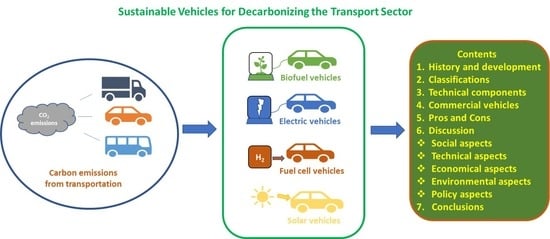

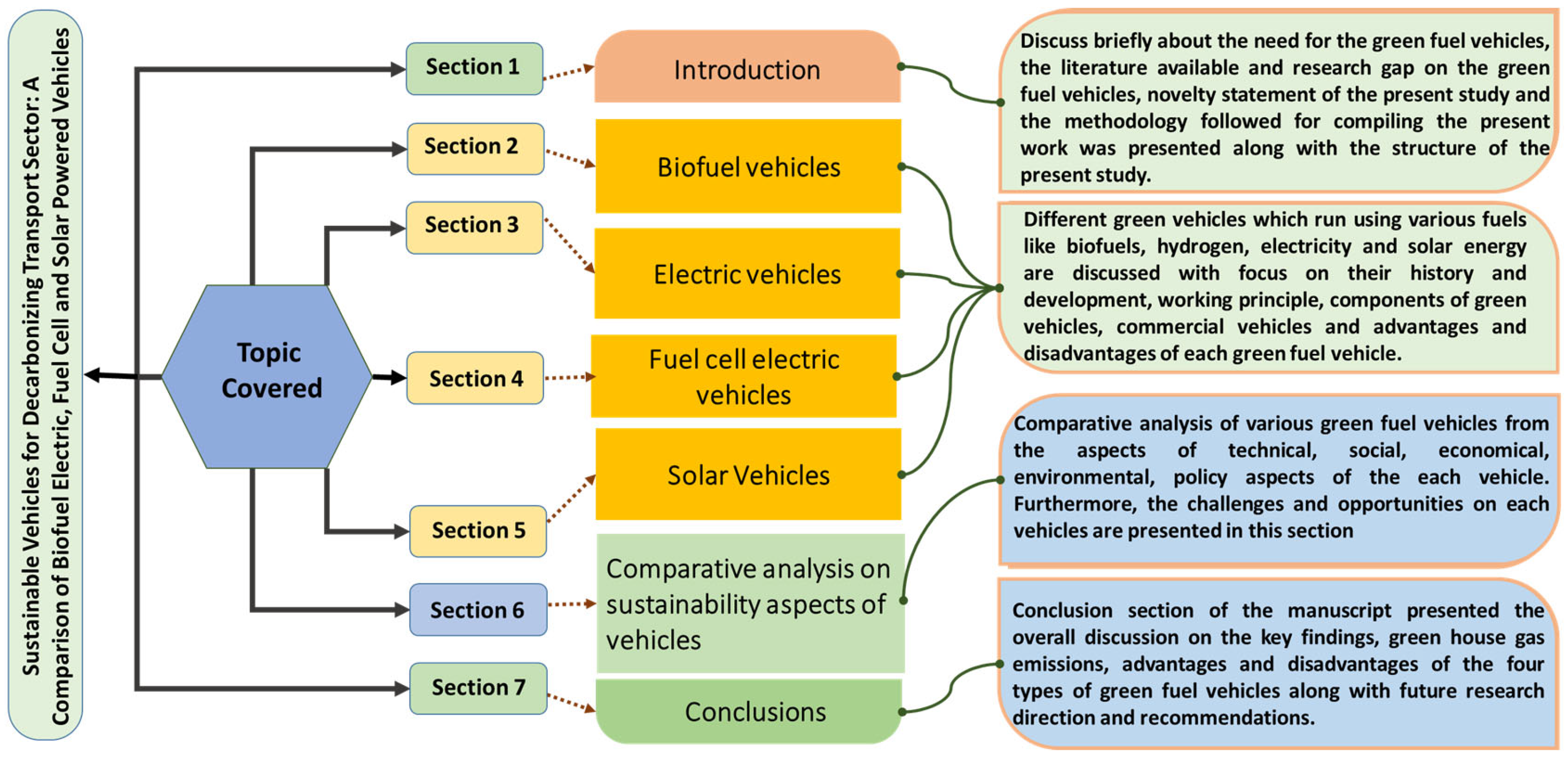

Sustainable Vehicles for Decarbonizing the Transport Sector: A Comparison of Biofuel, Electric, Fuel Cell and Solar-Powered Vehicles

