1. Introduction

The global 3D printing market is expected to register a compound annual growth rate of 23.5% from 2024 to 2030 [

1]. This indicates that 3D printing is constantly being used more widely. 3D printing is usually not associated with manufacturing, since in many cases it is more time-consuming than conventional technologies. In addition, there are many problems and difficulties in 3D printing [

2]. Prints often fail due to nozzle clogging or the print peeling off. Sometimes, the quality and accuracy of prints are insufficient. Despite this, in some areas of manufacturing 3D printing offers significant benefits. Verhoef et al. [

3] indicate that the use of 3D printing allows for shortening supply chains and, due to this, energy savings can amount to up to 25%. In addition, for conventional manufacturing technologies such as milling, up to 90% of material is lost during machining, whereas in 3D printing there is no such material loss [

4]. Moreover, the use of 3D printing for production allows for obtaining components of between 5% and 95% lighter weight than their traditionally manufactured parts. It is worth noting that traditional manufacturing methods (injection moulding or die casting) require tooling, and tooling costs can be over 80% of total production costs [

5,

6].

3D FDM (Fused Deposition Modelling) printing is one of the cheapest and easiest methods of 3D printing. Even though this method does not require expensive and advanced equipment, it allows us to produce various elements with customised geometries at a low cost [

7]. For instance, thanks to 3D FDM printing the production bench equipment which is tailored to the component being processed can be created [

8]. 3D FDM printing is also commonly used to produce fixtures/mounts for various types of processes [

9,

10,

11]. In this type of usage, printed components are very often exposed to abrasion. Furthermore, the printed components may come into direct contact with abrasive material [

12]. Thus, it would be valuable to know what material used in 3D printing provides good abrasion resistance.

Due to the great popularity of FDM 3D printing, research work related to it is still being carried out. Above all, new materials are being implemented, as well as the composites based on thermoplastic polymers already used in 3D FDM printing. These are characterised by an increased thermal conductivity [

13] or biodegradability [

14,

15,

16,

17]. What is more, much attention is being given to the 3D printing process itself and its improvement [

18,

19]. An important issue is also the determination of properties of 3D prints to apply printed components successfully in new areas. This can include, for example, testing the tribological properties of 3D FDM prints so that they can work with other materials.

The tribological properties of 3D FDM prints are mainly studied to determine the coefficient of friction and wear during sliding on steel [

20,

21,

22,

23,

24,

25,

26,

27]. It is possible to find papers presenting the abrasion resistance of 3D prints; however, there are limited studies about this issue. Abrasion resistance tests are often aimed at deciding whether 3D prints are suitable for specific applications, e.g., shoe heels or shoe bottoms [

28], or foundry models [

29]. There are also studies that aim to analyse the abrasion process of 3D prints. Suresha et al. [

30] introduced Short Carbon Fibers (SCFs) to polylactide (PLA) and acrylonitrile butadiene styrene (ABS). However, the effects of SCFs on the abrasive wear of PLA and ABS composites proved to be not always positive. The mentioned studies concern only the two most popular materials in FDM 3D printing, i.e., PLA and ABS. Furthermore, no comparison of abrasion resistance of printed and extruded materials was found in the literature.

In the literature, analyses of the abrasion process of various materials with a solid structure (e.g., extruded or cast) can be found; however, there is little information about this process for various materials with a structure specific to FDM 3D printing. For this reason, the abrasion resistance of components made from the same material but with different technologies—3D printing and extrusion—was compared. The abrasion resistance was determined for the eight most commonly used materials in 3D FDM printing. In this way, it can be determined whether the statements formulated for a solid structure are suitable for a 3D FDM printing structure.

2. Materials and Methods

Wear resistance was measured during the tests. Wear resistance is influenced by, among other things: the hardness of the material, its stiffness, or the condition of the surface [

31]. In view of this, the research was extended to include measurements of hardness and Young’s modulus, as well as an assessment of the surface of the samples using a microscope and profilometer. The specimens studied were made using FDM 3D printing technology and cut from extruded plates.

