Concept for Digital Product Twins in Battery Cell Production

Abstract

1. Introduction

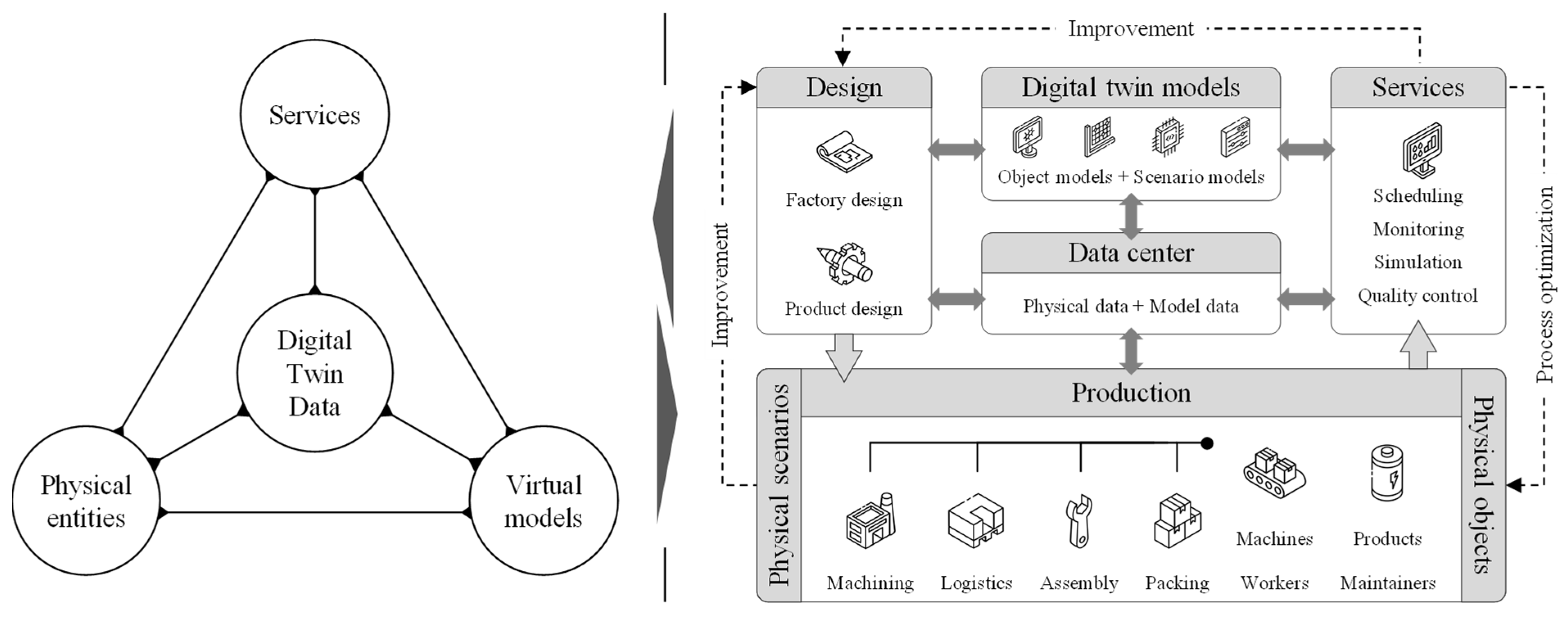

2. Fundamentals and Approach

2.1. Related Work on Digital Product Twins

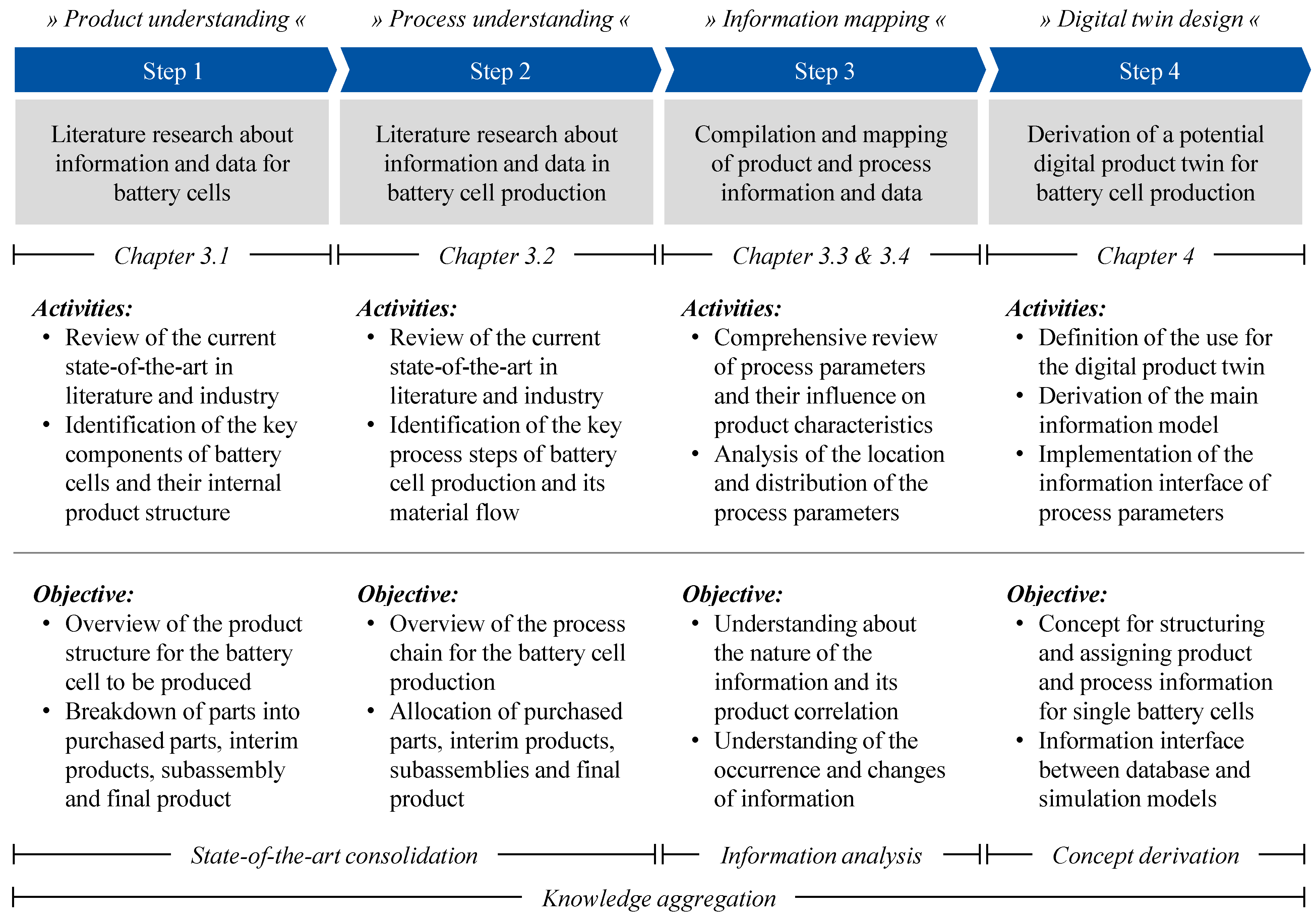

2.2. Methodological Approach

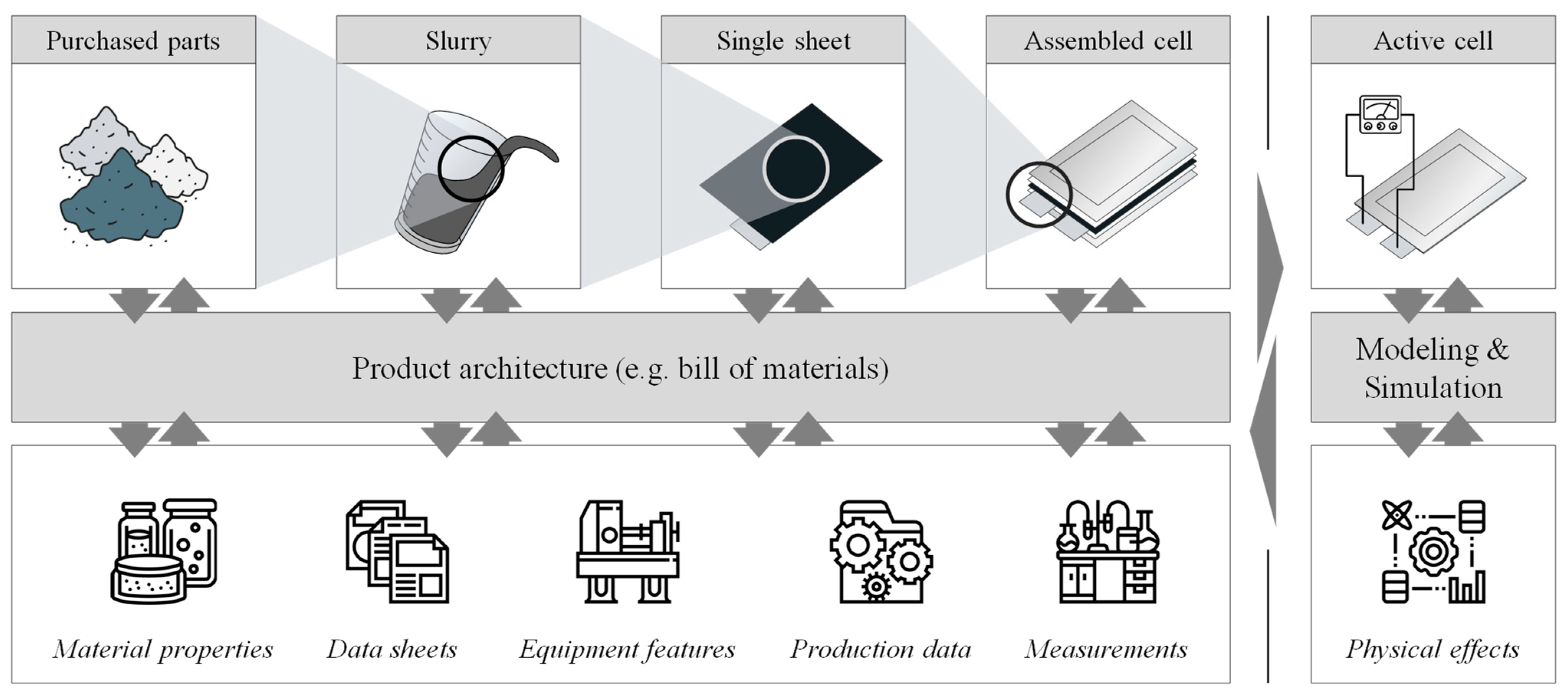

3. Product and Process Information in Battery Cell Production

3.1. Structure of a Lithium-Ion Battery Cell

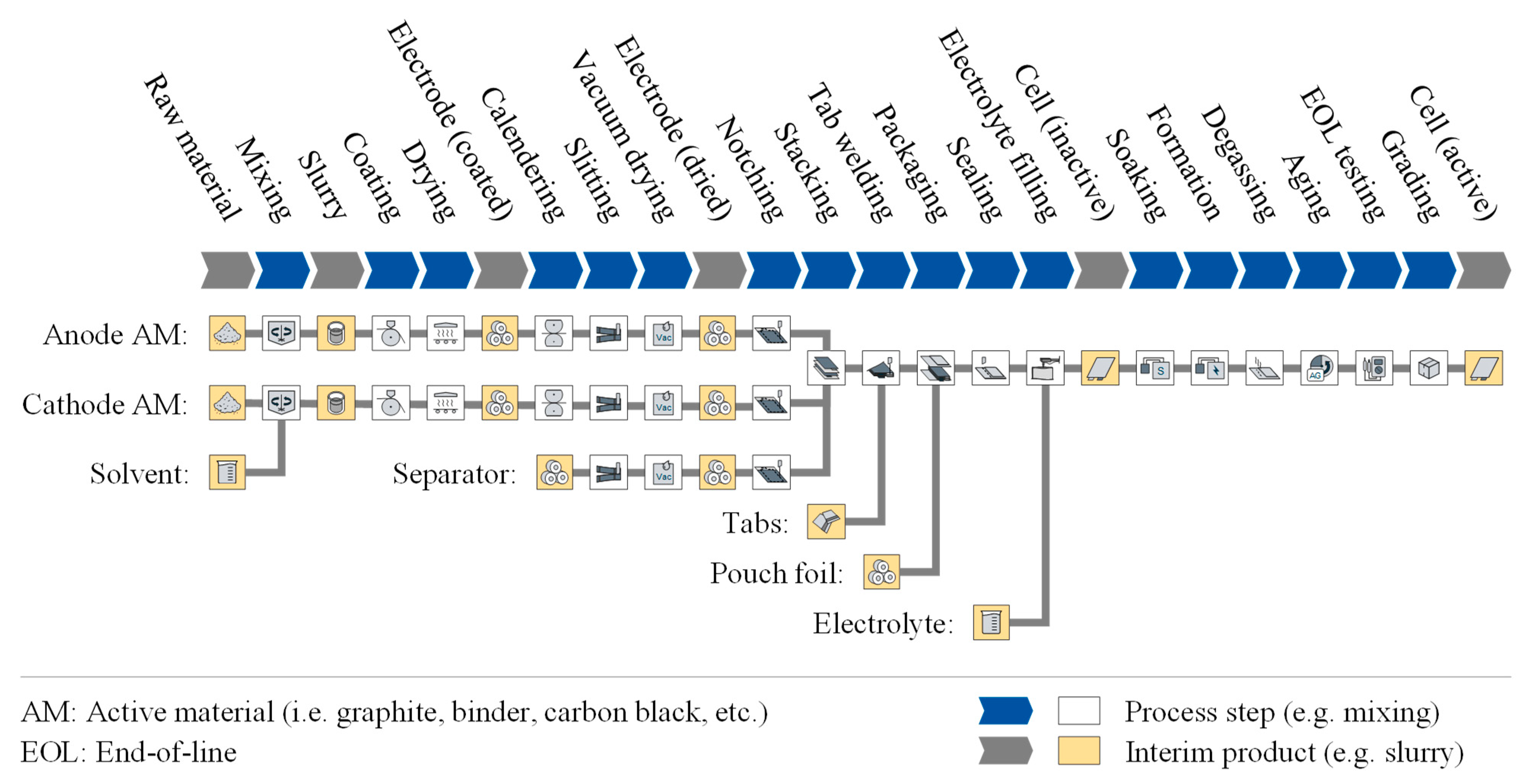

3.2. Process Chain for Battery Cell Production

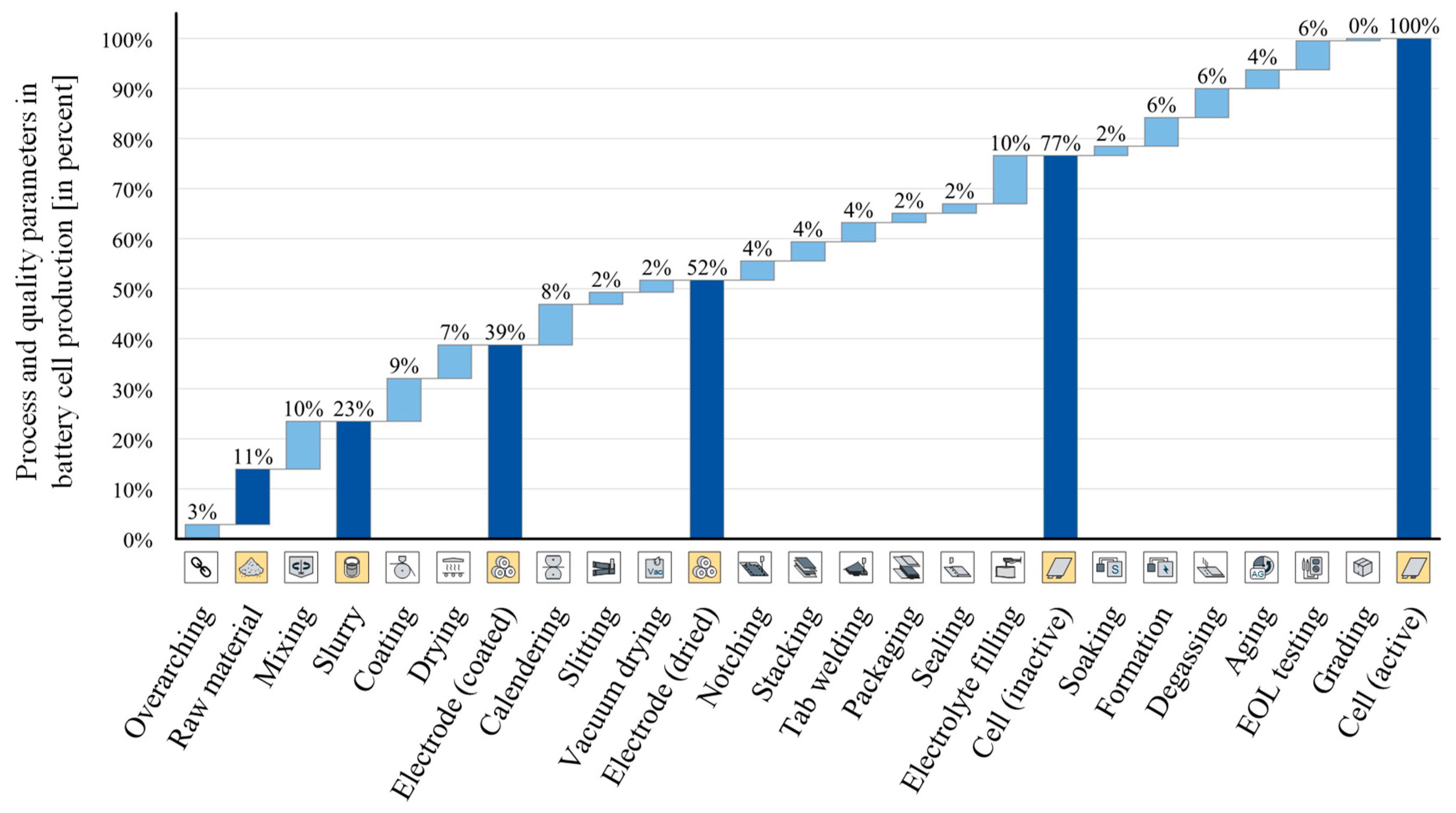

3.3. Process and Quality Parameters for Interim Products

3.4. Categorization and Mapping of Product and Production Information

- Product feature: all properties and characteristics of intermediate products and the final product (cell) that can be measured or are given by the supplier, such as slurry viscosity, coating thickness of the electrode, or internal resistance of the final cell.

- Process parameter: all parameters that can be set directly on the respective process, such as mixer speed, web speed, or welding frequency.

- Equipment feature: parameters that cannot be changed at short notice in the process and are defined by the design of the equipment or its tools. Slot die width, drying line length, and calender roller diameter are examples of these kind of parameters.

- Ambient parameter: parameters that describe the conditions prevailing in the production process (humidity, temperature, etc.) and cannot be set directly on the respective machine, but are ensured by the room conditioning systems.

