Analysis of Thick-Walled Oxygen-Free Copper Pipe Production in the Bridge Die Extrusion Process

Abstract

1. Introduction

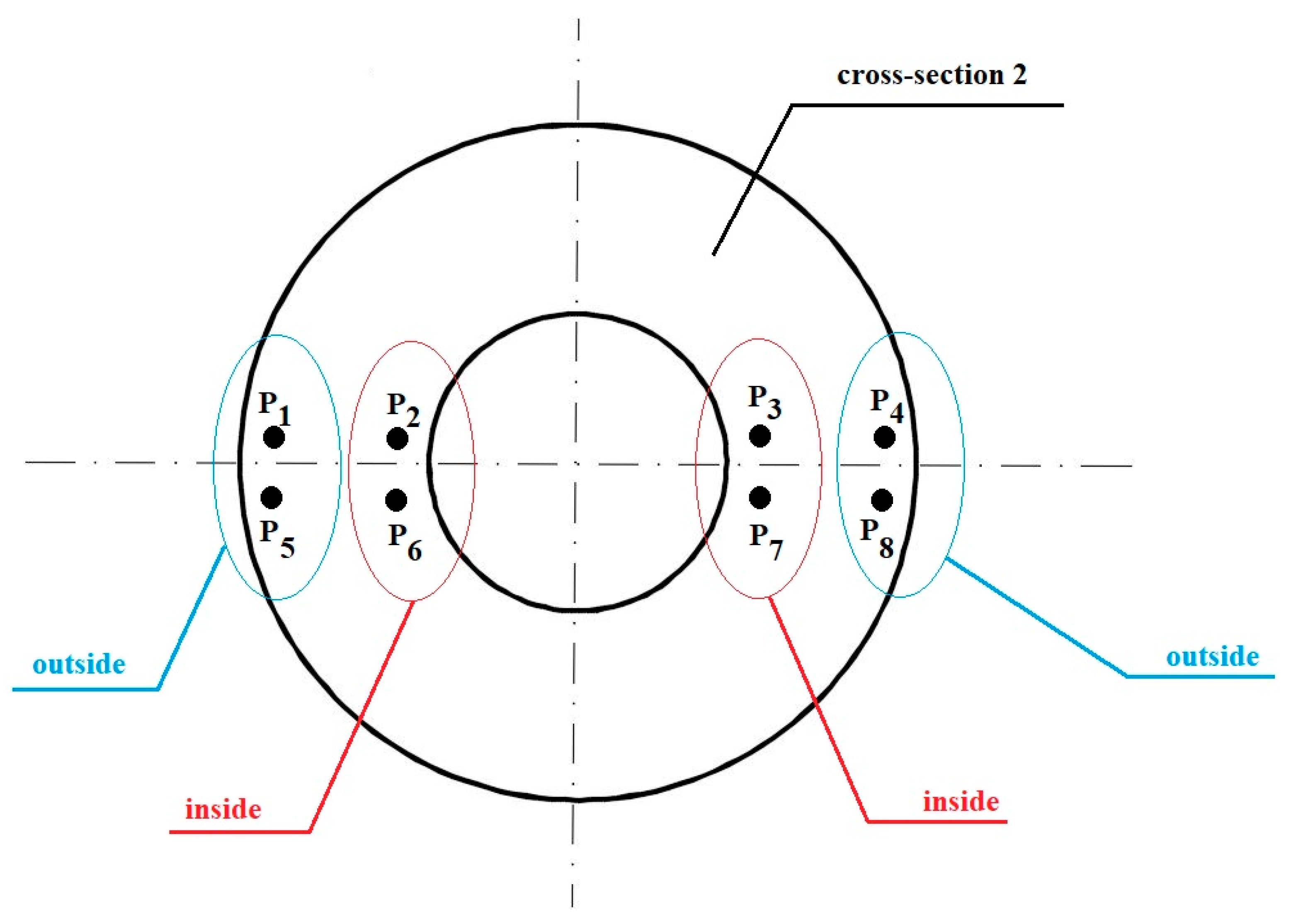

2. Material and Research Methodology

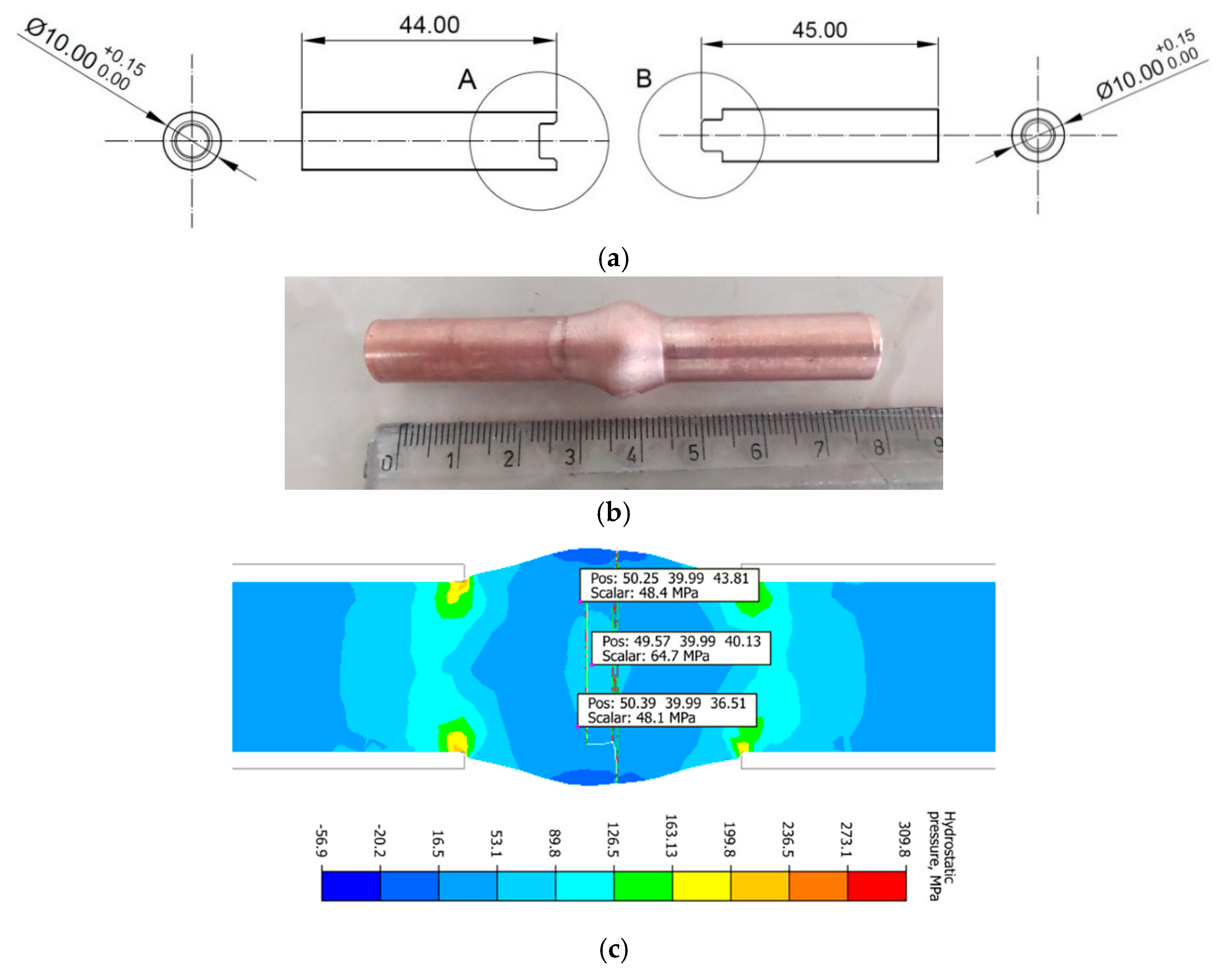

2.1. Methodology for Copper Weld Quality Analysis Under Physical Simulation Conditions

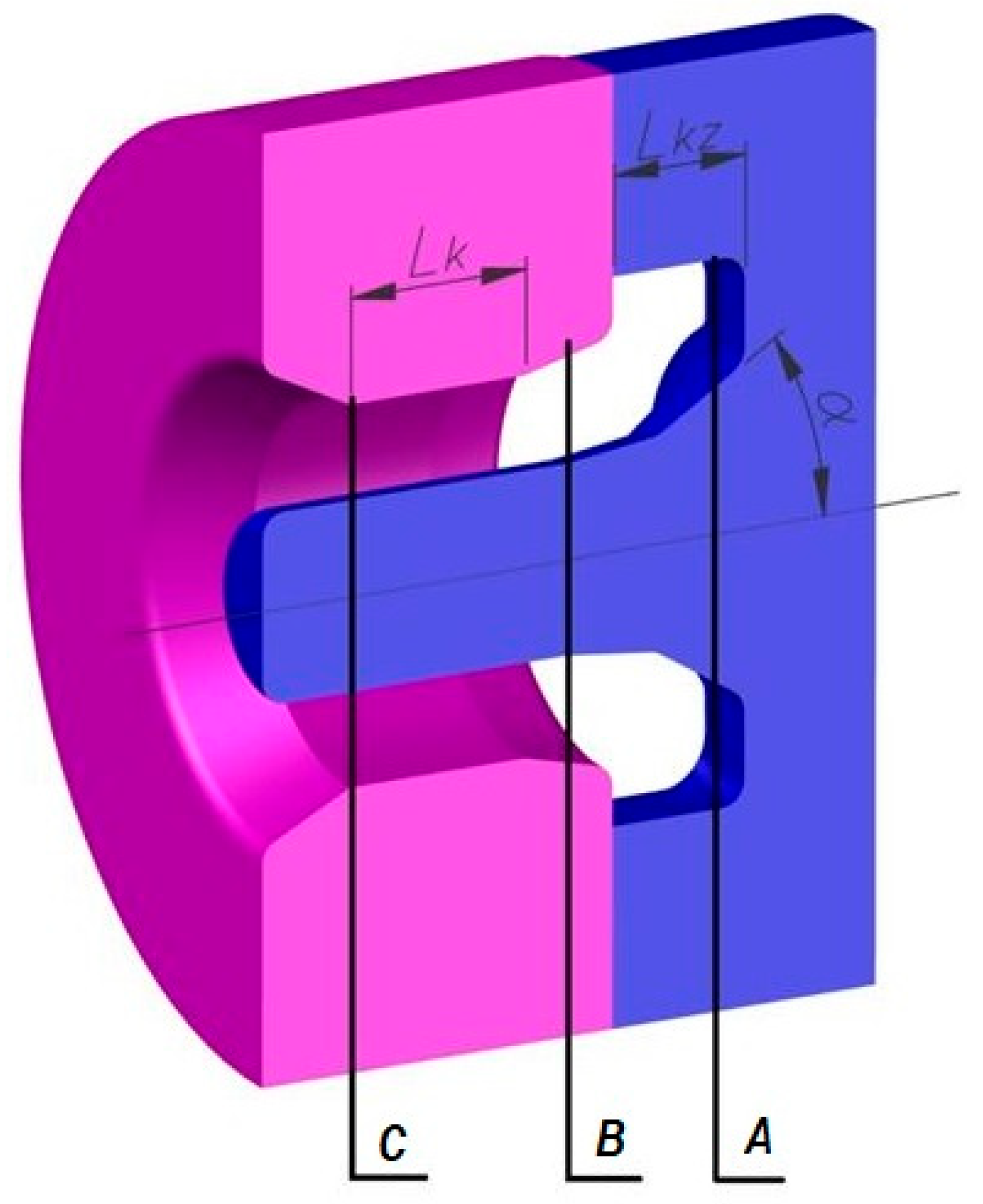

2.2. Methodology for Numerical Modelling of the Pipe Extrusion Process

- A coefficient of friction between the tool surfaces and the material of μ = 0.3,

- A coefficient of heat transfer between tools and material of λ = 8100 W/m2 K,

- A coefficient of heat transfer between Cu alloy and the environment of α = 7 W/m2 K.

- A piston feed speed of v = 10 mm/s,

- An initial charge temperature of 600 °C,

- An ambient temperature of 25 °C,

- A tool temperature of 350 °C,

- The length of the calibrating part of the die Lk was varied in the range of 1–4 mm,

- The length of the welding chamber Lkz was varied within the range of 2–3 mm,

- The angle of the mandrel in the welding chamber α was varied within the range of 21–41°.

