Study on Preparation Optimization Technology and Surface Properties of Decorated Bamboo Filament Board

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

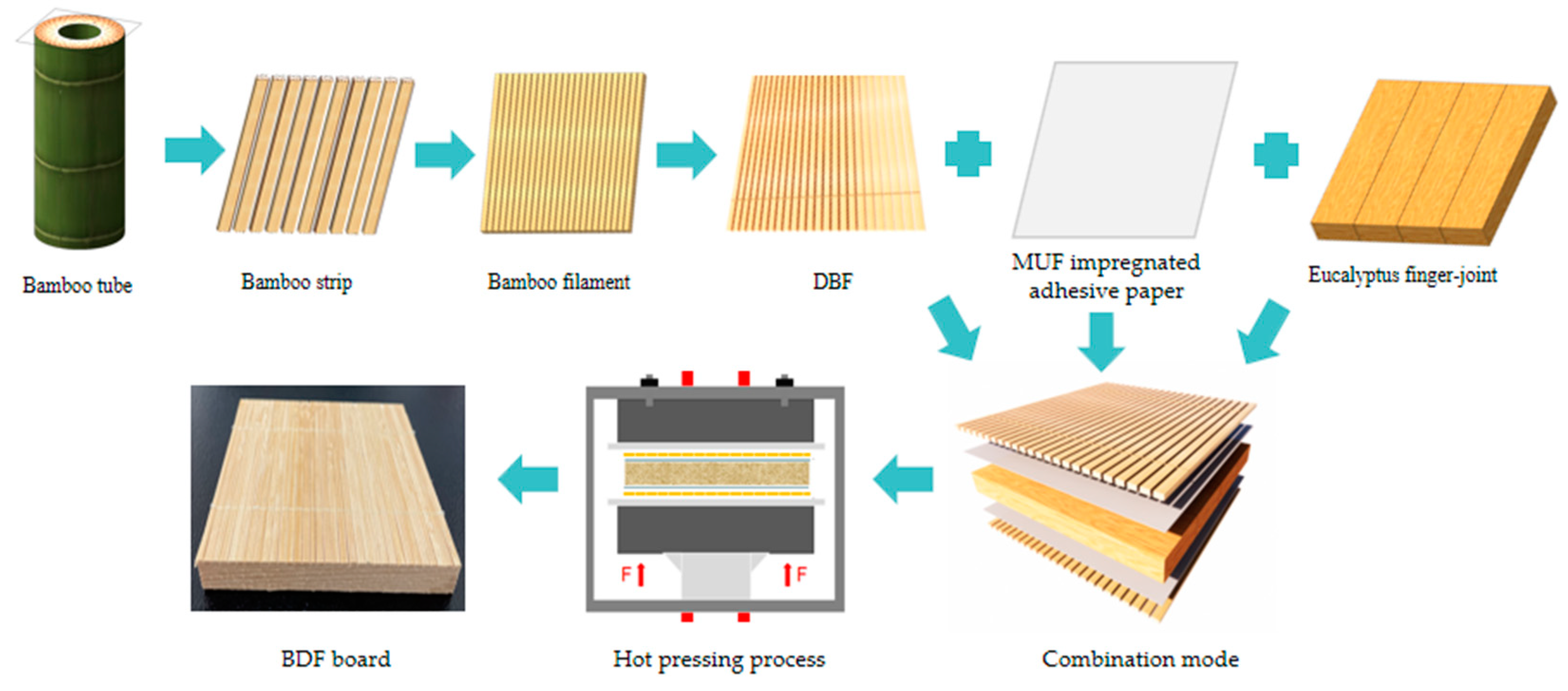

2.2. Methods

2.2.1. Experimental Design

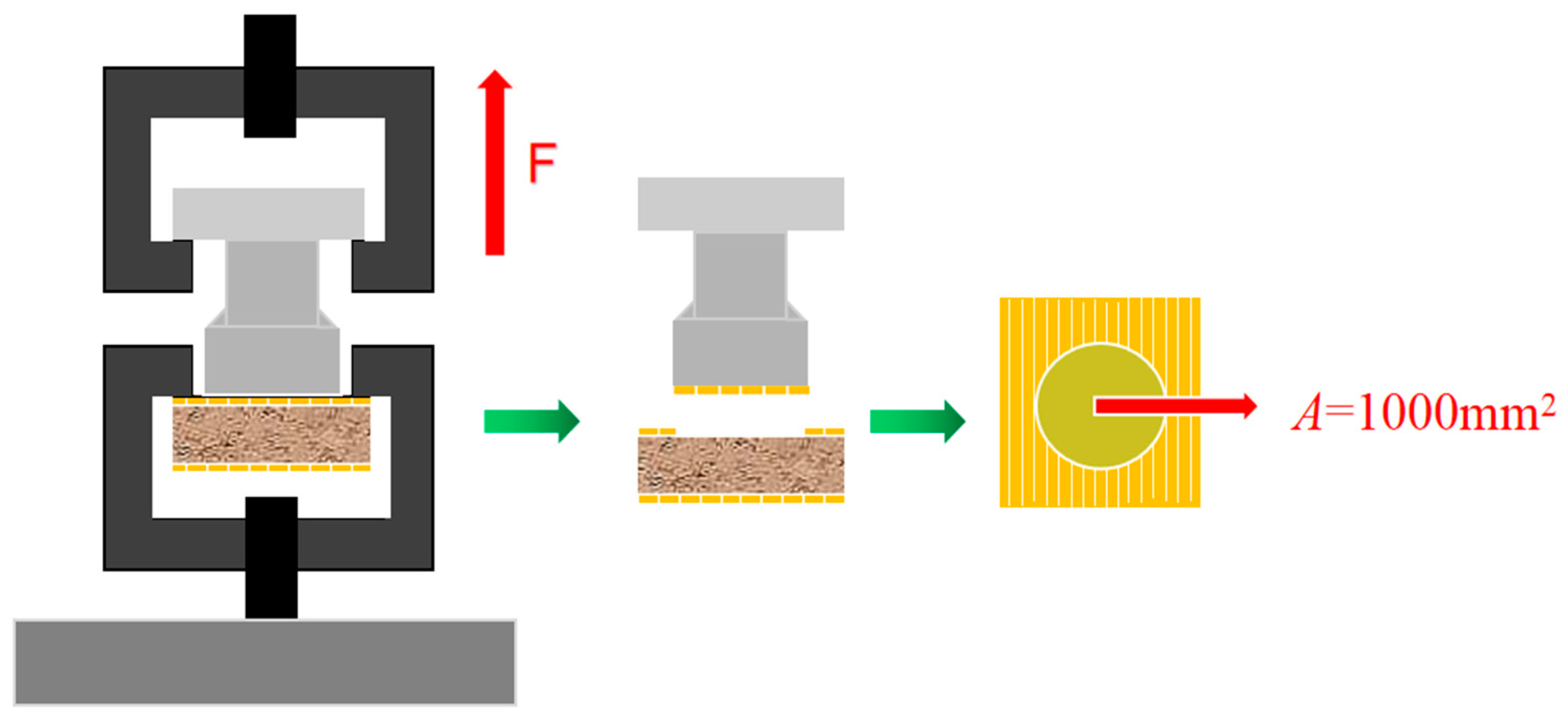

2.2.2. Surface Bonding Strength Test

2.2.3. Contact Angle Test

2.2.4. Surface Color Test

3. Results and Discussion

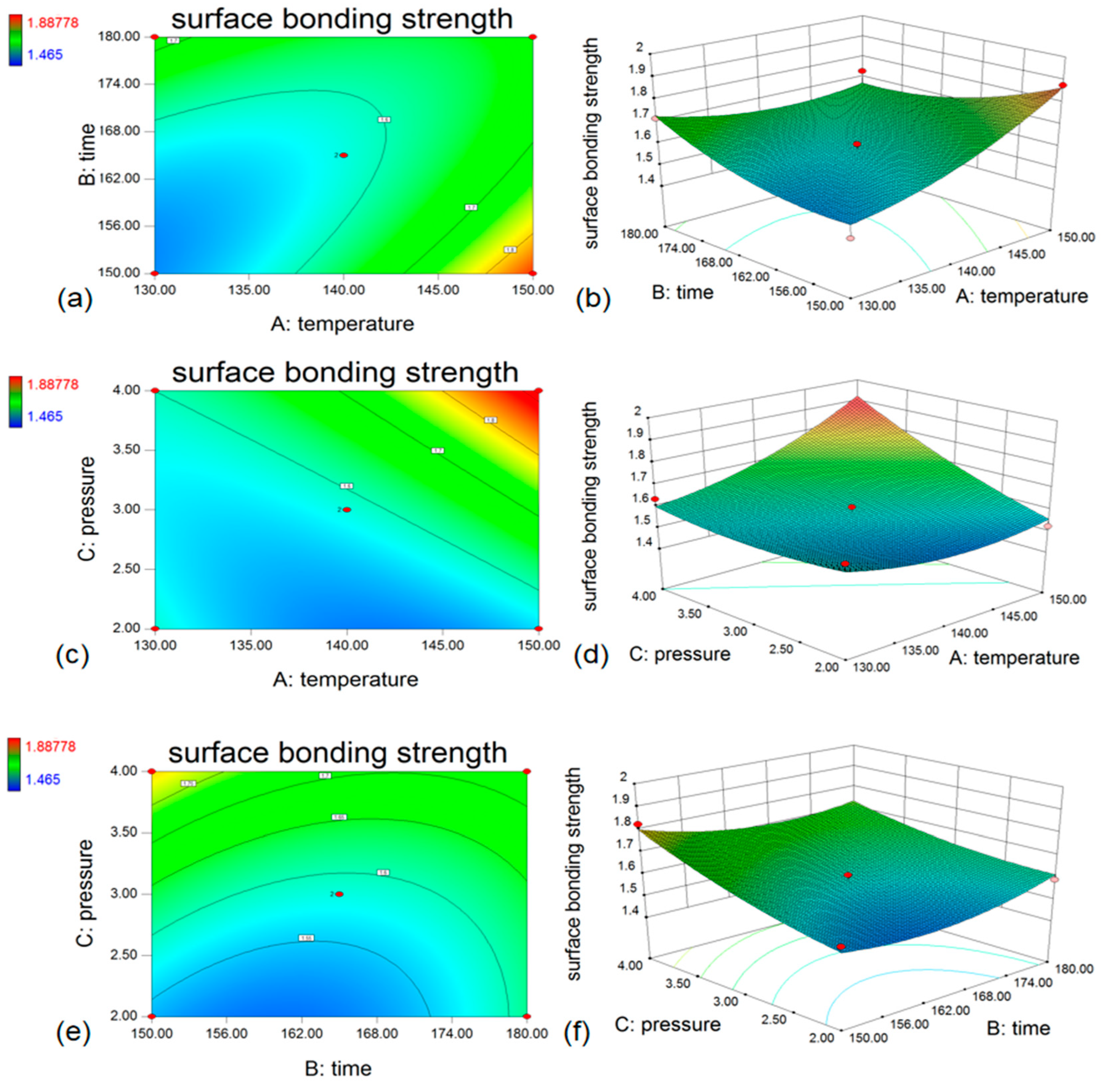

3.1. Response Surface Test

3.2. Optimization Process Prediction and Verification by Response Surface Method