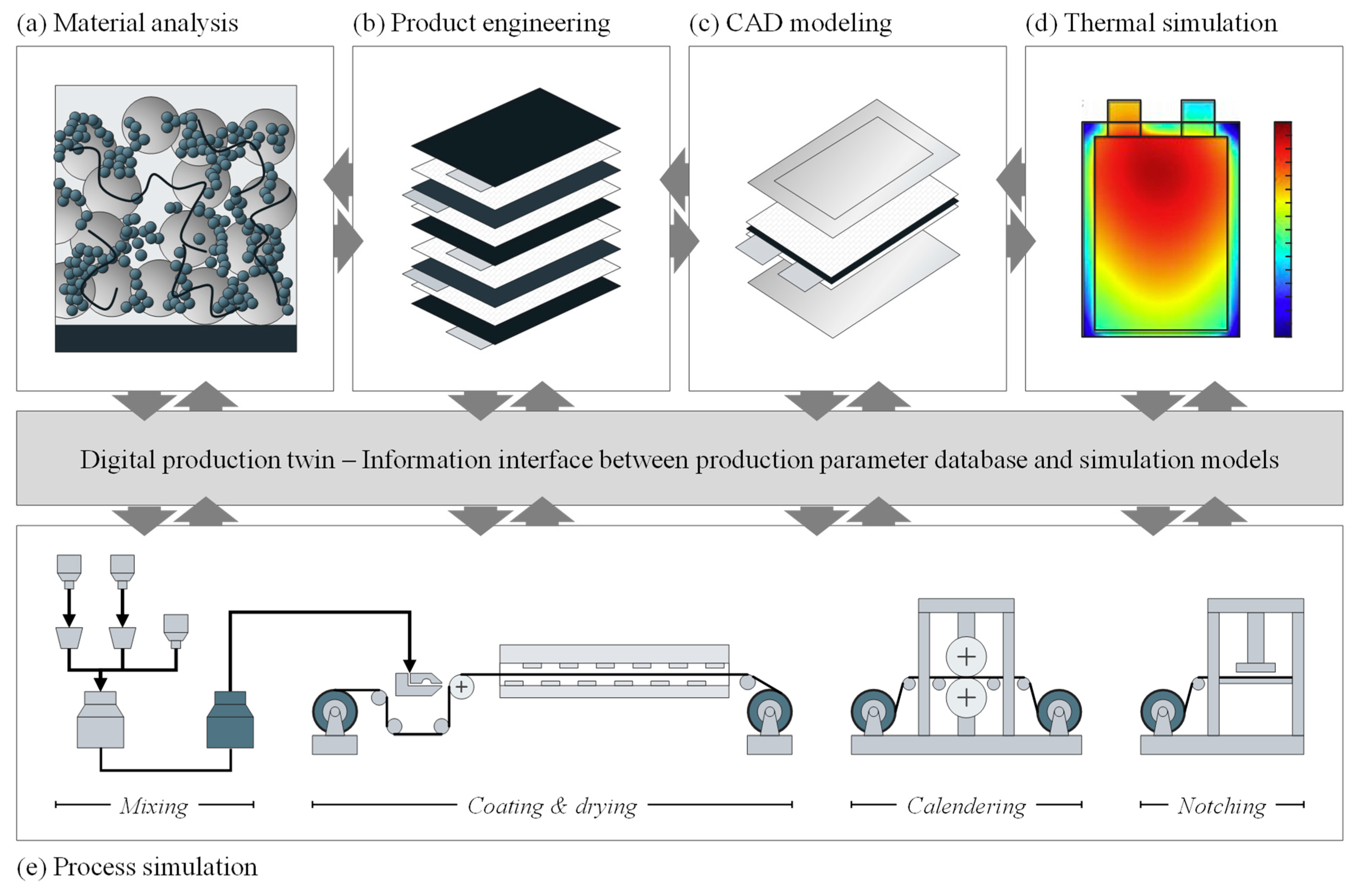

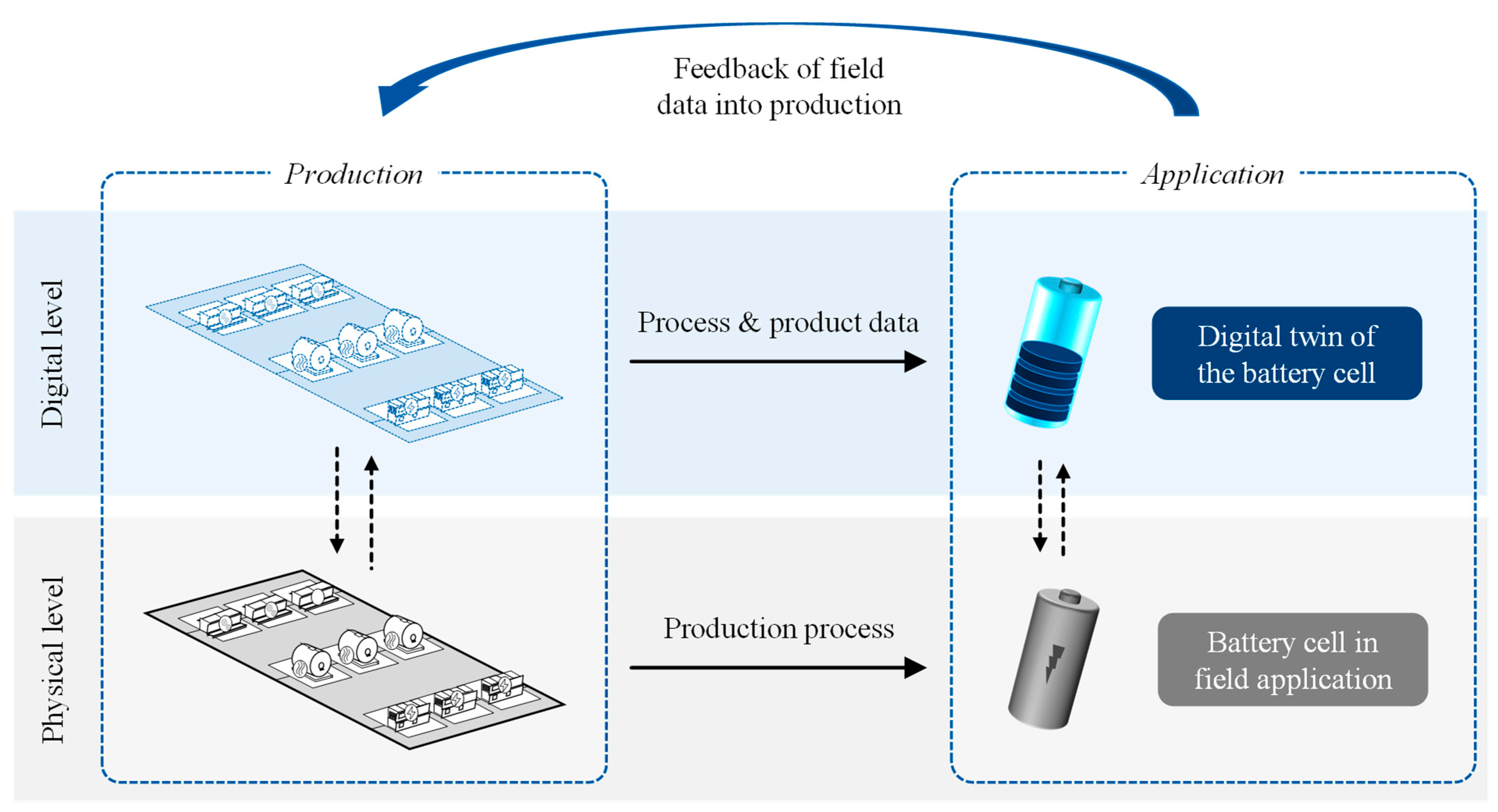

4. Digital Product Twin for Battery Cell Production

4.1. Framework of a Digital Battery Product Twin

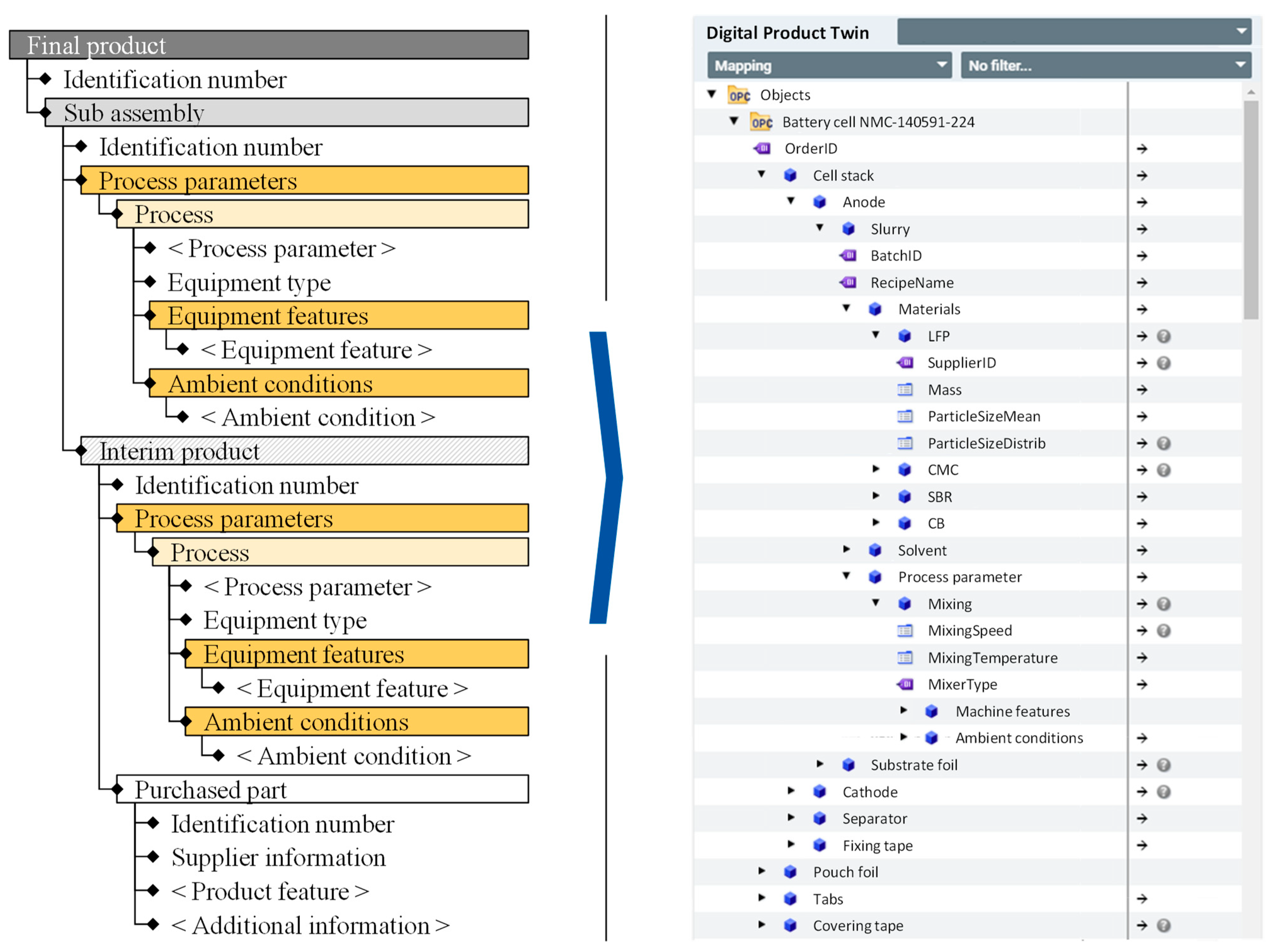

4.2. Implementation and Data Structuring

4.3. Information Interfaces and Interactions

5. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Process | Parameter | Information | Unit | Source |

|---|---|---|---|---|

| Overarching | Atmosphere | Ambient parameter | - | [31] |

| Humidity (dew point) | Ambient parameter | °C | [31] | |

| Clean room | Ambient parameter | ISO | [31] | |

| Ambient temperature | Ambient parameter | °C | [31,37,38] | |

| Process duration | Process parameter | min | [39] | |

| Power demand | Process parameter | kW | [39] | |

| Raw material | Tap density (active material) | Product feature | kg/m3 | [40,41] |

| Purity (active material) | Product feature | % or ppm | [42] | |

| Humidity (active material) | Product feature | % | [42,43] | |

| Particle size distribution (active material) | Product feature | µm | [40,42,44,45] | |

| Particle shape (active material) | Product feature | - | [42] | |

| Specific surface (active material) | Product feature | m2/g | [40] | |

| Chemical composition (active material) | Product feature | - | [44] | |

| Chemical composition (electrolyte) | Product feature | % | [43] | |

| Tortuosity (separator) | Product feature | - | [46] | |