3. Results and Analysis of Model Tests

3.1. Results of Tensile Tests of Copper After Bulging Process

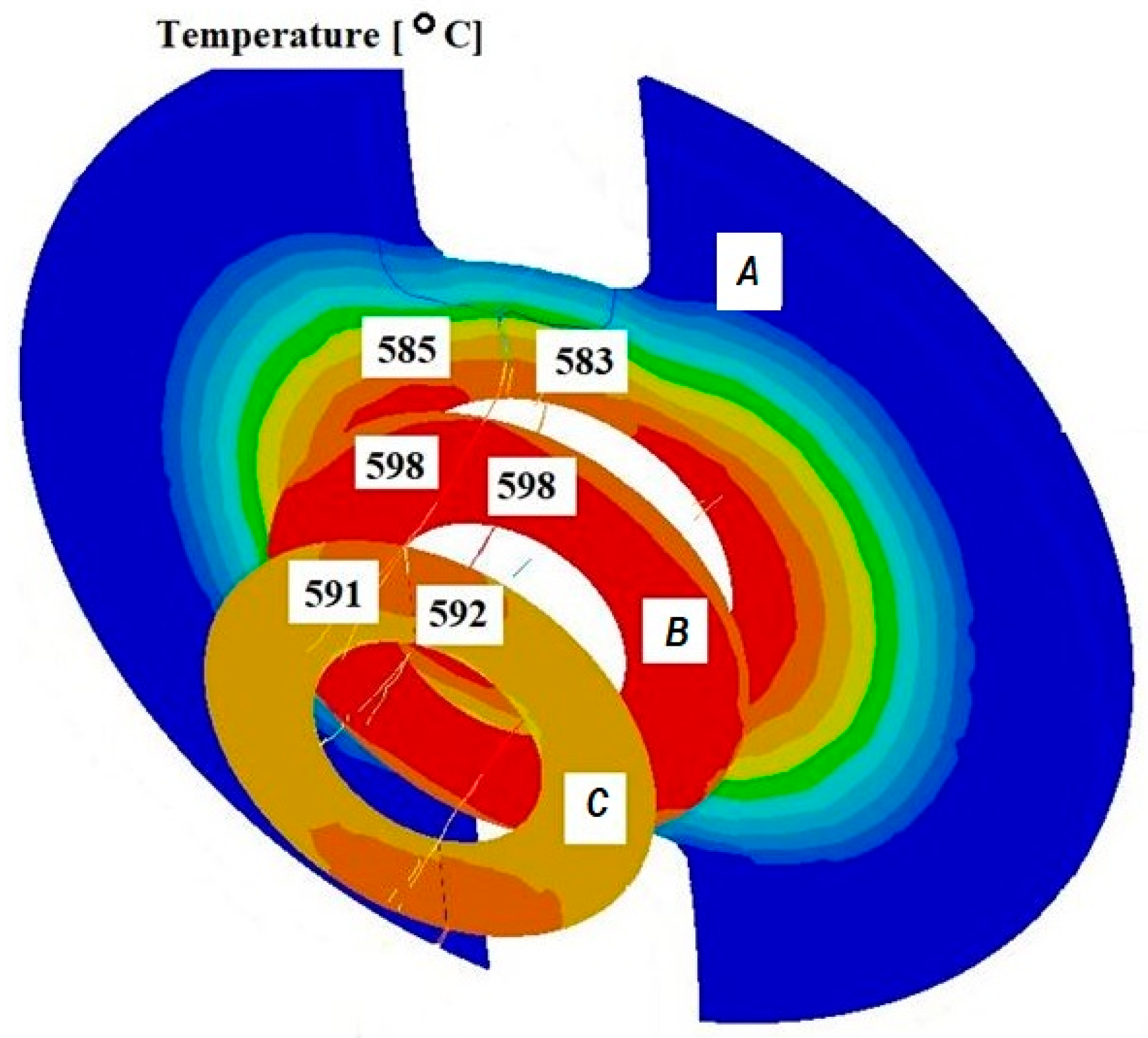

