Burst Ultrafast Laser Welding of Quartz Glass

Highlights

- Exploring the transient evolution of burst femtosecond laser welding of transparent materials.

- Analyzing the effect of different number of sub-pulses on welding performance.

- First to realize molten structures in the range of up to 5 mm.

- Providing a new welding method for curved surfaces and large-size transparent materials.

Abstract

1. Introductions

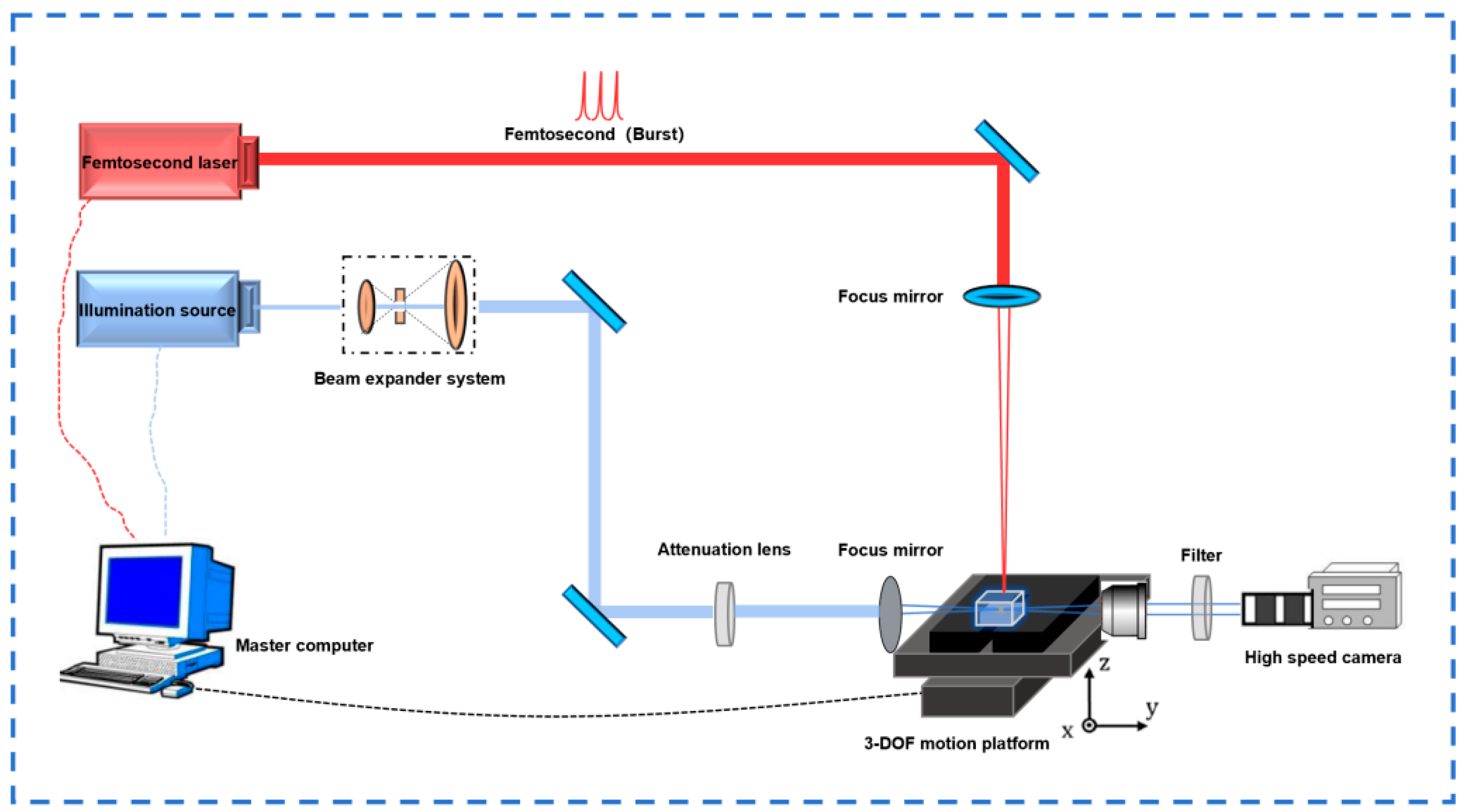

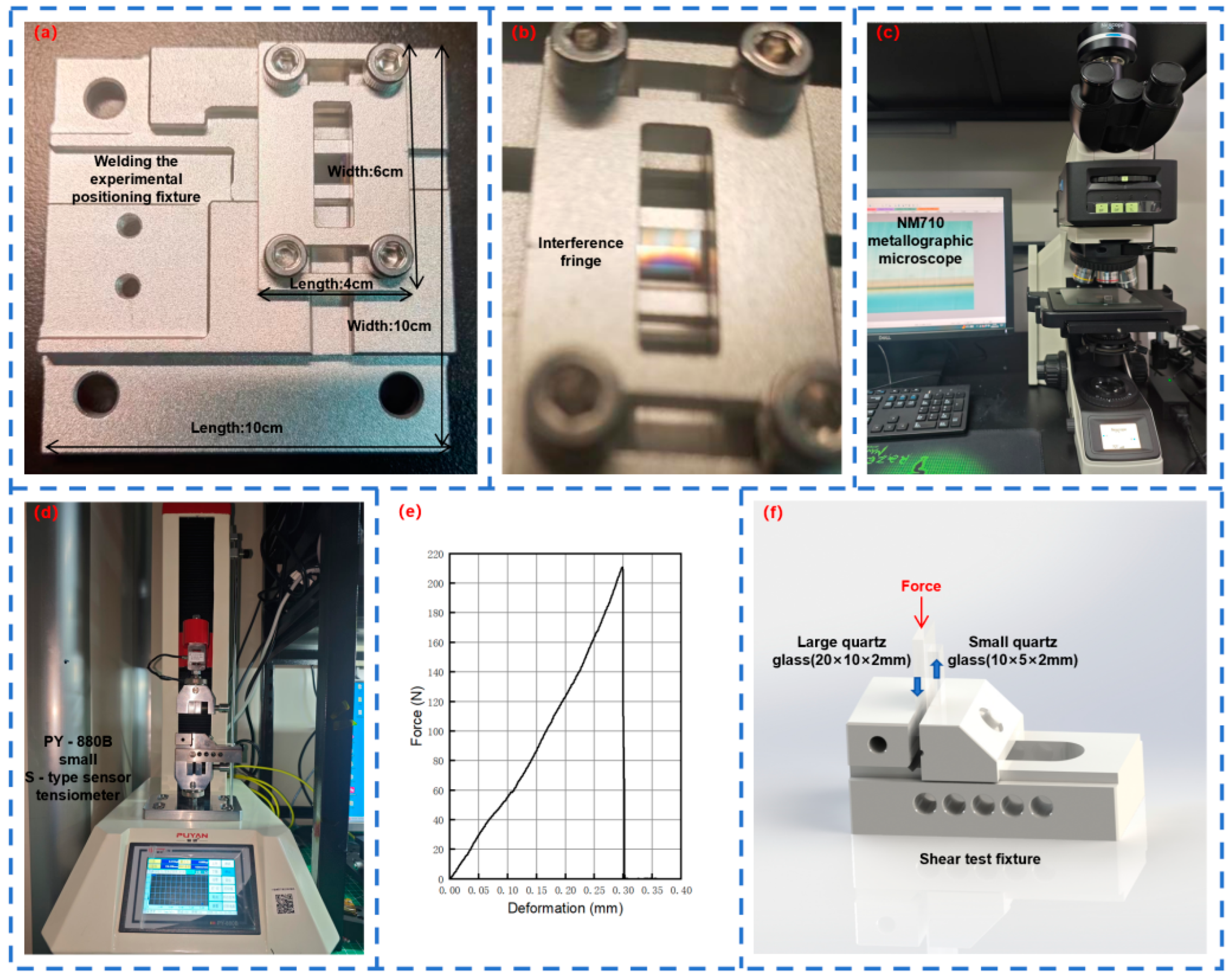

2. Materials and Methods

2.1. Equipment and Materials

2.2. Experiments and Characterization

3. Results and Discussion

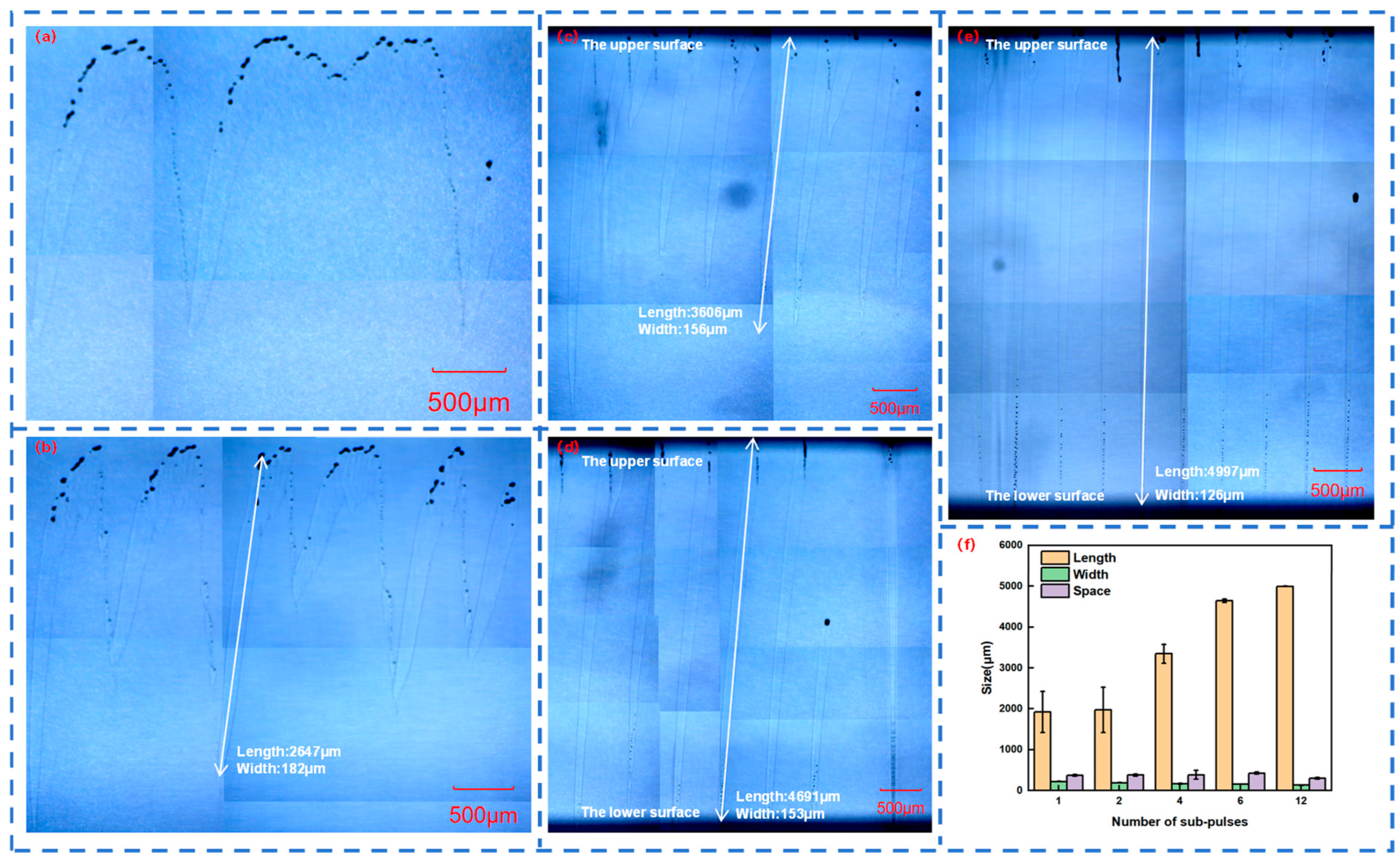

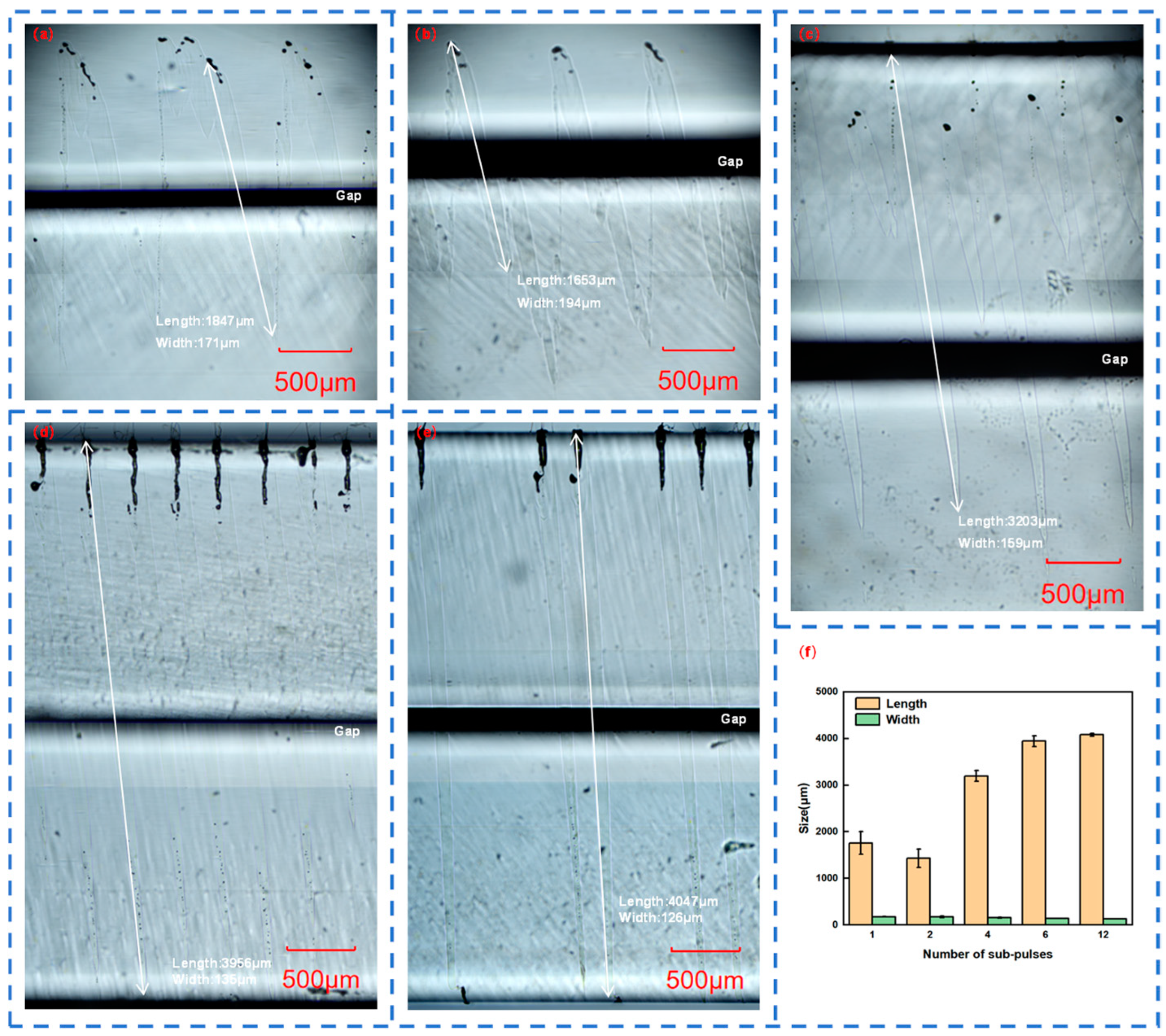

