On Unintentional Demagnetization Effect of Switched Flux Hybrid Magnet Memory Machine

Abstract

:1. Introduction

2. Unintentional Demagnetization Effects of SF-HMMM

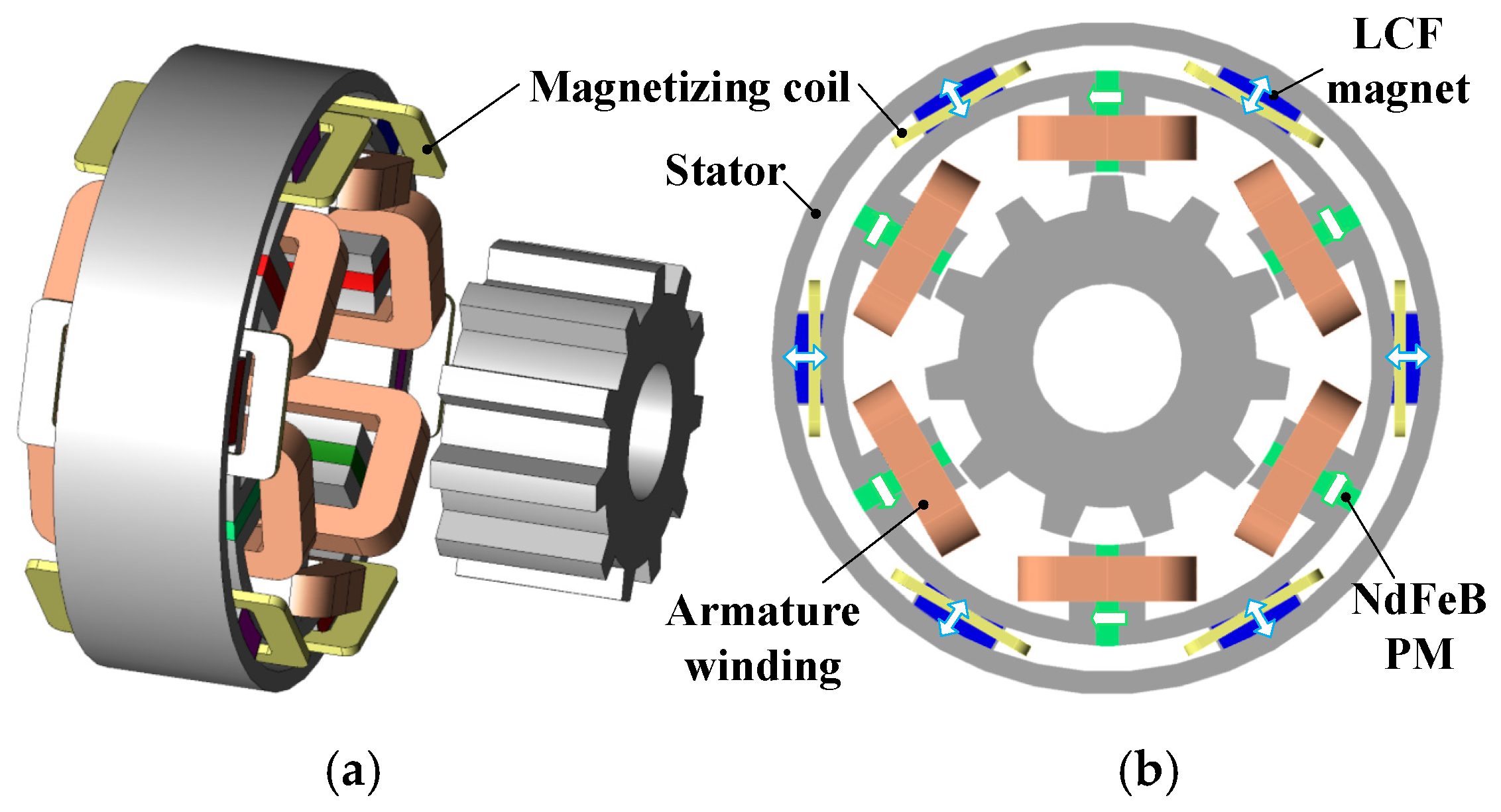

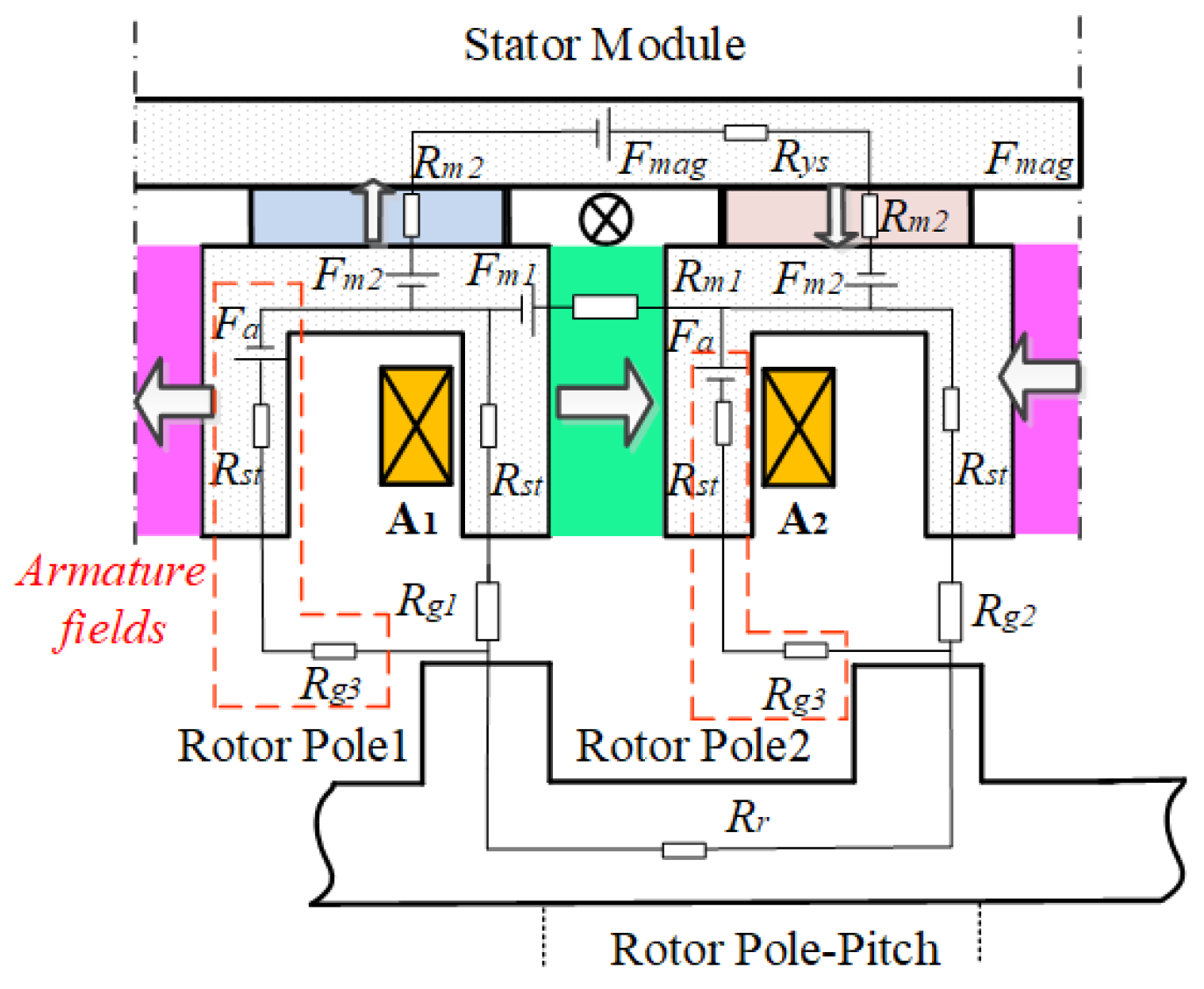

2.1. SF-HMMM Structure

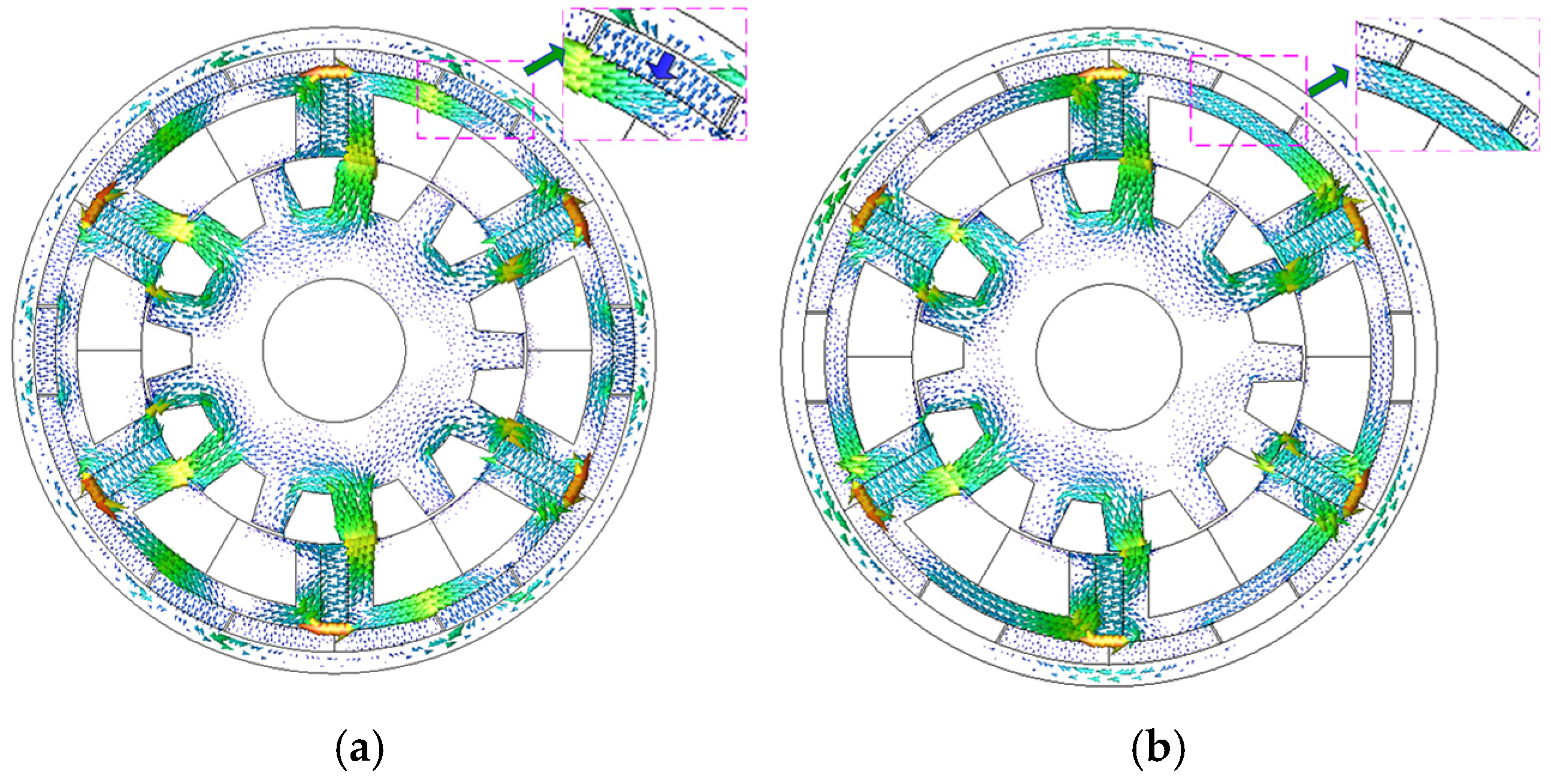

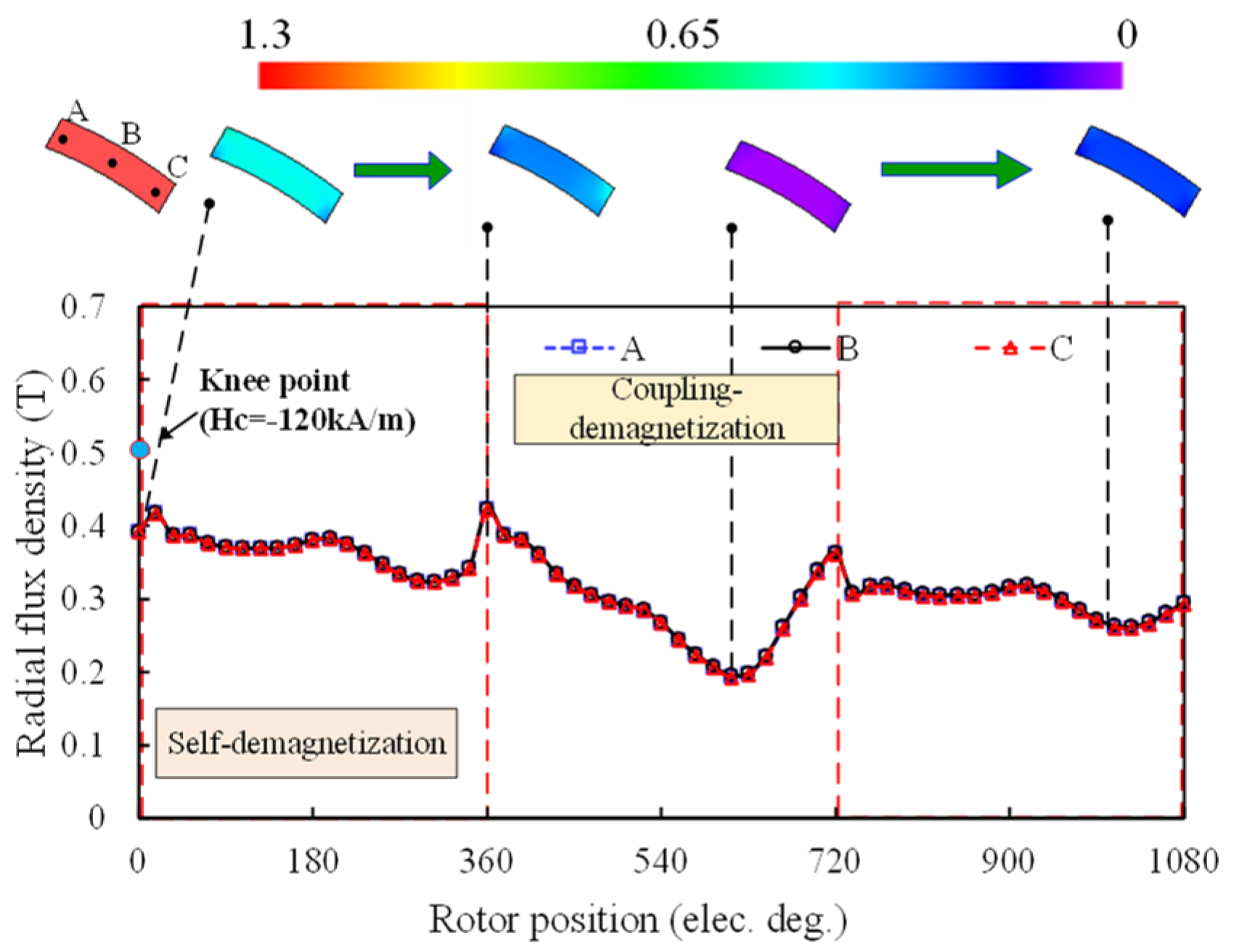

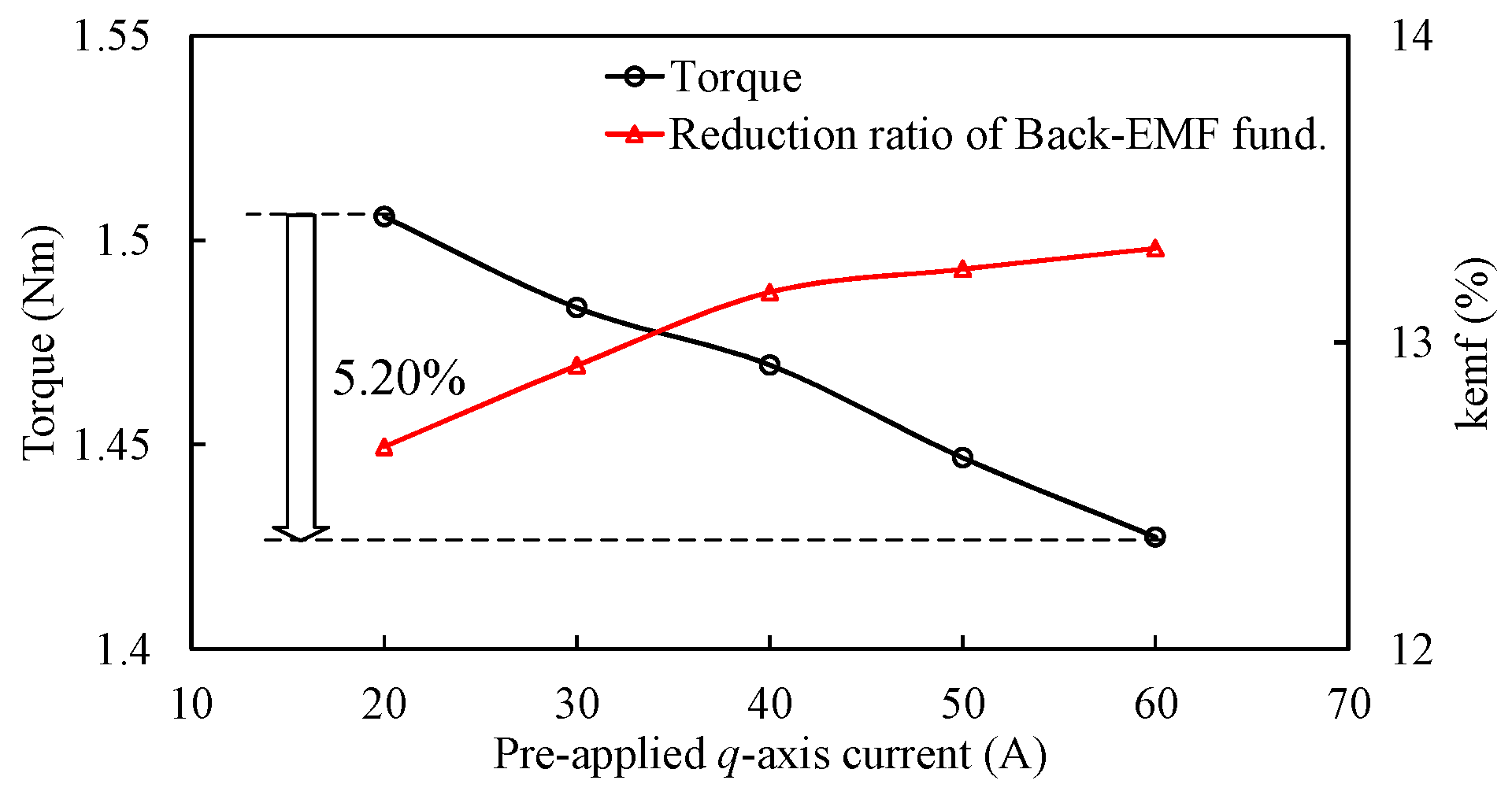

2.2. Description of UD Effect

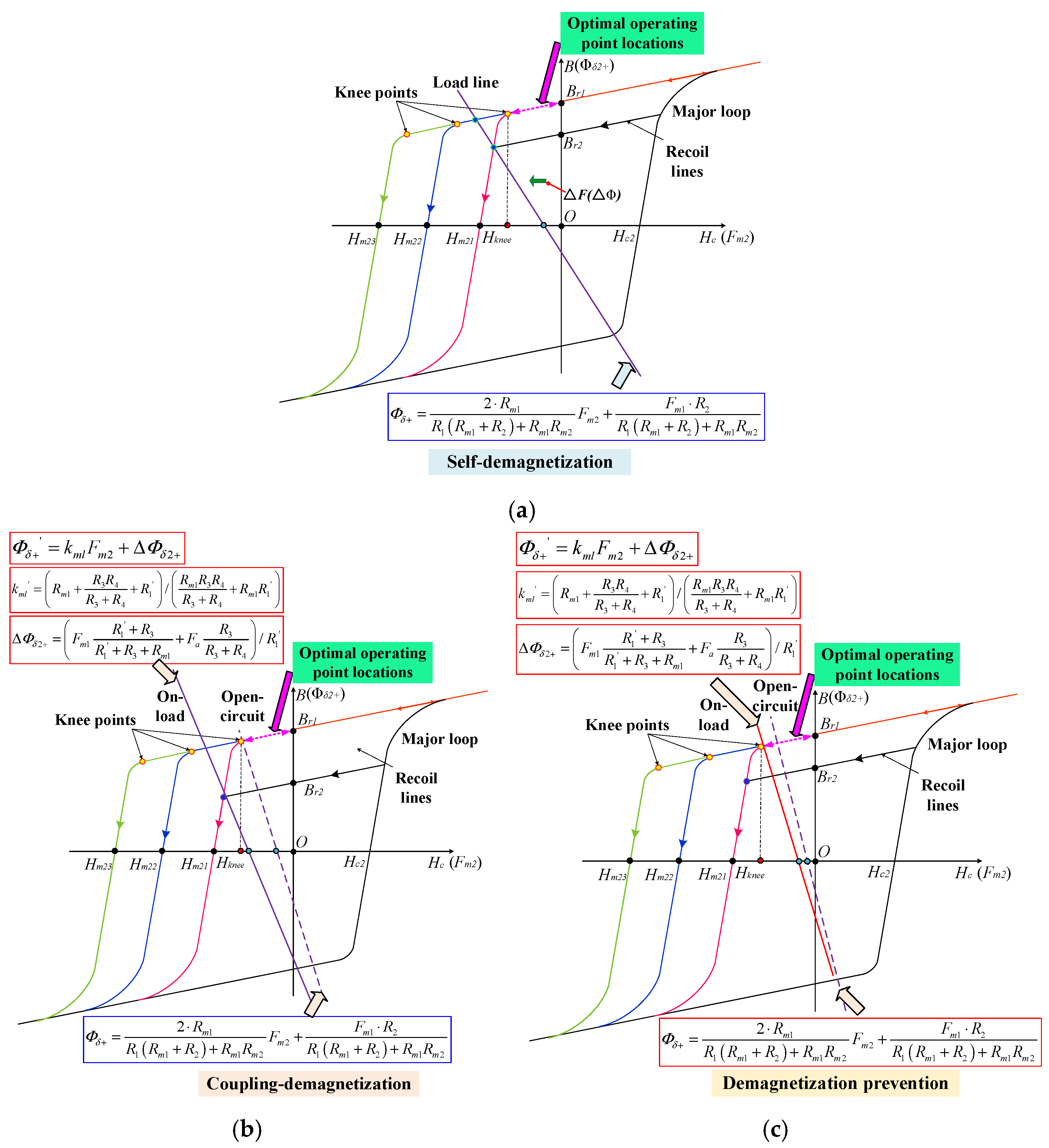

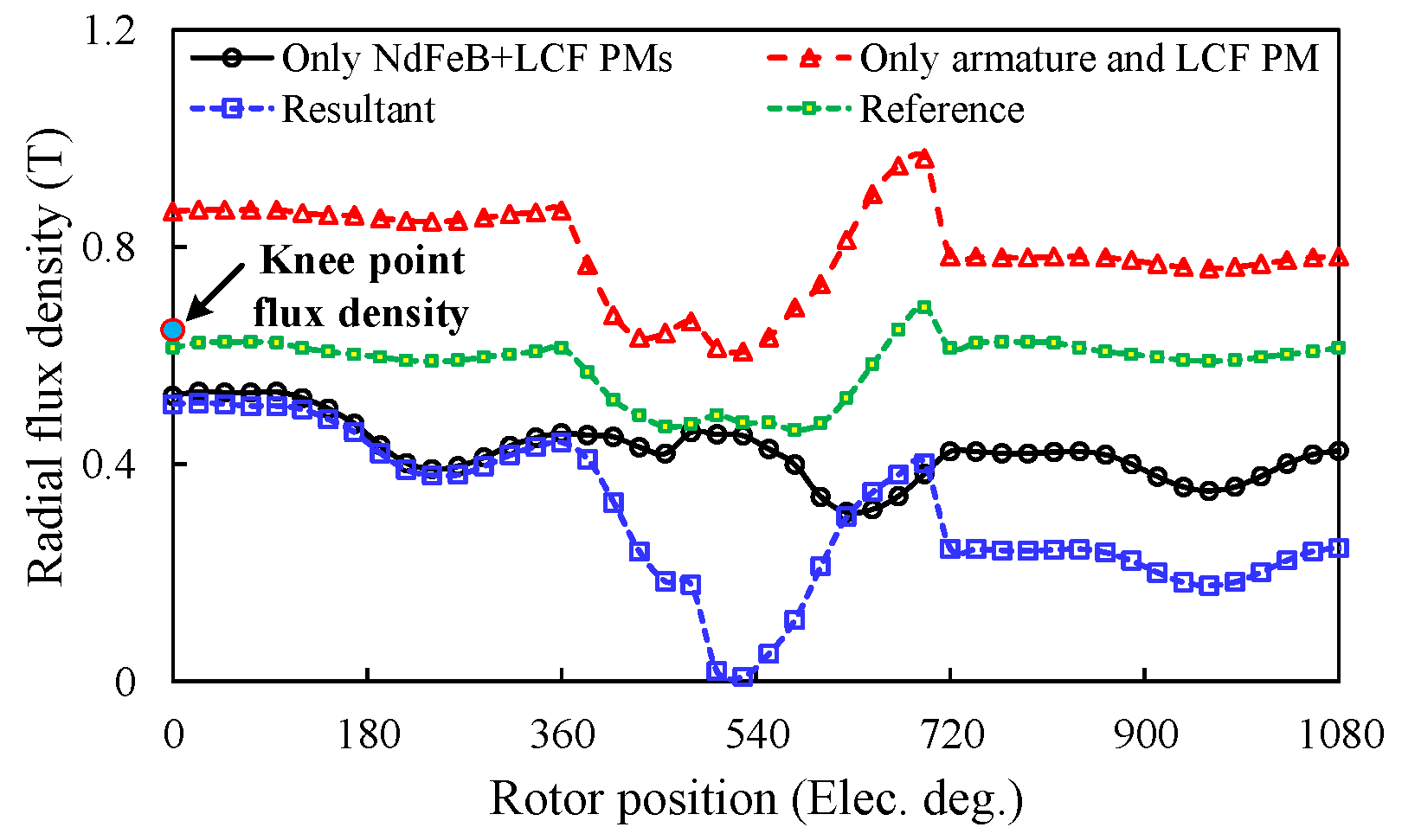

