1. Introduction

The European Green Deal outlines the climate change mitigation targets as follows: “all 27 EU Member States committed to turning the EU into the first climate neutral continent by 2050”. They pledged to reduce emissions by at least 55% by 2030, compared to 1990 levels, and to reach a fossil-free society by 2050 [

1]. The transportation sector is responsible for roughly one-quarter of the total greenhouse emissions in the EU with road vehicles contributing to over 60% of the emissions. Lorries, buses, and coaches are responsible for about a quarter of carbon dioxide (CO

2) emissions from road transport in the EU and for some 6% of total EU emissions. Despite some improvements in fuel consumption efficiency in recent years, these emissions are still rising, mainly due to increasing road freight traffic. This requires tremendous efforts in the coming years to introduce zero-emission powertrains and energy infrastructure into regional and long-haul trucking operations. Vehicle emission regulations and other policy measures will pave the way for the transition towards zero-emission transport curbing the total EU emissions of CO

2; although, for heavy-duty vehicles, the current regulation is still quite mild: −15% from 2025 onwards and −30% from 2030 onwards, compared with the 2019/2020 level [

2].

Even though electrification is only one tool among others to reduce vehicle emissions, it appears to be the most efficient and feasible technology. This has been studied by now in several research papers where many earlier ones found the status of technology not sufficient for competitive electric truck operations, for example, insufficient energy density and battery capacity on-board and slow charging capability [

3]. Later studies have concluded that the business case for electric trucks is emerging but the techno-economic competitiveness is depending a lot on the commodity being transported and the related use case and system level, with medium-duty trucks being able to operate battery electric for a large share of road freight haulage, whereas for heavy-duty and longer missions, the fraction is smaller [

4]. Continuous technology development, especially in batteries and charging equipment, has been the main driver towards competitiveness of heavy-duty trucks. The combination of shorter charging times and, therefore, higher vehicle availability through fast charging can improve competitiveness of battery electric trucks in an increasing share of transport missions [

5]. In the developing market, there is a dilemma between uptake of electric heavy-duty vehicles (e-HDVs) and the building up of the charging infrastructure. To resolve the chicken-and-egg problem of e-mobility, the three largest truck manufacturers joined in the project for establishing charging infrastructure for electric long-distance freight transport [

6]. The uptake of e-HDVs has been most feasible in conventional city deliveries that typically, like e-Buses, drive pre-defined work cycles, their energy consumption can be estimated quite accurately, and they can be charged overnight in their dedicated parking depots, while their daily driving range varies only a little. However, in long-haul operations and on shorter missions, if there are more variables in the logistics assignment, there should be flexibility in the system to use opportunity charging (fast charging, high-power charging, HPC) in addition to depot charging. Driving in multiple shifts creates the demand for HPC instead of slow depot charging. Ad hoc assignments (e.g., courier service, construction transports, maintenance and utility vehicles), logistics in greater metropolitan areas, long-haul transportation, etc., can be based on the depot but additionally would require HPC. Roughly put, the heavier the (articulated) vehicle is, the more the demand for HPC during the work shift will be. According to recent analysis on long-haul operations in Europe, about 40,000 overnight and 9000 fast megawatt chargers will be needed to support battery electric long-haul freight [

7].

In Nordic countries, the long-haul trucks are typically in a heavier weight class that is up to GVW 76 tonnes. These national regulations make Nordics a small and specific market area so that the newest innovations would rather need to be implemented by national or joint activities. Combining the harsh weather conditions with the higher vehicle masses makes the Nordics an ideal location for piloting new innovations. In 2021–2022 piloting case examples in the electrification of heavy transports, it was reported in Sweden that High-Capacity Transport (HCT)-articulated vehicles of 64 and 80 GVW tonnes can be electrified in certain routes and drive cycles [

8,

9]. Also, it was reported that the transportation safety norms for dangerous goods (ADR) can be fulfilled using e-HDVs [

10].

