Data-Driven Predictive Modeling for Investigating the Impact of Gear Manufacturing Parameters on Noise Levels in Electric Vehicle Drivetrains

Abstract

1. Introduction

2. Gear Noise Mechanisms and Manufacturing-Related Factors

Strategies for Gear Noise Reduction

| Author(s) & Year | Focus Area | Methodology/Tools | Key Findings |

|---|---|---|---|

| Houser et al. (2001) [5] | Frictional noise reduction | Experimental finishing methods | Superfinishing and optimized lubricants reduce frictional gear noise |

| Henriksson (2020) [7] | TE in lightweight gears | Nonlinear Multibody Dynamics (MBD) simulation, validation | Lightweight gears more sensitive to TE fluctuations |

| Wang et al. (2023) [8] | TE prediction in lightweight designs | Nonlinear multibody approach | Gear design must consider increased TE due to reduced mass |

| Lee & Park (2023) [6] | Gear whine prediction via ML | XGBoost, regression vs. ensemble methods | ML outperformed traditional regression in gear noise prediction |

| Choi et al. (2023) [12] | Macrogeometry impact on gear performance | Simulation & sensitivity analysis | Small macrogeometry errors can amplify excitation forces |

| Tian et al. (2024) [11] | Gear finishing techniques | Literature review of honing/grinding | Modern finishing reduces tonal noise via surface smoothing |

| Rajkumar et al. (2025) [14] | AI-Digital Twin for NVH components | ML + Digital Twin architecture | Enables dynamic tolerance adaptation for gear NVH |

| Zhong et al. (2023) [15] | Predictive maintenance with Digital Twin | Review of Digital Twin applications in manufacturing | Real-time deviation monitoring enhances prediction accuracy |

| Sun et al. (2024) [16] | Acoustic prediction under data imbalance | Multi-kernel SVR + regularization | Robust forecasting possible despite skewed data distributions |

| Gleason Corp. (2023) [17] | Inline gear noise inspection | GRSL system (rolling + laser) | Enables 100% inspection and predictive NVH evaluation |

| Scania (2017) [18] | Acoustic anomaly detection in engines | Deep learning anomaly detection | Augmentation + semi-supervised ML handles limited fault data |

| Chen & Xu (2010) [13] | Statistical modeling of gear noise | Regression analysis | Early quantitative attempts at noise estimation from gear geometry |

| Masuda et al. (1986) [10] | Tooth flank finish effect | Experimental vibration and finish comparison | Finishing method strongly affects noise generation |

| Aurich (2023) [19] | Electromobility gear noise challenges | Review of gear quality and manufacturing tech | Emphasizes e-mobility’s demand for quieter, high-quality gears |

| H2020 ECO-Drive (2021) [20] | System-level NVH optimization | EU-funded research project | Proposes integrated noise control across drivetrain system |