2.2.1. Rotor Position (0°~360°): Self-Demagnetization

2.2.2. Rotor Position (360°~720°): Coupling Demagnetization

2.2.3. Rotor Position (720°~1080°): Post-Demagnetization

2.3. Analytical Investigation for the UD Phenomenon

2.3.1. Self-Demagnetization

2.3.2. Coupling Demagnetization

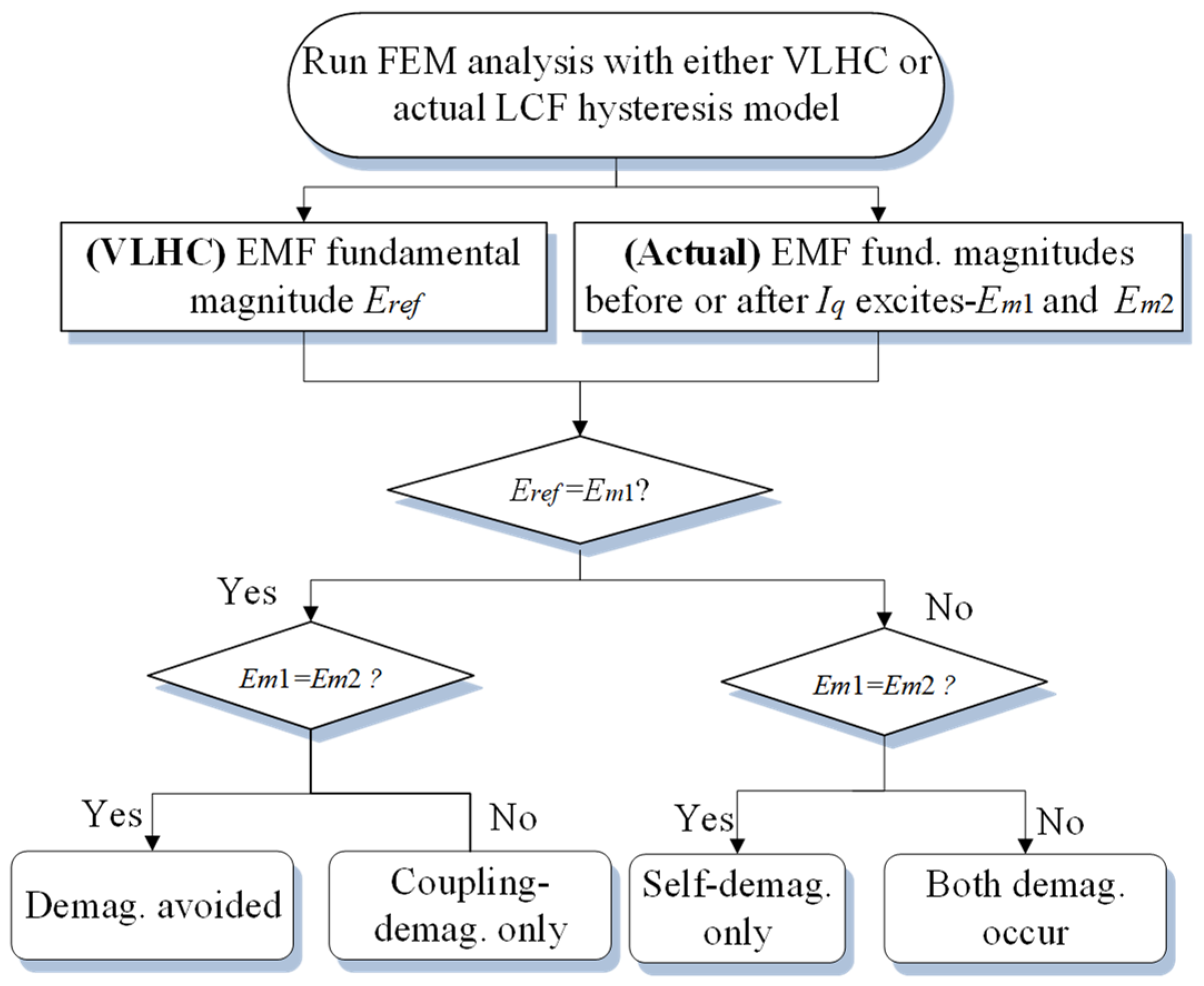

3. Demagnetization Type Identification

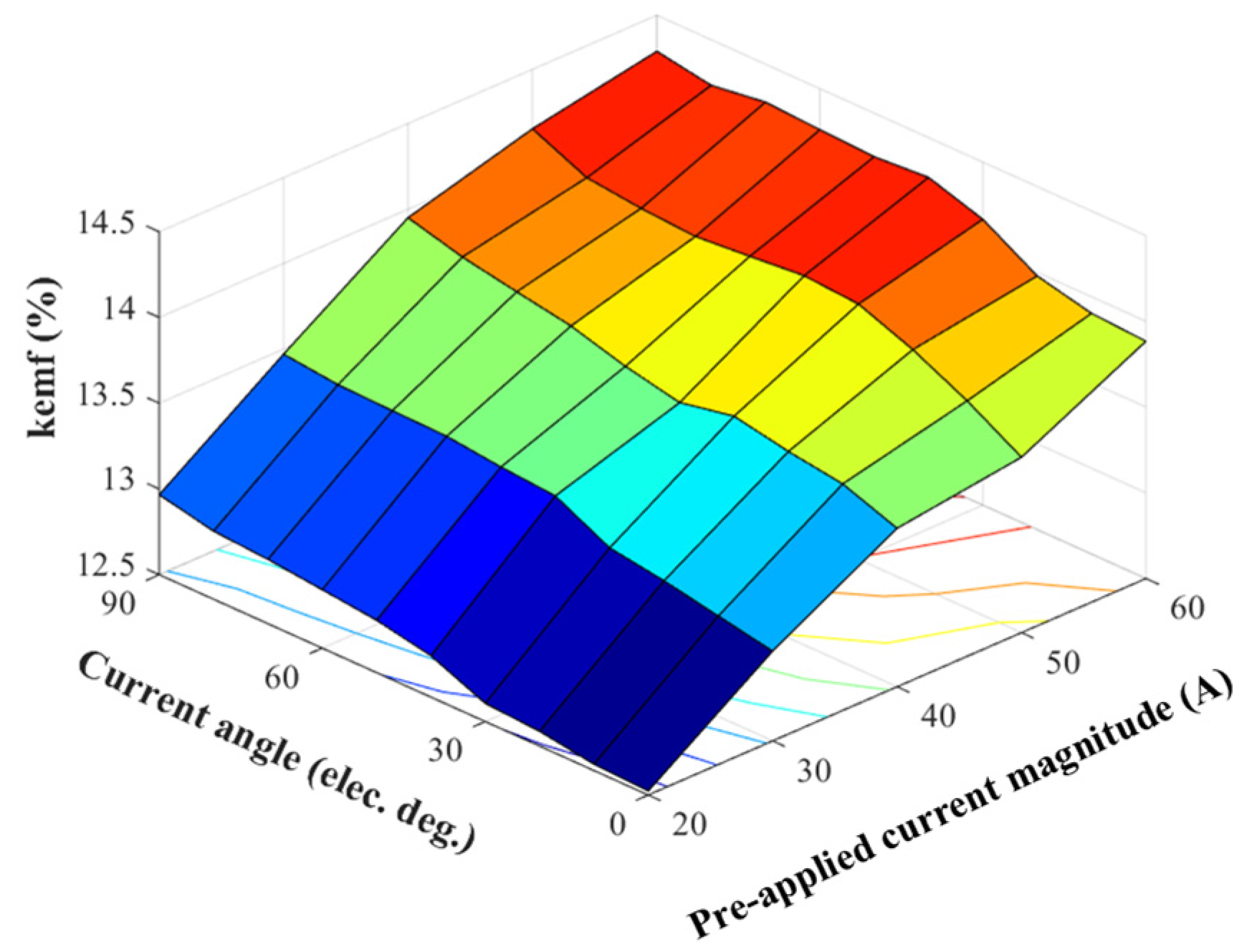

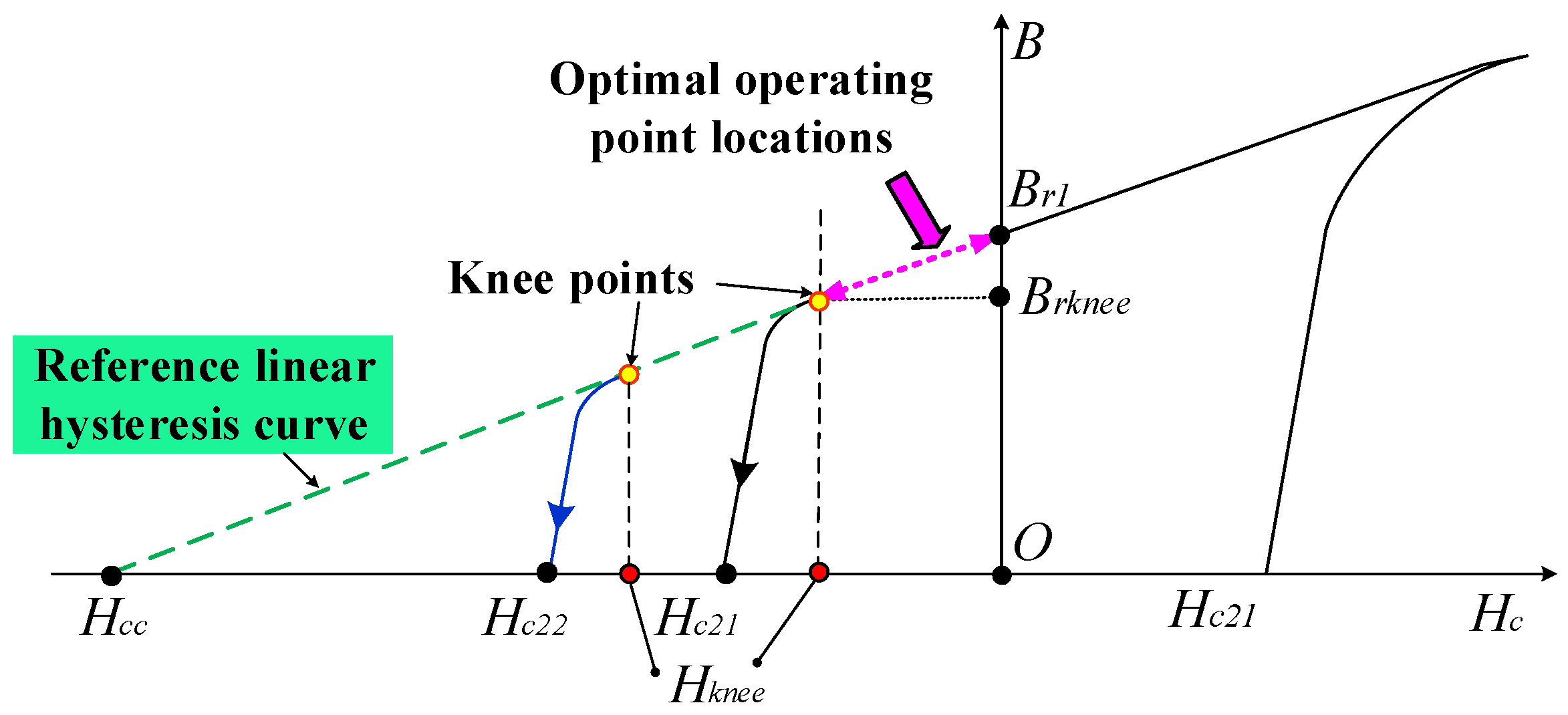

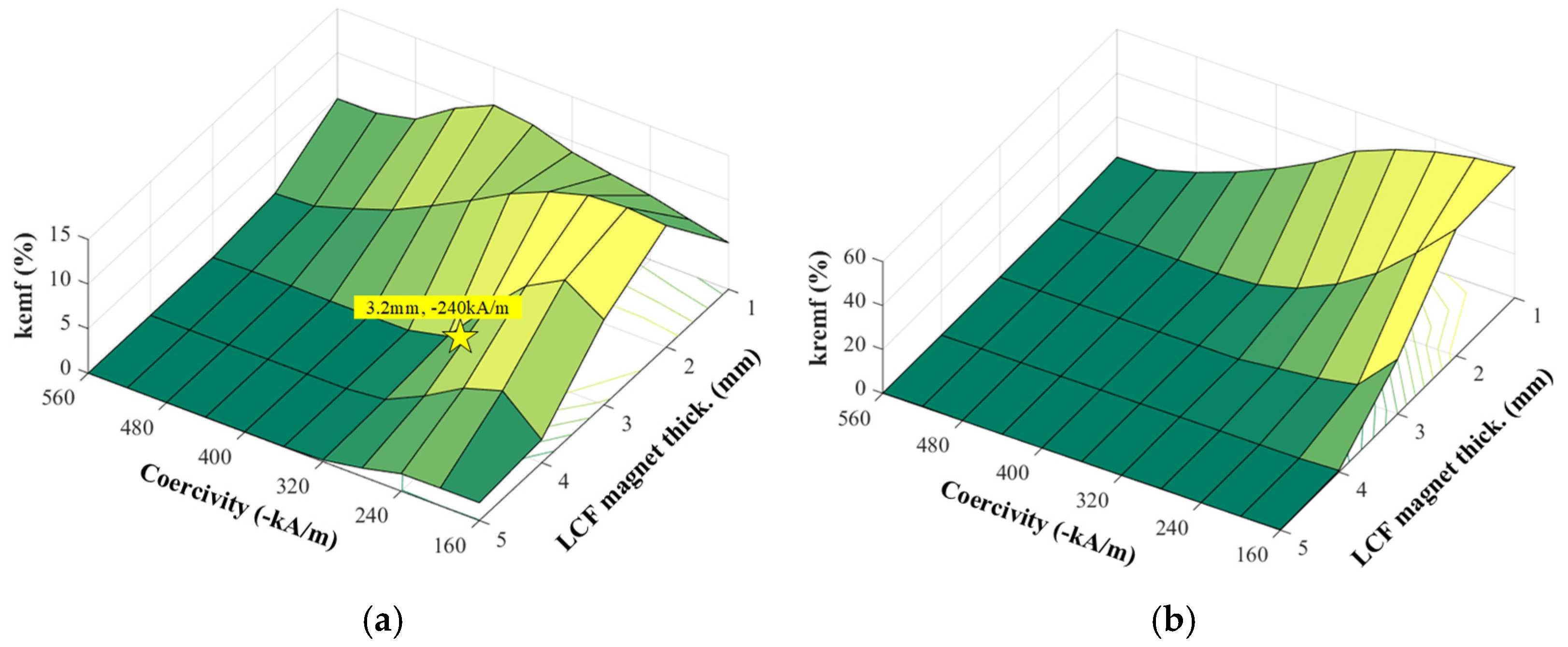

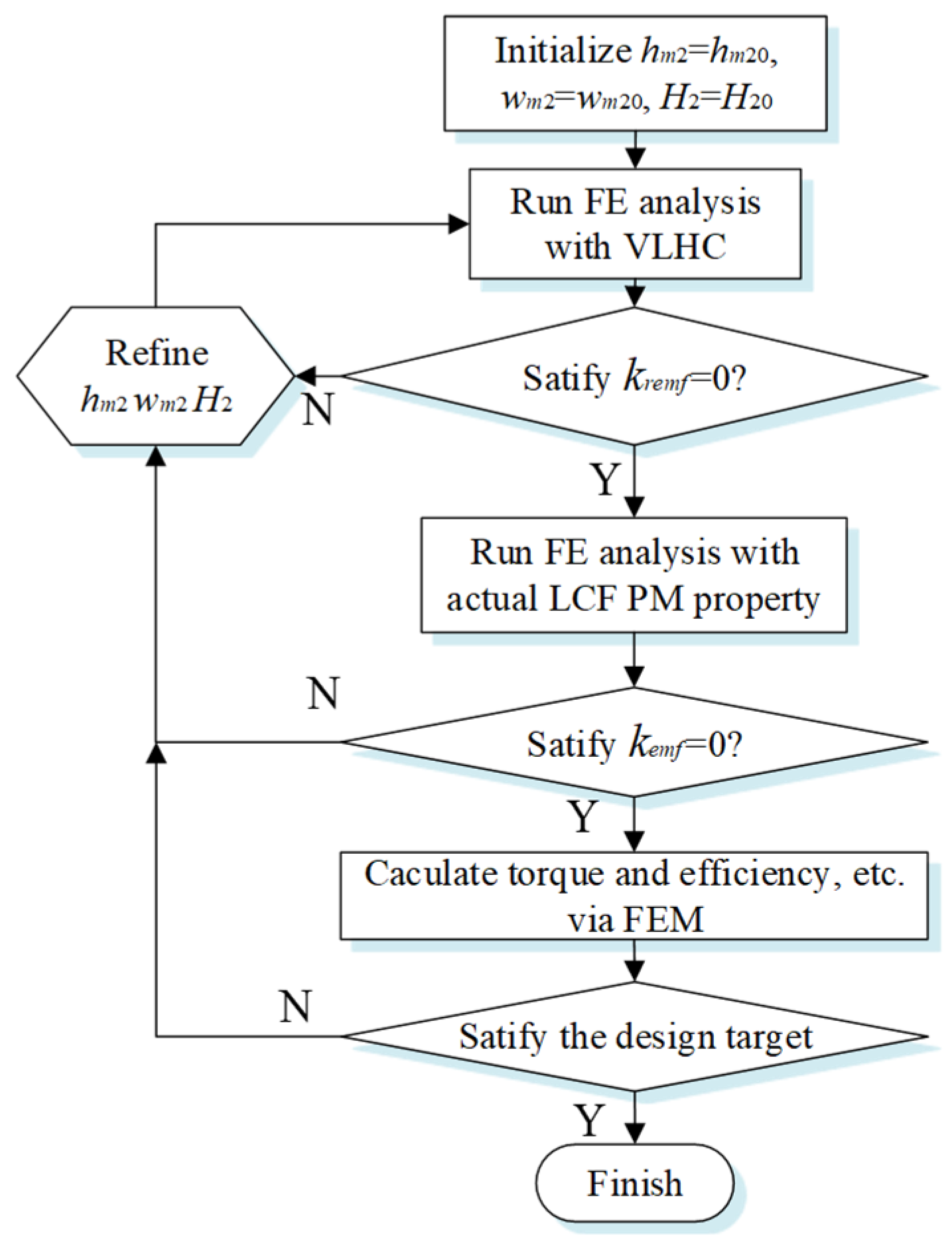

