An Evaluation of Input–Output Value for Sustainability in a Chinese Steel Production System Based on Emergy Analysis

Abstract

1. Introduction

2. Materials and Methodology

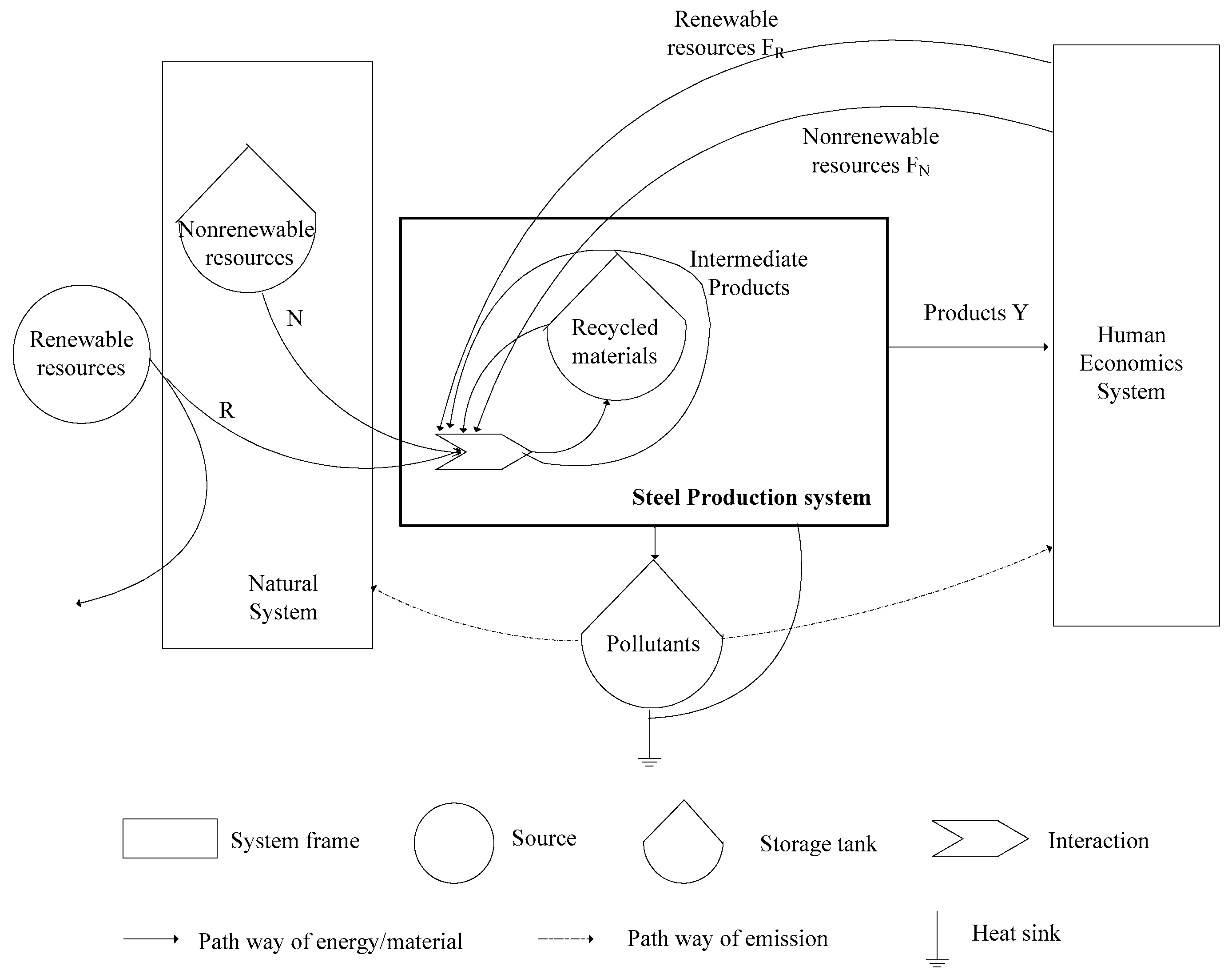

2.1. Evaluation Framework

2.2. Data Collection and Calculation of Emergy

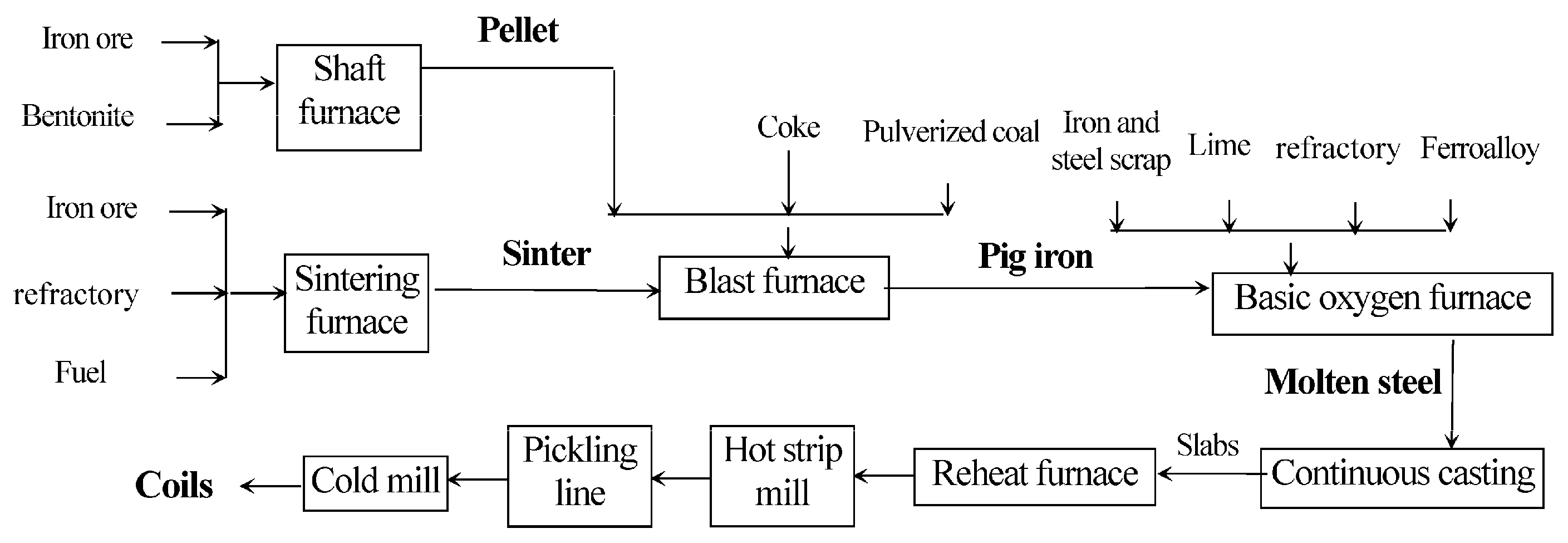

2.2.1. Data Collection

2.2.2. Impact Evaluation of Emissions

2.2.3. Emergy Evaluation of the Steel Industry

2.2.4. Emergy Indexes Used in This Study

3. Results and Discussion