3. Industrial Measurement Techniques and Noise Inspection Approaches

3.1. Industry Examples of Machine Learning-Based Noise Prediction

3.2. Machine Learning in Quality Control and Predictive Maintenance

4. Data-Driven Predictive Modeling Techniques and Best Practices

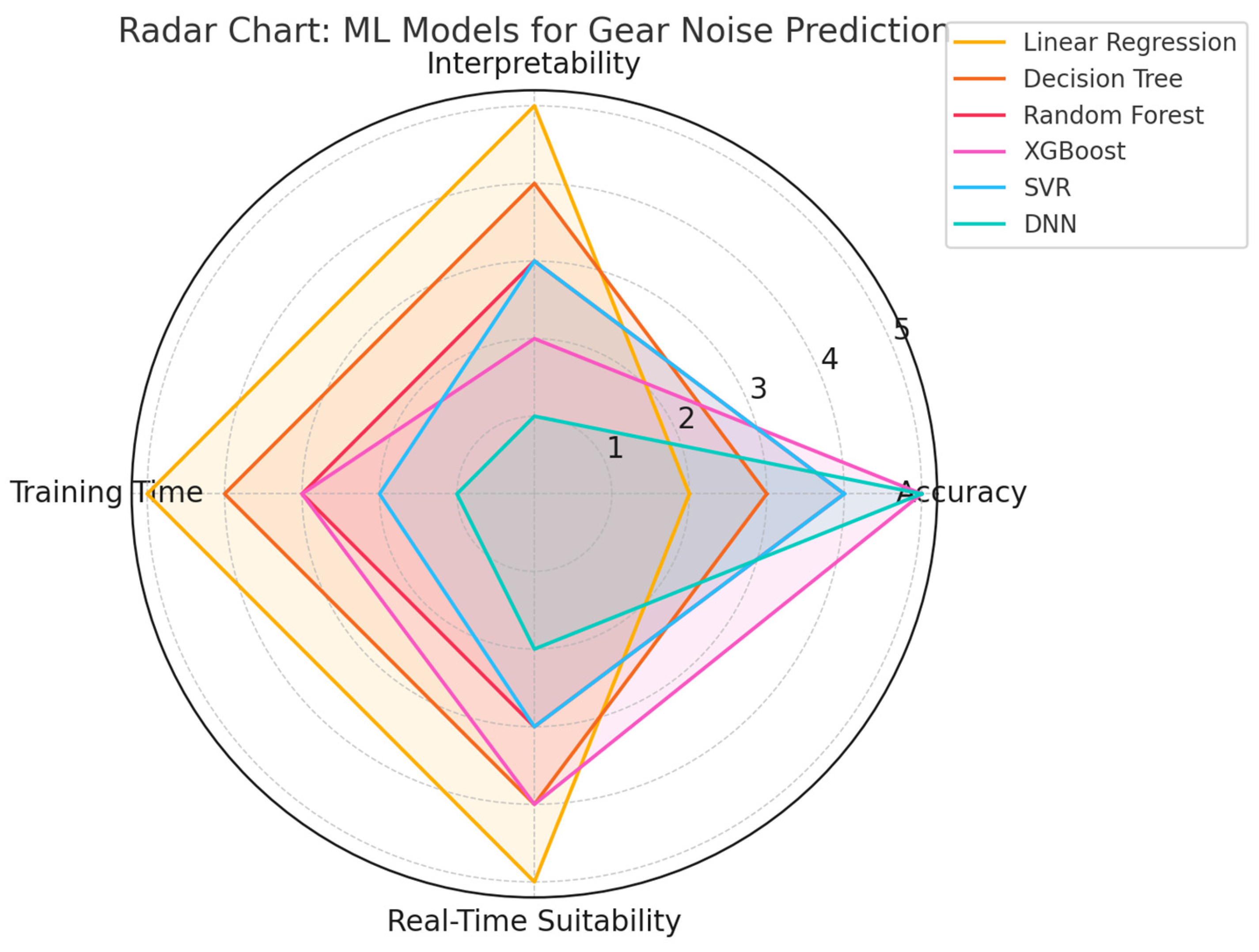

4.1. Applicable Machine Learning Models (Algorithms)

- Linear Regression: A baseline model assuming that noise levels are a linear combination of manufacturing parameters. While simple and interpretable, it struggles with nonlinear dependencies, which are common in real-world noise phenomena. Linear regression is often used as a benchmark against which more advanced models are evaluated.

- Decision Trees: A hierarchical model that splits data into progressively smaller subsets based on threshold conditions. Each terminal node represents a predicted noise level or category. Decision trees can capture nonlinear relationships and are easy to interpret, but they tend to overfit if not properly constrained.

- Random Forest: An ensemble method that constructs multiple decision trees on random data subsets and aggregates their outputs. This approach reduces variance and improves stability compared to a single decision tree. Random Forest is well-suited for industrial datasets with many input variables, automatically ranking feature importance. However, interpretability is lower than that of a single tree.

- Gradient Boosting (e.g., XGBoost, LightGBM): Another ensemble method that iteratively improves predictions by training new models to correct the errors of previous ones. These models have demonstrated high accuracy in industrial datasets, particularly for gear noise prediction. Studies have shown that XGBoost outperforms linear regression in predicting gear noise.

- Deep neural networks (DNNs): Multilayer artificial neural networks capable of learning complex patterns. Used in regression settings, deep neural networks (e.g., Generalized Regression Neural Networks, GRNNs) can approximate the relationship between microgeometry modifications and radiated noise. While powerful, neural networks require large datasets and extensive computational resources. They also function as black box models, making interpretability a challenge. A comparative summary of machine learning algorithms is presented in Table 2.

Detailed Comparison of the Three Most-Used ML Methods in Gear Noise Studies

4.2. Data Collection and Preparation in an Industrial Environment

- Dimensional and shape deviations (profile error, pitch error, runout, eccentricity).

- Surface roughness and waviness characteristics.

- Material properties (hardness, microstructure).

- Manufacturing process variables (cutting tool settings, grinding parameters, heat treatment profiles).