Abstract

1. Introduction

1.1. Literature Review and Research Gap

1.2. Novelty Statement

1.3. Research Objectives and Organization of the Study

1.4. Methodology

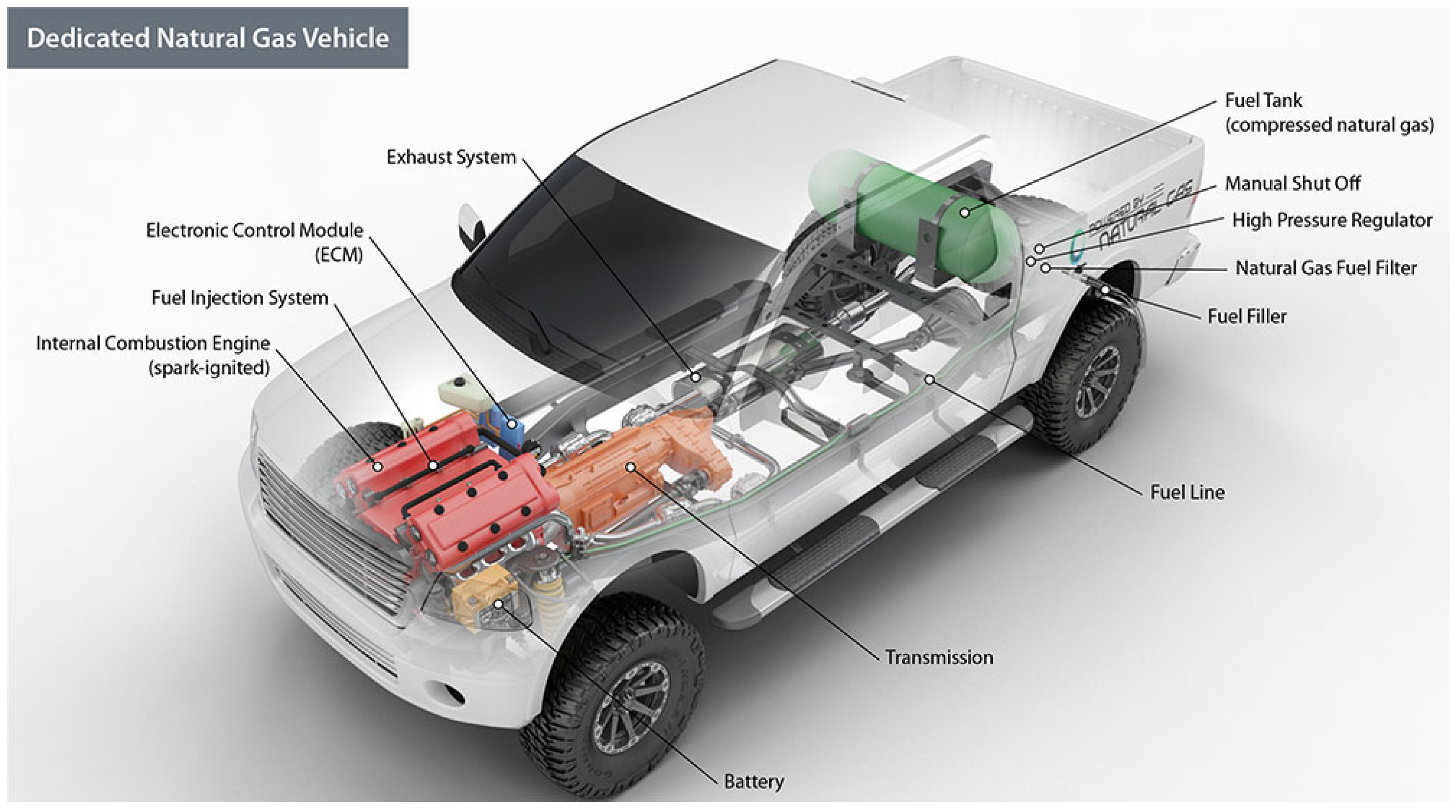

2. Overview of Biofuel Vehicles

2.1. History and Development

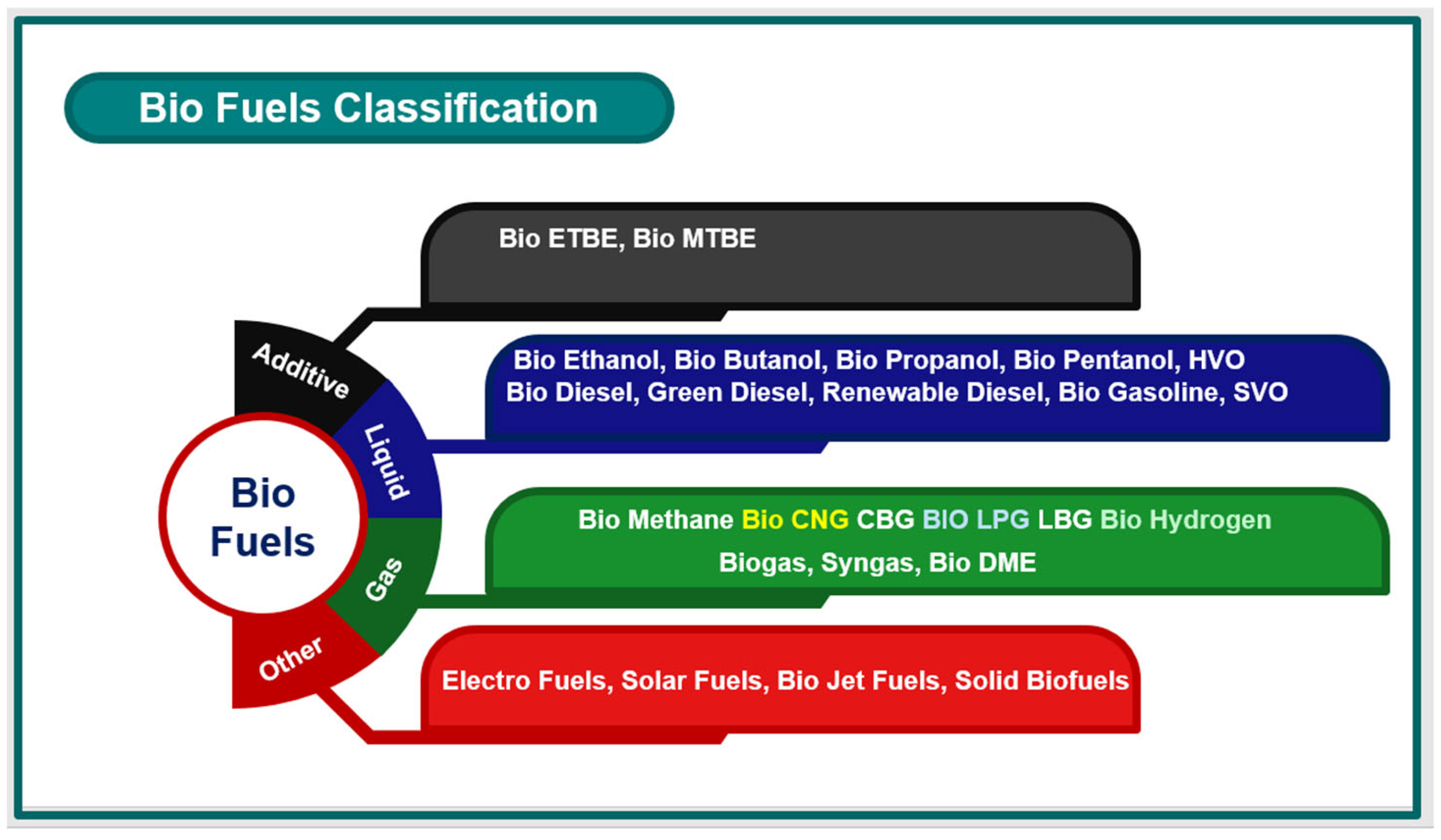

2.2. Classification of Biofuels

2.3. Key Components and Technological Features of Biofuel Vehicles

2.4. Commercial Biofuel Vehicles

2.5. Pros and Cons of Biofuel Vehicles

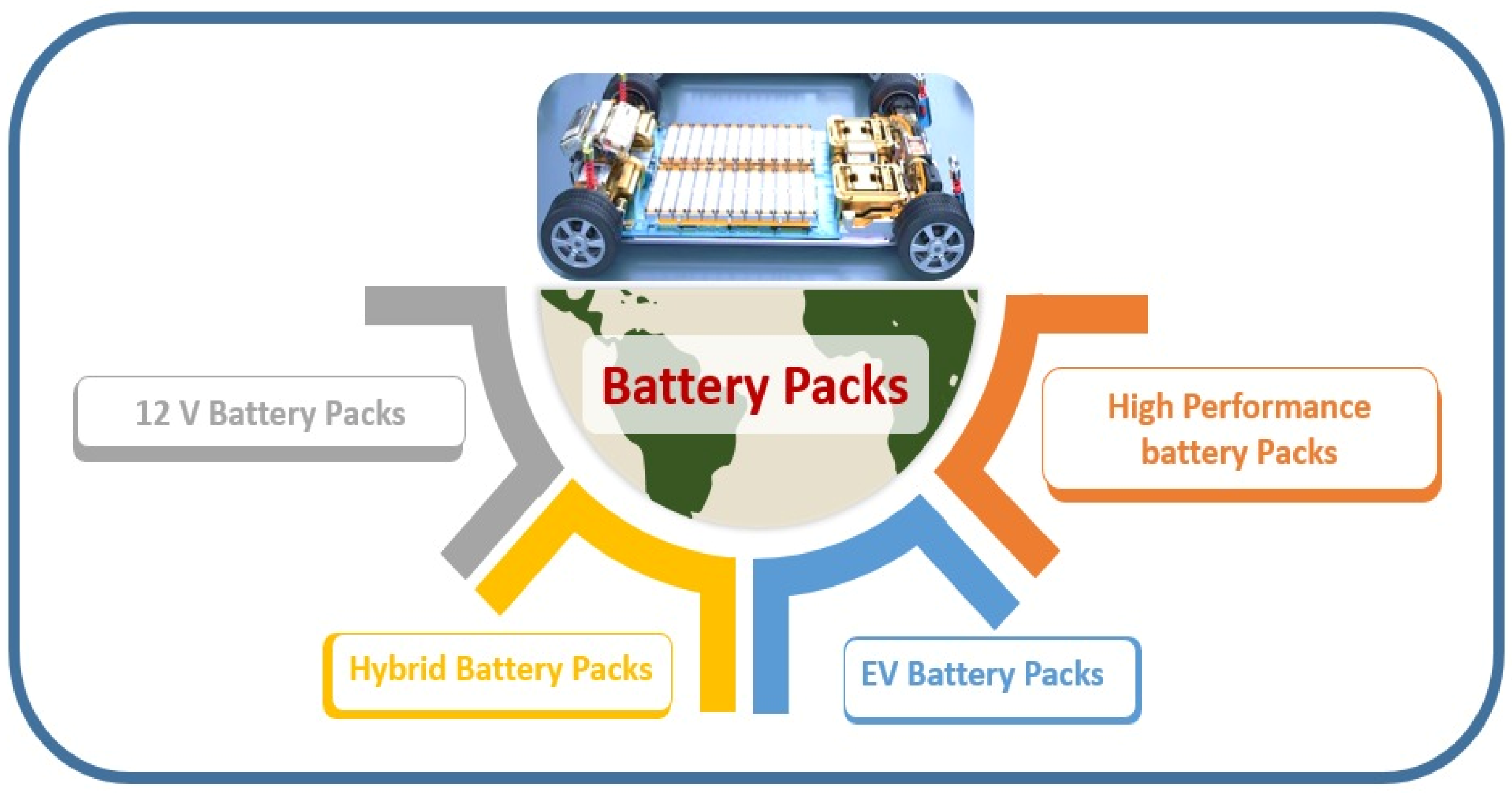

3. Overview of Electric Vehicles (EVs) and Hybrid Electric Vehicles

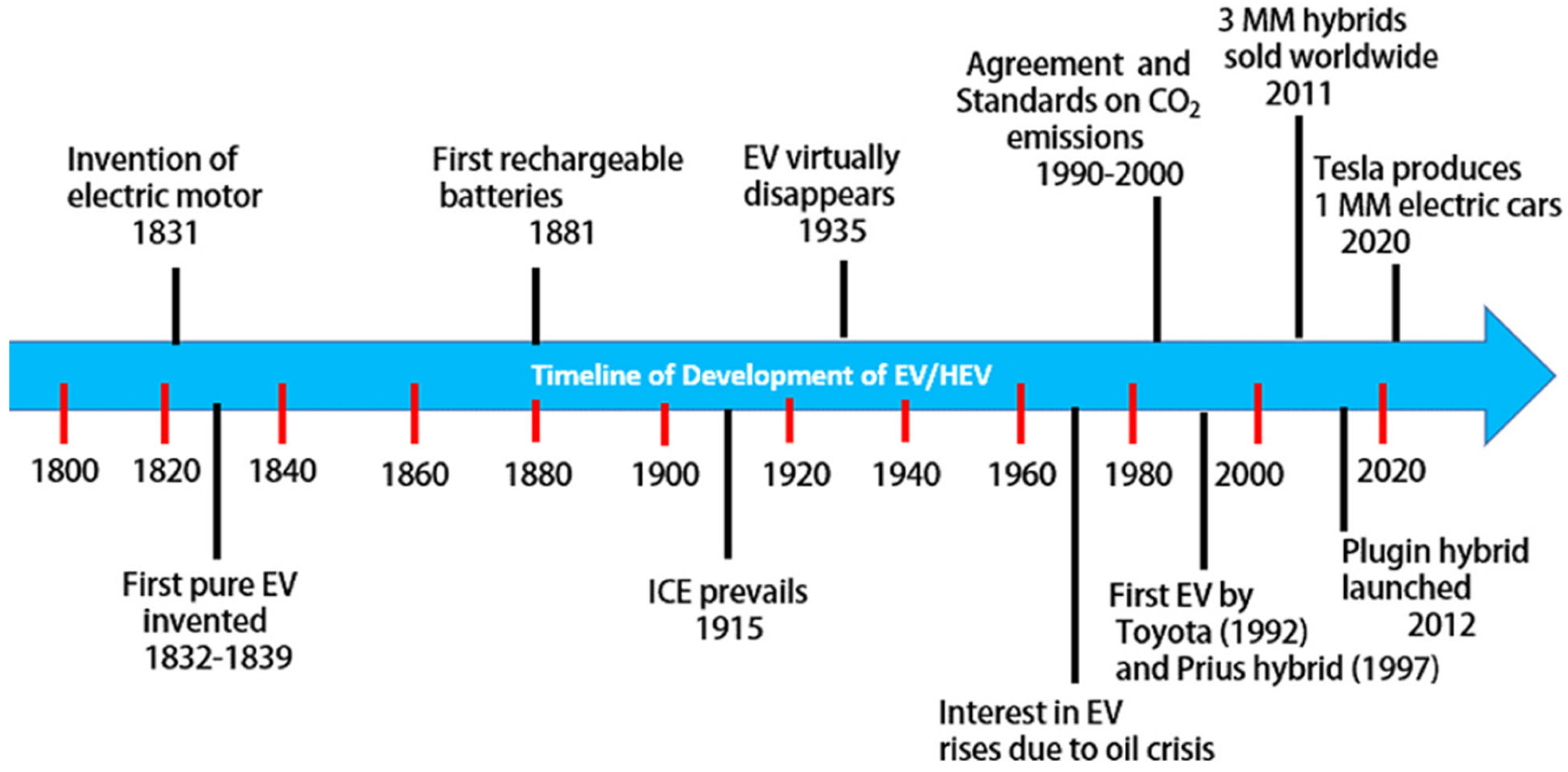

3.1. History and Development

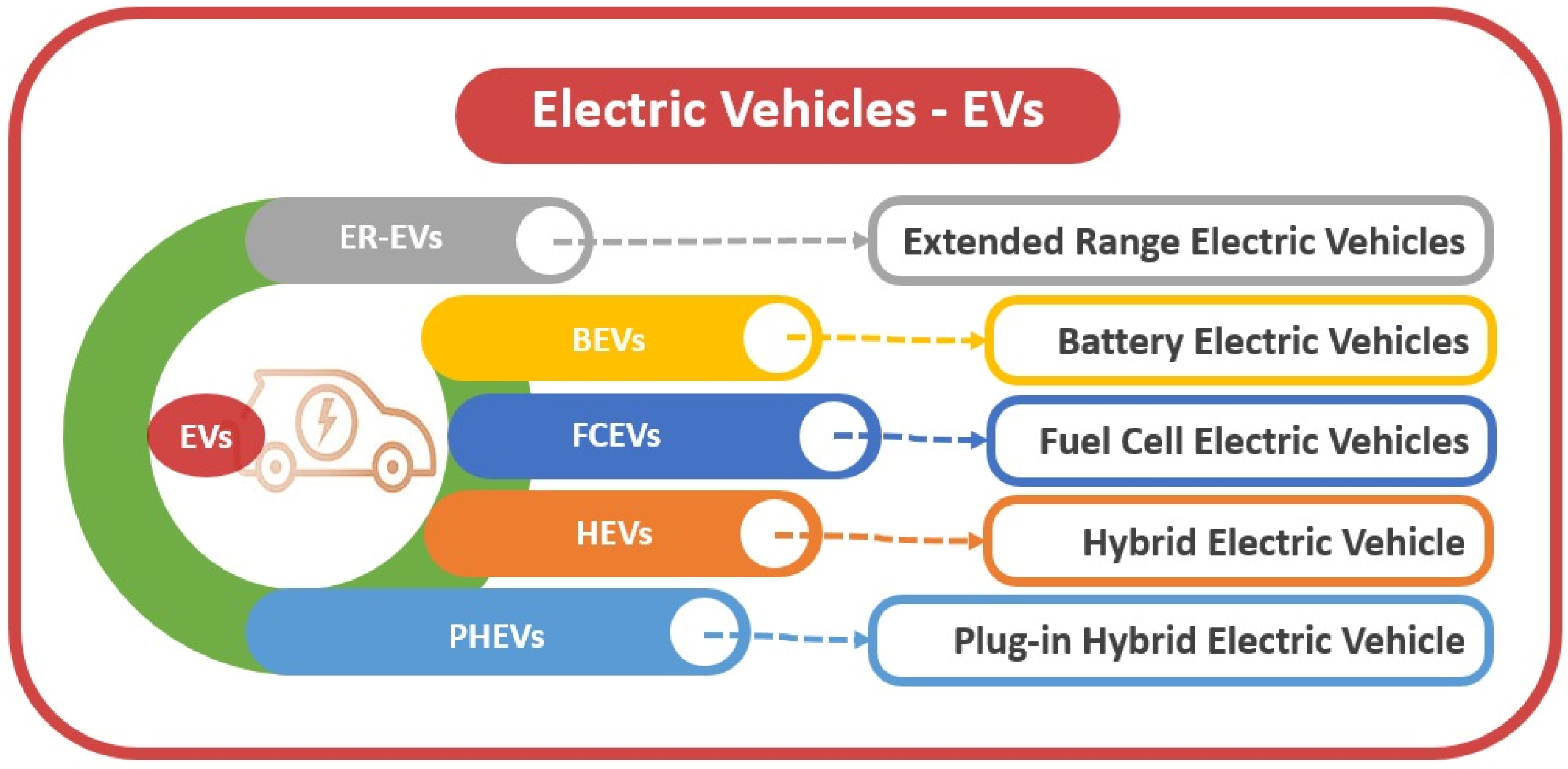

3.2. Classification of Electric Vehicles

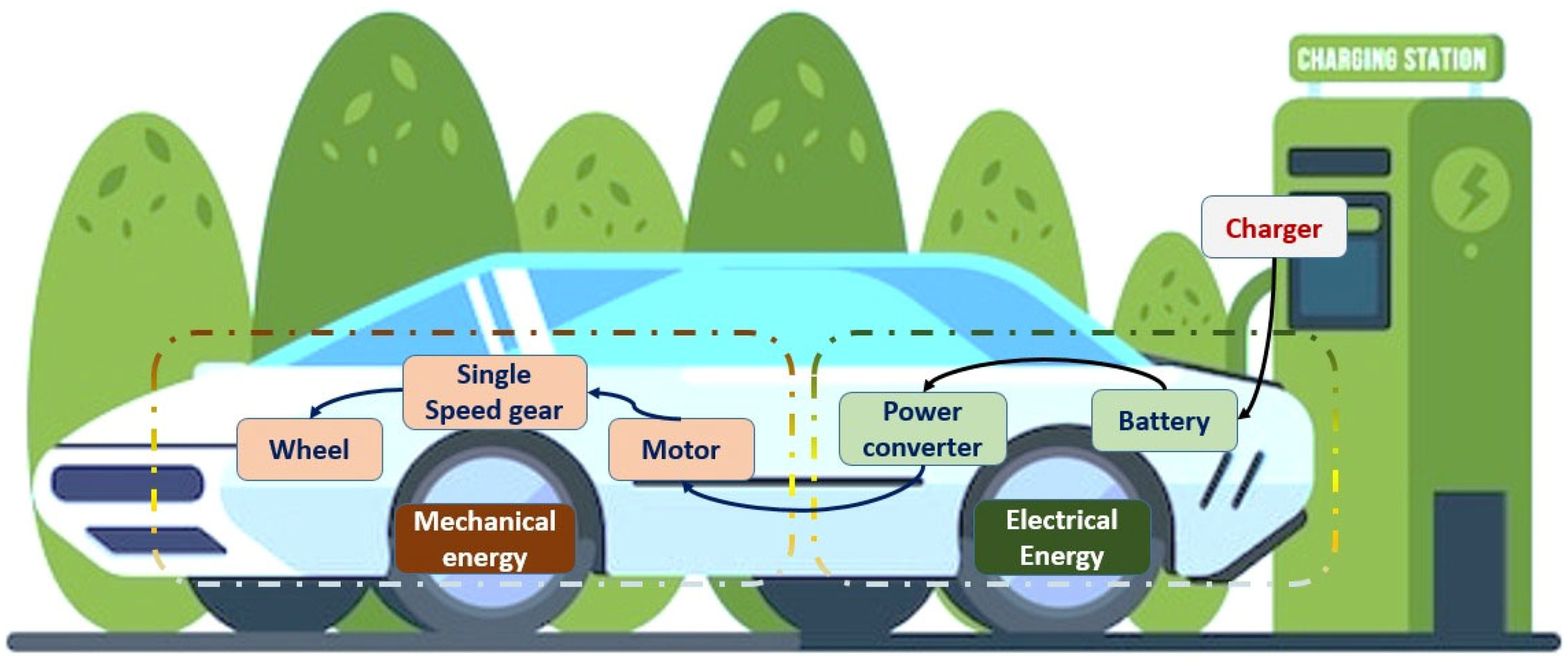

3.3. Key Components and Technological Features

3.4. Commercial Electric Vehicles

3.5. Pros and Cons of Electric Vehicles

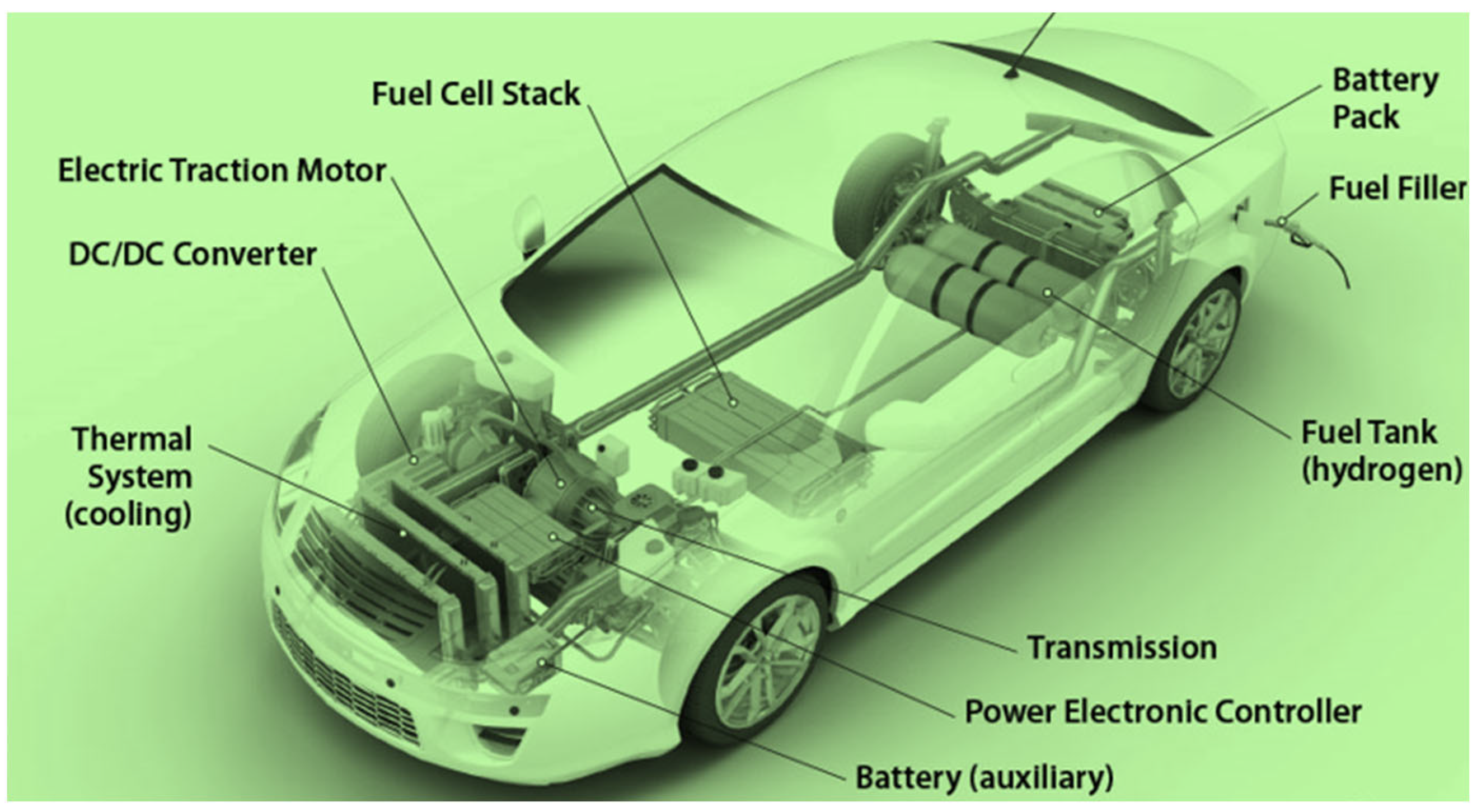

4. Overview of Fuel Cell Electric Vehicles (FCEVs)

4.1. History and Development

4.2. Classification of Fuel Cells

4.2.1. Alkaline Fuel Cell (AFC)

4.2.2. Polymer Electrolyte Membrane Fuel Cell (PEMFC)

4.2.3. Molten Carbonate Fuel Cell (MCFC)

4.2.4. Phosphoric Acid Fuel Cell (PAFC)

4.2.5. Solid Oxide Fuel Cell (SOFC)

4.2.6. Direct Methanol Fuel Cells

4.2.7. Reversible Fuel Cells

4.2.8. Fuel Cell Application for Electric Vehicles

4.3. Key Components and Technological Features

4.4. Commercial Fuel Cell Electric Vehicles

4.5. Pros and Cons of Fuel Cell Electric Vehicles

5. Vehicle-Integrated Photovoltaics (Solar-Powered Vehicles)

5.1. History and Development

- The concept of solar-powered vehicles has been around for decades, with early experiments dating back to the 1950s. However, significant development began in the 1980s and 1990s.

- The World Solar Challenge, a solar car race across Australia, has played a crucial role in driving innovation and promoting solar-powered vehicle development since its inception in 1987.

- Over the years, advancements in photovoltaic technology, energy storage, and vehicle design have contributed to the evolution of solar-powered vehicles. The use of VIPVs has been gaining traction in recent years to reduce the environmental impact of transportation.