4. LCF PM Design Guidelines for Elimination of UD Effect

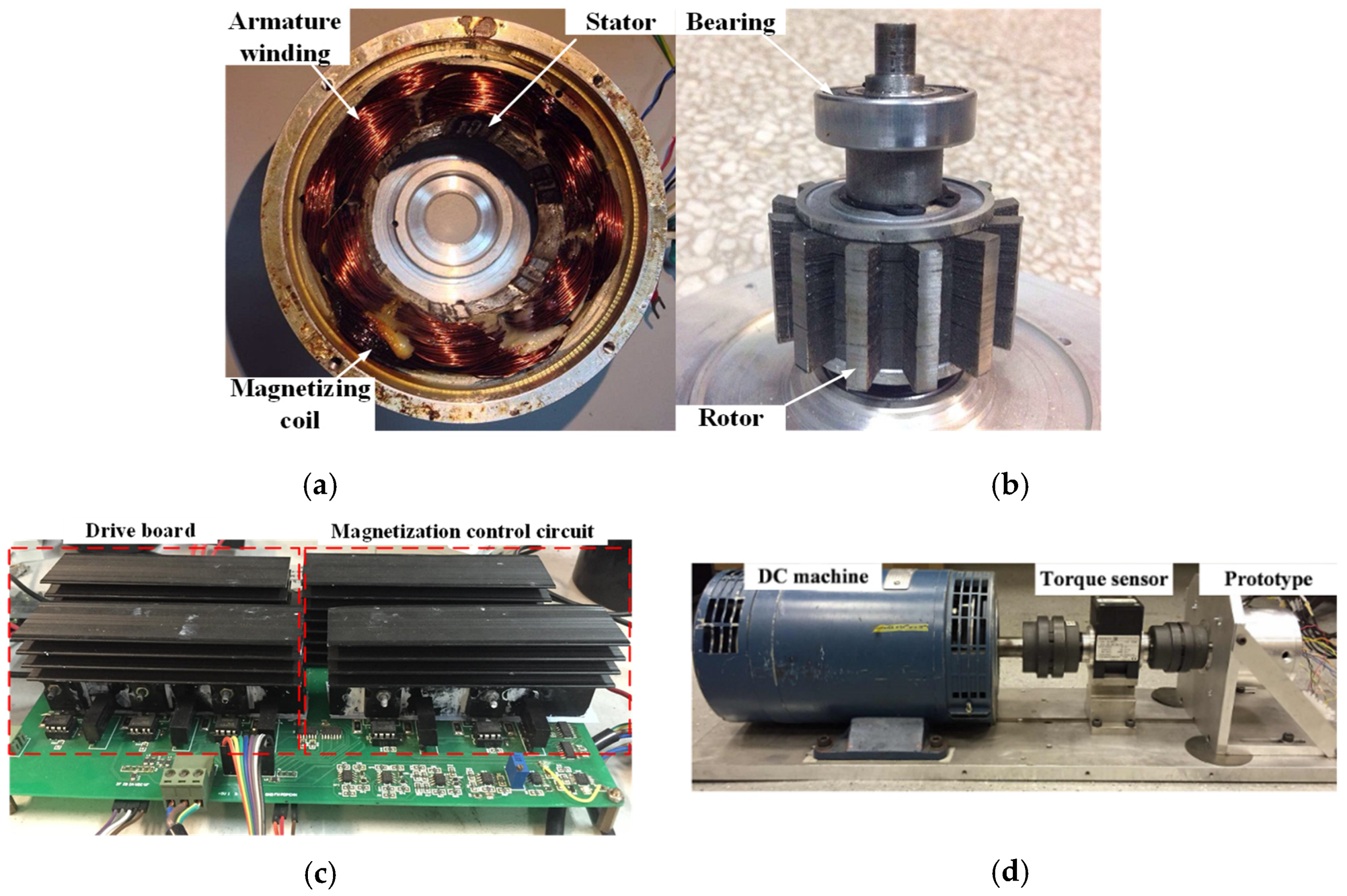

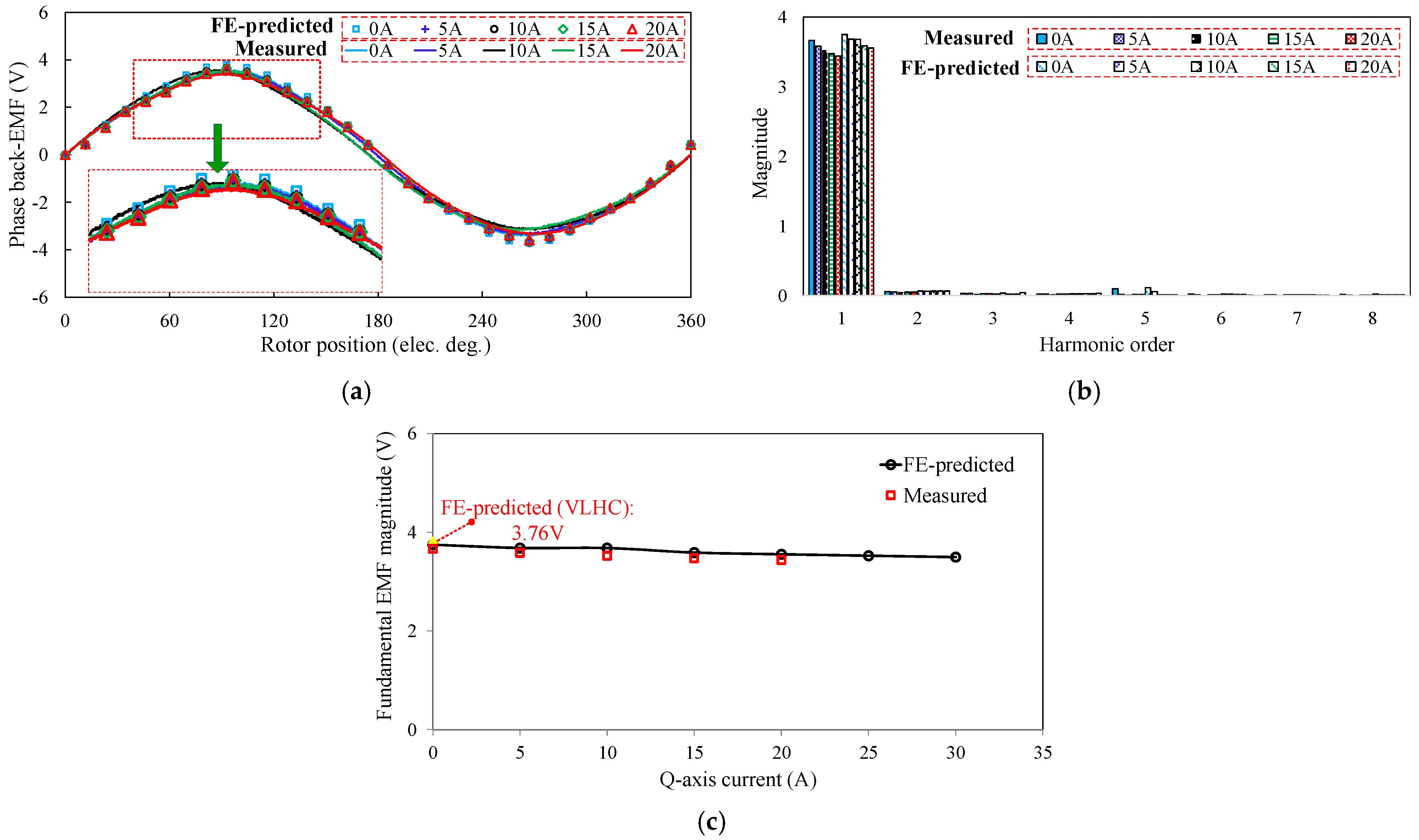

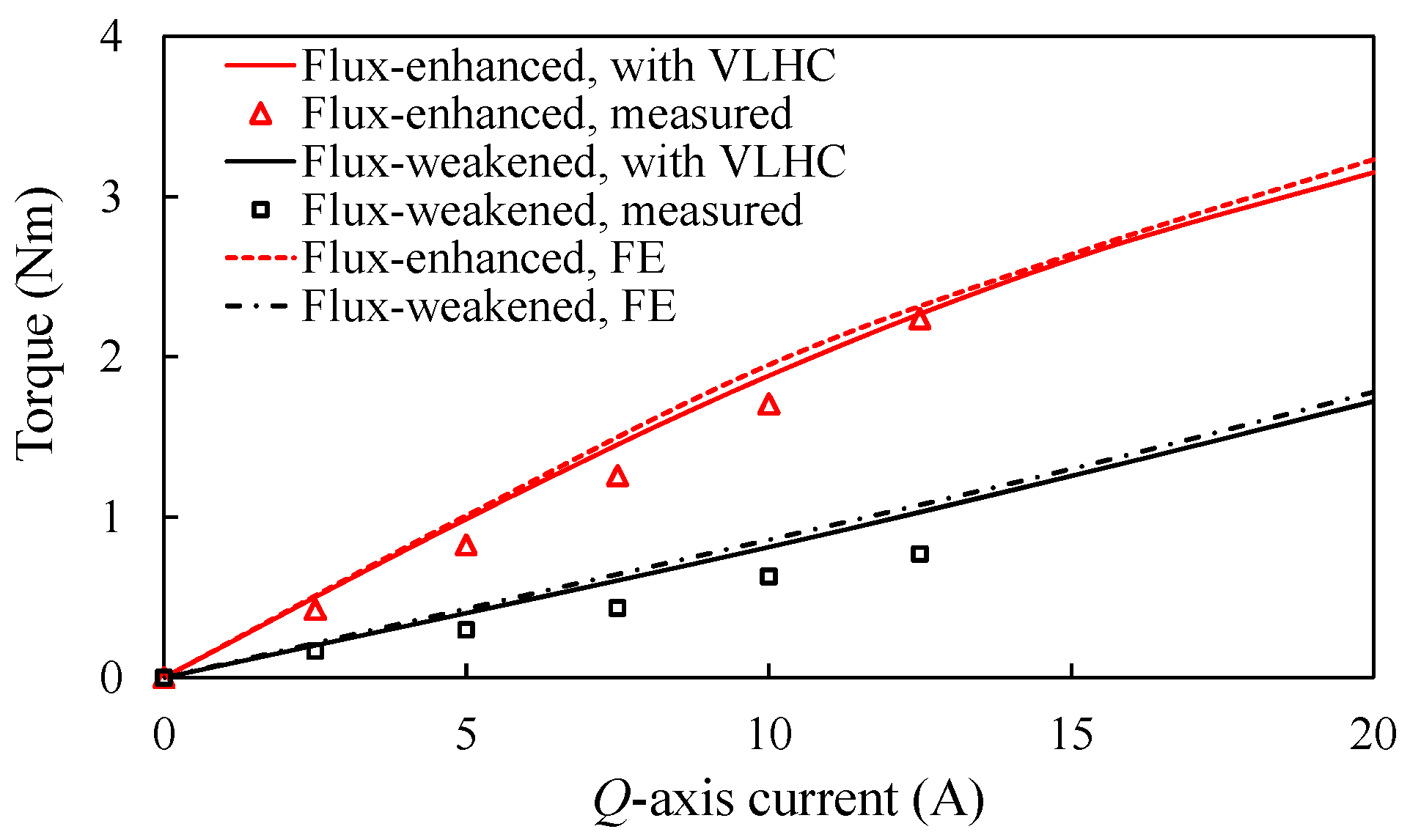

5. Experimental Validation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ullah, W.; Khan, F.; Sulaiman, E.; Umair, M. Torque characteristics of high torque density partitioned PM consequent pole flux switching machines with flux barriers. CES Trans. Electr. Mach. Syst. 2020, 4, 130–141. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Sarlioglu, B. Partial Irreversible Demagnetization Assessment of Flux-Switching Permanent Magnet Machine Using Ferrite Permanent Magnet Material. IEEE Trans Magn. 2015, 51, 1–9. [Google Scholar]

- Zhu, Z.Q.; Chen, J.T. Advanced flux-switching permanent magnet brushless machines. IEEE Trans. Magn. 2010, 46, 1447–1453. [Google Scholar] [CrossRef]

- Fasolo, A.; Alberti, L.; Bianchi, N. Performance comparison between switching-flux and IPM machine with rare earth and ferrite PMs. IEEE Trans. Ind. Appl. 2014, 50, 3708–3716. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, W.; Zhang, G. Analysis of Back-EMF Waveform of a Novel Outer-Rotor-Permanent-Magnet Flux-Switching Machine. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Ostovic, V. Memory motors. IEEE Ind. Appl. Mag. 2003, 9, 52–61. [Google Scholar] [CrossRef]

- Yang, H.; Lin, H.; Zhu, Z.Q. Recent advances in variable flux memory machines for traction applications: A review. CES Trans. Electr. Mach. Syst. 2018, 2, 34–50. [Google Scholar] [CrossRef]

- Wu, D.; Zhu, Z.Q.; Pride, A.; Deodhar, R.; Sasaki, T. Cross coupling effect in hybrid magnet memory machine. In Proceedings of the 7th IET International Conference on Power Electronics, Machines and Drives (PEMD 2014), Manchester, UK, 8–10 April 2014; pp. 1–6. [Google Scholar]

- Athavale, A.; Sasaki, K.; Kato, T.; Lorenz, R. Magnetization state estimation in variable-flux PMSMs. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; pp. 1–8. [Google Scholar]

- Song, J.Y.; Lee, J.H.; Kim, D.W.; Kim, Y.J.; Jung, S.Y. Analysis and modeling of permanent magnet variable flux memory motors using magnetic equivalent circuit method. IEEE Trans. Magn. 2017, 53, 1–5. [Google Scholar] [CrossRef]

- Maekawa, S.; Yuki, K.; Matsushita, M.; Nitta, I.; Hasegawa, Y.; Shiga, T.; Hosoito, T.; Nagai, K.; Kubota, H. Study of the magnetization method suitable for fractional-slot concentrated-winding variable magnetomotive-force memory motor. IEEE Trans. Power Electron. 2014, 29, 4877–4887. [Google Scholar] [CrossRef]