3.2. Analysis of Temperature Distribution in Numerical Modelling of the Extrusion Process

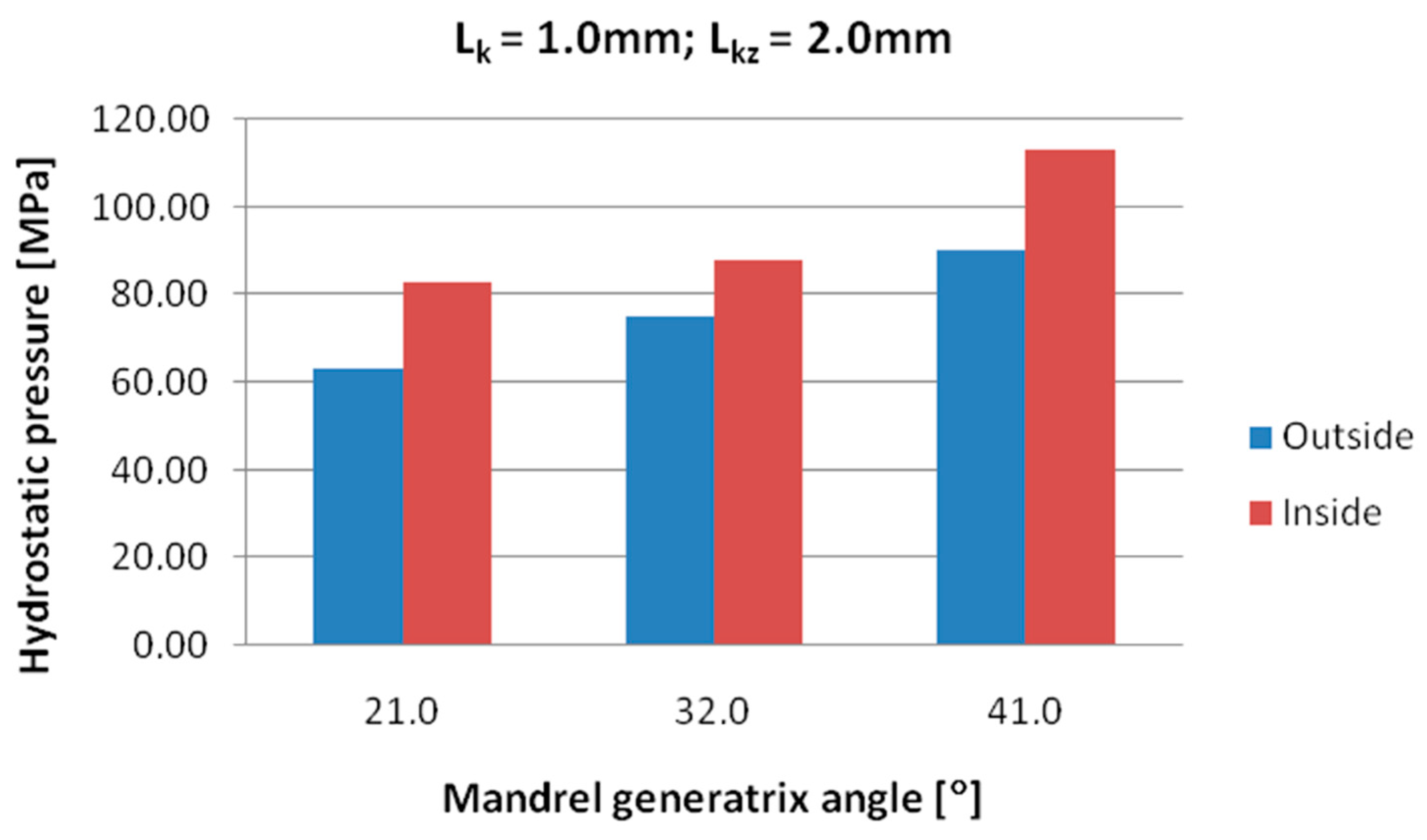

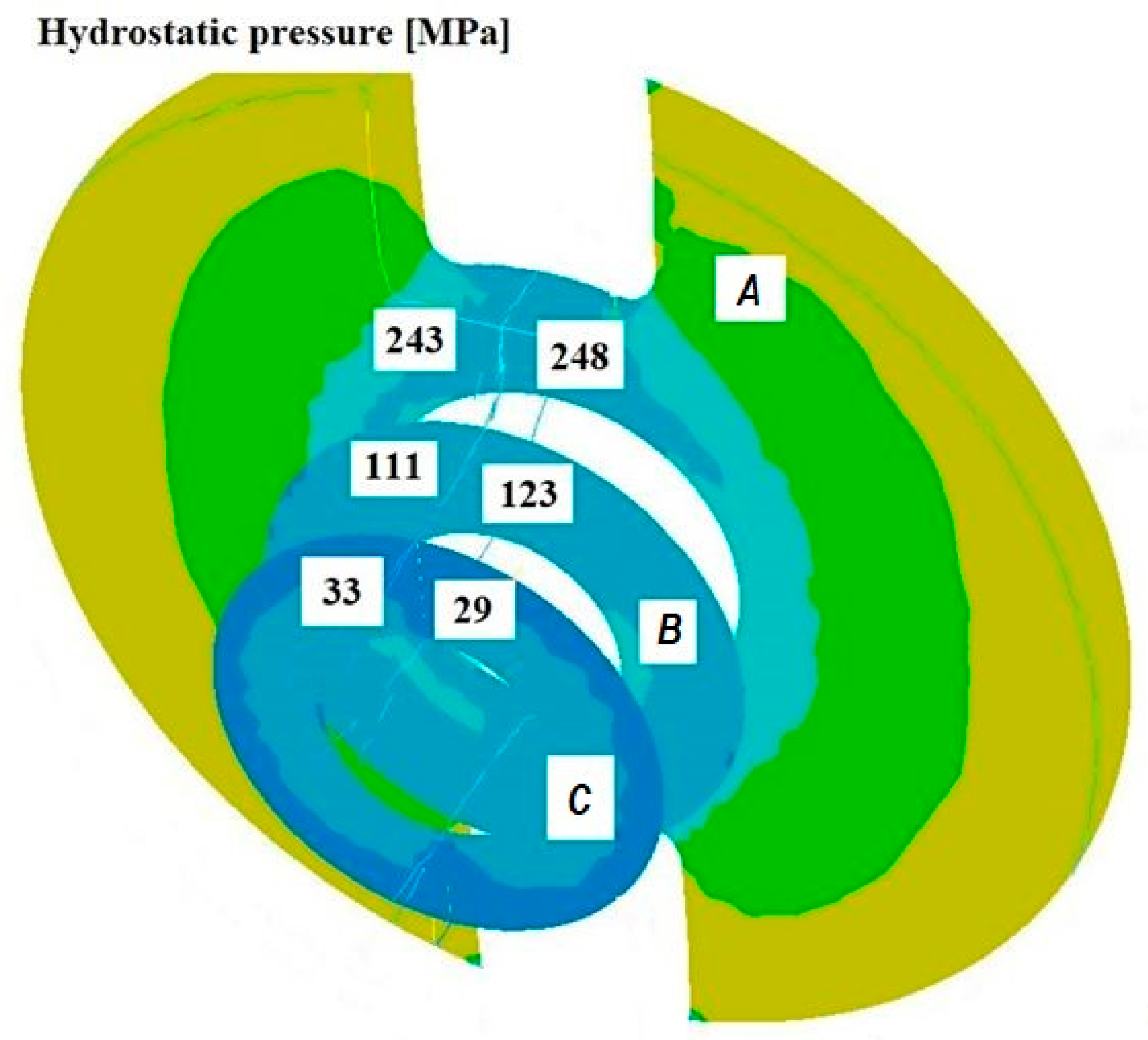

