1. Introduction

Lattice cell structures (LCSs) are widely employed in applications that demand lightweight, high strength, and energy absorption, particularly in the aerospace, automotive, and biomedical fields. By leveraging their repeating unit cell patterns, LCSs significantly reduce weight and material consumption compared to solid parts. Their geometry can be tailored to meet specific mechanical requirements, such as stiffness and energy absorption, with various configurations designed to enhance buckling resistance and energy absorption efficiency. Due to these characteristics, LCSs have been extensively studied as core materials for sandwich panels in aerospace structures, where they can offer an optimal balance between mechanical performance and weight reduction [

1,

2].

The adoption of lattice structures in the aerospace and industrial sectors is currently limited by high costs and manufacturing complexity. Advanced additive technologies, such as Selective Laser Sintering (SLS), ensure high geometrical quality and superior mechanical properties, but their use is often economically prohibitive for large-volume components. Conversely, Fused Deposition Modeling (FDM) could represent a low-cost alternative that could make the production of lattice structures more accessible, particularly as substitutes for traditional polymer foams used in sandwich panels. However, FDM has intrinsic limitations related to printing resolution, material deposition, and the geometrical stability of thin elements. Consequently, it is crucial to assess to what extent FDM technology can ensure sufficient dimensional and geometrical accuracy for its use in aerospace structural components, identifying potential constraints that may limit its manufacturability.

ABS, a widely utilized engineering thermoplastic polymer, is also one of the most commonly employed materials in FDM. Its composition includes over 40% styrene, which provides rigidity and processability; acrylonitrile, which enhances chemical resistance and thermal stability; and butadiene, which contributes toughness and impact strength [

3,

4,

5]. ABS lattice structures have been used in lightweight components in the aerospace industry due to their high strength-to-weight ratios. In biomedical applications, they have been used due to their biocompatibility and factors such as layer adhesion, print orientation, and infill density.

The mechanical behavior of ABS lattice structures fabricated via FDM has been widely investigated, providing valuable insights into their bending, compression, and overall structural integrity. However, inherent material characteristics of ABS, such as thermal expansion and shrinkage, induce geometrical deviations both during and after the printing process. These deviations primarily result from the semi-molten state of ABS during extrusion, which leads to dimensional instability as the material undergoes cooling and solidification [

6]. To improve stiffness and thermal stability, carbon fiber reinforcement is commonly integrated into ABS. While this reinforcement enhances mechanical performance, it also introduces complexities in dimensional precision due to the anisotropic behavior introduced by the deposition process [

7].

Research has emphasized the pivotal role of lattice designs in optimizing performance. Design parameters, including process-induced anisotropy and infill architecture, require careful consideration. The layer-by-layer deposition characteristic of FDM introduces anisotropic behavior, resulting in geometrical distortions, particularly in complex lattice structures. However, design strategies that account for these anisotropic effects, such as density-variable topology optimization, can mitigate these deviations [

8]. Additionally, infill architectures—such as grid, hexagonal, or triangular configurations—significantly impact both dimensional stability and mechanical performance. Among these, hexagonal patterns often provide an optimal balance in stress distribution, enhancing overall structural efficiency [

7].

The simple cubic (SC) lattice, as described by Libonati et al. [

9], serves as a fundamental framework structure for mechanical testing and analysis, while the BCC lattice, studied by Ali and Abdi [

10], is widely studied for its energy absorption capabilities. They optimized this structure using multi-objective genetic algorithms to enhance stiffness while minimizing stress under load. Libonati et al. [

9] also noted that the Face-Centered Cubic (FCC) lattice exhibits structural efficiency and is often employed in applications requiring lightweight materials with high strength. Arañez et al. [

11] and Maconachie et al. [

12] highlighted the excellent mechanical properties of Gyroid lattice structures, including high tensile strength and energy absorption capabilities. Furthermore, Arañez et al. [

11] demonstrated how these structures can be designed with varying material distributions to enhance performance under different loading conditions.

Shamim et al. [

13] have demonstrated that different lattice geometries result in varying mechanical properties. Tetrahedron-cubic lattice design has been identified as particularly effective in load-bearing applications, exhibiting superior bending rigidity (15.36 N/mm) and energy absorption capacity (38.54 J/g) compared to alternative lattice configurations. Similarly, Ghosh et al. [

14] demonstrated that incorporating plates into simple cubic and body-centered cubic lattices significantly enhances compressive performance, with modulus improvements between 125% and 393% and energy absorption increases ranging from 17% to 395% compared to traditional open lattice structures. Bouteldja et al. [

15] revealed that ABS lattice structures exhibit a notable increase in compressive strength under dynamic loading conditions, demonstrating strain rate sensitivity.

Poddar et al. [

16] explored the potential of advanced manufacturing techniques, such as axial lattice extrusion, to significantly enhance the compressive strength of ABS composites, achieving impressive values of around 17.4 MPa. The use of functionally graded materials and advanced manufacturing techniques, such as axial lattice extrusion, according to the study, improves the mechanical properties of ABS structures by optimizing fiber alignment and reducing polymer interfaces.

Further studies, such as those by Monkova et al. [

17], have evaluated the impact of relative density (also named volume fraction or specific volume) and cell topology on the tensile properties of various lattice structures. Cartesian, Octagonal, Starlit, and Rhomboid structures demonstrated unique behaviors under tensile stress, with the Cartesian structure achieving superior mechanical properties. The Rhomboid structure, despite its lower tensile strength, excelled in energy absorption and toughness, making it suitable for applications involving impact stresses. In bending studies, Monkova et al. [

18] found that the Starry structure exhibited the best overall bending properties, combining stiffness, energy absorption, and strength across tested relative densities.

The performance of lattice cell structures can also be enhanced through advanced manufacturing techniques. Alwattar et al. [

19] compared traditional BCC lattice cell structures with InsideBCC (named also as Cuboidal BCC) composite lattice designs, demonstrating that the addition of vertical and horizontal struts significantly improves stiffness, failure load, and energy absorption. Similar findings have been reported by other researchers who examined the effect of vertical struts on BCC lattice cell configurations [

20,

21,

22]. These improvements underscore the importance of optimizing strut arrangement and geometrical parameters to enhance mechanical behavior.

