The Research of Improved Active Disturbance Rejection Control Algorithm for Particleboard Glue System Based on Neural Network State Observer

Abstract

:1. Introduction

- (1)

- The process of mixing and dosing the glue for particleboard is introduced and so is the composition of the system. Then we establish the state space equation.

- (2)

- We construct an improved controller using ADRC approach. The improved NNSO is utilized to observe disturbance for control compensation and estimate the system state variables. To simplify the controller, the improved TD is used to achieve smooth transmission of differential signals and realize optimal configuration of closed-loop system transition processes. The SMC is introduced to improve the robustness for the disturbance not observed by NNSO.

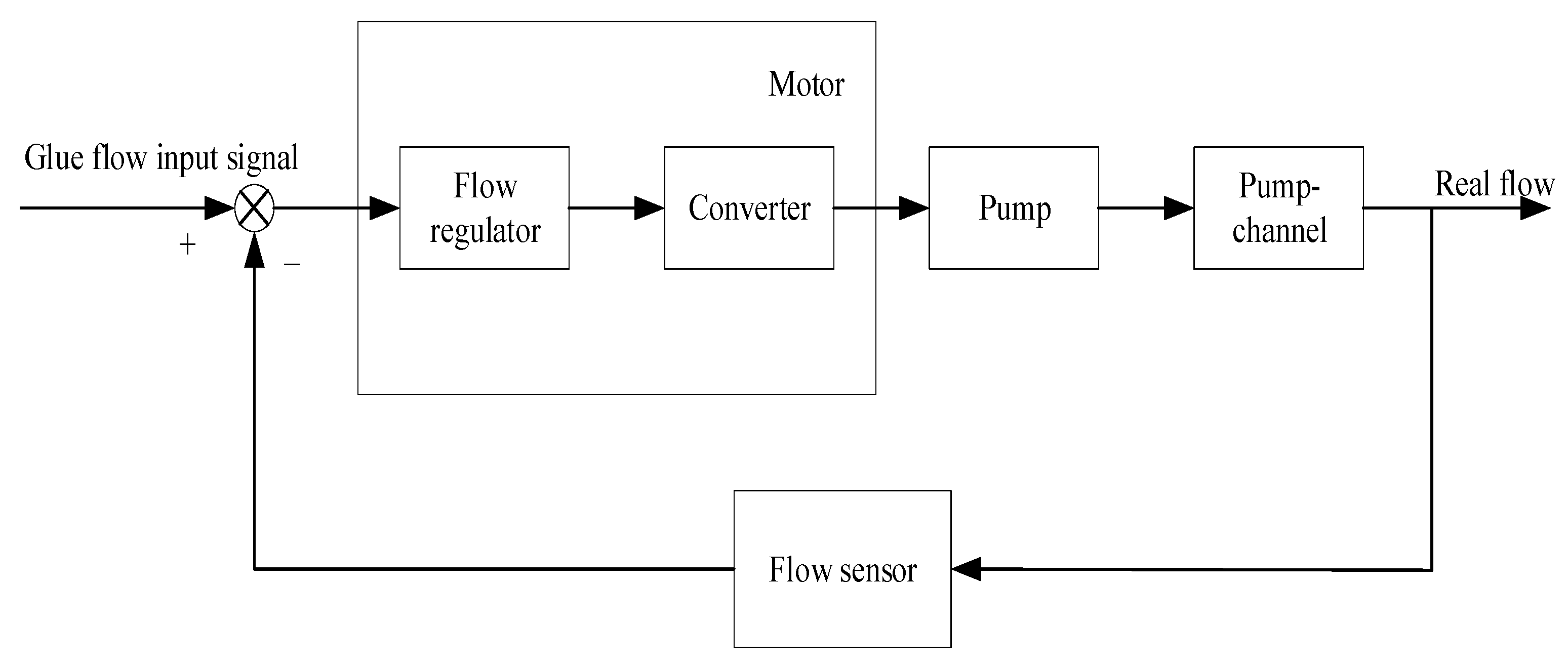

2. Process and System Description

3. Design of the Compound Controller

3.1. Designs of the Tracking Differentiator

3.2. Neural Network Extend State Observer

3.2.1. Designs of Neural Network State Observer

3.2.2. Stability Analysis of Neural Network Extend State Observer

- 1.

- , where,are positive definite symmetric matrices andandrepresent the minimum eigenvalue and the maximum eigenvalue of the matrix respectively,

- 2.

