Experimental and Molecular Dynamics Investigation of the Rejuvenation Effect of Bio-Oils on Aged High-Penetration Asphalt

Abstract

1. Introduction

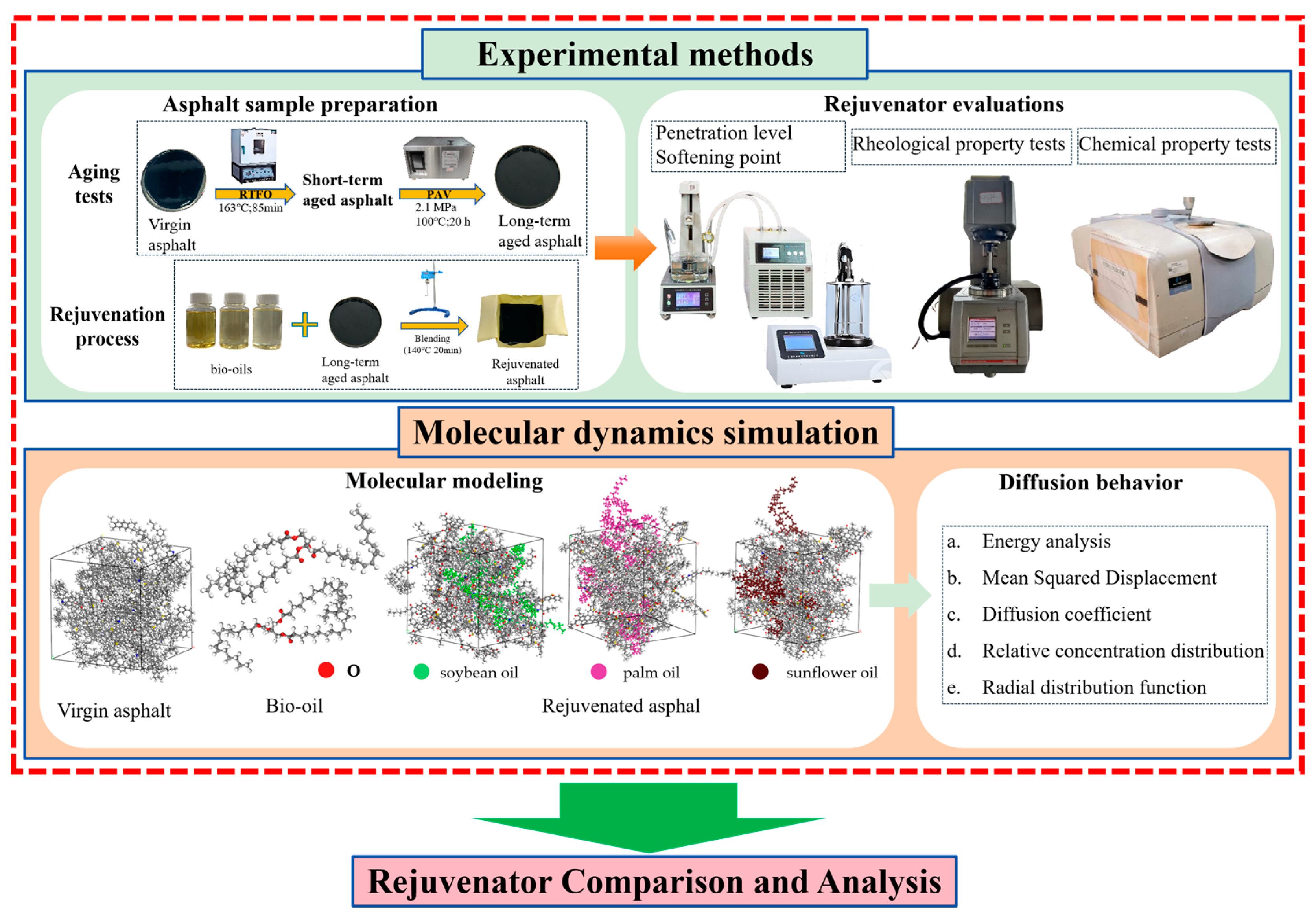

2. Materials and Experimental Methods

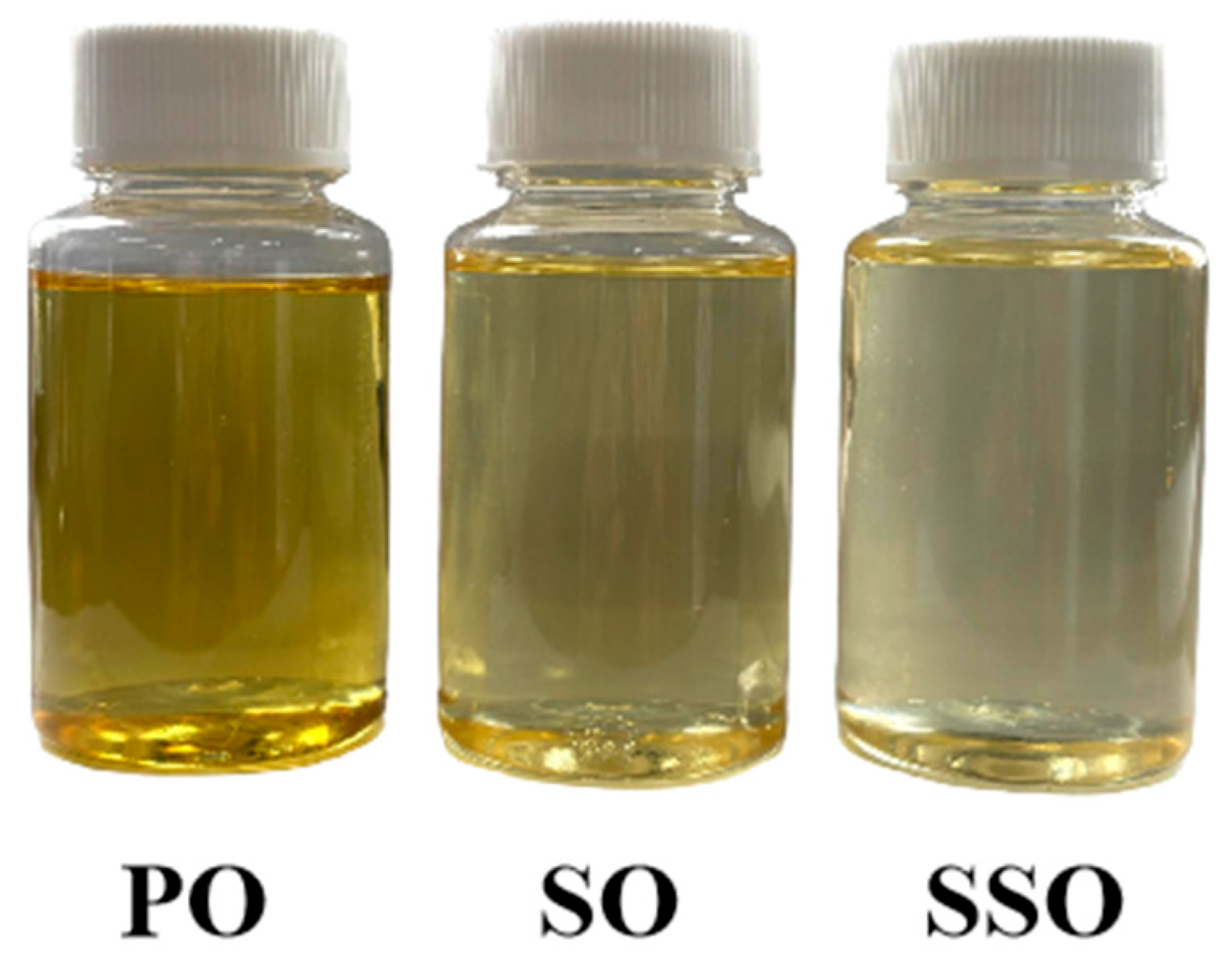

2.1. Asphalts and Rejuvenators

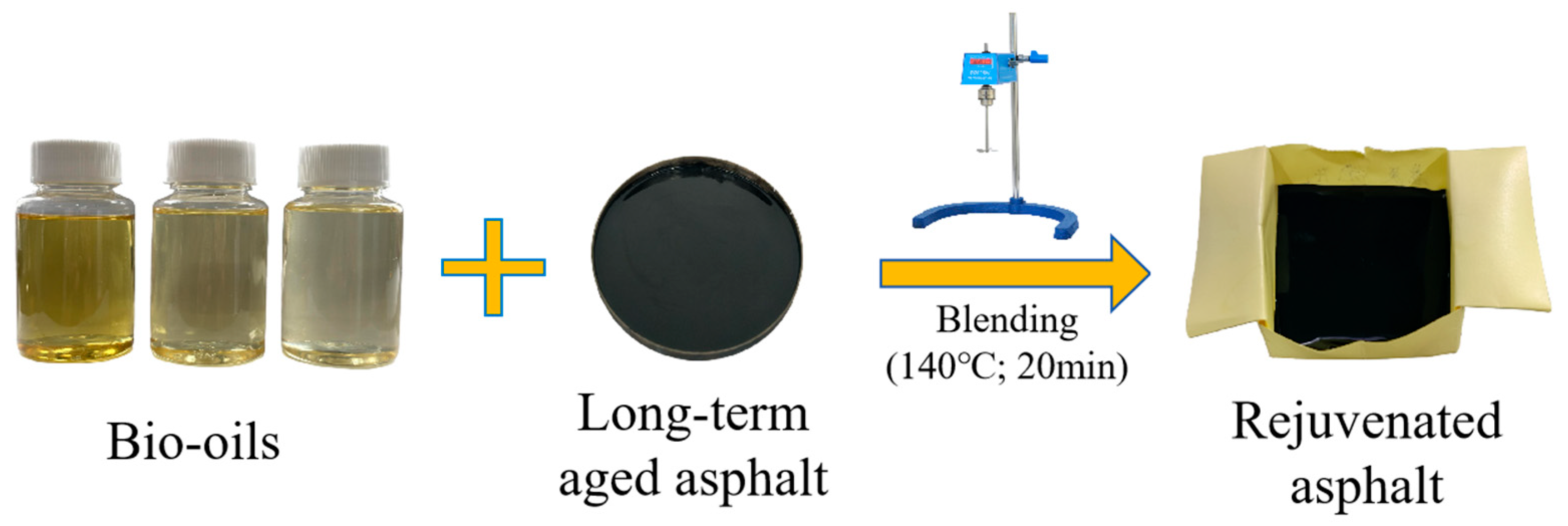

2.2. Preparation of Aged and Rejuvenated Asphalt

2.3. Experimental Methods

2.3.1. Penetration Level and Softening Point

2.3.2. Rheological Property Tests

2.3.3. Chemical Property Tests

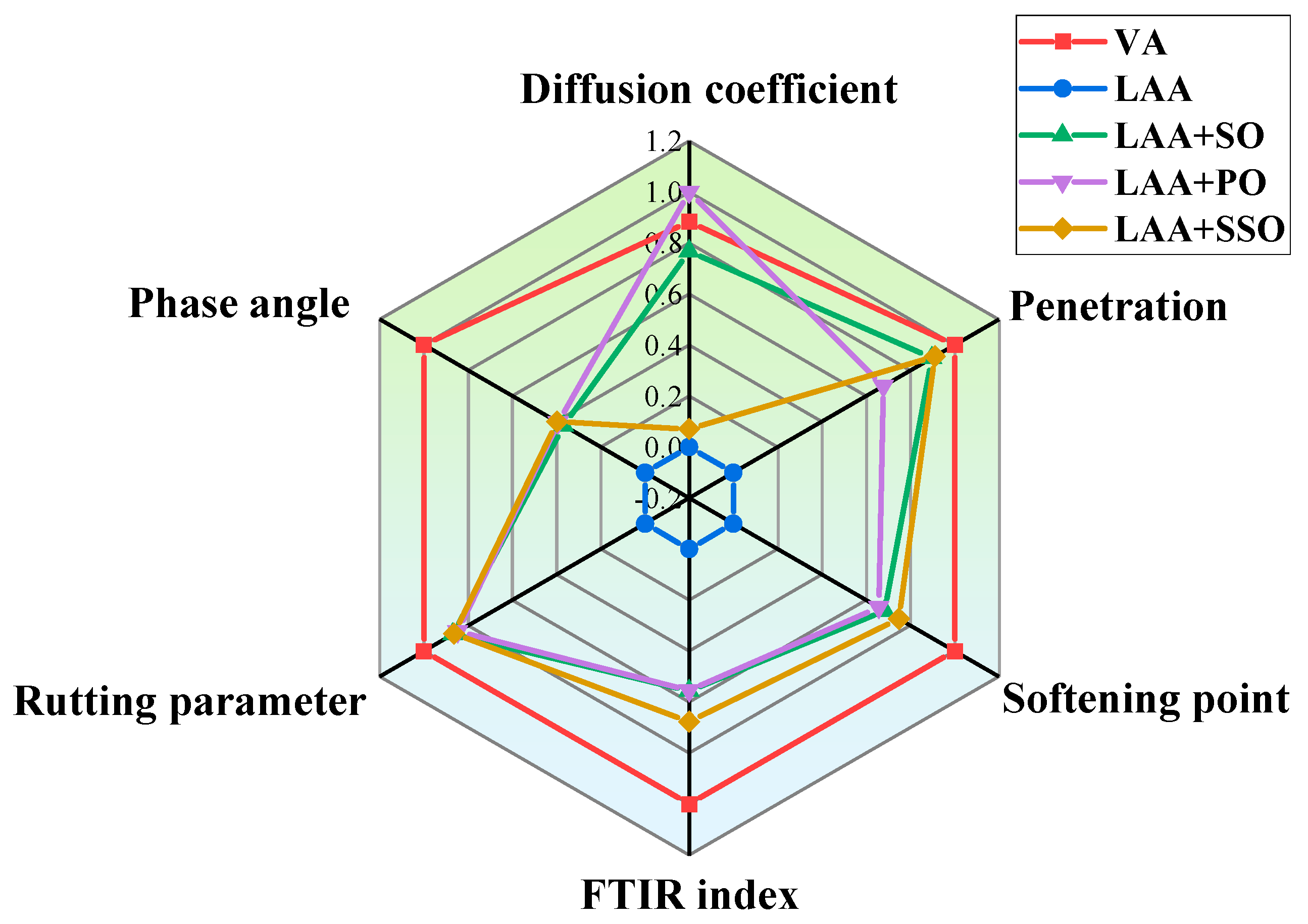

2.4. The Radar Chart Method

- 1.

- Confirm the bio-oil-rejuvenated asphalts for analysis and define the corresponding key performance indicators;

- 2.

- Determine the positive/negative attributes of each indicator, then process the raw data using the normalization formula to unify the order of magnitude of different indicators;

- 3.

- Import the normalized data into the data visualization tool for radar chart generation, which provides visual support for the subsequent quantitative analysis of comprehensive performance and the evaluation of performance superiority.

