Nonlinear Ultrasonic Characterization of Processing Defects in Wire Arc Additive Manufacturing 316L Stainless Steel

Highlights

- The effects of WAAM process parameters on the columnar grain, porosity, and defect types were systematically analyzed.

- The microstructures and defect characteristics of WAAM 316L stainless steel under different process parameters were observed in both the horizontal and vertical directions.

- Based on nonlinear ultrasonic testing, we proposed a method of evaluating the processing defects and porosity of WAAM 316L stainless steel.

Abstract

1. Introduction

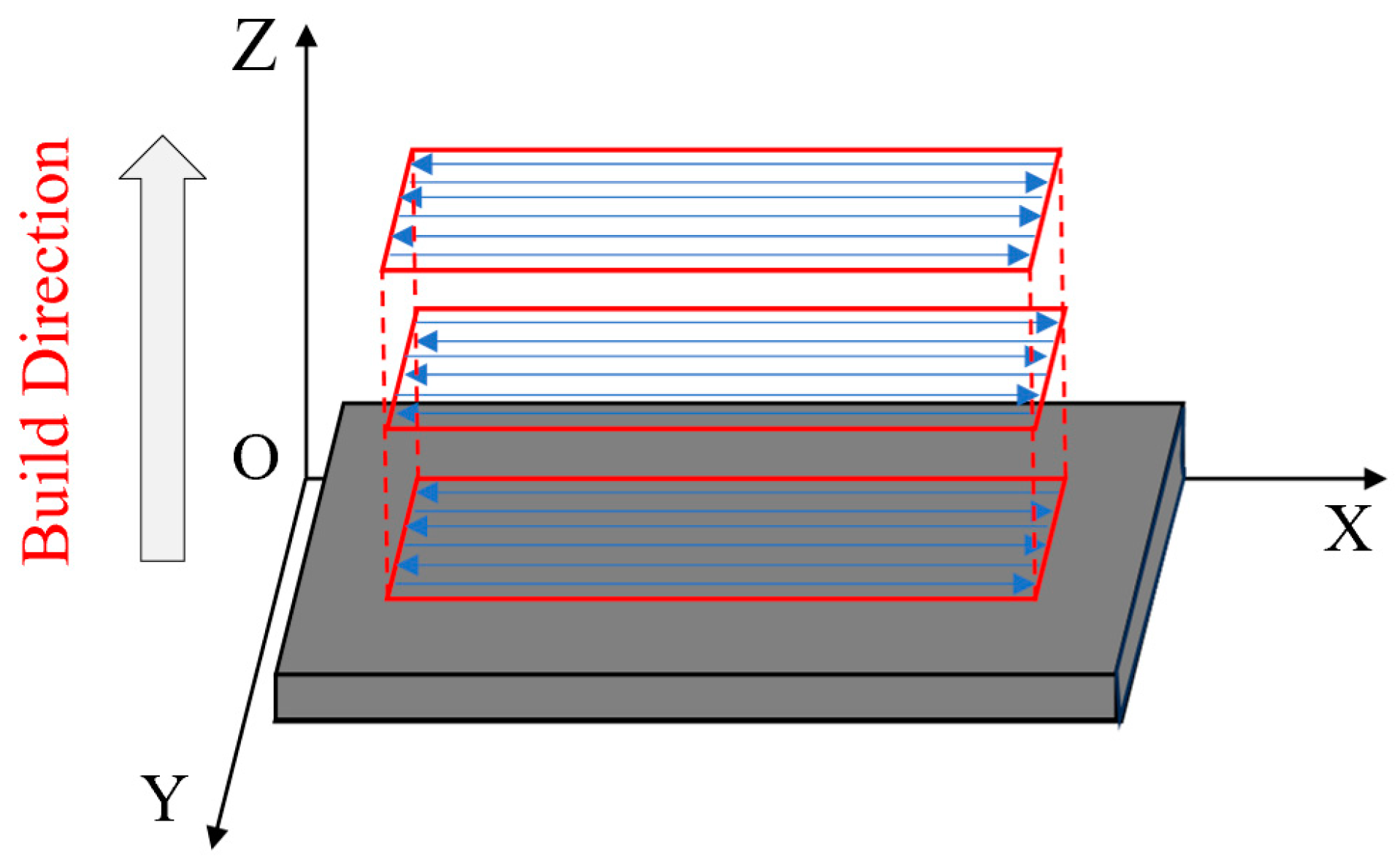

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

2.2.1. Microstructure Observation

2.2.2. Nonlinear Ultrasonic Detection