The strict definition of zero-emission road transport requires the prime mover to be electricity (battery electric vehicle, BEV) or hydrogen (fuel cell vehicle, FCV), or a hybridisation of the two, such as a battery electric truck with a H

2 fuel cell range extender. While battery electric trucks are, in terms of technology and market readiness, several years ahead of fuel-cell-powered trucks, research on the pros and cons of each and optimal ways to combine them from powertrain to systems merit a proper analysis. Published research suggests that for many freight operations, battery electric trucks offer the lowest total cost of ownership, but fuel cell trucks can still be a viable additional option in some use cases [

11]. When assessing the system-level viability for zero-emission trucking including vehicle use cases and missions, energy consumption and sensitivity to, e.g., payload, GVW, driving cycle, and conditions, and the viability of the different powertrain and infrastructure configurations, modelling, and simulation provide an invaluable tool to support decision making. As shown by previous research, an unfavourable combination of conditions can reduce the available operative range of battery electric trucks by 41–47% [

12]. The mitigation measures to reduce the risk for trucking operators from such a range reduction should contain elements from the powertrain, vehicular design, and infrastructure implementation. Relevant topics include sufficient margin in designed battery or H

2 tank capacity and powertrain efficiency, vehicular aspects such as minimising driving resistances and auxiliary consumption, as well as location, availability, and capacity of charging and H

2 refilling infrastructures.

The present paper deals with conceptualising and designing modular zero-emission powertrains suitable for regional and long-haul missions using trucks with GVW of 40 tonnes and beyond. In Europe, this relates to VECTO vehicle groups 4–12, and in the US, it relates to Class 8 trucks. The conceptual design object is a 6 × 4 tractor (VECTO 12, overview [

13]) prototype with a modular zero-emission powertrain capable of multiple zero-emission missions in regional and long-haul operations. The powertrain has an intermediate-sized traction battery for electric operation, fuel cell system capable of providing average power for selected missions, and a strategy for battery-fuel cell hybrid operations. The modular powertrain, therefore, enables three energy and operation strategies to be analysed in one demonstration setting: BEV operation, FCV operation, and fuel cell range-extended BEV (FCRE) operation.

In line with the European 2050 goals, the present paper has been produced through the project ESCALATE, which aims to demonstrate high-efficiency zero-emission HDV powertrains (up to 10% increase) for long-haul applications that will provide a range of 800 km without refuelling/recharging and cover at least 500 km average daily operation (6+ months) in real conditions. ESCALATE is built on the novel concepts around three main innovation areas, which are (i) standardised, well-designed, cost-effective modular and scalable multi-powertrain components; (ii) fast fuelling and grid-friendly charging solutions; and (iii) Digital Twin (DT) and AI-based management tools considering capacity, availability, speed, and nature of the charging infrastructures as well as the fleet structures. Throughout the project lifetime, five pilots, five DTs, and five case studies on TCO (with the target of 10% reduction), together with their environmental performance via LCA, will be performed.

2. Materials and Methods

Two design basis driving cycles for the GVW 40-tonne prototype tractor demonstrator were used. Vehicle configuration was as is seen in

Figure 1 (left). The first driving cycle is a single-charge and refill mission of 750 km based on the long-haul mission profile of the Vehicle Energy Consumption calculation TOol VECTO of the European Commission [

14], and the second one is a real roundtrip mission in Finland of 520 km exposed to various Nordic road conditions. The real route runs from the port of Helsinki in the south of Finland up to Jyväskylä in central parts of Finland, along the TEN-T core corridor. Modular powertrain and vehicle model was constructed to support the conceptual design, and driving cycles for both the VECTO long-haul and the real mission were constructed, utilising open road network and speed limit data. Charging and H

2 refuelling sites were planned to support the missions. Energy consumption on the said driving cycles and loading were estimated through simulation, and this information was used for preliminary dimensioning of the powertrain. The electric drives of the tractor were dimensioned so that a secondary mission of GVW up to 76 tonnes configuration,

Figure 1 (right), on a shorter route can be operated. The basic parameters of the powertrain and the vehicle combinations used in the simulation are given in

Table 1.

In the piloting phase, the electric truck (in BEV and/or FCEV configuration) will operate on a flexible time schedule. The vehicle will be depot-charged in Jyväskylä. It is possible to drive directly to Vuosaari port in Helsinki without need for opportunity charging on the road. The driver’s resting hours will be well enough to make each leg without additional breaks due to possible charging events. The time schedule allows the driver to unload the cargo plus having the lawful break in port before heading to second leg. Meanwhile, the truck can be opportunity-charged (high-power charging, HPC).