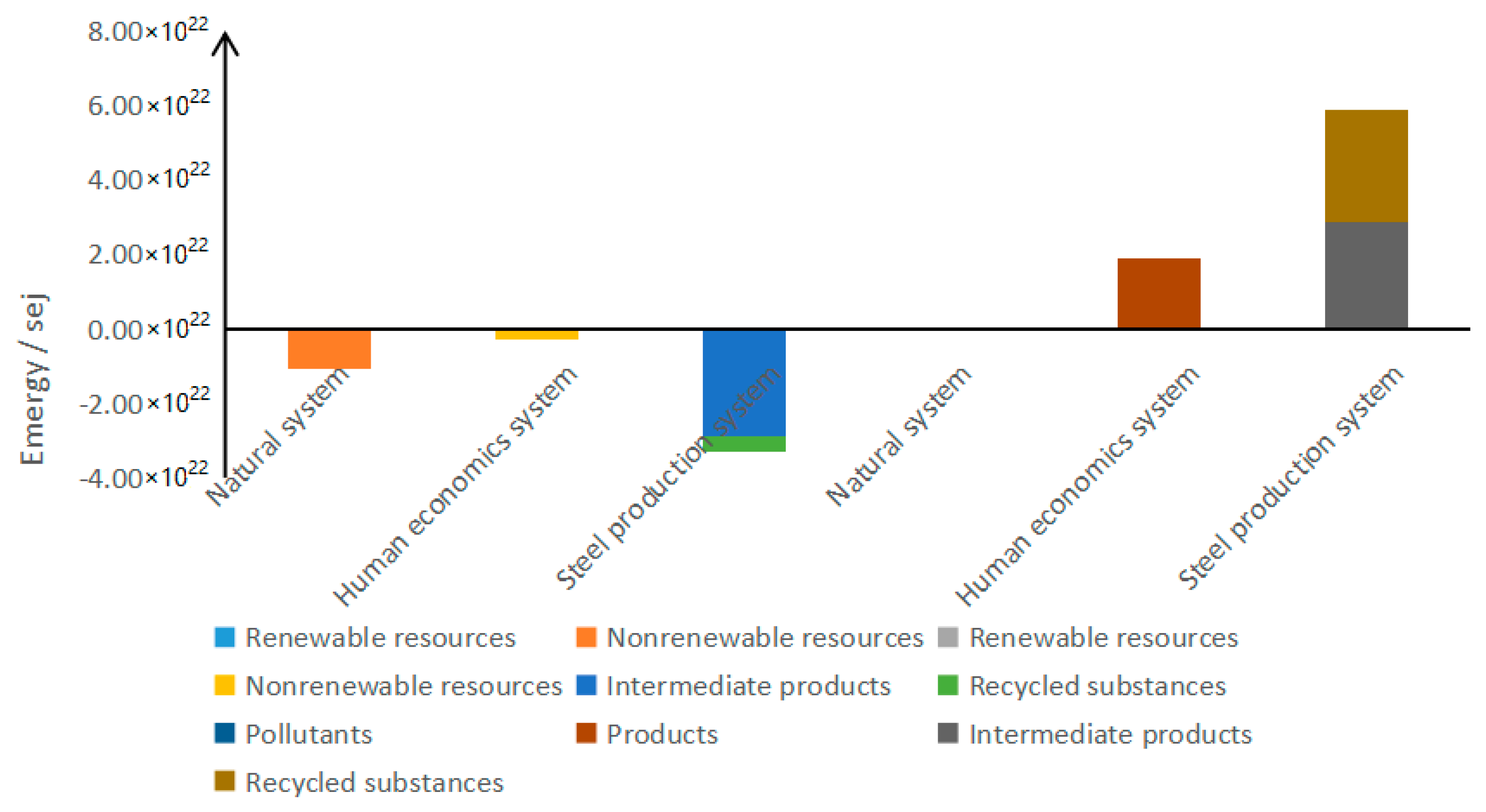

3.1. Structure of Inputs and Outputs in the Steel Industry

3.2. Variation in Emergy of Different Production Links

3.2.1. Input Indexes

3.2.2. Output Indexes

3.2.3. Input–Output Indexes

3.2.4. Sustainability Indexes

4. Conclusions and Recommendations

4.1. Conclusions

4.2. Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Production Process | System | Resource Type | Indicator | Unit | Raw Data | Emergy Conversion Rate sej/unit | Emergy sej |