3.1. Femtosecond Laser Melting Characteristics of Quartz Glass in Burst Mode

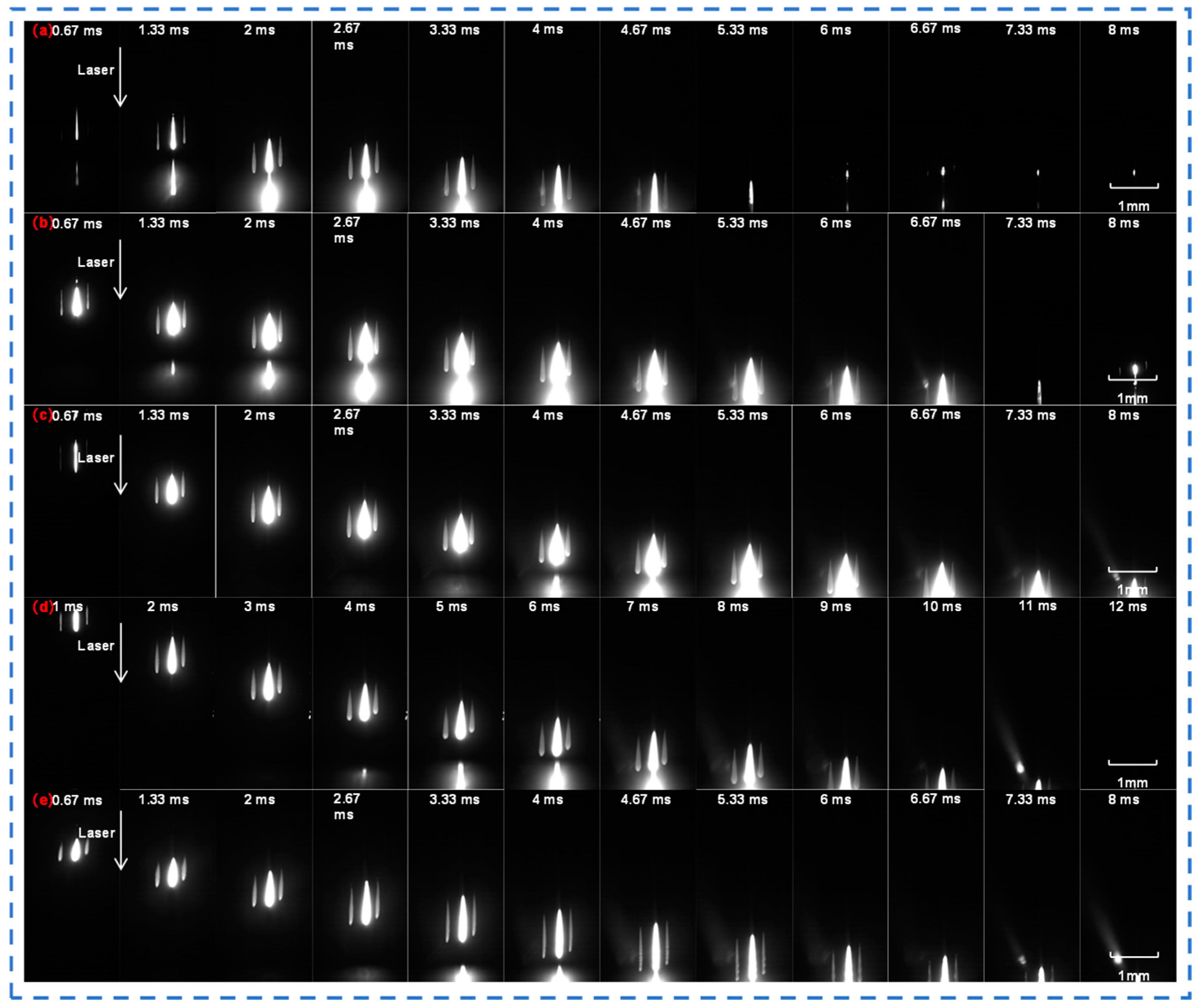

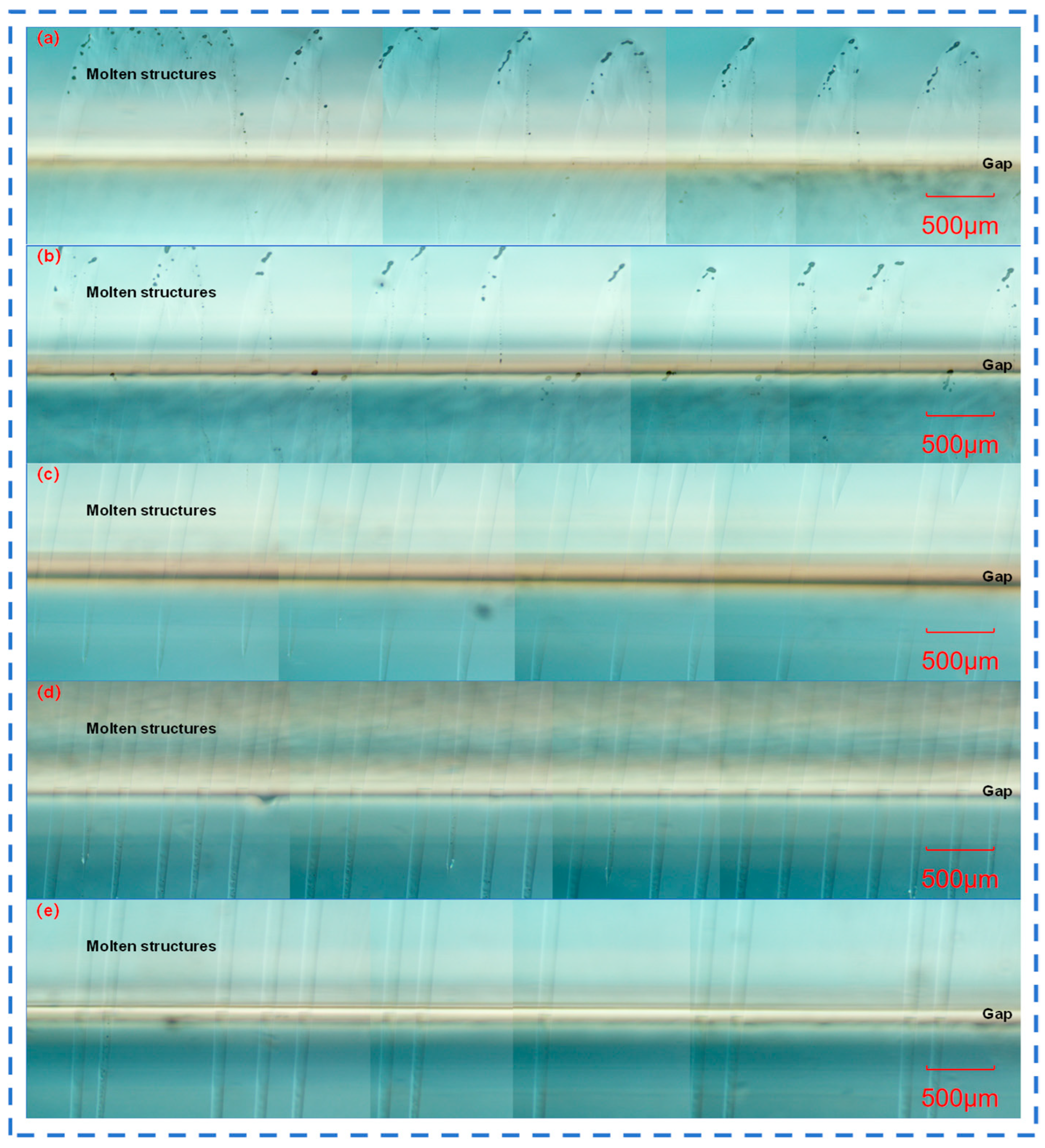

3.2. Dynamic Process of Femtosecond Laser Processing of Quartz Glass Under Burst Mode

3.3. Femtosecond Laser Welding Characteristics of Quartz Glass in Burst Mode

