Advances in Enhancing the Wear Performance of Ti-6Al-4V Biomedical Alloy Through Nb2O5 Coating

Abstract

1. Introduction

2. Experimental

2.1. Research Plan

2.2. Material

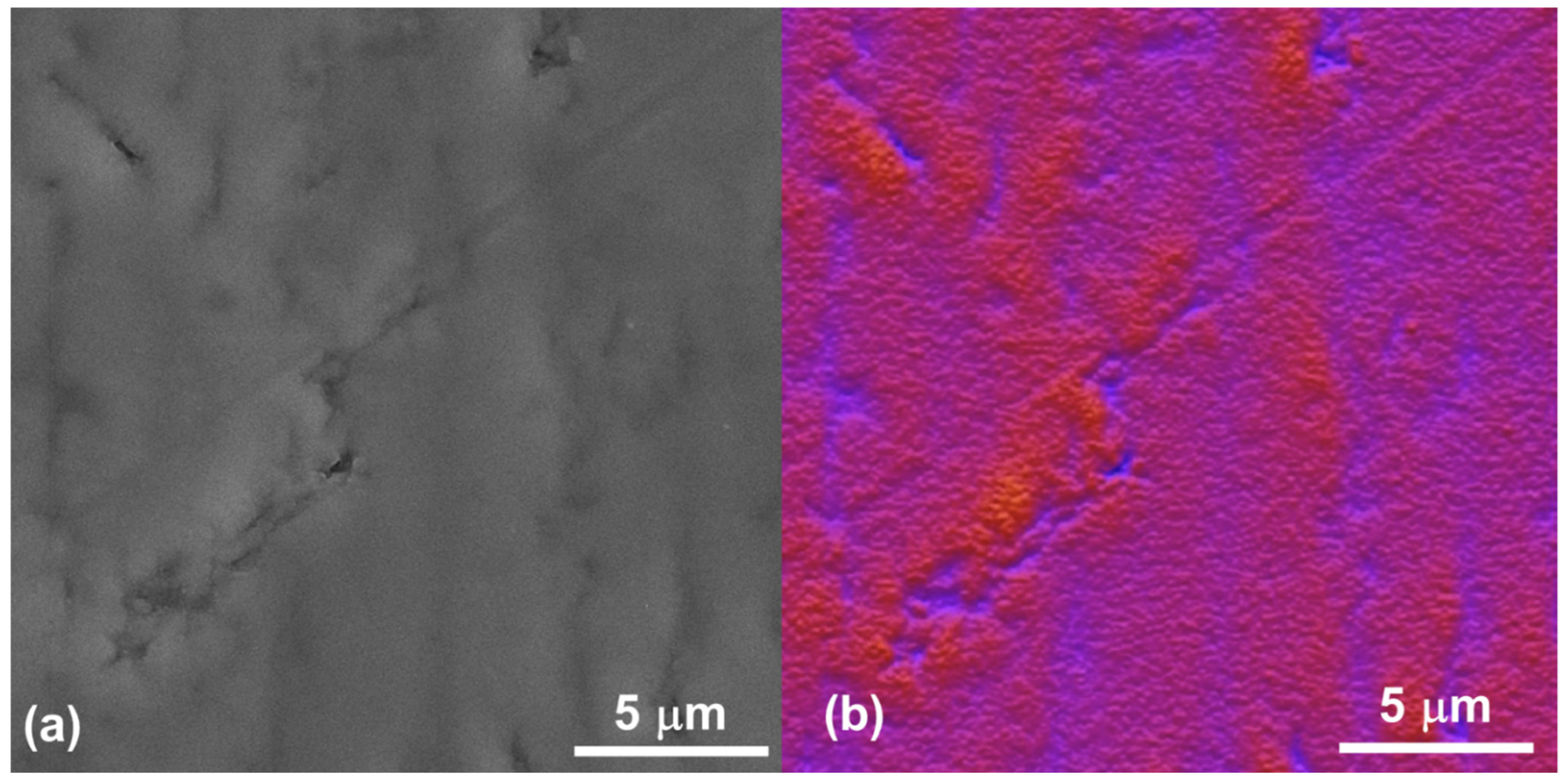

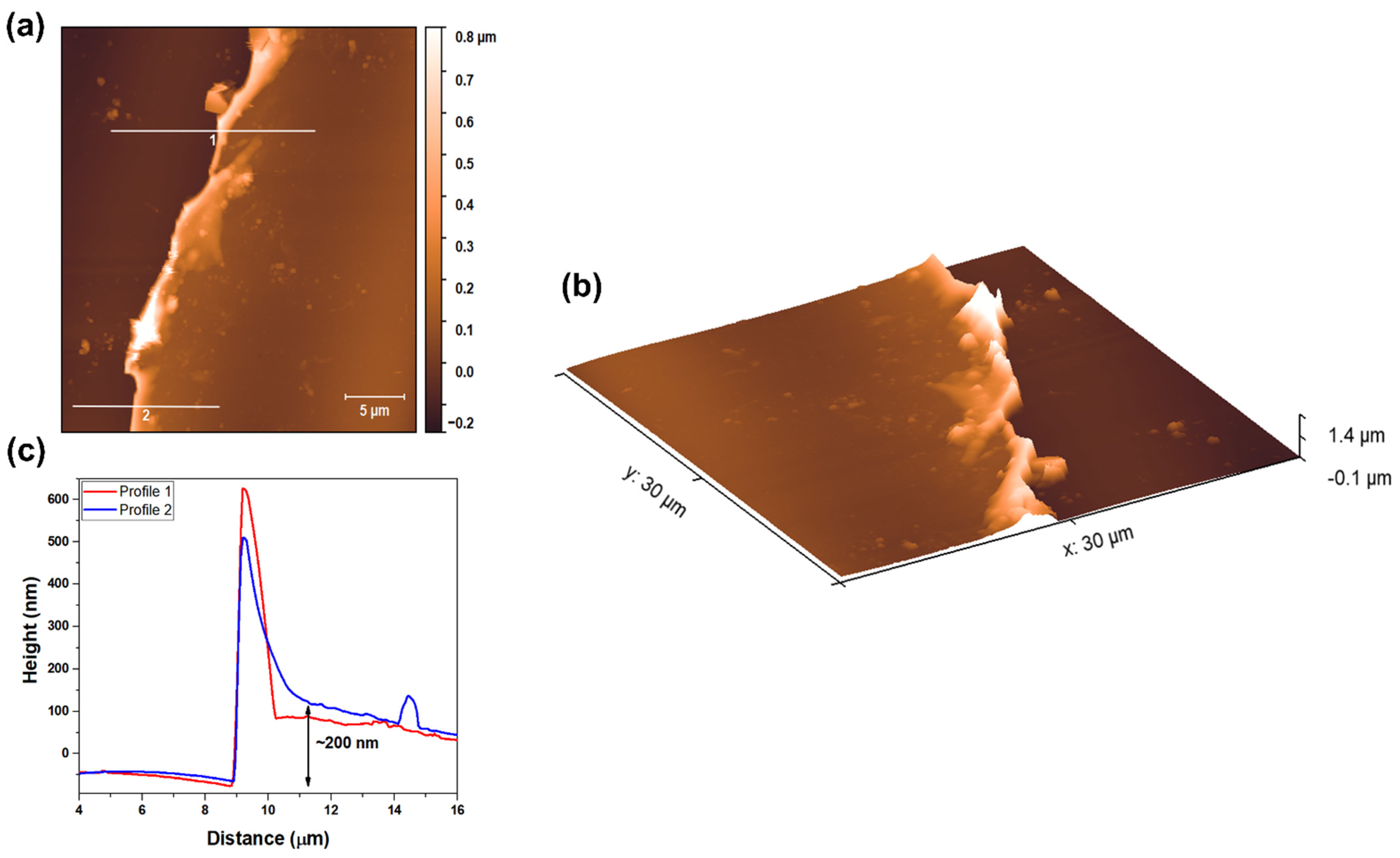

2.3. Nb2O5-Sputtered Coating Production and Morphological Characterization

2.4. Wear Tests

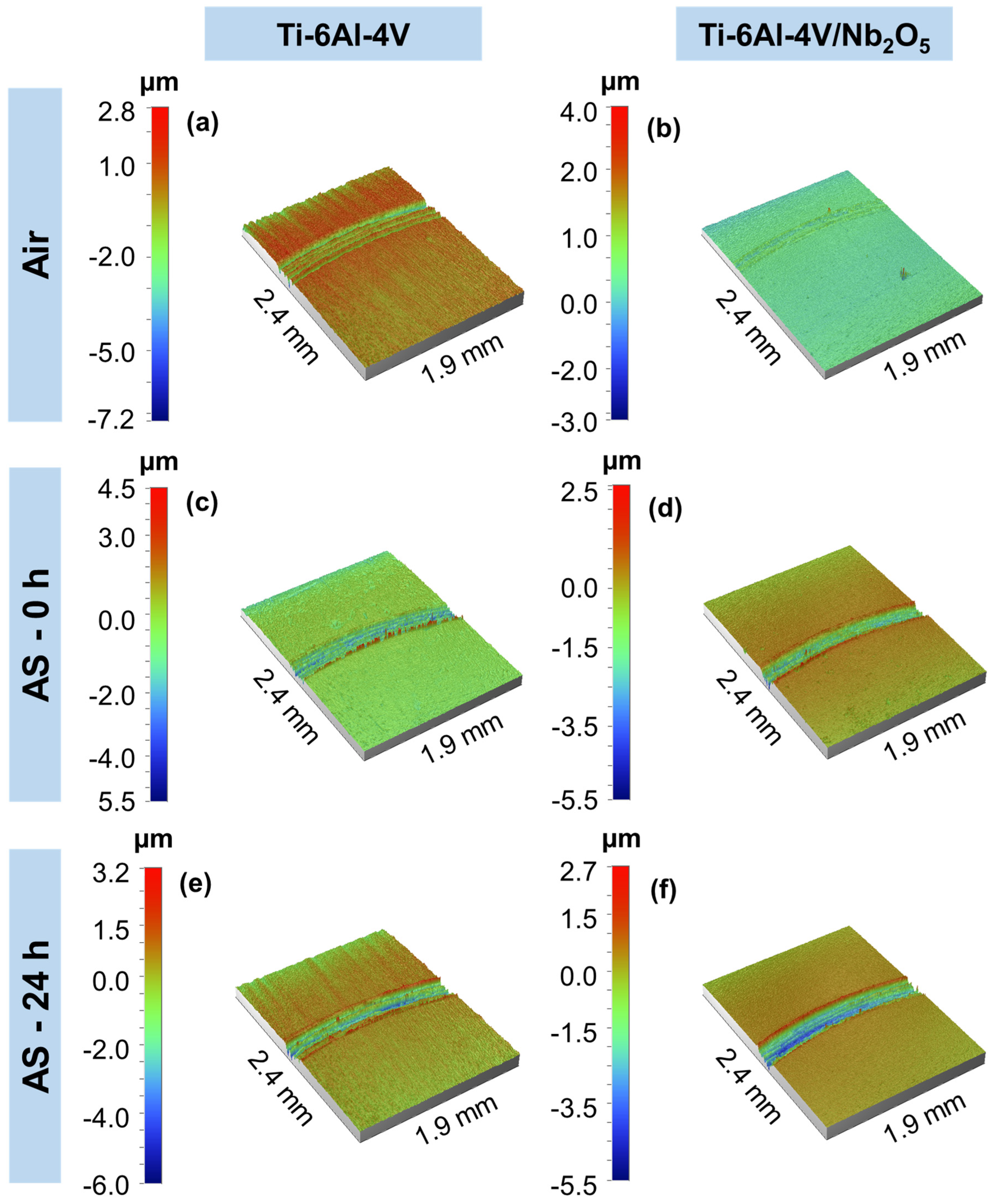

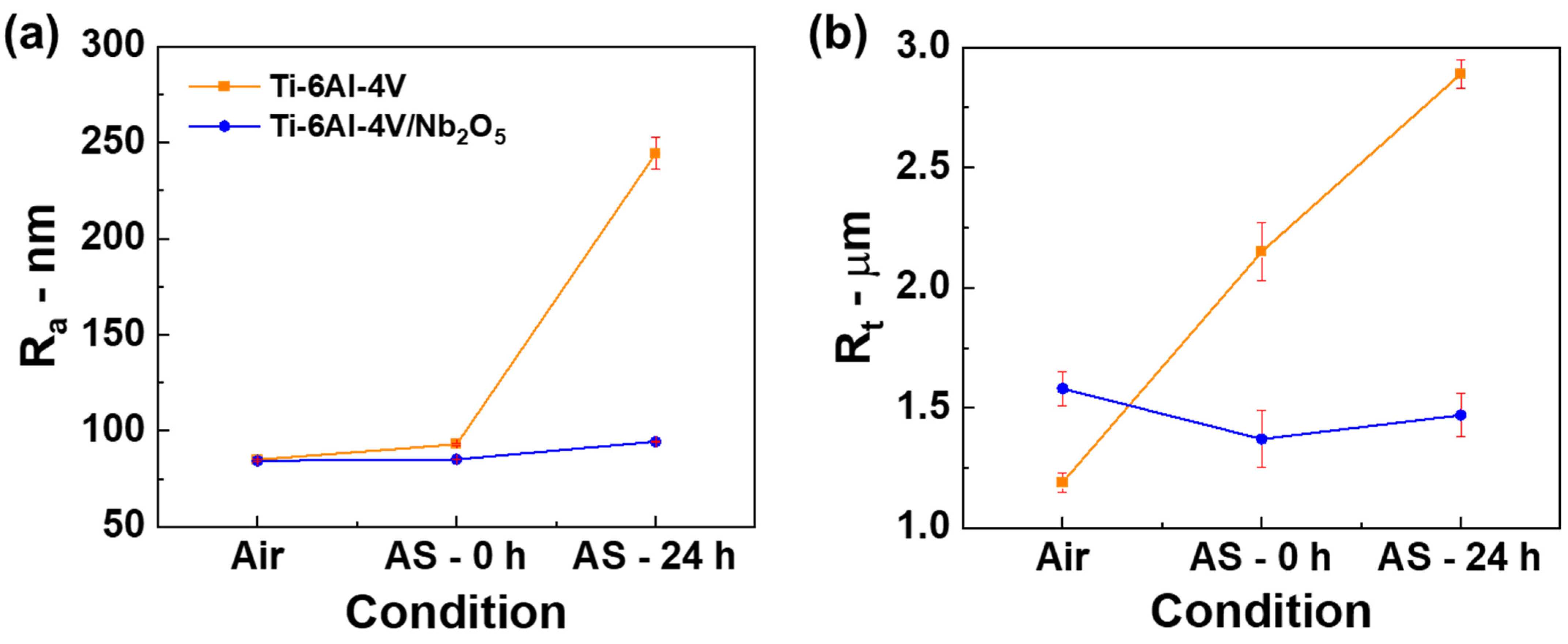

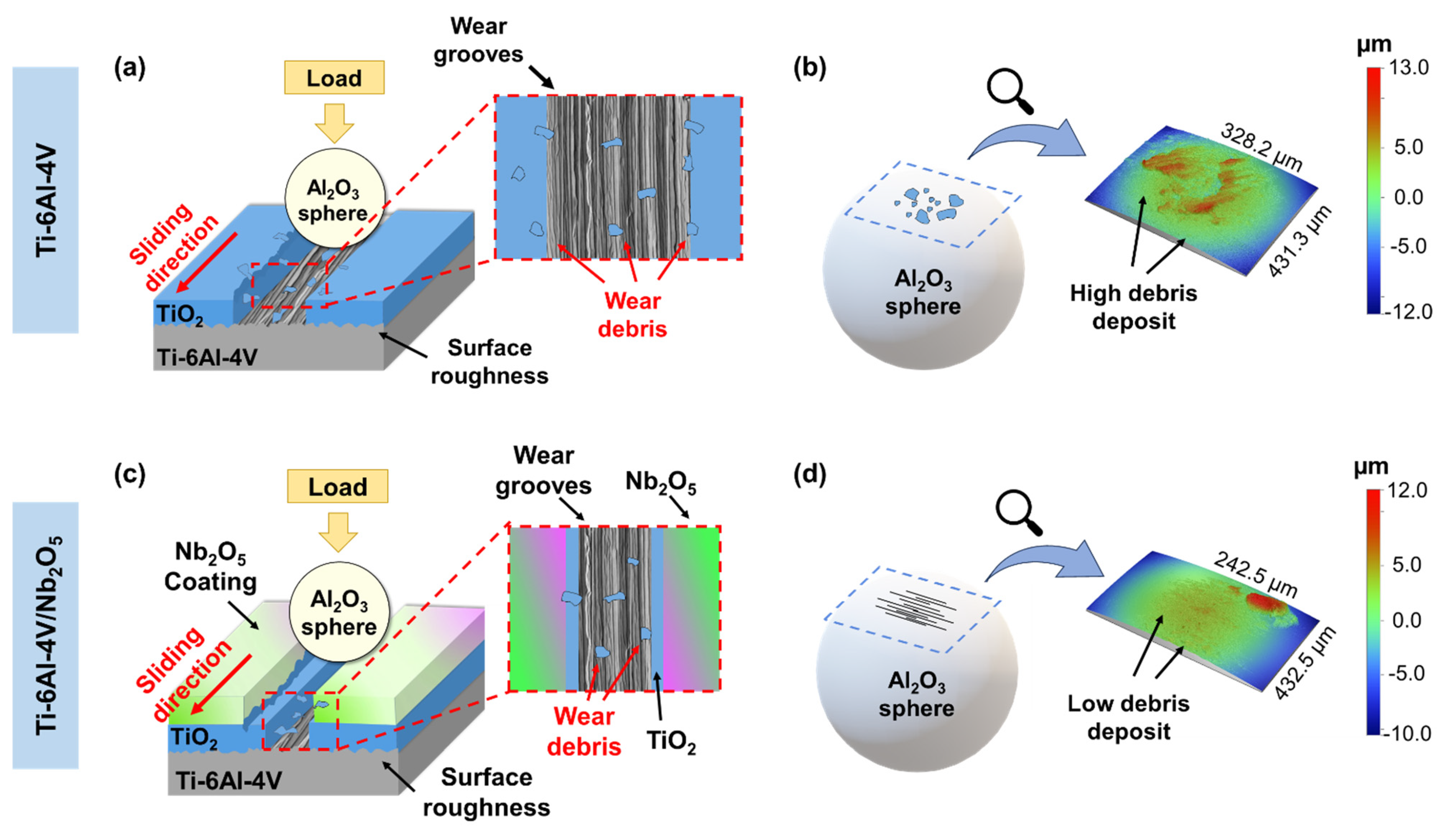

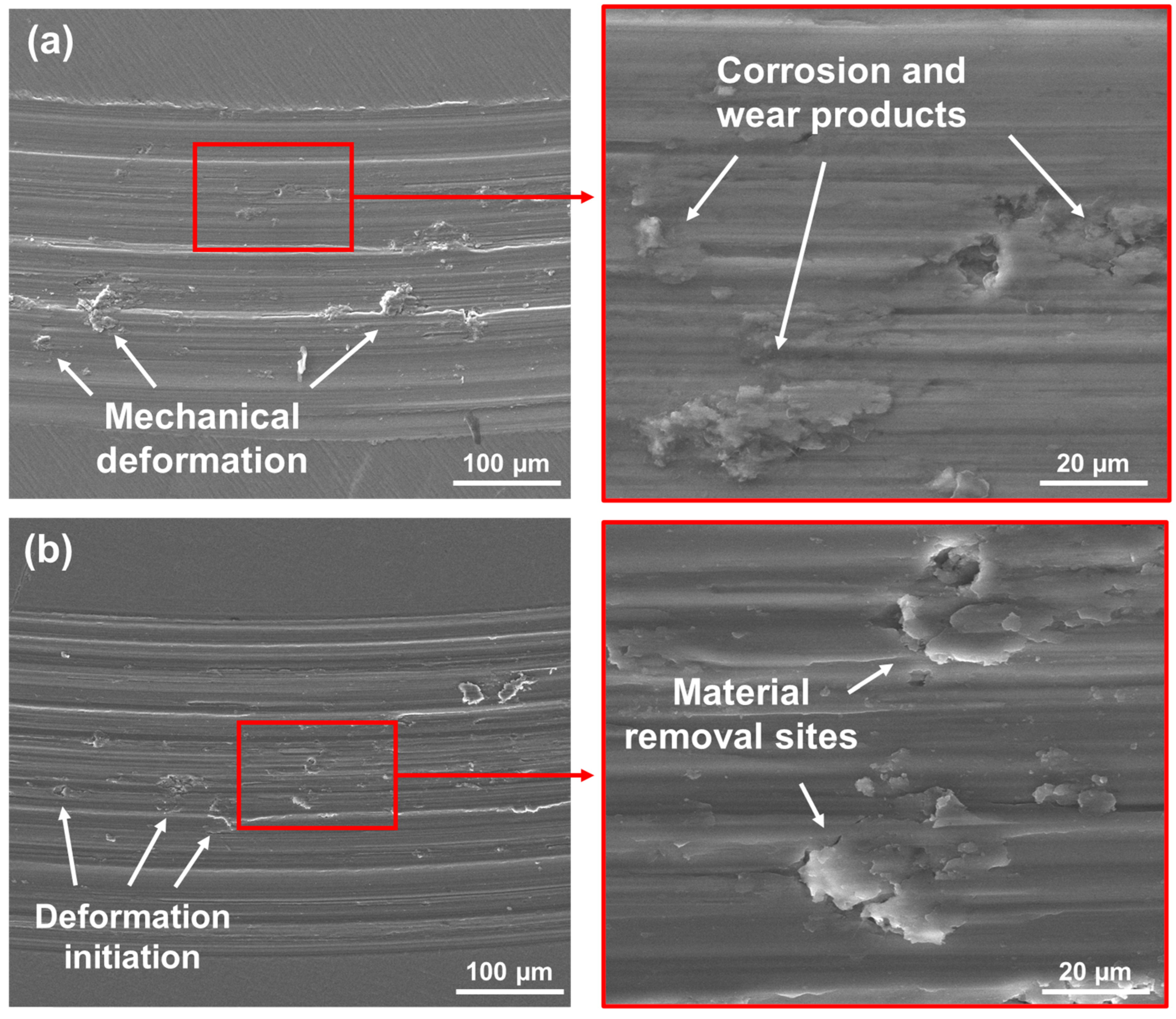