Despite the extensive study of ABS lattice structures, most research focuses on moderate-to-high-density configurations, which provide an optimal balance between mechanical strength and weight. However, in aerospace applications, where mass reduction is a top priority, ultra-low-density structures could serve as an effective core material for sandwich panels, potentially replacing traditional polymer foams. Despite their potential, the existing literature provides little information on the accuracy of these structures when manufactured using FDM, a process inherently limited by material deposition constraints and printing resolution. Moreover, FDM is rarely employed for fabricating core components; its primary advantage lies in its economic feasibility for prototyping and low-cost production. Indeed, while higher-resolution techniques such as SLS and SLA are commonly used for complex-shaped components [

23,

24], different studies have highlighted that FDM remains a viable alternative when economic considerations are paramount [

25,

26]. Dimensional and geometrical deviations in the struts can significantly affect the mechanical performance of low relative density lattice structures, altering their specific strength and energy absorption capacity.

This study aims to assess the manufacturability of low relative density Cuboidal BCC lattice structures fabricated via FDM, emphasizing their dimensional precision and overall geometric characteristics. The geometrical and dimensional accuracy of both lattice cells and individual struts is investigated through microscopic analysis, identifying fabrication-induced deviations. Particular attention is given to the limitations of the FDM process in accurately replicating fine strut features, considering the constraints imposed by its technological signature. Geometrical/dimensional deviations are quantified to evaluate the accuracy of the FDM process in the production of low-density ABS lattice cells, offering insights into their suitability as lightweight core materials in aerospace and structural engineering applications.

2. Materials and Methods

This section provides a detailed overview of the materials and methods employed in the investigation. It outlines the design and fabrication process of the structured specimens using FDM with ABS filament. Particular attention is given to the characterization of the specimens, including dimensional measurements and the evaluation of the geometrical accuracy.

The relative density percentage (M) can be expressed as (1).

where ρ

lattice and ρ

solid denote the density of the lattice and the density of the solid material constituting the lattice structure, respectively.

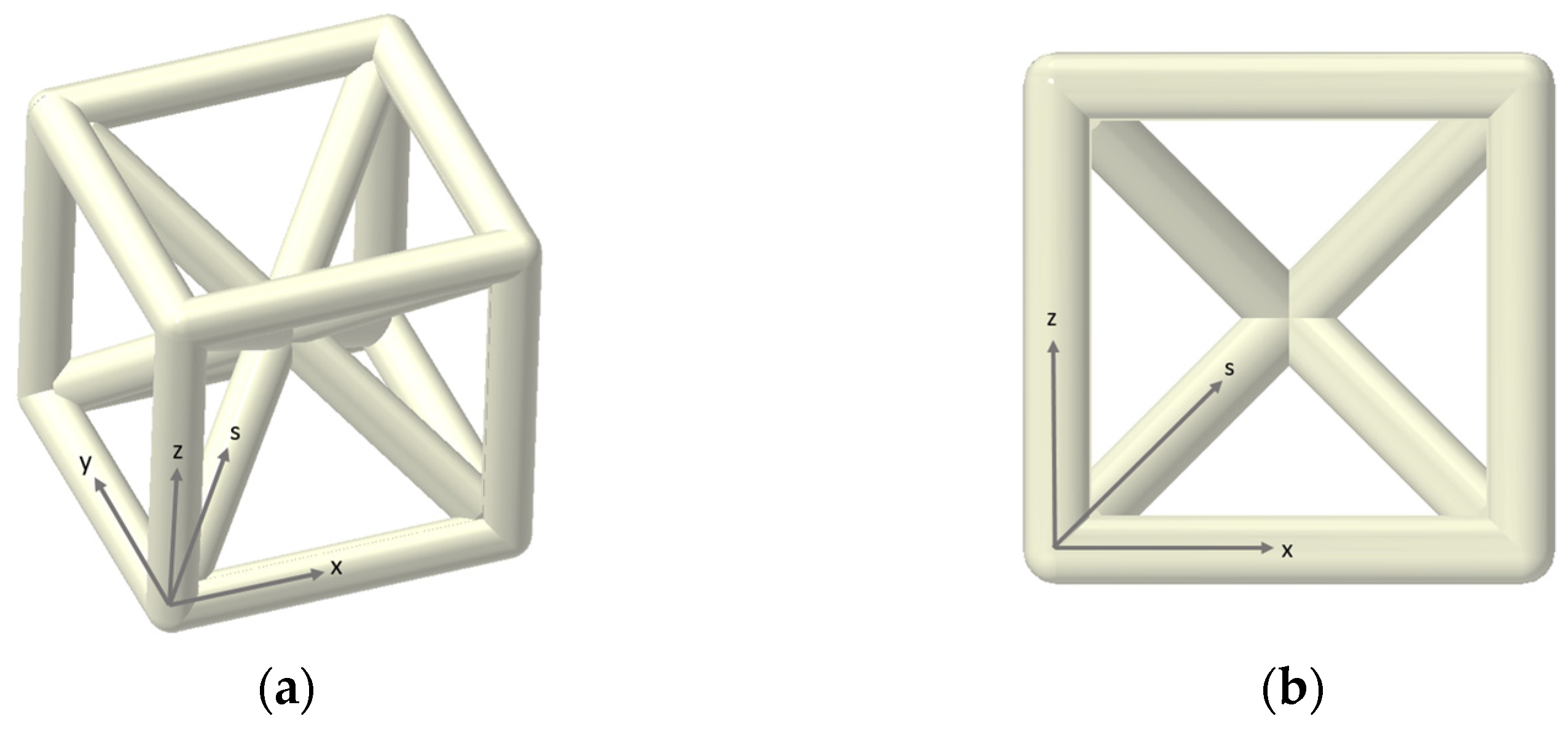

To systematically describe the orientation of the lattice struts, a reference system was defined, as shown in

Figure 1. The x and y directions correspond to struts parallel to the printing orientation, while the z direction represents struts orthogonal to the printing orientation. Additionally, the s direction is introduced to denote struts inclined with respect to the printing orientation.

2.1. Fabrication of ABS Lattice Cells

ABS Cuboidal BCC lattice structures were fabricated using FDM technology. ABS filament with a nominal diameter of 1.75 mm was used. This filament is recognized for its balanced mechanical properties and ease of processing, offering tensile strength in the range of 30 ÷ 50 MPa.

Printing was performed using a Stratasys F190 CR printer. The process parameters defined by Stratasys to optimize layer adhesion and minimize residual stresses were applied without modification in this study, as they are fixed by the manufacturer and not adjustable by the user. The manufacturer-specified settings are presented in

Table 1.

