Identification of Challenges for Second-Life Battery Systems—A Literature Review

Abstract

1. Introduction

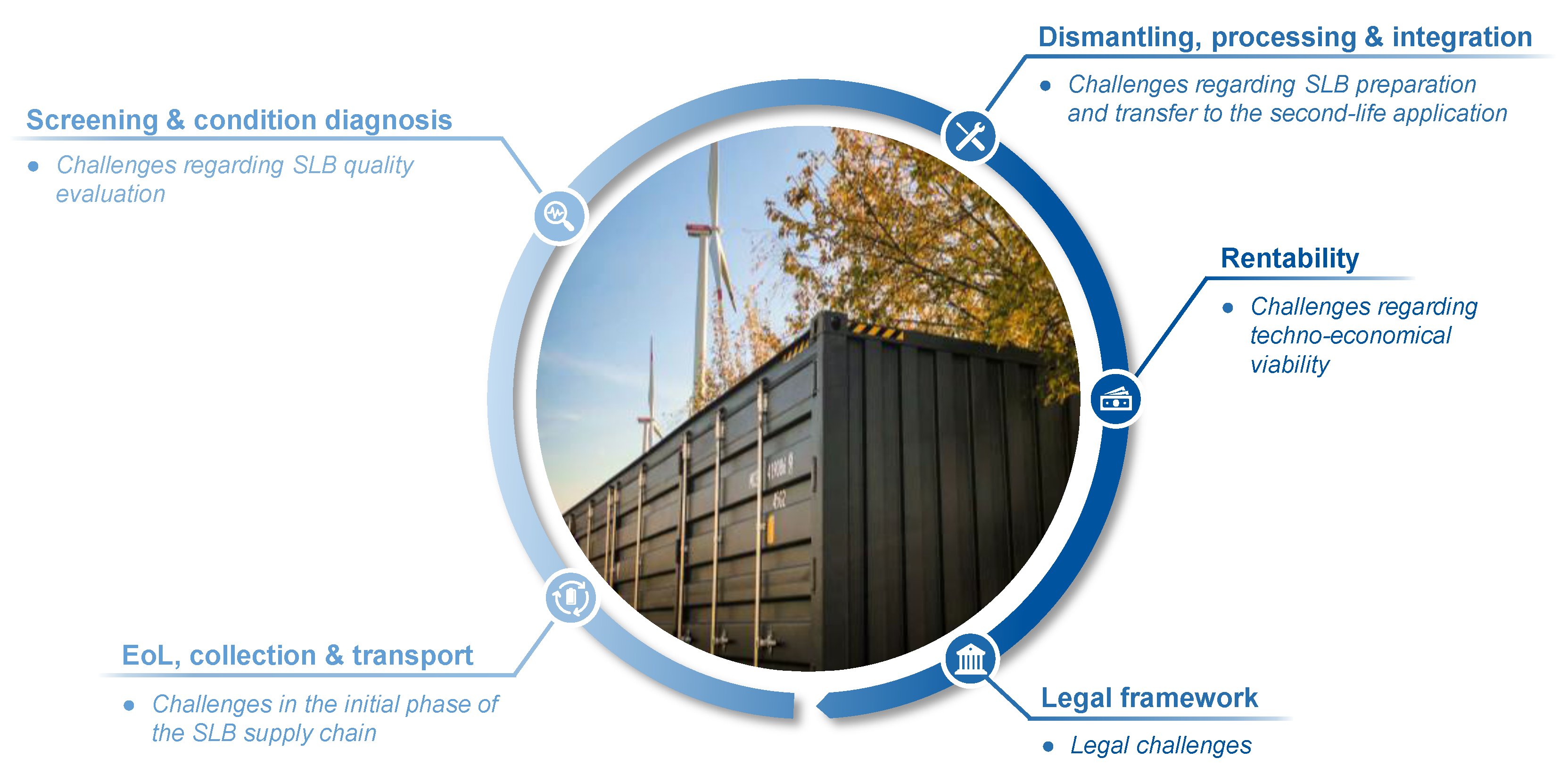

- End of first life, collection, and transport;

- Screening and condition diagnosis;

- Dismantling, processing, and integration.