3. Experimental Results and Discussion

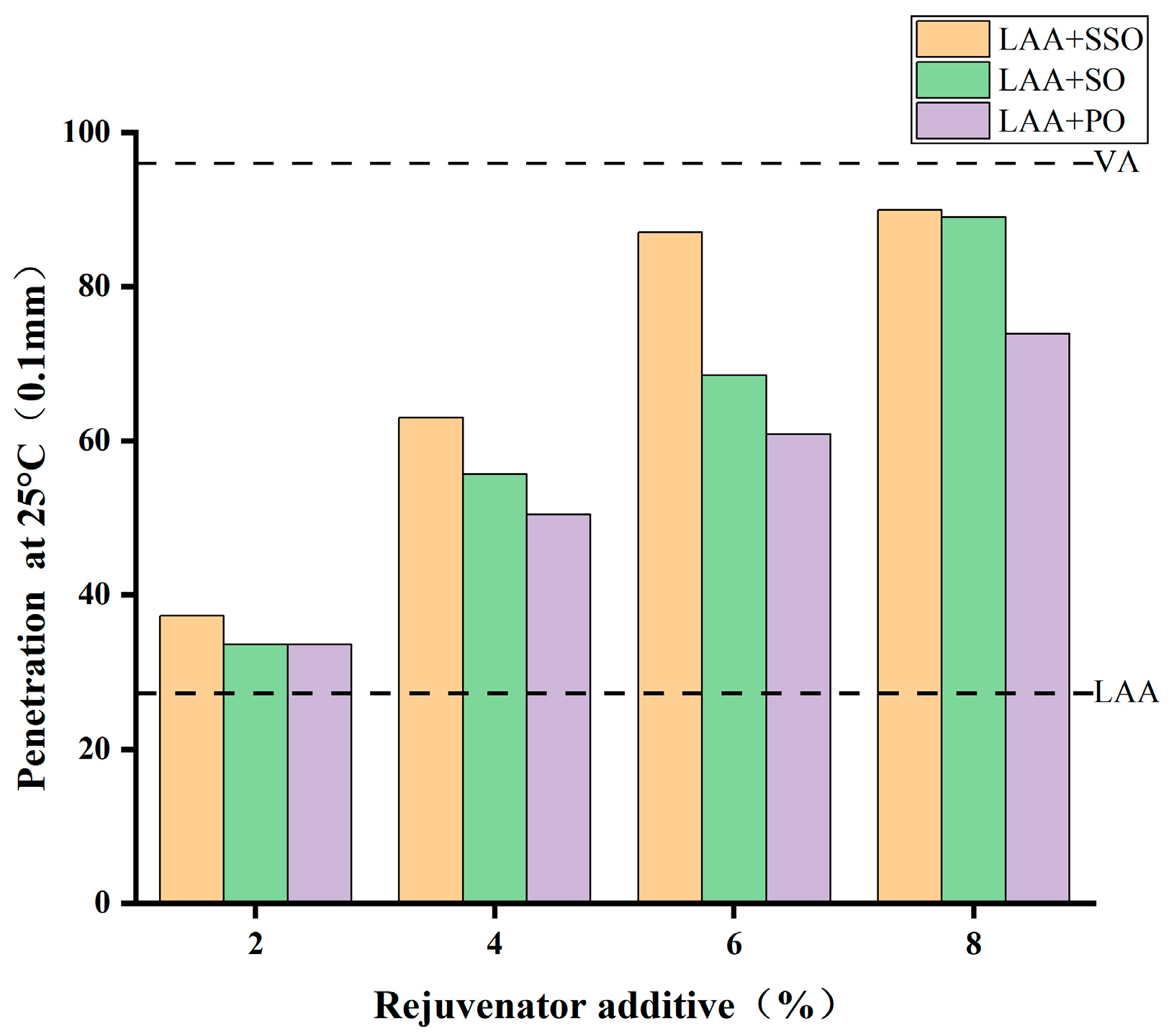