- AI, Q.; Wei, H.; Zhang, Y. Optimal design for Flux-intensifying Permanent Magnet Machine Based on Neural Network and Multi-objective optimization. In Proceedings of the 2020 4th CAA International Conference on Vehicular Control and Intelligence (CVCI), Hangzhou, China, 18–20 December 2020; pp. 596–601. [Google Scholar]

- Chen, J.; Li, J.; Qu, R. Maximum-torque-per-ampere and magnetization-state control of a variable-flux permanent magnet machine. IEEE Trans. Ind. Electron. 2018, 65, 1158–1169. [Google Scholar] [CrossRef]

- Ibrahim, M.; Masisi, L.; Pillay, P. Design of variable flux permanent magnet machine for reduced inverter rating. IEEE Trans. Ind. Appl. 2015, 51, 3666–3674. [Google Scholar] [CrossRef]

- Tsunata, R.; Takemoto, M.; Ogasawara, S.; Orikawa, K. Variable Flux Memory Motor Employing Double-Layer Delta-Type PM Arrangement and Large Flux Barrier for Traction Applications. IEEE Trans. Ind. Appl. 2021, 57, 3545–3561. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, B.; Xiao, Y.; Li, X.; Chen, J.; Fang, H. Comprehensive control of a hybrid-magnet variable-flux memory machine for washing machine applications. In Proceedings of the 2021 IEEE 4th International Electrical and Energy Conference (CIEEC), Wuhan, China, 28–30 May 2021; pp. 1–6. [Google Scholar]

- de Sousa, F.D.; Battiston, A.; Pierfederici, S.; Meibody-Tabar, F. Validation of the standstill magnetization strategy of a FeCrCo-based variable flux memory machine. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Korea, 31 October–3 November 2021; pp. 536–541. [Google Scholar]

- Sakai, K.; Yoneda, K.; Suzuki, W. Variable-magnetization interior permanent magnet motor yield widely variable flux due to small magnetizing current and operating at high power over a wide speed range. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 4205–4212. [Google Scholar]

- Xu, H.; Li, J.; Chen, J.; Lu, Y.; Ge, M. Analysis of a hybrid permanent magnet variable-flux machine for electric vehicle tractions considering magnetizing and demagnetizing current. IEEE Trans. Ind. Appl. 2021, 57, 5983–5992. [Google Scholar] [CrossRef]

- Zhu, X.; Xiang, Z.; Quan, L.; Wu, W.; Du, Y. Multimode optimization design methodology for a flux-controllable stator permanent magnet memory motor considering driving cycles. IEEE Trans. Ind. Electron. 2018, 65, 5353–5366. [Google Scholar] [CrossRef]

- Yang, H.; Lyu, S.; Lin, H.; Zhu, Z.; Zheng, H.; Wang, T. A Novel Hybrid-Magnetic-Circuit Variable Flux Memory Machine. IEEE Trans. Ind. Electron. 2020, 67, 5258–5268. [Google Scholar] [CrossRef]

- Chen, Z.; Lin, H.; Zhong, Y.; Lyu, S.; Yang, H. A Novel Current Control Strategy for Magnetization State Manipulation of Variable Flux Memory Machine Based on Linear Active Disturbance Rejection. IEEE Trans. Power Electron. 2022, 37, 1962–1971. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, Z.Q.; Lin, H.; Lyu, S. Comparative study of hybrid PM memory machines having single- and dual-stator configurations. IEEE Trans. Ind. Electron. 2018, 65, 9168–9178. [Google Scholar] [CrossRef]

- Yang, H.; Lyu, S.; Lin, H.; Zhu, Z. Stepwise Magnetization Control Strategy for DC-Magnetized Memory Machine. IEEE Trans. Ind. Electron. 2019, 66, 4273–4285. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Lin, H.; Zhu, Z.Q.; Wang, D.; Fang, S.; Huang, Y. A variable-flux hybrid-PM switched-flux memory machine for EV/HEV applications. IEEE Trans. Ind. Appl. 2016, 52, 2203–2214. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, Z.Q.; Lin, H.; Wu, D.; Hua, H.; Fang, S.; Huang, Y. Novel high-performance switched flux hybrid magnet memory machines with reduced rare-earth magnets. IEEE Trans. Ind. Appl. 2016, 52, 3901–3915. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, Z.Q.; Lin, H.; Guo, K.; Guo, Y.; Fang, S.; Huang, Y. Analysis of on-load magnetization characteristics in a novel partitioned stator hybrid magnet memory machine. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, Z.Q.; Lin, H.; Xu, P.L.; Zhan, H.L.; Fang, S.; Huang, Y. Design synthesis of switched flux hybrid-permanent magnet memory machines. IEEE Trans. Energy Convers. 2017, 32, 65–79. [Google Scholar] [CrossRef]

- Yang, H.; Lin, H.; Zhu, Z.Q.; Niu, S.; Lyu, S.; Zheng, H. A Novel Stator Spoke-Type Hybrid Magnet Memory Machine. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Deigo, CA, USA, 12–15 May 2019; pp. 1576–1580. [Google Scholar]

- Wu, D.; Liu, X.; Zhu, Z.Q.; Pride, A.; Deodhar, R.; Sasaki, T. Switched flux hybrid magnet memory machine. IET Electron. Power Appl. 2015, 9, 160–170. [Google Scholar] [CrossRef]

- Yang, G.; Lin, M.; Li, N.; Fu, X.; Liu, K. Maximum torque output control of hybrid permanent magnet axial field flux-switching memory machine. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 1212–1219. [Google Scholar]

- Jiang, J.; Niu, S. A novel slot-PM-assisted hybrid magnet memory machine. IEEE Trans. Magn. 2022; in press. [Google Scholar]

- Shuto, D.; Takahashi, Y.; Fujiwara, K. Frozen Permeability Method for Magnetic Field Analysis of Permanent Magnet Motors Considering Hysteretic Property. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

| Conditions | Open-Circuit | Armature + LCF PM | Resultant |

|---|---|---|---|

| Before Iq = 14.14 A | 0.388 | 0.776 | 0.234 |

| After Iq = 14.14 A | 0.470 | 0.860 | 0.412 |

| Demag. values | 0.083 | 0.084 | 0.179 |

| Items | Parameters |

|---|---|

| Rated speed (r/min) | 400 |

| Rated torque (Nm) | 2.67 |

| Rated current (Arms) | 10 |

| Rated current density (A/mm2) | 6.5 |

| Rated supply voltage (V) | 18 |

| Rated efficiency (%) | 83.6 |

| Outer diameter of stator (mm) | 90 |

| Split ratio | 0.6 |

| Air-gap length (mm) | 0.5 |

| Active stack length (mm) | 25 |

| Stator tooth width (mm) | 3.2 |

| Ratio of rotor pole to pitch | 0.43 |

| Turns of winding per phase | 84 |

| Turns of per magnetizing coil | 100 |

| LCF magnet thickness (mm) | 3.2 |

| LCF PM width (degree) | 20 |

| NdFeB/LCF PM grades | N35SH/SB12B |

| NdFeB magnet thickness (mm) | 3.5 |

| NdFeB PM length (mm) | 9.0 |

| LCF magnet coercivity (-kA/m) | 240 |

| LCF magnet remanence (T) | 0.8 |

| Slot packing factor | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, J.; Yang, H.; Ge, Y.; Zhang, W. On Unintentional Demagnetization Effect of Switched Flux Hybrid Magnet Memory Machine. World Electr. Veh. J. 2022, 13, 66. https://doi.org/10.3390/wevj13040066

Feng J, Yang H, Ge Y, Zhang W. On Unintentional Demagnetization Effect of Switched Flux Hybrid Magnet Memory Machine. World Electric Vehicle Journal. 2022; 13(4):66. https://doi.org/10.3390/wevj13040066

Chicago/Turabian StyleFeng, Jingjing, Hui Yang, Yongsheng Ge, and Wei Zhang. 2022. "On Unintentional Demagnetization Effect of Switched Flux Hybrid Magnet Memory Machine" World Electric Vehicle Journal 13, no. 4: 66. https://doi.org/10.3390/wevj13040066

APA StyleFeng, J., Yang, H., Ge, Y., & Zhang, W. (2022). On Unintentional Demagnetization Effect of Switched Flux Hybrid Magnet Memory Machine. World Electric Vehicle Journal, 13(4), 66. https://doi.org/10.3390/wevj13040066