2.1. Preparation of Samples

Samples were made according to the guidelines of GOST 23.208-79 standard. The samples were cuboids with dimensions of 30 mm × 30 mm × 2 mm (width × length × thickness) (

Figure 1).

2.1.1. 3D Printed Samples

The samples were made on a 3D printer working in FDM technology: the Zortrax M300 Dual (Olsztyn, Poland). The machine is equipped with a heated bed and a closed chamber (without heating the air in the chamber). Samples were printed from eight materials that are most commonly used in FDM 3D printing [

22] (

Table 1): polylactide (PLA), polyethylene terephthalate glycol-modified (PET-G), acrylonitrile butadiene styrene (ABS), polyamide 12 (PA12), polypropylene (PP), polycarbonate (PC), poly (methyl methacrylate) (PMMA) and high-impact polystyrene (HIPS). Filaments of the first four materials (PLA, PET-G, ABS and PA12) were purchased from the printer manufacturer (Zortrax, Olsztyn, Poland); the next (PC, PMMA, HIPS) were supplied by F3D Filament (Finnotech, Katowice, Poland), and the polypropylene (PP) filament, which was not available from the aforementioned manufacturers, came from the manufacturer Fiberlogy, Brzezie, Poland. The filaments which were used had a diameter of 1.75 mm. The most important material processing parameters for printing, i.e., nozzle temperature and bed temperature, are shown in

Table 1.

The 3D model of the sample was uploaded to Z-SUITE software version 3.5.0 (software provided by the printer manufacturer Zortrax, Olsztyn, Poland). With the help of this software, printer control files were obtained. The key parameters for the application of the material path of printing process are listed in

Table 2. The nozzle diameter, layer height and number of contour paths corresponded to the most commonly used parameters during 3D FDM printing. Infill was also laid out in the most common way at an angle of 45° to the edge of the sample (

Figure 2) (the fill of the next layer was laid out at an angle of 90° to the fill of the previous layer). The density of the infill was set at 100% (full infill) and no space was derived between the contour and the infill, so as to achieve a large infill and a strong merging of the infill with the contour. It appears that this will be beneficial in terms of abrasion resistance.

2.1.2. Samples Cut from Extruded Plates

Due to the time-consuming nature of the 3D printing process, it is mainly used for one-off or short-run production. The study was designed to provide information on whether it is more advantageous to produce a component using a 3D printer or to use conventional manufacturing methods, taking into account abrasion resistance. Conventional manufacturing methods are understood as the use of prefabricated plastic parts and their further processing and assembly. Prefabricated plastic parts are mainly obtained by extrusion. For this reason, the test specimens were cut from extruded sheets. Plates with a thickness of 2 mm were obtained from the Polish representative office of Plastics International. The samples cut from the plates had the same dimensions as the printed samples (30 mm × 30 mm × 2 mm—

Figure 1). The same set of materials was used as for the printed samples shown in

Table 1 (except for polyamide—explained in the next paragraph).

In the case of polyamide, polyamide 12 was used for the printed samples and polyamide 6 for the samples cut from extruded plates. These materials belong to the same group; however, they differ in chemical structure and properties.

When producing sheets, PA6 is overwhelmingly used, whereas sheets made of PA12 are rare. When producing filaments for FDM 3D printers, the opposite is true: PA12 is by far the predominant material and PA6 is rare.

It was decided to compare samples printed from PA12 against samples extruded from PA6, as the main aim of the research was to indicate whether 3D printing or prefabricated parts are better to use for the production of a component. Such a comparison will be more beneficial for 3D printer users, as it will help them decide whether to purchase a filament or a prefabricated part. Comparing the same grades of polyamide (PA6 sheet versus PA6 print and PA12 sheet versus PA12 print) would have made the research more scientific, but would have deprived it of the practical conclusions that the authors cared more about.