3. Results and Discussion

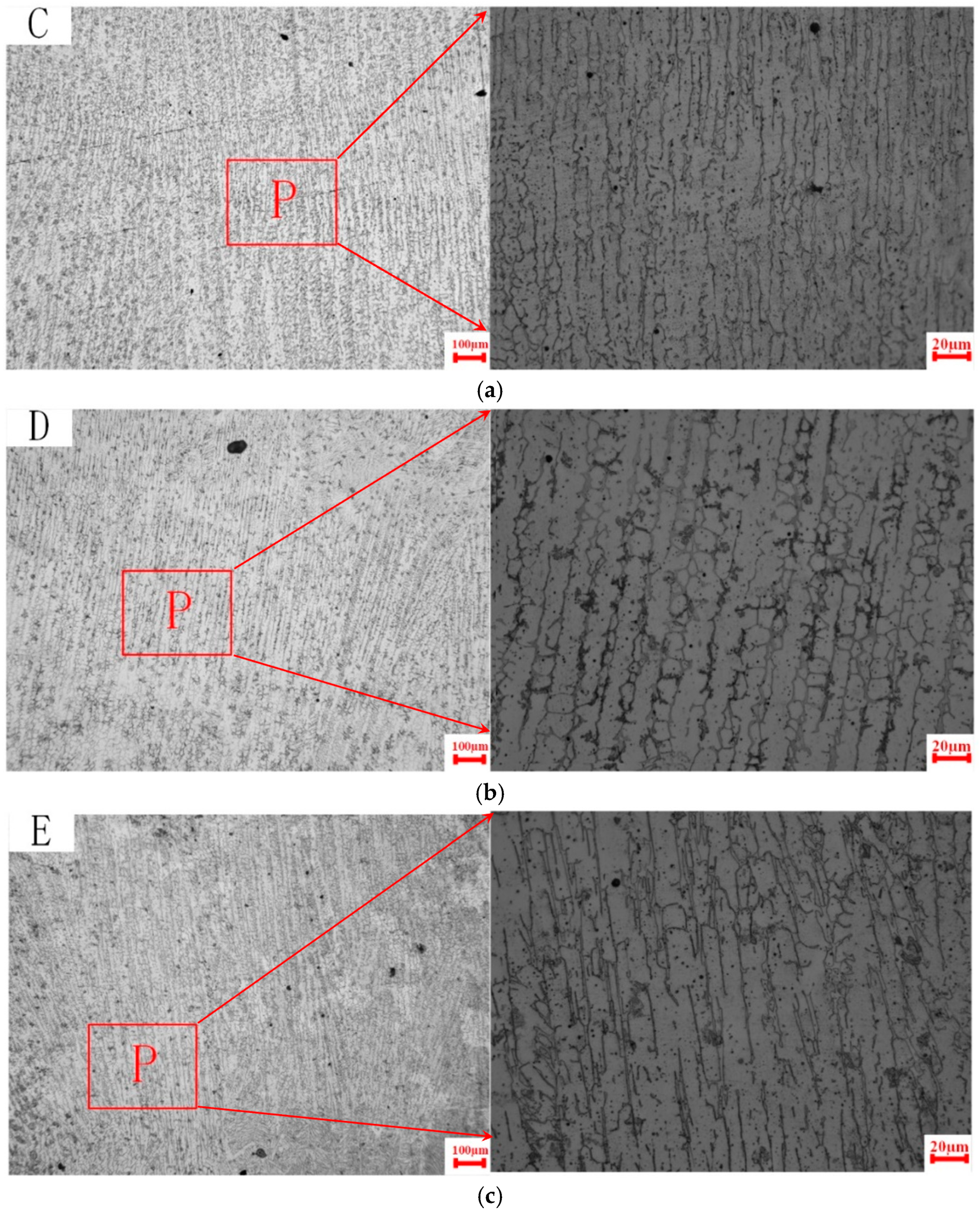

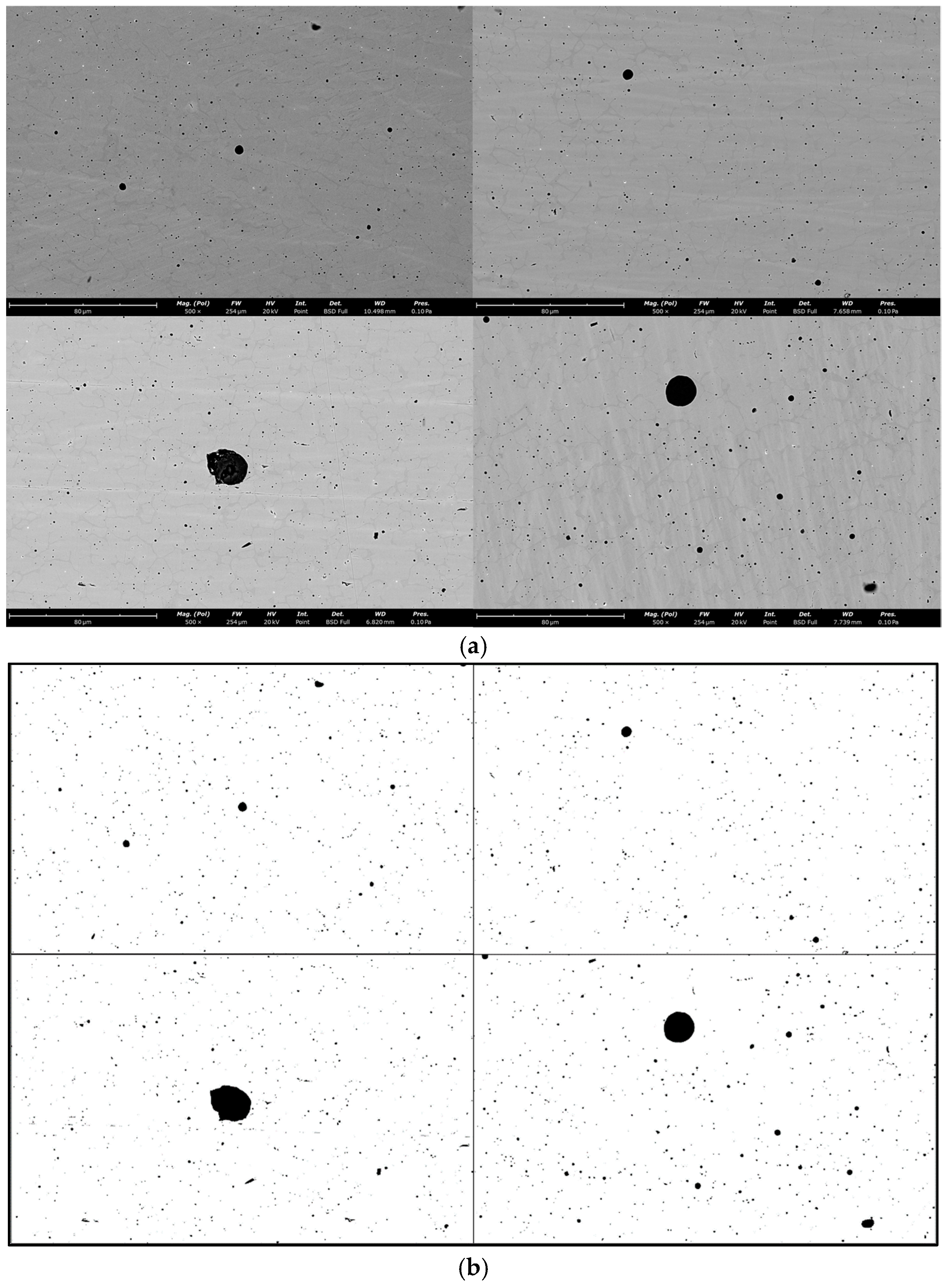

3.1. Characteristics of Processing Defects

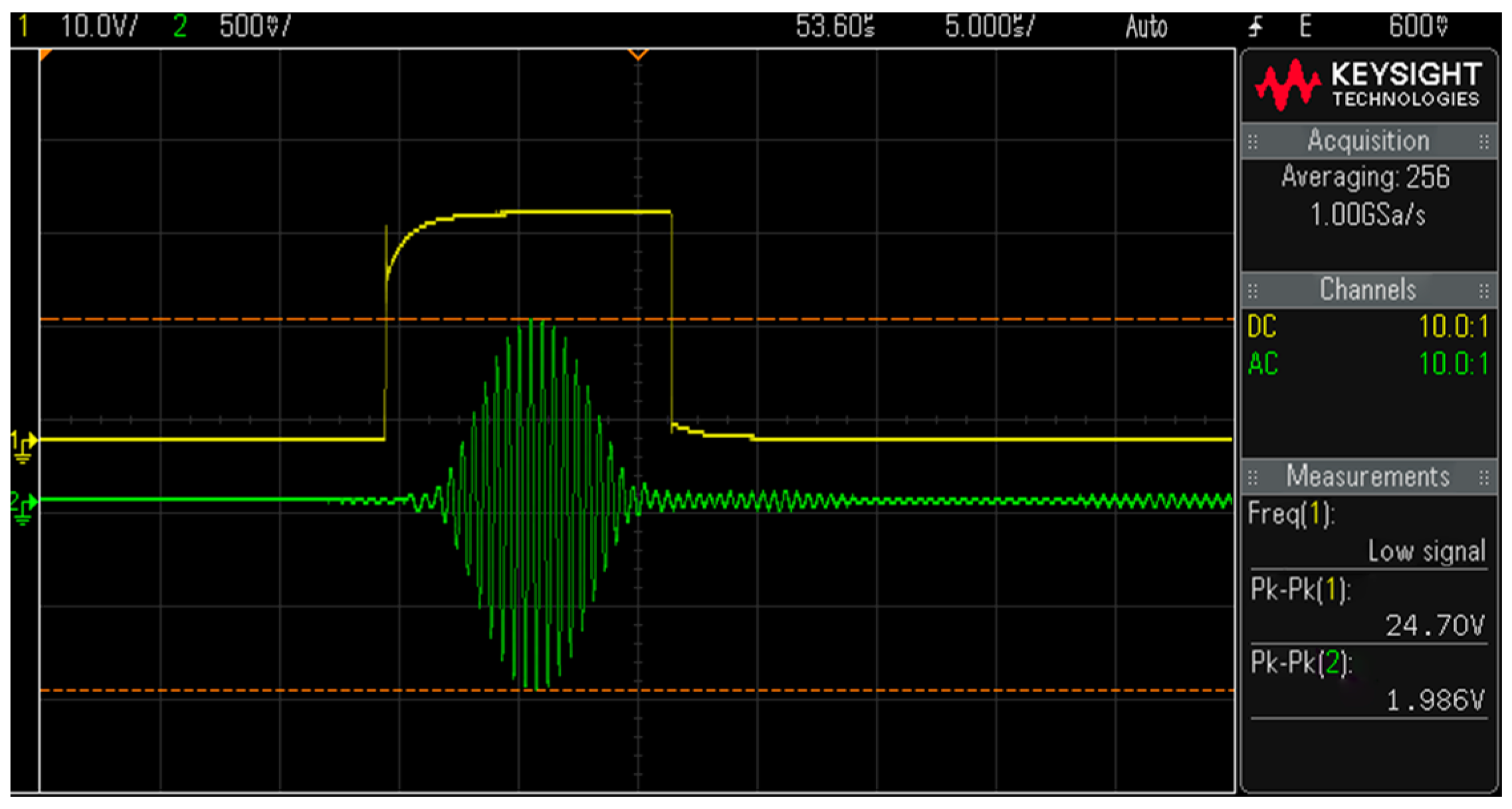

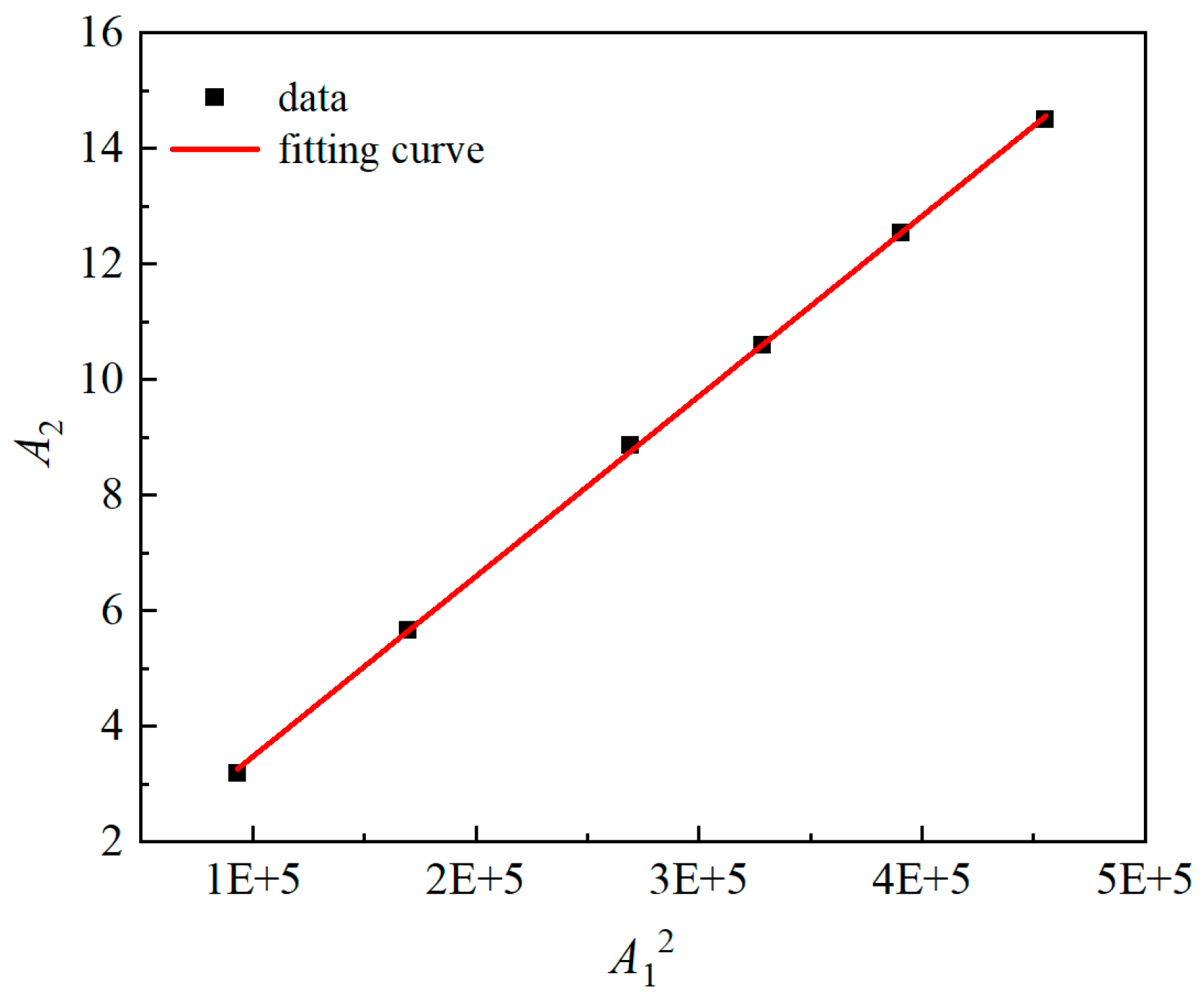

3.2. Reliability Validation of Nonlinear Ultrasonic Detection Systems

3.2.1. Output Level

3.2.2. Excitation Frequency

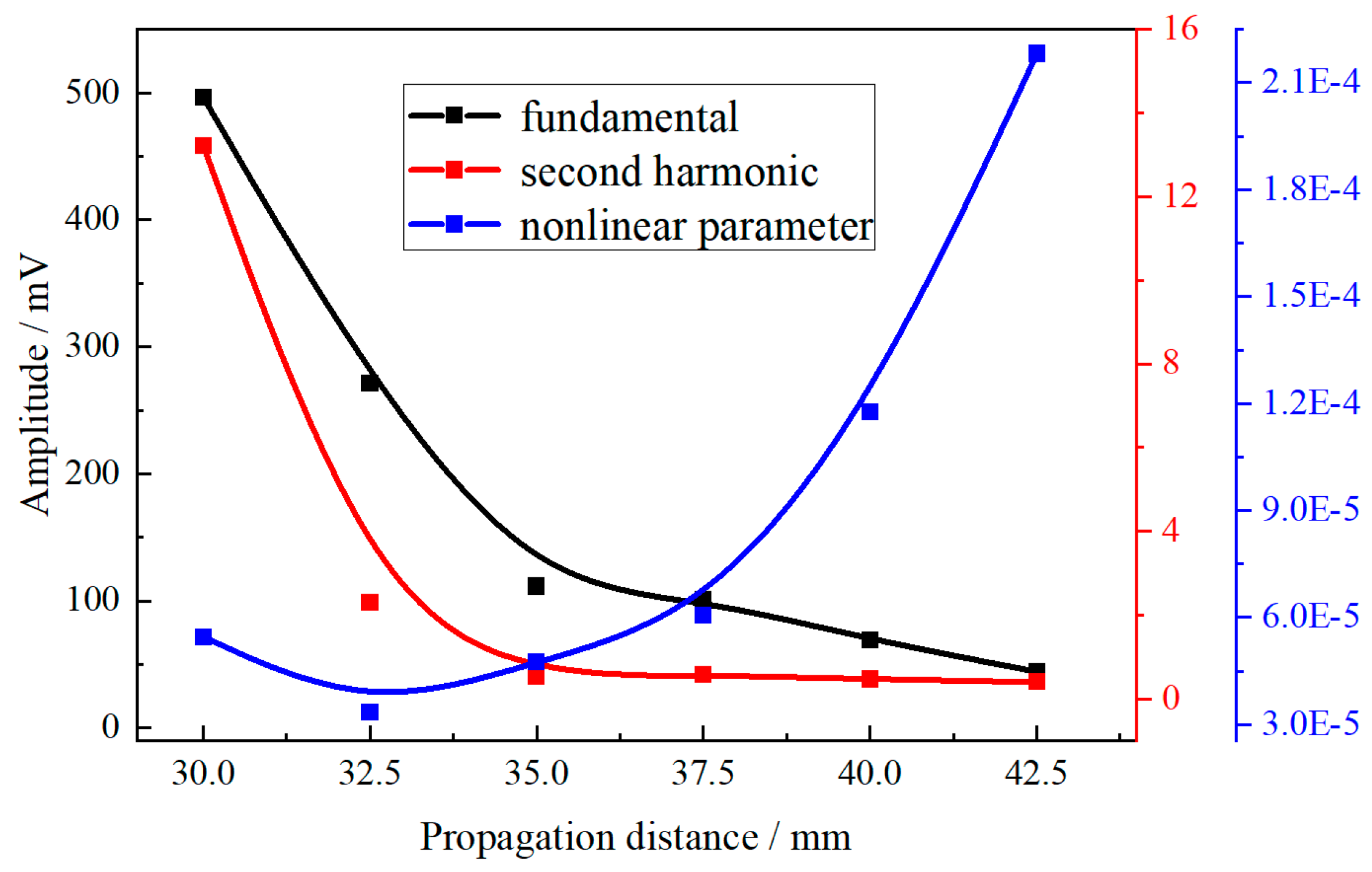

3.2.3. Propagation Distance

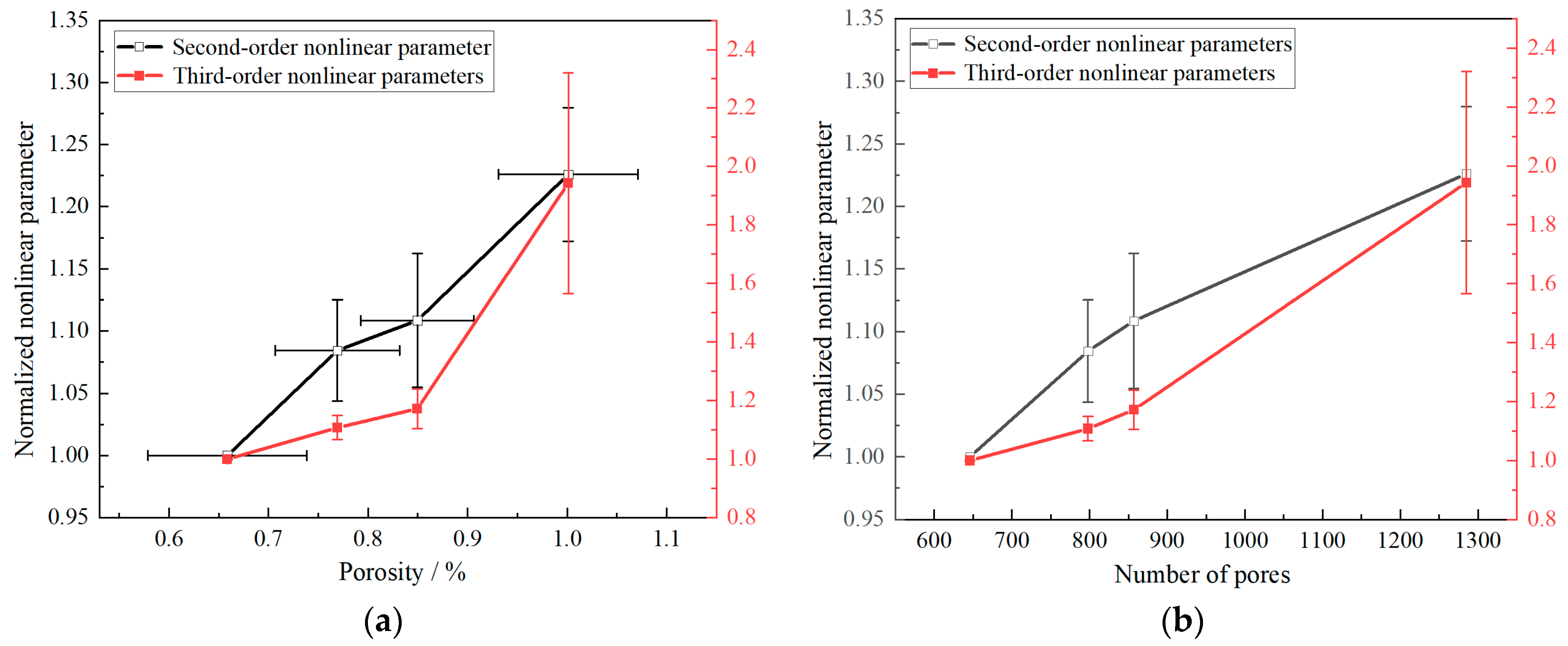

3.3. Relationship Between Porosity and Ultrasonic Nonlinear Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, K.; Liang, E.; Zhang, R.; Zhen, M.; Wei, L.; Huang, W.; Lin, X. Research status of additive manufacturing of metal materials and its application in civil aviation. Mater. Rev. 2021, 35, 3176–3182. [Google