2. End of First Life, Collection, and Transport

3. Screening and Condition Diagnosis

4. Dismantling, Processing, and Integration

5. Rentability

6. Legal Framework

7. Further Barriers

8. Conclusions and Future Work

- Current barriers for battery second-life can be divided into five major areas: end-of-first-life, collection and transport, screening, processing, rentability, and the legal framework in particular.

- There are further barriers in different fields such as stakeholder management and data security, which are summarized under “other.” However, the importance of these challenges is not inferior to the other barriers.

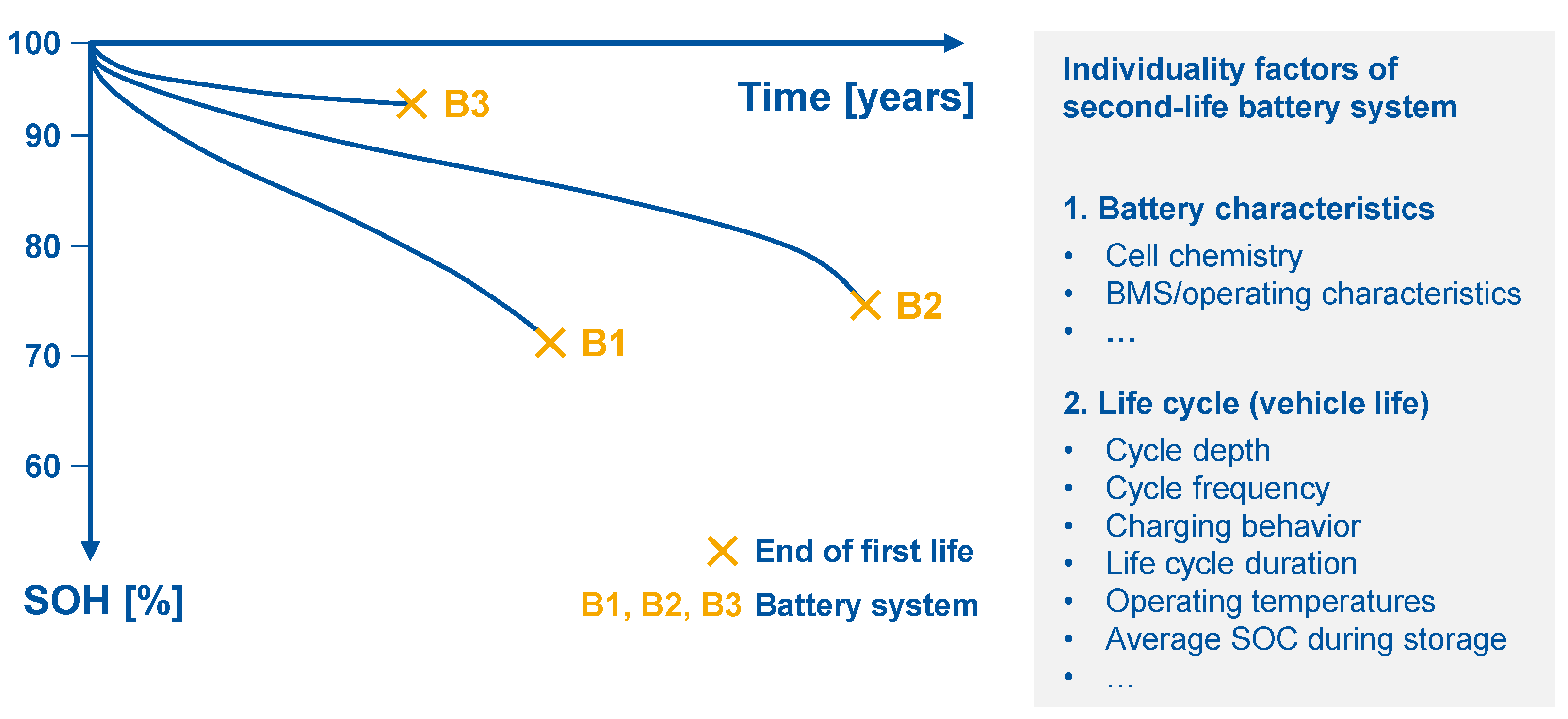

- The challenges most often mentioned in the literature focus on the wide variety of EoL batteries. The high level of diversification is influenced by numerous factors, such as cell chemistry, system architecture, user behavior, operating conditions, operating strategy, and market exit timing, leading to an unpredictable second-life product.