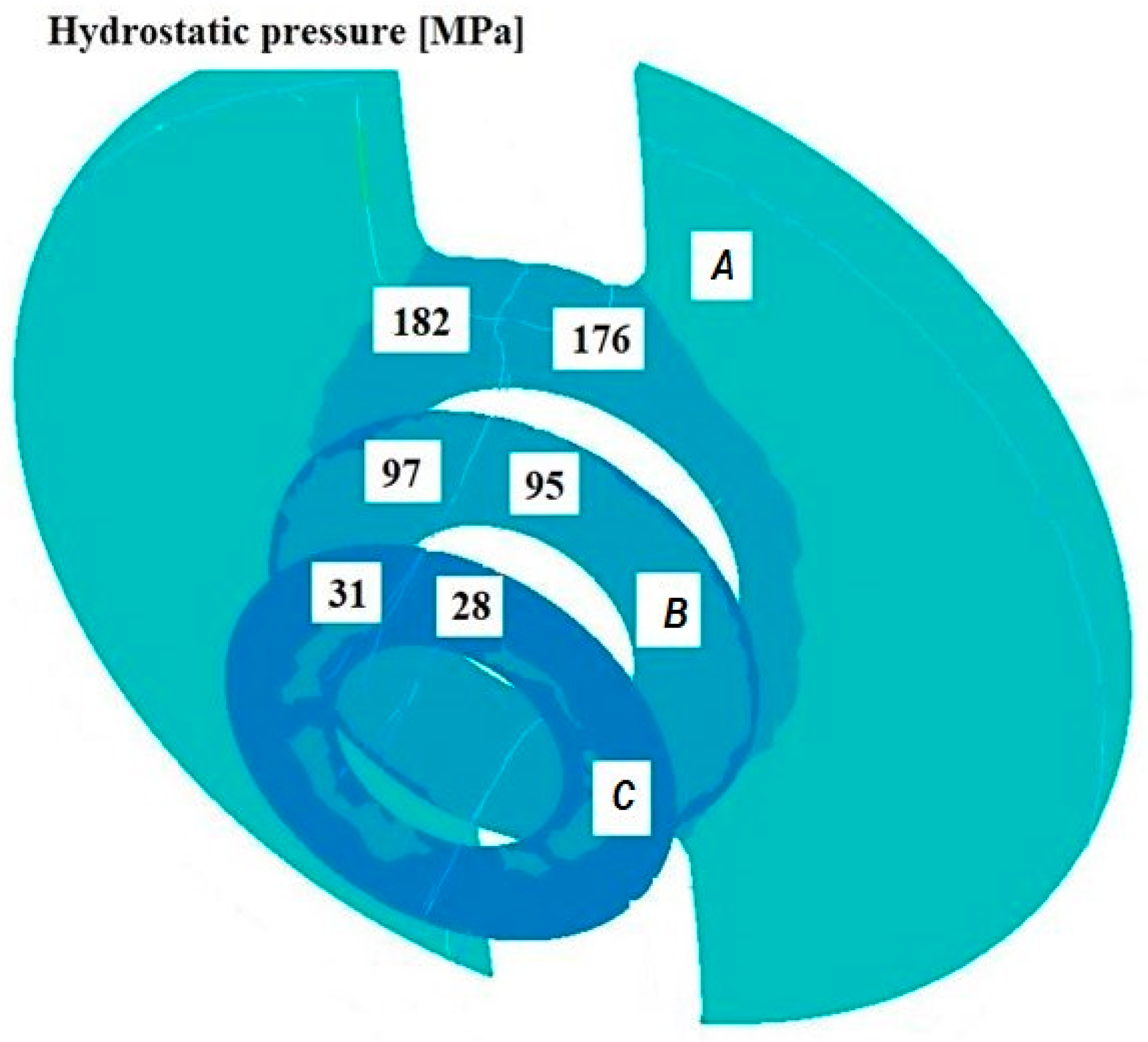

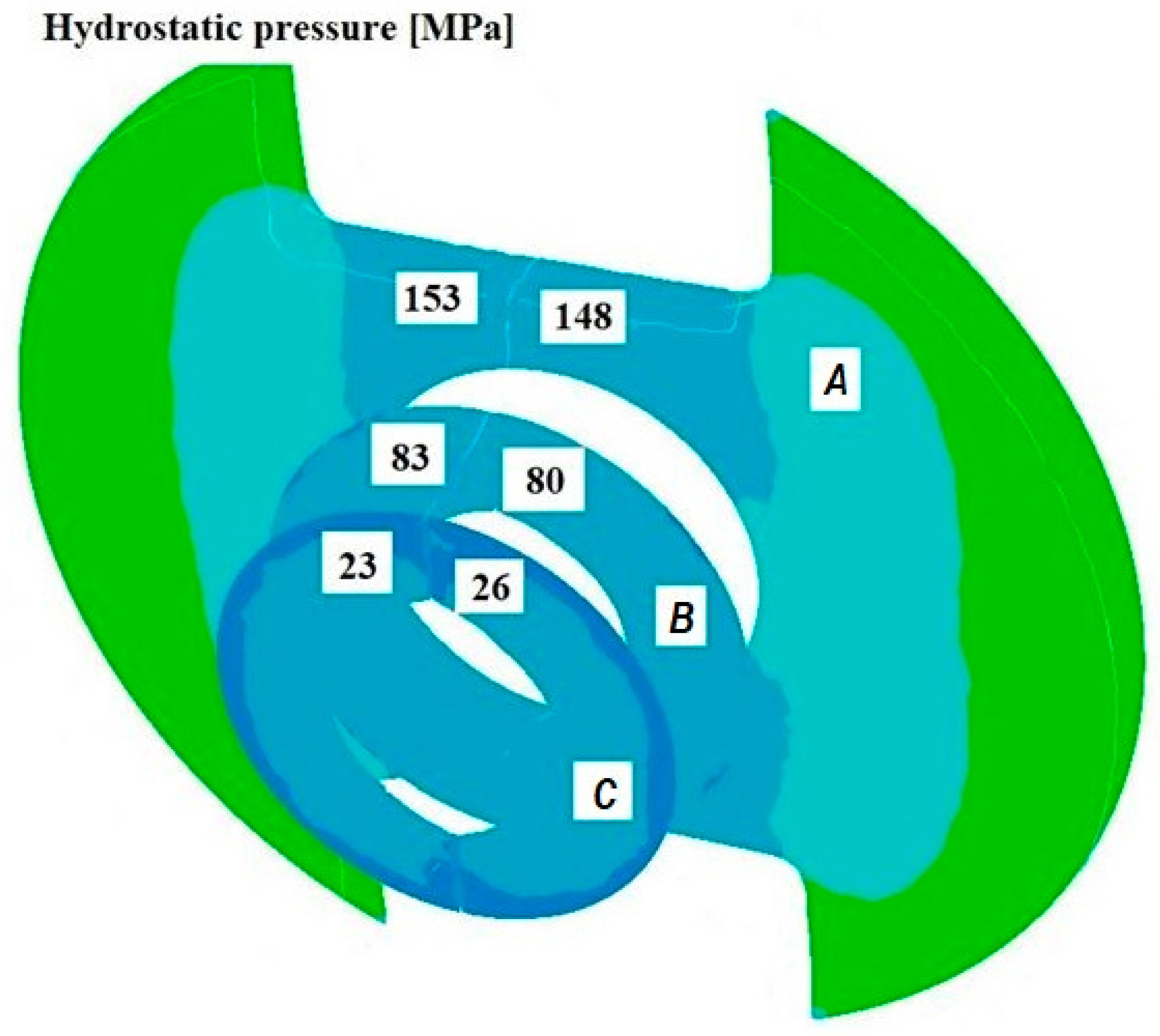

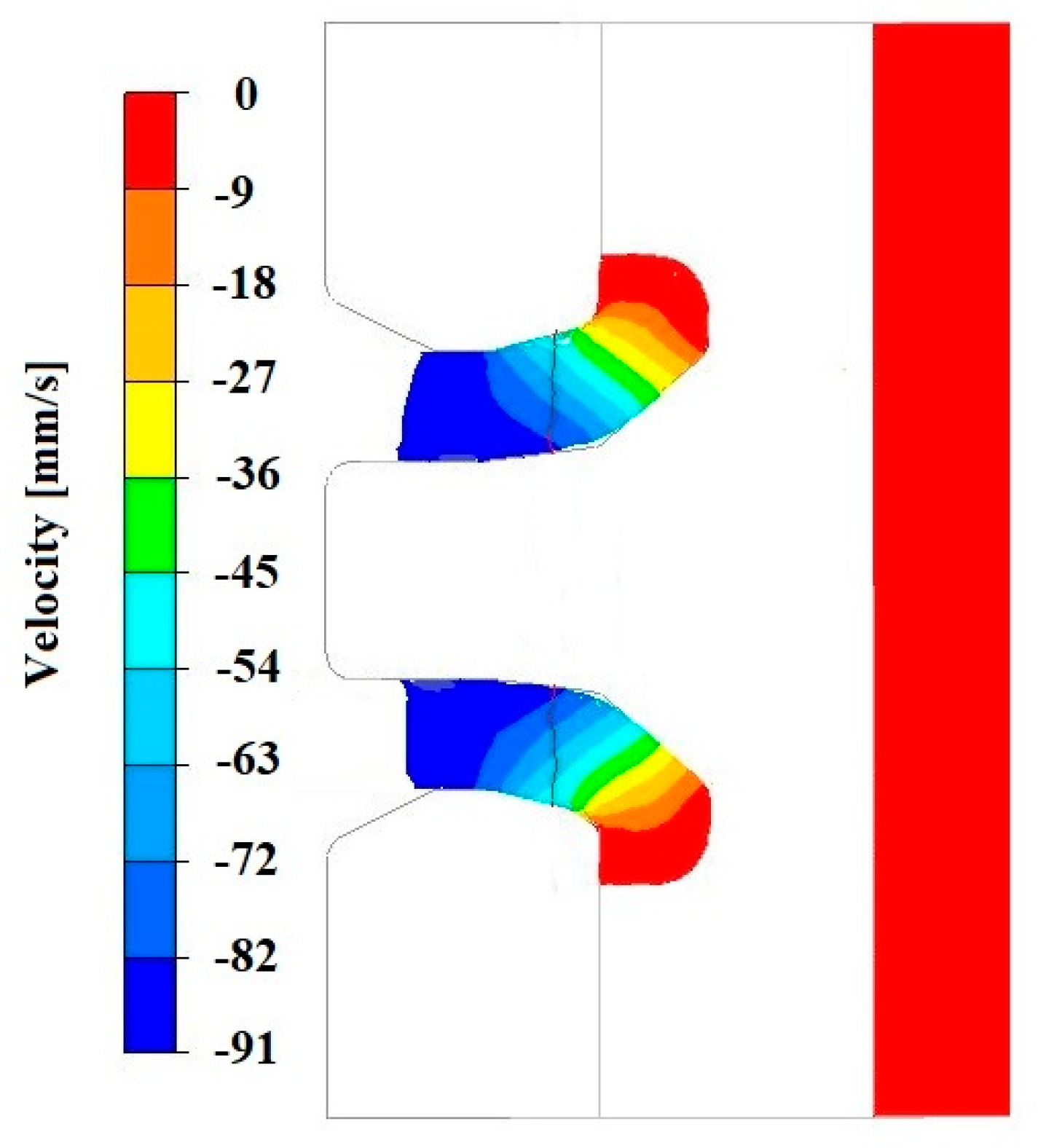

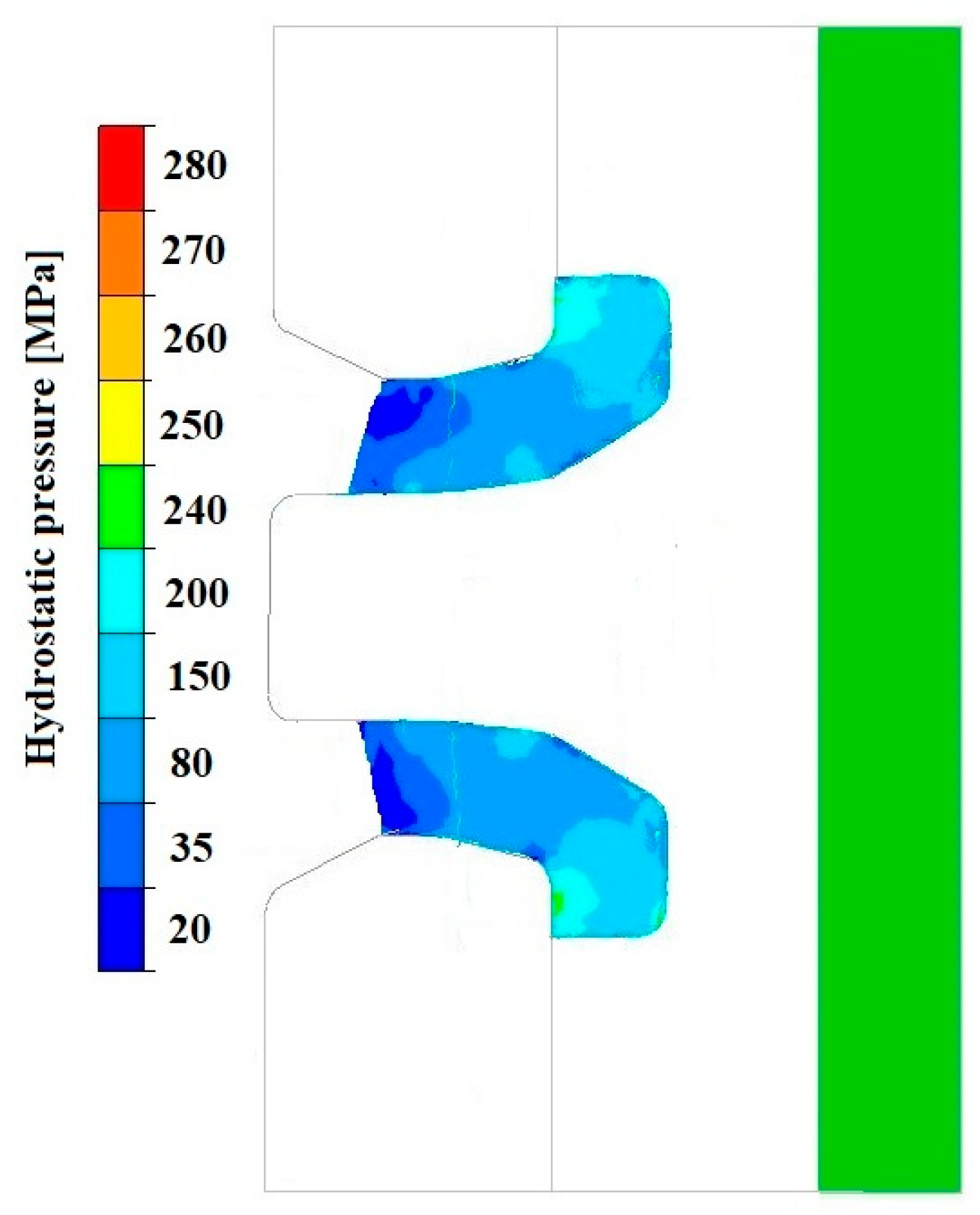