While the work cycle in the planned piloting phase offers high flexibility, it is crucial to design and validate the configuration also in work cycles of heavier gross vehicle weights. Typically, the long-haul trucks drive in three-shift work only by changing the driver by the road. The EC regulations for driver’s rest times require one 45 min break after each 4.5 h period of driving [

15]. The 45 min break can be split into 15 + 30 min, of which the 30 min need to take place after each 4.5 h of driving. Thus, it is important that the vehicle supports HPC in a way that enough energy can be charged for at least 2–2.5 h of driving. The validation of the functionality of the charging and terminal operations during the fast charging will be covered in other phases of the project.

The energy consumption of electric trucks was evaluated by means of simulations. For this purpose, the VTT’s in-house simulation platform ‘Smart eFleet’, originally developed for urban buses [

16] and validated based on measurements in [

17], was utilised. The simulation platform models the longitudinal dynamics of a vehicle travelling on a specific route. The route is in the simulations divided into short segments, of which each includes data on the topology, traffic lights, road curvature, speed limit, and length obtained from open data sources. In the simulation, a speed reference is formed for each vehicle based on the characteristics of the route, i.e., the speed limit and the road curvature. In addition to this, a traffic component can be included to model the impact of congestion. The speed of the vehicle is controlled by a PI controller. As the power flow of the simulation model is forward-facing, the powertrain design parameters automatically set limits on the acceleration, and the simulation model is well suited for cases where no speed measurement data are yet available.

Two different powertrain options for the zero-emission truck were modelled, a pure battery electric powertrain and a battery electric with a fuel cell acting as a range extender. The electric motor is modelled as an efficiency look-up table dependent on the rotational speed and the torque. The efficiencies of the gearbox, the battery, and the inverter are assumed to be constant. The power rating of the electric drive was dimensioned to enable operation with GVW of 76 tonnes and to meet the power requirement of 5 kW/GVW-tonne. A simple efficiency curve was implemented for the fuel cell, and the power of the fuel cell system will be scaled based on the degree of FC hybridisation. Estimated mass of the power source components will be taken into account as well. For battery use, a simple limitation of available output power on battery state of charge was implemented.

To ensure the traction performance of the vehicle combination, the mechanical driveline includes a 5-speed gearbox. The gear change logic uses fixed traction motor speeds for up and down shifting, keeping the traction motor speed in a range with sufficient power output capability and the highest possible efficiency. The traction power is delivered to the road using tandem-driven bogie axles. For the operation with 40 tonnes GVW, the tandem-driven axles would not be needed, but this selection is made to enable also the operation with 76 tonnes GVW. Losses in the mechanical driveline are taken into account using efficiency factors for the gearbox and driving axles. The road load model includes the gravity force due to slope and driving resistance forces for tire rolling resistance and aerodynamic drag.