2.2. Abrasion Resistance Measurement

Wear resistance was measured using a T-07 tester manufactured by MCNEMiT in Radom, Poland. This device carries out wear resistance tests according to the guidelines contained in GOST 23.208-79 standard. The described method of testing is very similar to the more widely used ASTM G65-16 standard. An abrasive is continuously introduced between a rotating steel disc with a rubber rim and the sample (

Figure 3). An abrasive was an electrocorundum indicated as 90. An electrocorundum is a synthetically produced form of aluminium oxide Al

2O

3 with regular and sharp crystals. The indication 90 states that the grain size of the abrasive ranged from 125 to 180 µm (according to PN-76/M-59115 standard).

The abrasive interacted with the sample causing it to lose mass. The mass loss was determined by weighing the sample before and after the test. However, the results were presented as a volume loss. The volume of material removed was calculated using the change in material mass and density. The material density of the sample was obtained by measuring its mass and dimensions (the volume of the sample was calculated from the dimensions).

Detailed apparatus and measurement parameters are included in

Table 3.

2.3. Microhardness

An HMV-2 microhardness tester (Shimadzu, Kyoto, Japan) was used during the research. For the Vickers microhardness measurements, the lowest load (98.07 mN) and the lowest load time (5 s) were used. The 3D printed PP was so flexible that no imprint was observed on it using the Vickers method. For this reason, the hardness of the PP was measured with a Sauter HDD 100-1 hardness tester showing values on the Shore D hardness scale. The Shore method involves determining the depth to which the intender penetrated the material. The Vickers method involves making an imprint with the pyramid-shaped intender, measuring the imprint’s diagonal and calculating the hardness (

HV) from the Formula:

where:

F—sample size the force applied to the intender;

A—the surface area of the imprint;

ddiagonal length of the imprint;

136°—angle between opposite faces of a pyramid-shaped intender.

2.4. Young’s Modulus

The calculation of the Young’s modulus (

E) was made using the three-point method for bending on the basis of the PN-82/C-89051 standard (

Figure 4). The samples made for testing had the shape of 10 mm × 4 mm beams. During the tests, the sample was evenly loaded to a maximum force equal to 5 N, the load was maintained for 20 s, and then the sample was evenly unloaded until the load was completely removed. The value of the Young’s modulus was calculated using mathematical Formula (2).

where:

F—force applied to the beam;

L—distance between supports;

z—deflection;

b—beam width;

h—beam height.

2.5. Sample Surface Evaluation

The surface parameters of the samples were evaluated using various methods. A ZEISS Discovery V12 optical microscope (Carl Zeiss, Jena, Germany) and SEM Phenom PRO X (ThermoFisher Scientific, Waltham, MA, USA) were used to assess the surface of the studied materials after tribological tests. A backscattered electron detector working in the topographic mode was used during the examinations of the SEM microscope at the accelerating voltage of 15 kV. A Leica DCM8 3D profilometer (Leica Microsystems, Wetzlar, Germany) was used to analyse the topography and quantify of the wear after testing. To describe the roughness of the surface, a Sa parameter (arithmetic mean height) was used since it provides a comprehensive representation of the overall surface topography. Sa is not sensitive to the occurrence of isolated peaks or valleys, as is the case with other parameters such as Sz or Sp. This is particularly important in abrasive processes, where material removal occurs uniformly over the surface. Furthermore, Sa is widely used in characterizing surfaces machined by abrasive techniques, which facilitates comparison with results presented in the literature.

2.6. Statistical Analysis

When presenting the results, the average value and the expanded uncertainty were given. The expanded uncertainty (

U) was calculated using Formula (3):

where:

k—coverage factor (k = 2);

S—standard deviation;

n—number of measurements.

In order to determine the relationship between two properties (e.g., volume loss and hardness), the Pearson correlation coefficient (

PCC) was calculated using the following equation:

where:

n—the sample size;

x—the individual sample points indexed with i;

the sample mean;

y—the individual sample points indexed with i;

—the sample mean.