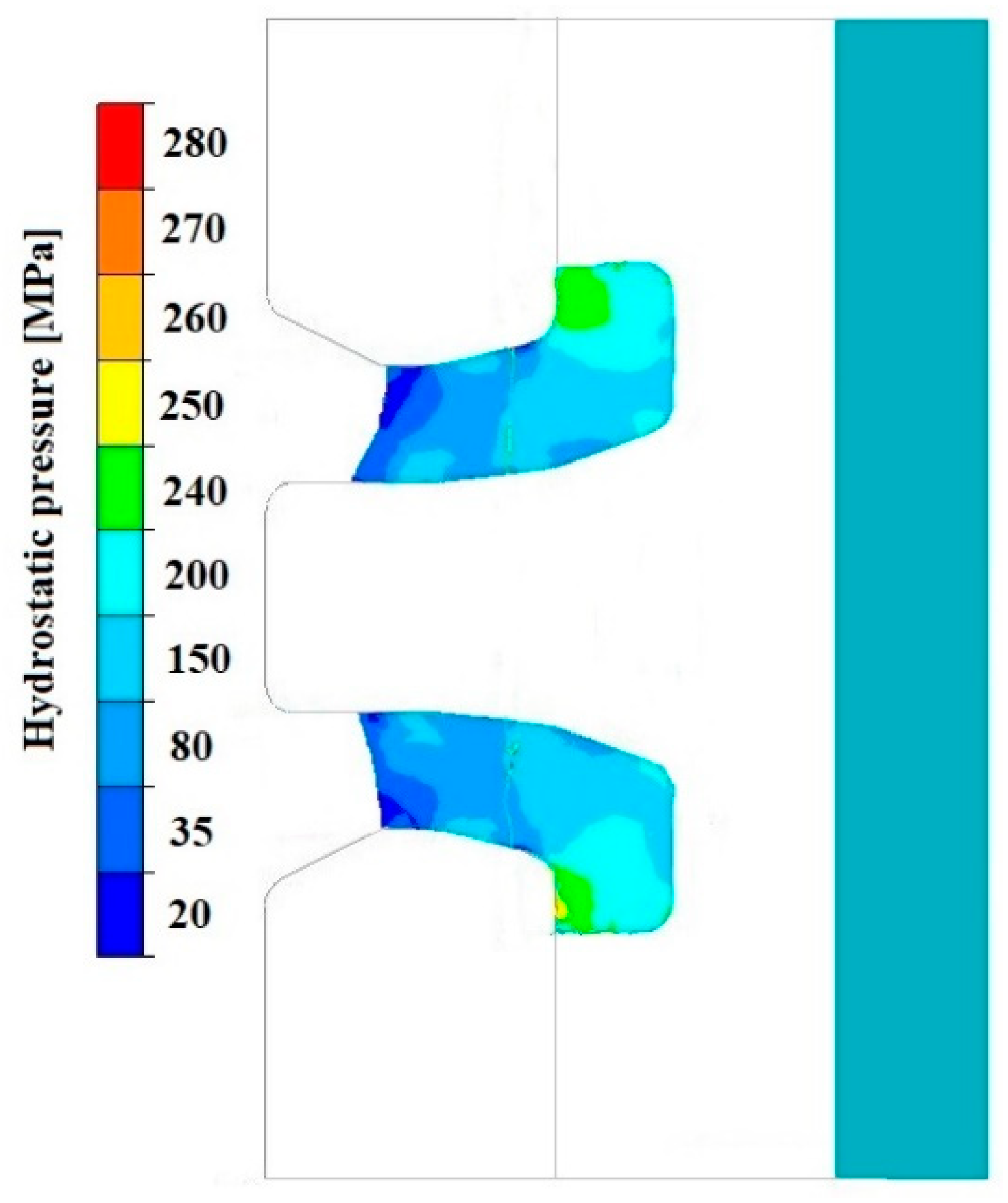

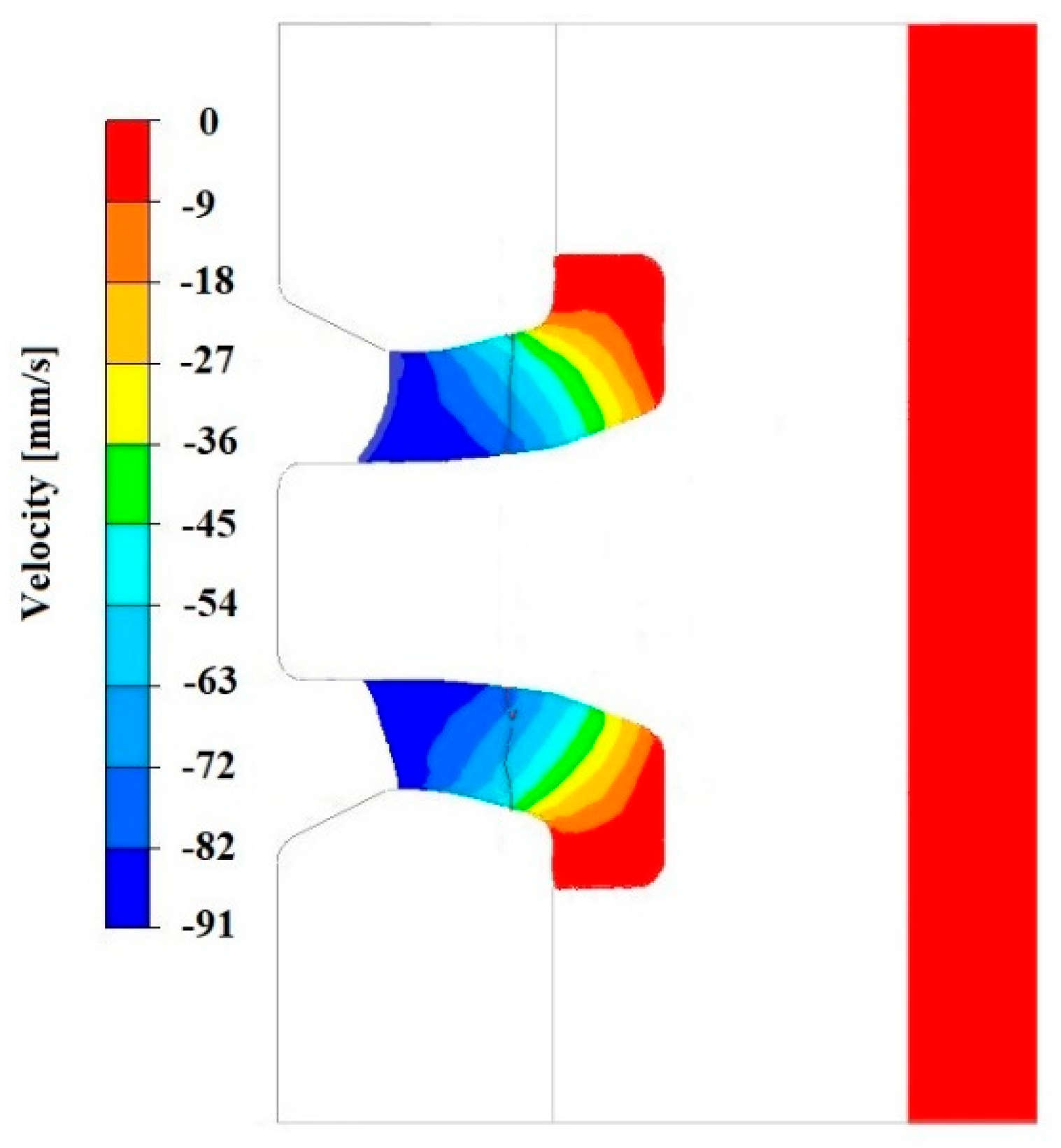

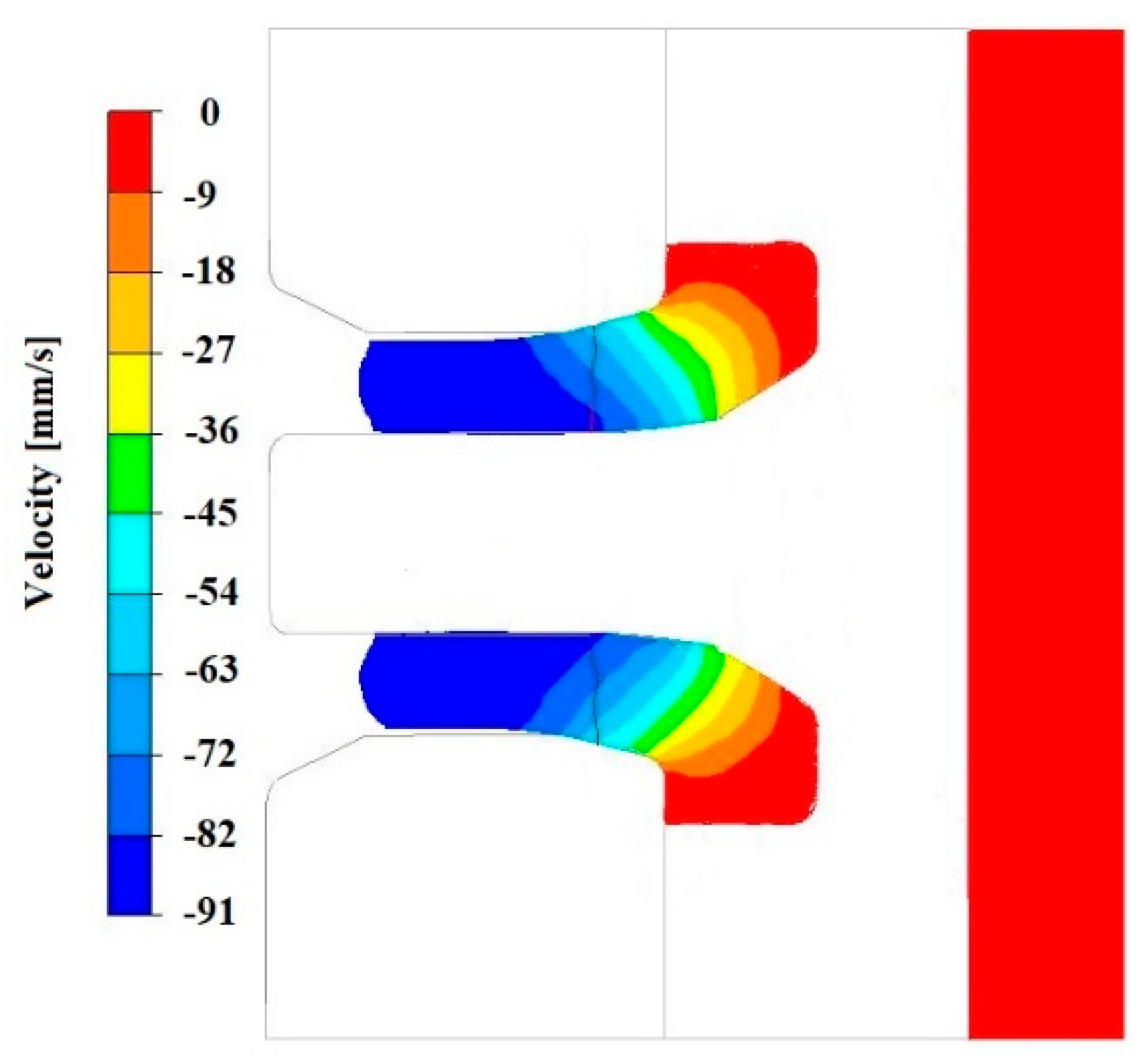