Scholar]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire+ arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Ahsan, M.N.; Bradley, R.; Pinkerton, A.J. Microcomputed tomography analysis of intralayer porosity generation in laser direct metal deposition and its causes. J. Laser Appl. 2011, 23, 022009. [Google Scholar] [CrossRef]

- Susan, D.F.; Puskar, J.D.; Brooks, J.A.; Robino, C. Quantitative characterization of porosity in stainless steel LENS powders and deposits. Mater. Charact. 2006, 57, 36–43. [Google Scholar] [CrossRef]

- Kim, F.H.; Kim, F.H.; Moylan, S.P. Literature Review of Metal Additive Manufacturing Defects; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018.

- Rauter, N.; Lammering, R.; Kühnrich, T. On the detection of fatigue damage in composites by use of second harmonic guided waves. Compos. Struct. 2016, 152, 247–258. [Google Scholar] [CrossRef]

- Marcantonio, V.; Monarca, D.; Colantoni, A.; Cecchini, M. Ultrasonic waves for materials evaluation in fatigue, thermal and corrosion damage: A review. Mech. Syst. Signal Process. 2019, 120, 32–42. [Google Scholar] [CrossRef]

- Matlack, K.H.; Kim, J.Y.; Jacobs, L.J.; Jacobs, L.J.; Qu, J. Review of second harmonic generation measurement techniques for material state determination in metals. J. Nondestruct. Eval. 2015, 34, 273. [Google Scholar] [CrossRef]

- Zhang, X.; Syed, A.K.; Biswal, R.; Martina, F.; Ding, J.; Williams, S. High cycle fatigue and fatigue crack growth rate in additive manufactured titanium alloys. In ICAF 2019–Structural Integrity in the