Assessment of Ejector-Expansion Heat Pump Systems with Low GWP Refrigerants for Electric Vehicles

Abstract

1. Introduction

2. System Description

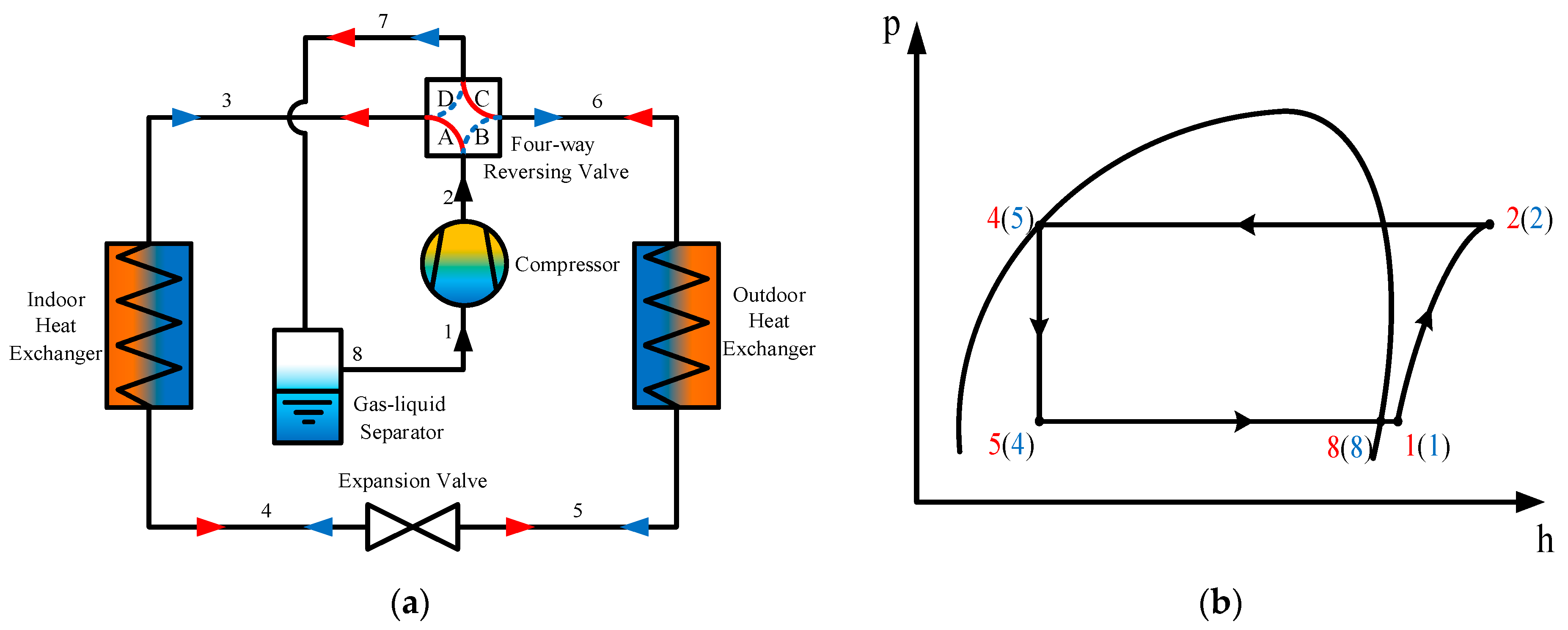

2.1. Conventional Basic Heat Pump System (CBHP)

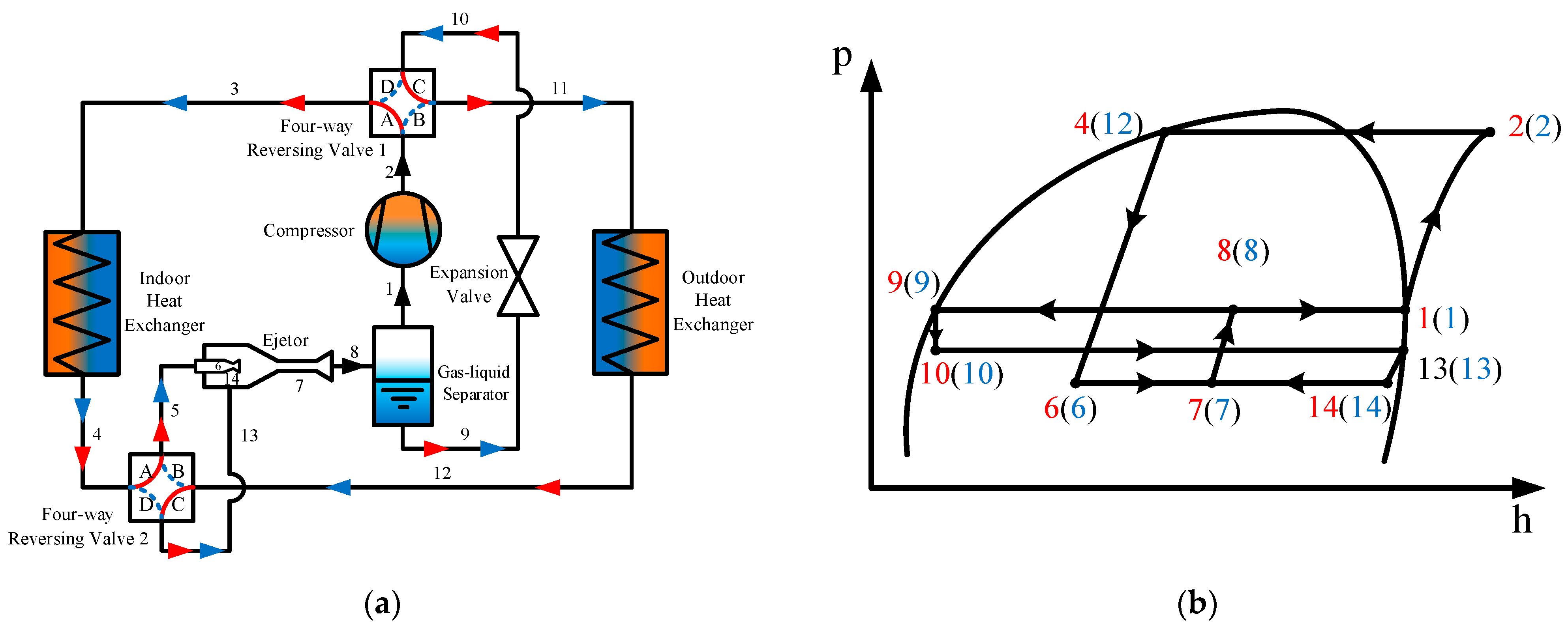

2.2. Vapor Injection Heat Pump System (VIHP)

2.3. Single-Evaporator Ejector-Expansion Heat Pump System (SEEHP)

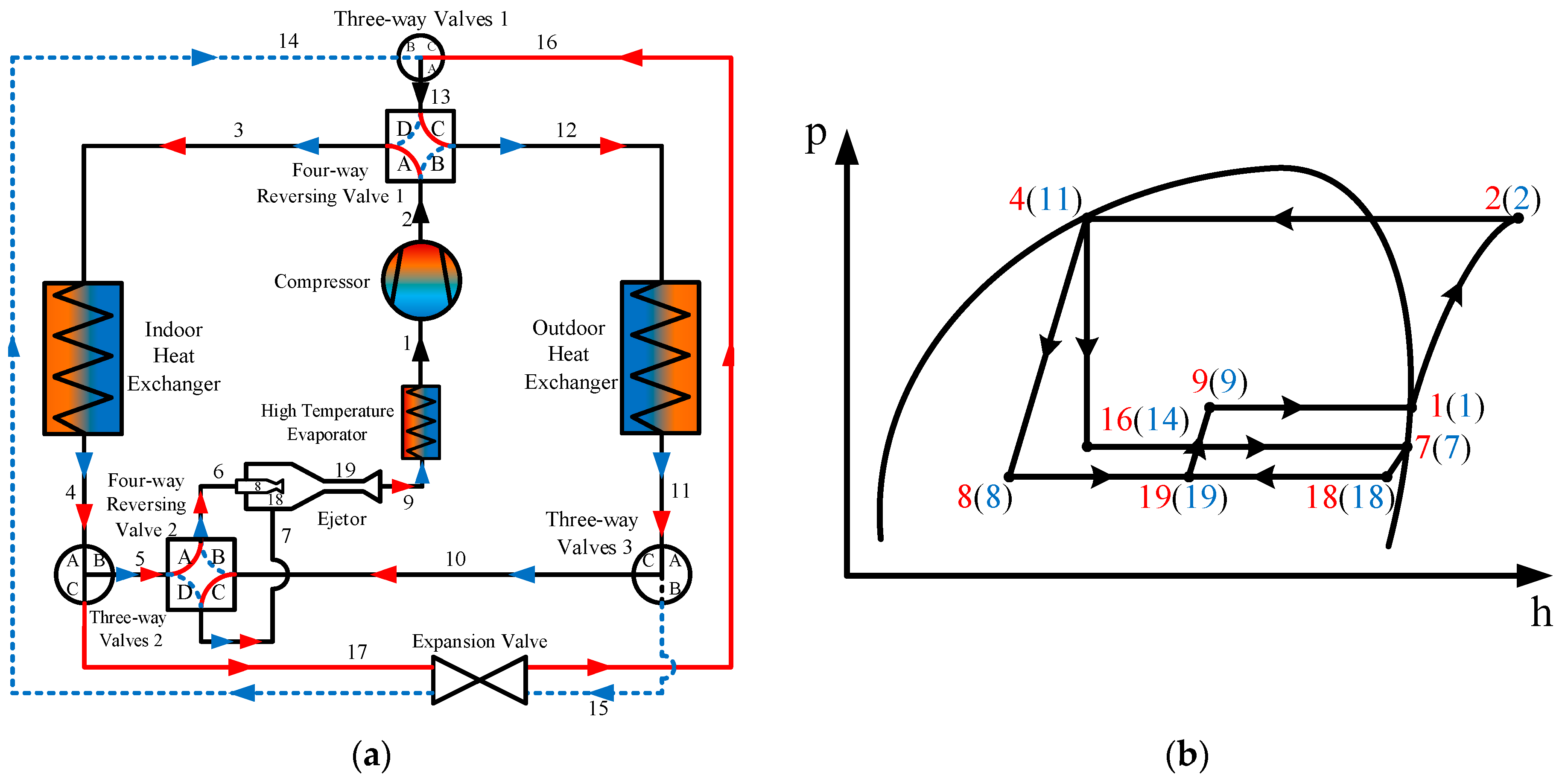

2.4. Dual-Evaporator Ejector-Expansion Heat Pump System (DEEHP)

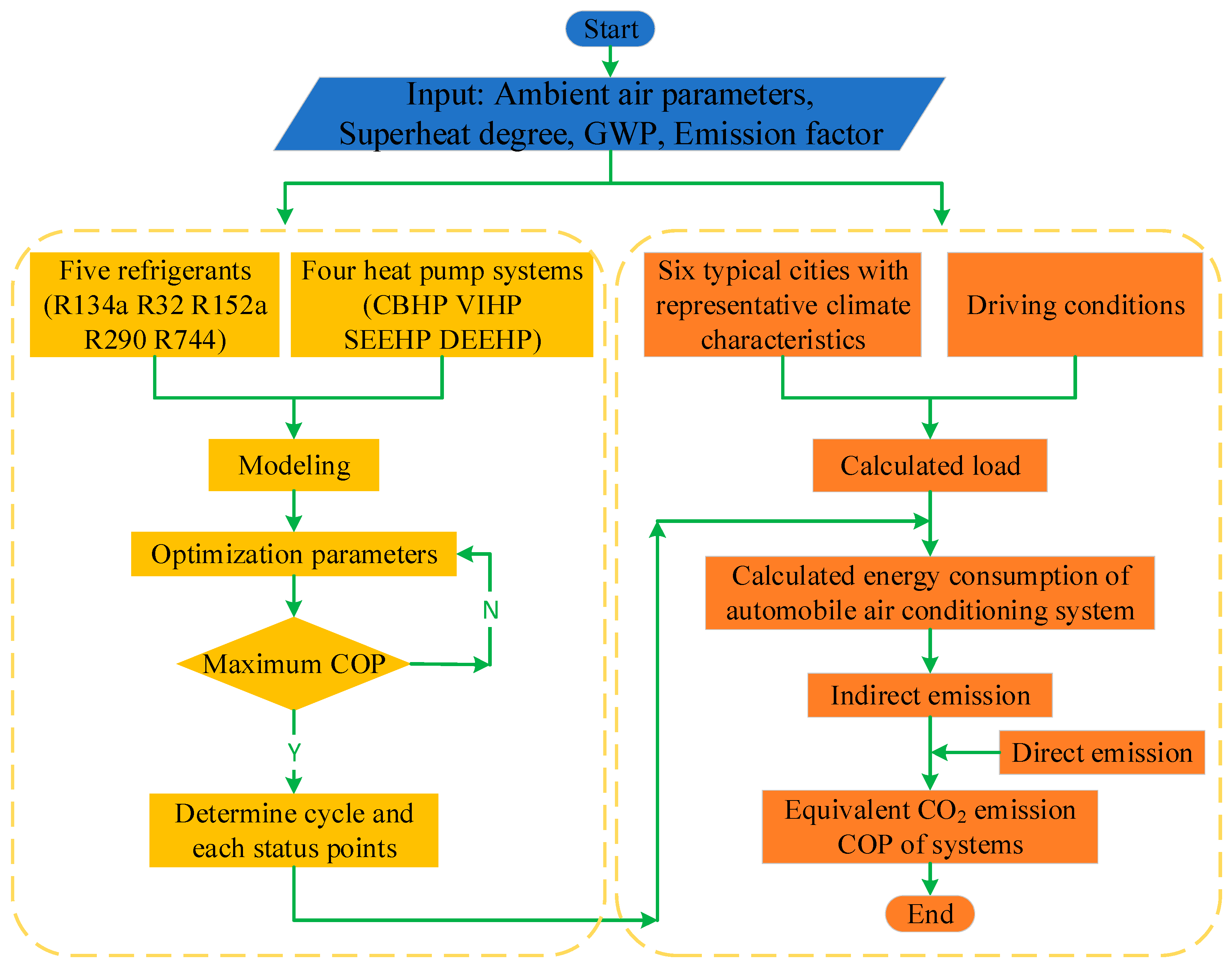

3. Assessment Methodology

3.1. The Investigated Refrigerants

3.2. Thermodynamic Model

- (1)

- The flow is one-dimensional and steady.

- (2)

- Heat exchanger and piping operate without appreciable pressure losses.

- (3)

- (4)

- All compression and expansion processes occur under adiabatic conditions.

- where and are the compressor inlet and outlet pressure, respectively.

- For CBHP system,

3.3. Energy Consumption Model

3.3.1. Selection of Working Conditions

3.3.2. Driving Conditions

3.3.3. Thermal Load Calculation

3.3.4. Operation Energy Consumption of Automobile Heat Pump System

- (1)

- At elevated ambient temperatures where the heat pump meets requirements, compressor power consumption is governed by the ratio of heating load to heating COP.

- (2)

- At depressed ambient temperatures with insufficient thermal output, supplemental heating via PTC devices becomes necessary. PTC heater operation reduces EV driving range by 30–65%, concurrently increasing production costs [57].