These parameters align with the study’s objective of evaluating FDM printing performance under constrained conditions, specifically assessing the printer’s capabilities within a predefined operational framework. Notably, this research addresses a gap in the existing literature by examining the manufacturability and dimensional and geometrical accuracy of low relative density BCC lattice structures produced by FDM.

The study focused on lattice structures with three relative densities “M” (5%, 10%, and 15%) and lattice cell dimensions “N” of 5 mm, 10 mm, 15, and 20 mm. The configurations are detailed in

Table 2.

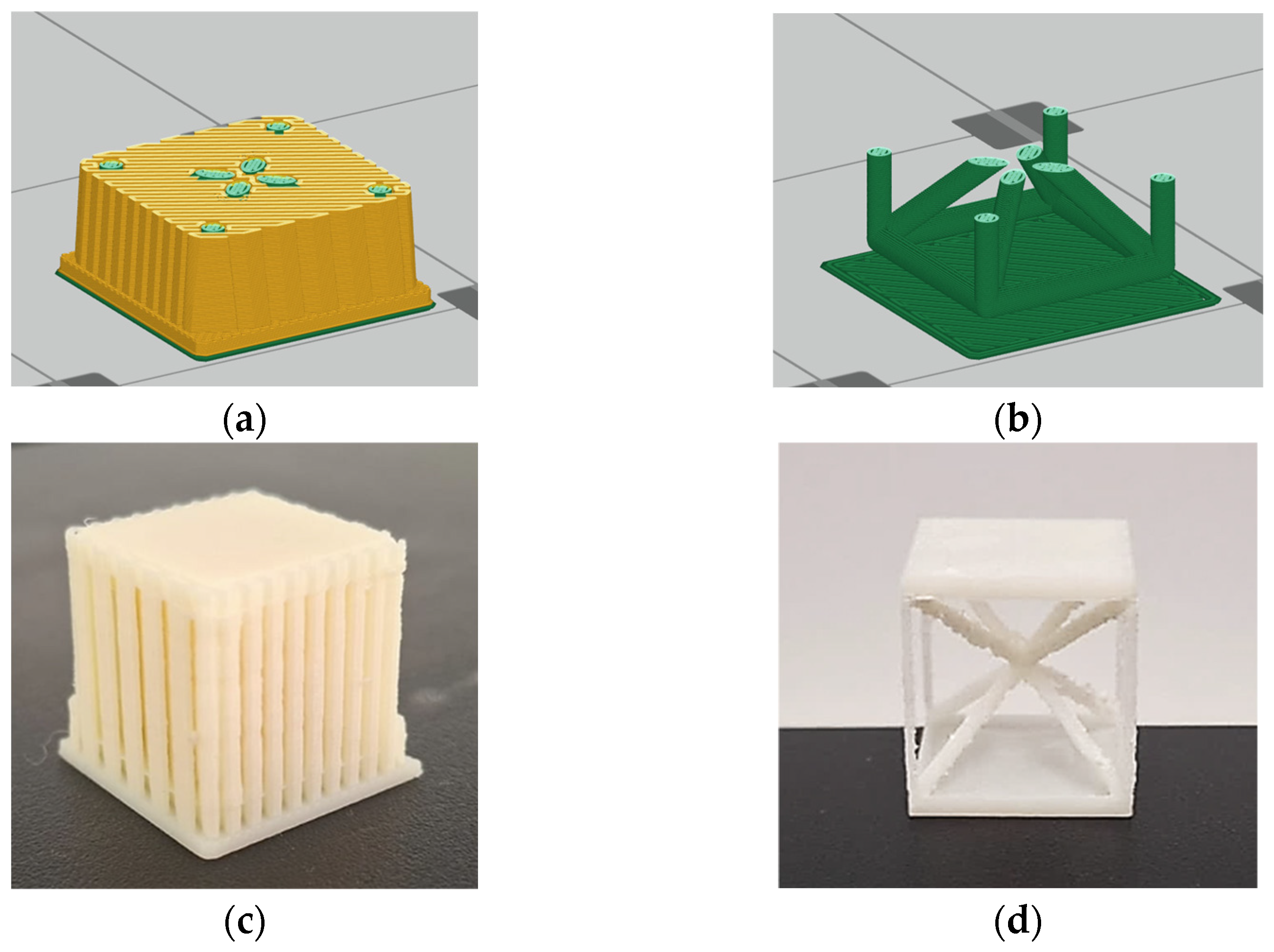

During fabrication, the lattice’s complex geometry, including overhanging struts and nodal connections, necessitated the use of water-soluble support material to maintain structural integrity. The supports were printed with maximum allowable filling density to enhance rigidity and reduce defects such as layer misalignment. The support material used was QSR (Quick Soluble Release), a proprietary water-soluble material commonly employed with Stratasys systems. After printing, the support material was dissolved in a mild water-based solution, consisting of water and a gentle sodium hydroxide (NaOH)-based solution, ensuring that the lattice cells were free of artifacts.

2.2. Quality Control of Printed Lattice Cells and Strut Diameter Characterization

This section presents the quality control measures adopted to ensure the fabricated lattice structures closely matched the nominal geometry and design specifications. The evaluation first focused on the dimensional and geometrical accuracy of the printed lattices, assessing deviations from the nominal design to quantify manufacturing precision. Following this, the strut diameter characterization was detailed, as it is critical for understanding the structural integrity and mechanical response of the lattices. This analysis quantified the average strut diameter and its variation with respect to the printing direction, providing insights into process-induced discrepancies. Finally, weight cell analysis was conducted, where the measured weight of the fabricated structures was compared against theoretical values to assess material deposition accuracy. This evaluation also served as an indirect measure of porosity, offering insights into the presence of voids or inconsistencies within the printed material, which may influence the mechanical performance of the lattice structures. By integrating these assessments, a comprehensive understanding of both geometric and dimensional accuracy, and material distribution was achieved, contributing to the overall reliability of the printed lattice structures.