- Many challenges relate to the economic viability of second-life batteries, considering their competitiveness against new battery systems and technologies that profit from cost reductions. Secondarily, it is necessary to evaluate second-life batteries individually based on their remaining service life and storable energy. As a result, investment costs for system integrators vary, and a generally valid business case is difficult to calculate.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statista. Electric Vehicles-Worldwide|Statista Market Forecast. Available online: https://www.statista.com/outlook/mmo/electric-vehicles/worldwide#unit-sales (accessed on 15 January 2023).

- Forinyak, E.; EV Production in Germany Nearly Doubles. GTAI—Markets Germany [Online], 19 May 2022. Available online: https://www.marketsgermany.com/ev-production-in-germany-nearly-doubles/ (accessed on 15 December 2022).

- Balagopal, B.; Chow, M.-Y. The state of the art approaches to estimate the state of health (SOH) and state of function (SOF) of lithium Ion batteries. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015; IEEE: Cambridge, UK, 2015; pp. 1302–1307, ISBN 978-1-4799-6649-3. [Google Scholar]

- Lee, J.W.; Haram, M.H.S.M.; Ramasamy, G.; Thiagarajah, S.P.; Ngu, E.E.; Lee, Y.H. Technical feasibility and economics of repurposed electric vehicles batteries for power peak shaving. J. Energy Storage 2021, 40, 102752. [Google Scholar] [CrossRef]

- Reid, G.; Julve, J. Second Life-Batterien als Flexible Speicher für Erneuerbare Energien; Kurzstudie im Auftrag des Bundesverbandes Erneuerbare Energie e. V. und der Hannover Messe: Berlin, Germany, 2016. [Google Scholar]

- Bräuer, S. Electric Vehicle Battery Second Use Future Trade, Business Models, and Information Systems Design. Ph.D. Thesis, Westfälische Wilhelms-Universität Münster, Münster, Germany, 2018. [Google Scholar]

- Richter, S.; Rehme, M.; Temmler, A.; Götze, U. Second-Life Battery Applications-Market Potentials and Contribution to the Cost Effectiveness of electric Vehicles. In Proceedings of the CoFAT 2016—Conference on Future Automotive Technology, München, Germany, 4 May 2016. [Google Scholar]

- Kamath, D.; Arsenault, R.; Kim, H.C.; Anctil, A. Economic and Environmental Feasibility of Second-Life Lithium-Ion Batteries as Fast-Charging Energy Storage. Environ. Sci. Technol. 2020, 54, 6878–6887. [Google Scholar] [CrossRef]

- Olsson, L.; Fallahi, S.; Schnurr, M.; Diener, D.; van Loon, P. Circular Business Models for Extended EV Battery Life. Batteries 2018, 4, 57. [Google Scholar] [CrossRef]

- Ahmadi, L.; Yip, A.; Fowler, M.; Young, S.B.; Fraser, R.A. Environmental feasibility of re-use of electric vehicle batteries. Sustain. Energy Technol. Assess. 2014, 6, 64–74. [Google Scholar] [CrossRef]

- Haram, M.H.S.M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of utilising second life EV batteries: Applications, lifespan, economics, environmental impact, assessment, and challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Cready, E.; Lippert, J.; Pihl, J.; Weinstock, I.; Symons, P. Technical and Economic Feasibility of Applying Used EV Batteries in Stationary Applications; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA; Sandia National Lab. (SNL-CA): Livermore, CA, USA, 2003. [Google Scholar]

- Cicconi, P.; Landi, D.; Morbidoni, A.; Germani, M. Feasibility analysis of second life applications for Li-Ion cells used in electric powertrain using environmental indicators. In Proceedings of the 2012 IEEE International Energy Conference (ENERGYCON 2012), Florence, Italy, 9–12 September 2012; IEEE: Cambridge, UK, 2012; pp. 985–990, ISBN 978-1-4673-1454-1. [Google Scholar]

- Bloomberg, N.E.F. Electric Vehicle Outlook 2019. Available online: https://legacy-assets.eenews.net/open_files/assets/2019/05/15/document_ew_02.pdf (accessed on 1 December 2022).

