Strength–Ductility Balance of HIP+HT-Treated LPBF GH3536 Alloy via In Situ EBSD: The Role of Annealing Twins

Abstract

1. Introduction

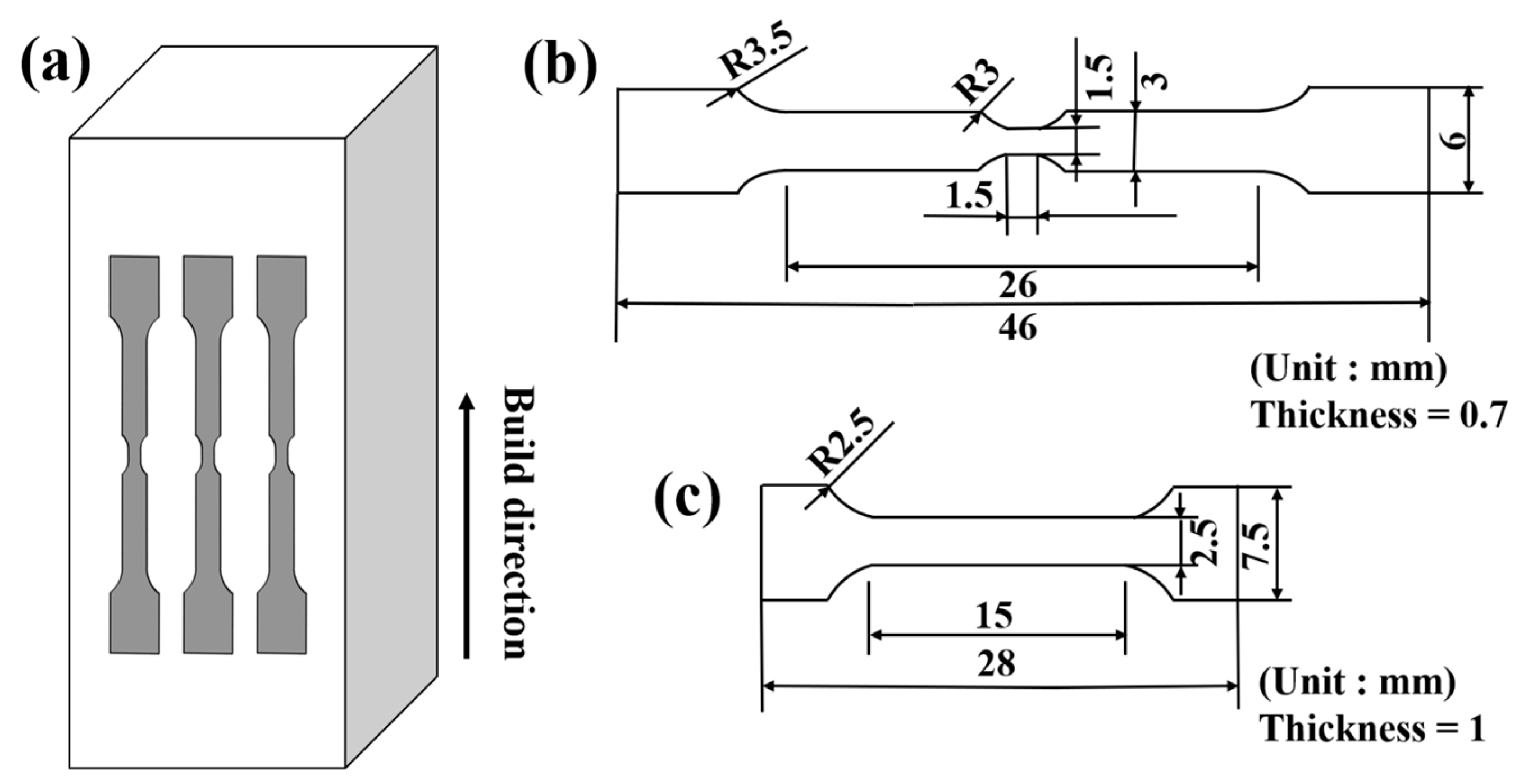

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

3. Results

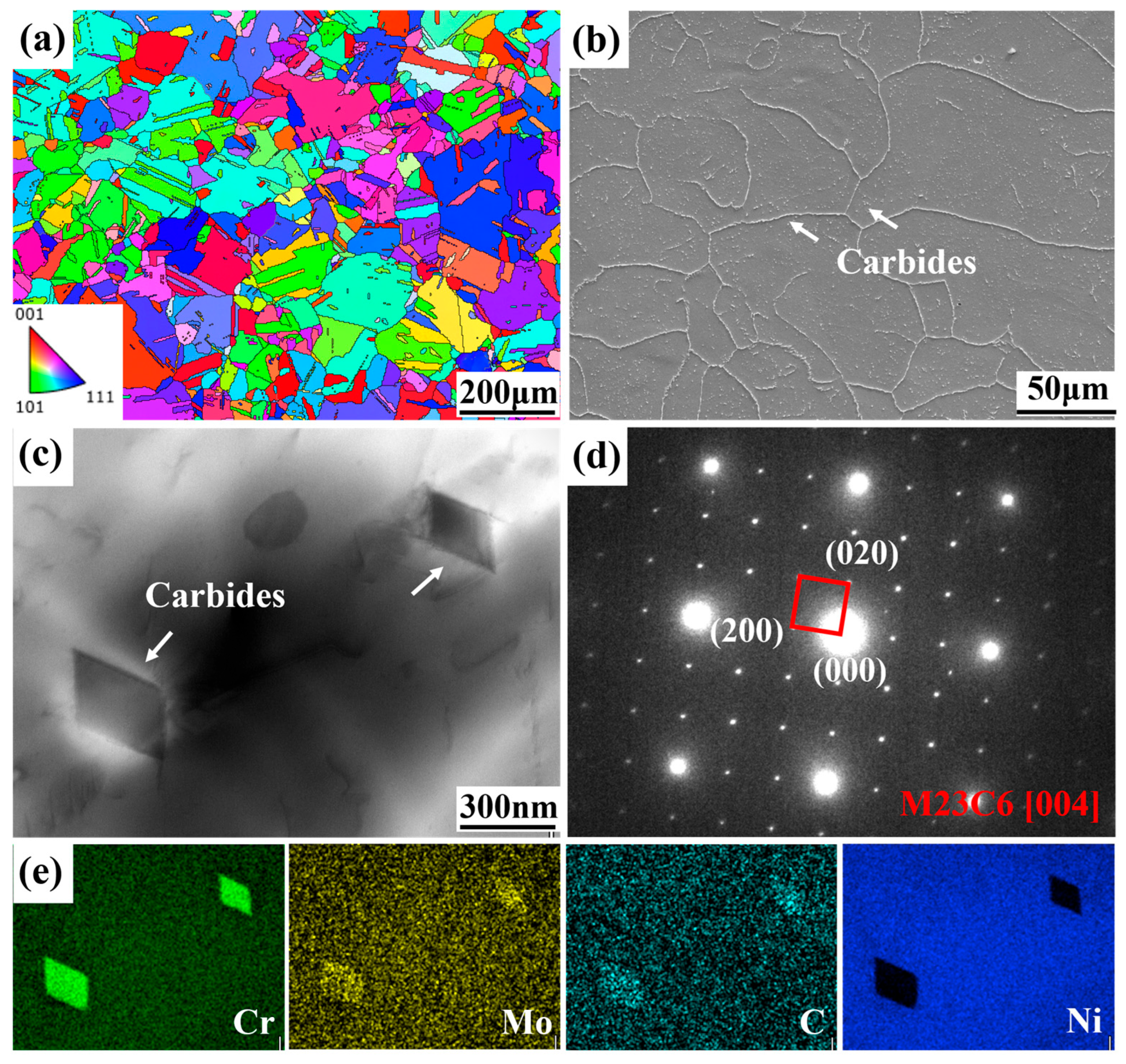

3.1. Microstructure Characterization

3.2. Tensile Properties

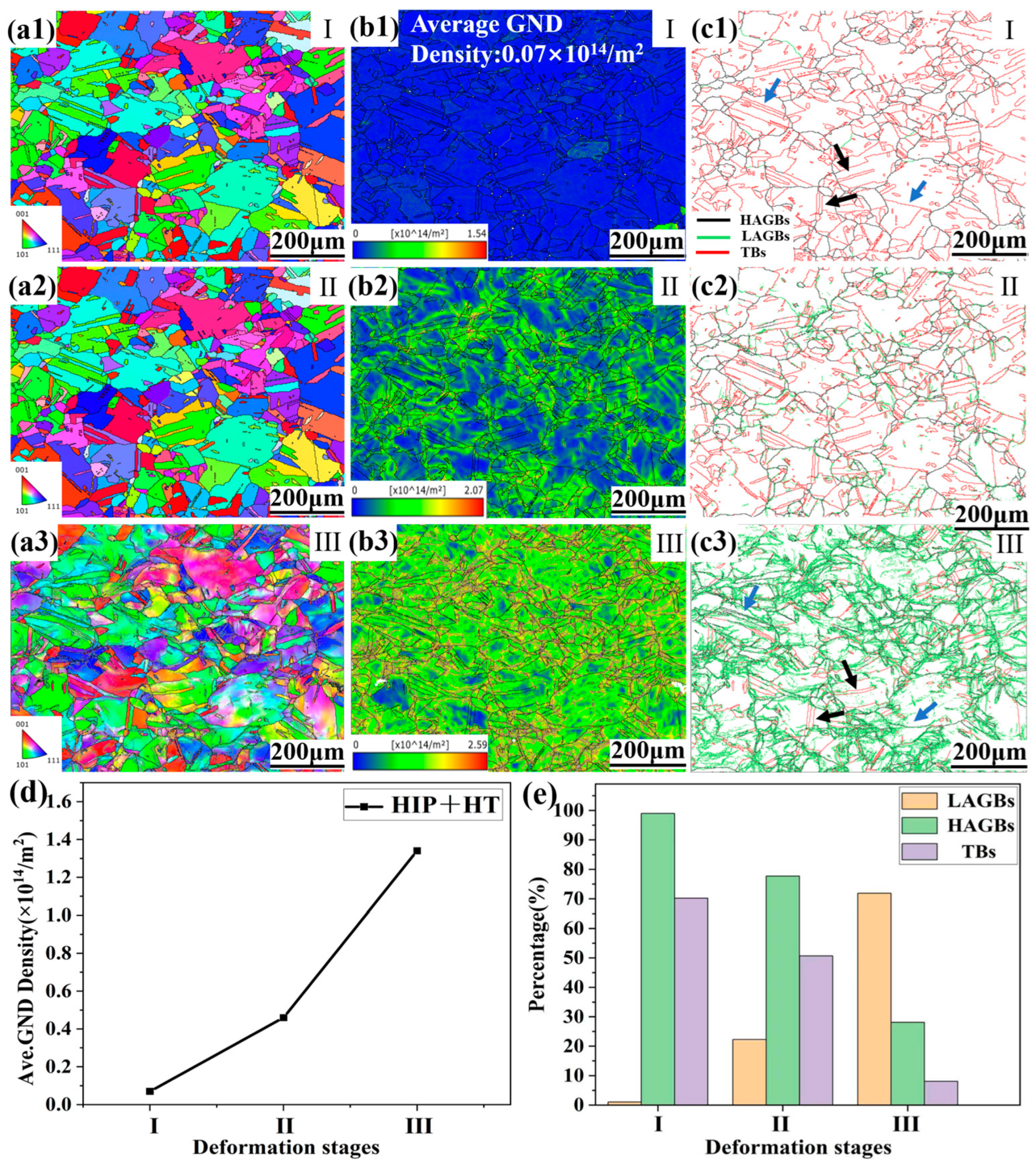

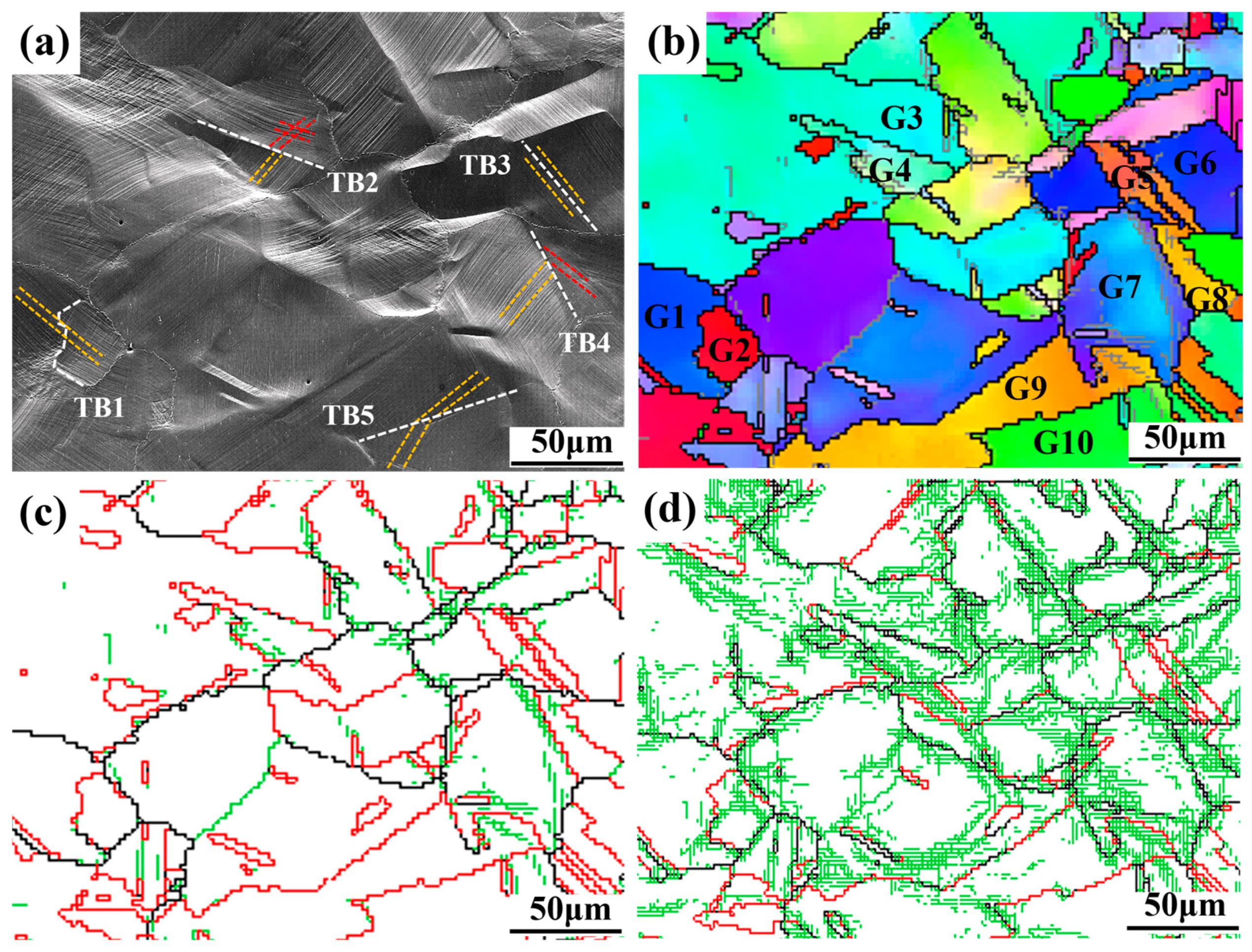

3.3. In Situ Microstructural Evolution During Tensile Testing

4. Discussion

5. Conclusions

- After HIP+HT treatment, the surface defects of the material were basically eliminated (the defect density