When the obtained results were compared, the percentage difference between them was given. The percentage differences (Δ) were calculated taking into account the average values of the measured values. Additionally, the minimum (Δ

min) and maximum (Δ

max) percentage differences were calculated. The obtained expanded uncertainty ranges were used for this purpose. The maximum percentage difference was given as the ratio of the average value increased by the expanded uncertainty value to the average value reduced by the expanded uncertainty value. The minimum percentage difference was given as the ratio of the average value reduced by the expanded uncertainty value to the average value increased by the expanded uncertainty value. The following formulas were used for these calculations Equations (5)–(7):

where:

—the sample mean;

—the sample mean.

where:

the sample mean;

—the sample mean;

U—the expanded uncertainty.

where:

—the sample mean;

—the sample mean;

U—the expanded uncertainty.

The percentage difference between the average values is given before the brackets. The range in which the percentage difference is located with the measurement uncertainty taken into account is given within the brackets. Analysis of the given ranges allowed us to find out if the observed differences between the examined samples are statistically significant. This illustrates whether for each value in the expanded uncertainty range the compared results are larger, smaller, or there is no certainty about this since observed differences among the examined samples are statistically insignificant.

3. Results

The chapter presents the results of abrasion resistance, hardness and Young’s modulus tests. In addition, the surface of the specimens is presented using an SEM microscope and profilometer.