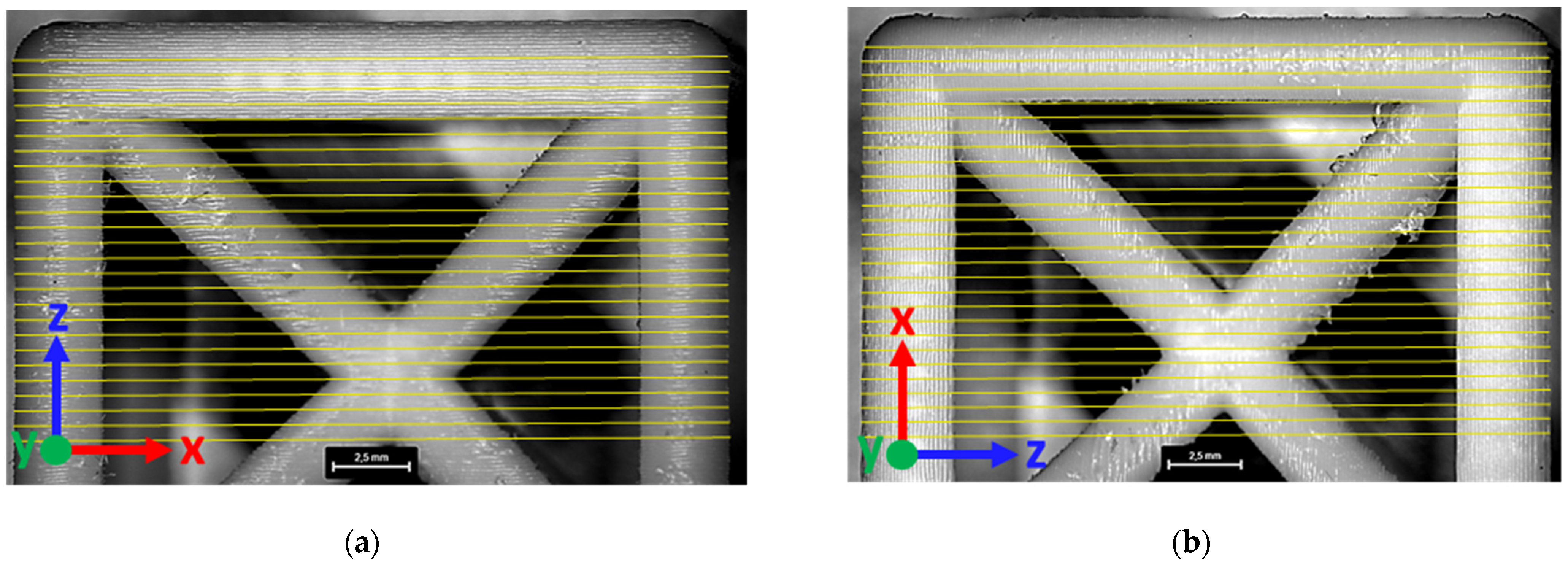

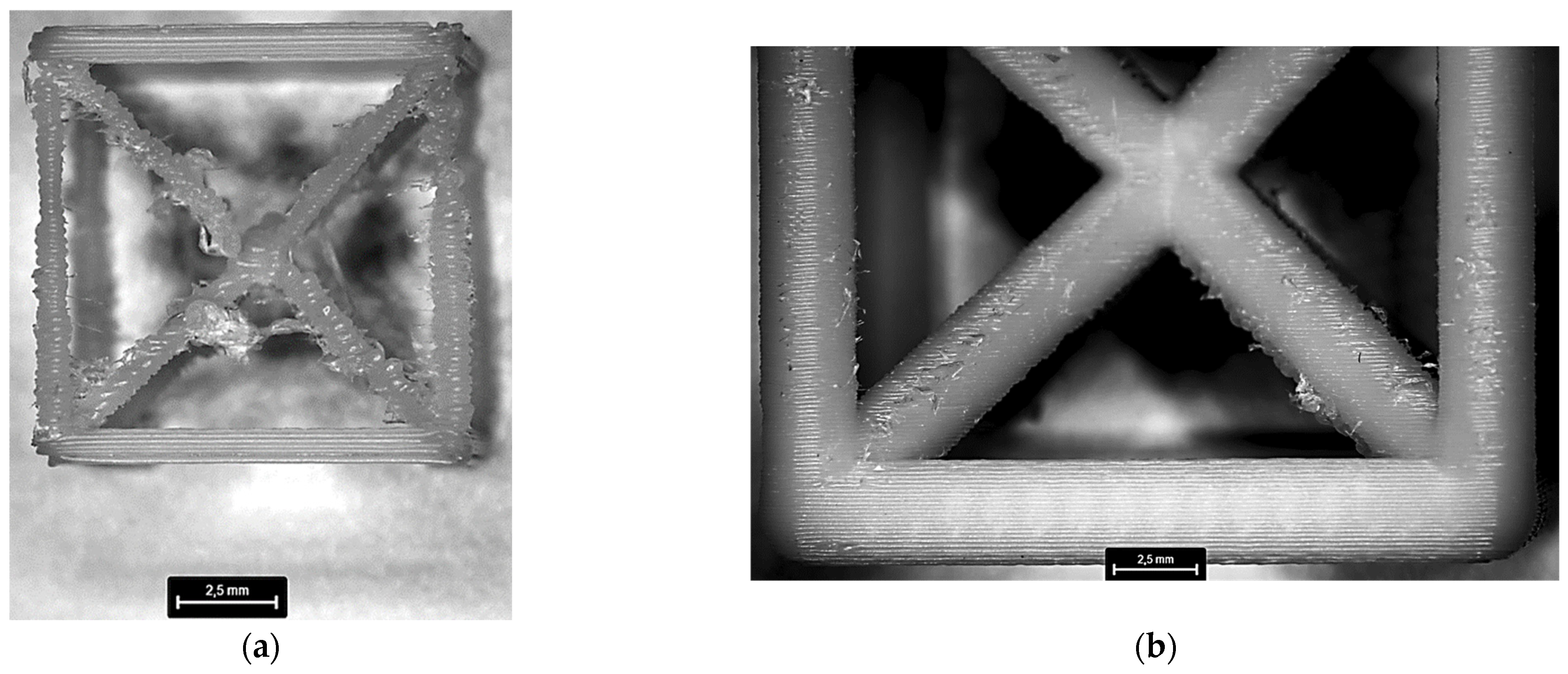

2.2.1. Geometric Assessment and Dimensional Accuracy of Printed Lattice Cells

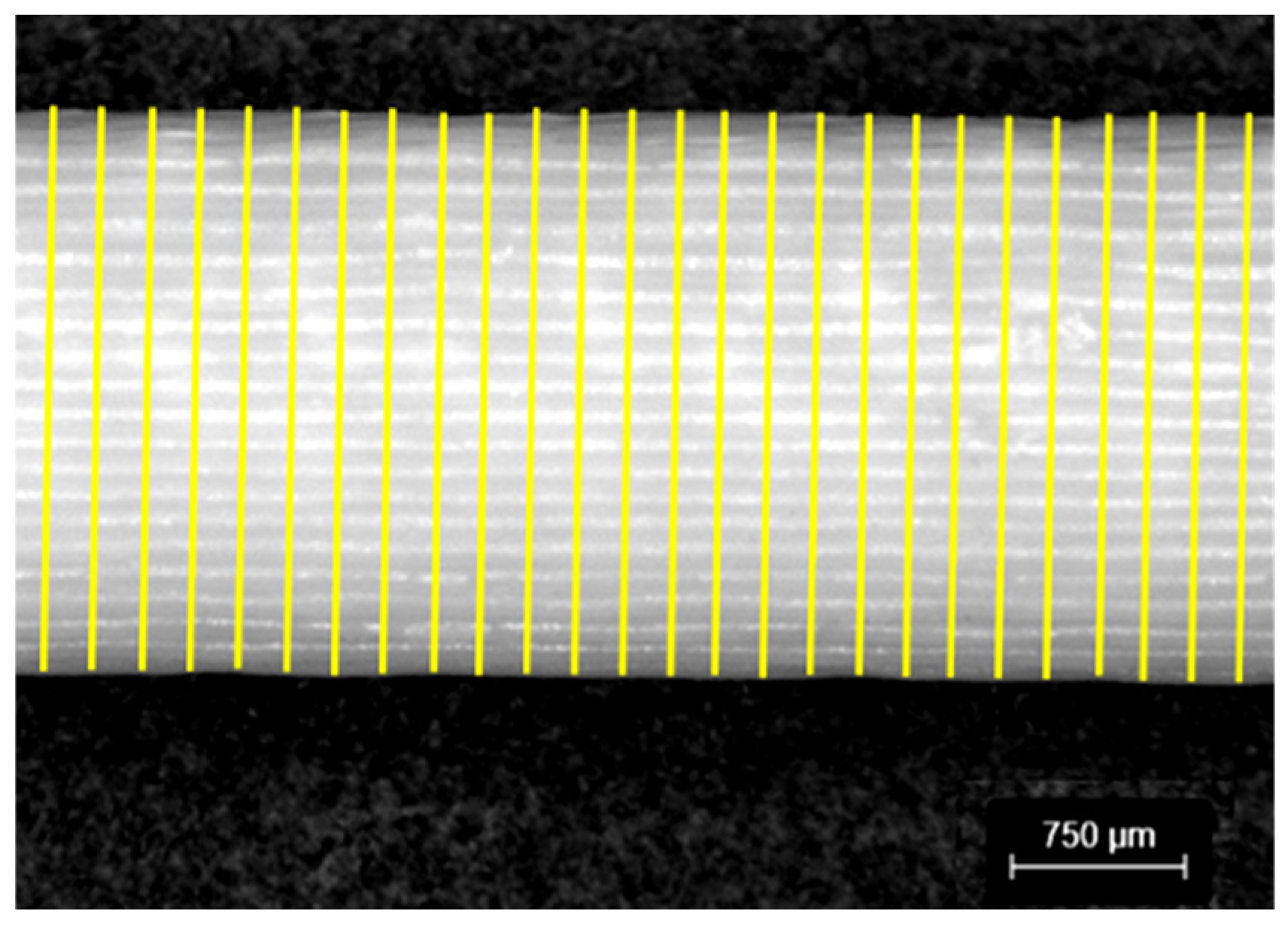

To evaluate the geometric and dimensional accuracy of the fabricated lattice structures, an optical microscopy analysis was conducted using a Leica Ivesta 3. The primary objective was to assess deviations from the nominal geometry and quantify manufacturing precision. High-resolution images were captured and processed using an image analysis software, enabling detailed measurements of the unit cell edge dimensions. These measurements were performed manually at 0.5 mm intervals along the x, y, and z directions, ensuring a comprehensive assessment of the dimensional consistency. This methodology directly accounted for variations, defects, and irregularities introduced during the printing process, providing an accurate representation of the fabricated structures.