3.4. Assessment Model of CO2 Emission

3.4.1. Direct Emission

3.4.2. Indirect Emission

4. Results and Discussion

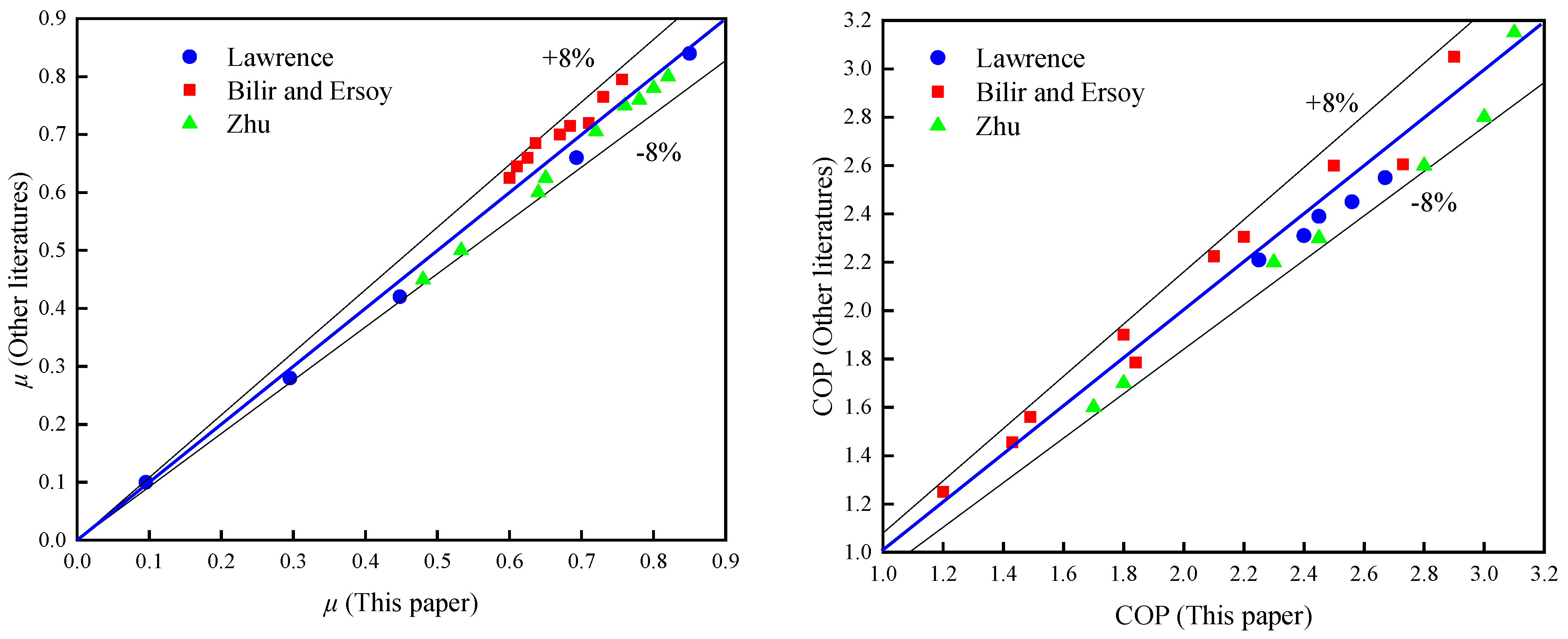

4.1. Validation of Thermodynamic Model

4.2. COP of Different Systems in Different Ambient Conditions

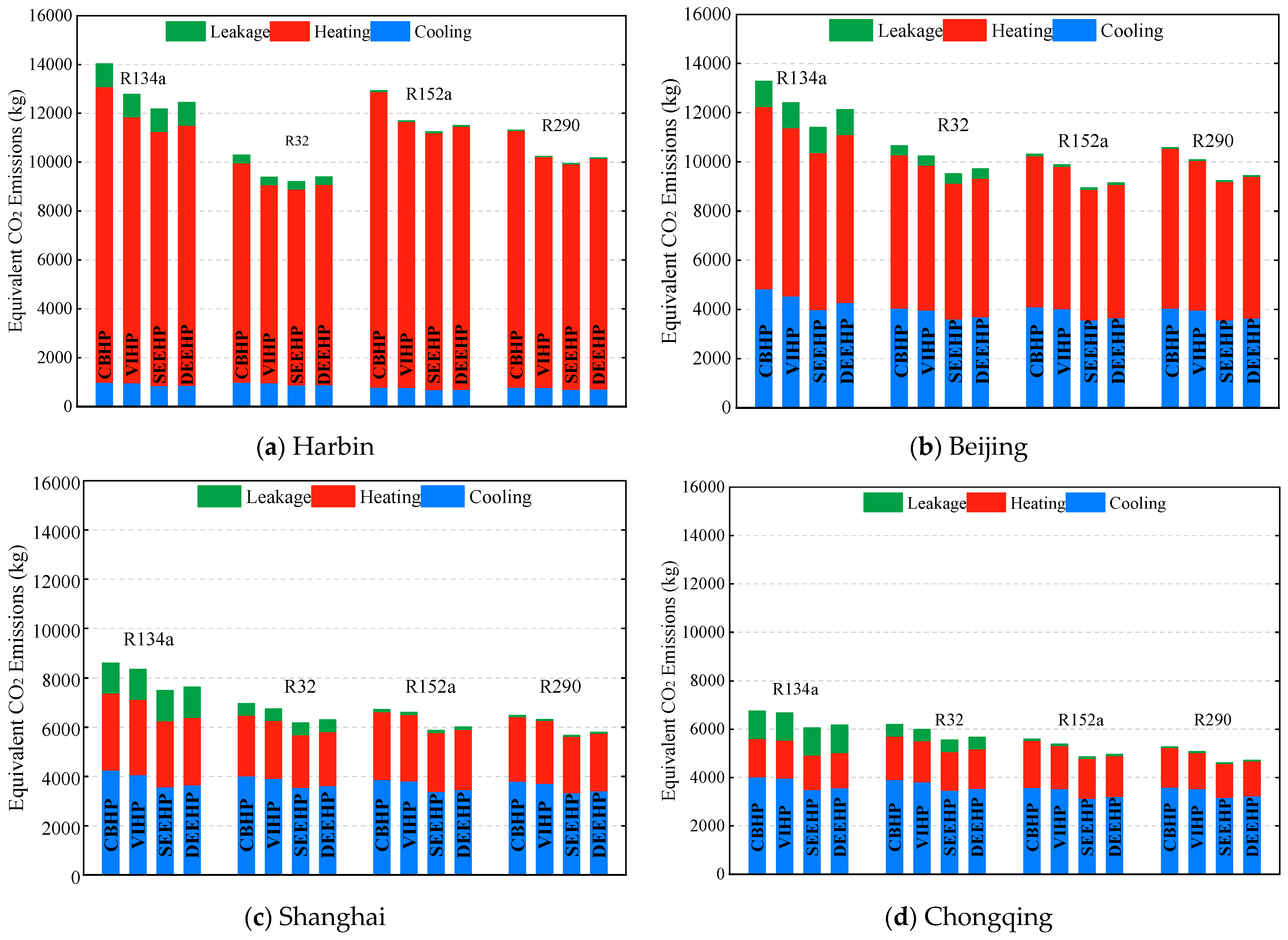

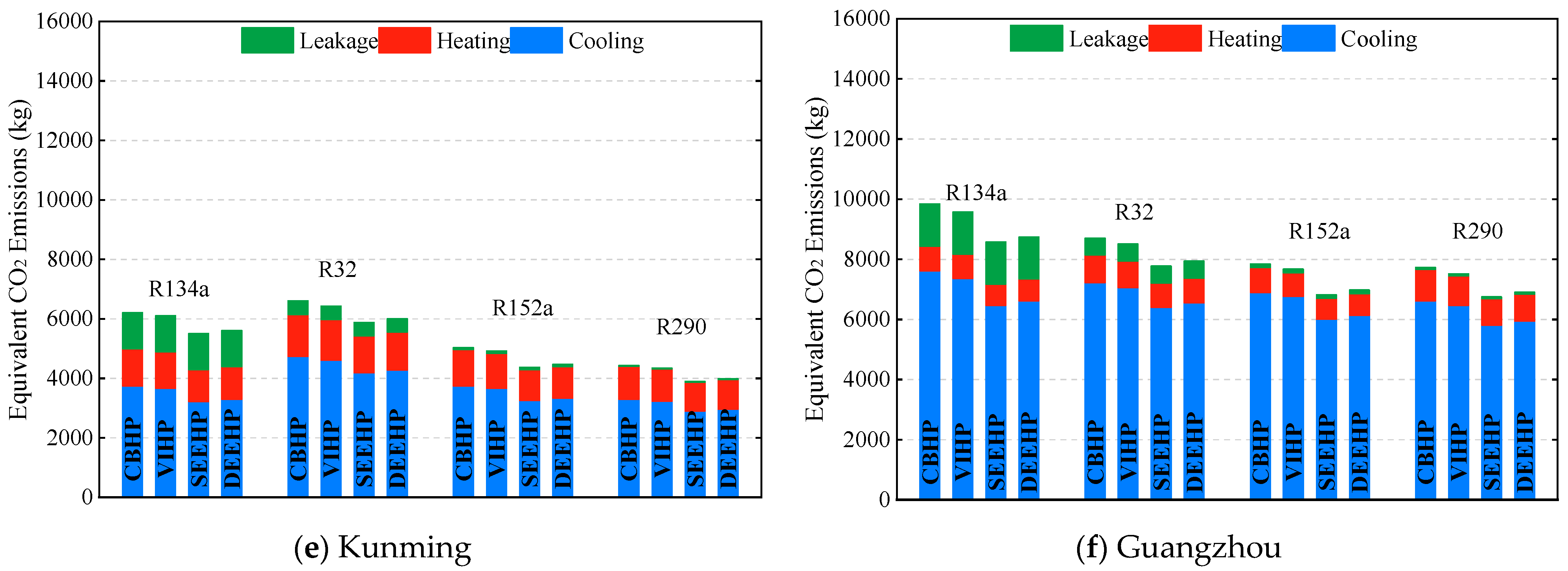

4.3. Equivalent CO2 Emissions Evaluation Results

5. Conclusions and Remarks

- (1)

- For all the refrigerants, the two ejector-expansion systems can enhance the COP effectively. The COP improvement of SEEHP and DEEHP can reach 10–30% and 7–15% compared with that of CBHP, respectively. For all the refrigerants, the COP improvements under moderate ambient conditions are significantly lower than those under higher or lower ambient conditions.

- (2)

- The ejector-expansion technique in EV heat pump systems can significantly lower the equivalent CO2 emission. The equivalent CO2 emission of the SEEHP decreases by about 9–14% and 2–10% compared with that of CBHP and VIHP, respectively. The equivalent CO2 emission of the DEEHP is reduced by about 2–11% compared with that of CBHP, and almost the same as that of VIHP.