3.3. Analysis of Surface Wettability

| No. | Temperature (°C) | Time (s) | Pressure (MPa) | Contact Angle (°) | SD |

|---|---|---|---|---|---|

| 1 | 130 | 165 | 4.00 | 72.21 | 5.8 |

| 2 | 140 | 165 | 3.00 | 69.43 | 5.3 |

| 3 | 130 | 180 | 3.00 | 67.32 | 1.19 |

| 4 | 140 | 150 | 2.00 | 70.35 | 6.18 |

| 5 | 140 | 165 | 3.00 | 78.58 | 1.45 |

| 6 | 140 | 150 | 4.00 | 82.53 | 3.35 |

| 7 | 140 | 180 | 2.00 | 80.14 | 1.02 |

| 8 | 150 | 180 | 3.00 | 83.97 | 4.41 |

| 9 | 150 | 165 | 2.00 | 69.32 | 5.19 |

| 10 | 130 | 150 | 3.00 | 74.83 | 5.54 |

| 11 | 140 | 180 | 4.00 | 84.01 | 4.97 |

| 12 | 150 | 150 | 3.00 | 76.63 | 3.21 |

| 13 | 150 | 165 | 4.00 | 72.47 | 6.52 |

| 14 | 130 | 165 | 2.00 | 70.73 | 2.69 |

| Control | 0 | 0 | 0 | 64.46 | 3.45 |

3.4. Analysis of Surface Color

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, L.; Luo, X.; Huang, B.; Ma, Y.F.; Fang, C.H.; Liu, H.R.; Fei, B.H. Properties and bonding interface characteristics of an innovative bamboo flattening and grooving unit (BFGU) for laminated bamboo lumber. Colloids Surf. A Physicochem. Eng. Asp. 2023, 676, 132185. [Google Scholar] [CrossRef]