2.2.2. Strut Diameter Characterization

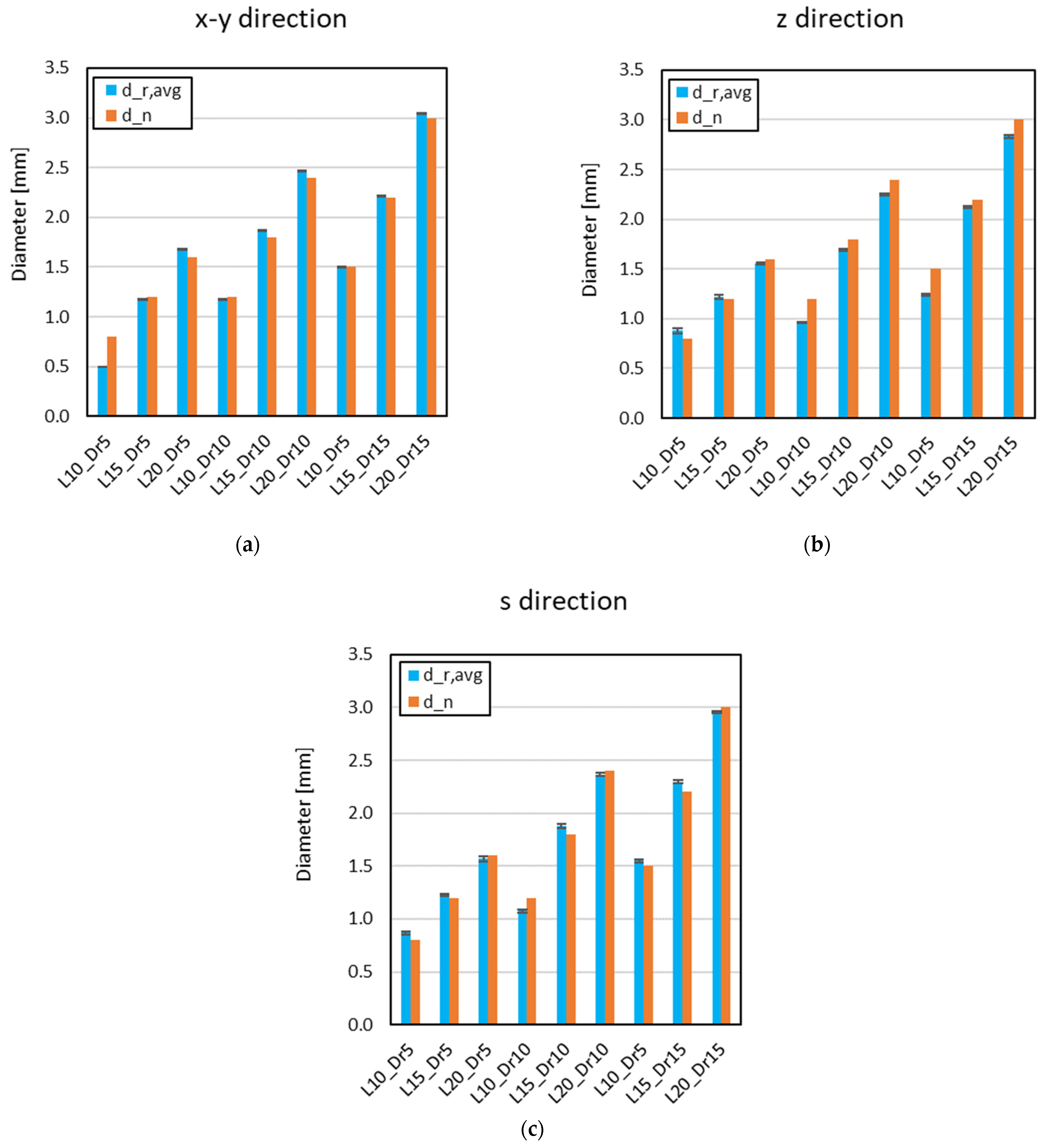

Strut diameter characterization was performed to analyze the dimensional consistency of the individual structural elements forming the lattice. The analysis considered the average strut diameter and its variation relative to the printing direction, as these parameters critically influence the mechanical performance of the structure. To ensure statistical reliability, measurements were conducted on five specimens per lattice configuration and across all principal orientations (x, y, z, and s directions), as defined in

Figure 1. Struts were carefully sectioned and positioned to lie in a planar orientation, improving measurement precision and ensuring proper focal alignment during microscopy examination. Image analysis software was used to determine cross-sectional dimensions at a spacing of 0.2 mm along the strut axis. Additionally, surface quality was assessed to identify potential irregularities induced by the additive manufacturing process. This characterization provided valuable insights into dimensional variations and process-induced inconsistencies, allowing for a comprehensive understanding of the printed struts.

2.2.3. Weight Cell Analysis

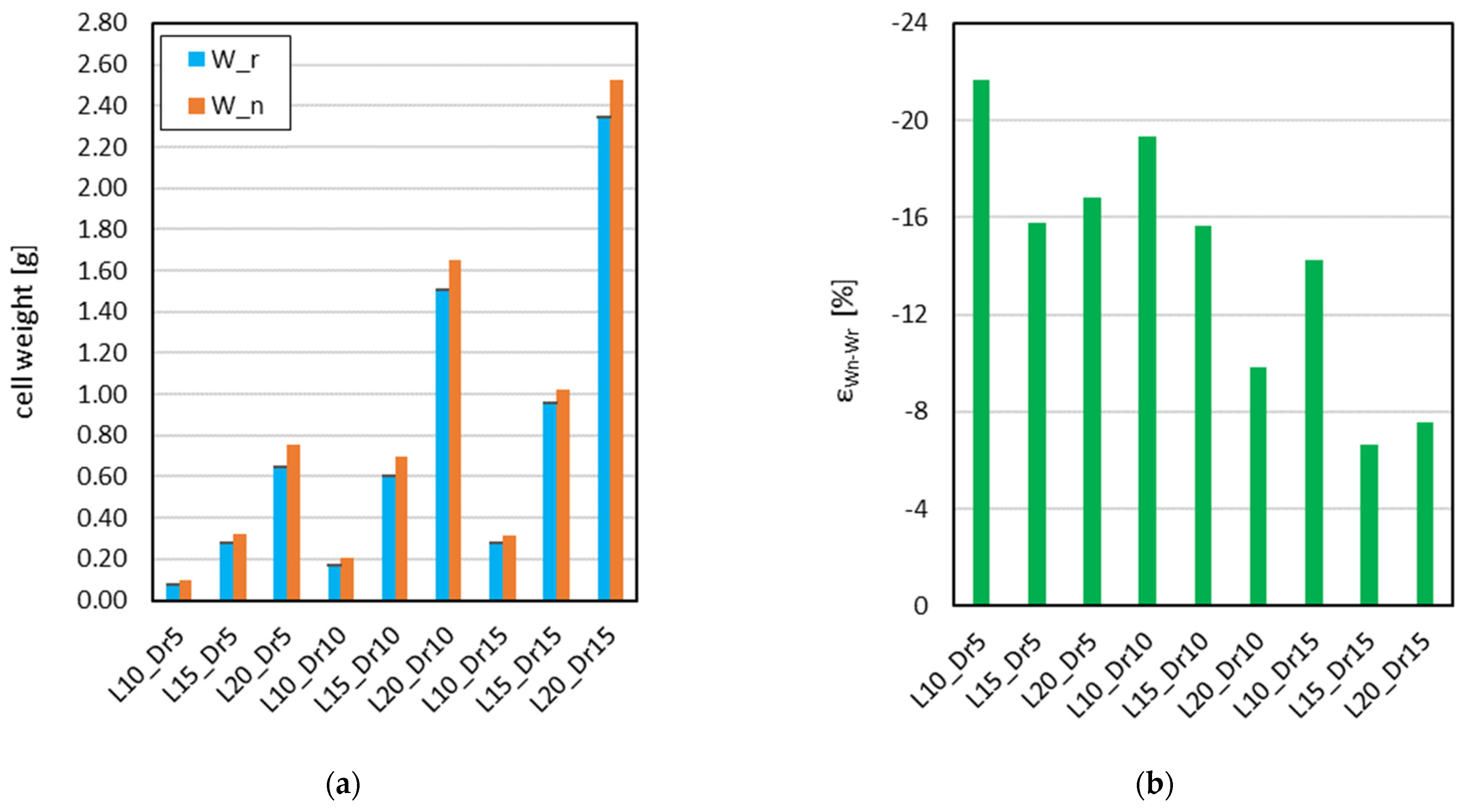

A weight analysis was conducted to evaluate material deposition accuracy and identify potential porosity within the printed structures. Each sample was weighed using a KERN ADB 200-4 high-precision analytical balance, ensuring reliable and repeatable measurements. To account for process variability, five specimens per lattice configuration were manufactured and measured, and the mean weight and standard deviation were calculated to assess fabrication consistency.