- the Lyapunov functionholds.

3.3. Designs of Sliding Mode Controller

4. Simulation Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kusumah, S.S.; Umemura, K.; Guswenrivo, I.; Yoshimura, T.; Kanayama, K. Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard II: Influences of pressing temperature and time on particleboard properties. J. Wood Sci. 2017, 63, 161–172. [Google Scholar] [CrossRef] [Green Version]

- Meng, Z.; Borja, P.; Ortega, R.; Liu, Z.; Su, H. Pid passivity-based control of port-hamiltonian systems. IEEE Trans. Autom. Control 2018, 63, 1032–1044. [Google Scholar]

- Mahto, T.; Mukherjee, V. Fractional order fuzzy pid controller for wind energy-based hybrid power system using quasi-oppositional harmony search algorithm. IET Gener. Transm. Distrib. 2017, 11, 3299–3309. [Google Scholar] [CrossRef]

- Li, D.; Ding, P.; Gao, Z. Fractional active disturbance rejection control. ISA Trans. 2016, 62, 109–119. [Google Scholar] [CrossRef]

- Li, M.; Li, D.; Wang, J.; Zhao, C. Active disturbance rejection control for fractional-order system. ISA Trans. 2013, 52, 365–374. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Vinagre, B.M.; Podlubny, I. Fractional order disturbance observer for robust vibration suppression. Nonlinear Dyn. 2004, 38, 355–367. [Google Scholar] [CrossRef]

- Sondhi, S.; Hote, Y.V. Fractional order PID controller for load frequency control. Energy Convers. Manag. 2014, 85, 343–353. [Google Scholar] [CrossRef]

- Li, W.; Hori, Y. Vibration suppression using single neuron-based PI fuzzy controller and fractional-order disturbance observer. IEEE Trans. Ind. Electron. 2007, 54, 117–126. [Google Scholar] [CrossRef]

- David, S.A.; de Sousa, R.V.; Valentim Jr, C.A.; Tabile, R.A.; Machado, J.A.T. Fractional PID controller in an active image stabilization system for mitigating vibration effects in agricultural tractors. Comput. Electron. Agric. 2016, 131, 1–9. [Google Scholar] [CrossRef]

- Ye, Y.; Yue, Z.; Gu, B. Adrc control of a 6-dof parallel manipulator for telescope secondary mirror. J. Instrum. 2017, 12, T03006. [Google Scholar] [CrossRef]

- Zhao, C.; Li, D.; Cui, J.; Tian, L. Decentralized low-order adrc design for mimo system with unknown order and relative degree. Pers. Ubiquitous Comput. 2018, 22, 1–18. [Google Scholar] [CrossRef]

- Yang, J.; Cui, H.; Li, S.; Zolotas, A. Optimized active disturbance rejection control for dc-dc buck converters with uncertainties using a reduced-order gpi observer. IEEE Trans. Circ. Syst. I Regul. Pap. 2018, 65, 832–841. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Duan, H.; Yang, Y. Active disturbance rejection control for small unmanned helicopters via levy flight-based pigeon-inspired optimization. Aircr. Eng. Aerosp. Technol. 2017, 89, 946–952. [Google Scholar] [CrossRef] [Green Version]

- Han, J. From PID to Active Disturbance Rejection Control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Rongxin, C.; Lepeng, C.; Chenguang, Y.; Mou, C. Correction to extended state observer-based integral sliding mode control for an underwater robot with unknown disturbances and uncertain nonlinearities. IEEE Trans. Ind. Electron. 2018, 66, 8279–8280. [Google Scholar]

- Peng, Z.; Wang, J. Output-feedback path-following control of autonomous underwater vehicles based on an extended state observer and projection neural networks. IEEE Trans. Syst. Man Cybern. Syst. 2017, 48, 535–544. [Google Scholar] [CrossRef]

- Wang, C.; Zuo, Z.; Qi, Z.; Ding, Z. Predictor-based extended-state-observer design for consensus of mass with delays and disturbances. IEEE Trans. Cybern. 2018, 49, 1259–1269. [Google Scholar] [CrossRef]

- Hua, C.C.; Wang, K.; Chen, J.N.; You, X. Tracking differentiator and extended state observer-based nonsingular fast terminal sliding mode attitude control for a quadrotor. Nonlinear Dyn. 2018, 94, 1–12. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Liu, S.; Li, Z.; Zhang, H.; Zhang, Z. An approach to suppress low-frequency oscillation by combining extended state observer with model predictive control of emus rectifier. IEEE Trans. Power Electron. 2019. Available online: https://www.researchgate.net/publication/330432768 (accessed on 2 December 2019). [CrossRef]