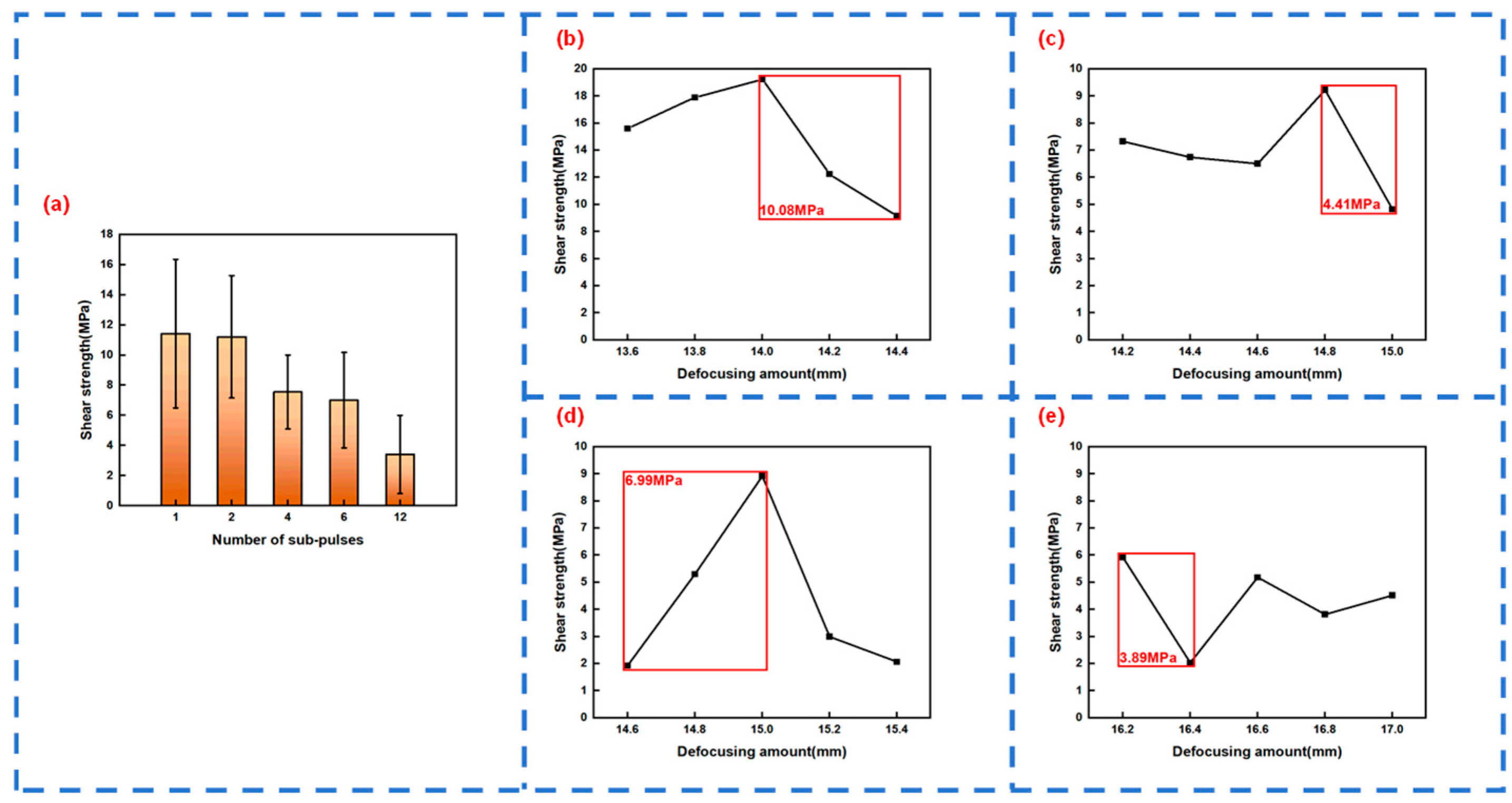

3.4. Analysis of Femtosecond Laser Welding Strength in Burst Mode

3.4.1. Variation of Quartz Glass Welding Strength with the Number of Bursts

3.4.2. Variation of Quartz Glass Welding Strength with the Defocusing Amount z-Value

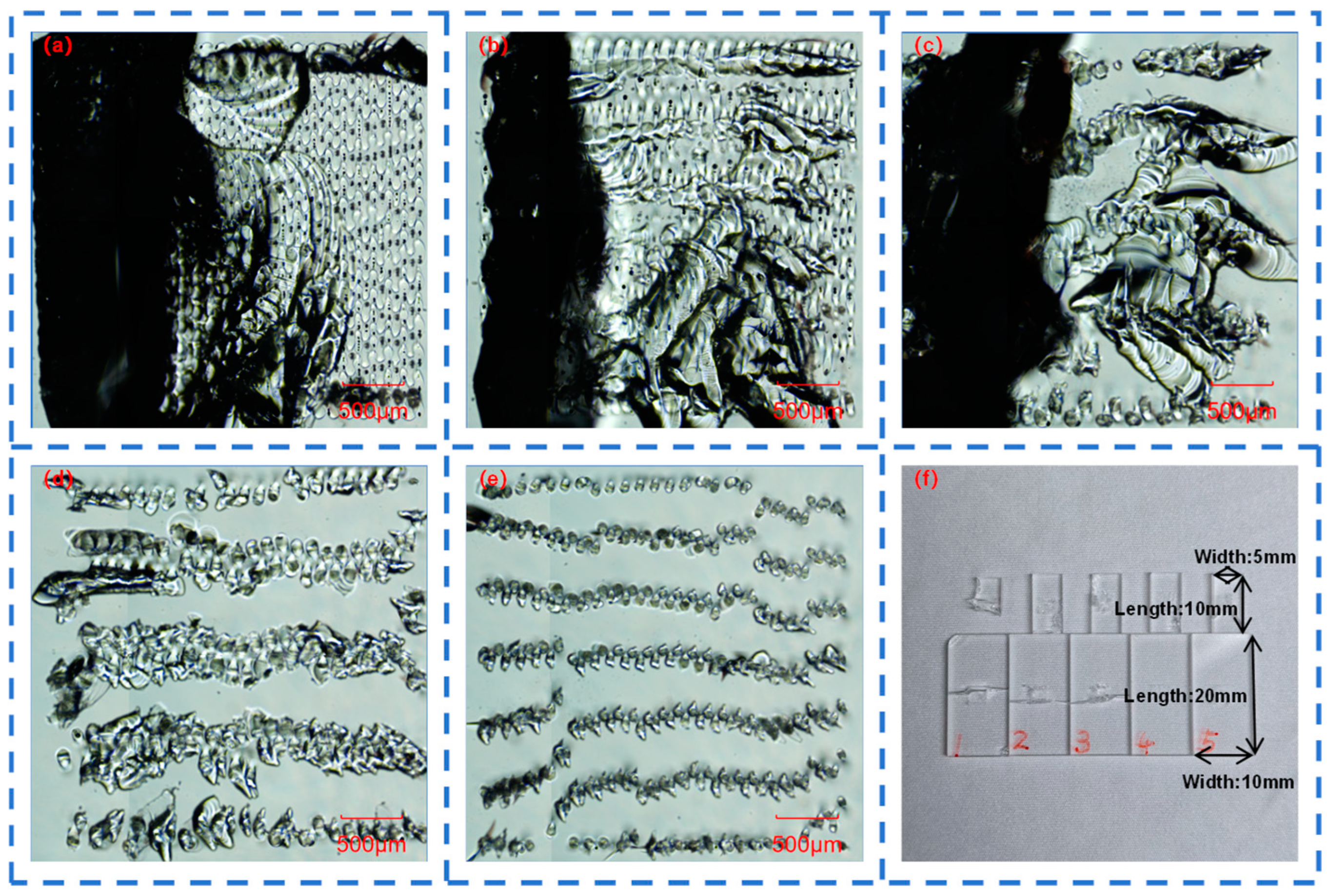

3.5. Fracture Interface of Welded Quartz Glass in Burst Mode

4. Conclusions

- (1)

- With the increase in the number of sub-pulses, the length of the molten structure gradually increases, while the width gradually decreases. When the number of sub-pulses is twelve, the average length of the molten structure exceeds 5 mm, the average width is 132 μm, and the average spacing is 300 μm.

- (2)

- The dynamic process of femtosecond laser acting on quartz glass was observed by using plasma imaging technology. With a resolution as high as 1024 × 1024 pixels and a frame rate reaching 3000 frames per second, it can accurately analyze the stability of the welding process and provide an intuitive basis for optimizing the welding parameters.