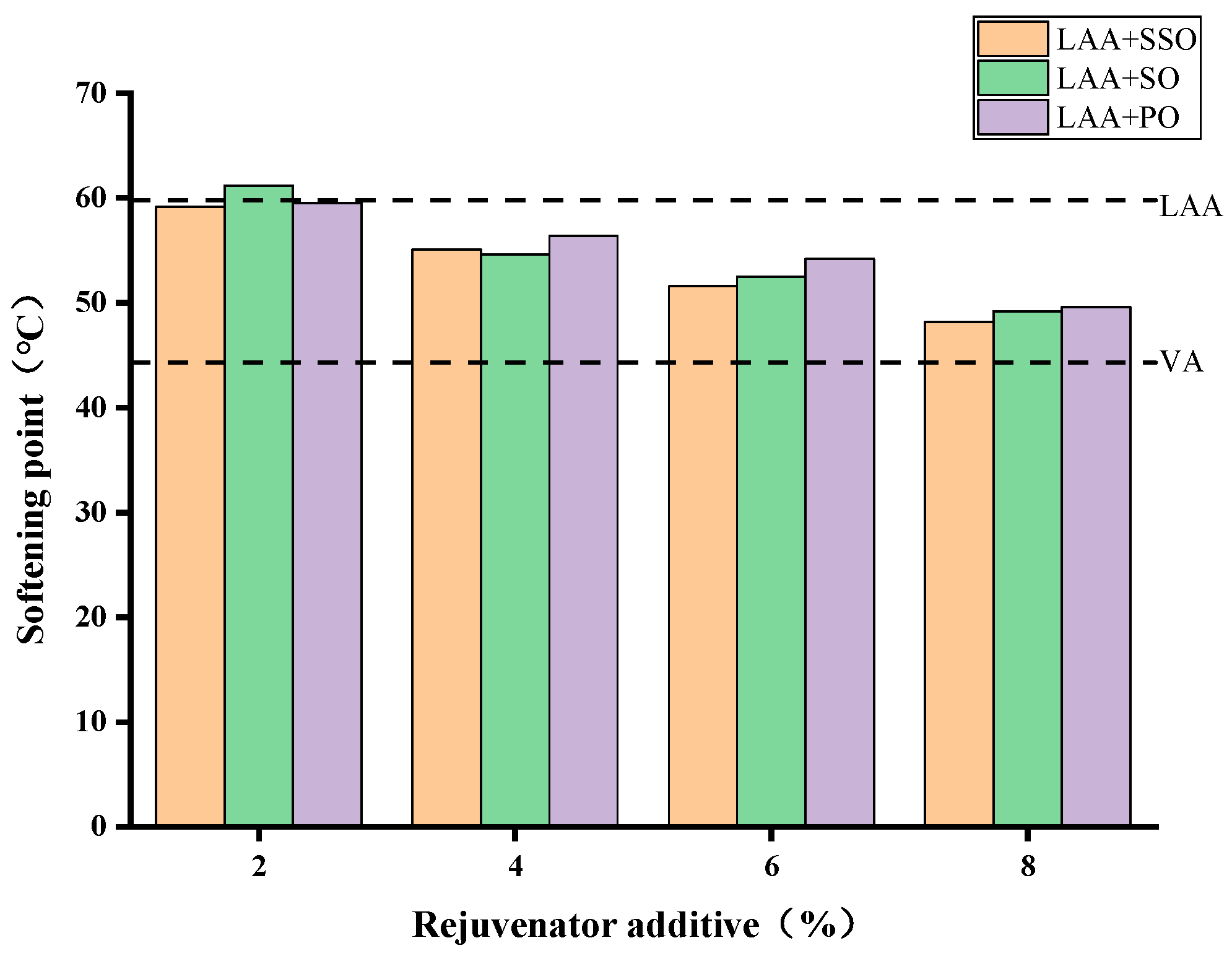

3.1. Physical Properties

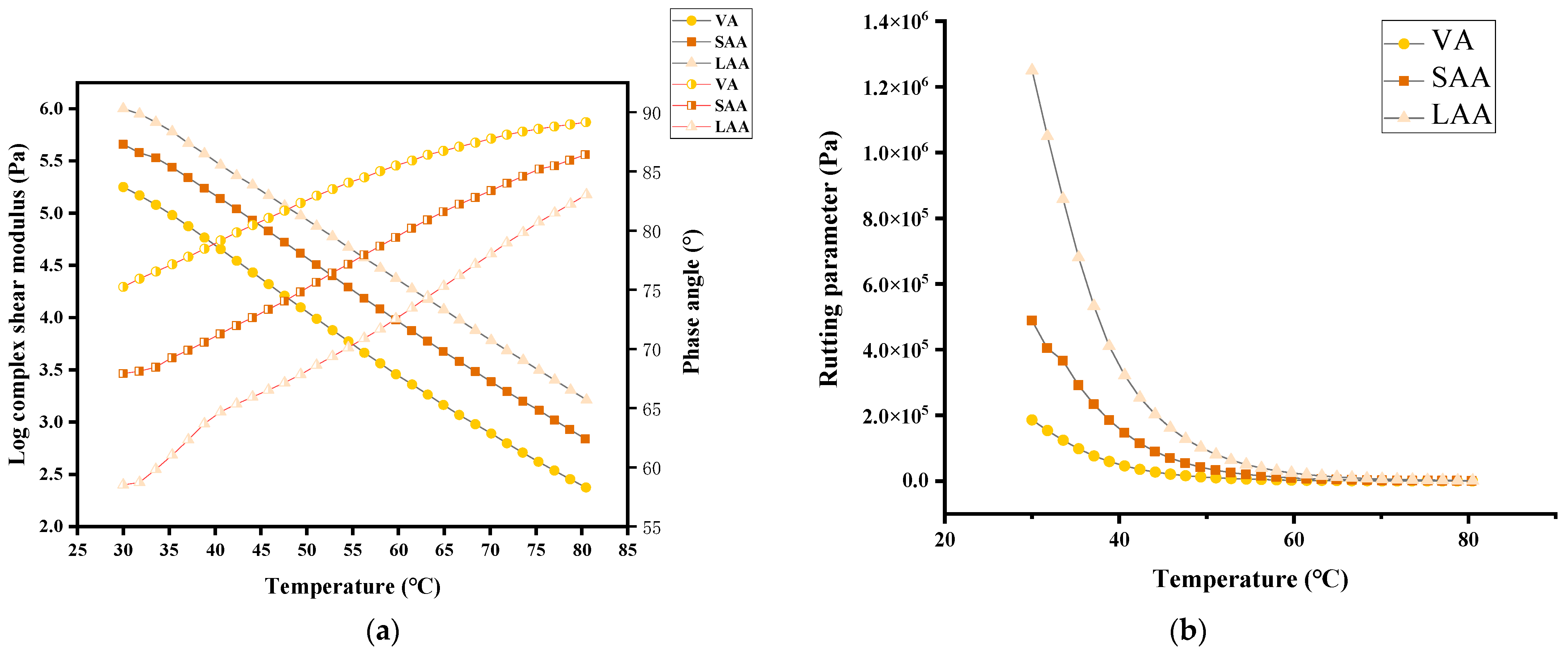