- Acoustic test results (sound pressure levels at different speeds and loads).

- Define the target variable(s): Decide whether the goal is to predict RMS sound pressure levels, classify parts based on noise thresholds, or rank gears by noise severity.

- Identify key input features: Gather relevant gear manufacturing data—e.g., tooth profile deviations, surface roughness (Ra, Rz), process temperature, tool wear indicators, etc.

- Synchronize measurement sources: Ensure that dimensional measurements and EOL noise tests are timestamp-aligned or batch-correlated.

- Clean and pre-process data: Remove outliers (e.g., due to measurement error), normalize data (especially when combining metrics with different scales), and consider dimensionality reduction if needed.

- Split data for training and testing: Use k-fold cross-validation for robustness; if data are limited, use Leave-One-Out (LOO) or time–series cross-validation if applicable.

- Select and train models: Start with interpretable models (e.g., decision trees), then proceed to ensemble models (e.g., RF, XGBoost) or SVR depending on data volume and complexity.

- Tune hyperparameters: Use techniques like grid search, random search, or more advanced Bayesian optimization for better accuracy.

- Validate model: Use metrics such as R2, MAE, and RMSE; visualize residuals and error distributions to identify patterns.

- Deploy the model in manufacturing: Connect prediction outputs to digital dashboards, programmable logic controllers (PLCs), or Manufacturing Execution Systems (MES).

- Monitor and retrain: Establish a feedback loop to detect data drift, update the model periodically, and involve manufacturing engineers in model interpretation.

4.3. Handling Imbalanced Data and Model Validation

- Oversampling: Generating additional “noisy” samples via data augmentation.

- Anomaly detection: Training models to recognize “unusual” cases instead of explicitly classifying normal vs. faulty parts.

- Train–test split (e.g., 80–20%): Training the model on most data and testing on a reserved subset.

- Cross-validation: Dividing data into multiple subsets and training on different partitions to ensure robustness.

- Performance metrics: Evaluating predictions using Root Mean Square Error (RMSE), Mean Absolute Error (MAE), and R2 scores.

4.4. Industrial Implementation and Continuous Improvement

- Embedding it into quality control software.

- Linking it to real-time manufacturing systems (e.g., machine PLCs).

- Using automated alerts when predicted noise levels exceed acceptable limits.

4.5. Hyperparameter Tuning Challenges in Industrial Contexts

4.6. Interpretability vs. Accuracy in Black Box Models

4.7. Handling Class Imbalance and Rare Failure Prediction

4.8. Illustrative Case Study—End-to-End Data Flow in an EV-Gearbox Line

- Inline vibration signals captured during dual-flank rolling.

- Optical waviness and profile maps from the laser scanners.

- Standard geometry + MES metadata (tool ID, feed rate, heat treatment batch).

- After hyperparameter tuning, XGBoost/LightGBM lifts accuracy to R2 ≈ 0.85–0.92 with 1.8–2.5 dB MAE, while keeping inference latency below the GRSL cycle time limit (<10 ms on an edge PC) [17].

- A compact deep neural network prototype attains R2 up to 0.94 when >10 k labelled samples are available but requires GPU hardware and longer training time; on smaller datasets, it offers only marginal gains [22].

4.9. Practical Implementation Challenges and Lessons Learned:

5. Current Trends, Applications, and Future Directions

5.1. Scalability and Applications in Other Manufacturing Processes

- Bearings: Rolling element bearings generate operational noise due to surface roughness, misalignment, and geometric deviations. Modern EOL noise tests already exist for bearings, where faulty parts are identified based on vibration signatures. A ML-based predictive model could anticipate bearing noise issues based on manufacturing metrology data before assembly.

- Electric Motors and Generators: EV motors and alternators are prone to electromagnetic and mechanical noise caused by imbalances, winding misalignments, or resonance effects. Predictive noise modeling could analyze manufacturing data to preemptively detect motors that may produce excessive noise under operation.

- Tires: Tire tread design significantly impacts rolling noise, which is a key NVH factor in EVs. Nexen Tire and Hyundai have already demonstrated how big data and deep learning can optimize tire tread patterns to minimize noise emissions. Expanding such models to other noise-sensitive rubber components, such as engine mounts or suspension bushings, is a promising direction.

- Gearboxes in Aerospace and Heavy Machinery: Helicopter transmissions, railway gearboxes, and industrial powertrains also require strict noise control. Predictive models could improve the selection of microgeometry modifications in aerospace and railway gearboxes, where weight constraints and extreme operating conditions make noise reduction particularly challenging.