- (3)

- R290 and R152a have relatively better performance in decreasing total equivalent CO2 emissions among the four working fluids due to their higher COP values. But the flammability risk is still the most troublesome problem in their application in EV heat pump systems. R32 is currently a viable alternative considering both CO2 emission reduction and flammability, but it has been on the list of HFCs to be cut in the Kigali Amendment.

- (4)

- The lifetime equivalent CO2 emission is affected significantly by the climate of the cities. The bitter-cold areas have the highest emissions, and warm areas have the lowest emissions. If bitter-cold areas are taken as the standard, the equivalent CO2 emissions decrease by approximately 2–21% cold areas, 21–57% in hot-summer/cold-winter areas, 32–61% in warm areas, and 5–39% in hot-summer/warm-winter areas, respectively. There is little difference among the areas for the SEEHP relative to CBHP in reducing CO2 emissions. But DEEHP is more remarkable in bitter-cold and cold areas. The equivalent CO2 emission of DEEHP relative to the corresponding CBHP decreases by about 9–11% in bitter-cold and cold areas, but this figure becomes 2–4% in other areas. These findings establish ejector-based systems as essential technologies for decarbonizing EV thermal management, particularly in extreme climates where conventional systems exhibit significant efficiency degradation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CBHP | Conventional basic heat pump system |

| COP | Coefficient of performance |

| DEEHP | Dual evaporator ejector-expansion heat pump system |

| ExV | Expansion valve |

| FLT | Flash tank |

| FwRV | Four-way reversing valve |

| GLS | Gas–liquid separator |

| GWP | Global warming potential |

| HFCs | Hydrofluorocarbons |

| HTE | High-temperature evaporator |

| IHE | Indoor heat exchanger |

| IPCC | Intergovernmental Panel on Climate Change |

| ODP | Ozone depletion potential |

| OHE | Outdoor heat exchanger |

| PTC | Positive Temperature Coefficient |

| SEEHP | Single evaporator ejector-expansion heat pump system |

| TEWI | Total Equivalent Warming Impact |

| TwV | Three-way valve |

| VIHP | Vapor injection heat pump system |

| Greek | |

| η | Efficiency |

| β | Emission factor |

| μ | Entrainment ratio of the ejector |

| Variables | |

| E | Energy consumption |

| h | Specific enthalpy |

| m | Mass flow rate |

| n | Lifetime in years |

| p | Pressure |

| Q | Heating or cooling load |

| T | Temperature |

| x | Dryness |

| Subscripts | |

| ad | Accidental leakage |

| cap | Capacity |

| com | compressor |

| cond | Condenser |

| EL | End-of-life leakage |

| eva | Evaporator |

| ft | Flash tank |

| gc | Gas cooler |

| ht | Heat transfer |

| im | Intermediate |

| in | Inlet |

| ma | Average annual ambient temperature |

| mot | Motive |

| mt | Maintenance leakage |

| out | Outlet |

| rt | Routine leakage |

| s | Isentropic |

| sr | Solar radiation |

| sub | Subcritical |

| suc | Suction |

| tot | Total |

| trans | Transcritical |

| ven | Ventilation or infiltration |

References

- Tie, S.F.; Tan, C.W. A Review of Energy Sources and Energy Management System in Electric Vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Feng, X.; Chang, L.; Chen, Y.; Wang, X. The Solutions to Electric Vehicle Air Conditioning Systems: A Review. Renew. Sustain. Energy Rev. 2018, 91, 443–463. [Google Scholar] [CrossRef]

- Lee, J.T.; Kwon, S.; Lim, Y.; Chon, M.S.; Kim, D. Effect of Air-Conditioning on Driving Range of Electric Vehicle for Various Driving Modes; SAE Technical Paper 2013-01-0040; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Farrington, R.; Rugh, J. Impact of Vehicle Air-Conditioning on Fuel Economy, Tailpipe Emissions, and Electric Vehicle Range: Preprint. Available online: https://media.runsular.com/me/6164bb0f8ba40ffb.pdf (accessed on 1 August 2015).

- Zhang, Z.; Li, W.; Zhang, C.; Chen, J. Climate Control Loads Prediction of Electric Vehicles. Appl. Therm. Eng. 2017, 110, 1183–1188. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, C.; Chen, X.; Zhang, C.; Chen, J. Annual Energy Consumption of Electric Vehicle Air Conditioning in China. Appl. Therm. Eng. 2017, 125, 567–574. [Google Scholar] [CrossRef]

- Peng, B.; Zhang, Y.; Zhang, P.; Ullah, H. Recent Advances on the Electric Vehicle Heat Pump Air Conditioning System. MENG 2021, 14, 354–365. [Google Scholar] [CrossRef]

- Li, K.; Luo, S.; Fan, L.; Hu, S.; Zhou, X.; Tu, R.; Zhang, H.; Jin, X.; Zhao, X.; Su, L. Investigation on the Performance and Characteristics of a Heat Pump System for Electric Vehicles under Extreme Temperature Conditions. Case Stud. Therm. Eng. 2021, 27, 101308. [Google Scholar] [CrossRef]

- Park, W.Y.; Shah, N.; Vine, E.; Blake, P.; Holuj, B.; Kim, J.H.; Kim, D.H. Ensuring the Climate Benefits of the Montreal Protocol: Global Governance Architecture for Cooling Efficiency and Alternative Refrigerants. Energy Res. Soc. Sci. 2021, 76, 102068. [Google Scholar] [CrossRef]

- Dai, B.; Qi, H.; Dou, W.; Liu, S.; Zhong, D.; Yang, H.; Nian, V.; Hao, Y. Life Cycle Energy, Emissions and Cost Evaluation of CO2 Air Source Heat Pump System to Replace Traditional Heating Methods for Residential Heating in China: System Configurations. Energy Convers. Manag. 2020, 218, 112954. [Google Scholar] [CrossRef]

- Direk, M.; Mert, M.S.; Soylu, E.; Yüksel, F. Experimental Investigation of an Automotive Air Conditioning System Using R444A and R152a Refrigerants as Alternatives of R134a. SV-JME 2019, 65, 212–218. [Google Scholar] [CrossRef]

- Yu, B.; Ouyang, H.; Shi, J.; Liu, W.; Chen, J. Evaluation of Low-GWP and Mildly Flammable Mixtures as New Alternatives for R410A in Air-Conditioning and Heat Pump System. Int. J. Refrig. 2021, 121, 95–104. [Google Scholar] [CrossRef]

- Yu, B.; Ouyang, H.; Shi, J.; Guo, Z.; Chen, J. Experimental Evaluation of Cycle Performance for New-Developed Refrigerants in the Electric Vehicle Heat Pump Systems. Int. J. Refrig. 2021, 129, 118–127. [Google Scholar] [CrossRef]