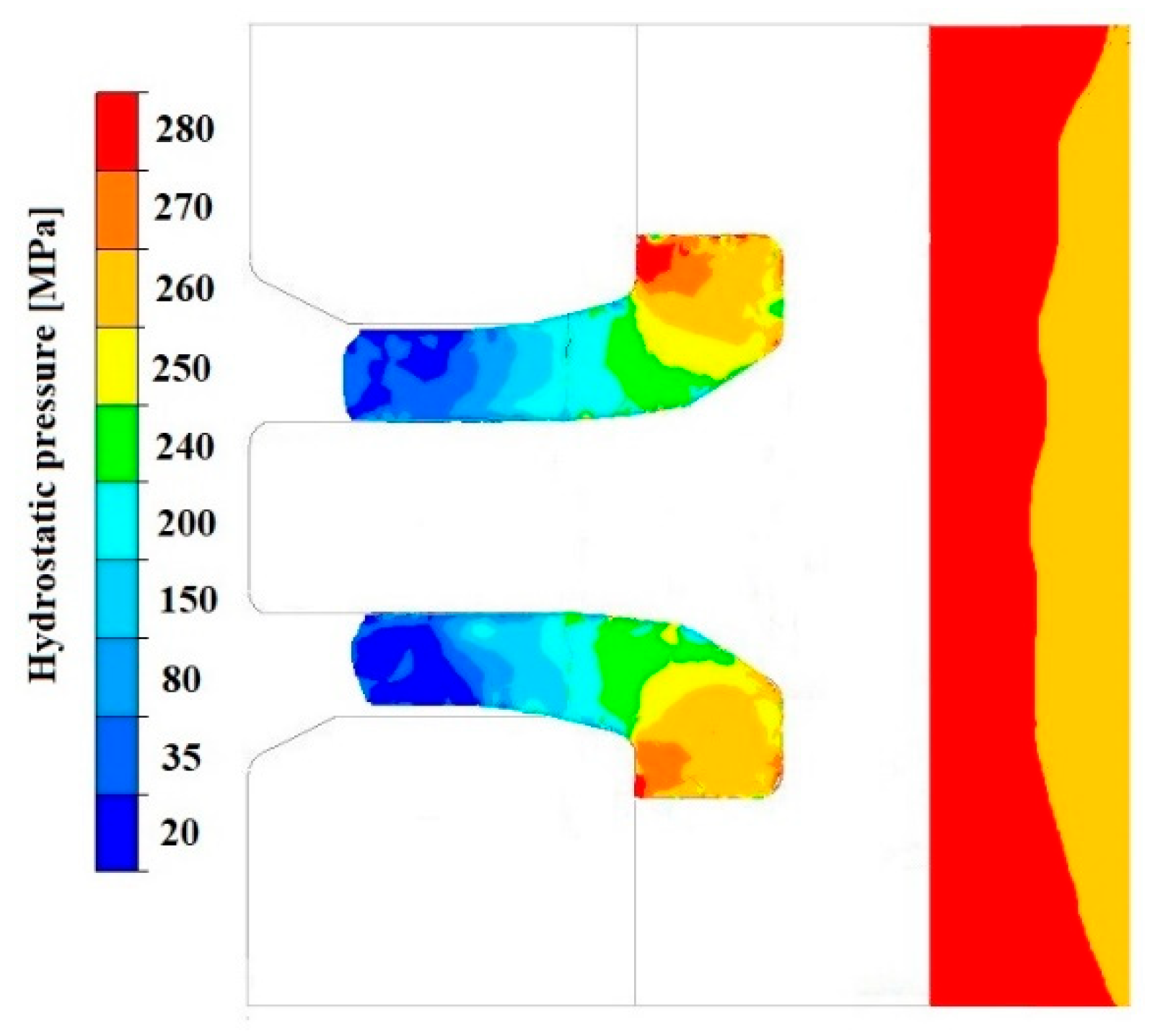

3.3. Analysis of the Hydrostatic Pressure Distribution and Material Flow Velocity in Numerical Modelling of the Extrusion Process