3.1. Abrasion Resistance

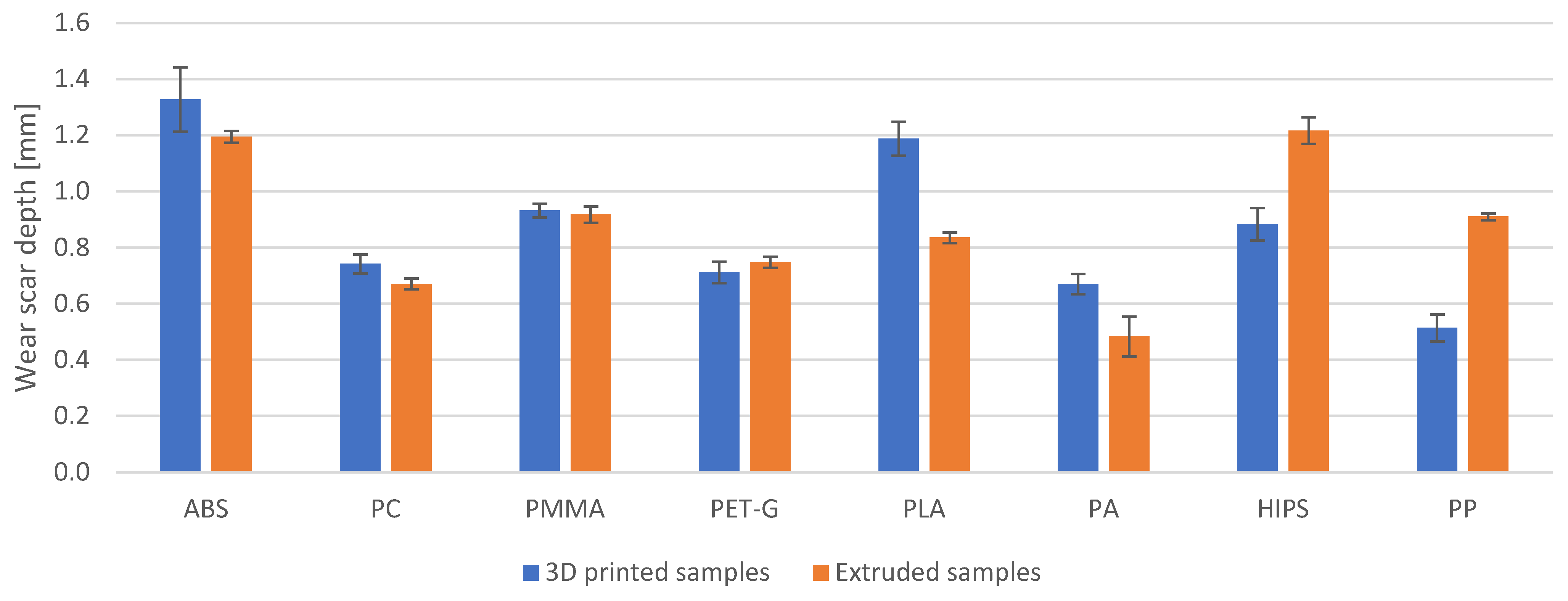

For six out of the eight samples tested, the extruded materials proved to be more resistant to abrasive wear than the printed ones (

Figure 5). In the majority of cases (

Table 4), the extruded samples had an abrasion wear resistance higher by about 10% (PET-G) to 20% (PC). The results obtained for PP, PA and HIPS break out of this trend. For PP and HIPS, the extruded sample had a lower abrasion wear resistance (by about 34% for PP and 16% for HIPS). For PA, the extruded sample was 75% more resistant to abrasive wear.

In addition, the wear scar depth at half its width was determined using a profilometer (

Figure 6). The depth of the wear scar is not constant over its entire width. What is more, the profile obtained halfway across the width of the wear scar will be slightly different to the profile obtained near the edge of the wear scar. For this reason, the volume loss (

Figure 5) is the most reliable. Thus, the analysis presented in this paper was based on the volume wear results. Nevertheless, the depth of the wear scar also provided valuable information.

The obtained wear scar depths are shown in

Figure 7, whereas the percentage differences in wear scar depth for the printed and extruded samples are given in

Table 5. While comparing the changes in volume loss and wear scar depth with each other (

Table 4 and

Table 5), it can be seen that they mostly differ by a few percentage points. This is most likely due to the fact that the wear scar is not a perfect section of the cylinder (as described in the paragraph above).

Furthermore, the values obtained for the PA and PP appear to be worth mentioning. Namely, the differences for these materials are 46.8 percentage points for PA and 43.1 for PP. Such significant differences indicate that the shape of the wear scar deviates significantly from a portion of a cylindrical surface with a circular cross-section. The 3D scans from the profilometer confirm this phenomenon (

Figure 8). Such a different geometry of the wear scar is most likely due to the different properties of PA and PP when printed and extruded. The other materials do not show such significantly different wear scar geometries.

3.2. Density

Density calculations of the printed and extruded samples were also performed during the study. The density was calculated from the measured weight and dimensions of the sample. The results are shown in

Figure 9 and

Table 6. The density of the printed samples was lower for seven of the eight materials tested. Only for the PP was there no difference in density between the printed and extruded sample. For the ABS, PC, PMMA, PA and PET-G, the differences are significant and are in the range of 23% (PET-G) to almost 39% (PC). For the PLA and HIPS, the differences are minor at 3.5% and 4%, respectively.

The correlation coefficient between volume loss and density for extruded samples was 0.73, while for printed samples it was only 0.17. It should be concluded that for extruded samples there is a clear correlation, while for printed samples there is no correlation between density and abrasion resistance.

3.3. Hardness

Microhardness measurements show that the majority of the extruded samples had a higher microhardness than the printed ones (

Figure 10). The differences in values ranged from about 9% to as much as 258% (

Table 7). The exception was ABS, for which the extruded samples had a microhardness about 7% lower than printed samples. The correlation coefficient between volume loss and microhardness for the extruded samples was 0.62, while for the printed samples it was only 0.08. It should be concluded that for the extruded samples there is a clear correlation between microhardness and abrasion resistance, whereas for the printed samples there is no such correlation. In the case of printed polypropylene, the material was so flexible that it was not possible to obtain an imprint on the surface and measure the microhardness. For this reason, the hardness of the PP is given on the Shore D hardness scale (

Figure 10b). The extruded PP sample is 1.63 times harder than the 3D printed sample.