- Ning, Q.; He, G.; Xiong, G.; Sun, W.; Song, H. Operation Strategy and Performance Investigation of a High-Efficiency Multifunctional Two-Stage Vapor Compression Heat Pump Air Conditioning System for Electric Vehicles in Severe Cold Regions. Sustain. Energy Technol. Assess. 2021, 48, 101617. [Google Scholar] [CrossRef]

- Song, X.; Lu, D.; Lei, Q.; Cai, Y.; Wang, D.; Shi, J.; Chen, J. Experimental Study on Heating Performance of a CO2 Heat Pump System for an Electric Bus. Appl. Therm. Eng. 2021, 190, 116789. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Y.; Jia, S.; Zhang, X.; Huang, L. Experimental Study of R744 Heat Pump System for Electric Vehicle Application. Appl. Therm. Eng. 2021, 183, 116191. [Google Scholar] [CrossRef]

- Wang, A.; Cao, F.; Yin, X.; Jia, F.; Fang, J.; Wang, X. Pseudo-Optimal Discharge Pressure Analysis of Transcritical CO2 Electric Vehicle Heat Pumps Due to Temperature Glide. Appl. Therm. Eng. 2022, 215, 118856. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, X.; Jing, J. Research on the Electric Vehicle Heat Pump Air Conditioning System Based on R290 Refrigerant. Energy Rep. 2022, 8, 447–455. [Google Scholar] [CrossRef]

- Khalid Shaker Al-Sayyab, A.; Navarro-Esbrí, J.; Barragán-Cervera, A.; Mota-Babiloni, A. Heating and cooling challenges for electric vehicles: A comprehensive experimental study. Therm. Sci. Eng. Prog. 2024, 53, 102687. [Google Scholar] [CrossRef]

- Kwon, S.; Lee, D.; Chung, J.Y.; Maeng, H.; Kim, Y. Performance comparison of a direct heat pump using R1234yf and indirect heat pumps using R1234yf and R290 designed for cabin heating of electric vehicles. Energy 2024, 297, 131311. [Google Scholar] [CrossRef]

- Zhao, J.; Xiong, S.; Luo, Z.; Zhang, Y.; Yakubu, A.U.; Ye, X.; Wen, M.; Jiang, Q.; Xia, C. Study on performance characteristics of a novel R290-based integrated thermal management system for electric vehicles. Appl. Therm. Eng. 2025, 278, 127224. [Google Scholar] [CrossRef]

- Qin, F.; Xue, Q.; Albarracin Velez, G.M.; Zhang, G.; Zou, H.; Tian, C. Experimental Investigation on Heating Performance of Heat Pump for Electric Vehicles at −20 °C Ambient Temperature. Energy Convers. Manag. 2015, 102, 39–49. [Google Scholar] [CrossRef]

- Tang, J.; Zuo, C. Structural Analysis of Heat Pump Scroll Compressor for Electric Automobile Air Conditioning. J. Refrig. 2014, 35, 54–58. [Google Scholar]

- Lai, J.-C.; Luo, W.-J.; Wu, J.-Y.; Faridah, D.; Lin, C.-M.; Fasya, F.R.; Nuriyadi, M.; Ng, W.-B. Performance Analysis of Single-Stage Air Source Heat Pump Utilizing Indirect Vapor Injection Design. Adv. Mech. Eng. 2018, 10, 1–12. [Google Scholar] [CrossRef]

- Luo, W.-J.; Lai, J.-C.; Hsieh, M.-C.; Huang, I.-H. Performance Analysis of High-Temperature Two-Stage Compression Heat Pump with Vapor Injection Dynamic Control. Sens. Mater. 2020, 32, 4259–4275. [Google Scholar] [CrossRef]

- Li, W.; Liu, R.; Liu, Q.; Liu, Y.; Wang, D.; Xia, S.; Shi, J.; Chen, J. Upstream and Downstream Injection Effects on R134a Economized Vapor Injection Heat Pump System at Low Temperatures for Electric Vehicles. Int. J. Refrig. 2020, 120, 1–11. [Google Scholar] [CrossRef]

- Xu, Q.; Wu, J.; Guo, Z.; Xu, G.; Chen, Y.; Yang, H.; Xue, X. Experimental Investigation on Control Strategy of Electric Vehicle Heat Pump with Refrigerant Injection at Low Temperature. Int. J. Refrig. 2022, 138, 40–51. [Google Scholar] [CrossRef]

- Li, W.; Liu, R.; Liu, Y.; Wang, D.; Shi, J.; Chen, J. Performance Evaluation of R1234yf Heat Pump System for an Electric Vehicle in Cold Climate. Int. J. Refrig. 2020, 115, 117–125. [Google Scholar] [CrossRef]

- Peng, X.; Wang, D.; Wang, G.; Yang, Y.; Xiang, S. Numerical Investigation on the Heating Performance of a Transcritical CO2 Vapor-Injection Heat Pump System. Appl. Therm. Eng. 2020, 166, 114656. [Google Scholar] [CrossRef]

- Lee, S.; Chung, Y.; Jeong, Y.; Kim, M.S. Experimental Study on an Electric Vehicle Heat Pump System with Multi-Level Waste Heat Recovery Using a Vapor Injection Technique at Low Ambient Temperatures. Energy Convers. Manag. 2022, 267, 115935. [Google Scholar] [CrossRef]

- Sumeru, K.; Nasution, H.; Ani, F.N. A Review on Two-Phase Ejector as an Expansion Device in Vapor Compression Refrigeration Cycle. Renew. Sustain. Energy Rev. 2012, 16, 4927–4937. [Google Scholar] [CrossRef]

- Gullo, P.; Kærn, M.R.; Haida, M.; Smolka, J.; Elbel, S. A Review on Current Status of Capacity Control Techniques for Two-Phase Ejectors. Int. J. Refrig. 2020, 119, 64–79. [Google Scholar] [CrossRef]

- Zhang, Z.; Feng, X.; Tian, D.; Yang, J.; Chang, L. Progress in Ejector-Expansion Vapor Compression Refrigeration and Heat Pump Systems. Energy Convers. Manag. 2020, 207, 112529. [Google Scholar] [CrossRef]

- Pérez, B.P.; Carrillo, J.A.E.; de La Flor, F.J.S.; Lissén, J.M.S.; Navarro, A.M. Thermoeconomic Analysis of CO2 Ejector-Expansion Refrigeration Cycle (EERC) for Low-Temperature Refrigeration in Warm Climates. Appl. Therm. Eng. 2021, 188, 116613. [Google Scholar] [CrossRef]