|---|---|---|---|---|---|---|---|

| Pelletizing | Input | ||||||

| Natural system | Renewable resources (R) | Fresh water | t | 60,000 | 6.64 × 1011 a | 3.98 × 1016 | |

| Non-renewable resources (N) | Bentonite | t | 19,200 | 1.00 × 1015 a | 1.92 × 1019 | ||

| Powdered iron | t | 1,212,000 | 8.55 × 1014 a | 1.04 × 1021 | |||

| Human economics system | Non-renewable resources (FN) | Electricity | J | 1.17 × 1015 | 160,000 b | 1.87 × 1020 | |

| Steel production system | Recycled materials | Blast furnace gas | J | 2.72 × 1014 | 66,000 a | 1.79 × 1019 | |

| Output | |||||||

| Natural system | Pollutant | SO2 | 2.43 × 1017 | ||||

| Dust | 4.25 × 1017 | ||||||

| NOx | 6.44 × 1017 | ||||||

| Human economics system | Products | Pellet | t | 1,200,000 | 1.09 × 1015 a | ||

| Recycled materials | Desulphurizing Slag | t | 6200 | 1.00 × 1015 a | 6.20 × 1018 | ||

| Pellet dust removal ash | t | 48 | 8.30 × 1014 a | 3.98 × 1016 | |||

| Sintering | Input | ||||||

| Natural system | Renewable resources (R) | Fresh water | t | 87,000 | 6.64 × 1011 a | 5.78 × 1016 | |

| Non-renewable resources(N) | Domestic powdered iron | t | 1,625,000 | 8.55 × 1014 a | 1.39 × 1021 | ||

| Powdered iron abroad | t | 6,025,000 | 8.55 × 1014 a | 5.15 × 1021 | |||

| Limestone | t | 1,464,000 | 1.00 × 1015 a | 1.46 × 1021 | |||

| High magnesium powder | t | 85,900 | 1.00 × 1015 a | 8.59 × 1019 | |||

| Human economics system | Non-renewable resources (FN) | Electricity | J | 1.17 × 1015 | 160,000 b | 1.87 × 1020 | |

| Coke powder | J | 1.11 × 1016 | 10,600 a | 1.18 × 1020 | |||

| Steel production system | Recycled materials | Dust removal ash | t | 48,200 | 8.30 × 1014 a | 4.00 × 1019 | |

| Water treatment sludge | t | 53,850 | 1.00 × 1015 a | 5.39 × 1019 | |||

| Sinter reentry | t | 184,400 | 1.09 × 1015 a | 2.01 × 1020 | |||

| Pellet return | t | 100,300 | 1.09 × 1015 a | 1.09 × 1020 | |||

| Blast furnace gas | J | 2.07 × 1015 | 66,000 a | 1.37 × 1020 | |||

| Use of steam | J | 8.64 × 1014 | 3090 a | 2.67 × 1018 | |||

| Output | |||||||

| Natural system | Pollutant | SO2 | 1.90 × 1018 | ||||

| Dust | 4.81 × 1018 | ||||||

| NOx | 5.46 × 1018 | ||||||

| Human economics system | Products | Sinter | t | 9,150,000 | 1.09 × 1015 a | 9.98 × 1021 | |

| Recycled materials | Desulphurized gypsum | t | 23,600 | 1.00 × 1015 c | 2.36 × 1019 | ||

| Desulphurization waste ash | t | 16,560 | 8.30 × 1014 a | 1.38 × 1019 | |||

| Sinter reentry | t | 757,360 | 1.09 × 1015 a | 8.26 × 1020 | |||

| Sintering dust | t | 75,900 | 8.30 × 1014 a | 6.30 × 1019 | |||

| Steam generation | J | 6.66 × 1014 | 3090 a | 2.06 × 1018 | |||

| Puddling | Input | ||||||

| Natural system | Renewable resources (R) | Compressed air | t | 1,217,695.5 | 5.16 × 1013 a | 6.29 × 1019 | |

| Fresh water | t | 1,260,000 | 6.64 × 1011 a | 8.37 × 1017 | |||

| Non-renewable resources (N) | Iron block | t | 101,700 | 8.55 × 1014 a | 8.70 × 1019 | ||

| Coal | J | 5.09 × 1015 | 39,801 a | 2.02 × 1020 | |||

| Pulverized coal | J | 6.59 × 1014 | 39,801 a | 2.62 × 1019 | |||

| Human economics system | Non-renewable resources (FN) | Electricity | J | 7.70 × 1014 | 160,000 b | 1.23 × 1020 | |

| Coke | J | 4.45 × 1016 | 10,600 a | 4.71 × 1020 | |||

| Nut coke | J | 7.32 × 1014 | 10,600 a | 7.76 × 1018 | |||

| Steel production system | Intermediate products | Sinter | t | 6,630,000 | 1.09 × 1015 a | 7.23 × 1021 | |

| Pellet | t | 1,200,000 | 1.09 × 1015 a | 1.31 × 1021 | |||

| Recycled materials | Use of steam | J | 1.73 × 1014 | 3090 a | 5.34 × 1017 | ||