3. Results and Discussion

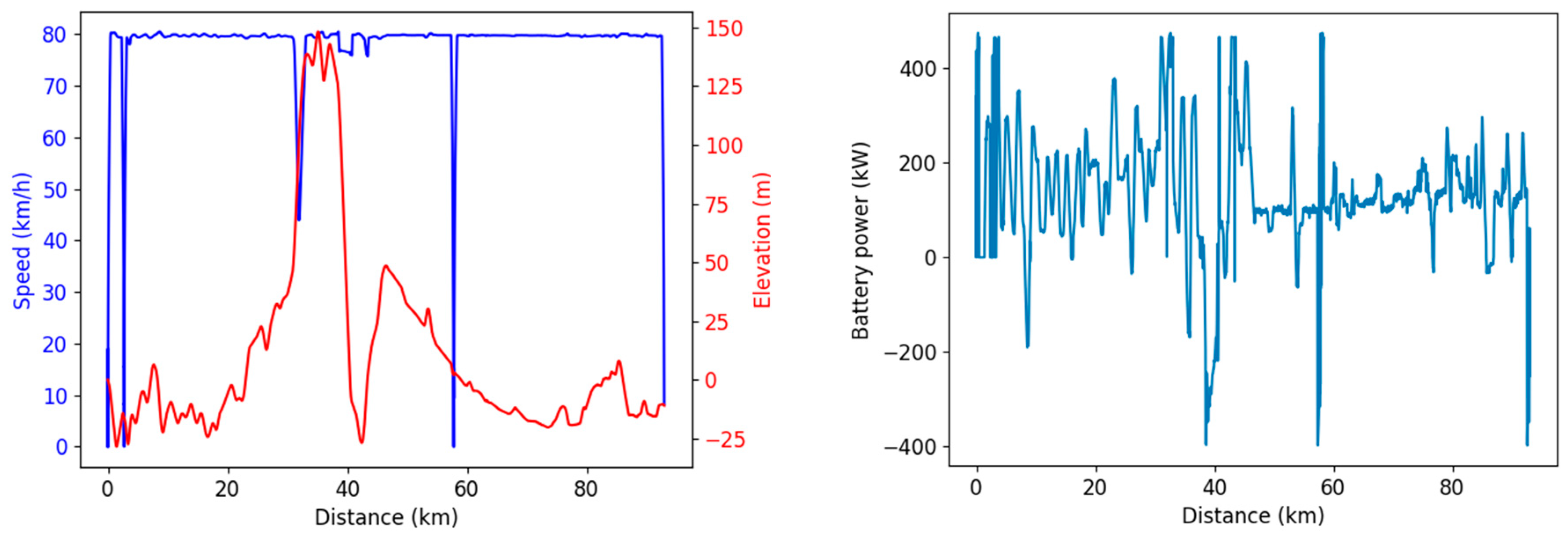

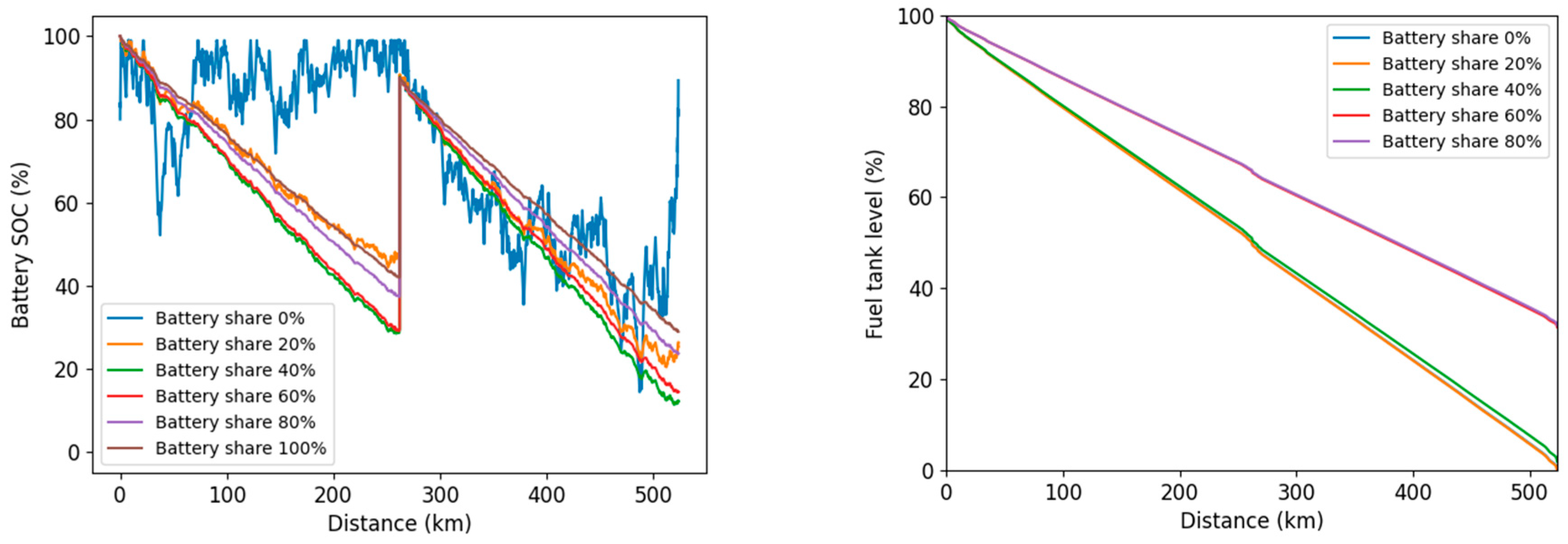

The results from the simulations are shown in

Figure 2 for the VECTO long-haul mission profile and in

Figure 3 for the actual long-haul mission with 40 tonnes configuration. In the synthesised results, the VECTO profile (