| Porosity (separator) | Product feature | % | [42,47] | |

| Thickness (separator) | Product feature | µm | [42,47] | |

| Puncture resistance (separator) | Product feature | J | [42] | |

| Temperature stability (separator) | Product feature | °C | [42] | |

| Yield stress (separator) | Product feature | MPa | [42] | |

| Yield strain (separator) | Product feature | % | [42] | |

| Max. stress (separator) | Product feature | MPa | [42] | |

| Nominal elongation at break (separator) | Product feature | % | [42] | |

| Polymer chain length (binder) | Product feature | - | [44] | |

| Polydispersity (binder) | Product feature | PI | [44] | |

| Purity (electrode foil) | Product feature | % | [42] | |

| Thickness (electrode foil) | Product feature | µm | [42,48] | |

| Surface roughness (electrode foil) | Product feature | µm | [49] | |

| Impurity (electrode foil) | Product feature | % | [42] | |

| Electrode manufacturing— Mixing (dry) | Slurry formulation | Product feature | g or wt% | [40,44,45,48,50,51] |

| Mixer type | Equipment feature | - | [44,45] | |

| Tank capacity | Equipment feature | L | [44] | |

| Mixing duration | Process parameter | min | [31,38,40,44,48,50] | |

| Mixing temperature | Process parameter | °C | [31,44,52] | |

| Mixing speed | Process parameter | RPM | [38,40,44,45,48] | |

| Agglomerate size | Product feature | µm | [44,53] | |

| Electrode manufacturing— Mixing (dispersing) | Mixer type | Equipment feature | - | [44,45] |