was only 0.07%). Under the effect of high temperature, the alloy underwent recrystallization. A large number of carbides precipitated at the grain boundaries, and within the grains, residual stress was released and a large number of annealing twins were generated.

- For the annealing twins formed by HIP+HT, they were able to separate the grains, therefore effectively avoiding the strength reduction caused by excessive grain size.

- During in situ stretching, the TBs selectively prevented the passage of dislocation. Some dislocations were able to pass through the TBs, avoiding the accumulation of dislocations at the TBs and therefore facilitating the improvement in the material’s plasticity. However, some dislocations were obstructed at the TBs and then accumulated here, causing the internal stress to increase and disrupting the symmetrical relationship between the TBs. This led to the transformation of the TBs into normal-angle GBs, effectively reducing stress concentrations and delaying the fracture of the sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, Q.; Bei, H.; Wei, X.; Gao, Y.F.; Zhang, Z. Nano-twin-induced exceptionally superior cryogenic mechanical properties of a Ni-based GH3536 (Hastelloy X) superalloy. Mater. Today Nano. 2021, 14, 100110. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based super alloys. Int. J. Mach. Tools Manuf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Zhang, X.S.; Chen, Y.J.; Hu, J.L. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Eyob Messele Sefene. State-of-the-art of selective laser melting process: A comprehensive review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Gu, D.D.; Shi, Q.M.; Lin, K.J.; Xi, L.X. Microstructure and performance evolution and underlying thermal mechanisms of Ni-based parts fabricated by selective laser melting. Addit. Manuf. 2018, 22, 265–278. [Google Scholar] [CrossRef]