4. Discussion of the Obtained Modelling Results

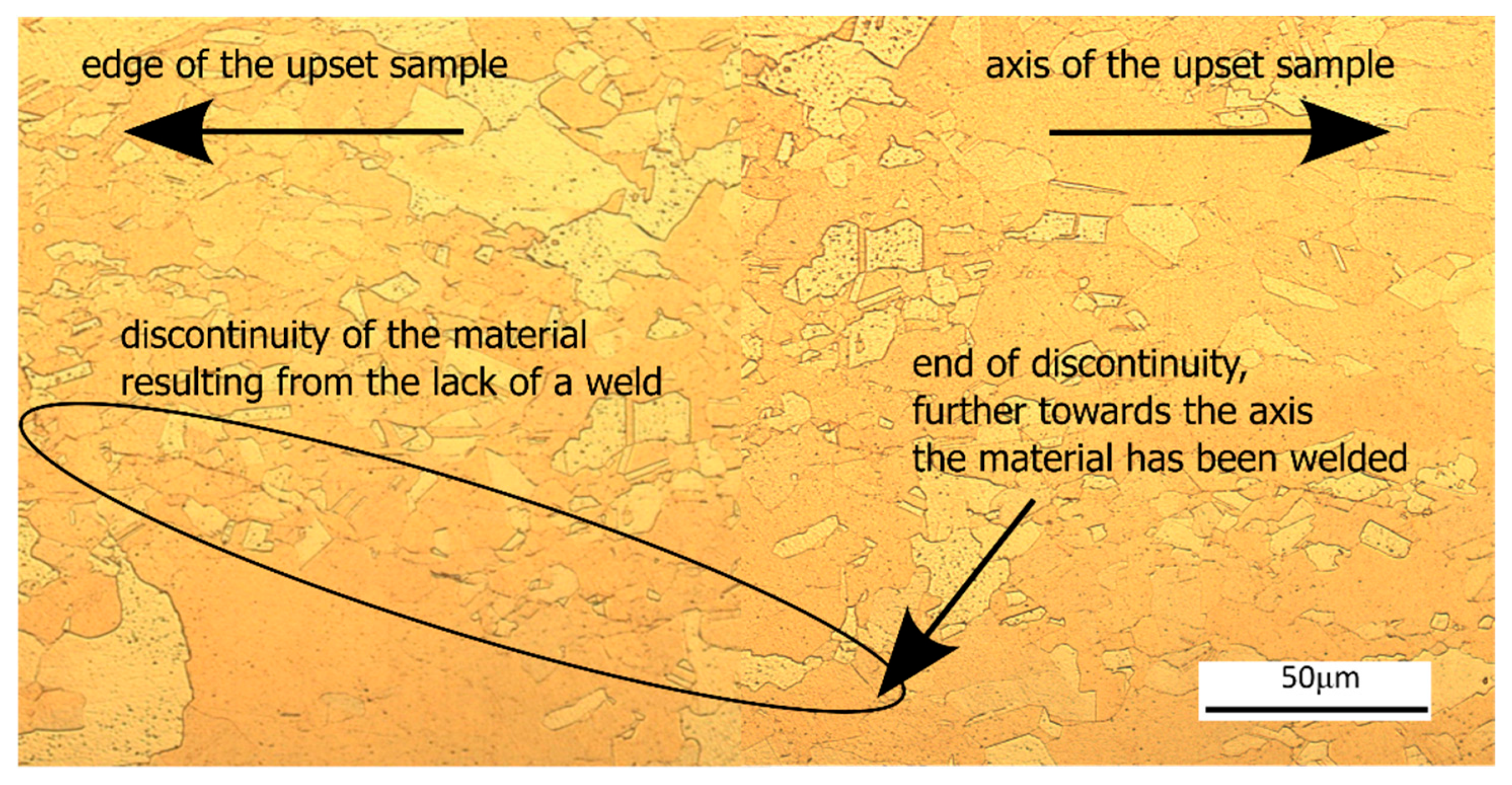

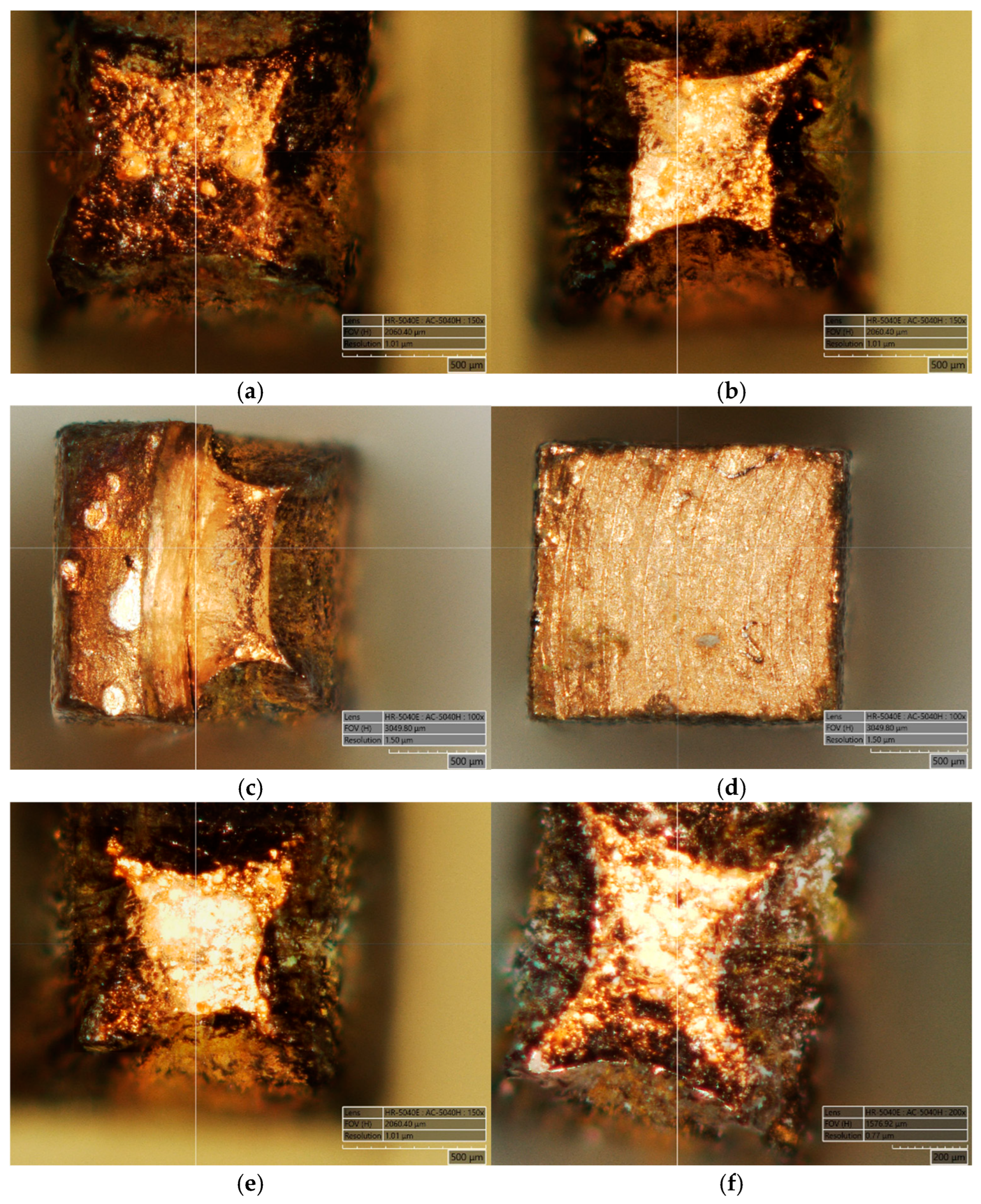

4.1. Discussion of the Physical Simulation Results of the Welding Process

4.2. Discussion of the Numerical Simulation Results of the Welding Process

5. Conclusions

- Tool geometry: the mandrel angle in the welding chamber, the length of the welding chamber, and the length of the calibration section of the die have a significant impact on the material flow kinematics in the tube welding process.