| Tank capacity | Equipment feature | L | [44] | |

| Mixing duration | Process parameter | min | [31,38,40,44,48,50] | |

| Mixing temperature | Process parameter | °C | [31,44,52] | |

| Mixing speed | Process parameter | RPM | [38,40,44,45,48] | |

| Viscosity | Product feature | mPas | [31,38,40,44,45,50,51,52,53] | |

| Agglomerate size | Product feature | µm | [31,44,45,52,53] | |

| Surface tension | Product feature | N/m | [44] | |

| Slurry density | Product feature | g/cm3 | [44] | |

| Solids content of the slurry | Product feature | wt% | [38,44,45,51,52,53,54] | |

| Slurry purity | Product feature | % | [31,52] | |

| Diffusion coefficient of the active material | Product feature | m2/s | [47] | |

| Electrical conductivity of the slurries | Product feature | S/m | [47,55] | |

| Electrode manufacturing— Coating | Slot die distance | Equipment feature | µm | [44,50,54] |

| Slot die angle | Equipment feature | ° | [44] | |

| Web tension | Process parameter | N/mm2 | [44,51] | |

| Foil folding (wrinkle) | Process parameter | µm | [51] | |

| Operating speed | Process parameter | m/min | [44,48,50] | |

| Pump flow rate | Process parameter | m3/min | [44] | |

| Slot width | Equipment feature | mm | [31,44] | |

| Temperature of the coating material | Process parameter | °C | [44,52] | |

| Coating accuracy (mismatch) | Product feature | % | [31,52] | |

| Web edge | Process parameter | µm | [50,52] | |

| Coating thickness (wet) | Product feature | µm | [38,44,45,47,50,52,54,55] | |

| Coating accuracy (wet) | Process parameter | % | [31,52] | |

| Coating weight/weight per unit | Product feature | g/m2 | [38,44,56] | |

| Shear rate (slot) | Process parameter | s−1 | [44] | |

| Viscosity | Product feature | mPas | [44,50,51,53] | |

| Defects | Product feature | - | [31,44] | |

| Particle sizes of the coating | Product feature | µm | [38,44,47] | |

| Coating porosity | Product feature | % | [38,44,47,52,56] | |

| Electrode manufacturing— Drying | Coating thickness (dry electrode, uncalendered) | Product feature | µm | [30,31,38,44,45,47,48,54,57] |

| Drying line | Equipment feature | m | [31,44] | |

| Number of temperature zones | Equipment feature | - | [44,54] | |

| Temperature profile in the dryer zone | Process parameter | °C | [31,38,44,54] | |

| Web speed | Process parameter | m/min | [31,38,44,50] | |

| Air velocity | Process parameter | m/s | [44,56] | |

| Air nozzle spacing | Equipment feature | m | [44] | |

| Air volume flow | Process parameter | m3/min | [38,44,56] | |

| Web tension | Process parameter | N/mm2 | [31,44,51] | |

| Fractures in the material | Product feature | µm | [31,44,52] | |

| Residual humidity | Product feature | % | [38,52] | |

| Binder and conductivity additive migration | Product feature | % or ppm | [50,51,52] | |

| Adhesion/adhesive strength | Product feature | N/mm2 | [38,44,45,49,51,52] | |

| Coating porosity | Product feature | % | [38,44,45,47,52,56] | |

| Electrode manufacturing—Calendering | Foil folding (wrinkle) | Process parameter | µm | [51] |

| Defects | Product feature | - | [44] | |

| Roller width | Equipment feature | m | [31] | |

| Roller surface roughness | Equipment feature | µm | [31] | |

| Roller concentricity | Equipment feature | µm | [31] | |

| Roller diameter | Equipment feature | mm | [31] | |

| Line pressure | Process parameter | N/mm | [31,38,44,50] | |

| Temperature control of the roller | Process parameter | °C | [31,38,44] | |

| Roller drive velocity | Process parameter | min−1 | [44] | |

| Gap size | Process parameter | µm | [44] | |

| Adhesion/adhesive strength | Product feature | N/mm2 | [31,38,44] | |

| Surface roughness | Product feature | µm | [31,38] | |

| Tortuosity | Product feature | - | [30,46,55] | |

| Pore size distribution | Product feature | (µm) | [30,44] | |

| Coating porosity | Product feature | % | [31,38,44,47,50,51,55,56,58] | |

| Coating weight/weight per unit | Product feature | g | [44,52] | |

| Coating thickness (calendered electrode) | Product feature | µm | [38,44,47,50,52,55] | |

| Electrode manufacturing— Slitting | Cutting speed | Process parameter | m/min | [31] |

| Cutting edge geometries | Process parameter | µm | [31,38,50,52] | |

| Foreign particles | Product feature | µm | [31,52,59] | |

| Microstructure deformation | Product feature | µm | [52] | |

| Burr height | Product feature | µm | [38] | |

| Electrode manufacturing—Vacuum drying | Temperature | Process parameter | °C | [31,38] |

| Drying time | Process parameter | h | [31,38,48,50] | |

| Vacuum pressure | Process parameter | mbar | [31,38,48] | |

| Humidity (dew point) | Process parameter | °C | [50] | |

| Residual humidity | Product feature | % or ppm | [31,38] | |

| Cell assembly— Notching | Punching time | Process parameter | s | [31,60] |

| Punching speed | Process parameter | s/sheet | [31,60] | |

| Wear resistance (tool life) | Equipment feature | - | [31,60] | |

| Electrode geometry | Product feature | mm | [31,60] | |

| Cutting accuracy | Process parameter | µm | [51,60] | |

| Electrode cutting height | Product feature | µm | [60] | |

| Cut size variation | Product feature | µm | [60] | |

| Electrode tortuosity | Product feature | - | [30,46,55] | |

| Cell assembly— Stacking | Positioning accuracy of the electrode sheets | Process parameter | µm | [31,51,52,61] |

| Suction pressure of the gripper | Process parameter | Pa | [38] | |

| Separator pre-tension | Process parameter | MPa | [62] | |

| Stacking accuracy | Product feature | µm | [31,43] | |

| Number of sheets | Product feature | - | [48] | |

| Foreign particle concentration | Product feature | 1/m3 | [52,59] | |

| Electrical charge | Product feature | C | [31,52] | |

| Clamping force of the hold-down | Process parameter | N | [38,43] | |

| Cell assembly— Tab welding | Amplitude | Process parameter | µm | [63] |

| Welding force | Process parameter | N | [43,63] | |

| Frequency | Process parameter | kHz | [31] | |

| Welding time | Process parameter | s | [63] | |

| Holding force of the cell tab contact | Process parameter | N | [52] | |

| Contact resistance of the cell tab | Product feature | S | [52] | |

| Optical inspection of the cell tab | Product feature | - | [31,52] | |

| Weld energy | Process parameter | kJ/cm | [63] | |

| Cell assembly— Packaging | Hold-down force | Process parameter | N | [64] |

| Stamp speed | Process parameter | Stroke/min | [64] | |

| Stamping force | Process parameter | N | [64] | |

| Temperature | Process parameter | °C | [64] | |

| Cell assembly— Sealing | Sealing pressure | Process parameter | N/mm2 | [31,43] |

| Sealing temperature | Process parameter | °C | [31] | |

| Sealing duration | Process parameter | s | [48] | |

| Vacuum pressure | Process parameter | mbar | [48] | |

| Cell assembly— Electrolyte filling (filling) | Volume flow | Process parameter | m3 | [37,43] |

| Electrolyte quantity | Process parameter | ml | [31,43,65,66,67] | |

| Number of filling cycles | Process parameter | - | [31,66,67] | |

| Vacuum pressure | Process parameter | mbar | [31,38,66] | |

| Vacuum time | Process parameter | s | [43] | |

| Filling duration | Process parameter | s | [51,66,67,68] | |

| Electrolyte temperature | Process parameter | °C | [37,38,52,67] | |

| Cell weight | Product feature | g | [48] | |

| Diffusion coefficient of the electrolyte | Product feature | m2/s | [55] | |

| Cell assembly— Electrolyte filling (wetting) | Wetting duration | Process parameter | s | [37,43,66,67,68] |

| Operating pressure | Process parameter | bar | [31,43,66,67,68] | |

| Degree of wetting/distribution of the electrolyte | Product feature | % | [31,38,66,67,68] | |

| Electrical insulation resistance | Product feature | Ω | [52] | |

| Cell assembly (pouch)— Electrolyte filling (sealing under vacuum) | Sealing temperature | Process parameter | °C | [48] |