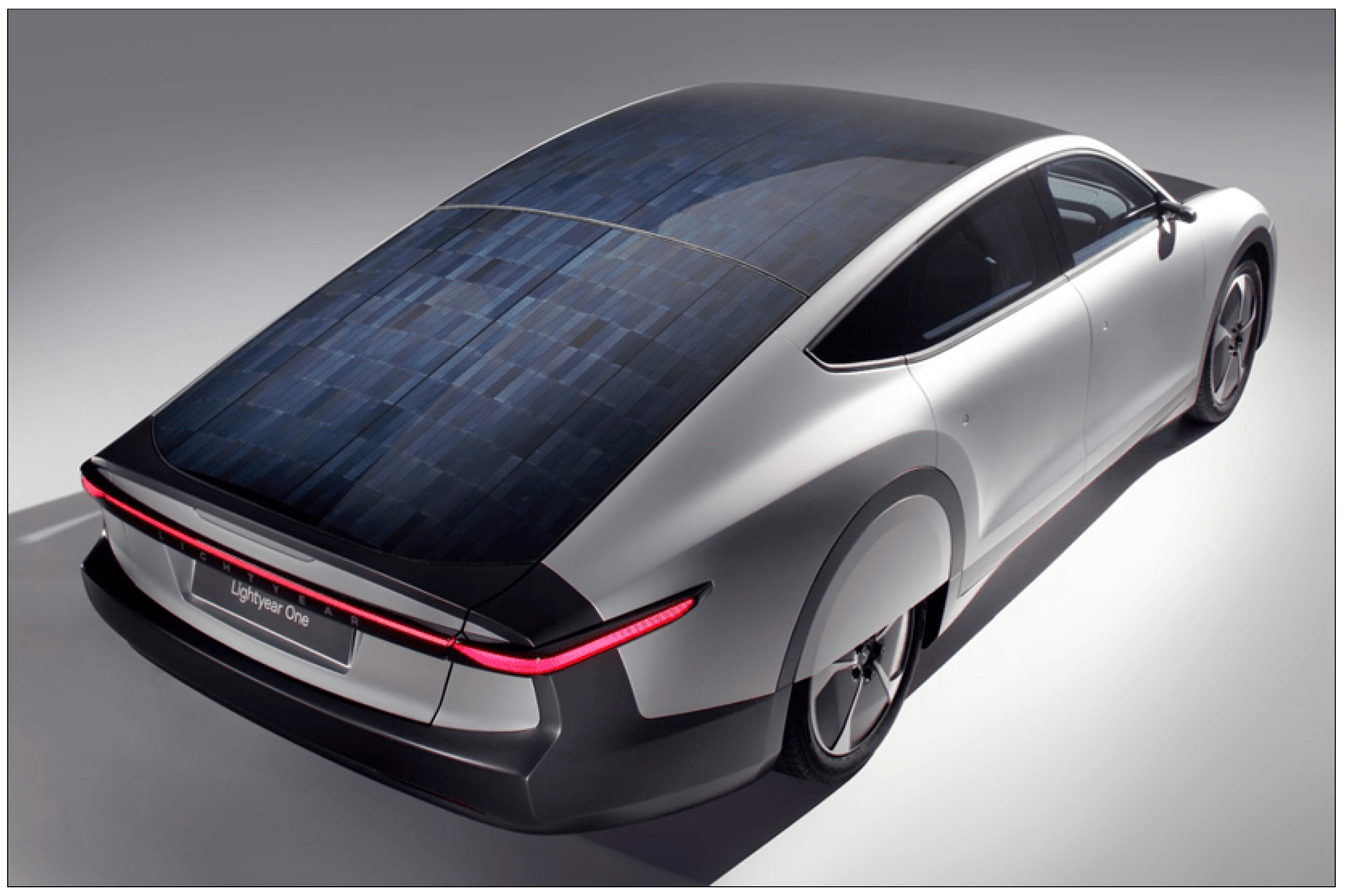

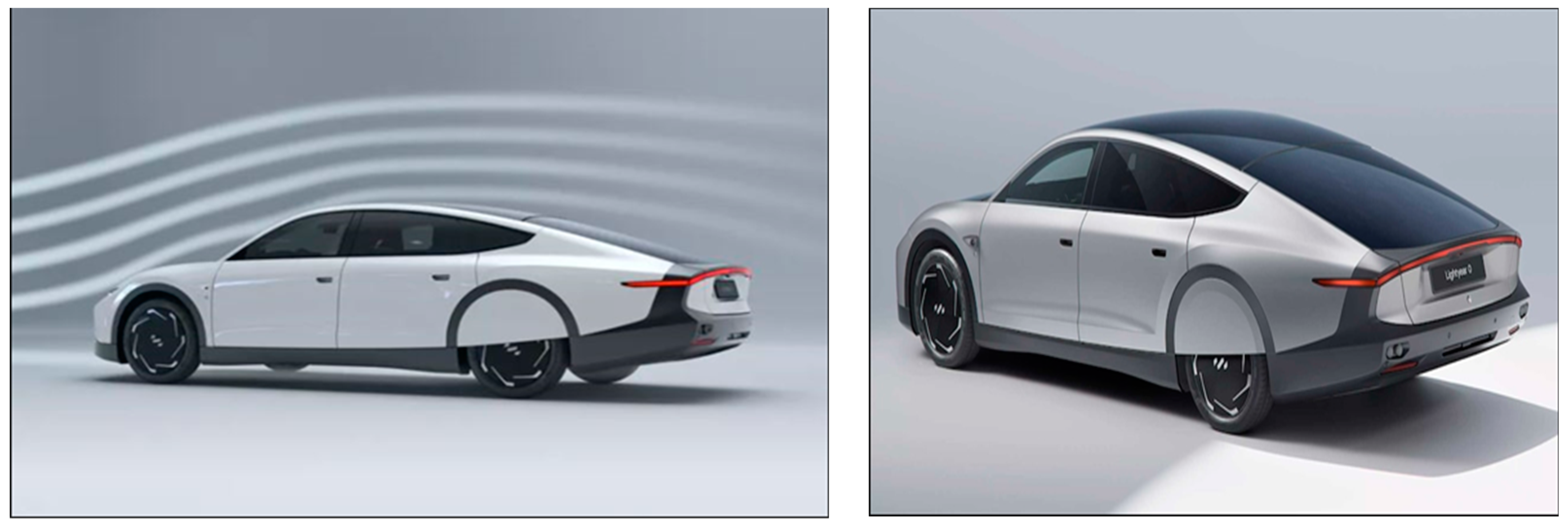

- Through transportation, industry players also started to introduce and produce battery electric vehicles (BEVs) as a way to support the movement to save the world from catastrophic climate failure. Figure 15 shows the model of a solar vehicle named as Lightyear One.

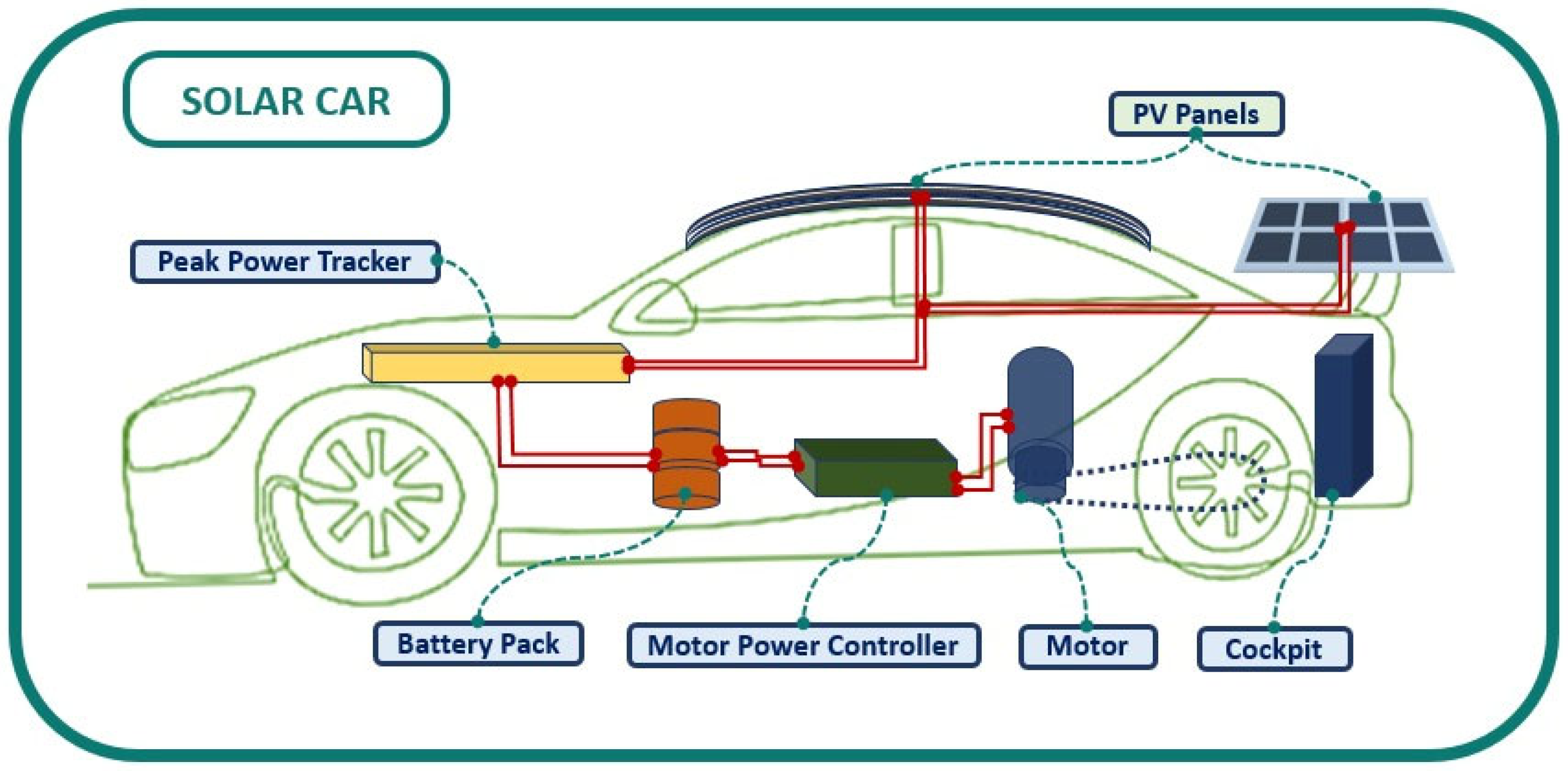

5.2. Working Principles of Solar-Powered Vehicle (Vehicle-Integrated Photovoltaics)

5.3. Technological Features of Solar Vehicles

5.3.1. Key Components

- Photovoltaic Cells: Solar panels mounted on the vehicle’s surface to capture sunlight. Also known as solar panels, lined with thousands of photovoltaic cells that convert the solar energy into usable electricity.

- Energy Storage: High-capacity batteries to store and manage the generated solar energy. Stores the energy required to run the motor and controller.

- Power Trackers: Assists in directing the solar energy generated toward the storage battery. They also serve as a stopper to avoid overcharging the batteries.

- Electric Motor: Drives the vehicle using the stored solar energy. Converts the electric energy into mechanical energy that helps in moving the wheels.

- Power Management System: Controls the distribution and usage of solar-generated electricity.

- Lightweight Material Chassis: Many solar vehicles use lightweight materials to enhance efficiency and maximize the vehicle’s range.

- Navigational Device: Steering or remote control helps in navigating the solar car in the desired direction. The outer framework on which the entire structure of the car sits upon.

- Wheel: Helps in maneuvering the direction and speed of movement of the vehicle

- Speed Controller: Aids in keeping track of the vehicle’s speed and controlling the engine and wheels accordingly.

5.3.2. Performance Based on Climate, Design and Emission Aspects of the VIPV

5.4. Commercial Status of the Solar Vehicles

- Lightyear 0

- Aerodynamics—Cd value 0.175;

- Energy use—10.5 kWh/100 km;

- *Tested at highway speeds of 100 km/h (62 miles).

- While solar-powered cars for daily commuting are still in the experimental stage, solar technology has found applications in certain commercial vehicles.

- Solar panels are being integrated into electric buses, trucks, and even some electric bicycles to extend their range and reduce reliance on external charging.

- Public transportation and delivery vehicles in urban areas are potential candidates for solar integration due to their frequent stops and starts, providing opportunities for solar recharging.

5.5. Pros and Cons of Solar Vehicles

- Pros:

- Renewable Energy: Solar power is a clean and renewable energy source, reducing dependence on non-renewable resources.

- Extended Range: Solar integration can extend the range of electric vehicles, especially in sunny regions.

- Low Operating Costs: Once installed, solar panels have minimal operating costs and can reduce the overall cost of vehicle ownership.

- Cons:

- Limited Efficiency: Current solar technology has limitations in terms of its efficiency, especially on compact vehicles with limited surface area for solar panels.

- Weather-Dependence: Solar power generation is dependent on sunlight, making it less effective during cloudy or night-time conditions.

- Initial Cost: The integration of solar technology can increase the initial cost of the vehicle, although this may be offset by lower operating costs over time.

6. Comparative Analysis of Sustainability Aspects of Various Green Vehicles

6.1. Biofuel Vehicles

6.1.1. Technical Aspects

6.1.2. Economical Aspects

6.1.3. Environmental Aspects

6.1.4. Social Aspects

6.1.5. Policy Aspects

6.1.6. Challenges and Opportunities

6.2. Electric Vehicles

6.2.1. Technical Aspects

6.2.2. Economical Aspects

6.2.3. Environmental Aspects

6.2.4. Social Aspects

6.2.5. Policy Aspects

6.2.6. Challenges and Opportunities

6.3. Fuel Cell Vehicles

6.3.1. Technical Aspects

6.3.2. Economical Aspects

6.3.3. Environmental Aspects

6.3.4. Social Aspects

6.3.5. Policy Aspects

6.3.6. Challenges and Opportunities

- Challenges:

- Opportunities:

6.4. Solar Vehicles

6.4.1. Technical Aspects

6.4.2. Economical Aspects

6.4.3. Environmental Aspects

6.4.4. Social Aspects

6.4.5. Policy Aspects

6.4.6. Challenges and Opportunities

- Opportunities of Solar Vehicles

- Challenges and Limitations

6.5. Insights into CO2 Emissions from Various Vehicles

- -

- Biofuel: 30–150% of gasoline vehicles’ emissions (depending on the feedstock and production)

- -

- Electric vehicle: 30–300 g CO2/km (depending on the grid mix and manufacturing)

- -

- Solar vehicle: 20–120 g CO2/km (manufacturing-focused emissions)

- -

- Fuel cell vehicle: 0–200 g CO2/km (depending on the hydrogen source)

7. Conclusions

- Electric vehicles (EVs) currently offer the greatest potential for significant CO2 emission reductions, boasting life-cycle emissions 50–80% lower than gasoline vehicles, even when accounting for grid mix variations. The adoption of sustainable vehicles contributes significantly to achieving carbon neutrality and net-zero emissions, promoting a cleaner and greener transportation landscape. The widespread adoption of EVs could lead to economic benefits through reduced fuel dependence, lower maintenance costs, and new job creation in the clean energy sector.

- The comparative analysis revealed that electric vehicles and solar vehicles currently stand out as the more feasible and sustainable options, while fully biofuel vehicles and fuel cell vehicles face challenges that need to be addressed.