Figure 2) is repeated until the design basis of a 750 km mission is reached. The average energy consumption for the VECTO long-haul driving cycle was 1.83 kWh/km, resulting in a total energy of 1373 kWh drawn from the battery in pure battery electric mode. Six different power source combinations to fulfil the 750 km mission are shown in

Table 2, and the corresponding simulation results for each variation are shown in

Figure 3. The fuel cell was selected individually for each powertrain combination. The maximum power and the average power on the VECTO profile are included in

Table 2. The H

2 tank indicates the minimum amount of hydrogen required for the VECTO long-haul mission, whereas the fuel cell is selected to be able to provide enough power also for a truck with a maximum weight of 76 tonnes. Therefore, the fuel cell does not operate at maximum power in the first three options, and the fuel cell efficiency is relatively good. The efficiency of the fuel cell system, including all auxiliary devices and cooling of the fuel cell, is shown in

Figure 4.

Conceptual powertrain design configurations for the power source capacities are given in

Table 2 for the VECTO long-haul profile. The design basis analysis assumes that the entire mission is carried out without intermediate or opportunity charging or H

2 refilling, in other words, energy storages are full at the start of the mission and will be depleted at the end.

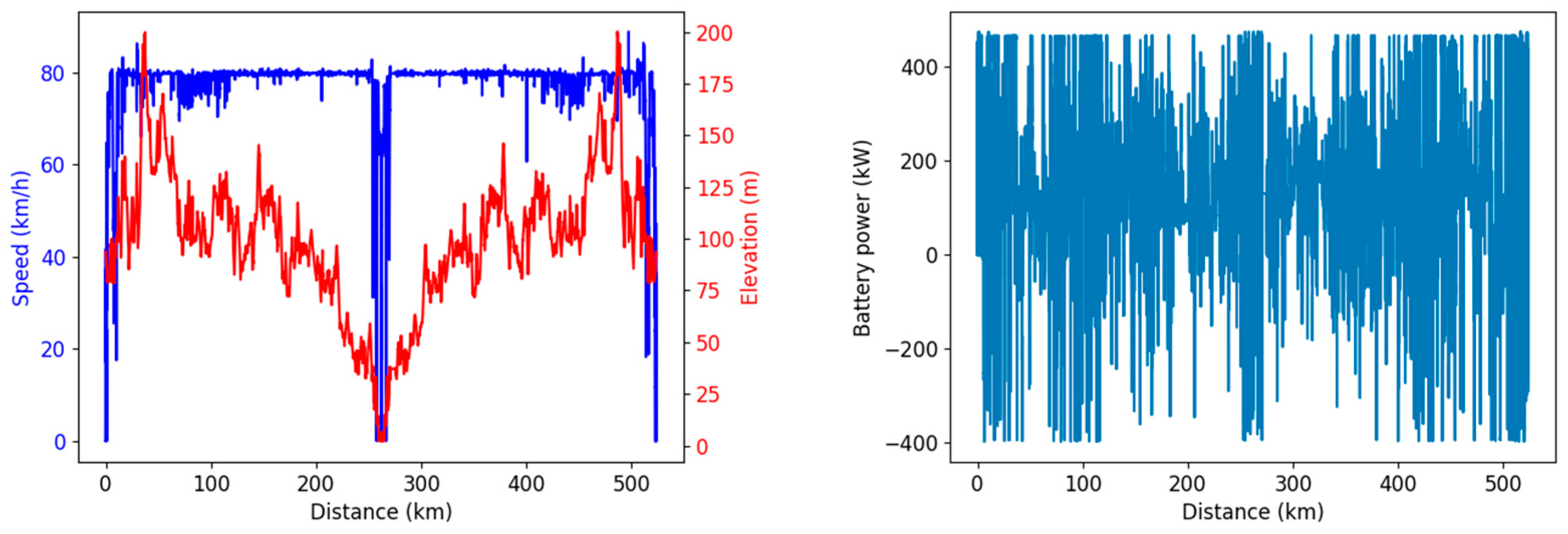

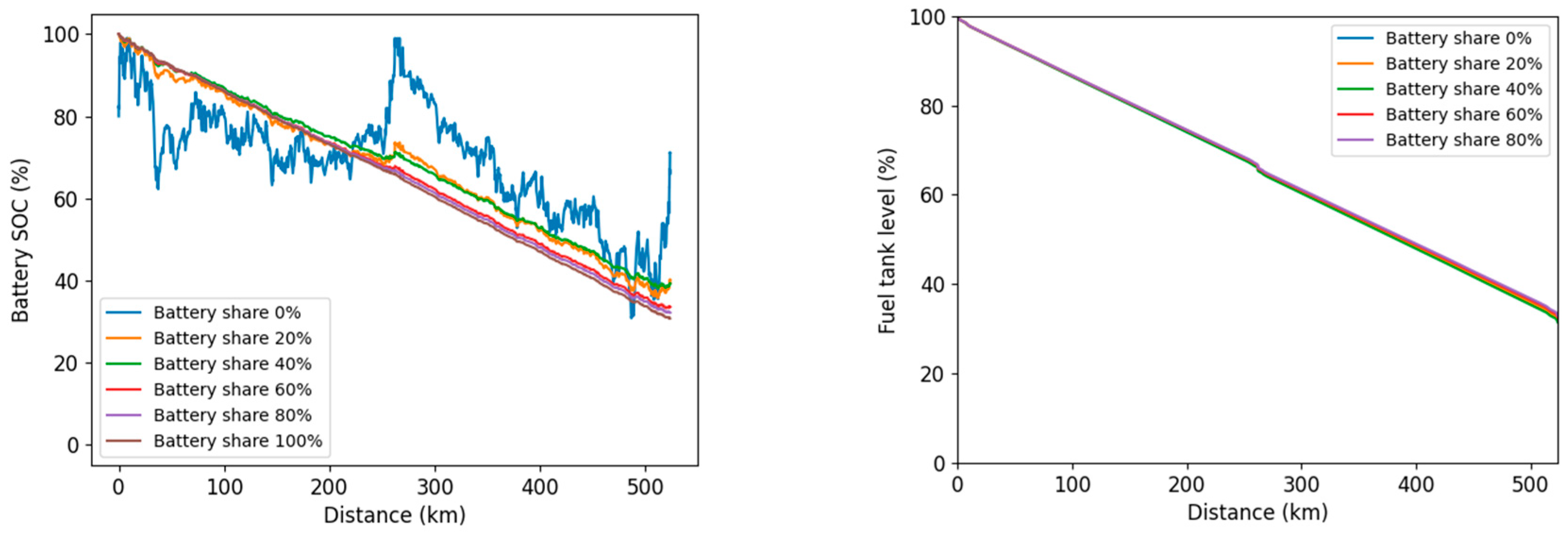

For the second use case, the driving cycle consists of a roundtrip, as shown in

Figure 5 (520 km). The route was simulated with the same powertrain configurations as in

Table 2, and the resulting energy consumption for the nominal GVW 40 tonnes configuration in pure battery electric mode was 1.82 kWh/km. The consumption in the direction Vuosaari—Jyväskylä was 1.85 kWh/km, and in the opposite direction, it was 1.78 kWh/km. The battery state of charge and fuel tank level are illustrated in

Figure 6. An additional vehicle configuration was analysed based on a GVW of 76 tonnes, as shown in the right side of

Figure 1, and using the same powertrain as previously described. The energy consumptions stated above can be considered to be slightly on the conservative side to provide sufficient margins at the preliminary design phase.