- (3)

- When using the Burst mode, the pulse width of the femtosecond laser is 238 fs, the wavelength is 1035 nm, and the repetition frequency is 1000 kHz (one sub-pulse and the total energy is 28.9 μJ). When the z-value is 14 mm, the maximum welding strength of the quartz glass can reach 18.18 MPa. The maximum welding strengths of the other four groups of experiments are 16.63 MPa, 11.11 MPa, 9.76 MPa, and 7.28 MPa, respectively.

- (4)

- With the increase in the number of sub-pulses, the area of the modified region decreases, and the average welding strength of the quartz glass gradually decreases from 11.425 MPa to 3.415 MPa. When the number of sub-pulses is determined, with the increase of the defocusing amount z-value, the welding strength generally shows a trend of first increasing and then decreasing. The morphology of the fractured part fully confirms the magnitude of the welding strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Quazi, M.M.; Ezazi, M.; Arslan, A.; Bashir, M.N.; Ali, M.M. Overview: Focus on laser-based manufacturing and materials processing. Mater. Res. Express 2024, 11, 100201. [Google Scholar] [CrossRef]

- Song, D.; Wang, J.; Wu, X.; Gao, L.; Yang, J.; Liu, X.; Luo, Q.; Wang, D.; Wang, Y. Microscopic Processing of Transparent Material with Nanosecond and Ultrafast Lasers. Micromachines 2024, 15, 1101. [Google Scholar] [CrossRef]

- Guo, H.; Xie, J.; He, G.; Zhu, D.; Qiao, M.; Yan, J.; Yu, J.; Li, J.; Zhao, Y.; Luo, M.; et al. A review of ultrafast laser micro/nano fabrication: Material processing, surface/interface controlling, and devices fabrication. Nano Res. 2024, 17, 6212–6230. [Google Scholar] [CrossRef]

- Jin, J.; Geng, S.; Shu, L.; Jiang, P.; Shao, X.; Han, C.; Ren, L.; Li, Y.; Yang, L.; Wang, X. High-strength and crack-free welding of 2024 aluminium alloy via Zr-core-Al-shell wire. Nat. Commun. 2024, 15, 1748. [Google Scholar] [CrossRef] [PubMed]

- Jia, X.; Luo, J.; Li, K.; Wang, C.; Li, Z.; Wang, M.; Jiang, Z.; Veiko, V.P.; Duan, J. Ultrafast laser welding of transparent materials: From principles to applications. Int. J. Extrem. Manuf. 2025, 7, 032001. [Google Scholar] [CrossRef]

- Zheng, C.; Hu, A.; Chen, T.; Oakes, K.D.; Liu, S. Femtosecond laser internal manufacturing of three-dimensional microstructure devices. Appl. Phys. A 2015, 121, 163–177. [Google Scholar] [CrossRef]

- Li, Z.; Lin, J.; Jia, X.; Li, X.; Li, K.; Wang, C.; Sun, K.; Ma, Z.; Duan, J. High efficiency femtosecond laser ablation of alumina ceramics under the filament induced plasma shock wave. Ceram. Int. 2024, 50, 47472–47484. [Google Scholar] [CrossRef]

- Obata, K.; Caballero-Lucas, F.; Kawabata, S.; Miyaji, G.; Sugioka, K. GHz bursts in MHz burst (BiBurst) enabling high-speed femtosecond laser ablation of silicon due to prevention of air ionization. Int. J. Extrem. Manuf. 2023, 5, 025002. [Google Scholar] [CrossRef]

- Wang, J.; Fang, F.; An, H.; Wu, S.; Qi, H.; Cai, Y.; Guo, G. Laser machining fundamentals: Micro, nano, atomic and close-to-atomic scales. Int. J. Extrem. Manuf. 2023, 5, 012005. [Google Scholar] [CrossRef]

- Wang, H.; Liu, B.; Pang, D.; Hu, M. Welding of glass and single crystal graphite film using a high repetition fs laser. J. Non-Cryst. Solids 2025, 647, 123268. [Google Scholar] [CrossRef]

- Chen, C.; Li, L.; Zhang, M.; Zhang, W. Effects of Different Surface Treatment Methods on Laser Welding of Aluminum Alloy and Glass. Coatings 2024, 14, 1318. [Google Scholar] [CrossRef]

- Rakhimov, R.R.; Saubanov, R.R.; Pesoshin, A.V. Controlling Laser Welding Process Parameters to Reduce Spatter Defects. High Energy Chem. 2024, 58 (Suppl. 2), S200-–S203. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, Z.; Wang, X.; Li, L.; Yang, L.; Li, M.; Zhu, W. Process study of picosecond laser welding of soda-lime glass. Opt. Laser Technol. 2025, 182, 112095. [Google Scholar] [CrossRef]

- Zhang, G.; Pan, Y.; Wu, P.; Guo, Z.; Lv, J.; Zhang, H.; Wang, J.; Zhang, W.; Xu, J.; Wang, L.; et al. Glass micro welding in thermal accumulation regime with using spatially shaped ultrafast laser. Opt. Laser Technol. 2024, 168, 109845. [Google Scholar] [CrossRef]

- Chen, H.; Li, Z.; Han, M.; Yang, X.; Bai, S. Improved Femtosecond Laser Welding of Nonoptical Contact Glass by Pressure and a Water Intermediate Layer. ACS Omega 2024, 9, 38878–38886. [Google Scholar] [CrossRef]