- This analysis reveals the strengths and weaknesses of each technology:

- ❖

- BPVs: Offer reduced greenhouse gas emissions, but concerns exist regarding feedstock sustainability and land use.

- ❖

- FCVs: Produce minimal emissions at the tailpipe, but require clean hydrogen infrastructure and face cost challenges.

- ❖

- EVs: Boast significant emission reductions, but rely on grid decarbonization and face challenges with charging infrastructure and battery cost.

- ❖

- SVs: Present the potential for zero emissions with limited environmental impact, but require further development to address the range limitations and weather dependence.

- Several challenges, like biofuel scarcity, increased weight, faster wear of car tires, range anxiety for EVs, infrastructure constraints for FCVs, and the intermittency of solar power for solar vehicles, need to be addressed.

- Early studies suggest solar vehicles could achieve even lower emissions in sunny regions, though further research is needed. The performance of solar-powered vehicles is influenced by the solar radiation, temperature, and shading. Solar-powered vehicles will be viable with the integration of hybrid backup systems to overcome challenges associated with seasonal variations and reduced sunlight availability. Evaluating the local climate is crucial for integrating photovoltaics into electric vehicles, leading to successful solar-powered transportation solutions. This ensures optimal functioning in various regions.

- Research and Development: R&D efforts should focus on addressing various technical challenges to foster widespread sustainable mobility. This includes advancements in battery technology, reduce charging time, minimize battery degradation, develop light-weight solar panels, improve solar panel efficiency, improving charging infrastructure, hydrogen production methods and disposal practices to enhance the viability of green vehicles.

- Industry stakeholders: Industry stakeholders should invest in the expansion of solar charging infrastructure, hydrogen refueling infrastructure, and efficient recycling to support the growth of electric and solar vehicles. This includes the development of charging stations, battery-swapping facilities, and grid integration technologies to enhance reliability and accessibility.

- Role of Policymakers: Policymakers should prioritize measures such as tax incentives, tax credits, tax rebates, and subsidies to promote the purchase and use of electric and solar vehicles. Additionally, regulatory measures can be implemented to promote the development of solar charging infrastructure for biofuels and fuel cells. Introduce carbon pricing mechanisms to incentivize the transition away from fossil fuel-powered vehicles. Large-scale renewable energy deployment is critical to overcoming barriers to adoption and facilitating the transition toward a more sustainable transportation system.

- Collaboration between governments, industry, academia, and non-profit organizations is essential for driving innovation and knowledge-sharing in the field of sustainable mobility. This includes collaborative research projects, technology demonstration programs, and information-sharing platforms to facilitate the exchange of best practices and lessons learned.

- Limitations of the study: This study is subject to the availability of current data and may be influenced by rapid technological advancements and evolving policies. Future research should address these limitations for a comprehensive understanding of sustainable mobility.

Funding

Conflicts of Interest

References

- Andaloro, L.; Micari, S.; Napoli, G.; Polimeni, A.; Antonucci, V. A hybrid electric fuel cell minibus: Drive test. World Electr. Veh. J. 2016, 8, 131–138. [Google Scholar] [CrossRef]

- De Lorenzo, G.; Ruffo, R.M.; Fragiacomo, P. Preliminary Design of the Fuel Cells Based Energy Systems for a Cruise Ship. World Electr. Veh. J. 2023, 14, 263. [Google Scholar] [CrossRef]

- Aslan, V. Fuel characterization, engine performance characteristics and emissions analysis of different mustard seed biodiesel: An overview. J. Biotechnol. 2023, 370, 12–30. [Google Scholar] [CrossRef] [PubMed]

- Biscoff, R.K.; Enweremadu, C.C. Cashew nutshell liquid: A potential inedible source of biodiesel for heavy duty vehicles in sub-Saharan Africa. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 905–923. [Google Scholar] [CrossRef]

- Tanwar, M.D.; Torres, F.A.; Alqahtani, A.M.; Tanwar, P.K.; Bhand, Y.; Doustdar, O. Promising Bioalcohols for Low-Emission Vehicles. Energies 2023, 16, 597. [Google Scholar] [CrossRef]

- Mallouppas, G.; Yfantis, E.A.; Ioannou, C.; Paradeisiotis, A.; Ktoris, A. Application of Biogas and Biomethane as Maritime Fuels: A Review of Research, Technology Development, Innovation Proposals, and Market Potentials. Energies 2023, 16, 66. [Google Scholar] [CrossRef]

- Maiorino, A.; Cilenti, C.; Petruzziello, F.; Aprea, C. A review on thermal management of battery packs for electric vehicles. Appl. Therm. Eng. 2024, 238, 122035. [Google Scholar] [CrossRef]

- Ali, Z.M.; Calasan, M.; Gandoman, F.H.; Jurado, F.; Aleem, S.H.E.A. Review of batteries reliability in electric vehicle and E-mobility applications. Ain Shams Eng. J. 2023, 15, 102442. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.; Fu, L.; Zhen, D.; Gu, F.; Ball, A.D. A review on rapid state of health estimation of lithium-ion batteries in electric vehicles. Sustain. Energy Technol. Assess. 2023, 60, 103457. [Google Scholar] [CrossRef]

- Leoncini, G.; Mothier, R.; Michel, B.; Clausse, M. A review on challenges concerning thermal management system design for medium duty electric vehicles. Appl. Therm. Eng. 2024, 236, 121464. [Google Scholar] [CrossRef]

- Waseem, M.; Amir, M.; Lakshmi, G.S.; Harivardhagini, S.; Ahmad, M. Fuel Cell-based Hybrid Electric Vehicles: An Integrated Review of Current Status, Key Challenges, Recommended Policies, and Future Prospects. Green Energy Intell. Transp. 2023, 2, 100121. [Google Scholar] [CrossRef]

- Aminudin, M.A.; Kamarudin, S.K.; Lim, B.H.; Majilan, E.H.; Masdar, M.S.; Shaari, N. An overview: Current progress on hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2023, 48, 4371–4388. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Atnaw, S.M.; Salau, A.O.; Eneh, J.N. Review of optimal sizing and power management strategies for fuel cell/battery/super capacitor hybrid electric vehicles. Energy Rep. 2023, 9, 2213–2228. [Google Scholar] [CrossRef]

- Mancino, A.N.; Menale, C.; Vellucci, F.; Pasquali, M.; Bubbico, R. PEM Fuel Cell Applications in Road Transport. Energies 2023, 16, 6129. [Google Scholar] [CrossRef]

- Minak, G. Solar Energy-Powered Boats: State of the Art and Perspectives. J. Mar. Sci. Eng. 2023, 11, 1519. [Google Scholar] [CrossRef]

- Pochont, N.R.; Raja Sekhar, Y. Recent trends in photovoltaic technologies for sustainable transportation in passenger vehicles—A review. Renew. Sustain. Energy Rev. 2023, 181, 113317. [Google Scholar] [CrossRef]

- Samadi, H.; Ala, G.; Brano, V.L.; Romano, P.; Viola, F. Investigation of Effective Factors on Vehicles Integrated Photovoltaic (VIPV) Performance: A Review. World Electr. Veh. J. 2023, 14, 154. [Google Scholar] [CrossRef]

- Sandaka, B.P.; Kumar, J. Alternative vehicular fuels for environmental decarbonization: A critical review of challenges in using electricity, hydrogen, and biofuels as a sustainable vehicular fuel. Chem. Eng. J. Adv. 2023, 14, 100442. [Google Scholar] [CrossRef]

- Shahzad, K.; Cheema, I.I. Low-carbon technologies in automotive industry and decarbonizing transport. J. Power Sources 2024, 591, 233888. [Google Scholar] [CrossRef]

- Zhang, W.; Fang, X.; Sun, C. The alternative path for fossil oil: Electric vehicles or hydrogen fuel cell vehicles? J. Environ. Manag. 2023, 341, 118019. [Google Scholar] [CrossRef]

- Nordelöf, A.; Messagie, M.; Tillman, A.M.; Söderman, M.L.; Van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—What can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Arcese, G.; Bella, G. Environmental Analysis Based on Life Cycle Assessment: An Empirical Investigation on the Conventional and Hybrid Powertrain. In SAE Technical Papers; SAE International: Pittsburgh, PA, USA, 2019. [Google Scholar] [CrossRef]

- Deshmukh, M.K.G.; Sameeroddin, M.; Abdul, D.; Sattar, M.A. Renewable energy in the 21st century: A review. Mater. Today Proc. 2023, 80, 1756–1759. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F. Future Role of Bioenergy. In The Role of Bioenergy in the Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 435–547. [Google Scholar] [CrossRef]

- Duarah, P.; Haldar, D.; Patel, A.K.; Dong, C.-D.; Singhania, R.R.; Purkait, M.K. A review on global perspectives of sustainable development in bioenergy generation. Bioresour. Technol. 2022, 348, 126791. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Liu, B.; Jia, L.; Yan, D.; Li, J. Liquid biofuels for solid oxide fuel cells: A review. J. Power Sources 2023, 556, 232437. [Google Scholar] [CrossRef]

- Velvizhi, G.; Jacqueline, P.J.; Shetti, N.P.; Latha, K.; Mohanakrishna, G.; Aminabhavi, T.M. Emerging trends and advances in valorization of lignocellulosic biomass to biofuels. J. Environ. Manag. 2023, 345, 118527. [Google Scholar] [CrossRef] [PubMed]

- Liaquat, A.M.; Kalam, M.A.; Masjuki, H.H.; Jayed, M.H. Potential emissions reduction in road transport sector using biofuel in developing countries. Atmos. Env. 2010, 44, 3869–3877. [Google Scholar] [CrossRef]

- Songstad, D.D.; Lakshmanan, P.; Chen, J.; Gibbons, W.; Hughes, S.; Nelson, R. Historical perspective of biofuels: Learning from the past to rediscover the future. In Vitro Cell. Dev. Biol. Plant 2009, 45, 189–192. [Google Scholar] [CrossRef]

- Balasubramanian, N.; Steward, K.F. Biodiesel: History of Plant Based Oil Usage and Modern Innovations. Int. J. Hist. Chem. 2019, 3, 57–71. [Google Scholar] [CrossRef]

- Singh, R.S.; Walia, A. Biofuels Historical Perspectives and Public Opinions. 2017. Available online: https://www.researchgate.net/publication/311575858 (accessed on 7 December 2023).