- Gunther, C. How Long Do EV Batteries Last? Review Geek, 19 April 2022. [Google Scholar]

- What Happens to Old Electric Car Batteries?|National Grid Group. Available online: https://www.nationalgrid.com/stories/journey-to-net-zero-stories/what-happens-old-electric-car-batteries (accessed on 1 December 2022).

- The Global Electric Vehicle Market In 2022–Virta. Available online: https://www.virta.global/en/global-electric-vehicle-market (accessed on 1 December 2022).

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A Review on Battery Market Trends, Second-Life Reuse, and Recycling. Sustain. Chem. 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Kelly, J.C. Battery Second Life: Frequently Asked Questions; Argonne National Lab.: Argonne, IL, USA, 2020. Available online: https://www.osti.gov/servlets/purl/1599759 (accessed on 1 December 2022).

- Kelly, J.C.; Winjobi, O. Battery Second Life: A Review of Challenges and Opportunities. In Proceedings of the 33nd Electric Vehicle Symposium (EVS33), Portland, OR, USA, 14–17 June 2020. [Google Scholar] [CrossRef]

- Shahjalal, M.; Roy, P.K.; Shams, T.; Fly, A.; Chowdhury, J.I.; Ahmed, M.R.; Liu, K. A review on second-life of Li-ion batteries: Prospects, challenges, and issues. Energy 2022, 241, 122881. [Google Scholar] [CrossRef]

- Schulz, D. (Ed.) . NEIS Conference 2016: Nachhaltige Energieversorgung und Integration von Speichern = Sustainable Energy Supply and Energy Storage Systems; Springer Vieweg: Wiesbaden, Germany, 2017; ISBN 9783658150280. [Google Scholar]

- Thein, S.; Chang, Y.S. Decision making model for lifecycle assessment of lithium-ion battery for electric vehicle—A case study for smart electric bus project in Korea. J. Power Sources 2014, 249, 142–147. [Google Scholar] [CrossRef]

- Saxena, S.; Le Floch, C.; MacDonald, J.; Moura, S. Quantifying EV battery end-of-life through analysis of travel needs with vehicle powertrain models. J. Power Sources 2015, 282, 265–276. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Sarasketa-Zabala, E.; Villarreal Sarria, I.; Stroe, D.-I.; Swierczynski, M.; Warnecke, A.; Timmermans, J.-M.; Goutam, S.; Omar, N.; Rodriguez, P. Technical Viability of Battery Second Life: A Study From the Ageing Perspective. IEEE Trans. Ind. Applicat. 2018, 54, 2703–2713. [Google Scholar] [CrossRef]

- Neubauer, J.; Smith, K.; Wood, E.; Pesaran, A. Identifying and Overcoming Critical Barriers to Widespread Second Use of PEV Batteries; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2015. [Google Scholar]

- Schuster, S.F.; Bach, T.; Fleder, E.; Müller, J.; Brand, M.; Sextl, G.; Jossen, A. Nonlinear aging characteristics of lithium-ion cells under different operational conditions. J. Energy Storage 2015, 1, 44–53. [Google Scholar] [CrossRef]

- Becker, J.; Beverungen, D.; Winter, M.; Menne, S. Umwidmung und Weiterverwendung von Traktionsbatterien; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019; ISBN 978-3-658-21020-5. [Google Scholar]

- Viswanathan, V.V.; Kintner-Meyer, M.C. Repurposing of batteries from electric vehicles. In Advances in Battery Technologies for Electric Vehicles; Elsevier: Cambridge, UK, 2015; pp. 389–415. ISBN 9781782423775. [Google Scholar]

- Wrålsen, B.; Prieto-Sandoval, V.; Mejia-Villa, A.; O’Born, R.; Hellström, M.; Faessler, B. Circular business models for lithium-ion batteries—Stakeholders, barriers, and drivers. J. Clean. Prod. 2021, 317, 128393. [Google Scholar] [CrossRef]

- Huo, H.; Xing, Y.; Pecht, M.; Züger, B.J.; Khare, N.; Vezzini, A. Safety Requirements for Transportation of Lithium Batteries. Energies 2017, 10, 793. [Google Scholar] [CrossRef]

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- About the ADR|UNECE. Available online: https://unece.org/about-adr (accessed on 15 January 2023).