- Xiao, L.R.; Peng, Z.W.; Zhao, X.J.; Tu, X.X.; Cai, Z.Y. Microstructure and mechanical properties of crack-free Ni-based GH3536 superalloy fabricated by laser solid forming. J. Alloys Compd. 2022, 921, 165950. [Google Scholar] [CrossRef]

- Iveković, A.; Maria, L.; Montero-Sistiaga, M.L.; Vleugels, J.; Kruth, J.P. Crack mitigation in Laser Powder Bed Fusion processed Hastelloy X using a combined numerical-experimental approach. J. Alloys Compd. 2021, 864, 158803. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2015, 61, 315–360. [Google Scholar] [CrossRef]

- Lu, J.X.; Chang, L.; Wang, J.; Sang, L.J.; Wu, S.K.; Zhang, Y.F. In-situ investigation of the anisotropic mechanical properties of laser direct metal deposition Ti6Al4V alloy. Mater. Sci. Eng. A 2018, 712, 199–205. [Google Scholar] [CrossRef]

- Yuan, Z.W.; Zhang, Z.H.; Bai, J. Quantitative and qualitative characterization of the damage, deformation mechanisms, and failure modes of a nickel-based GH3536 alloy prepared via laser powder bed fusion after various heat treatments. Mater. Sci. Eng. A 2023, 876, 145143. [Google Scholar] [CrossRef]

- Tomus, D.; Tian, Y.; Rometsch, P.A.; Heilmaier, M.; Wu, X.H. Influence of post heat treatments on anisotropy of mechanical behaviour and microstructure of Hastelloy-X parts produced by selective laser melting. Mater. Sci. Eng. A 2016, 667, 42–53. [Google Scholar] [CrossRef]

- Wu, H.; Fan, G.H. An overview of tailoring strain delocalization for strength-ductility synergy. Prog. Mater. Sci. 2020, 113, 100675. [Google Scholar] [CrossRef]

- Liu, L.Y.; Zhang, Y.; Zhang, Z.W.; Li, J.P.; Jiang, W.G.; Sun, L.X. Nanoprecipitate and stacking fault-induced high strength and ductility in a multiscale heterostructured high-entropy alloy. Int. J. Plast. 2024, 172, 103853. [Google Scholar] [CrossRef]

- Gan, K.F.; Yan, D.S.; Zhang, Y. Origins of strengthening and toughening effects in twinned nanocrystalline alloys of low stacking fault energy with heterogeneous grain structure. J. Mech. Phys. Solids. 2023, 176, 105305. [Google Scholar] [CrossRef]

- Ren, Q.; Chen, J.T.; Lu, J.X.; Cheng, X.P.; Zhang, Y.F. In-situ study of microstructure and mechanical properties of GH3536 alloy manufactured by selective laser melting at 750 °C. Mater. Sci. Eng. A 2024, 900, 146452. [Google Scholar] [CrossRef]

- Chen, J.T.; Lu, J.X.; Cai, W.; Zhang, Y.F.; Wang, Y.F.; Jiang, W.X.; Zhang, Z. In-situ study of adjacent grains slip transfer of Inconel 718 during tensile process at high temperature. Int. J. Plast. 2023, 163, 103554. [Google Scholar] [CrossRef]

- Jiang, W.X.; Lu, J.X.; Guan, H.; Wang, M.M.; Cheng, X.P.; Liu, L.L.; Liu, X.Q.; Wang, J.; Zhang, Y.F.; Zhang, Z.; et al. Study of pre-precipitated δ phase promoting deformation twinning and recrystallization behavior of Inconel 718 superalloy during hot compression. Mater. Des. 2023, 226, 111693. [Google Scholar] [CrossRef]

- Gao, W.J.; Lu, J.X.; Zhou, J.L.; Liu, L.E.; Wang, J.; Zhang, Y.F. Effect of grain size on deformation and fracture of Inconel718: An in-situ SEM-EBSD-DIC investigation. Mater. Sci. Eng. A 2022, 861, 144361. [Google Scholar] [CrossRef]

- Lu, J.X.; Liu, X.D.; Zhu, Y.F.; Chen, J.T.; Cheng, X.P.; Huang, S. Thermal-mechanical behavior of LPBF GH3536 superalloy using in-situ SEM tensile. Eng. Fail. Anal. 2025, 173, 109423. [Google Scholar] [CrossRef]