5.2. Leveraging AI for Real-Time, Large-Scale Noise Prediction

- Dynamic process control: If an ML model predicts that a part is likely to exceed noise limits, then the manufacturing process (e.g., grinding parameters, heat treatment conditions) can be adjusted in real-time to compensate.

- Automated defect detection: Integration with inline laser scanning could allow automated sorting of potentially noisy gears, preventing faulty parts from entering final assembly.

- Continuous process optimization: Long-term trend analysis of noise levels can guide maintenance scheduling and process adjustments to ensure stable manufacturing quality.

5.3. Integration of Digital Twin Technology

- Monitor noise quality throughout the production process: Instead of waiting for final product testing, noise trends could be tracked as components move through different production stages.

- Predict noise performance before final assembly: If a specific batch of components shows a higher likelihood of noise issues, then adjustments can be made before parts are assembled into a final product.

- Optimize process parameters dynamically: ML algorithms could recommend real-time parameter adjustments to maintain optimal quality with minimal scrap and rework.

5.4. Combining Data-Driven and Physics-Based Noise Prediction

- ML models can be trained on simulation data to create faster, surrogate models (metamodels) that approximate the noise response of a system without running full simulations.

- Experimental noise measurements can be fed into ML models to calibrate FEM simulations, improving their accuracy by incorporating real-world variability.

- Optimization algorithms (e.g., Particle Swarm Optimization, Genetic Algorithms) can be combined with ML models to search for the optimal microgeometry modifications that minimize noise, as seen in previous research on neural network-based gear noise reduction.

5.5. Predictive Maintenance and Lifecycle Monitoring

- EV drivetrain monitoring: ML models could analyze real-time gearbox vibration data to predict when noise levels will exceed acceptable limits, enabling proactive servicing before a vehicle reaches an unacceptable noise level.

- Industrial gearbox monitoring: Predicting gear wear and pitting based on noise trends in heavy machinery and wind turbines.

- Automated warranty claim analysis: Manufacturers could track production data and customer complaints to determine if certain manufacturing deviations correlate with long-term noise problems in vehicles.

5.6. Current Research Status

5.6.1. Evolution from Physics-Only to Hybrid Models

5.6.2. Emerging Trends: Digital Twins and Inline ML

5.6.3. Remaining Gaps and Future Directions

5.7. Future Research Directions

- Expanding data sources for noise modeling: Combining manufacturing metrology data, operational sensor data, and subjective noise perception studies could provide a holistic understanding of gear noise [39].

- Integrating AI-based noise models into design workflows: Closing the loop between manufacturing, testing, and product design would allow early-stage noise performance evaluation, reducing the need for costly prototypes [40].

- Another promising research stream lies in combining explainable AI (XAI) with digital twin environments. As Kobayashi (2024) Nagrani (2025) suggest, integrating interpretable models in smart manufacturing allows engineers not only to trust predictions but to understand the physical meaning behind anomalies, forming the basis for continuous NVH improvement [41,42].

5.8. Industrial Applications of ML in NVH Quality

5.9. Suggested Research Framework for Future Studies

- Multiscale modeling, from gear microgeometry to full system housing simulations.

- Physical measurements, including vibration spectra, transmission error, and material microstructure.

- Data-driven models, utilizing both supervised and unsupervised methods for pattern discovery and predictive analytics.

6. Concluding Remarks and Practical Recommendations

- For small datasets, Support Vector Regression (SVR) or decision trees may provide stable, interpretable results.

- For nonlinear, multisource datasets, ensemble methods (e.g., Random Forest, XGBoost) offer an optimal trade-off between accuracy and speed.

- In real-time applications, models must prioritize inference speed, robustness, and maintainability over black box complexity.