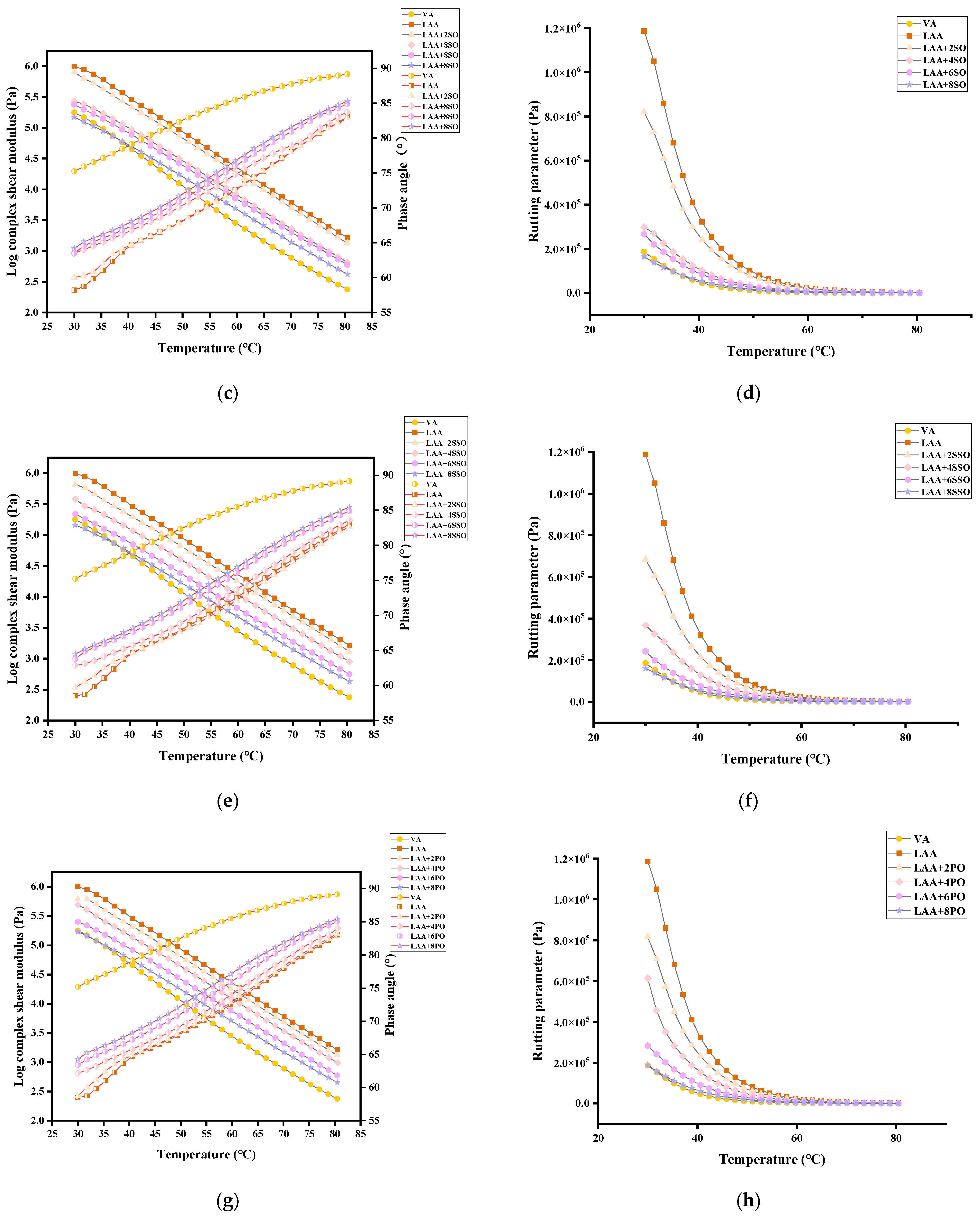

3.2. Rheological Properties

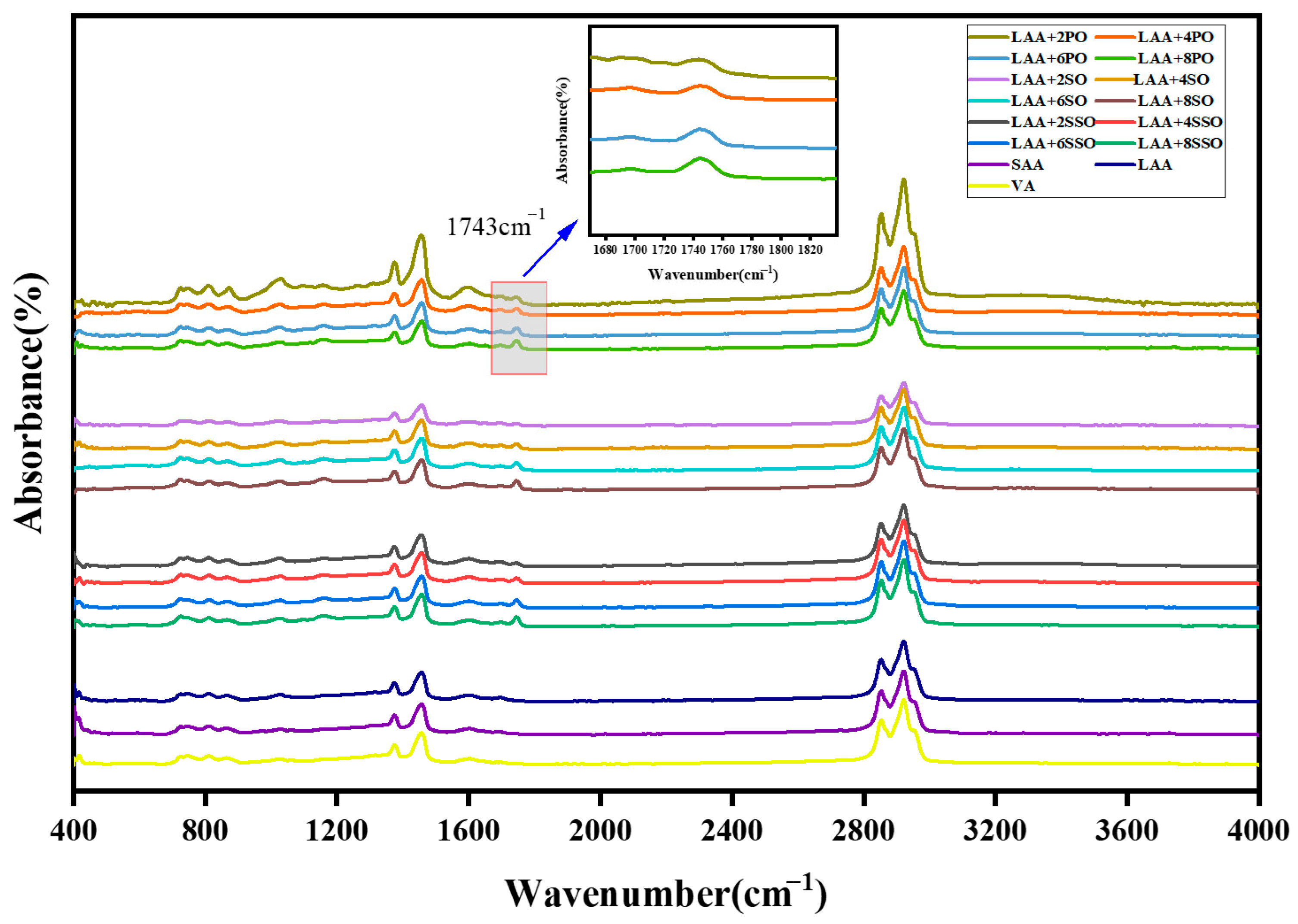