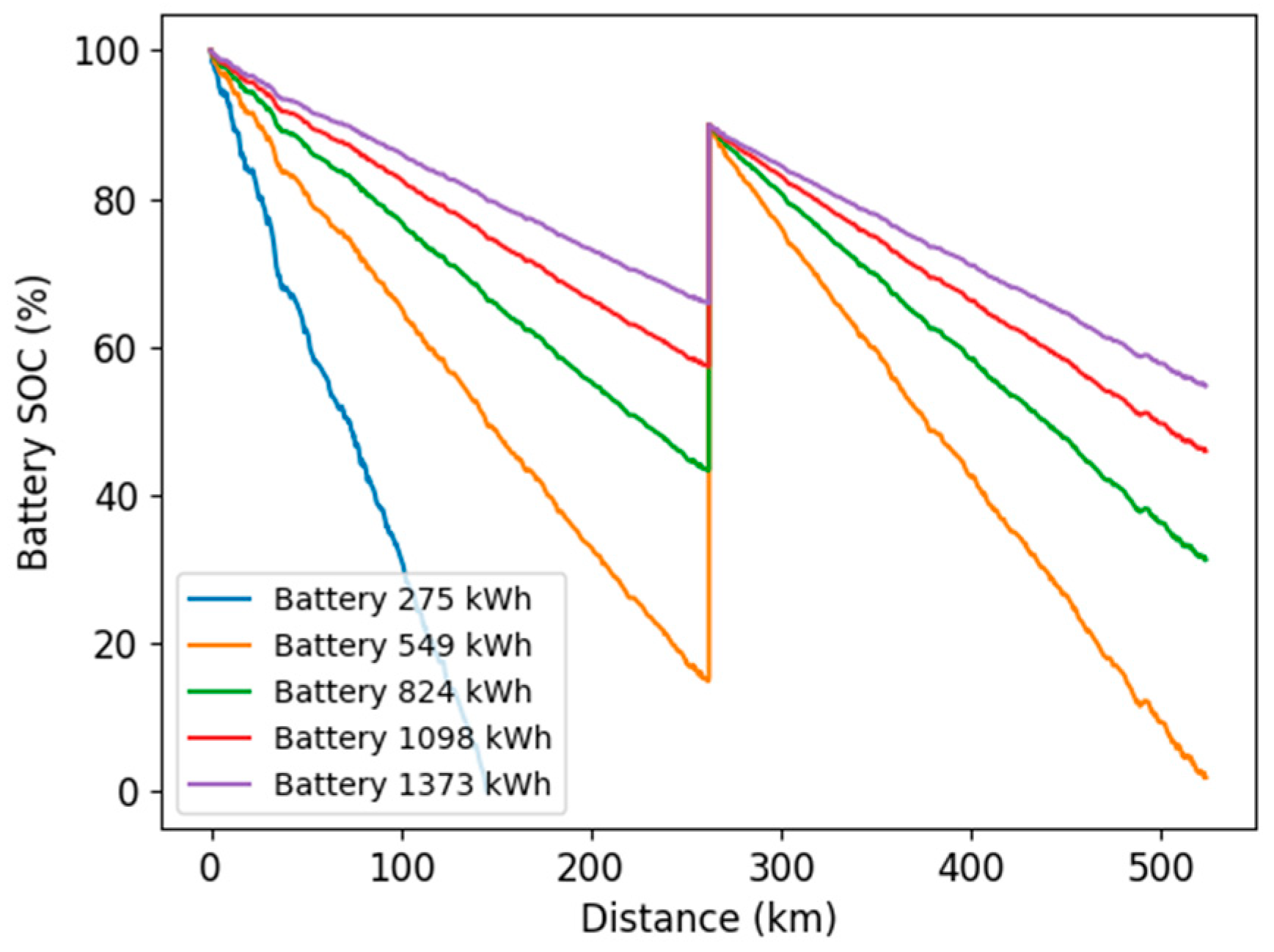

The results with the 76 tonnes configuration are illustrated in

Figure 7. The battery was charged in Vuosaari for roughly 45 min with a charging power of maximum 1 MW, and the fuel cell power was raised to the maximum level for all powertrain configurations. In addition, a larger H

2 tank was used for the first two powertrain configurations operating with 0% and 20% battery shares, respectively. H

2 refilling in Vuosaari could be an option to minimise the H

2 tank. The resulting total energy consumption levels on the Jyväskylä—Vuosaari route are shown in

Table 3. It is to be noted that these consumption numbers are not fully optimised. The energy management strategy could be tuned based on the mission to prioritise battery electric energy and minimise the use of hydrogen, especially in the case that it is more expensive than charged electricity. The fuel cell efficiency varied in the range 48–53% in the simulations, while the battery efficiency was 97%. In other words, 1 kg of hydrogen corresponds to 16–17 kWh of usable energy. The energy management strategy should be selected based on the available recharging infrastructure. The strategy chosen here allows the vehicle to operate on long distances on the expense of high energy consumption when relying heavily on the fuel cell.