- Wei, X.; Wang, G.; Chen, X.Y.; Jiang, H.; Lee, M.S. Natural bamboo coil springs with high cyclic-compression durability fabricated via a hydrothermal-molding-fixing method. Ind. Crops Prod. 2022, 184, 115055. [Google Scholar] [CrossRef]

- Fei, B.H. Accelerate the development of bamboo industry with new ideas. World Bamboo Ratt. 2019, 17, 1–6. [Google Scholar] [CrossRef]

- Li, X.Y.; Rao, F.; Li, N.; Lei, W.C.; Bao, M.Z.; Bao, Y.J.; Li, L.M.; Duan, Z.J.; Zu, Q.; Zhang, Y.H.; et al. High-performance bamboo scrimber composite prepared from heat-treated Bambusa chungii units with different resin contents for outdoor use. Ind. Crops Prod. 2023, 205, 117503. [Google Scholar] [CrossRef]

- Chen, F.M.; He, Y.Y.; Wei, X.; Han, S.Y.; Ji, J.G.; Wang, G. Advances in strength and toughness of hierarchical bamboo under humidity and heat. J. For. Eng. 2023, 8, 10–18. [Google Scholar] [CrossRef]

- Li, X.; Peng, H.; Niu, S.; Liu, X.; Li, Y. Effect of High-Temperature Hydrothermal Treatment on Chemical, Mechanical, Physical, and Surface Properties of Moso Bamboo. Forests 2022, 13, 712. [Google Scholar] [CrossRef]

- Chen, M.; Ye, L.; Semple, K.; Ma, J.; Zhang, J.; Weng, Y.; Yan, H.; Fei, B.; Dai, C. A new protocol for rapid assessment of bond durability of bio-based pipes: Bamboo winding composite pipe as a case study. Eur. J. Wood Wood Prod. 2022, 80, 947–959. [Google Scholar] [CrossRef]

- Wang, X.; Chen, X.; Huang, B.; Chen, L.; Fang, C.H.; Ma, X.X.; Fei, B.H. Gradient changes in fiber bundle content and mechanical properties lead to asymmetric bending of bamboo. Constr. Build. Mater. 2023, 395, 132328. [Google Scholar] [CrossRef]

- Lian, C.P.; Wu, Z.H. Research progress on environmental characteristics of bamboo materials and its products. J. For. Eng. 2022, 7, 23–30. [Google Scholar] [CrossRef]

- He, L.; Chen, L.; Xiang, L.; Liu, H.; Shao, H.J.; Qi, J.Q.; Jiang, Y.Z.; Xie, J.L. Improving the anti-mould property of Moso bamboo surface by using a bamboo green colour preservation approach. Wood Mater. Sci. Eng. 2023, 18, 161–171. [Google Scholar] [CrossRef]

- Wu, C.J.; Song, S.S.; Liu, Y.; Liu, H.R. Innovative design of bamboo chair furniture based on KANO model and TRIZ theory. J. For. Eng. 2024, 9, 177–183. [Google Scholar] [CrossRef]

- Wang, J.; Wu, X.; Wang, Y.; Zhao, W.; Zhao, Y.; Zhou, M.; Wu, Y.; Ji, G. Green, sustainable architectural bamboo with high light transmission and excellent electromagnetic shielding as a candidate for energy-Saving buildings. Nano-Micro Lett. 2022, 15, 11. [Google Scholar] [CrossRef]

- Yu, L.L.; Liu, X.M.; Qiu, F.Q.; Ren, H.Q.; Fei, B.H. Exploitation and application of bamboo filament decorative materials. China For. Prod. Ind. 2015, 7, 5–9. [Google Scholar]

- Xu, Y.Q.; Chen, H.; Yang, F. Effects of low temperature plasma treatment on the surface properties of bamboo filament decorative Materials. Furniture 2019, 4, 21–27. [Google Scholar]

- Li, Z.Z.; Luan, Y.; Hu, J.B.; Fang, C.H.; Liu, L.T.; Ma, Y.F.; Liu, Y.; Fei, B.H. Bamboo heat treatments and their effects on bamboo properties. Constr. Build. Mater. 2022, 331, 127320. [Google Scholar] [CrossRef]