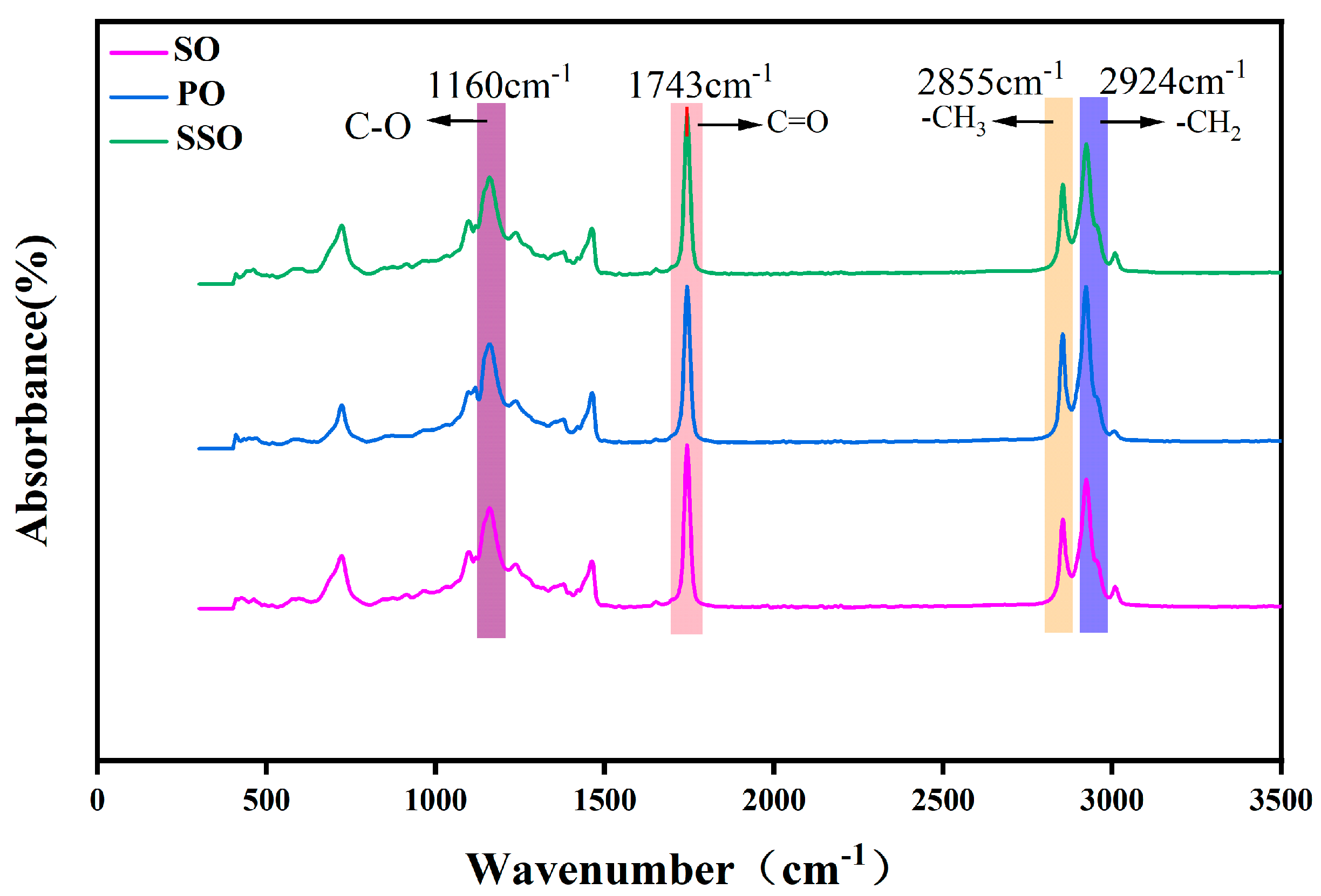

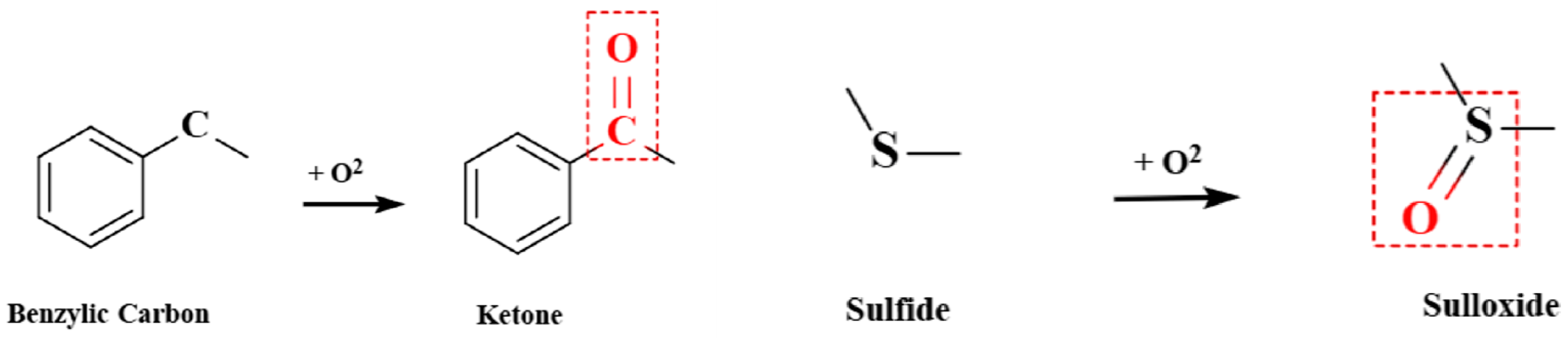

