++ | +++ | ++ | +++ | ++ | − | − | − |

| 2017 | +++++ | ++ | +++ | ++ | +++ | ++ | +++ | ++ | − | − | − |

| 2018 | +++++ | ++ | +++ | ++ | +++ | ++ | +++ | ++ | − | − | + |

| Nr | Source | Publisher |

|---|---|---|

| 1 | “Applied Ergonomics” | “Elsevier B.V.” |

| 2 | “Accident Analysis and Prevention” | |

| 3 | “Journal of Cleaner Production” | |

| 4 | “Journal of Operations Management” | |

| 5 | “Safety Science” | |

| 6 | “Journal of Loss Prevention in the Process Industries” | |

| 7 | “International Journal of Industrial Ergonomics” | |

| 8 | “Journal of Safety Research” | |

| 9 | “Architectural Science Review” | “Taylor & Francis” |

| 10 | “Professional Safety” | “American Society of Safety Engineers” |

| Characteristics | OHSMS Standards | |||||||

|---|---|---|---|---|---|---|---|---|

| ISO 14001 | ILOOSH 2001 | BS 8800 | OHSAS 18001 | HSG65 | ANSI/AIHA Z10 | AS/NZS 4801 | SS 506 | |

| General requirements | YES | NO | NO | YES | NO | NO | NO | NO |

| Initial or periodic status review | NO | NO | YES | NO | YES | NO | NO | NO |

| Management leadership and Labour participation | NO | NO | NO | NO | NO | YES | NO | NO |

| Policy | YES | YES | YES | YES | YES | NO | YES | YES |

| Organising | NO | YES | YES | NO | YES | NO | NO | NO |

| Planning | YES | YES | YES | YES | YES | YES | YES | YES |

| Implemention/Operation | YES | YES | YES | YES | YES | YES | YES | YES |

| Inspection and Evaluation | YES | YES | NO | YES | NO | YES | YES | YES |

| Performance measurement | NO | NO | YES | NO | YES | NO | YES | NO |

| Improvement actions | NO | YES | NO | NO | NO | NO | NO | NO |

| Corrective actions | YES | NO | NO | YES | NO | YES | NO | YES |

| Management Review | YES | NO | NO | YES | YES | YES | YES | YES |

| Audit | NO | NO | YES | NO | YES | NO | NO | NO |

| Continuous Improvement | YES | NO | NO | YES | NO | YES | YES | YES |

| Performance inspection | YES | YES | YES | YES | YES | YES | YES | YES |

| Origin | International | International | UK | International | UK | USA | Australia/ New Zealand | Singapore |

| Year of establishment | 1992 | 2001 | 1996 | 1999 | 1991 | 2005 | 1999 | 2004 |

| Update | YES | YES | YES | YES | YES | YES | YES | YES |

| Good embedded OHS practices | NO | YES | YES | YES | NO | YES | NO | YES |

| Weak issues | YES | YES | YES | YES | YES | YES | YES | YES |

| Glossary Terms and definitions | YES | YES | YES | YES | NO | NO | NO | NO |

| Workers participation | NO | YES | NO | NO | NO | NO | NO | NO |

| Documentation | YES | YES | YES | YES | YES | YES | YES | YES |

| Free of Charge Manual | NO | YES | NO | NO | NO | NO | NO | NO |

| Risk assessment technique | NO | NO | YES | YES | NO | YES | NO | NO |

| Application on Organisations of any type and size | NO | YES | YES | YES | NO | YES | NO | YES |

| Accompanied with extra guidelines series | NO | NO | YES | YES | NO | NO | YES | YES |

| Incorporated examples | NO | NO | YES | NO | NO | YES | NO | NO |

| Annexes | YES | YES | YES | YES | YES | YES | YES | YES |

| Embedded comparisons with other OHSMS standards | NO | NO | YES | YES | NO | YES | NO | NO |

| Possible combination with other OHSMS standards | NO | NO | YES | YES | NO | YES | NO | NO |

| Compatibility with other OHSMS standards | YES | YES | YES | YES | NO | YES | NO | NO |

| Compatibility with Quality and/or Environmental IMS standards | YES | NO | YES | YES | YES | YES | YES | YES |

| Future improvement | YES | YES | YES | YES | YES | YES | YES | YES |

| Taking into account recent legislative changes | NO | NO | YES | NO | NO | NO | NO | NO |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marhavilas, P.; Koulouriotis, D.; Nikolaou, I.; Tsotoulidou, S. International Occupational Health and Safety Management-Systems Standards as a Frame for the Sustainability: Mapping the Territory. Sustainability 2018, 10, 3663. https://doi.org/10.3390/su10103663

Marhavilas P, Koulouriotis D, Nikolaou I, Tsotoulidou S. International Occupational Health and Safety Management-Systems Standards as a Frame for the Sustainability: Mapping the Territory. Sustainability. 2018; 10(10):3663. https://doi.org/10.3390/su10103663

Chicago/Turabian StyleMarhavilas, Panagiotis, Dimitrios Koulouriotis, Ioannis Nikolaou, and Sotiria Tsotoulidou. 2018. "International Occupational Health and Safety Management-Systems Standards as a Frame for the Sustainability: Mapping the Territory" Sustainability 10, no. 10: 3663. https://doi.org/10.3390/su10103663