3.4. Surface Topography

The examination of the specimen surface with a profilometer allowed the roughness parameter Sa to be determined (

Figure 11). The roughness parameter Sa was defined for the surface of the specimen before the abrasion test (

Table 8) as well as for the wear scar surface after the test (

Table 9). No correlation between the surface Sa parameter and the fabrication method of the sample was found. For ABS and PP materials, the Sa values for printed and extruded samples are similar, for PET-G, PLA and HIPS the Sa of printed samples is higher than that of extruded samples, and for PC, PMMA and PA the Sa of printed samples is lower than that of extruded samples.

The correlation coefficient between volume loss and the value of the parameter Sa of the sample’s surface for the extruded samples was 0.55, whereas for the printed samples it was 0.36. It ought to be noted that for the extruded samples there is a correlation between sample surface roughness and abrasion resistance, whereas for the printed samples there is no such significant correlation.

Similar observations were noted in studies on the abrasion sensitivity of engineering polymers and biocomposites, where the effect of surface roughness on abrasion resistance depended on the type of material and test conditions [

32].

The correlation coefficient between volume loss and the value of the parameter Sa of the wear scar surface for extruded samples was 0.52, and for printed samples it was 0.45. No significant correlation between wear scar surface roughness and abrasion resistance was observed.

The correlation coefficient between hardness and roughness of the wear scar surface (the value of the parameter Sa) for extruded samples was 0.18, and for printed samples it was 0.52. For extruded samples with a homogeneous and compact structure, the effect of hardness on the roughness of the wear scar surface is low. For 3D printed samples, this effect is not significant but is slightly noticeable. It is possible that the structure of 3D prints consisting of paths and layers intensifies the effect of hardness on wear.

3.5. Microscopic Observations

Despite printing at full fill (100%), the surface of the printed sample showed clear traces created by the movement of the nozzle (

Figure 12a). The wear scar that could be observed on the sample revealed existing layers inside the sample, on which the paths applied by the nozzle are also clearly visible (

Figure 12b,c). In the case of the extruded sample, only minor scratches from the cutting of the samples from the plates are visible on the surface (

Figure 12d). The observed wear scar revealed a compact and homogeneous structure within the material (

Figure 12e,f).

The analysis of the images obtained with the SEM microscope appears to confirm the influence of hardness on the abrasive wear process (a clear correlation between microhardness and abrasion resistance was found for extruded samples,

Section 3.4—hardness). The images of extruded samples with a higher hardness had significantly different characteristics on the surface than those with a lower hardness. For the extruded plastics of a lower hardness (ABS, PLA), while observing the wear scar, more electrocorundum grains were observed pressed into the plastic (

Figure 13a) than for the samples of a higher hardness (

Figure 13b) (PC, PMMA, PET-G, PA, HIPS). For the samples with a higher hardness, clearly visible scratches oriented parallel to the direction of rotation of the rubber rim appeared on the wear scar. Moreover, the pressed electrocorundum particles were smaller in size. It is likely that due to the significant hardness of the surface, the electrocorundum particles did not penetrate the material as easily, but were first moved and worked around it. As a result, the particles fragmented and left the scratches.

The surfaces of the wear scar for the 3D-printed specimens looked significantly different from those of the extruded specimens. For the extruded specimens, a surface with no detachments from the material was observed. On the other hand, for printed samples, surface deformation was observed. It was in the form of detached material particles resembling threads protruding above the wear scar surface (

Figure 14a,b). Such a deformation most likely appeared as the result of a material delamination. It is very possible that larger fragments of material were detached during the wear process. Furthermore, it is also possible that there were connections between the specimen and the piece being torn off. Connections might be torn apart after the piece has been completely detached, leaving fragments in the form of the previously mentioned threads. The shape of the deformation depends on the irregularities and the size of the abrasive particles.