3.3. Chemical Properties

4. Molecular Dynamics Simulation

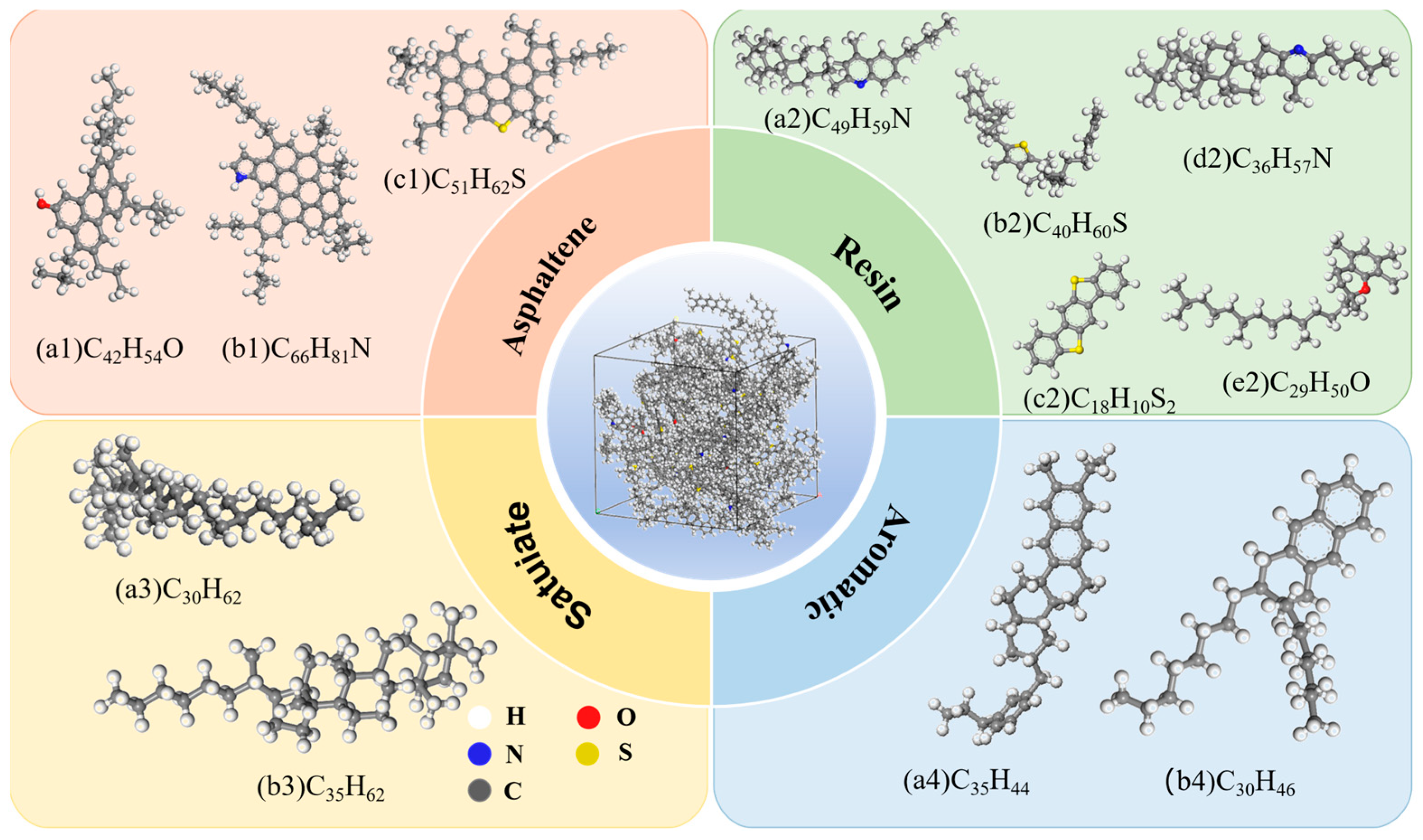