| Blast furnace gas | J | 1.43 × 1016 | 66,000 a | 9.43 × 1020 | |||

| Output | |||||||

| Natural system | Pollutant | SO2 | 1.47 × 1017 | ||||

| Dust | 3.55 × 1018 | ||||||

| NOx | 5.44 × 1017 | ||||||

| Human economics system | Products | Pig iron | t | 4,650,000 | 2.71 × 1015 a | 1.26 × 1022 | |

| Recycled materials | Blast furnace slag | t | 1,417,000 | 8.55 × 1014 a | 1.21 × 1021 | ||

| Gas ash | t | 57,500 | 8.30 × 1014 a | 4.77 × 1019 | |||

| Blast furnace gas | J | 1.79 × 1016 | 66,000 a | 2.12 × 1021 | |||

| Hot blast stove flue gas | t | 27,619,708.4 | 8.30 × 1014 a | 2.29 × 1022 | |||

| Dust and ash | t | 39,100 | 8.30 × 1014 a | 3.25 × 1019 | |||

| Steel-making | Input | ||||||

| Natural system | Renewable resources (R) | Fresh water | t | 1,176,000 | 6.64 × 1011 a | 7.81 × 1017 | |

| Nitrogen consumption | t | 4,515,739.44 | 2.00 × 1014 d | 9.03 × 1020 | |||

| Oxygen consumption | t | 2,667,180.15 | 5.16 × 1013 b | 1.38 × 1020 | |||

| Compressed air | t | 1,178,415 | 5.16 × 1013 | 6.08 × 1019 | |||

| Non-renewable resources (N) | Iron block | t | 110,000 | 8.55 × 1014 | 9.41 × 1019 | ||

| Ferroalloy | t | 13,300 | 8.55 × 1014 | 1.14 × 1019 | |||

| Doomite | t | 65,500 | 1.00 × 1015 a | 6.55 × 1019 | |||

| Flour | t | 600 | 1.00 × 1015 a | 6.00 × 1017 | |||

| Human economics system | Non-renewable resources (FN) | Electricity | J | 7.85 × 1014 | 160,000 b | 1.26 × 1020 | |

| White ash | t | 468,000 | 2.16 × 1015 a | 1.01 × 1021 | |||

| Steel production system | Intermediate products | Pig iron | t | 4,650,000 | 2.17 × 1015 a | 1.01 × 1022 | |

| Recycled materials | Steel scrap | t | 32,000 | 3.09 × 1015 a | 9.89 × 1019 | ||

| Blast furnace gas | J | 2.86 × 1014 | 66,000 a | 1.89 × 1019 | |||

| Convertor gas | J | 1.29 × 1015 | 66,000 a | 8.52 × 1019 | |||

| Output | |||||||

| Natural system | Pollutant | Dust | 2.63 × 1018 | ||||

| Human economics system | Products | Billet steel | t | 4,500,000 | 3.09 × 1015 a | ||

| Recycled materials | Steel slag | t | 427,600 | 3.09 × 1015 a | 1.32 × 1021 | ||

| Dust mud | t | 53,800 | 1.00 × 1015 a | 5.38 × 1019 | |||

| Dust | t | 120 | 8.30 × 1014 a | 9.96 × 1016 | |||

| Iron oxide skin | t | 27,800 | 8.55 × 1014 a | 2.38 × 1019 | |||

| Remainder residue | t | 19,500 | 8.30 × 1014 a | 1.62 × 1019 | |||

| Steam generation | J | 1.01 × 1015 | 3090 a | 3.13 × 1018 | |||

| Convertor gas | J | 4.35 × 1015 | 66,000 a | 2.87 × 1020 | |||

| Rolling | Input | ||||||

| Natural system | Renewable resources (R) | compressed air | t | 104,472.48 | 5.16 × 1013 a | 5.39 × 1018 | |

| Fresh water | t | 670,000 | 6.64 × 1011 a | 4.45 × 1017 | |||

| Human economics system | Non-renewable resources (FN) | Electricity | J | 1.44 × 1015 | 160,000 b | 2.30 × 1020 | |

| Steel production system | Intermediate products | Billet steel | t | 3,243,700 | 3.09 × 1015 a | 1.00 × 1022 | |

| Recycled materials | Blast furnace gas | J | 3.90 × 1015 | 66,000 a | 2.58 × 1020 | ||

| Output | |||||||

| Natural system | Pollutant | SO2 | 6.95 × 1016 | ||||

| Dust | 1.88 × 1017 | ||||||

| NOx | 2.07 × 1017 | ||||||

| Human economics system | Products | Rolled steel | t | 3,200,000 | 3.09 × 1015 a | ||

| Recycled materials | Iron oxide sludge | t | 21,900 | 1.00 × 1015 a | 2.19 × 1019 | ||

| Steel scrap | t | 28,300 | 3.09 × 1015 a | 8.74 × 1019 | |||

| Steam generation | J | 3.95× 1014 | 3090 a | 1.22 × 1018 | |||

| Oxygen production | Input | ||||||

| Natural system | Renewable resources (R) | air | t | 1,964,117.14 | 5.16 × 1013 a | 1.01 × 1020 | |

| Fresh water | t | 286,651.81 | 6.64 × 1011 a | 1.90 × 1017 | |||

| Human economics system | Non-renewable resources (FN) | Electricity | J | 7.93× 1014 | 160,000 b | 1.27 × 1020 | |

| Power plant | Input | ||||||

| Steel production system | Recycled materials | Blast furnace gas | J | 1.14 × 1016 | 65,999 a | 7.50 × 1020 | |