- Nigl, T.; Rutrecht, B.; Altendorfer, M.; Scherhaufer, S.; Meyer, I.; Sommer, M.; Beigl, P. Lithium-Ionen-Batterien–Kreislaufwirtschaftliche Herausforderungen am Ende des Lebenszyklus und im Recycling. Berg Huettenmaenn Mon. 2021, 166, 144–149. [Google Scholar] [CrossRef]

- Halleux, V. New EU Regulatory Framework for Batteries. 2022. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2021/689337/EPRS_BRI(2021)689337_EN.pdf (accessed on 19 December 2021).

- Berger, K.; Schöggl, J.-P.; Baumgartner, R.J. Digital battery passports to enable circular and sustainable value chains: Conceptualization and use cases. J. Clean. Prod. 2022, 353, 131492. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Catton, J.; Walker, S.B.; McInnis, P.; Fowler, M.; Fraser, R.; Young, S.B.; Gaffney, B. Comparative safety risk and the use of repurposed EV batteries for stationary energy storage. In Proceedings of the 2017 IEEE International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 14–17 August 2017; IEEE: Cambridge, UK, 2017; pp. 200–209, ISBN 978-1-5386-1775-5. [Google Scholar]

- Casals, L.C.; Garca, B.A. Assessing Electric Vehicles Battery Second Life Remanufacture and Management. JGE 2016, 6, 77–98. [Google Scholar] [CrossRef]

- Zhu, J.; Mathews, I.; Ren, D.; Li, W.; Cogswell, D.; Xing, B.; Sedlatschek, T.; Kantareddy, S.N.R.; Yi, M.; Gao, T.; et al. End-of-life or second-life options for retired electric vehicle batteries. Cell Rep. Phys. Sci. 2021, 2, 100537. [Google Scholar] [CrossRef]

- Groenewald, J.; Grandjean, T.; Marco, J. Accelerated energy capacity measurement of lithium-ion cells to support future circular economy strategies for electric vehicles. Renew. Sustain. Energy Rev. 2017, 69, 98–111. [Google Scholar] [CrossRef]

- Li, J.; Gu, Y.; Wang, L.; Wu, X. Review on state of health estimation of retired lithium-ion batteries. Energy Storage Sci. Technol. 2019, 8, 807. [Google Scholar] [CrossRef]

- Cimprich, A.; Skinner, D.; Oh, B.; Booth, K.; Leutenegger, A. Responsible Stewardship of Electrified Vehicles; University of Waterloo: Waterloo, ON, Canada, 2015. [Google Scholar]

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Haque Sunny, M.S.; Mohammad, N. A Comprehensive Review on Second-Life Batteries: Current State, Manufacturing Considerations, Applications, Impacts, Barriers & Potential Solutions, Business Strategies, and Policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2021, 168, 105249. [Google Scholar] [CrossRef]

- Elkind, E. Reuse and Repower: How to Save Money and Clean the Grid with Second-Life Electric Vehicle Batteries; Berkeley Low: Berkeley, CA, USA, 2014. [Google Scholar]

- Montes, T.; Etxandi-Santolaya, M.; Eichman, J.; Ferreira, V.J.; Trilla, L.; Corchero, C. Procedure for Assessing the Suitability of Battery Second Life Applications after EV First Life. Batteries 2022, 8, 122. [Google Scholar] [CrossRef]

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects. Chem. Rev. 2020, 120, 7020–7063. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, L.; Fowler, M.; Young, S.B.; Fraser, R.A.; Gaffney, B.; Walker, S.B. Energy efficiency of Li-ion battery packs re-used in stationary power applications. Sustain. Energy Technol. Assess. 2014, 8, 9–17. [Google Scholar] [CrossRef]

- Beverungen, D.; Fabry, C.; Ganz, W.; Matzner, M.; Satzger, G. (Eds.) Dienstleistungsinnovationen für Elektromobilität: Märkte, Geschäftsmodelle, Kooperationen; Fraunhofer-Verlag: Stuttgart, Germany, 2015; ISBN 978-3839603604. [Google Scholar]

- Rallo, H.; Benveniste, G.; Gestoso, I.; Amante, B. Economic analysis of the disassembling activities to the reuse of electric vehicles Li-ion batteries. Resour. Conserv. Recycl. 2020, 159, 104785. [Google Scholar] [CrossRef]

- Engel, H.; Hertzke, P.; Siccardo, G. Second-Life EV Batteries: The Newest Value Pool in Energy Storage. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/second-life-ev-batteries-the-newest-value-pool-in-energy-storage (accessed on 1 December 2022).