- Ameur, K.; Aidoun, Z. Two-Phase Ejector Enhanced Carbon Dioxide Transcritical Heat Pump for Cold Climate. Energy Convers. Manag. 2021, 243, 114421. [Google Scholar] [CrossRef]

- Elbarghthi, A.F.A.; Dvorak, V.; Hafner, A.; Banasiak, K. The Potential Impact of the Small-Scale Ejector on the R744 Transcritical Refrigeration System. Energy Convers. Manag. 2021, 249, 114860. [Google Scholar] [CrossRef]

- Gao, Y.; He, G.; Cai, D.; Fan, M. Performance Evaluation of a Modified R290 Dual-Evaporator Refrigeration Cycle Using Two-Phase Ejector as Expansion Device. Energy 2020, 212, 118614. [Google Scholar] [CrossRef]

- Cao, X.; Liang, X.; Shao, L.; Zhang, C. Performance Analysis of an Ejector-Assisted Two-Stage Evaporation Single-Stage Vapor-Compression Cycle. Appl. Therm. Eng. 2022, 205, 118005. [Google Scholar] [CrossRef]

- Qin, X.; Zhang, Y.; Wang, D.; Chen, J. System Development and Simulation Investigation on a Novel Compression/Ejection Transcritical CO2 Heat Pump System for Simultaneous Cooling and Heating. Energy Convers. Manag. 2022, 259, 115579. [Google Scholar] [CrossRef]

- Oshitani, H.; Yamanaka, Y.; Takeuchi, H.; Kusano, K.; Ikegami, M.; Takano, Y.; Ishizaka, N.; Sugiura, T. Vapor Compression Cycle Having Ejector. U.S. Patent 7254961-B2, 13 August 2007. [Google Scholar]

- Talley, E. Hybrid Air Conditioning Systems Overview. Presented at the Spring 2011 ICAIA Conference, Hong Kong, China, 16–18 March 2011. [Google Scholar]

- Brodie, B.R.; Takano, Y.; Gocho, M. Evaporator with Integrated Ejector for Automotive Cabin Cooling; SAE Technical Paper 2012-01-1048; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Boumaraf, L.; Haberschill, P.; Lallemand, A. Investigation of a Novel Ejector Expansion Refrigeration System Using the Working Fluid R134a and Its Potential Substitute R1234yf. Int. J. Refrig. 2014, 45, 148–159. [Google Scholar] [CrossRef]

- Ünal, Ş. Determination of the Ejector Dimensions of a Bus Air-Conditioning System Using Analytical and Numerical Methods. Appl. Therm. Eng. 2015, 90, 110–119. [Google Scholar] [CrossRef]

- Ünal, Ş.; Erdinç, M.T.; Kutlu, Ç. Optimal Thermodynamic Parameters of Two-Phase Ejector Refrigeration System for Buses. Appl. Therm. Eng. 2017, 124, 1354–1367. [Google Scholar] [CrossRef]

- Zou, H.; Yang, T.; Tang, M.; Tian, C.; Butrymowicz, D. Ejector Optimization and Performance Analysis of Electric Vehicle CO2 Heat Pump with Dual Ejectors. Energy 2022, 239, 122452. [Google Scholar] [CrossRef]

- Yang, T.; Yang, Y.; Zou, H.; Tian, C.; Butrymowicz, D. Comprehensive performance evaluation on a transcritical CO2 ejector-expansion heat pump system. Appl. Therm. Eng. 2024, 254, 123697. [Google Scholar] [CrossRef]

- Ren, Z.; Song, Y.; Yin, X.; Cao, F.; Wang, Y. Energetic and driving range investigation of the ejector enhanced CO2 thermal management system used in electric vehicles. Energy 2025, 324, 135702. [Google Scholar] [CrossRef]

- Zhang, Z.; Tong, L.; Chang, L.; Chen, Y.; Wang, X. Energetic and Exergetic Analysis of an Ejector-Expansion Refrigeration Cycle Using the Working Fluid R32. Entropy 2015, 17, 4744–4761. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Z.; Yang, M.; Chang, L.; Li, Y.; Zhang, Z. Parametric Effects of Mixing Channel Geometry on Entrainment Characteristics of Ejector in R410A Heat Pump Systems. Processes 2025, 13, 1933. [Google Scholar] [CrossRef]

- Deng, M.; Ma, R.; Lu, F.; Nie, Y.; Li, P.; Ding, X.; Yuan, Y.; Shan, M.; Yang, X. Techno-Economic Performances of Clean Heating Solutions to Replace Raw Coal for Heating in Northern Rural China. Energy Build. 2021, 240, 110881. [Google Scholar] [CrossRef]

- Bilir, N.; Ersoy, H.K. Performance Improvement of the Vapour Compression Refrigeration Cycle by a Two-Phase Constant Area Ejector. Int. J. Energy Res. 2009, 33, 469–480. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, L. Effect of Suction Nozzle Pressure Drop on the Performance of an Ejector-Expansion Transcritical CO2 Refrigeration Cycle. Entropy 2014, 16, 4309–4321. [Google Scholar] [CrossRef]

- Brunin, O.; Feidt, M.; Hivet, B. Comparison of the Working Domains of Some Compression Heat Pumps and a Compression-Absorption Heat Pump. Int. J. Refrig. 1997, 20, 308–318. [Google Scholar] [CrossRef]

- Yang, Y. Heating Carbon Emission and System Improvement for Rural Building of Beijing. Master’s Thesis, China Academy of Building Research, Beijing, China, 2019. [Google Scholar]

- Wang, A.; Yin, X.; Fang, J.; Cao, F. Refrigerant distributions and dynamic migration characteristics of the transcritical CO2 air conditioning system. Int. J. Refrig. 2021, 130, 233–241. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Cho, C.-W.; Won, J.-P.; Park, Y.C.; Lee, M.-Y. Performance Characteristics of Mobile Heat Pump for a Large Passenger Electric Vehicle. Appl. Therm. Eng. 2013, 50, 660–669. [Google Scholar] [CrossRef]

- Neveu, D.; Claeys, J.P. Thermal Management of Electrical Vehicle—“VEGA/THOP” project. In Proceedings of the SAE Convergence 2010, Warrendale, PE, USA, 10 November 2010. [Google Scholar]

- Wu, J.; Zhou, G.; Wang, M. A Comprehensive Assessment of Refrigerants for Cabin Heating and Cooling on Electric Vehicles. Appl. Therm. Eng. 2020, 174, 115258. [Google Scholar] [CrossRef]

- Makhnatch, P.; Khodabandeh, R. The Role of Environmental Metrics (GWP, TEWI, LCCP) in the Selection of Low GWP Refrigerant. Energy Procedia 2014, 61, 2460–2463. [Google Scholar] [CrossRef]