- Wu, J.Y.; Chen, H.; Lian, C.P.; Wu, Z.H. Research on application of bamboo in modern furniture design. China For. Prod. Ind. 2021, 58, 51–54. [Google Scholar] [CrossRef]

- Enyinwa, P.C.; Ren, X.; Zou, C.F.; Han, S.B.; Zhang, Y.; Wu, X.X.; Sun, F.L. Novel formulated chitosan copper complex as a green color protection agent of Moso bamboo and its reaction characteristics on bamboo epidermis. Ind. Crops Prod. 2023, 195, 116391. [Google Scholar] [CrossRef]

- Wu, J.Y.; Chen, H.; Fei, B.H.; Ma, X.X.; Zhang, L.W. Study on bamboo weaving process characteristics in zhejiang province. China For. Prod. Ind. 2020, 57, 61–64. [Google Scholar]

- Xu, B. The application of integration of traditional bamboo weaving technology and modern furniture design. Packag. Eng. 2019, 40, 186–191. [Google Scholar] [CrossRef]

- Chen, Z.J.; He, X.Q. Design and Analysis of Materials of the Bamboo Weaving Veneer Furniture. Furnit. Inter. Decor. 2016, 6, 13–15. [Google Scholar]

- Li, H.; Gu, Z.C.; Wang, X.; Du, Y.Y.; Yang, Z.B. Optimization hot pressing process of bamboo filament decorative blockboard process based on response surface method. J. Cent. South. Univ. For. Technol. 2020, 40, 156–163. [Google Scholar] [CrossRef]

- Li, H.; Chen, M.L.; Hu, L.X.; Wang, X.; Gu, Z.C.; Li, J.Z.; Yang, Z.B. Optimization design of bamboo filament decorated board process based on response surface. Bioresources 2023, 18, 73–86. [Google Scholar] [CrossRef]

- Wu, K.Q.; Guo, Z.Y.; Wei, Q.H.; Lin, D.M.; Zeng, Q.Z.; Liu, X.H.; Rao, J.P. Preparation process optimization for juncao scrimber via response surface methodology. J. For. Eng. 2024, 9, 75–84. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Roslan, S.A.; Sapuan, S.M.; Rasid, Z.A.; Yusoff, M.Z.M. Mercerization optimization of bamboo (Bambusa vulgaris) fiber-reinforced epoxy composite structures using a box-behnken design. Polymers 2020, 12, 1367. [Google Scholar] [CrossRef]

- Gao, L.; Luo, S.P.; Guo, W.J. Optimization of performance of bamboo mat corrugated sheets using response surface methodology. Wood Fiber Sci. 2019, 51, 1–12. [Google Scholar]

- GB/T 17657-2022; Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels. National Standardization Technical Committee: Beijing, China, 2022.

- Li, N.; Bao, M.Z.; Rao, F.; Shu, Y.; Huang, C.J.; Huang, Z.H.; Chen, Y.H.; Bao, Y.J.; Guo, R.C.; Xiu, C.M. Improvement of surface photostability of bamboo scrimber by application of organic UV absorber coatings. J. Wood Sci. 2019, 65, 7. [Google Scholar] [CrossRef]

- Qin, W.L.; Yu, H.X.; Xu, M.P.; Zhuang, X.W.; Wang, H.Y.; Yin, M.; Pan, X.; Liang, Y.J. Effects of microwave softening treatment on dynamic mechanical and chemical properties of bamboo. J. Mater. Sci. 2024, 59, 3488–3503. [Google Scholar] [CrossRef]

- Zuo, Y.F.; Wu, Y.Q.; Xiao, J.H.; Li, X.J.; Long, K.Q. Hot pressing process of recombinant bamboo based on response surface methodology. J. Funct. Mater. 2016, 47, 196–200. [Google Scholar] [CrossRef]

- Wu, J.Y.; Zhang, Y.H.; Ji, Y.H.; Zhu, R.X.; Sun, Y.H.; Yu, Y.L.; Yu, W.J. Engineering the surface properties of bamboo scrimber to enhance the gluing properties. Polym. Compos. 2022, 43, 5465–5475. [Google Scholar] [CrossRef]