| Convertor gas | J | 3.06 × 1015 | 66,000 a | 2.02 × 1020 | |||

| Steam generation | J | 1.67 × 1016 | 3090 a | 5.15 × 1019 | |||

| Use of steam | J | 1.67 × 1016 | 3090 a | 5.15 × 1019 | |||

| Electricity | J | 1.89 × 1015 | 160,000 b | 3.03 × 1020 | |||

| Output | |||||||

| Natural system | Pollutant | SO2 | 4.42 × 1017 | ||||

| Dust | 4.34 × 1017 | ||||||

| NOx | 5.15 × 1017 | ||||||

| Whole process | Input | ||||||

| Human economics system | Renewable resources (R) | Labor | 人 | 8500 | 3.10 × 1016 a | 2.64 × 1020 | |

| Investment in fixed assets | $ | 46,937,658.6 | 4.94 × 1012 e | 2.32 × 1020 | |||

| Soil loss | g | 4.43 × 1011 | 1.70 × 109 c | 7.53 × 1020 |

References

- Renzulli, P.A.; Notarnicola, B.; Tassielli, G.; Arcese, G.; Di Capua, R. Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill. Sustainability 2016, 8, 719. [Google Scholar] [CrossRef]

- Kim, Y.; Worrell, E. International comparison of CO2 emission trends in the iron and steel industry. Energy Policy 2002, 30, 827–838. [Google Scholar] [CrossRef]

- Chen, B.; Yang, J.X.; Ouyang, Z.Y. Life Cycle Assessment of Internal Recycling Options of Steel Slag in Chinese Iron and Steel Industry. J. Iron Steel Res. Int. 2011, 18, 33–40. [Google Scholar] [CrossRef]

- Michaelis, P.; Jackson, T. Material and energy flow through the UK iron and steel sector (Part 1: 1954–1994H). Resour. Conserv. Recycl. 2000, 29, 131–156. [Google Scholar] [CrossRef]

- Michaelis, P.; Jackson, T. Material and energy flow through the UK iron and steel sector (Part 2: 1994–2019). Resour. Conserv. Recycl. 2000, 29, 209–230. [Google Scholar] [CrossRef]

- Huang, Z.; Ding, X.; Sun, H.; Liu, S. Identification of main influencing factors of life cycle CO2 emissions from the integrated steel works using sensitivity analysis. J. Clean. Prod. 2010, 18, 1052–1058. [Google Scholar] [CrossRef]

- Lin, B.; Wang, X. Promoting energy conservation in China’s iron & steel sector. Energy 2014, 73, 465–474. [Google Scholar]

- Lin, B.Q.; Wang, X.L. Exploring energy efficiency in China’s iron and steel industry: A stochastic frontier approach. Energy Policy 2014, 72, 87–96. [Google Scholar] [CrossRef]

- Odum, H.T. Environmental Accounting: Emergy and Environmental Decision Making; John Wiley: New York, NY, USA, 1996; p. 370. [Google Scholar]

- Cleveland, C.J.; Kaufmann, R.K.; Stern, D.I. Aggregation and the role of energy in the economy. Ecol. Econ. 2000, 32, 301–317. [Google Scholar] [CrossRef]

- Giannetti, B.F.; Demétrio, J.F.C.; Bonilla, S.H.; Agostinho, F.; Almeida, C.M.V.B. Emergy diagnosis and reflections towards Brazilian sustainable development. Energy Policy 2013, 63, 1002–1012. [Google Scholar] [CrossRef]

- Zhang, L.X.; Song, B.; Chen, B. Emergy-based analysis of four farming systems: Insight into agricultural diversification in rural China. J. Clean. Prod. 2012, 28, 33–44. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, H.; Zhang, R.; Deng, S. Interactions between China’s economy, energy and the air emissions and their policy implications. Renew. Sustain. Energy Rev. 2014, 38, 624–638. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Liu, J.; Zhang, J.; Wang, R. Emergy-based evaluation of system sustainability and ecosystem value of a large-scale constructed wetland in North China. Environ. Monit. Assess. 2013, 185, 5595–5609. [Google Scholar] [CrossRef]

- Li, Q.; Yan, M. Assessing the health of agricultural land with emergy analysis and fuzzy logic in the major grain-producing region. Catena 2012, 99, 9–17. [Google Scholar] [CrossRef]

- Zhang, X.L.; Hu, Q.H.; Wang, C.B. Emergy evaluation of environmental sustainability of poultry farming that produces products with organic claims on the outskirts of mega-cities in China. Ecol. Eng. 2013, 54, 128–135. [Google Scholar] [CrossRef]

- Brown, M.T.; Ulgiati, S. Emergy evaluations and environmental loading of electricity production systems. J. Clean. Prod. 2002, 10, 321–334. [Google Scholar] [CrossRef]

- Geng, Y.; Zhang, P.; Ulgiati, S.; Sarkis, J. Emergy analysis of an industrial park: The case of Dalian, China. Sci. Total Environ. 2010, 408, 5273–5283. [Google Scholar] [CrossRef] [PubMed]

- Yuan, F.; Shen, L.Y.; Li, M.Q. Emergy analysis of the recycling options for construction and demolition waste. Waste Manag. 2011, 31, 2503–2511. [Google Scholar] [CrossRef] [PubMed]

- Ulgiati, S. A comprehensive energy and economic assessment of biofuels: When “green” is not enough. Crit. Rev. Plant Sci. 2001, 20, 71–106. [Google Scholar] [CrossRef]

- Takahashi, F.; Ortega, E. Assessing the sustainability of Brazilian oleaginous crops—Possible raw material to produce biodiesel. Energy Policy 2010, 38, 2446–2454. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Zhang, B.; Cai, Z.F. Emergy analysis of a farm biogas project in China: A biophysical perspective of agricultural ecological engineering. Commun. Nonlinear Sci. 2010, 15, 1408–1418. [Google Scholar] [CrossRef]