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Moravvej, Z.; Makarem, M.A.; Rahimpour, M.R. The fourth generation of biofuel. In Second and Third Generation of Feedstocks: The Evolution of Biofuels; Elsevier: Amsterdam, The Netherlands, 2019; pp. 557–597. [Google Scholar] [CrossRef]

- De Luca, D.; Fragiacomo, P.; De Lorenzo, G.; Czarnetski, W.T.; Schneider, W. Strategies for Dimensioning Two-Wheeled Fuel Cell Hybrid Electric Vehicles Using Numerical Analysis Software. Fuel Cells 2016, 16, 628–639. [Google Scholar] [CrossRef]

- Liu, H.; Qin, S.; Sirohi, R.; Ahluwalia, V.; Zhou, Y.; Sindhu, R.; Binod, P.; Singhnia, R.R.; Patel, A.K.; Juneja, A.; et al. Sustainable blueberry waste recycling towards biorefinery strategy and circular bioeconomy: A review. Bioresour. Technol. 2021, 332, 125181. [Google Scholar] [CrossRef] [PubMed]

- Vaishnav, N.; Singh, A.; Adsul, M.; Dixit, P.; Sandhu, S.K.; Mathur, A.; Puri, S.K.; Singhania, R.R. Penicillium: The next emerging champion for cellulase production. Bioresour. Technol. Rep. 2018, 2, 131–140. [Google Scholar] [CrossRef]

- Patel, A.K.; Singhania, R.R.; Sim, S.J.; Pandey, A. Thermostable cellulases: Current status and perspectives. Bioresour. Technol. 2019, 279, 385–392. [Google Scholar] [CrossRef] [PubMed]

- Khan, N.; Sudhakar, K.; Mamat, R. Role of Biofuels in Energy Transition, Green Economy and Carbon Neutrality. Sustainability 2021, 13, 12374. [Google Scholar] [CrossRef]

- Singhania, R.R.; Ruiz, H.A.; Awasthi, M.K.; Dong, C.-D.; Chen, C.-W.; Patel, A.K. Challenges in cellulase bioprocess for biofuel applications. Renew. Sustain. Energy Rev. 2021, 151, 111622. [Google Scholar] [CrossRef]

- Chang, K.S.; Kim, J.; Park, H.; Hong, S.-J.; Lee, C.-G.; Jin, E. Enhanced lipid productivity in AGP knockout marine microalga Tetraselmis sp. using a DNA-free CRISPR-Cas9 RNP method. Bioresour. Technol. 2020, 303, 122932. [Google Scholar] [CrossRef] [PubMed]

- Shin, Y.S.; Jeong, J.; Nguyen, T.H.T.; Kim, J.Y.H.; Jin, E.; Sim, S.J. Targeted knockout of phospholipase A2 to increase lipid productivity in Chlamydomonas reinhardtii for biodiesel production. Bioresour. Technol. 2019, 271, 368–374. [Google Scholar] [CrossRef]

- Abdullah, B.; Muhammad, S.A.F.S.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Patel, A.; Hrůzová, K.; Rova, U.; Christakopoulos, P.; Matsakas, L. Sustainable biorefinery concept for biofuel production through holistic volarization of food waste. Bioresour. Technol. 2019, 294, 122247. [Google Scholar] [CrossRef]

- Mushtaq, Z.; Maqbool, R.; Bhat, K.A. Genetic engineering and fifth-generation biofuels. In Environmental Sustainability of Biofuels; Elsevier: Amsterdam, The Netherlands, 2023; pp. 237–251. [Google Scholar] [CrossRef]

- Debnath, D.; Khanna, M.; Rajagopal, D.; Zilberman, D. The Future of Biofuels in an Electrifying Global Transportation Sector: Imperative, Prospects and Challenges. Appl. Econ. Perspect. Policy 2019, 41, 563–582. [Google Scholar] [CrossRef]

- Ng, J.-H.; Ng, H.K.; Gan, S. Recent trends in policies, socioeconomy and future directions of the biodiesel industry. Clean Technol. Environ. Policy 2010, 12, 213–238. [Google Scholar] [CrossRef]

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.-D.; Patel, A.K.; Puri, M. Global status of lignocellulosic biorefinery: Challenges and perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef] [PubMed]

- International Energy Agency. Renewables 2020—Analysis and Forecast to 2025. 2020. Available online: https://www.iea.org/reports/renewables-2020 (accessed on 17 February 2024).

- Hemansi; Himanshu; Patel, A.K.; Saini, J.K.; Singhania, R.R. Development of multiple inhibitor tolerant yeast via adaptive laboratory evolution for sustainable bioethanol production. Bioresour. Technol. 2022, 344, 126247. [Google Scholar] [CrossRef] [PubMed]

- Singhania, R.R.; Patel, A.K.; Raj, T.; Chen, C.-W.; Ponnusamy, V.K.; Tahir, N.; Kim, S.-H.; Dong, C.-D. Lignin valorisation via enzymes: A sustainable approach. Fuel 2022, 311, 122608. [Google Scholar] [CrossRef]

- Gautam, P.; Neha; Upadhyay, S.N.; Dubey, S.K. Bio-methanol as a renewable fuel from waste biomass: Current trends and future perspective. Fuel 2020, 273, 117783. [Google Scholar] [CrossRef]

- Baena-Moreno, F.M.; Pastor-Pérez, L.; Wang, Q.; Reina, T.R. Bio-methane and bio-methanol co-production from biogas: A profitability analysis to explore new sustainable chemical processes. J. Clean. Prod. 2020, 265, 121909. [Google Scholar] [CrossRef]

- Liu, Y.; Yuan, Y.; Ramya, G.; Singh, S.M.; Chi, N.T.L.; Pugazhendhi, A.; Xia, C.; Mathimani, T. A review on the promising fuel of the future—Biobutanol; the hindrances and future perspectives. Fuel 2022, 327, 125166. [Google Scholar] [CrossRef]

- Karthick, C.; Nanthagopal, K. A comprehensive review on ecological approaches of waste to wealth strategies for production of sustainable biobutanol and its suitability in automotive applications. Energy Convers. Manag. 2021, 239, 114219. [Google Scholar] [CrossRef]

- Krishnan, M.G.; Rajkumar, S.; Thangaraja, J.; Devarajan, Y. Exploring the synergistic potential of higher alcohols and biodiesel in blended and dual fuel combustion modes in diesel engines: A comprehensive review. Sustain. Chem. Pharm. 2023, 35, 101180. [Google Scholar] [CrossRef]

- Aguado-Deblas, L.; López-Tenllado, F.J.; Luna, D.; Bautista, F.M.; Romero, A.A.; Estevez, R. Advanced Biofuels from ABE (Acetone/Butanol/Ethanol) and Vegetable Oils (Castor or Sunflower Oil) for Using in Triple Blends with Diesel: Evaluation on a Diesel Engine. Materials 2022, 15, 6493. [Google Scholar] [CrossRef]

- Roque, L.F.A.; da Costa, R.B.R.; de Souza, T.A.Z.; Coronado, C.J.R.; Pinto, G.M.; Cintra, A.J.A.; Raats, O.O.; Oliveira, B.M.; Frez, G.V.; Alves, L.F.R. Experimental analysis and life cycle assessment of green diesel (HVO) in dual-fuel operation with bioethanol. J. Clean. Prod. 2023, 389, 135989. [Google Scholar] [CrossRef]

- Ershov, M.A.; Savelenko, V.D.; Makhova, U.A.; Makhmudova, A.E.; Zuikov, A.V.; Kapustin, V.M.; Abdellatief, T.M.M.; Burov, N.O.; Geng, T.; Abdelkareem, M.A.; et al. Current Challenge and Innovative Progress for Producing HVO and FAME Biodiesel Fuels and Their Applications. Waste Biomass Valorization 2023, 14, 505–521. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Wang, J.; Tan, D.; Zhang, Z.; Yang, D. Effects of Different Biodiesel-Diesel Blend Fuel on Combustion and Emission Characteristics of a Diesel Engine. Processes 2021, 9, 1984. [Google Scholar] [CrossRef]

- Reksowardojo, I.K.; Setiapraja, H.; Mokhtar; Yubaidah, S.; Mansur, D.; Putri, A.K. A Study on Utilization of High-Ratio Biodiesel and Pure Biodiesel in Advanced Vehicle Technologies. Energies 2023, 16, 718. [Google Scholar] [CrossRef]

- Xu, H.; Lee, U.; Wang, M. Life-cycle energy use and greenhouse gas emissions of palm fatty acid distillate derived renewable diesel. Renew. Sustain. Energy Rev. 2020, 134, 110144. [Google Scholar] [CrossRef]

- Xu, H.; Ou, L.; Li, Y.; Hawkins, T.R.; Wang, M. Life Cycle Greenhouse Gas Emissions of Biodiesel and Renewable Diesel Production in the United States. Environ. Sci. Technol. 2022, 56, 7512–7521. [Google Scholar] [CrossRef] [PubMed]

- Tirumareddy, P.; Esmi, F.; Masoumi, S.; Borugadda, V.B.; Dalai, A.K. Introduction to Green Diesel. In Green Diesel: An Alternative to Biodiesel and Petrodiesel; Springer: Singapore, 2022; pp. 1–40. [Google Scholar] [CrossRef]

- Zuorro, A.; García-Martínez, J.B.; Barajas-Solano, A.F. The Application of Catalytic Processes on the Production of Algae-Based Biofuels: A Review. Catalysts 2020, 11, 22. [Google Scholar] [CrossRef]

- Zhu, P.; Abdelaziz, O.Y.; Hulteberg, C.P.; Riisager, A. New synthetic approaches to biofuels from lignocellulosic biomass. Curr. Opin. Green Sustain. Chem. 2020, 21, 16–21. [Google Scholar] [CrossRef]

- Ardebili, S.M.S.; Khademalrasoul, A. An assessment of feasibility and potential of gaseous biofuel production from agricultural/animal wastes: A case study. Biomass Convers Biorefin. 2022, 12, 5105–5114. [Google Scholar] [CrossRef]

- Ternel, C.; Bouter, A.; Melgar, J. Life cycle assessment of mid-range passenger cars powered by liquid and gaseous biofuels: Comparison with greenhouse gas emissions of electric vehicles and forecast to 2030. Transp. Res. D Transp. Environ. 2021, 97, 102897. [Google Scholar] [CrossRef]

- Marconi, P.; Rosa, L. Role of biomethane to offset natural gas. Renew. Sustain. Energy Rev. 2023, 187, 113697. [Google Scholar] [CrossRef]

- de Jong, P.; Torres, E.A.; de Melo, S.A.B.V.; Mendes-Santana, D.; Pontes, K.V. Socio-economic and environmental aspects of bio-LPG and bio-dimethyl ether (Bio-DME) production and usage in developing countries: The case of Brazil. Clean. Circ. Bioecon. 2023, 6, 100055. [Google Scholar] [CrossRef]

- Michalopoulou, D.-P.; Komiotou, M.; Zannikou, Y.; Karonis, D. Impact of Bio-Ethanol, Bio-ETBE Addition on the Volatility of Gasoline with Oxygen Content at the Level of E10. Fuels 2021, 2, 501–520. [Google Scholar] [CrossRef]

- Li, S.; Li, F.; Zhu, X.; Liao, Q.; Chang, J.-S.; Ho, S.-H. Biohydrogen production from microalgae for environmental sustainability. Chemosphere 2022, 291, 132717. [Google Scholar] [CrossRef] [PubMed]

- Amer, M.; Hoeven, R.; Kelly, P.; Faulkner, M.; Smith, M.H.; Toogood, H.S.; Scrutton, N.S. Renewable and tuneable bio-LPG blends derived from amino acids. Biotechnol. Biofuels 2020, 13, 125. [Google Scholar] [CrossRef] [PubMed]

- Munagala, M.; Shastri, Y.; Nagarajan, S.; Ranade, V. Production of Bio-CNG from sugarcane bagasse: Commercialization potential assessment in Indian context. Ind. Crops Prod. 2022, 188, 115590. [Google Scholar] [CrossRef]

- Sudhakar, K.; Premalatha, M. A Mathematical Model to Assess the Potential of Algal Bio-fuels in India. Energy Sources Part A Recovery Util. Environ. Eff. 2012, 34, 1114–1120. [Google Scholar] [CrossRef]

- Dahlgren, S. Biogas-based fuels as renewable energy in the transport sector: An overview of the potential of using CBG, LBG and other vehicle fuels produced from biogas. Biofuels 2022, 13, 587–599. [Google Scholar] [CrossRef]

- Gustafsson, M.; Cruz, I.; Svensson, N.; Karlsson, M. Scenarios for upgrading and distribution of compressed and liquefied biogas—Energy, environmental, and economic analysis. J. Clean. Prod. 2020, 256, 120473. [Google Scholar] [CrossRef]

- Channappagoudra, M. Comparative study of baseline and modified engine performance operated with dairy scum biodiesel and Bio-CNG. Renew Energy 2020, 151, 604–618. [Google Scholar] [CrossRef]

- Cignini, F.; Genovese, A.; Ortenzi, F.; Valentini, S.; Caprioli, A. Performance and Emissions Comparison between Biomethane and Natural Gas Fuel in Passenger Vehicles. E3S Web Conf. 2020, 197, 08019. [Google Scholar] [CrossRef]

- Limpachoti, T.; Theinnoi, K. The Comparative Study on Compressed Natural Gas (CNG) and Compressed Biomethane Gas (CBG) Fueled in a Spark Ignition Engine. E3S Web Conf. 2021, 302, 01005. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Alternative Fuels Data Center. How Do Natural Gas Vehicles Work? Available online: https://afdc.energy.gov/vehicles/how-do-natural-gas-cars-work (accessed on 20 February 2024).