- Gao, X.; Li, M.; Zhang, H.; Tang, X.; Chen, K. Fabrication of regenerated cellulose films by DMAc dissolution using parenchyma cells via low-temperature pulping from Yunnan-endemic bamboos. Ind. Crops Prod. 2021, 160, 113116. [Google Scholar] [CrossRef]

- Huo, X.S.; Yang, G.C.; Zhang, Q.H. Research Progress of Effects of Heat Treatment on Physical and Chemical Properties of Bamboo. Packag. Eng. 2023, 44, 24–33. [Google Scholar] [CrossRef]

- Chen, X.H.; Wang, X.K.; Shang, L.L.; Ma, X.X.; Fang, C.H.; Fei, B.H.; Liu, H.R.; Zhang, S.Q. Three-dimensional structural characterization and mechanical properties of bamboo parenchyma tissue. Ind. Crops Prod. 2024, 208, 117833. [Google Scholar] [CrossRef]

- Jia, H.; Chen, L.; Fang, C.H.; Liu, H.R.; Ma, X.X.; Zhang, X.B.; Fei, B.H.; Sun, F.B. Visual evaluation of warehousing humidity and time on bamboo performance. Ind. Crops Prod. 2023, 194, 116334. [Google Scholar] [CrossRef]

- Song, L.L.; Ren, H.Q.; Wang, X.Z.; Ma, J.M.; Li, Y.C.; Li, Y.J.; Xu, B. Effects of microstructure and chemical composition on the visual characteristics of flattened bamboo board. J. For. Eng. 2018, 3, 23–28. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, Y.; Lou, Z.; Li, Y. Study on the effect of flattening modification on bamboo cutting board and corresponding carbon footprint evaluation. Forests 2023, 14, 809. [Google Scholar] [CrossRef]

- Yuan, J.; Lei, Y.F.; Mi, B.B.; Chen, M.L.; Chen, Q.; Fang, C.H.; Chen, L.; Yan, L. Differences in the hygroscopic behavior of bamboo fiber and parenchyma. Wood Sci. Technol. 2024, 1–13. [Google Scholar] [CrossRef]

- Wang, G.F.; Zhang, W.; Diao, X.L.; Ji, M.; Miao, H.; Chen, M.L. Enhancing Afforestation Practices in Hilly Terrain: A Study on Soil Disturbance by Earth Augers Based on the Discrete Element Method. Forests 2024, 15, 190. [Google Scholar] [CrossRef]

| Factor | Variable | Unit | Actual and Coded Values | ||

|---|---|---|---|---|---|

| −1 | 0 | 1 | |||

| X1 | Temperature | °C | 130 | 140 | 150 |

| X2 | Time | s | 150 | 165 | 180 |

| X3 | Pressure | MPa | 2 | 3 | 4 |

| Run | Actual Value | Response Value Y | ||

|---|---|---|---|---|

| Temperature (°C) | Time (s) | Pressure (MPa) | Surface Bonding Strength (MPa) | |

| 1 | 130 | 165 | 4.00 | 1.63 |

| 2 | 140 | 165 | 3.00 | 1.60 |

| 3 | 130 | 180 | 3.00 | 1.72 |

| 4 | 140 | 150 | 2.00 | 1.56 |

| 5 | 140 | 165 | 3.00 | 1.57 |

| 6 | 140 | 150 | 4.00 | 1.82 |

| 7 | 140 | 180 | 2.00 | 1.59 |

| 8 | 150 | 180 | 3.00 | 1.73 |

| 9 | 150 | 165 | 2.00 | 1.52 |

| 10 | 130 | 150 | 3.00 | 1.46 |

| 11 | 140 | 180 | 4.00 | 1.71 |

| 12 | 150 | 150 | 3.00 | 1.88 |

| 13 | 150 | 165 | 4.00 | 1.89 |

| 14 | 130 | 165 | 2.00 | 1.63 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | Sig. |