Further simulations were performed on the Vuosaari—Jyväskylä route. Operation in pure battery electric mode is possible with intermittent charging halfway. The simulated results, when charging at a power of 1 MW is available in Jyväskylä, are shown in

Figure 8. The charging break is assumed to be roughly 45 min with a couple of minutes reserved for connecting and disconnecting. The smallest batteries are obviously not enough for this case, while a battery of minimum 549 kWh is sufficient.

The current study is partly based on conservative vehicle parameter values to ensure that the vehicle will meet the required performance criteria. In future studies concentrating on detailed system design and operational optimisation, the impact of the design parameters will be studied and the potential to minimise energy consumption will be evaluated. Various energy management strategies will be evaluated and the battery models will be enhanced to properly take into account the power variation during high-power charging. Secondly, in the case of a hybrid battery-fuel cell power source, control strategies will be investigated to optimise various parameters, such as total energy consumption, operational reliability to complete given missions, or the total cost of ownership. Furthermore, the impact of environmental conditions and driving behaviours, such as statistical variation in temperature, wind conditions, and driving resistances, will be analysed in more detail once reliable information on these based on statistics, operator data, or real piloting operations is available.

The final and optimal choice for the power source and prime mover split depends on additional factors such as infrastructure availability, electricity and hydrogen prices, required payload capacity, and system level availability and productivity. These data will become available when the final design of the demonstrator vehicle as the fuel cell range-extended electric truck is manufactured and put in trial operation. The final prototype design is expected to have battery and fuel cell capacities in mid-area, between the 40% and 60% rows of

Table 2 and

Table 3. The testing and data from the piloting operations will include operation in both purely electric and fuel cell modes as well as their various combinations.

As part of this subsequent analysis, an additional element of the research approach will be to assess and compare the system-level techno-economics of the powertrain and system configurations in the said use cases and missions. The analysis is upcoming based on the results of the vehicle and mission simulations and related technical and operational data. The methodology is based on earlier total cost of ownership (TCO) analysis on electric city buses [

18] and the related literature.

4. Conclusions

Approach and methodology for the conceptual design of zero-emission truck powertrains intended for regional and long-haul missions are presented. Various scenarios with the developed vehicle and powertrain models were analysed, taking into account infrastructure and charging/refuelling all along the missions, as well as their impact on the operative planning.

The approach starts from the design basis of an uninterrupted 750 km mission in the VECTO long-haul profile, and secondly, a 520 km mission on a real route in southern Finland. The powertrain designed is capable for vehicle combinations flexibly from a GVW of 40 tonnes all the way up to 76 tonnes. The energy infrastructure analysed included overnight depot charging to start the driving missions with a 100% charged battery and an intermediate fast charging halfway through the roundtrip. Energy use for two truck configurations was estimated through simulation for both use cases.

Six different conceptual powertrain designs with varying degrees of charged electric fuel cell operation were presented. For fully electric operation, the estimated battery capacity required 1373 kWh of traction battery capacity, whereas the other extreme of power source design with H2 as the prime mover gives a hydrogen storage capacity of 83 kg. The four intermediate powertrain options combine battery and H2 tank capacities in various ways. In terms of total energy consumption (tank to wheel), the smallest overall mission energy consumption is with fully electric operation—this depends on the relative efficiencies of battery electric and fuel cell electric powertrains.

The conceptual pre-design analysis shows that operation of the GVW 40 tonnes truck is viable in the nominal design basis driving cycles in a battery electric mode with a fuel cell range extender. Additionally, a number of modular powertrain concepts were proposed to meet the design criteria. The work also provides requirements for the energy infrastructure to support operations, pointing to megawatt-level opportunity charging being mandatory for operating the heaviest payload case in purely electric mode.

This research has been presented at the EVS36 Symposium in Sacramento, USA, in June 2023.