- lhyfe Heroes. Different Types of Hydrogen Vehicles. Available online: https://www.lhyfe-heroes.com/about-hydrogen/what-are-the-different-types-of-hydrogen-vehicles (accessed on 7 December 2023).

- Poullikkas, A. Sustainable options for electric vehicle technologies. Renew. Sustain. Energy Rev. 2015, 41, 1277–1287. [Google Scholar] [CrossRef]

- Brown, S.; Pyke, D.; Steenhof, P. Electric vehicles: The role and importance of standards in an emerging market. Energy Policy 2010, 38, 3797–3806. [Google Scholar] [CrossRef]

- Allaoua, B.; Asnoune, K.; Mebarki, B. Energy management of PEM fuel cell/ supercapacitor hybrid power sources for an electric vehicle. Int. J. Hydrogen Energy 2017, 42, 21158–21166. [Google Scholar] [CrossRef]

- Institute of Electrical and Electronics Engineers; Changchun Shi Fan Da Xue; Jilin Da Xue; Dongbei Shi Fan Da Xue (China). Literature review of electric vehicle technology and its applications. In Proceedings of the 2016 5th International Conference on Computer Science and Network Technology, Changchun, China, 10–11 December 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar]

- Ntombela, M.; Musasa, K.; Moloi, K. A Comprehensive Review for Battery Electric Vehicles (BEV) Drive Circuits Technology, Operations, and Challenges. World Electr. Veh. J. 2023, 14, 195. [Google Scholar] [CrossRef]

- Hannan, M.A.; Azidin, F.A.; Mohamed, A. Hybrid electric vehicles and their challenges: A review. Renew. Sustain. Energy Rev. 2014, 29, 135–150. [Google Scholar] [CrossRef]

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Chan, C.C. An Overview of Electric Vehicle Technology. Proc. IEEE 1993, 81, 1202–1213. [Google Scholar] [CrossRef]

- Chen, Y.; Jha, S.; Raut, A.; Zhang, W.; Liang, H. Performance Characteristics of Lubricants in Electric and Hybrid Vehicles: A Review of Current and Future Needs. Front. Mech. Eng. 2020, 6, 571464. [Google Scholar] [CrossRef]

- Mitsubishi Motors Confidence. Available online: https://www.mitsubishicars.com/confidence (accessed on 7 December 2023).

- Duquet, D. 2014 Toyota Prius PHV: To Plug in or Not to Plug in? The Car Guide: Montreal, QC, Canada, 2013. [Google Scholar]

- De Lorenzo, G.; Andaloro, L.; Sergi, F.; Napoli, G.; Ferraro, M.; Antonucci, V. Numerical simulation model for the preliminary design of hybrid electric city bus power train with polymer electrolyte fuel cell. Int. J. Hydrogen Energy 2014, 39, 12934–12947. [Google Scholar] [CrossRef]

- Hyundai NEXO Press Kit. Available online: https://www.hyundai.news/eu/models/electrified/nexo/press-kit.html (accessed on 7 December 2023).

- Inside EVs. Available online: https://insideevs.com/ (accessed on 7 December 2023).

- De Lorenzo, G.; Piraino, F.; Longo, F.; Tinè, G.; Boscaino, V.; Panzavecchia, N.; Caccia, M.; Fragiacomo, P. Modelling and Performance Analysis of an Autonomous Marine Vehicle Powered by a Fuel Cell Hybrid Powertrain. Energies 2022, 15, 6926. [Google Scholar] [CrossRef]

- Alanazi, F. Electric Vehicles: Benefits, Challenges, and Potential Solutions for Widespread Adaptation. Appl. Sci. 2023, 13, 6016. [Google Scholar] [CrossRef]

- Brenna, M.; Foiadelli, F.; Leone, C.; Longo, M. Electric Vehicles Charging Technology Review and Optimal Size Estimation. J. Electr. Eng. Technol. 2020, 15, 2539–2552. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Soleymani, M.; Kelouwani, S.; Amamou, A.A. Energy Recovery and Energy Harvesting in Electric and Fuel Cell Vehicles, a Review of Recent Advances. IEEE Access 2023, 11, 83107–83135. [Google Scholar] [CrossRef]

- Corti, F.; Gulino, M.S.; Laschi, M.; Lozito, G.M.; Pugi, L.; Reatti, A.; Vangi, D. Time-domain circuit modelling for hybrid supercapacitors. Energies 2021, 14, 6837. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Li, B.; Mo, T.; Li, Y.; Feng, S.P.; Qu, J.; Chu, P.K. Development and application of fuel cells in the automobile industry. J. Energy Storage 2021, 42, 103124. [Google Scholar] [CrossRef]

- Pramuanjaroenkij, A.; Kakaç, S. The fuel cell electric vehicles: The highlight review. Int. J. Hydrogen Energy 2023, 48, 9401–9425. [Google Scholar] [CrossRef]

- Andújar, J.M.; Segura, F. Fuel cells: History and updating. A walk along two centuries. Renew. Sustain. Energy Rev. 2009, 13, 2309–2322. [Google Scholar] [CrossRef]

- Qin, N.; Raissi, A.; Brooker, P. Analysis of Fuel Cell Vehicle Developments. 2014. Available online: https://www.fsec.ucf.edu/en/publications/pdf/FSEC-CR-1987-14.pdf (accessed on 7 December 2023).

- Fakhreddine, O.; Gharbia, Y.; Derakhshandeh, J.F.; Amer, A.M. Challenges and Solutions of Hydrogen Fuel Cells in Transportation Systems: A Review and Prospects. World Electr. Veh. J. 2023, 14, 156. [Google Scholar] [CrossRef]

- FASTECH. The Past, Present and Future of Hydrogen Vehicles: 2023 Update. Available online: https://www.fastechus.com/blog/the-surprising-history-of-hydrogen-vehicles (accessed on 7 December 2023).

- Fuelcellstore.com. History of Fuel Cells. Available online: https://www.fuelcellstore.com/blog-section/history-of-fuel-cells (accessed on 12 December 2023).

- Filsinger, D.; Kuwata, G.; Ikeya, N. Tailored Centrifugal Turbomachinery for Electric Fuel Cell Turbocharger. Int. J. Rotating Mach. 2021, 2021, 3972387. [Google Scholar] [CrossRef]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen fuel cell vehicles; Current status and future prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- U.S. Department of Energy, Hydrogen and Fuel Cell Technology Office. Types of Fuel Cells. Available online: https://www.energy.gov/eere/fuelcells/types-fuel-cells (accessed on 7 December 2023).

- Muthukumar, M.; Rengarajan, N.; Velliyangiri, B.; Omprakas, M.A.; Rohit, C.B.; Raja, U.K. The development of fuel cell electric vehicles—A review. Mater. Today Proc. 2021, 45, 1181–1187. [Google Scholar] [CrossRef]

- Ghasemi, R.; Sedighi, M.; Ghasemi, M.; Ghazanfarpoor, B.S. Design of a Fuzzy Adaptive Voltage Controller for a Nonlinear Polymer Electrolyte Membrane Fuel Cell with an Unknown Dynamical System. Sustainability 2023, 15, 13609. [Google Scholar] [CrossRef]

- Shin, H.K.; Ha, S.K. A Review on the Cost Analysis of Hydrogen Gas Storage Tanks for Fuel Cell Vehicles. Energies 2023, 16, 5233. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Alternative Fuel Data Center, Fuel Cell Electric Vehicles. Available online: https://afdc.energy.gov/vehicles/fuel_cell.html (accessed on 7 December 2023).

- Gupta, S.; Perveen, R. Fuel cell in electric vehicle. Mater. Today Proc. 2023, 79, 434–437. [Google Scholar] [CrossRef]

- Rajabi, A.; Shahir, F.M.; Sedaghati, R. New unidirectional step-up DC-DC converter for fuel-cell vehicle: Design and implementation. Electr. Power Syst. Res. 2022, 212, 108653. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, C.; Wan, Z.; Chen, X.; Chan, S.H.; Tu, Z. Progress and perspectives of integrated thermal management systems in PEM fuel cell vehicles: A review. Renew. Sustain. Energy Rev. 2022, 155, 111908. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratories. Fuel Cell Electric Vehicle Components. Available online: https://www.nrel.gov/research/transportation-fuel-cells.html (accessed on 7 December 2023).

- H2.Live. Hydrogen Vehicles. Available online: https://h2.live/en/fcev/ (accessed on 7 December 2023).

- Susskind, L.; Chun, J.; Goldberg, S.; Gordon, J.A.; Smith, G.; Zaerpoor, Y. Breaking Out of Carbon Lock-In: Malaysia’s Path to Decarbonization. Front. Built Environ. 2020, 6, 21. [Google Scholar] [CrossRef]

- Light Year. Lightyear 0 Paving the Way for Clean Mobility. Available online: https://lightyear.one/lightyear-0/ (accessed on 5 January 2024).

- Guo, W.; Kong, L.; Chow, T.; Li, C.; Zhu, Q.; Qiu, Z.; Li, L.; Wang, Y.; Riffat, S.B. Energy performance of photovoltaic (PV) windows under typical climates of China in terms of transmittance and orientation. Energy 2020, 213, 118794. [Google Scholar] [CrossRef]

- Thiel, C.; Amillo, A.G.; Tansini, A.; Tsakalidis, A.; Fontaras, G.; Dunlop, E.; Taylor, N.; Jäger-Waldau, A.; Araki, K.; Nishioka, K.; et al. Impact of climatic conditions on prospects for integrated photovoltaics in electric vehicles. Renew. Sustain. Energy Rev. 2022, 158, 112109. [Google Scholar] [CrossRef]

- Ng, C.W.; Zhang, J.; Tay, S.E. A Tropical Case Study Quantifying Solar Irradiance Collected on a Car Roof for Vehicle Integrated Photovoltaics Towards Low-Carbon. In Proceedings of the 47th IEEE Photovoltaic Specialists Conference(PVSC), Calgary, AB, Canada, 15 June–21 August 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 2461–2464. [Google Scholar]

- Nukunudompanich, M.; Sriprapai, D.; Sontikaew, S. Aspects of optical and thermal performances in flexible perovskite solar cells made of nanomaterials with potential for development of vehicle-integrated photovoltaics. Mater. Today Proc. 2022, 66, 3163–3167. [Google Scholar] [CrossRef]

- Fernández, R.Á. A more realistic approach to electric vehicle contribution to greenhouse gas emissions in the city. J. Clean. Prod. 2018, 172, 949–959. [Google Scholar] [CrossRef]

- Hoekstra, A. The Underestimated Potential of Battery Electric Vehicles to Reduce Emissions. Joule 2019, 3, 1412–1414. [Google Scholar] [CrossRef]

- Requia, W.J.; Mohamed, M.; Higgins, C.D.; Arain, A.; Ferguson, M. How clean are electric vehicles? Evidence-based review of the effects of electric mobility on air pollutants, greenhouse gas emissions and human health. Atmos. Environ. 2018, 185, 64–77. [Google Scholar] [CrossRef]

- Xing, J.; Leard, B.; Li, S. What does an electric vehicle replace? J. Environ. Econ. Manag. 2021, 107, 102432. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Greenhouse Gas Emissions from Electric and Plug-In Hybrid Vehicles—Results. Office of Energy Efficiency and Renewable Energy. Available online: https://www.fueleconomy.gov/feg/Find.do?year=2016&vehicleId=37066&zipCode=94102&action=bt3 (accessed on 20 February 2024).

- Kobashi, T.; Yoshida, T.; Yamagata, Y.; Naito, K.; Pfenninger, S.; Say, K.; Takeda, Y.; Ahl, A.; Yarime, M.; Hara, K. On the potential of “Photovoltaics + Electric vehicles” for deep decarbonization of Kyoto’s power systems: Techno-economic-social considerations. Appl. Energy 2020, 275, 115419. [Google Scholar] [CrossRef]

- Ghodusinejad, M.H.; Ghodrati, A.; Zahedi, R.; Yousefi, H. Multi-criteria modeling and assessment of PV system performance in different climate areas of Iran. Sustain. Energy Technol. Assess. 2022, 53, 102520. [Google Scholar] [CrossRef]

- Ecoinvent.org. Ecoinvent Database. European Environment Agency. Available online: https://ecoinvent.org/database/ (accessed on 20 February 2024).