- Zhang, Z.; Pan, L.; Wang, T.; Chen, J. Life Cycle Climate Performance Assessment of A/C System in Electric Vehicles. Automot. Eng. 2017, 39, 961–967. [Google Scholar] [CrossRef]

- Papasavva, S.; Hill, W.R.; Andersen, S.O. GREEN-MAC-LCCP: A Tool for Assessing the Life Cycle Climate Performance of MAC Systems. Environ. Sci. Technol. 2010, 44, 7666–7672. [Google Scholar] [CrossRef]

- Llopis, R.; Calleja-Anta, D.; Maiorino, A.; Nebot-Andrés, L.; Sánchez, D.; Cabello, R. TEWI Analysis of a Stand-Alone Refrigeration System Using Low-GWP Fluids with Leakage Ratio Consideration. Int. J. Refrig. 2020, 118, 279–289. [Google Scholar] [CrossRef]

- Zhang, X. Study on the Performance of a Heat Pump System Using R744-Based Natural Binary Mixture. J. Zhengzhou Univ. (Eng. Sci.) 2015, 36, P44–P48. [Google Scholar]

- Lawrence, N.; Elbel, S. Experimental Investigation of a Two-Phase Ejector Cycle Suitable for Use with Low-Pressure Refrigerants R134a and R1234yf. Int. J. Refrig. 2014, 38, 310–322. [Google Scholar] [CrossRef]

- Bilir Sag, N.; Ersoy, H.K. Experimental Investigation on Motive Nozzle Throat Diameter for an Ejector Expansion Refrigeration System. Energy Convers. Manag. 2016, 124, 1–12. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, C.; Zhang, F.; Jiang, P.-X. Comprehensive Experimental Study on a Transcritical CO2 Ejector-Expansion Refrigeration System. Energy Convers. Manag. 2017, 151, 98–106. [Google Scholar] [CrossRef]

| Refrigerants | R134a | R152a | R290 | R32 |

|---|---|---|---|---|

| Chemical formula | CF3CH2F | CHF2CH3 | CH3CH2CH3 | CH2F2 |

| Molecular mass (g/mol) | 102.03 | 66.05 | 44.1 | 52.02 |

| Critical temperature (°C) | 101.1 | 113.3 | 96.7 | 78.1 |

| Critical pressure (MPa) | 4.07 | 4.52 | 4.24 | 5.8 |

| Normal boiling point (°C) | −26.1 | −25 | −42.2 | −51.6 |

| GWP (100 years) | 1430 | 124 | 3 | 675 |

| Safety | A1 | A2 | A3 | A2L |

| Lower flammability level (LFL) (% volume in air) | None | 3.9% | 2.2% | 14% |

| City | Harbin | Beijing | Shanghai | Chongqing | Kunming | Guangzhou |

|---|---|---|---|---|---|---|

| Average temperature (°C) | 5.0 | 13.0 | 16.7 | 18.4 | 15.4 | 22.5 |

| Runtime (h/y) | 336 | 675 | 664 | 493 | 365 | 631 |

| Population (ten thousand) | 1066.5 | 2154 | 2424 | 3102 | 667.7 | 1530.6 |

| Speed (km∙h−1) | 0~10 | 10~25 | 25~50 | 50~75 | 75~100 | >100 |

|---|---|---|---|---|---|---|

| Percentage | 30.2% | 21.3% | 27.1% | 15.1% | 4.3% | 2% |

| Components | Heat Transfer Area (m2) |

|---|---|

| Rear windshield | 0.88 |

| Front windshield | 1.21 |

| Side windows | 3.04 |

| Roof | 1.56 |

| Floor | 2.12 |

| Ambient Temperature (°C) | Harbin | Beijing | Shanghai | Chongqing | Kunming | Guangzhou | |

|---|---|---|---|---|---|---|---|

| C1 | −25~−15 | 2.26 | / | / | / | / | / |

| C2 | −15~−5 | 1.63 | / | / | / | / | / |

| C3 | −5~5 | 1.38 | 1.47 | 1.39 | / | 1.34 | / |

| C4 | 5~15 | 0.95 | 1.03 | 0.97 | 0.82 | 0.89 | 0.78 |

| C5 | 15~25 | 2.43 | 2.72 | 2.46 | 2.28 | 2.35 | 2.25 |

| C6 | 25~35 | / | 3.45 | 3.2 | 2.95 | 3.09 | 2.87 |

| Ambient Temperature (°C) | Air Conditioning Mode | Cabin Supply Temperature (°C) | Evaporation Temperature (°C) | Condensation Temperature (°C) | |

|---|---|---|---|---|---|

| C1 | −25~−15 | Heating | 56 | −30 | 70 |

| C2 | −15~−5 | Heating | 46 | −20 | 60 |

| C3 | −5~5 | Heating | 38 | −10 | 55 |

| C4 | 5~15 | Heating | 28 | 0 | 45 |

| C5 | 15~25 | Refrigeration | 15 | 5 | 40 |

| C6 | 25~35 | Refrigeration | 7 | −5 | 50 |

| Region | North | Northeast | East | Central | Northwest | Southern |

|---|---|---|---|---|---|---|

| Emission factor | 0.9419 | 1.0826 | 0.7921 | 0.8587 | 0.8922 | 0.8042 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Wang, Y.; Zhou, Z.; Guan, Z.; Chang, L.; Yang, M. Assessment of Ejector-Expansion Heat Pump Systems with Low GWP Refrigerants for Electric Vehicles. World Electr. Veh. J. 2025, 16, 505. https://doi.org/10.3390/wevj16090505

Zhang Z, Wang Y, Zhou Z, Guan Z, Chang L, Yang M. Assessment of Ejector-Expansion Heat Pump Systems with Low GWP Refrigerants for Electric Vehicles. World Electric Vehicle Journal. 2025; 16(9):505. https://doi.org/10.3390/wevj16090505

Chicago/Turabian StyleZhang, Zhenying, Yuying Wang, Zhengdao Zhou, Zheng Guan, Li Chang, and Meiyuan Yang. 2025. "Assessment of Ejector-Expansion Heat Pump Systems with Low GWP Refrigerants for Electric Vehicles" World Electric Vehicle Journal 16, no. 9: 505. https://doi.org/10.3390/wevj16090505

APA StyleZhang, Z., Wang, Y., Zhou, Z., Guan, Z., Chang, L., & Yang, M. (2025). Assessment of Ejector-Expansion Heat Pump Systems with Low GWP Refrigerants for Electric Vehicles. World Electric Vehicle Journal, 16(9), 505. https://doi.org/10.3390/wevj16090505