- Abdel-Monem, M.; Hegazy, O.; Omar, N.; Trad, K.; van den Bossche, P.; van Mierlo, J. Lithium-ion batteries: Comprehensive technical analysis of second-life batteries for smart grid applications. In Proceedings of the 2017 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017; IEEE: Cambridge, UK, 2017; pp. 1–16, ISBN 978-90-75815-27-6. [Google Scholar]

- Soto, A.; Berrueta, A.; Zorrilla, P.; Iribarren, A.; Castillo, D.H.; Rodriguez, W.E.; Rodriguez, A.J.; Vargas, D.T.; Matias, I.R.; Sanchis, P.; et al. Integration of second-life battery packs for self-consumption applications: Analysis of a real experience. In Proceedings of the 2021 IEEE International Conference on Environment and Electrical Engineering and 2021 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Bari, Italy, 7–10 September 2021; IEEE: Cambridge, UK, 2021; pp. 1–6, ISBN 978-1-6654-3613-7. [Google Scholar]

- Song, Z.; Feng, S.; Zhang, L.; Hu, Z.; Hu, X.; Yao, R. Economy analysis of second-life battery in wind power systems considering battery degradation in dynamic processes: Real case scenarios. Appl. Energy 2019, 251, 113411. [Google Scholar] [CrossRef]

- Casals, L.C.; Garca, B.A. Communications concerns for reused electric vehicle batteries in smart grids. IEEE Commun. Mag. 2016, 54, 120–125. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.-I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Jiao, N.; Evans, S. Market Diffusion of Second-life Electric Vehicle Batteries: Barriers and Enablers. WEVJ 2016, 8, 599–608. [Google Scholar] [CrossRef]

- Jiao, N.; Evans, S. Business Models for Repurposing a Second-Life for Retired Electric Vehicle Batteries. In Behaviour of Lithium-Ion Batteries in Electric Vehicles; Springer: Cham, The Netherlands, 2018; pp. 323–344. [Google Scholar]

- Wu, W.; Lin, B.; Xie, C.; Elliott, R.J.; Radcliffe, J. Does energy storage provide a profitable second life for electric vehicle batteries? Energy Econ. 2020, 92, 105010. [Google Scholar] [CrossRef]

- Deshwal, D.; Sangwan, P.; Dahiya, N. Economic Analysis of Lithium Ion Battery Recycling in India. Wirel. Pers. Commun. 2022, 124, 3263–3286. [Google Scholar] [CrossRef]

- EU: Parlament und Rat Einigen sich auf neue Batterieverordnung (1. Update)—Das neue Batteriegesetz (BattG). 2022. Available online: https://www.batteriegesetz.de/eu-parlament-und-rat-einigen-sich-auf-neue-batterieverordnung/ (accessed on 16 December 2022).

- Europäische Kommission. Vorschlag für eine Verordnung des Europäischen Parlaments und des Rates über Batterien und Altbatterien, zur Aufhebung der Richtlinie 2006/66/EG und zur Änderung der Verordnung (EU) 2019/1020; Europäische Kommission: Belgium, Brussel, 2020. [Google Scholar]

- McCrossan, C.; Shankaravelu, K. A Review of the Second Life Electric Vehicle Battery Landscape from a Business and Technology Perspective. In Proceedings of the 2021 IEEE Green Technologies Conference (GreenTech), Denver, CO, USA, 7–9 April 2021; IEEE: Cambridge, UK, 2021; pp. 416–423, ISBN 978-1-7281-9139-3. [Google Scholar]