- Zhang, X.H.; Jiang, W.J.; Deng, S.H.; Peng, K. Emergy evaluation of the sustainability of Chinese steel production during 1998–2004. J. Clean. Prod. 2009, 17, 1030–1038. [Google Scholar] [CrossRef]

- Pan, H.Y.; Zhang, X.H.; Wu, J.; Zhang, Y.; Lin, L.; Yang, G.; Deng, S.; Li, L.; Yu, X.; Qi, H.; et al. Sustainability evaluation of a steel production system in China based on emergy. J. Clean. Prod. 2016, 112, 1498–1509. [Google Scholar] [CrossRef]

- Ulgiati, S.; Brown, M.T. Quantifying the environmental support for dilution and abatement of process emissions: The case of electricity production. J. Clean. Prod. 2002, 10, 335–348. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Metrics: Disability-adjusted Life Year (DALY). 2013. Available online: http://www.who.int/healthinfo/global_burden_disease/metrics_daly/en/ (accessed on 7 December 2014).

- Ministry of Environmental Protection of the People’s Republic China (MEPPRC). Ambient Air Quality Standard (GB3095-2012). 2012. Available online: http://kjs.mep.gov.cn/hjbhbz/bzwb/dqhjbh/dqhjzlbz/201203/t20120302_224165.htm (accessed on 7 December 2014). (In Chinese)

- Ukidwe, N.U.; Bakshi, B.R. Industrial and ecological cumulative exergy consumption of the United States via the 1997 input-output benchmark model. Energy 2007, 32, 1560–1592. [Google Scholar] [CrossRef]

- Liu, G.; Yang, Z.; Chen, B.; Zhang, Y.; Su, M.; Zhang, L. Emergy evaluation of the urban solid waste Handling in Liaoning Province, China. Energies 2013, 6, 5486–5506. [Google Scholar] [CrossRef]

- Ulgiati, S.; Brown, M.T. Monitoring Patterns of Sustainability in Natural and Man-made Ecosystems. Ecol. Model. 1998, 108, 23–36. [Google Scholar] [CrossRef]

- Burchart-Korol, D. Significance of Environmental Life Cycle Assessment (Lca) Method in The Iron And Steel Industry. Metalurgija 2011, 50, 205–208. [Google Scholar]

- Iosif, A.M.; Hanrot, F.; Birat, J.P.; Ablitzer, D. Physicochemical modelling of the classical steelmaking route for life cycle inventory analysis. Int. J. Life Cycle Assess. 2010, 15, 304–310. [Google Scholar] [CrossRef]

- Xiao, L.S.; Wang, R.; Chiang, P.C.; Pan, S.Y.; Guo, Q.H.; Chang, E.E. Comparative Life Cycle Assessment (LCA) of Accelerated Carbonation Processes Using Steelmaking Slag for CO2 Fixation. Aerosol Air Qual. Res. 2014, 14, 892–904. [Google Scholar] [CrossRef]

- Vadenbo, C.O.; Boesch, M.E.; Hellweg, S. Life Cycle Assessment Model for the Use of Alternative Resources in Ironmaking. J. Ind. Ecol. 2013, 17, 363–374. [Google Scholar] [CrossRef]

- Chen, X. Evaluation of the sustainability of Iron and Steel Eco-Industrial Parks Based on Emergy and Exergy Theory; Dalian University of Technology: Shenyang, China, 2009. [Google Scholar]

- Lan, S.F.; Qin, P.; Lu, H.F. Emergy Analysis of Ecological Economic System; Chemical Industry Press: Beijing, China, 2002; p. 328. [Google Scholar]

- Brown, M.T.; Bardi, E. Handbook of Emergy Evaluation: Folio #3 Emegy of Ecosystems; University of Florida: Gainesville, FL, USA, 2001; Available online: www.emergysystems.org (accessed on 2 July 2010).

- Ma, F.J.; Liu, J.T. Agricultural Ecosystem Services Assessment Based on Emergy Analysis—A Case Study of Luancheng County. Resour. Sci. 2014, 36, 1949–1957. [Google Scholar]

| Production Process | Pollutant | Pollutant Discharge Mass/t | Discharge Volume of Waste Gas/m3 | Acceptable Concentration/μg/m3 [27] | Mass of the Air Used to Dilute Pollutant/t | Emergy of the Air Used to Dilute Pollutant/sej | DALY/Kg of Emission | Emergy Loss of Emission/sej | Emergy of Total Impacts of Pollutants/sej |

|---|---|---|---|---|---|---|---|---|---|

| Pelletizing | SO2 | 295.26 | 3.11 × 109 | 20 | 1.82 × 1010 | 3.06 × 1016 | 5.46 × 10−5 [28] | 2.13 × 1017 | 2.43 × 1017 |

| Dust | 85.51 | 5.10 × 109 | 80 | 1.31 × 109 | 2.21 × 1015 | 3.75 × 10−4 [28] | 4.23 × 1017 | 4.25 × 1017 | |

| NOx | 530.91 | 3.12 × 109 | 50 | 1.31 × 1010 | 2.20 × 1016 | 8.87 × 10−5 [29] | 6.22 × 1017 | 6.44 × 1017 | |

| Sintering | SO2 | 2315.38 | 1.99 × 1010 | 20 | 1.42 × 1011 | 2.40 × 1017 | 5.46 × 10−5 [28] | 1.67 × 1018 | 1.91 × 1018 |