|---|---|---|---|---|---|---|

| Model | 0.21 | 9 | 0.023 | 6.34 | 0.0455 | |

| X1 | 0.042 | 1 | 0.042 | 11.38 | 0.0279 | |

| X2 | 1.125 × 10−4 | 1 | 1.125 × 10−4 | 0.030 | 0.8699 | >0.05 |

| X3 | 0.070 | 1 | 0.070 | 19.04 | 0.0120 | |

| X1X2 | 0.042 | 1 | 0.042 | 11.38 | 0.0280 | |

| X1X3 | 0.034 | 1 | 0.034 | 9.27 | 0.0383 | |

| X2X3 | 4.900 × 10−3 | 1 | 4.900 × 10−3 | 1.33 | 0.3136 | >0.05 |

| X12 | 9.680 × 10−3 | 1 | 9.680 × 10−3 | 2.62 | 0.1808 | >0.05 |

| X22 | 0.011 | 1 | 0.011 | 2.86 | 0.1658 | >0.05 |

| X32 | 2.420 × 10−3 | 1 | 2.420 × 10−3 | 0.66 | 0.4637 | >0.05 |

| Residual | 0.015 | 4 | 3.694 × 10−3 | |||

| Lack of Fit | 0.014 | 3 | 4.775 × 10−3 | 10.61 | 0.2211 | >0.05 |

| Pure Error | 4.500 × 10−4 | 1 | 4.500 × 10−4 | |||

| Cor Total | 0.23 | 13 | ||||

| R2 | 0.9345 | Adjusted R2 | 0.7871 |

| No. | Temperature (°C) | Time (S) | Pressure (MPa) | Surface Bonding Strength (MPa) | Relative Error (%) |

|---|---|---|---|---|---|

| Predicted Value | 130 | 165 | 2.00 | 1.60 | — |

| Measured Value 1 | 130 | 165 | 2.00 | 1.67 | 4.38 |

| Measured Value 2 | 130 | 165 | 2.00 | 1.52 | 5.00 |

| Measured Value 3 | 130 | 165 | 2.00 | 1.55 | 3.13 |

| Average Value | 130 | 165 | 2.00 | 1.58 | 4.17 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | Sig. |

|---|---|---|---|---|---|---|

| Model | 313.58 | 9 | 34.84 | 1.14 | 0.4868 | >0.05 |

| X1 | 37.41 | 1 | 37.41 | 1.22 | 0.3311 | >0.05 |

| X2 | 15.40 | 1 | 15.40 | 0.50 | 0.5174 | >0.05 |

| X3 | 53.46 | 1 | 53.46 | 1.74 | 0.2570 | >0.05 |

| X1X2 | 55.13 | 1 | 55.13 | 1.80 | 0.2509 | >0.05 |

| X1X3 | 0.70 | 1 | 0.70 | 0.023 | 0.8874 | >0.05 |

| X2X3 | 17.26 | 1 | 17.26 | 0.56 | 0.4946 | >0.05 |

| X12 | 32.69 | 1 | 32.69 | 1.07 | 0.3600 | >0.05 |

| X22 | 76.17 | 1 | 76.17 | 2.49 | 0.1900 | >0.05 |

| X32 | 0.45 | 1 | 0.45 | 0.015 | 0.9097 | >0.05 |

| Residual | 122.54 | 4 | 30.64 | |||

| Lack of Fit | 80.68 | 3 | 26.89 | 0.64 | 0.6993 | >0.05 |

| Pure Error | 41.86 | 1 | 41.86 | |||

| Cor Total | 436.12 | 13 | ||||

| R2 | 0.7190 | Adjusted R2 | 0.0868 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Chen, M.; Bao, Y.; Wang, X.; Gao, J.; Li, Y.; Li, J.; Huang, C. Study on Preparation Optimization Technology and Surface Properties of Decorated Bamboo Filament Board. Forests 2024, 15, 932. https://doi.org/10.3390/f15060932

Li H, Chen M, Bao Y, Wang X, Gao J, Li Y, Li J, Huang C. Study on Preparation Optimization Technology and Surface Properties of Decorated Bamboo Filament Board. Forests. 2024; 15(6):932. https://doi.org/10.3390/f15060932

Chicago/Turabian StyleLi, Hui, Meiling Chen, Yongjie Bao, Xiao Wang, Jie Gao, Yu Li, Junzhang Li, and Chengjian Huang. 2024. "Study on Preparation Optimization Technology and Surface Properties of Decorated Bamboo Filament Board" Forests 15, no. 6: 932. https://doi.org/10.3390/f15060932

APA StyleLi, H., Chen, M., Bao, Y., Wang, X., Gao, J., Li, Y., Li, J., & Huang, C. (2024). Study on Preparation Optimization Technology and Surface Properties of Decorated Bamboo Filament Board. Forests, 15(6), 932. https://doi.org/10.3390/f15060932