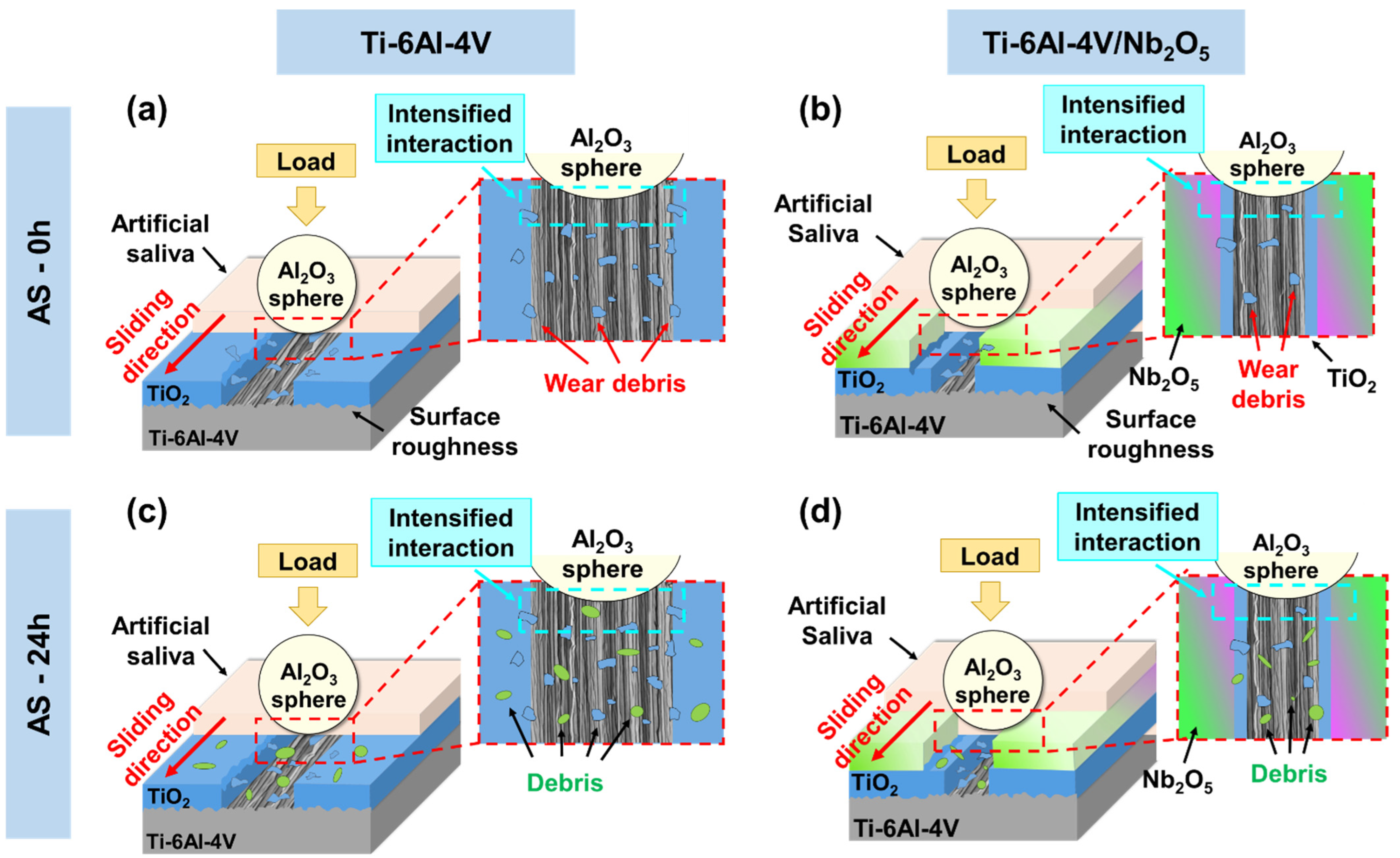

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, X.; Xu, X.; Zhou, Y.; Wu, Z.; Wei, L.; Zhang, D. Surface electropulsing-induced texture evolution in electron beam melted Ti-6Al-4V alloy for biomedical application. Surf. Coat. Technol. 2024, 479, 130509. [Google Scholar] [CrossRef]

- Ju, J.; Zan, R.; Shen, Z.; Wang, C.; Peng, P.; Wang, J.; Sun, B.; Xiao, B.; Li, Q.; Liu, S.; et al. Remarkable bioactivity, bio-tribological, antibacterial, and anti-corrosion properties