Age of Additive Manufacturing, Proceedings of the 30th Symposium of the International Committee on Aeronautical Fatigue, Krakow, Poland, 2–7 June 2019; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 31–42. [Google Scholar]

- Voisin, T.; Calta, N.P.; Khairallah, S.A.; Forien, J.-B.; Balogh, L.; Cunningham, R.W.; Rollett, A.D.; Wang, Y.M. Defects-dictated tensile properties of selective laser melted Ti-6Al-4V. Mater. Des. 2018, 158, 113–126. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Ram, G.D.J.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti–6Al–4 V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Acevedo, R.; Sedlak, P.; Kolman, R.; Fredel, M. Residual stress analysis of additive manufacturing of metallic parts using ultrasonic waves: State of the art review. J. Mater. Res. Technol. 2020, 9, 9457–9477. [Google Scholar] [CrossRef]

- Honarvar, F.; Varvani-Farahani, A. A review of ultrasonic testing applications in additive manufacturing: Defect evaluation, material characterization, and process control. Ultrasonics 2020, 108, 106227. [Google Scholar] [CrossRef]

- Prevorovsky, Z.; Krofta, J.; Kober, J. NDT in Additive Manufacturing of Metals; NDT Prog: Hague, The Netherlands, 2017; pp. 75–84. [Google Scholar]

- Liu, P.; Yang, L.; Yi, K.; Kundu, T.; Sohn, H. Application of nonlinear ultrasonic analysis for in situ monitoring of metal additive manufacturing. Struct. Health Monit. 2023, 22, 1760–1775. [Google Scholar] [CrossRef]

- Zamen, S.; Dehghan-Niri, E.; Al-Beer, H.; Lindahl, J.; Hassen, A.A. Characterization of nonlinear ultrasonic waves behavior while interacting with poor interlayer bonds in large-scale additive manufactured materials. NDT E Int. 2022, 127, 102602. [Google Scholar] [CrossRef]

- Wang, P.; Wang, W.; Zheng, S.; Chen, B.; Gao, Z. Fatigue Damage Evaluation of Compressor Blade Based on Nonlinear Ultrasonic Nondestructive Testing. J. Mar. Sci. Eng. 2021, 9, 1358. [Google Scholar] [CrossRef]

- Wang, P.; Zhou, Q.; Chen, B.; Zheng, S.; Wang, C.; Gao, Z. Research on high cycle fatigue damage characterization of FV520B steel based on the nonlinear Lamb wave. J. Strain Anal. Eng. Des. 2021, 57, 484–495. [Google Scholar] [CrossRef]

- ISO 4063; Welding, Brazing, Soldering and Cutting—Nomenclature of Processes and Reference Numbers. ISO: Geneva, Switzerland, 2023.