- Liu, Y.J.; Tong, S.; Li, D.J.; Gao, Y. Fuzzy adaptive control with state observer for a class of nonlinear discrete-time systems with input constraint. IEEE Trans. Fuzzy Syst. 2015, 24, 1147–1158. [Google Scholar] [CrossRef]

- Sanz, R.; Garcia, P.; Fridman, E.; Albertos, P. Rejection of mismatched disturbances for systems with input delay via a predictive extended state observer. Int. J. Robust Nonlinear Control 2018, 28, 2457–2467. [Google Scholar] [CrossRef]

- Long, L.; Si, T. Small-gain technique-based adaptive NN control for switched pure-feedback nonlinear systems. IEEE Trans. Cybern. 2018, 49, 1873–1884. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, Y.; Liu, L. Adaptive Finite-Time NN Control for 3-DOF Active Suspension Systems with Displacement Constraints. IEEE Access 2019, 7, 13577–13588. [Google Scholar] [CrossRef]

- Xing, H.L.; Jeon, J.H.; Park, K.C.; Oh, I.K. Active disturbance rejection control for precise position tracking of ionic polymer–metal composite actuators. IEEE/ASME Trans. Mechatron. 2011, 18, 86–95. [Google Scholar] [CrossRef]

- Li, R.G.; Wu, H.N. Secure communication on fractional-order chaotic systems via adaptive sliding mode control with teaching–learning–feedback-based optimization. Nonlinear Dyn. 2019, 95, 1221–1243. [Google Scholar] [CrossRef]

- Yang, Q.; Saeedifard, M.; Perez, M.A. Sliding mode control of the modular multilevel converter. IEEE Trans. Ind. Electron. 2018, 66, 887–897. [Google Scholar] [CrossRef]

- Karami-Mollaee, A.; Tirandaz, H.; Barambones, O. On dynamic sliding mode control of nonlinear fractional-order systems using sliding observer. Nonlinear Dyn. 2018, 92, 1379–1393. [Google Scholar] [CrossRef]

- Guo, B.Z.; Jin, F.F. The active disturbance rejection and sliding mode control approach to the stabilization of the Euler–Bernoulli beam equation with boundary input disturbance. Automatica 2013, 49, 2911–2918. [Google Scholar] [CrossRef]

- Shilin, A.A.; Bukreev, V.G. Linearization of a heat-transfer system model with approximation of transport time delay. Therm. Eng. 2014, 61, 741–746. [Google Scholar] [CrossRef]

- Ge, S.S.; Hang, C.C.; Lee, T.H.; Zhang, T. Stable Adaptive Neural Network Control; Springer Science Business Media: Berlin, Germany, 2013; Volume 13. [Google Scholar]

- Miroslav, K.; Kanellakopoulos, I.; Petar, V. Nonlinear and Adaptive Control Design; Wiley: New York, NY, USA, 1995. [Google Scholar]

- Dong, Q.; Yongkai, L.; Zhang, Y.; Gao, S.; Chen, T. Improved adrc with ilc control of a ccd-based tracking loop for fast steering mirror system. IEEE Photonics J. 2018, 10, 1–14. [Google Scholar] [CrossRef]

- Ioannou, P.A.; Sun, J. Robust Adaptive Control; Prentice-Hall: Englewood Cliffs, NJ, USA, 1996. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Zhang, C.; Zhu, L.; Wang, C. The Research of Improved Active Disturbance Rejection Control Algorithm for Particleboard Glue System Based on Neural Network State Observer. Algorithms 2019, 12, 259. https://doi.org/10.3390/a12120259

Wang P, Zhang C, Zhu L, Wang C. The Research of Improved Active Disturbance Rejection Control Algorithm for Particleboard Glue System Based on Neural Network State Observer. Algorithms. 2019; 12(12):259. https://doi.org/10.3390/a12120259

Chicago/Turabian StyleWang, Peiyu, Chunrui Zhang, Liangkuan Zhu, and Chengcheng Wang. 2019. "The Research of Improved Active Disturbance Rejection Control Algorithm for Particleboard Glue System Based on Neural Network State Observer" Algorithms 12, no. 12: 259. https://doi.org/10.3390/a12120259