in a Ti-6Al-4V-xCu alloy by laser powder bed fusion for superior biomedical implant applications. Chem. Eng. J. 2023, 471, 144656. [Google Scholar] [CrossRef]

- Esmaeili, M.M.; Mahmoodi, M.; Mokhtarzade, A.; Imani, R. In Vitro Corrosion and Tribological Behavior of Multiwall Carbon Nanotube-Coated Ti-6Al-4V/Tantalum Carbide Surface for Implant Applications. J. Mater. Eng. Perform. 2022, 31, 7719–7733. [Google Scholar] [CrossRef]

- Kawahara, M.; Kato-Negishi, M. Link between Aluminum, and the Pathogenesis of Alzheimer’s Disease: The Integration of the Aluminum and Amyloid Cascade Hypotheses. Int. J. Alzheimer’s Dis. 2011, 2011, 276393. [Google Scholar] [CrossRef] [PubMed]

- Gelamo, R.V.; Leite, N.B.; Amadeu, N.; Muniz Tavares, M.R.P.; Oberschmidt, D.; Klemm, S.; Fleck, C.; Cakir, C.T.; Radtke, M.; Moreto, J.A. Exploring the Nb2O5 coating deposited on the Ti-6Al-4V alloy by a novel GE-XANES technique and nanoindentation load-depth. Mater. Lett. 2024, 355, 135584. [Google Scholar] [CrossRef]

- Hussein, M.; Kumar, M.; Ankah, N.; Abdelaal, A. Surface, mechanical, and in vitro corrosion properties of arc-deposited TiAlN ceramic coating on biomedical Ti6Al4V alloy. Trans. Nonferrous Met. Soc. China 2023, 33, 494–506. [Google Scholar] [CrossRef]

- Mohin, M.; Akram, S.; Babutskyi, A.; Chrysanthou, A.; Randviir, E.P.; Doyle, A.M. Improved corrosion and cavitation erosion resistance of laser-based powder bed fusion produced Ti-6Al-4V alloy by pulsed magnetic field treatment. Mater. Today Commun. 2024, 38, 108394. [Google Scholar] [CrossRef]