| Vacuum pressure | Process parameter | N/mm2 | [48] | |

| Sealing temperature | Process parameter | °C | [31] | |

| Sealing pressure | Process parameter | N/mm2 | [31,37] | |

| Sealing duration | Process parameter | s | [48] | |

| Inspection of the sealing | Product feature | - | [52] | |

| Leakage | Product feature | - | [31,52] | |

| Cell finishing—Soaking | Soaking time | Process parameter | h | [39,43,69] |

| Temperature | Process parameter | °C | [39] | |

| Vacuum pressure | Process parameter | Mbar | [43] | |

| Vacuum time | Process parameter | h | [43] | |

| Cell finishing—Formation | Contact resistances at the spring contacts | Process parameter | S | [31] |

| Formation cycle duration | Process parameter | h | [38] | |

| Charging range (SOC) | Process parameter | % | [31,70] | |

| Charging voltage | Process parameter | V | [31,37] | |

| Charging current | Process parameter | A | [31,37] | |

| Charge and discharge cycles | Process parameter | Cycles | [31] | |

| Temperature | Process parameter | °C | [31,38] | |

| Compression pressure during formation | Process parameter | MPa | [31,37] | |

| Precharge duration | Process parameter | h | [31,38] | |

| Cell temperature | Product feature | °C | [37,52] | |

| Cycle efficiency | Product feature | - | [38,70] | |

| Discharge capacity | Product feature | Ah | [51,70] | |

| Cell finishing— Degassing (piercing the gas bag and suction of gas) | Contact pressure on the cell | Process parameter | MPa | [31] |

| Weight | Product feature | g | [37] | |

| Residual gas inside cell | Product feature | ml | [67,68] | |

| Cell finishing (pouch)— Degassing (final sealing) | Sealing temperature | Process parameter | °C | [31] |

| Sealing pressure | Process parameter | N/mm2 | [31] | |

| Sealing duration | Process parameter | s | [48] | |

| Vacuum pressure | Process parameter | bar | [31] | |

| Vacuum time | Process parameter | s | [31] | |

| Seam width | Product feature | mm | [31] | |

| Heat input | Product feature | W | [31] | |

| Cell finishing— Degassing (folding) | Leakage | Product feature | - | [31,38,52] |

| Folding edge geometry | Product feature | µm | [31] | |

| Cell finishing—Aging (HT-aging) | Aging duration | Process parameter | h | [31] |

| Aging temperature | Process parameter | °C | [31] | |

| SOC | Process parameter | % | [30,31] | |

| Voltage loss rate | Product feature | % | [30] | |

| Cell finishing—Aging (NT-aging) | Aging duration | Process parameter | days | [31] |

| Aging temperature | Process parameter | °C | [31] | |

| SOC | Process parameter | % | [30,31] | |

| Voltage loss rate | Product feature | % | [30] | |

| Cell finishing—EOL testing | SOC of the cell for shipping | Product feature | % | [20,30,71] |

| Optical inspection | Product feature | - | [31,71] | |

| Electrical-dynamic behavior | Product feature | - | [31,52,71] | |

| Electrical internal resistance | Product feature | Ω | [31,52,71] | |

| Impedance | Product feature | Ω | [56,70] | |

| Voltage | Product feature | V | [30,71] | |

| Leakage | Product feature | - | [31,52] | |

| Foreign particle concentration | Product feature | 1/m3 | [59] | |

| Thermal conductivity of the cell | Product feature | W/mK | [72] | |

| Heat capacity of the cell | Product feature | J/kg·K | [72] | |

| Cell temperature | Product feature | °C | [37,38] | |

| Cell weight | Product feature | g | [37,71] | |

| Grading | Grade | Product feature | - | [31,71] |

References

- Usai, L.; Lamb, J.J.; Hertwich, E.; Burheim, O.S.; Strømman, A.H. Analysis of the Li-ion battery industry in light of the global transition to electric passenger light duty vehicles until 2050. Environ. Res. Infrastruct. Sustain. 2022, 2, 011002. [Google Scholar] [CrossRef]

- Krauß, J.; Schmetz, A.; Fitzner, A.; Krauß, J.; Schmetz, A.; Fitzner, A.; Ackermann, T.; Pouls, K.B.; Hülsmann, T.-H.; Roth, D.; et al. Der Digitale Zwilling in der Batteriezellfertigung. 2023. Available online: https://publica.fraunhofer.de/entities/publication/05cc0964-10f5-43fd-b8b5-6b4d05bad628/details (accessed on 26 February 2023).

- Kehrer, M.; Locke, M.; Offermanns, C.; Heimes, H.; Kampker, A. Analysis of Possible Reductions of Rejects in Battery Cell Production during Switch-On and Operating Processes. Energy Technol. 2021, 9, 2001113. [Google Scholar] [CrossRef]

- Ventura Silva, G.; Thomitzek, M.; Lippke, M.; Heckmann, T.; Karaki, H.; Lischka, C. Digitalization Platform for Sustainable Battery Cell Production: Coupling of Process, Production, and Product Models. Energy Technol. 2022, 2200801. [Google Scholar] [CrossRef]

- Ayerbe, E.; Berecibar, M.; Clark, S.; Franco, A.A.; Ruhland, J. Digitalization of Battery Manufacturing: Current Status, Challenges, and Opportunities. Adv. Energy Mater. 2022, 12, 2102696. [Google Scholar] [CrossRef]

- Zanotto, F.M.; Dominguez, D.Z.; Ayerbe, E.; Boyano, I.; Burmeister, C.; Duquesnoy, M.; Eisentraeger, M.; Montaño, J.F.; Gallo-Bueno, A.; Gold, L.; et al. Data Specifications for Battery Manufacturing Digitalization: Current Status, Challenges, and Opportunities. Batter. Supercaps 2022, 5, e202200224. [Google Scholar] [CrossRef]

- Puchta, A.; Schmied, J.; Scharmann, T.; Töpper, H.-C.; Fleischer, J.; Kampker, A.; Dröder, K.; Daub, R. Industrie 4. 0 in der Batteriezellproduktion. WT Werkstattstech Online 2022, 112, 496–500. [Google Scholar] [CrossRef]

- Kan, C.; Anumba, C.J.; Kan, C.; Anumba, C.J. Digital Twins as the Next Phase of Cyber-Physical Systems in Construction. In Proceedings of the ASCE International Conference on Computing in Civil Engineering, Atlanta, GA, USA, 17–19 June 2019; pp. 256–264. [Google Scholar]

- Qi, Q.; Fei, T.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Qi, Q.; Tao, F.; Hu, T.; et al. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Kukushkin, K.; Ryabov, Y.; Borovkov, A. Digital Twins: A Systematic Literature Review Based on Data Analysis and Topic Modeling. Data 2022, 7, 173. [Google Scholar] [CrossRef]

- Sjarov, M.; Lechler, T.; Fuchs, J.; Sjarov, M.; Lechler, T.; Fuchs, J. The Digital Twin Concept in Industry—A Review and Systematization. In Proceedings of the 25th International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 1789–1796. [Google Scholar]

- Bergs, T.; Gierlings, S.; Auerbach, T.; Klink, A.; Schraknepper, D.; Augspurger, T. The Concept of Digital Twin and Digital Shadow in Manufacturing. Procedia CIRP 2021, 101, 81–84. [Google Scholar] [CrossRef]

- Preut, A.; Kopka, J.-P.; Clausen, U. Digital Twins for the Circular Economy. Sustainability 2021, 13, 10467. [Google Scholar] [CrossRef]

- Bonney, M.S.; Wagg, D. Historical Perspective of the Development of Digital Twins Special Topics in Structural Dynamics & Experimental Techniques; Epp, D.S., Ed.; Springer International Publishing: Cham, Switzerland, 2022; Volume 5, pp. 15–20. [Google Scholar]

- Rosen, R.; Fischer, J.; Boschert, S. Next Generation Digital Twin: An Ecosystem for Mechatronic Systems? IFAC-Pap. 2019, 52, 265–270. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Cheng, X.U.; Zuo, H.; Cheng, Z. The Development of Digital Twin Technology Review. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 4901–4906. [Google Scholar]

- Bartelt, M.; Prior, J.; Sinnemann, J.; Kuhlenkötter, B. A template-based approach to support an automated digital production plant engineering. Procedia CIRP 2022, 107, 821–826. [Google Scholar] [CrossRef]

- Eickhoff, T.; Forte, S.; Göbel, J.C. Approach for Developing Digital Twins of Smart Products Based on Linked Lifecycle Information. Proc. Des. Soc. 2022, 2, 1559–1568. [Google Scholar] [CrossRef]