The nominal weight of each configuration was determined using the corresponding CAD model, where the material density provided by the ABS manufacturer (ρ = 1.05 g/cm3) was assigned. Since this theoretical weight assumes a fully dense material without voids, discrepancies between the measured and nominal weight can be attributed to porosity, internal voids, or printing inconsistencies.

The weight relative error (ε

Wn-Wr) was determined by comparing the measured weight of the specimens to their nominal weight (2).

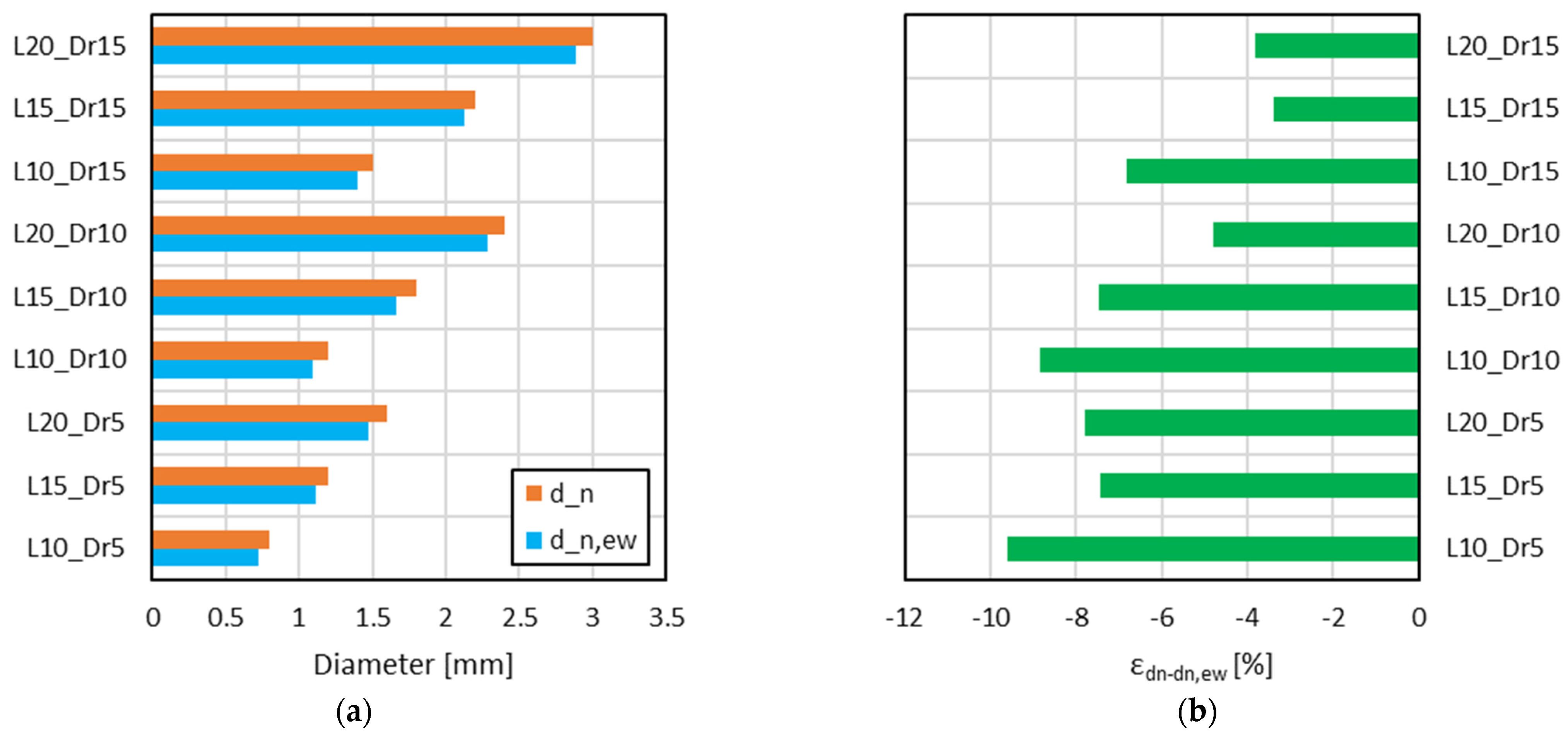

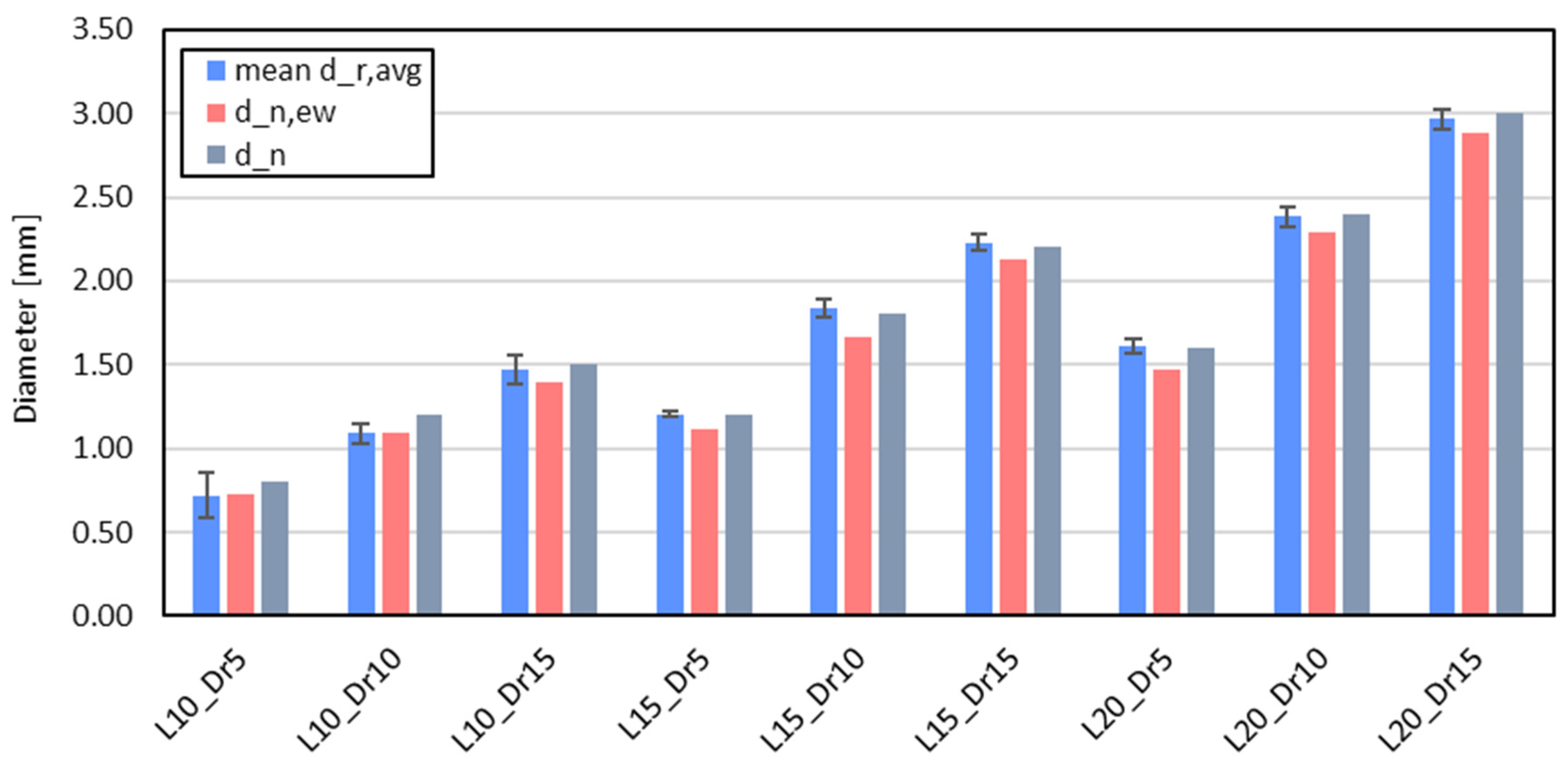

To further quantify the impact of porosity on the lattice structure, an effective weighted diameter (dn,ew) was derived to account for the void presence and non-uniform material distribution along the lattice struts. This parameter was obtained by iteratively adjusting the strut diameter within the CAD model until the weight calculated from the CAD—multiplying the volume derived through the CAD model to the ABS material density provided by the manufacturer—matched the experimentally measured weight. In other words, the iterative process continued until the weight error, defined as the difference between the computed and measured weight, was reduced to zero. As a result, dn,ew provides a simplified yet accurate representation of the lattice structure by incorporating the effects of porosity and the variability in material distribution along the struts. The analysis was conducted under the assumption of uniform strut geometry, implying that the struts exhibited a consistent diameter along their length and were devoid of printing defects or material inconsistencies. This assumption enabled an indirect yet quantitative evaluation of the effects of porosity.

To further assess the discrepancy between the nominal strut diameter (d

n) and the effective weighted diameter (d

n,ew), the relative error (ε

dn-dn,ew) was calculated (3)

By integrating this weight-based analysis with the dimensional characterization, a more comprehensive understanding of material distribution and process-induced variations was obtained.

4. Conclusions

This study investigates the geometric and dimensional accuracy of ABS-based Cuboidal BCC lattice cells produced through a Fused Deposition Modeling process, addressing the challenges in fabrication, material deposition, and structural integrity.

The investigation centers on lattice structures with predefined geometries characterized by cell edge dimensions of 5, 10, 15, and 20 mm, and low relative densities of 5%, 10%, and 15%, where relative density is defined as the ratio of the lattice structure’s density to that of the solid material from which it is composed.

The results revealed that lattice cells with nominal dimensions of 5 mm presented critical issues, as their small size led to fragile struts that fractured during or immediately after the printing process. This highlighted the limitations of FDM in producing reliable lattice structures at smaller scales, which led to the exclusion of these cells from further analysis. Dimensional characterization showed that the printed lattice structures exhibited deviations from the nominal values ranging from 0.6% to 1.8%. These variations, however, did not correlate consistently with specific lattice parameters such as cell size, strut diameter, or relative density, suggesting that other process-induced factors contributed to the discrepancies. Further analysis of the strut