- Anees, E.; Riaz, M.; Hussain, T. Electrochemical corrosion study of CH-xTiO2 (x = Ag, Mg, Sr, and Zn) coated Ti–6Al–4V alloy for dental implant. Mater. Chem. Phys. 2024, 327, 129895. [Google Scholar] [CrossRef]

- Peyghan, R.A.; Pouyafar, V.; Asghari, E.; Meshkabadi, R. Electrophoretic deposition of novel antibacterial and biocompatible polydopamine and ZIF-8 hybrid composite coating on anodized Ti-6Al-4V alloy with silane primary substrate. Surf. Interfaces 2024, 54, 105265. [Google Scholar] [CrossRef]

- Nisar, S.S.; Choe, H.-C. TiO2 coatings doped with MoS2 nanoparticles using plasma electrolytic oxidation on Ti–6Al–4V alloy: Application for enhanced and functional bio-implant surface. J. Mater. Res. Technol. 2024, 33, 2035–2056. [Google Scholar] [CrossRef]

- Liu, Z.; Li, L.; Liu, X.; Meng, J.; Zang, M. Wear and corrosion resistance behavior of hydrophobic surface on Ti-6Al-4V prepared by nitrogen gas-assisted EDM. Surf. Coat. Technol. 2024, 489, 131150. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, X.; Lu, Q.; Hu, T.; Hong, Y.; Li, C.; Zhong, R.; Chen, W. Promoted low-temperature plasma nitriding for improving wear performance of arc-deposited ceramic coatings on Ti6Al4V alloy via shot peening pretreatment. J. Mater. Res. Technol. 2022, 19, 2981–2990. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Kermanpur, A.; Kharaziha, M.; Bagherifard, S. Engineering of multilayered coating on additively manufactured Ti-6Al-4V porous implants to promote tribological and fatigue performances. Surf. Coat. Technol. 2024, 494, 131400. [Google Scholar] [CrossRef]

- Azizi-Malekabadi, M.; Bakhshi, H.; Shahbazi, H.; Nosrati, H. Enhancement of the Ti-6Al-4V alloy corrosion resistance by applying CrN/CrAlN multilayer coating via Arc-PVD method. Int. J. Appl. Ceram. Technol. 2021, 18, 1288–1296. [Google Scholar] [CrossRef]

- Gabor, R.; Cvrček, L.; Doubková, M.; Nehasil, V.; Hlinka, J.; Unucka, P.; Buřil, M.; Podepřelová, A.; Seidlerová, J.; Bačáková, L. Hybrid coatings for orthopaedic implants formed by physical vapour deposition and microarc oxidation. Mater. Des. 2022, 219, 110811. [Google Scholar] [CrossRef]

- Bao, Y.; Wang, W.; Cui, W.; Qin, G. Corrosion resistance and antibacterial activity of Ti-N-O coatings deposited on dental titanium alloy. Surf. Coat. Technol. 2021, 419, 127296. [Google Scholar] [CrossRef]

- Vella, K.A.; Buhagiar, J.; Cassar, G.; Attard, B.; Chen, J.; Zammit, A. Microstructural analysis of additively manufactured Ti–6Al–4V subjected to duplex surface treatment. Mater. Chem. Phys. 2024, 319, 129303. [Google Scholar] [CrossRef]

- Ramoul, C.; Beliardouh, N.E.; Bahi, R.; Nouveau, C.; Djahoudi, A.; Walock, M.J. Surface performances of PVD ZrN coatings in biological environments. Tribol. Mater. Surf. Interfaces 2019, 13, 12–19. [Google Scholar] [CrossRef]

- Grabarczyk, J.; Batory, D.; Kaczorowski, W.; Pązik, B.; Januszewicz, B.; Burnat, B.; Czerniak-Reczulska, M.; Makówka, M.; Niedzielski, P. Comparison of Different Thermo-Chemical Treatments Methods of Ti-6Al-4V Alloy in Terms of Tribological and Corrosion Properties. Materials 2020, 13, 5192. [Google Scholar] [CrossRef]

- Oliveira, V.M.C.A.D.; Aguiar, C.; Vazquez, A.M.; Robin, A.L.M.; Barboza, M.J.R. Corrosion Behavior Analysis of Plasma-assited PVD Coated Ti-6Al-4V alloy in 2 M NaOH Solution. J. Mater. Res. 2017, 20, 436–444. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Z.; Chen, J.; Ma, Y.; Yan, Y.; Qiao, L. Effect of frictional frequency on the subsurface evolution of 316L stainless steel in tribocorrosion and its influence on the synergistic effect between corrosion and wear. Tribol. Int. 2023, 178, 108026. [Google Scholar] [CrossRef]

- Sun, Y.; Bailey, R. Comparison of Wear Performance of Low Temperature Nitrided and Carburized 316L Stainless Steel under Dry Sliding and Corrosive-Wear Conditions. J. Mater. Eng. Perform. 2023, 32, 1238–1247. [Google Scholar] [CrossRef]

- Su, Z.; Jie, X.; Li, W.; Liao, Z.; Li, Y.; Zhu, W. Effect of C2H2 flow rate and a Ti/TiN/TiCN interlayer on the structure, mechanical and tribological properties of a-C:H films deposited using a hybrid PVD/PECVD process with an anode-layer ion source. Vacuum 2023, 209, 111753. [Google Scholar] [CrossRef]

- Fangaia, S.I.G.; Messias, A.; Guerra, F.A.D.R.A.; Ribeiro, A.C.F.; Valente, A.J.M.; Nicolau, P.M.G. Evaluation of the Tribocorrosion Behavior of Ti-6Al-4V Biomedical Alloy in Simulated Oral Environments. Processes 2024, 12, 1283. [Google Scholar] [CrossRef]

- Elshaer, R.N.; Ibrahim, K.M. Study of Microstructure, Mechanical Properties, and Corrosion Behavior of As-Cast Ni-Ti and Ti-6Al-4V Alloys. J. Mater. Eng. Perform. 2023, 32, 7831–7845. [Google Scholar] [CrossRef]