Scratches oriented perpendicular to the direction of the roll rotation were observed on the surface of the wear scar. In terms of the printed specimens, the scratches were oriented parallel to the direction of the rim rotation. The grooves between the paths of the applied material (shown in the optical microscope images—

Figure 12a) were oriented at an angle of 45° to the direction of the roll rotation. It is likely that the abrasive fell into these grooves and was guided through them, resulting in a perpendicular scratch.

On the surface of the wear scar for the printed samples, “pressed, smushed” fragments of plastic were also visible (

Figure 14c,d). It is probable these fragments had become detached from the sample and were later pressed into the surface by the rubber rim.

3.6. Young’s Modulus

Young’s modulus tests were carried out only for the PP, as only in this case was a noticeably significant difference in the stiffness of the printed and extruded samples observed. The beam deflection tests show that the Young’s modulus of the printed PP is 0.395 ± 0.027 GPa, which is more than four times lower than the Young’s modulus of the extruded PP of 1.760 ± 0.026 GPa (

Figure 15).

4. Discussion

The tested plastics significantly differed from each other and presented a wide spectrum of properties. Despite these differences, it can be stated that extruded samples are more resistant to abrasive wear than 3D-printed samples (six out of the eight extruded materials appeared to be more resistant to abrasive wear). The first part of the discussion tries to explain this phenomenon. The second part focuses on the materials for which extruded samples are less resistant to abrasive wear.

The extruded samples are from 9% to 22% more abrasion-resistant than the printed ones. The abrasion resistance of the extruded samples is dependent on factors reported in the literature such as hardness, density and surface roughness (proved by the values of the correlation coefficients). In the case of 3D-printed samples, no such correlation was found (proved by the values of the correlation coefficients). For this reason, the researchers of the current study believe that the explanation for the reduced abrasion resistance of printed samples should be sought by analysing their internal structure.

On the basis of the surface topography measurements, it may be stated that the surface of the 3D-printed specimens is quite similar to that of the extruded materials, as quite similar roughness values were obtained after measurements. However, macroscopically, grooves parallel to each other are present on the surface of the printed samples. Such grooves are a result of laid paths of molten material. It is possible that at the beginning of the interaction between the abrasive and the sample, the abrasive material catches on the surface with greater intensity as a result of the presence of these grooves.

The interior of the printed sample was also made up of layered parallel paths. When one layer was removed as a result of wear, another layer was exposed, on which the grooves were also present. Most likely, the internal inhomogeneity of the samples is another factor that increases the intensity of abrasive wear.

Subramaniyan et al. [

24] indicate that even at a 100% fill, there are wear-increasing voids in the printed sample, and the layered structure of the print promotes layer delamination and increased wear.

The 3D-printed parts may have lower strength than the extruded parts [

25]. Furthermore, the strength of 3D prints is dependent on the orientation of the force direction relative to the direction of the applied paths [

26]. It is also very likely that during abrasive wear, fragments of the 3D-printed samples detach more easily in comparison to the extruded samples.

Extruded samples are from 9% to 22% more abrasion-resistant than printed samples.

An extruded PA sample was 75% more abrasion-resistant than a printed sample (for the other plastics tested, this difference is in the range of 9% to 22%). It is important to explain why there is such a large difference. In the case of polyamide, polyamide 12 was tested for printed samples and polyamide 6 for samples cut from extruded sheets. These materials belong to the same group, but differ in chemical structure and properties. For the production of plates, PA6 is used overwhelmingly; plates with PA12 are rare. When producing filaments for FDM 3D printers, the opposite is true: PA12 is by far the predominant material and PA6 is rare. Moreover, it is likely that the difference in PA grade is the reason for the variation in wear scar geometry (

Section 3.1. abrasion resistance,

Figure 8).