- Fischhaber, S.; Regett, A.; Schuster, S.F.; Hesse, H. Second-Life-Konzepte für Lithium-Ionen-Batterien aus Elektrofahrzeugen: Analyse von Nachnutzungsanwendungen, Ökonomischen und Ökologischen Potenzialen; Schaufenster Elektromobilität (BuW): Frankfurt, Germany, 2016. [Google Scholar]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Ziegler, A.; Oeser, D.; Hein, T.; Montesinos-Miracle, D.; Ackva, A. Run to Failure: Aging of Commercial Battery Cells beyond Their End of Life. Energies 2020, 13, 1858. [Google Scholar] [CrossRef]

- Börner, M.F.; Frieges, M.H.; Späth, B.; Spütz, K.; Heimes, H.H.; Sauer, D.U.; Li, W. Challenges of second-life concepts for retired electric vehicle batteries. Cell Rep. Phys. Sci. 2022, 3, 101095. [Google Scholar] [CrossRef]

- Hu, X.; Deng, X.; Wang, F.; Deng, Z.; Lin, X.; Teodorescu, R.; Pecht, M.G. A Review of Second-Life Lithium-Ion Batteries for Stationary Energy Storage Applications. Proc. IEEE 2022, 110, 735–753. [Google Scholar] [CrossRef]

| Individual Barriers | Source |

|---|---|

| Challenge 1: Uncertainty about how many EoL batteries have a sufficiently good SOH to be used as SLBs | [12] |

| Challenge 2: Difficulty in predicting whether a battery system is still suitable for rededication | [27,28] |

| Challenge 3: Transport is expensive due to regulations, involves safety risks | [29,30,31] |

| Individual Barriers | Source |

|---|---|

| Challenge 4: Identification process not standardized, difficult and time-consuming | [28,34] |

| Challenge 5: Great variety of batteries makes uniform SOH determination and rededication challenging | [11] |

| Challenge 6: SOH determination without access to BMS data is time consuming and requires special equipment | [32,39,41,42] |

| Challenge 7: Lack of battery data from the first life complicates the decision of reuse | [12,26,44] |