- Wagner, R.; Schleich, B.; Haefner, B.; Kuhnle, A.; Wartzack, S.; Lanza, G. Challenges and Potentials of Digital Twins and Industry 4.0 in Product Design and Production for High Performance Products. Procedia CIRP 2019, 84, 88–93. [Google Scholar] [CrossRef]

- Onaji, I.; Tiwari, D.; Soulatiantork, P.; Song, B.; Tiwari, A. Digital twin in manufacturing: Conceptual framework and case studies. Int. J. Comput. Integr. Manuf. 2022, 35, 831–858. [Google Scholar] [CrossRef]

- Göbel, J.C.; Eickhoff, T.; Eigner, M.; Detzner, A.; Schmidt, P.H.; Tharma, R. Definition des Digital Twin im Produktlebenszyklus. Z. Wirtsch. Fabr. 2019, 114, 345–350. [Google Scholar]

- Prior, J.; Penczek, L.N.; Brisse, M.; Hundt, L.; Kuhlenkotter, B. A method for mapping novel product groups in AutomationML as the first step for creating their virtual twin. In Proceedings of the International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Germany, 6–9 September 2022; Volume 27, pp. 1–8. [Google Scholar]

- Zheng, M.; Tian, L.; Zheng, M.; Tian, L. Digital product twin modeling of massive dynamic data based on a time-series database. J. Tsinghua Univ. 2021, 61, 1281–1288. [Google Scholar]

- Kies, A.D.; Krauß, J.; Schmetz, A.; Schmitt, R.H.; Brecher, C. Interaction of Digital Twins in a Sustainable Battery Cell Production. Procedia CIRP 2022, 107, 1216–1220. [Google Scholar] [CrossRef]

- Achim, K.; Heimes, H.H.; Offermanns, C.; Sasse, K.; Frieges, M.H.; Spath, B. Domain based product architecture approach for innovative battery system design. In Proceedings of the International Symposium on Electromobility, Puebla, Mexico, 17–19 October 2022; pp. 1–6. [Google Scholar]

- Heimes, H.H.; Kampker, A.; Haunreiter, A.; Davids, H.; Klohs, D. Product-requirement-model to approach the identification of uncertainties in battery systems development. Int. J. Interact. Des. Manuf. (IJIDeM) 2020, 14, 911–922. [Google Scholar] [CrossRef]

- Vuorilehto, K. Materialien und Funktion Handbuch Lithium-Ionen-Batterien; Korthauer, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 21–29. [Google Scholar]

- Or, T.; Gourley, S.W.D.; Kaliyappan, K.; Yu, A.; Chen, Z. Recycling of mixed cathode lithium-ion batteries for electric vehicles: Current status and future outlook. Carbon Energy 2020, 2, 6–43. [Google Scholar] [CrossRef]

- Brodd, R.J.; Helou, C. Cost comparison of producing high-performance Li-ion batteries in the U.S. and in China. J. Power Sources 2013, 231, 293–300. [Google Scholar] [CrossRef]

- Kwade, A.; Haselrieder, W.; Leithoff, R.; Modlinger, A.; Dietrich, F.; Droeder, K. Current status and challenges for automotive battery production technologies. Nat. Energy 2018, 3, 290–300. [Google Scholar] [CrossRef]

- Heimes, H.H.; Kampker, A.; Lienemann, C.; Locke, M.; Offermanns, C.; Michaelis, S.; Rahimzei, E. Produktionsprozess einer Lithium-Ion Batteriezelle, 3rd ed.; PEM RWTH Aachen: Aachen, Germany; VDMA: Frankfurt am Main, Germany, 2018. [Google Scholar]

- Thomitzek, M.; Schmidt, O.; Röder, F.; Krewer, U.; Herrmann, C.; Thiede, S. Simulating Process-Product Interdependencies in Battery Production Systems. Procedia CIRP 2018, 72, 346–351. [Google Scholar] [CrossRef]

- Cushing, A.; Zheng, T.; Higa, K.; Liu, G. Viscosity Analysis of Battery Electrode Slurry. Polymers 2021, 13, 4033. [Google Scholar] [CrossRef] [PubMed]

- Diehm, R.; Müller, M.; Burger, D.; Kumberg, J.; Spiegel, S.; Bauer, W.; Scharfer, P.; Schabel, W. High-Speed Coating of Primer Layer for Li-Ion Battery Electrodes by Using Slot-Die Coating. Energy Technol. 2020, 8, 2000259. [Google Scholar] [CrossRef]

- Ahmed, S.; Nelson, P.A.; Dees, D.W. Study of a dry room in a battery manufacturing plant using a process model. J. Power Sources 2016, 326, 490–497. [Google Scholar] [CrossRef]

- Park, Y.-T.; Lee, K.-T.; Park, J.-W.; Lee, S.-H. Effect of Impurities on Electrochemical Performance of Low-Purity Natural Graphite As Anode Active Material for Lithium Ion Batteries. ECS Meet. Abstr. 2016, MA2016-02, 3918. [Google Scholar] [CrossRef]

- Stock, S.; Ceruti, A.; Günter, F.J.; Reinhart, G. Introducing Inline Process and Product Analysis for the Lean Cell Finalization in Lithium-Ion Battery Production. Procedia CIRP 2021, 104, 1052–1058. [Google Scholar] [CrossRef]

- Westermeier, M.; Reinhart, G.; Zeilinger, T. Method for quality parameter identification and classification in battery cell production quality planning of complex production chains for battery cells. In Proceedings of the International Electric Drives Production Conference, Nuremberg, Germany, 29–30 October 2013; Volume 3, pp. 1–10. [Google Scholar]

- Wanner, J.; Weeber, M.; Birke, K.P.; Sauer, A. Production planning and process optimization of a cell finishing process in battery cell manufacturing. Procedia CIRP 2022, 112, 507–512. [Google Scholar] [CrossRef]

- Lim, S.; Kim, S.; Ahn, K.H.; Lee, S.J. The effect of binders on the rheological properties and the microstructure formation of lithium-ion battery anode slurries. J. Power Sources 2015, 299, 221–230. [Google Scholar] [CrossRef]

- Liu, P. Improving the Tapped Density of the Cathode Material to Make a Lithium-ion Battery Hold More Energy. 2021. Available online: https://www.researchgate.net/publication/355982509_Improving_the_Tapped_Density_of_the_Cathode_Material_to_make_a_Lithium-ion_Battery_Hold_More_Energy (accessed on 26 February 2023).

- Heimes, H.; Kampker, A.; Hemdt, A.; Kreisköther, K.; Michaelis, S.; Rahimzei, E. Manufacturing of Lithium-Ion Battery Cell Components, 1st ed.; VDMA: Frankfurt am Main, Germany, 2019. [Google Scholar]

- Dai, F.; Cai, M. Best practices in lithium battery cell preparation and evaluation. Commun. Mater. 2022, 3, 64. [Google Scholar] [CrossRef]

- Reynolds, C.D.; Slater, P.R.; Hare, S.D.; Simmons, M.J.; Kendrick, E. A review of metrology in lithium-ion electrode coating processes. Mater. Des. 2021, 209, 109971. [Google Scholar] [CrossRef]

- Bitsch, B.; Willenbacher, N.; Wenzel, V.; Schmelzle, S.; Nirschl, H. Einflüsse der mechanischen Verfahrenstechnik auf die Herstellung von Elektroden für Lithium-Ionen-Batterien. Chem. Ing. Tech. 2015, 87, 466–474. [Google Scholar] [CrossRef]

- Landesfeind, J.; Hattendorff, J.; Ehrl, A.; Wall, W.A.; Gasteiger, H.A. Tortuosity Determination of Battery Electrodes and Separators by Impedance Spectroscopy. J. Electrochem. Soc. 2016, 163, A1373–A1387. [Google Scholar] [CrossRef]

- Laue, V.; Schmidt, O.; Dreger, H.; Xie, X.; Röder, F.; Schenkendorf, R.; Kwade, A.; Krewer, U. Model-Based Uncertainty Quantification for the Product Properties of Lithium-Ion Batteries. Energy Technol. 2020, 8, 1900201. [Google Scholar] [CrossRef]

- Schreiner, D.; Zünd, T.; Günter, F.J.; Kraft, L.; Stumper, B.; Linsenmann, F.; Schüßler, M.; Wilhelm, R.; Jossen, A.; Reinhart, G.; et al. Comparative Evaluation of LMR-NCM and NCA Cathode Active Materials in Multilayer Lithium-Ion Pouch Cells: Part I. Production, Electrode Characterization, and Formation. J. Electrochem. Soc. 2021, 168, 030507. [Google Scholar] [CrossRef]