As the main aim of the study was to indicate whether 3D printing or prefabricated parts are better to use for the production of a component, it was decided to compare samples printed from PA12 against samples extruded from PA6. Such a comparison ought to be more beneficial for 3D printer users, as it will help them decide whether to purchase a filament or a prefabricated part. Comparing the same grades of polyamide (PA6 plate versus PA6 print and PA12 plate versus PA12 print) would have made the research more scientific, but would have deprived it of the practical applications that the authors cared more about.

The previously described regularity with which extruded samples were more resistant to abrasive wear than printed ones is not true for PP and HIPS. In the case of PP, a significant difference in the stiffness of the printed (Young’s modulus is 0.395 ± 0.027 GPa) and extruded (Young’s modulus is 1.760 ± 0.026 GPa) specimen was observed. Furthermore, the difference in stiffness became apparent during hardness measurements. When tested by the Vickers method for PP, the printed impression was not observed. During indentation, the material deflected and returned to its original shape when the indenter was withdrawn. For extruded PP, the imprint was visible. For this reason, the hardness of the PP was measured using a Shore D hardness tester. It is most likely that when the abrasive rolls over the surface of the printed PP, the lower stiffness causes the material to deflect and this minimises the abrasive catching on the sample. Extruded PP is not as flexible and, thus, the abrasive catches on the material more easily and causes more intense specimen weight loss.

The difference in PP stiffness most likely contributes to the different shape of the wear scar for printed and extruded PP (

Section 3.1. abrasion resistance,

Figure 8). The less stiff printed PP lays down more freely under the rubber rim, which results in more varied wear scar geometry. The stiffer extruded PP gives a more regular, cylindrical wear scar shape.

The difference in the hardness and stiffness of the printed and the extruded PP samples may be due to differences in processing parameters, which leads, among other things, to differences in the crystallization process and its evolution [

27].

HIPS is a polymer blend produced by in situ polymerisation of styrene in solution with polybutadiene rubber. Polybutadiene can have different particle configurations in the polymer chain, and as indicated by Rovere et al. it has strong influence on the mechanical properties [

28]. Material manufacturers very rarely provide information on the form of polybutadiene used in a given HIPS, and sometimes it is even a company secret. It is highly possible that the HIPS used for extruding the sheets and the HIPS used for 3D printing differ in the polybutadiene used, which affected the mechanical properties to such an extent that different abrasion resistance was obtained.

5. Conclusions

This paper presents a comparison of the abrasion resistance of FDM 3D prints and extruded materials. The abrasion resistance of 3D prints and extruded samples has already been analysed [

28,

29,

30]; however, these materials were analysed separately and their comparison was not available. The research presented in this paper has shown that almost all of the extruded samples (for six out of the eight materials tested) were more resistant to abrasive wear than the printed ones (between 10% and 24%).

The abrasion resistance of samples made by extrusion technology is dependent on factors reported in the literature, such as hardness, density and surface roughness. In the case of the 3D-printed samples, no such relationship was found. This is proved by the values of the correlation coefficients. For this reason, the researchers believe that the reduced abrasion wear resistance of printed samples is due to their internal structure.

In some cases, fabrication by the 3D printing led to a higher abrasion wear resistance (HIPS and PP) or was significantly different from the value obtained for the extruded sample (almost 75% difference for the PA). A material for 3D printing can be described by the same name but exhibit different properties. For example, in the case of PA, a different type of this material was used in 3D printing (PA6 for extrusion and a mixture of PA6 and PA 12 for 3D printing). Very often, material manufacturers simply call the material polyamide, and details about the polyamide types used can only be found in the detailed data. In the case of parts exposed to abrasive wear, when aiming to produce with FDM 3D printing a component that was previously made with extrusion technology, it should be verified that the filament used for 3D printing has the same properties as the material after extrusion.

In terms of elements that are exposed to abrasion, polymer-based composites are very often used. Plastics are reinforced with, among others, carbon or glass fibres, as well as graphite powders or molybdenum disulfide powders. In the next stages of research, it would be worth carrying out measurements for composites.