| Dust | 967.46 | 4.23 × 1010 | 80 | 1.48 × 1010 | 2.50 × 1016 | 3.75 × 10−4 [28] | 4.79 × 1018 | 4.81 × 1018 | |

| NOx | 4503.19 | 2.02 × 1010 | 50 | 1.11 × 1011 | 1.87 × 1017 | 8.87 × 10−5 [29] | 5.27 × 1018 | 5.46 × 1018 | |

| Puddling | SO2 | 178.81 | 3.85 × 109 | 20 | 1.10 × 1010 | 1.85 × 1016 | 5.46 × 10−5 [28] | 1.29 × 1017 | 1.47 × 1017 |

| Dust | 713.47 | 3.54 × 1010 | 80 | 1.09 × 1010 | 1.84 × 1016 | 3.75 × 10−4 [28] | 3.53 × 1018 | 3.55 × 1018 | |

| NOx | 449.03 | 3.85 × 109 | 50 | 1.00 × 1010 | 1.86 × 1016 | 8.87 × 10−5 [29] | 5.26 × 1017 | 5.44 × 1017 | |

| Steel-making | Dust | 528.30 | 2.24 × 1010 | 80 | 8.11 × 109 | 1.37 × 1016 | 3.75 × 10−4 [28] | 2.62 × 1018 | 2.63 × 1018 |

| Rolling | SO2 | 84.33 | 2.00 × 109 | 20 | 5.18 × 109 | 8.75 × 1015 | 5.46 × 10−5 [28] | 6.08 × 1016 | 6.95 × 1016 |

| Dust | 37.85 | 2.00 × 109 | 80 | 5.80 × 108 | 9.78 × 1014 | 3.75 × 10−4 [28] | 1.87 × 1017 | 1.88 × 1017 | |

| NOx | 170.97 | 2.00 × 109 | 50 | 4.20 × 109 | 7.09 × 1015 | 8.87 × 10−5 [29] | 2.00 × 1017 | 2.07 × 1017 | |

| Power Plant | SO2 | 535.52 | 1.08 × 1010 | 20 | 3.29 × 1010 | 5.56 × 1016 | 5.46 × 10−5 [28] | 3.86 × 1017 | 4.42 × 1017 |

| Dust | 87.18 | 1.08 × 1010 | 80 | 1.33 × 109 | 2.24 × 1015 | 3.75 × 10−4 [28] | 4.32 × 1017 | 4.34 × 1017 | |

| NOx | 424.64 | 1.08 × 1010 | 50 | 1.04 × 1010 | 1.76 × 1016 | 8.87 × 10−5 [29] | 4.97 × 1017 | 5.15 × 1017 |

| Items | Resource Type | Indexes | Emergy | Items | Resource Type | Indexes | Emergy |

|---|---|---|---|---|---|---|---|

| sej | sej | ||||||

| Input | Output | ||||||

| Natural system | Renewable resources (R) | Fresh water | 2.35 × 1018 | Natural system | Pollutants | SO2 | 2.81 × 1018 |

| Air | 2.30 × 1020 | Dust | 1.20 × 1019 | ||||

| Non-renewable resources (N) | Bentonite | 1.92 × 1019 | NOx | 7.37 × 1018 | |||

| Powdered iron | 7.58 × 1021 | Human economics system | Products (Y) | Sinter | 2.75 × 1021 | ||

| Limestone | 1.46 × 1021 | Pig iron | 2.51 × 1021 | ||||

| High magnesium powder | 8.59 × 1019 | Billet steel | 3.88 × 1021 | ||||

| Iron ore | 8.70 × 1019 | Rolled steel | 9.89 × 1021 | ||||

| Coal | 2.02 × 1020 | Steel production system | Intermediate products | Pellet | 1.31 × 1021 | ||

| Pulverized coal | 2.62 × 1019 | Sinter | 7.23 × 1021 | ||||

| Iron block | 9.41 × 1019 | Pig iron | 1.01 × 1022 | ||||

| Ferroalloy | 1.14 × 1019 | Billet steel | 1.00 × 1022 | ||||

| Doomite | 6.55 × 1019 | Recycled materials | Desulphurizing Slag | 6.20 × 1018 | |||

| Flour | 6.00 × 1017 | Dust and ash | 1.57 × 1020 | ||||

| Soil loss | 7.53 × 1020 | Desulphurized gypsum | 2.36 × 1019 | ||||

| Human economics system | Renewable resources (FR) | Labor | 2.64 × 1020 | Sinter reentry | 8.26 × 1020 | ||

| Investment in fixed assets | 2.32 × 1020 | Blast furnace slag | 1.21 × 1021 | ||||

| Non-renewable resources (FN) | Thermal power electricity | 6.78 × 1020 | Blast furnace gas | 2.12 × 1021 | |||

| Coke powder | 4.15 × 109 | Hot blast stove flue gas | 2.29 × 1022 | ||||

| Coke | 4.71 × 1020 | Steel slag | 1.32 × 1021 | ||||

| Nut coke | 7.76 × 1018 | Dust mud | 5.38 × 1019 | ||||

| White ash | 1.01 × 1021 | Iron oxide skin | 2.38 × 1019 | ||||

| Steel production system | Intermediate products | Sinter | 7.23 × 1021 | Remainder residue | 1.62 × 1019 | ||

| Pellet | 1.31 × 1021 | Steam production | 5.58 × 1019 | ||||

| Pig iron | 1.01 × 1022 | Converter gas production | 2.87 × 1020 | ||||

| Billet steel | 1.001 × 1022 | Iron oxide sludge | 2.19 × 1019 | ||||

| Recycled materials | Blast furnace gas | 2.121 × 1021 | Steel scrap | 8.75 × 1019 | |||