| Individual Barriers | Source |

|---|---|

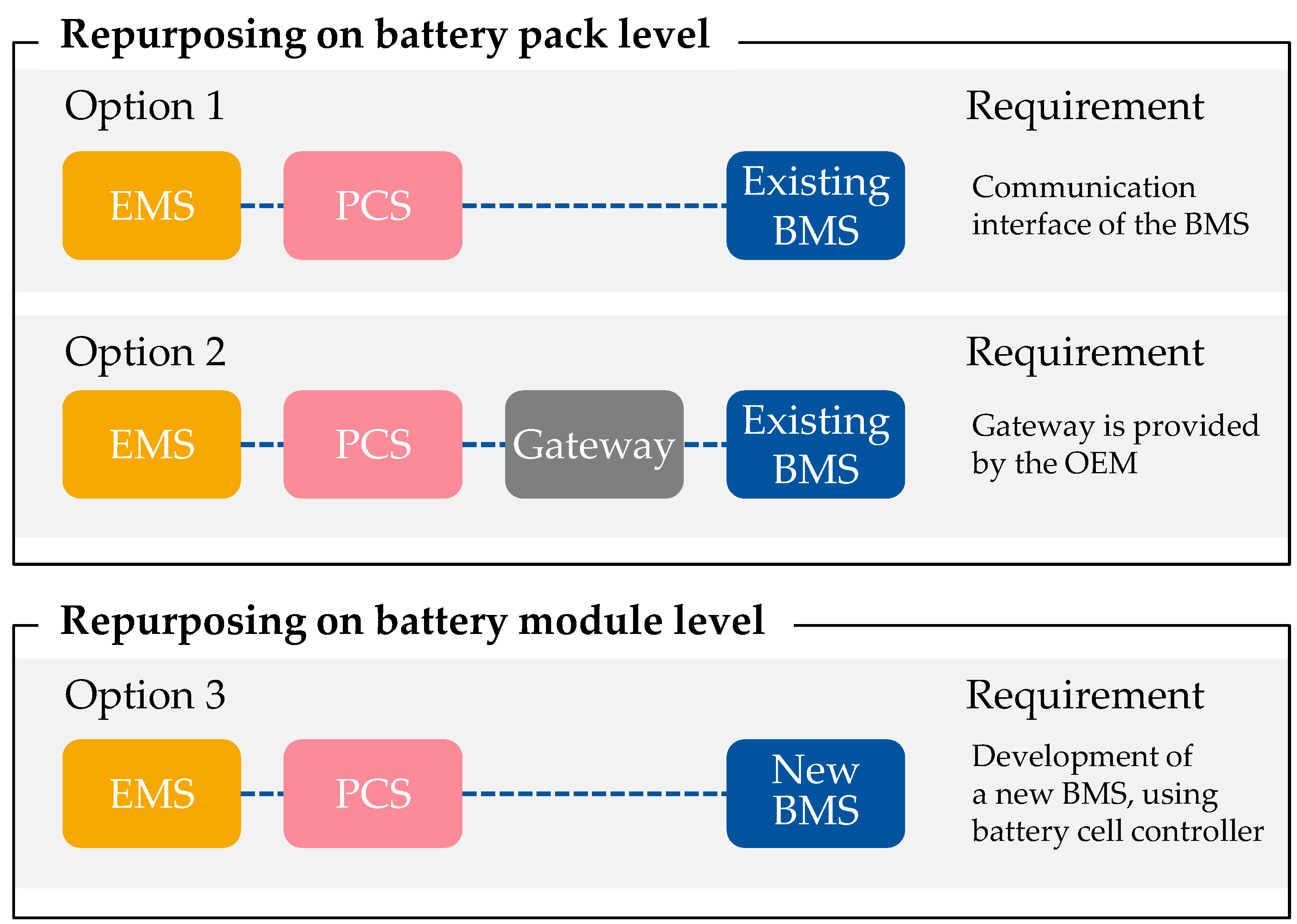

| Challenge 8: Inconsistent disassembly and difficult automation because of the absence of a unified battery standard | [34,38,52] |

| Challenge 9: Difficulties in assembling a matched battery string | [12,19] |

| Challenge 10: Potential need to develop a new BMS and/or EMS to control retired batteries | [19,20,47] |

| Challenge 11: Missing long-term experience in processing and integrating SLBs | [6,9] |

| Individual Barriers | Source |

|---|---|

| Challenge 12: Price competitiveness between second-life batteries and first-life battery systems | [46,58,59] |

| Challenge 13: Used goods are perceived with a lower value | [12,28] |

| Challenge 14: Uncertainty regarding residual value and capacity lower the “willing price to pay” | [29] |

| Challenge 15: Costs for condition assessment, rededication and subsequent warranties question the economic viability. | [9,28] |

| Individual Barriers | Source |

|---|---|

| Challenge 16: Uncertain liability picture. E.g., regarding the transfer of liability from OEM to SLB provider | [34,46] |

| Challenge 17: Automakers might prevent a second use if they were still liable for their batteries | [29,46] |

| Challenge 18: Absence of previous statistics lead to problems in the insurance market | [12,38] |

| Challenge 19: Existing regulations for electric utilities complicate the repurposing process | [9] |

| Challenge 20: It is unclear who will be responsible for disposal and recycling at the end of the second life | [39,64] |

| Challenge 21: Privacy issues hamper the sharing of first life usage data by the OEM | [34] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kampker, A.; Heimes, H.H.; Offermanns, C.; Vienenkötter, J.; Frank, M.; Holz, D. Identification of Challenges for Second-Life Battery Systems—A Literature Review. World Electr. Veh. J. 2023, 14, 80. https://doi.org/10.3390/wevj14040080

Kampker A, Heimes HH, Offermanns C, Vienenkötter J, Frank M, Holz D. Identification of Challenges for Second-Life Battery Systems—A Literature Review. World Electric Vehicle Journal. 2023; 14(4):80. https://doi.org/10.3390/wevj14040080

Chicago/Turabian StyleKampker, Achim, Heiner Hans Heimes, Christian Offermanns, Janis Vienenkötter, Merlin Frank, and Daniel Holz. 2023. "Identification of Challenges for Second-Life Battery Systems—A Literature Review" World Electric Vehicle Journal 14, no. 4: 80. https://doi.org/10.3390/wevj14040080

APA StyleKampker, A., Heimes, H. H., Offermanns, C., Vienenkötter, J., Frank, M., & Holz, D. (2023). Identification of Challenges for Second-Life Battery Systems—A Literature Review. World Electric Vehicle Journal, 14(4), 80. https://doi.org/10.3390/wevj14040080