Funding

Data Availability Statement

Conflicts of Interest

References

- Chin, Z.; Smith, W.; Borghesani, P.; Randall, R.; Peng, Z. Absolute transmission error: A simple new tool for assessing gear wear. Mech. Syst. Signal Process. 2021, 146, 107070. [Google Scholar] [CrossRef]

- Chen, Z.; Shao, Y. Dynamic features of planetary gear train with tooth errors. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1769–1781. [Google Scholar] [CrossRef]

- Davoli, P.; Gorla, C.; Rosa, F.; Rossi, F.; Boni, G. Transmission error and noise emission of spur gears: A theoretical and experimental approach. In Proceedings of the ASME 2007 IDETC/CIE Conference, Las Vegas, NV, USA, 4–7 September 2007; American Society of Mechanical Engineers: New York, NY, USA, 2007; pp. 443–449. [Google Scholar] [CrossRef]

- Ahmad, M.; Brimmers, J.; Brecher, C. Influence of long-wave deviations on the quasi-static and dynamic excitation behaviour at higher speeds. Appl. Acoust. 2020, 165, 107307. [Google Scholar] [CrossRef]

- Houser, D.R.; Harianto, J.; Harianto, J. Gear noise: Causes and control. Gear Technol. 2001, 18, 10–19. [Google Scholar]

- Lee, S.H.; Park, K.P. Development of a prediction model for the gear-whine noise of transmission using machine learning. Int. J. Precis. Eng. Manuf. 2023, 24, 1793–1803. [Google Scholar] [CrossRef]

- Henriksson, J. Simulation and validation of the transmission error, meshing stiffness and vibration in gear systems. J. Sound Vibration, 2020; Advance Online Publication. [Google Scholar]

- Wang, J.; Zhang, Y.; Liu, X.; Zhou, Q. Evaluating lightweight gear transmission error: A novel nonlinear multibody approach. Front. Mech. Eng. 2023, 9, 1228696. [Google Scholar] [CrossRef]

- Winkelmann, L. Tackling EV noise reduction. Gear Solutions Magazine. 15 October 2022. Available online: https://gearsolutions.com/departments/materials-matter/tackling-ev-noise-reduction/ (accessed on 27 July 2025).

- Masuda, T.; Inoue, M.; Iida, T.; Aoki, T. Prediction of gear noise considering the influence of tooth-flank finishing method. J. Vib. Acoust. Stress Reliab. Des. 1986, 108, 121–130. [Google Scholar] [CrossRef]

- Tian, X.; Li, Y.; Liu, Z.; Sun, J. High-speed and low-noise gear finishing by gear grinding and honing: A review. Chin. J. Mech. Eng. 2024, 37, 10. [Google Scholar] [CrossRef]

- Choi, W.J.; Kim, J.; Lee, Y.; Park, K.P. Effects of manufacturing errors of gear macro-geometry on gear performance. Sci. Rep. 2023, 13, 27204. [Google Scholar] [CrossRef]

- Chen, G.; Xu, Y. A statistical model for gear noise prediction in gearbox manufacturing. In Proceedings of the 2010 IEEE International Conference on Industrial Engineering and Engineering Management 2010, Xiamen, China, 29–31 October 2010. [Google Scholar] [CrossRef]

- Rajkumar, S.; Singh, R.; Kumar, P.; Gupta, A. Predictive maintenance algorithms, artificial intelligence, digital twin. Mathematics 2025, 13, 981. [Google Scholar] [CrossRef]

- Zhong, D.; Zhao, X.; Li, Y.; Zhang, D. Overview of predictive maintenance based on digital-twin technology. Heliyon 2023, 9, e14534. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.; Huang, J.; Zhang, L.; Liu, Y. Multi-objective prediction of the sound-insulation performance of a vehicle body system using multiple kernel learning–support vector regression. Electronics 2024, 13, 538. [Google Scholar] [CrossRef]

- Gleason Corporation. GRSL: Gear Rolling System with Integrated Laser for 100 % Noise Inspection [White Paper]; Gleason Corporation: Ludwigsburg, Germany, 2023. [Google Scholar]

- Scania. Machine Learning in Industrial Quality Control-Acoustic Deviation Detection. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2017.

- Aurich, B. Aspects of gear noise, quality, and manufacturing technologies for electromobility. Gear Technology Magazine, 21 February 2023; 60–64. [Google Scholar]

- H2020 ECO-Drive Project. System-Level NVH Optimisation for Sustainable Electric Drivetrains. Horizon 2020 Grant Agreement No 858018 (1 March 2020–29 February 2024). Available online: https://cordis.europa.eu/project/id/858018 (accessed on 27 July 2025).

- Türich, A.; Deininger, K. Noise Analysis for e-Drive Gears and in-Process Gear Inspection. Gear Solutions Magazine. 15 February 2024. Available online: https://gearsolutions.com/features/noise-analysis-for-e-drive-gears-and-in-process-gear-inspection/ (accessed on 27 July 2025).