- Wang, H.; Guo, L.; Zhang, X.; Dong, J.; Lue, Q.; Zhang, Q.; Jiang, Q.; Chen, T.; Li, J. Influence of processing parameters on the quality of titanium-coated glass welded by nanosecond pulse laser. Opt. Laser Technol. 2021, 144, 107411. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, S.; Luo, Z.; Ding, K.; Liu, B.; Duan, J. High-quality welding of glass by a femtosecond laser assisted with silver nanofilm. Appl. Opt. 2021, 60, 5360–5364. [Google Scholar] [CrossRef]

- Bu, Y.; Zhang, B.; Zhao, D.; Liu, S.; Zhu, X.; Hou, J. Direct generation of all-fiber GHz Burst-mode laser with flexible temporal tunability. Opt. Laser Technol. 2025, 182, 112122. [Google Scholar] [CrossRef]

- Huang, Y.; Ni, H.; Wang, X. Optimizing laser surface texturing effect via synergy of Burst-mode and advanced scanning paths. Appl. Phys. B 2024, 130, 195. [Google Scholar] [CrossRef]

- Guilberteau, T.; Balage, P.; Lafargue, M.; Lopez, J.; Gemini, L.; Manek-Hönninger, I. Bessel Beam Femtosecond Laser Interaction with Fused Silica Before and After Chemical Etching: Comparison of Single Pulse, MHz-Burst, and GHz-Burst. Micromachines 2024, 15, 1313. [Google Scholar] [CrossRef]

- Mackevičiūtė, M.; Dudutis, J.; Gečys, P. A comparative study on MHz and GHz Bursts addressing the polarization-based control of laser-induced modifications in fused silica. Opt. Laser Technol. 2025, 181, 111289. [Google Scholar] [CrossRef]

- Murzakov, M.A.; Evtikhiev, N.N.; Grezev, N.V.; Kataev, D.M.; Shchekin, A.S. Effect of Burst mode modulation ultrashort pulse laser on the laser processing transparent dielectrics. Laser Phys. Lett. 2024, 21, 025601. [Google Scholar] [CrossRef]

- Xie, X.; Ou, D.; Ma, D.; He, J.; Peng, H. High-quality laser processing of fused silica with Bursts of ultrafast pulses. Appl. Phys. A 2022, 128, 1062. [Google Scholar] [CrossRef]

- He, K.; Ren, Y.; Dai, Z.; Zhang, J.; Tu, X.; Cheng, L.; Xin, Z.; Cai, L.; Ye, Y. Theoretical and experimental study of ablation of fused silica by femtosecond laser bursts. Opt. Commun. 2023, 537, 129440. [Google Scholar] [CrossRef]

- Li, Z.; Yi, Z.; Jia, X.; Li, K.; Wang, C.; Duan, J. Micro-welding of non-optical contact sapphire/metal using Burst femtosecond laser. Mater. Lett. 2024, 377, 137540. [Google Scholar] [CrossRef]

- Ren, H.; Tian, C.; Shen, H. Ultrafast laser Bursts welding glass and metal with solder paste to create an ultra-large molten pool. Opt. Lett. 2024, 49, 1717–1720. [Google Scholar] [CrossRef]

- Jia, X.; Lin, J.; Li, Z.; Wang, C.; Li, K.; Wang, C.; Duan, J. Continuous wave laser ablation of alumina ceramics under long focusing condition. J. Manuf. Process. 2025, 134, 530–546. [Google Scholar] [CrossRef]

- Gao, C.; Gao, W.; Liao, Y.; Du, J.; Xie, S.; Chen, C.; Liu, K.; Peng, Y.; Leng, Y. High-Efficiency Femtosecond Laser Scribing on Fused Silica Assisted by Dynamic Oscillatory Scanning. Chin. J. Lasers 2024, 51, 2002403. [Google Scholar]

| Parameter | Value |

|---|---|

| Central wavelength | 1035 nm |

| Focused spot diameter | 33.245 μm |

| Repetition rate | 1000 kHz |

| Pulse width | 200 fs |

| Burst total energy | 28.9 μJ |

| Number of sub-pulses | 1/2/4/6/12 |

| Sub-pulse interval time | 22 ns |

| Processing speed | 20 mm/s |

| Processing area | 3 × 3 mm2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, X.; Fu, Y.; Li, K.; Wang, C.; Li, Z.; Wang, C.; Duan, J. Burst Ultrafast Laser Welding of Quartz Glass. Materials 2025, 18, 1169. https://doi.org/10.3390/ma18051169

Jia X, Fu Y, Li K, Wang C, Li Z, Wang C, Duan J. Burst Ultrafast Laser Welding of Quartz Glass. Materials. 2025; 18(5):1169. https://doi.org/10.3390/ma18051169

Chicago/Turabian StyleJia, Xianshi, Yinzhi Fu, Kai Li, Chengaonan Wang, Zhou Li, Cong Wang, and Ji’an Duan. 2025. "Burst Ultrafast Laser Welding of Quartz Glass" Materials 18, no. 5: 1169. https://doi.org/10.3390/ma18051169

APA StyleJia, X., Fu, Y., Li, K., Wang, C., Li, Z., Wang, C., & Duan, J. (2025). Burst Ultrafast Laser Welding of Quartz Glass. Materials, 18(5), 1169. https://doi.org/10.3390/ma18051169