- Messé, O.M.D.M.; Muñoz-Moreno, R.; Illston, T.; Baker, S. Metastable carbides and their impact on recrystallisation in IN738LC processed by selective laser melting. Addit. Manuf. 2018, 22, 394–404. [Google Scholar] [CrossRef]

- Karapuzha, A.S.; Fraser, D.; Zhu, Y.M.; Wu, X.H.; Huang, A.J. Effect of solution heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Hastelloy X manufactured by electron beam powder bed fusion. J. Mater. Sci. Technol. 2022, 98, 99–117. [Google Scholar] [CrossRef]

- Heat and Corrosion Resistant Castings: Their Engineering Properties and Applications; International Nickel Company: New York, NY, USA, 1978.

- HAYNES International, HASTELLOY® X Alloy. 2019. Available online: https://haynesintl.com/en/alloys/alloy-portfolio/high-temperature-alloys/hastelloy-x/ (accessed on 18 November 2025).

- Luster, J.; Morris, M.A. Compatibility of deformation in two-phase Ti-Al alloys: Dependence on microstructure and orientation relationships. Metall. Mater. Trans. A 1995, 26, 1745–1756. [Google Scholar] [CrossRef]

- Bieler, T.R.; Alizadeh, R.; Peña-Ortega, M.; Llorca, J. An analysis of (the lack of) slip transfer between near-cube oriented grains in pure Al. Int. J. Plast. 2019, 118, 269–290. [Google Scholar] [CrossRef]

- Gao, Q.; Sang, B.; Wang, W.B.; Wang, Q.; Ren, J.Q.; Lu, X.F. In-situ study of dislocation coordinated plastic deformation mechanism in as-cast Ni33Co40Mn27 medium entropy alloy. Mater. Sci. Eng. A 2025, 924, 147818. [Google Scholar] [CrossRef]

- Alizadeh, R.; Peña-Ortega, M.; Bieler, T.R. A criterion for slip transfer at grain boundaries in Al. Scr. Mater. 2020, 178, 408–412. [Google Scholar] [CrossRef]

- Nieto-Valeiras, E.; Haouala, S.; Llorca, J. On the effect of slip transfer at grain boundaries on the strength of FCC polycrystals. Eur. J. Mech. A Solids. 2022, 91, 104427. [Google Scholar] [CrossRef]

| State | YS (MPa) | UTS (MPa) | Elongation (%) | Ref. |

|---|---|---|---|---|

| HIP+HT | 325 ± 15.6 | 725 ± 12.8 | 45.3 ± 1.6 | This study |

| As-built | 562 | 785 | 36.5 | [19] |

| Cast | 248 | 448 | 10 | [22] |

| Wrought | 376 | 783 | 46.5 | [23] |

| TB | Grain | ||

|---|---|---|---|

| 1 | G1 | 0.992 | 0.0718 |

| G2 | |||

| 2 | G3 | 0.2045 | 0.9568 |

| G4 | |||

| 3 | G5 | 0.9994 | 0.02 |

| G6 | |||

| 4 | G7 | 0.5097 | 0.4474 |

| G8 | |||

| 5 | G9 | 0.7814 | 0.0065 |

| G10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Cheng, X.; Lu, J.; Huang, S.; Chen, B. Strength–Ductility Balance of HIP+HT-Treated LPBF GH3536 Alloy via In Situ EBSD: The Role of Annealing Twins. Materials 2025, 18, 5306. https://doi.org/10.3390/ma18235306

Zhang C, Cheng X, Lu J, Huang S, Chen B. Strength–Ductility Balance of HIP+HT-Treated LPBF GH3536 Alloy via In Situ EBSD: The Role of Annealing Twins. Materials. 2025; 18(23):5306. https://doi.org/10.3390/ma18235306

Chicago/Turabian StyleZhang, Changshuo, Xiaopeng Cheng, Junxia Lu, Shuai Huang, and Bingqing Chen. 2025. "Strength–Ductility Balance of HIP+HT-Treated LPBF GH3536 Alloy via In Situ EBSD: The Role of Annealing Twins" Materials 18, no. 23: 5306. https://doi.org/10.3390/ma18235306

APA StyleZhang, C., Cheng, X., Lu, J., Huang, S., & Chen, B. (2025). Strength–Ductility Balance of HIP+HT-Treated LPBF GH3536 Alloy via In Situ EBSD: The Role of Annealing Twins. Materials, 18(23), 5306. https://doi.org/10.3390/ma18235306