- Nexen Tire. Prediction System to Reduce Tire Noise Using AI and Big Data [Press Release]; Nexen Tire: Yangsan-si, Republic of Korea, 2020. [Google Scholar]

- Hyundai Motor Group & Hoseo University. Big Data Analysis for Vehicle NVH Development; Technical Report; Hoseo University; Hyundai Motor Group: Seoul, Republic of Korea, 2022. [Google Scholar]

- Sun, H.; Wang, C.; Cao, X. An adaptive anti-noise gear fault diagnosis method based on attention residual prototypical network under limited samples. Appl. Soft Comput. 2022, 125, 109120. [Google Scholar] [CrossRef]

- Cihan, P. Bayesian hyperparameter optimization of machine-learning models for predicting biomass gasification gases. Appl. Sci. 2025, 15, 1018. [Google Scholar] [CrossRef]

- González-Duque, M.; Michael, R.; Bartels, S.; Zainchkovskyy, Y.; Hauberg, S.; Boomsma, W. A survey and benchmark of high-dimensional Bayesian optimization of discrete sequences. arXiv 2024, arXiv:2406.04739. [Google Scholar] [CrossRef]

- Molnar, C. Interpretable Machine Learning: A Guide for Making Black-Box Models Explainable, 3rd ed.; Leanpub: Victoria, BC, Canada, 2023. [Google Scholar]

- Liew, W.Y.; Nee, A.Y.C. Hybrid predictive models for surface roughness in gear manufacturing. Procedia CIRP 2015, 34, 225–230. [Google Scholar] [CrossRef]

- Chawla, N.V.; Bowyer, K.W.; Hall, L.O.; Kegelmeyer, W.P. SMOTE: Synthetic minority over-sampling technique. J. Artif. Intell. Res. 2002, 16, 321–357. [Google Scholar] [CrossRef]

- Han, Y.; Wei, Z.; Huang, G. An imbalance data quality monitoring based on SMOTE-XGBoost supported by edge computing. Sci. Rep. 2024, 14, 10151. [Google Scholar] [CrossRef]

- Bischl, B.; Binder, M.; Lang, M.; Pfahringer, B.; Kotthoff, L. Hyperparameter tuning in machine learning. J. Mach. Learn. Res. 2021, 22, 1–114. [Google Scholar]

- Snoek, J.; Larochelle, H.; Adams, R.P. Practical Bayesian optimization of machine learning algorithms. In Advances in Neural Information Processing Systems 25, Proceedings of the 26th Annual Conference on Neural Information Processing Systems 2012, Lake Tahoe, NV, USA, 3–6 December 2012; Curran Associates, Inc.: Red Hook, NY, USA, 2012; pp. 2951–2959. [Google Scholar]

- Varma, S.; Simon, R. Bias in error estimation when using cross-validation for model selection. BMC Bioinform. 2006, 7, 91. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.-I. A unified approach to interpreting model predictions. In Advances in Neural Information Processing Systems 30, Proceedings of the 31st Annual Conference on Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017; Curran Associates, Inc.: Red Hook, NY, USA, 2017; pp. 4765–4774. [Google Scholar] [CrossRef]

- Tan, Y.; Yang, G.; Zhu, X. Interpretable surrogate trees for gradient boosting. Int. J. Data Sci. Anal. 2022, 13, 59–73. [Google Scholar]

- Han, H.; Wang, W.; Mao, B. Borderline-SMOTE: A new over-sampling method in imbalanced data sets learning. In Proceedings of the 2005 International Conference on Intelligent Computing, Hefei, China, 23–26 August 2005; pp. 878–887. [Google Scholar] [CrossRef]

- Saito, T.; Rehmsmeier, M. The precision–recall plot is more informative than the ROC plot when evaluating binary classifiers on imbalanced datasets. PLoS ONE 2015, 10, e0118432. [Google Scholar] [CrossRef] [PubMed]

- Puthanveettil Madathil, A.; Luo, X.; Liu, Q.; Walker, C.; Madarkar, R.; Qin, Y. A review of explainable artificial intelligence in smart manufacturing. Int. J. Prod. Res. 2025, 1–44. [Google Scholar] [CrossRef]

- Kibrete, F.; Woldemichael, D.E.; Gebremedhen, H.S. Multi-sensor data fusion in intelligent fault diagnosis of rotating machines: A comprehensive review. Measurement 2024, 232, 114658. [Google Scholar] [CrossRef]