| Convertor gas | 2.87 × 1020 | Electricity | 3.03 × 1020 | ||||

| Dust and ash | 4.00 × 1019 | Nitrogen | 9.03 × 1020 | ||||

| Water treatment sludge | 5.39 × 1019 | Oxygen | 1.38 × 1020 | ||||

| Sinter reentry | 2.01 × 1020 | ||||||

| Pellet return | 1.09 × 1020 | ||||||

| Steam consumption | 5.74 × 1019 | ||||||

| Steel scrap | 9.89 × 1019 | ||||||

| Electricity | 3.03 × 1020 | ||||||

| Nitrogen | 9.03 × 1020 | ||||||

| Oxygen | 1.38 × 1020 |

| Items | Indexes | Formulation |

|---|---|---|

| Input index | Environment loading ratio (ELR) | Non-renewable resources (N + FN)/Renewable resources (R + FR) |

| Proportion of recycled materials used (PRM) | Recycled materials used/Total input | |

| Emergy investment ratio (EIR) | Human economics system input/Natural system input | |

| Output index | Environmental impact rate (EnIR) | Pollutants/Products |

| Product rate (PR) | Products/Total output | |

| Input–output index | Emergy yield ratio (EYR) | Products/Human economics system input |

| Total emergy yield ratio (TEYR) | (Products + Intermediate products + Recycled materials)/(Human economics system input + Natural system input) | |

| Net emergy yield ratio (NEYR) | (Products + Intermediate products + Recycled materials-Pollutants)/(Human economics system input + Natural system input) | |

| Emergy input–output rate (EIOR) | Products/Total input | |

| Total emergy input–output ratio (TEIOR) | (Products + Intermediate products + Recycled materials)/Total input | |

| Net emergy input–output ratio (NEIOR) | (Products + Intermediate products + Recycled materials − Pollutants)/Total input | |

| Sustainability index | Emergy sustainable development index (ESDI) | Emergy yield ratio (EYR)/Environment loading ratio (ELR) |

| Total emergy sustainable development index (TESDI) | Total emergy yield ratio (TEYR)/Environment loading ratio (ELR) | |

| Net emergy sustainable development index (NESDI) | Net emergy yield ratio (NEYR)/Environment loading ratio (ELR) |

| Items | Indexes | Pelletizing | Sintering | Puddling | Steel-Making | Rolling | Whole Process |

|---|---|---|---|---|---|---|---|

| Input index | Environment loading ratio (ELR) | 31,191.381 | 145,338.975 | 14.418 | 21.239 | 39.481 | 17.242 |

| Proportion of recycled materials used (PRM) | 0.014 | 0.061 | 0.090 | 0.098 | 0.024 | 0.093 | |

| Emergy investment ratio (EIR) | 0.177 | 0.038 | 1.588 | 4.876 | 39.481 | 0.251 | |

| Output index | Environmental impact rate (EnIR) | 0.001 | 0.001 | 0.000 | 0.000 | 0.000 | 0.001 |

| Product rate (PR) | 0.994 | 0.914 | 0.324 | 0.891 | 0.989 | 0.243 | |

| Input–output index | Emergy yield ratio (EYR) | 6.987 | 32.669 | 20.920 | 12.234 | 42.917 | 8.777 |

| Total emergy yield ratio (TEYR) | 7.020 | 35.708 | 64.647 | 13.735 | 43.397 | 21.992 | |

| Net emergy yield ratio (NEYR) | 7.013 | 35.668 | 64.640 | 13.732 | 43.395 | 21.982 | |

| Emergy input–output rate (EIOR) | 1.038 | 1.116 | 1.205 | 1.095 | 0.940 | 0.411 | |

| Total emergy input–output ratio (TEIOR) | 1.043 | 1.219 | 3.723 | 1.229 | 0.951 | 1.031 | |

| Net emergy input–output ratio (NEIOR) | 1.041 | 1.218 | 3.723 | 1.229 | 0.951 | 1.030 | |

| Sustainability index | Emergy sustainable development index (ESDI) | 0.000 | 0.000 | 1.451 | 0.576 | 1.087 | 0.509 |

| Total emergy sustainable development index (TESDI) | 0.000 | 587.384 | 4.484 | 0.647 | 1.099 | 1.276 | |

| Net emergy sustainable development index (NESDI) | 0.000 | 945.265 | 4.483 | 0.647 | 1.099 | 1.275 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, F.; Eneji, A.E.; Wu, Y. An Evaluation of Input–Output Value for Sustainability in a Chinese Steel Production System Based on Emergy Analysis. Sustainability 2018, 10, 4749. https://doi.org/10.3390/su10124749

Ma F, Eneji AE, Wu Y. An Evaluation of Input–Output Value for Sustainability in a Chinese Steel Production System Based on Emergy Analysis. Sustainability. 2018; 10(12):4749. https://doi.org/10.3390/su10124749

Chicago/Turabian StyleMa, Fengjiao, A. Egrinya Eneji, and Yanbin Wu. 2018. "An Evaluation of Input–Output Value for Sustainability in a Chinese Steel Production System Based on Emergy Analysis" Sustainability 10, no. 12: 4749. https://doi.org/10.3390/su10124749

APA StyleMa, F., Eneji, A. E., & Wu, Y. (2018). An Evaluation of Input–Output Value for Sustainability in a Chinese Steel Production System Based on Emergy Analysis. Sustainability, 10(12), 4749. https://doi.org/10.3390/su10124749