- Wei, G.; Tan, M.; Attarilar, S.; Li, J.; Uglov, V.V.; Wang, B.; Liu, J.; Lu, L.; Wang, L. An overview of surface modification, A way toward fabrication of nascent biomedical Ti–6Al–4V alloys. J. Mater. Res. Technol. 2023, 24, 5896–5921. [Google Scholar] [CrossRef]

- Bahi, R.; Nouveau, C.; Beliardouh, N.E.; Ramoul, C.E.; Meddah, S.; Ghelloudj, O. Surface performances of Ti-6Al-4V substrates coated PVD multilayered films in biological environments. Surf. Coat. Technol. 2020, 385, 125412. [Google Scholar] [CrossRef]

- Fazel, Z.A.; Elmkhah, H.; Fattah-Alhosseini, A.; Babaei, K.; Meghdari, M. Comparing electrochemical behavior of applied CrN/TiN nanoscale multilayer and TiN single-layer coatings deposited by CAE-PVD method. J. Asian Ceram. Soc. 2020, 8, 510–518. [Google Scholar] [CrossRef]

- Sarraf, M.; Razak, B.A.; Nasiri-Tabrizi, B.; Dabbagh, A.; Kasim, N.H.A.; Basirun, W.J.; Bin Sulaiman, E. Nanomechanical properties, wear resistance and in-vitro characterization of Ta2O5 nanotubes coating on biomedical grade Ti–6Al–4V. J. Mech. Behav. Biomed. Mater. 2017, 66, 159–171. [Google Scholar] [CrossRef]

- Ferreira, M.O.A.; Morgado, V.A.F.; dos Santos, K.R.; Gelamo, R.V.; Mariani, F.E.; Slade, N.B.L.; Morais, M.M.; Fortulan, C.A.; Galo, R.; Jasinevicius, R.G.; et al. Enhancing the wear performance of 316L stainless steel with Nb2O5 coatings deposited via DC sputtering at room temperature under varied environmental conditions. Lubricants 2024, 12, 345. [Google Scholar] [CrossRef]

- Ferreira, M.O.A.; Santos, K.R.; Mariani, F.E.; Gelamo, R.V.; Leite Slade, N.B.; Morais, M.M.; Fortulan, C.A.; Pinto, H.C.; Moreto, J.A. Highlighting the significant potential of Nb2O5 and a-C coatings to improve the wear and corrosion resistance of 316L stainless steel. Emergent Mater. 2025. [Google Scholar] [CrossRef]

- Instituto Brasileiro de Mineração. Plano Estadual da Mineração—Diagnóstico do Setor Mineral de Minas Gerais 2021. Available online: https://ibram.org.br/wp-content/uploads/2021/02/PEM-MG.pdf (accessed on 22 February 2025).

- Machuno, L.G.B.; Lima, A.B.; Buso, R.R.; Abdanur, R.M.F.; Rangel, E.C.; Gelamo, R.V. Desenvolvimento e avaliação de uma fonte DC de alta tensão para utilização em sistema de deposição de filmes finos por pulverização catódica. Matéria 2016, 21, 492–500. [Google Scholar] [CrossRef]

- ASTM B348-13; Standard Specification for Titanium and Titanium Alloy Bars and Billets. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM G99-05; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2005.

- Zaniboni, J.F.; Silva, A.M.; Alencar, C.D.; Porto, T.S.; Jasinevicius, R.G.; Fortulan, C.A.; de Campos, E.A. Influence of different glaze firing protocols on the mechanical properties of CAD-CAM ceramic materials. J. Prosthet. Dent. 2022, 127, 925.e1–925.e8. [Google Scholar] [CrossRef]

- Tkachuk, O.V.; Sheykin, S.E.; Lavrys, S.M.; Rostotskii, I.Y.; Danyliak, M.-O.M.; Pohrelyuk, I.M.; Proskurnyak, R.V. Effect of stage gas nitriding on corrosion and wear resistance of Ti6Al4V alloy in physiological environment. Vacuum 2024, 230, 113713. [Google Scholar] [CrossRef]

- Lemm, J.D.; Warmuth, A.R.; Pearson, S.R.; Shipway, P.H. The influence of surface hardness on the fretting wear of steel pairs—Its role in debris retention in the contact. Tribol. Int. 2015, 81, 258–266. [Google Scholar] [CrossRef]

- Grymak, A.; Aarts, J.M.; Cameron, A.B.; Choi, J.J.E. Evaluation of wear resistance and surface properties of additively manufactured restorative dental materials. J. Dent. 2024, 147, 105120. [Google Scholar] [CrossRef]

- Tao, H.; Zhylinski, V.; Vereschaka, A.; Chayeuski, V.; Yuanming, H.; Milovich, F.; Sotova, C.; Seleznev, A.; Salychits, O. Comparison of the Mechanical Properties and Corrosion Resistance of the Cr-CrN, Ti-TiN, Zr-ZrN, and Mo-MoN Coatings. Coatings 2023, 13, 750. [Google Scholar] [CrossRef]

- Mercer, A.P.; Hutchings, I.M. The influence of atmospheric composition on the abrasive wear of titanium and Ti-6Al-4V. Wear 1988, 124, 165–176. [Google Scholar] [CrossRef]

- Cui, X.H.; Mao, Y.S.; Wei, M.X.; Wang, S.Q. Wear characteristics of Ti-6Al-4V alloy at 20–400 °C. Tribol. Trans. 2012, 55, 185–190. [Google Scholar] [CrossRef]

- Bergmann, B.; Schaper, F. Study of the effect of oxygen level on tool wear in machining Ti-6Al-4V. CIRP Ann. 2024, 73, 41–44. [Google Scholar] [CrossRef]