- Argonne National Laboratory. Publications of the GREET Model Development and Applications Center for Transportation Research. Available online: https://greet.anl.gov/list.php (accessed on 20 February 2024).

- ICCT. ZERO-EMISSION VEHICLES. The International Council on Clean Transportation. Available online: https://theicct.org/decarbonizing/zero-emission-vehicles/ (accessed on 20 February 2024).

| Company Name | Vehicle Model | Specifications |

|---|---|---|

| Cadillac | Cadillac Escalade 2WD (2024) | Fuel: Biodiesel (B20) Type of Vehicle: SUV Conventional Fuel Economy: 23 mpg Engine/Motor(s): 3.0L V6 Transmission: Auto Drivetrain: RWD |

| GMC | GMC Yukon/Yukon XL 2WD (2024) | Fuel: Biodiesel (B20) Type of Vehicle: SUV Conventional Fuel Economy: 23 mpg Engine/Motor(s): 3.0L V6 Transmission: Auto Drivetrain: RWD |

| Chevrolet | Chevrolet Silverado 2WD (2024) | Fuel: Biodiesel (B20) Type of Vehicle: pickup Conventional Fuel Economy: 26 mpg Engine/Motor(s): 3.0L V6 Transmission: Auto Drivetrain: RWD |

| Ford | Ford Explorer AWD FFV (2022) | Fuel: Ethanol (E85) Type of Vehicle: SUV Alternative Fuel Economy: 13 mpg Conventional Fuel Economy: 19 mpg Engine/Motor(s): 3.3L V6 Transmission: Auto Drivetrain: AWD |

| Dodge | Dodge Challenger SRT Demon 170 (2023) | Fuel: Ethanol (E85) Type of Vehicle: sedan/wagon Alternative Fuel Economy: 15 mpg Conventional Fuel Economy: 9 mpg Engine/Motor(s): 6.2L V8 Transmission: Auto Drivetrain: RWD |

| GMC | GMC Sierra 2WD (2023) | Fuel: Ethanol (E85) Type of Vehicle: pickup Alternative Fuel Economy: 13 mpg Conventional Fuel Economy: 18 mpg Engine/Motor(s): 5.3L V8 Transmission: Auto Drivetrain: RWD |

| Pros | Cons |

|---|---|

| Biofuels are renewable and promote sustainability. | Biofuels require pre-treatment processes before use. |

| Offer higher reliability. | Developing biofuel technologies can be expensive. |

| Can be produced locally. | Need to improve the efficiency of biofuel production technologies. |

| Reduce dependence on foreign energy sources. | Procurement of subsidies for biofuel production is needed. |

| Can help stabilize energy prices. | Funding for research and development is needed. |

| Biofuels support rural development. | Scaling up biofuel production to commercial levels can be challenging. |

| Biofuels help reduce air pollution. | Establishing an efficient collection network for biofuel feedstock can be complex. |

| Biofuel production can make use of marginal lands and agricultural waste. | Biofuels require specialized storage facilities. |

| Biofuels enable carbon sequestration. | Biofuel production can compete with food production. |

| Energy Storage Technology | Characteristics | Parameters |

|---|---|---|

| Li-ion Battery | High energy storage capacity [99] | Temperature Range: −20 °C to +60 °C |

| Rapid charging [100] | Specific Energy: 100–240 Wh/kg [100] | |

| Low self-discharge rate | Cost: 0.3 to 0.6 €/Wh | |

| Wide range of operating temperature | Efficiency: 95% [99] | |

| Hybrid Supercapacitor | Higher specific energy density than Li-ion battery | Temperature: −20 °C to 70 °C |

| More cycles of charging | Specific Energy: 10–15 Wh/kg | |

| Good thermal management | Cost: 0.3 to 20 €/Wh | |

| Very fast discharge rate | Efficiency: 95% | |

| New-Gen EDLCs | Higher capacitance than electrolytic capacitor | Temperature: −40 °C to +70 °C |

| Lower cost than Li-ion or hybrid supercapacitor | Specific Energy: 30–70 Wh/kg | |

| Ideal for fast energy release | Cost: 0.3 to 2 €/Wh | |

| Very minimal degradation | Efficiency: 95% |

| Company Name | Electric Vehicle Model | Specifications |

|---|---|---|

| NETA | Neta V | Battery Electric Vehicles Battery Type: Lithium Battery Electric motor: 135.33 kW Battery capacity: 38.54 kWh Driving Range: 380 km Maximum Torque: 160 Nm Top Speed: 120 km/h |

| Smart | #1 Pro | Battery Electric Vehicles Battery Type: LFP Battery Electric motor: 147.09 kW Battery capacity: 66/44 kWh Driving Range: 315/440 km Maximum Torque: 343 Nm Top Speed: 180 km/h |

| BYD | Atto 3 | Battery Electric Vehicles Battery Type: LFP Battery Electric motor: 203 Battery capacity: 60.48/49.92 kWh Driving Range: 410/480 km Maximum Torque: 310 Nm |

| Tesla | Model Y | Battery Electric Vehicles Battery Type: LFP Battery Electric motor: 255 kW Battery capacity: 62 kWh Driving Range: 455 km Maximum Torque: 420 Nm Top Speed: 217 km/h |

| Hyundai | Ioniq 6 RWD | Battery Electric Vehicles Battery Type: Lithium Battery Electric motor: 168 kW Battery capacity: 77 kWh Driving Range: 614 km Maximum Torque: 310 Nm |

| Tesla | Cybertruck | Battery Electric Vehicles Battery Type: Lithium Battery Electric motor: 450 kW Battery capacity: 123 kWh Driving Range: 350 km Maximum Torque: 310 Nm |

| Pros | Cons |

|---|---|

| Higher efficiency of powertrain | Limited refuel infrastructure |

| Higher energy density than other conventional fuels | Higher upfront cost |

| Improved acceleration and power transmission compared to combustion-engine technology | Production cost of the vehicle is high |

| Rechargeability of the battery system | Highly flammable |

| Noise-free working of the motor | Cost of battery and battery degradation |

| Fuel Cell | AFC | SOFC | PEMFC | PAFC | MCFC |

|---|---|---|---|---|---|

| Cathode reaction | 1/2 O2 + H2O + 2 e− → 2 (OH)−1 | 1/2 O2 + 2 e− → O2- | 1/2 O2 + 2 H+ + 2 e- → H2O | 1/2 O2 + 2 H+ + 2 e− → H2O | 1/2 O2 + CO2 + 2 e− → CO3−2 |

| Anode reaction | H2 + 2 OH− → 2 H2O + 2 e− | H2 + O2− → H2O + 2 e− CO + O2− → CO2 + 2 e− CH4 + 4 O2− → 2 H2O + CO2 + 8 e− | H2 → 2 H+ + 2 e− | H2 → 2 H+ + 2 e− | H2 + CO3−2→ H2O + CO2 + 2 e− |

| Electrolyte | KOH aqueous solution | Yttria-stabilized zirconia (YSZ) | Polymer membrane | Phosphoric acid (H3PO4) | Molten carbonate |

| Stack size | 1–200 kW | 1 kW–2 MW | <1 kW–100 kW | 100 kW | 300 kW–3 MW |

| Operating temperature | ≤100 °C | ≤1000 °C | ≤120 °C | ≤200 °C | ≤700 °C |

| Fuels | Hydrogen, Ammonia | Natural gas, Methanol, Ethanol, Biogas, Coal gas | Hydrogen | Hydrogen, Methanol | Natural gas, Methanol, Ethanol, Biogas, Coal gas |

| Electrical efficiency (LHV) | ≤70% | ≤60% | ≤60% | ≤50% | ≤50% |

| Company Name | Fuel Cell Vehicle Model | Tank Capacity (kg) | Electric Motor | Range (km) | Carbon Emissions (g/km) |

|---|---|---|---|---|---|

| Toyota | MIRAI 2016 Sedan  | 5.6 | 135.33 kW | 650 | 0 |

| MIRAI II 2021 Sedan  | 5.6 | 135.33 kW | 650 | 0 | |

| Hyundai | NEXO 2018 SUV  | 6.33 | 120 kW | 756 | 0 |

| ix35 2012 SUV  | 5.64 | 100 kW | 594 | 0 | |

| Honda | Clarity Fuel Cell 2008 Saloon  | 5.0 | 130 kW | 589 | 0 |

| Mercedes-Benz FCEV with Li-ion battery | GLC F-CELL 2018 SUV  | 4.4 | 155 kW | 478 | 0 |

| Citroen | e-Jumpy Hydrogen 2019 Transporter  | 4.4 | 100 kW | 400 | 0 |

| PEUGEOT | e-Expert Hydrogen 2019 Transporter  | 4.4 | 100 kW | 400 | 0 |

| Opel | Vivaro e-HYDROGEN 2021 Transporter  | 4.4 | 100 kW | 400 | 0 |

| Pros | Cons |

|---|---|

| Zero tailpipe emissions | Limited refuel infrastructure |

| Higher energy density than other conventional fuels | Storage of hydrogen |

| Renewable fuel such as H2 can be generated using solar wind power | Production cost of hydrogen |

| Long range of journey | Production cost of the vehicle |

| Short refueling time | Highly flammable |

| Noise-free working of motor | Cost of cathode/anode materials |

| Parameters | Bio Fuels | Solar | Fuel Cell | Electrical | |

|---|---|---|---|---|---|

| Technical | Power Supply Core Components | Engine | Solar Cell Battery and Motor | Fuel Cell and Electric Motor | Battery and Electric Motor |

| Fuel | Bio-Derived Fuels | Sunlight | Hydrogen | Electricity | |

| Mileage/Range | Very High | Low | High | Moderate | |

| Possible Hazards | Fuel Flammability | Battery Explosion | Hydrogen Flammability | Battery explosion | |

| Infrastructure | Established | Not Needed | Low | Moderate | |

| Hybridization Possibility | Yes | No | No | Yes | |

| Economical | Initial Cost | Low | Very High | High | Moderate |

| Running Cost | High | Nil | Moderate | Low | |

| Environmental | Tailpipe Emissions | Depends on Fuels | zero | Zero (Water Vapor) | Zero |

| Social | Social Perception | Moderate | Low | Low | High |

| Policy | Government Policy Support | Yes | No | No | Yes |

| Market trend | Commercial Status | Commercial Blending is Available | Lightyear | Honda, Toyota, Mercedes, Hyundai | More Companies |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reddy, V.J.; Hariram, N.P.; Maity, R.; Ghazali, M.F.; Kumarasamy, S. Sustainable Vehicles for Decarbonizing the Transport Sector: A Comparison of Biofuel, Electric, Fuel Cell and Solar-Powered Vehicles. World Electr. Veh. J. 2024, 15, 93. https://doi.org/10.3390/wevj15030093

Reddy VJ, Hariram NP, Maity R, Ghazali MF, Kumarasamy S. Sustainable Vehicles for Decarbonizing the Transport Sector: A Comparison of Biofuel, Electric, Fuel Cell and Solar-Powered Vehicles. World Electric Vehicle Journal. 2024; 15(3):93. https://doi.org/10.3390/wevj15030093

Chicago/Turabian StyleReddy, Vennapusa Jagadeeswara, N. P. Hariram, Rittick Maity, Mohd Fairusham Ghazali, and Sudhakar Kumarasamy. 2024. "Sustainable Vehicles for Decarbonizing the Transport Sector: A Comparison of Biofuel, Electric, Fuel Cell and Solar-Powered Vehicles" World Electric Vehicle Journal 15, no. 3: 93. https://doi.org/10.3390/wevj15030093

APA StyleReddy, V. J., Hariram, N. P., Maity, R., Ghazali, M. F., & Kumarasamy, S. (2024). Sustainable Vehicles for Decarbonizing the Transport Sector: A Comparison of Biofuel, Electric, Fuel Cell and Solar-Powered Vehicles. World Electric Vehicle Journal, 15(3), 93. https://doi.org/10.3390/wevj15030093