geometry revealed that parallel-oriented struts achieved the highest dimensional/geometrical accuracy, with minimal deviation from the nominal values. The discrepancies observed in certain configurations, particularly L10_Dr5, were attributed to the optimization process of the slicing algorithm, which affected the deposition of material, leading to local material accumulation or insufficient deposition in some instances. The analysis also highlighted the influence of printing orientation on the overall dimensional/geometrical fidelity of the struts.

In addition to the dimensional and geometrical analysis, weight measurements provided valuable insight into the manufacturing consistency, revealing that the printed lattice cells consistently exhibited lower weight than the theoretical values derived from the CAD models. The observed weight discrepancies were primarily attributed to variations in material deposition and the presence of internal voids, which are characteristic of the FDM process. By iteratively adjusting the strut diameter to match the experimentally measured weight, it was possible to determine an effective weighted diameter for each configuration, which was generally smaller than the nominal values. This trend was more pronounced in smaller cell dimensions and lower relative densities, where limited extrusion capacity and insufficient support material resulted in greater deviations. Conversely, larger cells and higher relative densities exhibited improved fabrication accuracy, as larger strut sizes allowed for better material deposition and structural support.

From a practical perspective, this study provides a framework for assessing the manufacturability of lattice structures via FDM, offering quantitative insights into expected dimensional deviations. These findings are particularly relevant for industries such as aerospace, where precise control over geometrical/dimensional accuracy and material consistency is crucial for lightweight structural applications. Notably, the ability to fabricate lattice structures with controlled geometries and low relative densities, including those investigated in the present work with relative densities of 5, 10, and 15%, makes them strong candidates for use as core materials in sandwich structures, where weight reduction and energy absorption are critical design considerations. However, further optimization of the FDM process is necessary to improve the reliability of these structures for such applications. Future research should explore strategies to enhance print precision, including refined slicing algorithms, optimized extrusion parameters, and alternative support structures, to further advance the use of FDM in fabricating complex lightweight lattices for high-performance engineering applications.

While optical microscopy was utilized to assess external geometric features, its limitations in capturing internal microstructural details highlight the need for advanced imaging techniques. Future studies should incorporate scanning electron microscopy (SEM) to investigate filament arrangement, void distribution, and material consolidation in greater detail. Furthermore, analyzing the effect of printing direction on the geometrical and dimensional accuracy of the lattice structure would offer deeper insights. Additionally, mechanical performance testing of the produced lattice structures is essential for a more comprehensive evaluation of their suitability for load-bearing applications.