- Biswas, A.; Srikant, P.V.S.; Manna, I.; Chatterjee, U.K.; Dutta Majumdar, J. Chemical oxidation of Ti–6Al–4V for improved wear and corrosion resistance. Surf. Eng. 2008, 24, 442–446. [Google Scholar] [CrossRef]

- Ahmad, K.; Batool, S.A.; Farooq, M.T.; Minhas, B.; Manzur, J.; Yasir, M.; Wadood, A.; Avcu, E.; Ur Rehman, M.A. Corrosion, surface, and tribological behavior of electrophoretically deposited polyether ether ketone coatings on 316L stainless steel for orthopedic applications. J. Mech. Behav. Biomed. Mater. 2023, 148, 106188. [Google Scholar] [CrossRef]

- Vinothraj, U.T.; Xavior, M.A. Wear and Frictional Behaviour of Additive Manufactured SS 316L Through Powder Bed Fusion. J. Appl. Sci. Eng. 2024, 27, 3601–3612. [Google Scholar] [CrossRef]

- Fazel, Z.A.; Elmkhah, H.; Molaei, M.; Riahi-Noori, N.; Fattah-alhosseini, A. Corrosion behavior of TiN monolayer and CrN/TiN multilayer coatings: Impact of immersion time and saline solution type. Int. J. Appl. Ceram. Tech. 2024, 21, 4270–4279. [Google Scholar] [CrossRef]

- Moreto, J.A.; Rodrigues, A.C.; Leite, R.R.D.S.; Rossi, A.; Silva, L.A.D.; Alves, V.A. Effect of Temperature, Electrolyte Composition and Immersion Time on the Electrochemical Corrosion Behavior of CoCrMo Implant Alloy Exposed to Physiological Serum and Hank’s Solution. Mater. Res. 2018, 21, e20170659. [Google Scholar] [CrossRef]

- Liu, X.-B.; Meng, X.-J.; Liu, H.-Q.; Shi, G.-L.; Wu, S.-H.; Sun, C.-F.; Wang, M.-D.; Qi, L.-H. Development and characterization of laser clad high temperature self-lubricating wear resistant composite coatings on Ti–6Al–4V alloy. Mater. Des. 2014, 55, 404–409. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.; Chen, C.; Liu, J.; Zhao, L.; Dai, J.; Zhao, Z. Effect of process parameters on the microstructure evolution and wear property of the laser cladding coatings on Ti-6Al-4V alloy. J. Alloys Compd. 2017, 692, 989–996. [Google Scholar] [CrossRef]

| Chemical Composition | % Weight |

|---|---|

| Glucitol | 20 |

| AS concentrate | 10 |

| CMC (Thickener) | 0.3 |

| Phenochem+ | 0.2 |

| Deionized water | Balance |

| Conditions | Ti-6Al-4V | Ti-6Al-4V/Nb2O5 | ||||

|---|---|---|---|---|---|---|

| Air | 0.12 | ± | 0.01 | 0.16 | ± | 0.01 |

| AS-0 h | 0.35 | ± | 0.03 | 0.36 | ± | 0.04 |

| AS-24 h | 0.33 | ± | 0.02 | 0.33 | ± | 0.03 |

| Condition | Sample | Track Depth | Track Width | Wear Volume |

|---|---|---|---|---|

| (µm) | (mm) | (mm3) | ||

| Air | Ti-6Al-4V | 6.21 ± 0.87 | 0.42 ± 0.02 | 2.77 × 10−2 ± 0.32 × 10−2 |

| Ti-6Al-4V/Nb2O5 | 0.58 ± 0.19 | 0.21 ± 0.01 | 3.32 × 10−3 ± 0.11 × 10−3 | |

| AS—0 h | Ti-6Al-4V | 4.01 ± 0.56 | 0.35 ± 0.01 | 1.69 × 10−2 ± 0.16 × 10−2 |

| Ti-6Al-4V/Nb2O5 | 4.61 ± 0.18 | 0.31 ± 0.01 | 1.16 × 10−2 ± 0.12 × 10−2 | |

| AS—24 h | Ti-6Al-4V | 4.87 ± 0.39 | 0.39 ± 0.02 | 2.34 × 10−2 ± 0.30 × 10−2 |

| Ti-6Al-4V/Nb2O5 | 4.27 ± 0.38 | 0.34 ± 0.01 | 1.54 × 10−2 ± 0.18 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, M.O.A.; Wolf, W.; Gelamo, R.V.; Slade, N.B.L.; Galo, R.; Jasinevicius, R.G.; Fortulan, C.A.; Moreto, J.A. Advances in Enhancing the Wear Performance of Ti-6Al-4V Biomedical Alloy Through Nb2O5 Coating. Materials 2025, 18, 1593. https://doi.org/10.3390/ma18071593

Ferreira MOA, Wolf W, Gelamo RV, Slade NBL, Galo R, Jasinevicius RG, Fortulan CA, Moreto JA. Advances in Enhancing the Wear Performance of Ti-6Al-4V Biomedical Alloy Through Nb2O5 Coating. Materials. 2025; 18(7):1593. https://doi.org/10.3390/ma18071593

Chicago/Turabian StyleFerreira, Murilo Oliveira Alves, Witor Wolf, Rogério Valentim Gelamo, Natália Bueno Leite Slade, Rodrigo Galo, Renato Goulart Jasinevicius, Carlos Alberto Fortulan, and Jéferson Aparecido Moreto. 2025. "Advances in Enhancing the Wear Performance of Ti-6Al-4V Biomedical Alloy Through Nb2O5 Coating" Materials 18, no. 7: 1593. https://doi.org/10.3390/ma18071593

APA StyleFerreira, M. O. A., Wolf, W., Gelamo, R. V., Slade, N. B. L., Galo, R., Jasinevicius, R. G., Fortulan, C. A., & Moreto, J. A. (2025). Advances in Enhancing the Wear Performance of Ti-6Al-4V Biomedical Alloy Through Nb2O5 Coating. Materials, 18(7), 1593. https://doi.org/10.3390/ma18071593