- Wang, J.; Shi, L.; Ding, F.; Jinli, L.; Hou, L.; Enming, M. A digital twin modeling and application for gear rack drilling rigs lifting system. Sci. Rep. 2024, 14, 23711. [Google Scholar] [CrossRef]

- Kobayashi, K.; Alam, S.B. Explainable, interpretable and trustworthy AI for an intelligent digital twin: A case study on remaining useful life. Eng. Appl. Artif. Intell. 2024, 129, 107620. [Google Scholar] [CrossRef]

- Nagrani, S.R.; Narwane, V.S. Systematic literature review on digital twins in predictive maintenance. Ind. Eng. J. 2025, 18, 19–25. [Google Scholar]

- Zhang, Q.; Wu, Z.; An, B.; Sun, R.; Cui, Y. Digital Twin-Based Technical Research on Comprehensive Gear Fault Diagnosis and Structural Performance Evaluation. Sensors 2025, 25, 2775. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.L.; Pawlik, L.; Frej, D.; Wilk-Jakubowski, G. The Evolution of Machine Learning in Vibration and Acoustics: A Decade of Innovation (2015–2024). Appl. Sci. 2025, 15, 6549. [Google Scholar] [CrossRef]

- Shi, Z.; Liu, B.; Yue, H.; Wu, X.; Wang, S. Noise Reduction of Two-Speed Automatic Transmission for Pure Electric Vehicles. Vehicles 2023, 5, 248–265. [Google Scholar] [CrossRef]

- Habbouche, H.; Amirat, Y.; Benbouzid, M. Leveraging Digital Twins and AI for Enhanced Gearbox Condition Monitoring in Wind Turbines: A Review. Appl. Sci. 2025, 15, 5725. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.; Yang, J.; Zhang, H.; Zhao, H. A Digital Twin-Based State Monitoring Method of Gear Test Bench. Appl. Sci. 2023, 13, 3291. [Google Scholar] [CrossRef]

- You, K.; Lian, Z.; Gu, Y. A performance-interpretable intelligent fusion of sound and vibration signals for bearing fault diagnosis via dynamic CAME. Nonlinear Dyn. 2024, 112, 20903–20940. [Google Scholar] [CrossRef]

| Algorithm | Strengths | Limitations | Industrial Suitability (NVH) | Example References |

|---|---|---|---|---|

| Linear Regression | Simple. Fast. Interpretable. Good baseline | Struggles with nonlinearity. Low accuracy in complex data | Suitable as baseline model. Not recommended for nonlinear gear noise cases | Chen & Xu (2010) [13] |

| Decision Tree | Interpretable. Handles nonlinearity. Fast inference | Prone to overfitting. Unstable predictions | Useful for feature selection or as part of ensembles | Choi et al. (2023) [12] |

| Random Forest | Robust. Handles high-dimensional data. Provides feature importance | Slower inference. Less interpretable than single trees | Common in gear and bearing fault detection | Lee & Park (2023); [6] Chen & Xu (2010) [13] |

| XGBoost/LightGBM | High accuracy. Handles nonlinearity. Fast training/inference | Sensitive to hyperparameters. Less transparent | Excellent for gear whine and TE-based noise prediction | Lee & Park (2023) [6] |

| Support Vector Regression (SVR) | Performs well on small datasets. Good generalization. | Sensitive to kernel choice. Slow for large data | Suitable for precise NVH estimation in limited data regimes | Sun et al. (2024) [16] |

| Deep Neural Network (DNN) | Captures complex patterns. Suitable for big data | Requires large datasets. Black box nature. High computational cost | Used in tire and motor NVH. Less common for gear unless data-rich | Nexen & Hyundai (2020) [22,23] |

| Criterion | Random Forest (RF) | Gradient Boosting (XGBoost/LightGBM) | Deep Neural Networks (DNN) | Key Sources |

|---|---|---|---|---|

| Typical accuracy trend | Good baseline; usually within ±2–4 dB of best ensemble on tabular gear metrology data | Consistently highest accuracy on tabular data (≈5–10% MAE improvement over RF) | Can surpass tree models when >10 k labelled samples or raw spectra/images are used | [6,25] |

| Data volume needed for stable model | ≈500–1000 labelled parts | ≈1000–2000 parts (benefits strongly from >2 k) | ≥10,000 parts for reliable generalization | [6,25] |

| Training & inference speed (CPU/edge) | Fast (seconds–minutes); inference <10 ms | Moderate (needs hyperparameter tuning); inference <10 ms (GPU/CPU) | Slowest (minutes–hours train; 10–50 ms inference) | [25] |