- ISO 4967:2013; Steel—Determination of Content of Non-Metallic Inclusions—Micrographic Method Using Standard Diagrams. ISO: Geneva, Switzerland, 2013.

| C | Mn | Si | Ni | Cr | Mo | S | P | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.04 | 1.3 | ≤1.0 | 12.0 | 18.65 | 2.42 | ≤0.03 | ≤0.04 | ≤0.75 | Remaining |

| No. | Scanning Speed (cm/min) | Shielding Gas |

|---|---|---|

| V20 | 20 | 98%Ar + 2%O2 |

| V30 | 30 | 98%Ar + 2%O2 |

| V40 | 40 | 98%Ar + 2%O2 |

| V20(CO2) | 20 | 100%CO2 |

| Element | Atomic Percentage/% | Weight Percentage/% | |

|---|---|---|---|

| Precipitate | Si | 1.575 | 0.799 |

| Cr | 27.751 | 26.074 | |

| Mn | 1.107 | 1.099 | |

| Fe | 61.971 | 62.537 | |

| Ni | 5.464 | 5.794 | |

| Mo | 2.132 | 3.696 | |

| Matrix | Si | 0.989 | 0.501 |

| Cr | 21.268 | 19.920 | |

| Mn | 1.416 | 1.401 | |

| Fe | 62.690 | 63.063 | |

| Ni | 12.594 | 13.313 | |

| Mo | 1.043 | 1.802 |

| Output Level (%) | 30 | 40 | 50 | 55 | 60 | 65 |

|---|---|---|---|---|---|---|

| A1 (mV) | 305.02 | 411.91 | 518.68 | 572.85 | 624.97 | 674.87 |

| A2 (mV) | 3.19 | 5.66 | 8.86 | 10.60 | 12.53 | 14.50 |

| β | 3.42 E-5 | 3.34 E-5 | 3.29 E-5 | 3.23 E-5 | 3.21 E-5 | 3.18 E-5 |

| No. | Second-Order Nonlinear Parameter β | Third-Order Nonlinear Parameter δ | Porosity/% | Number of Pores |

|---|---|---|---|---|

| V20 | 2.2806 E-5 | 3.39 E-9 | 0.65865 | 646 |

| V30 | 2.4731 E-5 | 3.76 E-9 | 0.7692 | 798 |

| V40 | 2.528 E-5 | 3.97 E-9 | 0.8495 | 857 |

| V20(CO2) | 2.7961 E-5 | 6.59 E-9 | 1.00105 | 1285 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Zeng, J.; Lou, D.; Zheng, W.; Zheng, S.; Chen, B.; Gao, Z. Nonlinear Ultrasonic Characterization of Processing Defects in Wire Arc Additive Manufacturing 316L Stainless Steel. Materials 2025, 18, 805. https://doi.org/10.3390/ma18040805

Wang P, Zeng J, Lou D, Zheng W, Zheng S, Chen B, Gao Z. Nonlinear Ultrasonic Characterization of Processing Defects in Wire Arc Additive Manufacturing 316L Stainless Steel. Materials. 2025; 18(4):805. https://doi.org/10.3390/ma18040805

Chicago/Turabian StyleWang, Pengfei, Jia Zeng, Dong Lou, Wenjian Zheng, Sanlong Zheng, Bingbing Chen, and Zengliang Gao. 2025. "Nonlinear Ultrasonic Characterization of Processing Defects in Wire Arc Additive Manufacturing 316L Stainless Steel" Materials 18, no. 4: 805. https://doi.org/10.3390/ma18040805

APA StyleWang, P., Zeng, J., Lou, D., Zheng, W., Zheng, S., Chen, B., & Gao, Z. (2025). Nonlinear Ultrasonic Characterization of Processing Defects in Wire Arc Additive Manufacturing 316L Stainless Steel. Materials, 18(4), 805. https://doi.org/10.3390/ma18040805