- Increasing the mandrel angle in the welding chamber leads to higher hydrostatic pressure values in the deformation cavity.

- Extending the welding chamber improves welding conditions by increasing hydrostatic pressure; however, excessive extension increases frictional resistance and hinders material flow.

- The length of the die calibration section significantly affects welding conditions—its extension increases hydrostatic pressure and promotes welding, but at the same time raises flow resistance and reduces extrusion efficiency.

- The minimum geometric parameters of the die required to achieve a durable joint are mandrel angle in the welding chamber—21°, length of the welding chamber—2 mm, and length of the calibration section of the die—1 mm.

- The results of the numerical simulations were confirmed by physical experiments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Benzarti, Z.; Arrousse, N.; Serra, R.; Cruz, S.; Bastos, A.; Tedim, J.; Salgueiro, R.; Cavaleiro, A.; Carvalho, S. Copper corrosion mechanisms, influencing factors, and mitigation strategies for water circuits of heat exchangers: Critical review and current advances. Corros. Rev. 2024, 43, 429–455. [Google Scholar] [CrossRef]

- Schestak, I.; Spriet, J.; Styles, D.D.; Williams, A.P. Emissions down the drain: Balancing life cycle energy and greenhouse gas savings with resource use for heat recovery from kitchen drains. J. Environ. Manag. 2020, 271, 110988. [Google Scholar] [CrossRef] [PubMed]

- Schlesinger, M.E.; Sole, K.C.; Davenport, W.G.; Flores, G.R. Extractive Metallurgy of Copper; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Houben, G.; Sander, J. Preventing the growth of iron bacteria in water wells by copper and silver coating. Water Supply 2020, 20, 1195–1206. [Google Scholar] [CrossRef]

- Maydanik, Y.F.; Pastukhov, V.G. Copper−water loop heat pipes: Issues and achievements. Heat Pipe Sci. Technol. 2015, 6, 534–542. [Google Scholar] [CrossRef]

- Khammayom, N.; Maruyama, N.; Chaichana, C.; Hirota, M. Experimental analysis of local air temperature and thermal performance of a serpentine copper pipe. Energy Rep. 2023, 9, 653–661. [Google Scholar] [CrossRef]

- Jahromi, M.S.B.; Kalantar, V.; Samimi-Akhijahani, H. Design and performance analysis of a new flat solar heating porous collector equipped with vertical copper pipe and porous medium for medicinal plant drying. Energy 2025, 334, 137653. [Google Scholar] [CrossRef]

- Ghoochani, S.; Hadiuzzaman, M.; Mirza, N.; Brown, S.P.; Salehi, M. Effects of water chemistry and flow on lead release from plastic pipes versus copper pipes, implications for plumbing decontamination. Environ. Pollut. 2023, 337, 122520. [Google Scholar] [CrossRef]

- Kumari, S.; Rai, A.K.; Sinha, D.K.; Francis, R.C. Deformation behavior and characterization of copper alloy in extrusion process. Int. J. Mech. Eng. Technol. 2015, 6, 72–78. [Google Scholar]

- Liu, Z.W.; Li, L.X.; Yi, J.; Wang, G. Entrance shape design of spread extrusion die for large-scale aluminum panel. Int. J. Adv. Manuf. Technol. 2018, 101, 1725–1740. [Google Scholar] [CrossRef]

- Song, L.; Yuan, Y.; Yin, Z. Microstructural evolution in Cu-Mg alloy processed by conform. Int. J. Nonferrous Metall. 2013, 2, 100–105. [Google Scholar] [CrossRef]

- Knapiński, M.; Bajor, T.; Kawałek, A.; Banaszek, G. Analysis of copper welding parameters during the manufacture of tubular profiles using unconventional extrusion processes. Materials 2024, 17, 4737. [Google Scholar] [CrossRef]

- Yousif, A.D.; Enab, T.A.; Galal, A.M.; El-Gayyar, M.S. Effect of Die Material and Hardness on the Productivity of Copper Strips via Hot Continuous Extrusion Process. Int. J. Mech. Eng. 2016, 4, 22–27. [Google Scholar]

- Bajor, T.; Kawałek, A.; Berski, S.; Jurczak, H.; Borowski, J. Analysis of the extrusion process of aluminium alloy profiles. Materials 2022, 15, 8311. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, C.; Wang, C.; Zhao, G.; Chen, L.; Wenchao, S. Application and analysis of spread die and flat container in the extrusion of a large-size, hollow, and flat-wide aluminum alloy profile. Int. J. Adv. Manuf. Technol. 2018, 94, 4247–4263. [Google Scholar] [CrossRef]

- Sheppard, T.; Nisaratanaporn, E.; McShane, H.B. Material Flow and Pressure Prediction when Extruding through Bridge Dies. Int. J. Mater. Res. 2021, 89, 327–337. [Google Scholar]

- Zhang, L.; Li, L.X.; He, H.; Liu, Z.W.; Zhang, L. Influence of dynamic recrystallization on microstructure and mechanical properties of welding zone in Al–Mg–Si aluminum profile during porthole die extrusion. Trans. Nonferrous Met. Soc. China 2019, 29, 1803–1815. [Google Scholar]

- Leśniak, D.; Libura, W.; Leszczyńska-Madej, B.; Bogusz, M.; Madura, J.; Płonka, B.; Boczkal, S.; Jurczak, H. FEM Numerical and Experimental Work on Extrusion Welding of 7021 Aluminum Alloy. Materials 2023, 16, 5817. [Google Scholar] [CrossRef] [PubMed]

- Remsak, K.; Boczkal, S.; Limanówka, K.; Płonka, B.; Żyłka, K.; Węgrzyn, M.; Leśniak, D. Effects of Zn, Mg, and Cu Content on the Properties and Microstructure of Extrusion-Welded Al–Zn–Mg–Cu Alloys. Materials 2023, 16, 6429. [Google Scholar] [CrossRef] [PubMed]

- Yun, X.B.; Yao, M.L.; Wu, Y.; Song, B.Y. Numerical simulation of continuous extrusion extending forming under the large expansion ratio for copper strip. Appl. Mech. Mater. 2011, 80, 91–95. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W.; Yang, B. Study of size effect in micro-extrusion process of pure copper. Mater. Des. 2011, 32, 3772–3782. [Google Scholar] [CrossRef]

- Kawałek, A.; Dyja, H.; Gałkin, A.M.; Ozhmegov, K.V.; Sawicki, S. Physical modelling of the plastic working processes of zirconium alloy bars and tubes in thermomechanical condition. Arch. Metall. Mater. 2014, 59, 935–940. [Google Scholar] [CrossRef]

- Kawalek, A.; Rapalska-Nowakowska, J.; Dyja, H.; Koczurkiewicz, B. Physical and numerical modeling of heat treatment of the precipitation-hardening complex-phase steel (CP). Metalurgija 2013, 52, 23–26. [Google Scholar]

- Knapinski, M.; Dyja, H.; Kawalek, A.; Kwapisz, M.; Koczurkiewicz, B. Physical Simulations of the Controlled Rolling Process of Plate X100 with Accelerated Cooling. In Mechatronic Systems and Materials V, Solid State Phenomena; Trans Tech Publications Ltd.: Zurich, Switzerland, 2013; Volume 199, pp. 484–489. [Google Scholar]

- Transvalor Solution: How to Run Forge 2008, Users Guide, Sophia Antipolis, France. 2008. Available online: www.transvalor.com (accessed on 23 September 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knapiński, M.; Banaszek, G.; Kawałek, A.; Bajor, T.; Boczkal, G. Analysis of Thick-Walled Oxygen-Free Copper Pipe Production in the Bridge Die Extrusion Process. Materials 2025, 18, 5304. https://doi.org/10.3390/ma18235304

Knapiński M, Banaszek G, Kawałek A, Bajor T, Boczkal G. Analysis of Thick-Walled Oxygen-Free Copper Pipe Production in the Bridge Die Extrusion Process. Materials. 2025; 18(23):5304. https://doi.org/10.3390/ma18235304

Chicago/Turabian StyleKnapiński, Marcin, Grzegorz Banaszek, Anna Kawałek, Teresa Bajor, and Grzegorz Boczkal. 2025. "Analysis of Thick-Walled Oxygen-Free Copper Pipe Production in the Bridge Die Extrusion Process" Materials 18, no. 23: 5304. https://doi.org/10.3390/ma18235304

APA StyleKnapiński, M., Banaszek, G., Kawałek, A., Bajor, T., & Boczkal, G. (2025). Analysis of Thick-Walled Oxygen-Free Copper Pipe Production in the Bridge Die Extrusion Process. Materials, 18(23), 5304. https://doi.org/10.3390/ma18235304