| Interpretability | Medium—built-in feature importance, partial dependence | Medium/low—needs SHAP/gain analysis | Low—requires XAI (SHAP, surrogate trees) | [27] |

| Hyperparameter sensitivity | Low–moderate (n trees, depth) | High (learning rate, depth, subsample) | Very high (layers, LR, dropout) | [25] |

| Overfitting tendency | Moderate; bagging mitigates | Moderate–high; needs early stopping & regularisation | High without strong regularisation & dropout | [25] |

| Inline/real-time suitability | Proven in PLC/PC-based inline QC | LightGBM & XGBoost demonstrably run cycle time (<1 s) | Edge-GPU ok; heavy for PLC | [17] |

| Best-fit role in pipeline | Rapid prototyping, feature screening, small-to-mid datasets | Production-grade regression/classification with balanced speed/accuracy | Vision or raw spectra pipelines, large-scale R&D, anomaly detection |

| Manufacturing Parameter | Typical Range | Noise Sensitivity | Effect on Noise (dB) |

|---|---|---|---|

| Tooth Profile Modification (µm) | 0–30 | High | ↑ if overmodified |

| Lead Modification (µm) | 0–25 | Medium | ↕ depends on meshing |

| Tooth Crowning (µm) | 0–20 | High | ↑ in high-speed |

| Surface Roughness (Ra, µm) | 0.2–0.8 | Medium | ↑ with poor lubrication |

| Pitch Error (µm) | ±10 | Very High | ↑↑ tonal noise |

| Runout (µm) | ±5 | High | ↑ amplitude modulation |

| Material Batch Variance | Low/Medium/High | Medium | ↕ varies with stiffness |

| Heat Treatment Deviation | ±20 °C/±15 min | Low–Medium | ↕ affects residual stress and dynamic response |

| Company/Consortium | Application Area | ML Method | Context/Notes |

|---|---|---|---|

| Nexen Tire | Tire NVH quality classification | CNN (DL) | Vibration-based defect detection |

| Hyundai Motor | Powertrain NVH fault detection | Deep NN | Anomaly detection during EOL testing |

| BMW | EOL NVH diagnostics | XGBoost | Engine/gearbox vibration classification |

| ZF Friedrichshafen | Gearbox NVH clustering | Auto-encoder + KMeans | Noise pattern mining from end-of-line data |

| Bosch | Electric motor noise detection | LSTM | Temporal analysis of NVH data streams |

| Toyota | Cabin NVH profiling | CNN, SVM | Mapping subjective noise comfort to design variants |

| Continental | Tire–road interaction NVH | CNN | Predictive modeling of pattern-induced noise |

| Year | Focus Area | Expected Outcome |

|---|---|---|

| 2025 | Data pipeline integration | Full digital traceability from machining to acoustic test benches |

| 2026 | Real-time predictive-model deployment | Inline XGBoost/SVR models running within cycle time limits |

| 2027 | Hybrid AI + physics-based simulation models | Fast surrogate models for TE + NVH prediction |

| 2028 | Explainable AI and uncertainty quantification | Visual dashboards to support decision-making and root cause analysis |

| 2029 | Closed-loop manufacturing + AI self-tuning systems | Automatic parameter tuning in grinding/honing based on ML feedback |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horváth, K. Data-Driven Predictive Modeling for Investigating the Impact of Gear Manufacturing Parameters on Noise Levels in Electric Vehicle Drivetrains. World Electr. Veh. J. 2025, 16, 426. https://doi.org/10.3390/wevj16080426

Horváth K. Data-Driven Predictive Modeling for Investigating the Impact of Gear Manufacturing Parameters on Noise Levels in Electric Vehicle Drivetrains. World Electric Vehicle Journal. 2025; 16(8):426. https://doi.org/10.3390/wevj16080426

Chicago/Turabian StyleHorváth, Krisztián. 2025. "Data-Driven Predictive Modeling for Investigating the Impact of Gear Manufacturing Parameters on Noise Levels in Electric Vehicle Drivetrains" World Electric Vehicle Journal 16, no. 8: 426. https://doi.org/10.3390/wevj16080426

APA StyleHorváth, K. (2025). Data-Driven Predictive Modeling for Investigating the Impact of Gear Manufacturing Parameters on Noise Levels in Electric Vehicle Drivetrains. World Electric Vehicle Journal, 16(8), 426. https://doi.org/10.3390/wevj16080426