- Billot, N.; Günther, T.; Schreiner, D.; Stahl, R.; Kranner, J.; Beyer, M.; Reinhart, G. Investigation of the Adhesion Strength along the Electrode Manufacturing Process for Improved Lithium-Ion Anodes. Energy Technol. 2020, 8, 1801136. [Google Scholar] [CrossRef]

- Kaiser, J.; Wenzel, V.; Nirschl, H.; Bitsch, B.; Willenbacher, N.; Baunach, M.; Schmitt, M.; Jaiser, S.; Scharfer, P.; Schabel, W. Prozess- und Produktentwicklung von Elektroden für Li-Ionen-Zellen. Chem. Ing. Tech. 2014, 86, 695–706. [Google Scholar] [CrossRef]

- Günther, T.; Billot, N.; Schuster, J.; Schnell, J.; Spingler, F.B.; Gasteiger, H.A. The Manufacturing of Electrodes: Key Process for the Future Success of Lithium-Ion Batteries. Adv. Mater. Res. 2016, 1140, 304–311. [Google Scholar] [CrossRef]

- Michaelis, S.; Rahimzei, E.; Kampker, A.; Heimes, H.; Offermanns, C.; Locke, M.; Maiser, E.; Müller, D.; Deutskens, C.; Sarovic, N.; et al. Roadmap Batterie-Produktionsmittel 2030; Update 2020; VDMA: Frankfurt am Main, Germany, 2021. [Google Scholar]

- Hawley, W.B.; Li, J. Electrode manufacturing for lithium-ion batteries—Analysis of current and next generation processing. J. Energy Storage 2019, 25, 100862. [Google Scholar] [CrossRef]

- Duquesnoy, M.; Boyano, I.; Ganborena, L.; Cereijo, P.; Ayerbe, E.; Franco, A.A. Machine learning-based assessment of the impact of the manufacturing process on battery electrode heterogeneity. Energy AI 2021, 5, 100090. [Google Scholar] [CrossRef]

- Schmidt, O.; Thomitzek, M.; Röder, F.; Thiede, S.; Herrmann, C.; Krewer, U. Modeling the Impact of Manufacturing Uncertainties on Lithium-Ion Batteries. J. Electrochem. Soc. 2020, 167, 060501. [Google Scholar] [CrossRef]

- Román-Ramírez, L.A.; Apachitei, G.; Faraji-Niri, M.; Lain, M.; Widanage, D.; Marco, J. Effect of coating operating parameters on electrode physical characteristics and final electrochemical performance of lithium-ion batteries. Int. J. Energy Environ. Eng. 2022, 13, 943–953. [Google Scholar] [CrossRef]

- Duffner, F.; Mauler, L.; Wentker, M.; Leker, J.; Winter, M. Large-scale automotive battery cell manufacturing: Analyzing strategic and operational effects on manufacturing costs. Int. J. Prod. Econ. 2021, 232, 107982. [Google Scholar] [CrossRef]

- Oladimeji, C.F.; Moss, P.L.; Weatherspoon, M.H. Analyses of the Calendaring Process for Performance Optimization of Li-Ion Battery Cathode. Adv. Chem. 2016, 2016, 7395060. [Google Scholar] [CrossRef]

- Wu, Y.; Saxena, S.; Xing, Y.; Wang, Y.; Li, C.; Yung, W.; Pecht, M. Analysis of Manufacturing-Induced Defects and Structural Deformations in Lithium-Ion Batteries Using Computed Tomography. Energies 2018, 11, 925. [Google Scholar] [CrossRef]

- Luetke, M.; Franke, V.; Techel, A.; Himmer, T.; Klotzbach, U.; Wetzig, A.; Beyer, E. A Comparative Study on Cutting Electrodes for Batteries with Lasers. Phys. Procedia 2011, 12, 286–291. [Google Scholar] [CrossRef]

- Leithoff, R.; Fröhlich, A.; Dröder, K. Investigation of the Influence of Deposition Accuracy of Electrodes on the Electrochemical Properties of Lithium-Ion Batteries. Energy Technol. 2020, 8, 1900129. [Google Scholar] [CrossRef]

- Schmitt, J.; Posselt, G.; Dietrich, F.; Thiede, S.; Raatz, A.; Herrmann, C.; Dröder, K. Technical Performance and Energy Intensity of the Electrode-Separator Composite Manufacturing Process. Procedia CIRP 2015, 29, 269–274. [Google Scholar] [CrossRef]

- Balz, I.; Raad, E.A.; Rosenthal, E.; Lohoff, R.; Schiebahn, A.; Reisgen, U.; Vorländer, M. Process monitoring of ultrasonic metal welding of battery tabs using external sensor data. J. Adv. Join. Process. 2020, 1, 100005. [Google Scholar] [CrossRef]

- Angasu, G.; Reddy, K.S. Deep Drawing Process Parameters: A Review. Int. J. Curr. Eng. Technol. 2011, 6, 1204–1215. [Google Scholar]

- Günter, F.J.; Burgstaller, C.; Konwitschny, F.; Reinhart, G. Influence of the Electrolyte Quantity on Lithium-Ion Cells. J. Electrochem. Soc. 2019, 166, A1709–A1714. [Google Scholar] [CrossRef]

- Knoche, T.; Surek, F.; Reinhart, G. A Process Model for the Electrolyte Filling of Lithium-ion Batteries. Procedia CIRP 2016, 41, 405–410. [Google Scholar] [CrossRef]

- Lautenschlaeger, M.P.; Prifling, B.; Kellers, B.; Weinmiller, J.; Danner, T.; Schmidt, V.; Latz, A. Understanding Electrolyte Filling of Lithium-Ion Battery Electrodes on the Pore Scale Using the Lattice Boltzmann Method. Batter. Supercaps 2022, 5, e202200090. [Google Scholar] [CrossRef]

- Sauter, C.; Zahn, R.; Wood, V. Understanding Electrolyte Infilling of Lithium Ion Batteries. J. Electrochem. Soc. 2020, 167, 100546. [Google Scholar] [CrossRef]

- Schilling, A.; Gümbel, P.; Möller, M.; Kalkan, F.; Dietrich, F.; Dröder, K. X-ray Based Visualization of the Electrolyte Filling Process of Lithium Ion Batteries. J. Electrochem. Soc. 2019, 166, A5163–A5167. [Google Scholar] [CrossRef]

- Wolter, M.; Fauser, G.; Bretthauer, C.; Roscher, M.A. End-of-line testing and formation process in Li-ion battery assembly lines. In Proceedings of the International Multi-Conference on Systems Signals and Devices, Chemnitz, Germany, 20–23 March 2012; Volume 9, pp. 1–3. [Google Scholar]

- Ryll, K.; Hoffmann, L.; Landrath, O.; Lienesch, F.; Kurrat, M. Key Figure Based Incoming Inspection of Lithium-Ion Battery Cells. Batteries 2021, 7, 9. [Google Scholar] [CrossRef]

- Tang, Y.; Li, T.; Cheng, X. Review of Specific Heat Capacity Determination of Lithium-Ion Battery. Energy Procedia 2019, 158, 4967–4973. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kampker, A.; Heimes, H.H.; Dorn, B.; Clever, H.; Ludwigs, R.; Li, R.; Drescher, M. Concept for Digital Product Twins in Battery Cell Production. World Electr. Veh. J. 2023, 14, 108. https://doi.org/10.3390/wevj14040108

Kampker A, Heimes HH, Dorn B, Clever H, Ludwigs R, Li R, Drescher M. Concept for Digital Product Twins in Battery Cell Production. World Electric Vehicle Journal. 2023; 14(4):108. https://doi.org/10.3390/wevj14040108

Chicago/Turabian StyleKampker, Achim, Heiner Hans Heimes, Benjamin Dorn, Henning Clever, Robert Ludwigs, Ruiyan Li, and Marcel Drescher. 2023. "Concept for Digital Product Twins in Battery Cell Production" World Electric Vehicle Journal 14, no. 4: 108. https://doi.org/10.3390/wevj14040108

APA StyleKampker, A., Heimes, H. H., Dorn, B., Clever, H., Ludwigs, R., Li, R., & Drescher, M. (2023). Concept for Digital Product Twins in Battery Cell Production. World Electric Vehicle Journal, 14(4), 108. https://doi.org/10.3390/wevj14040108