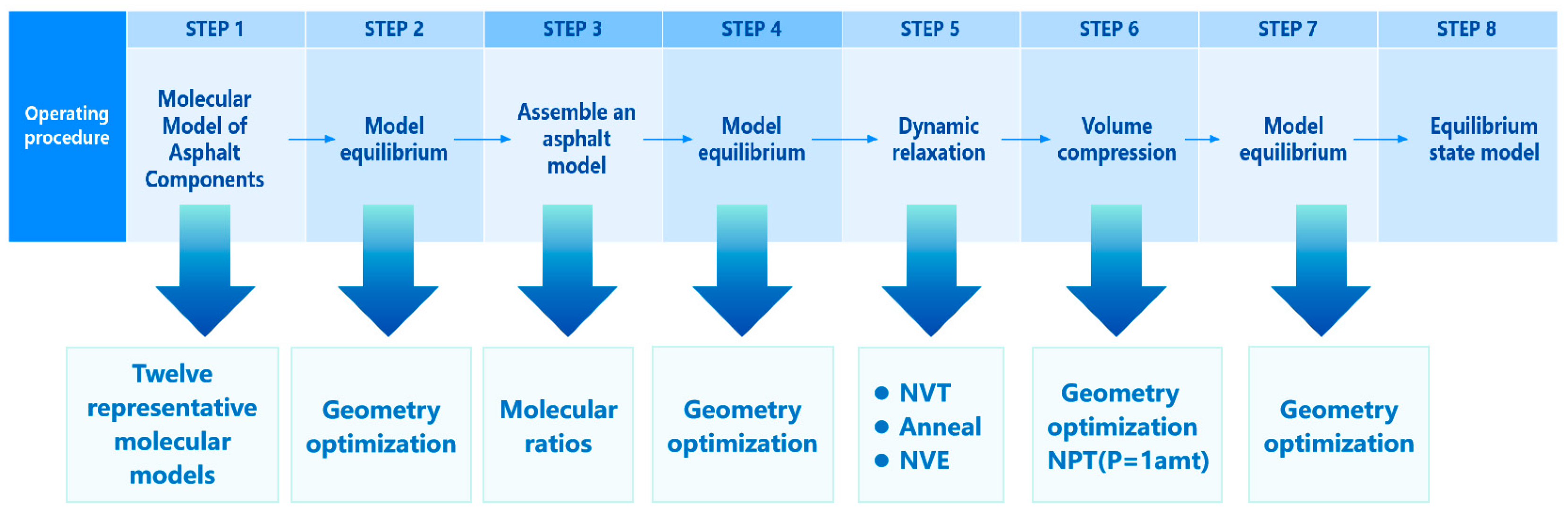

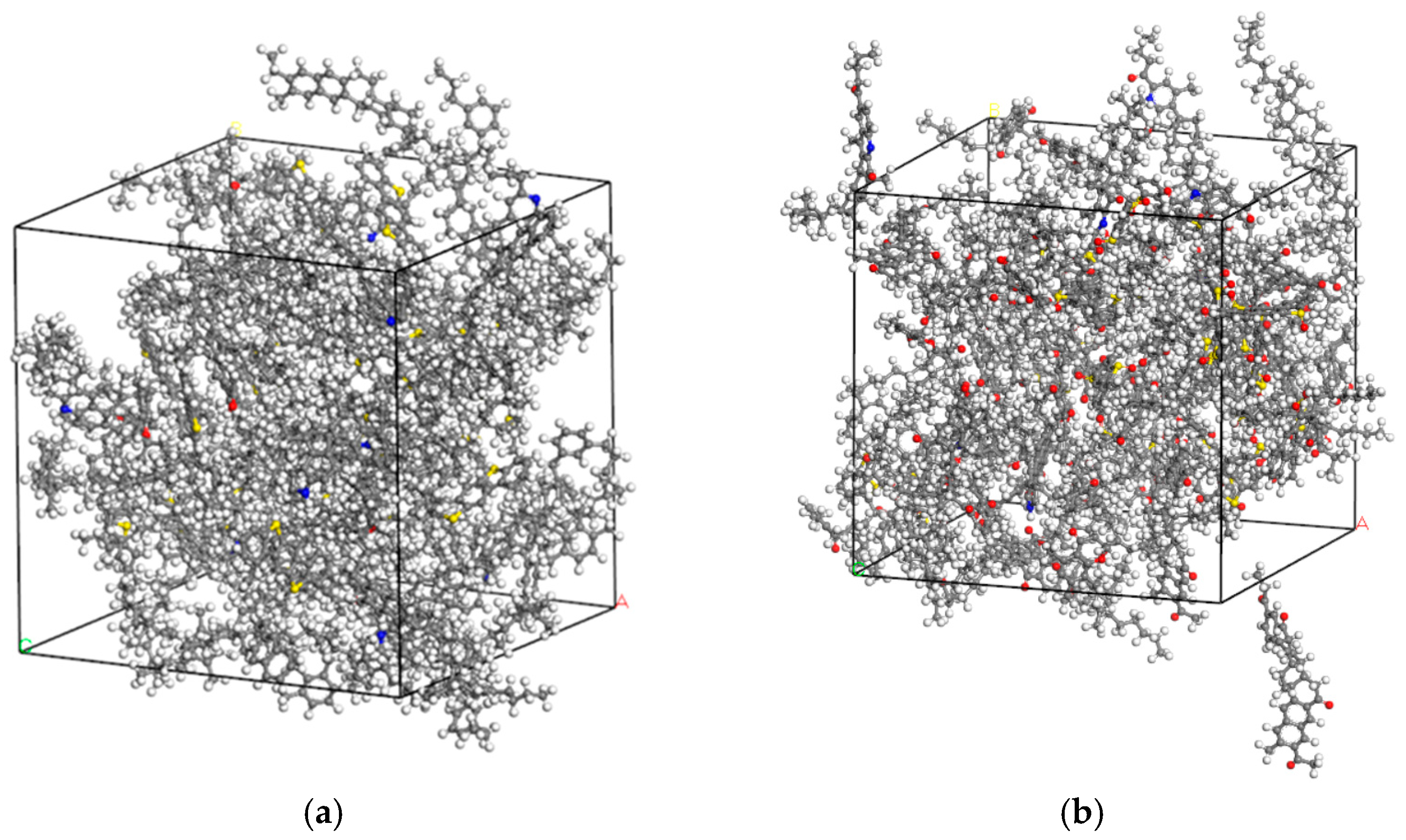

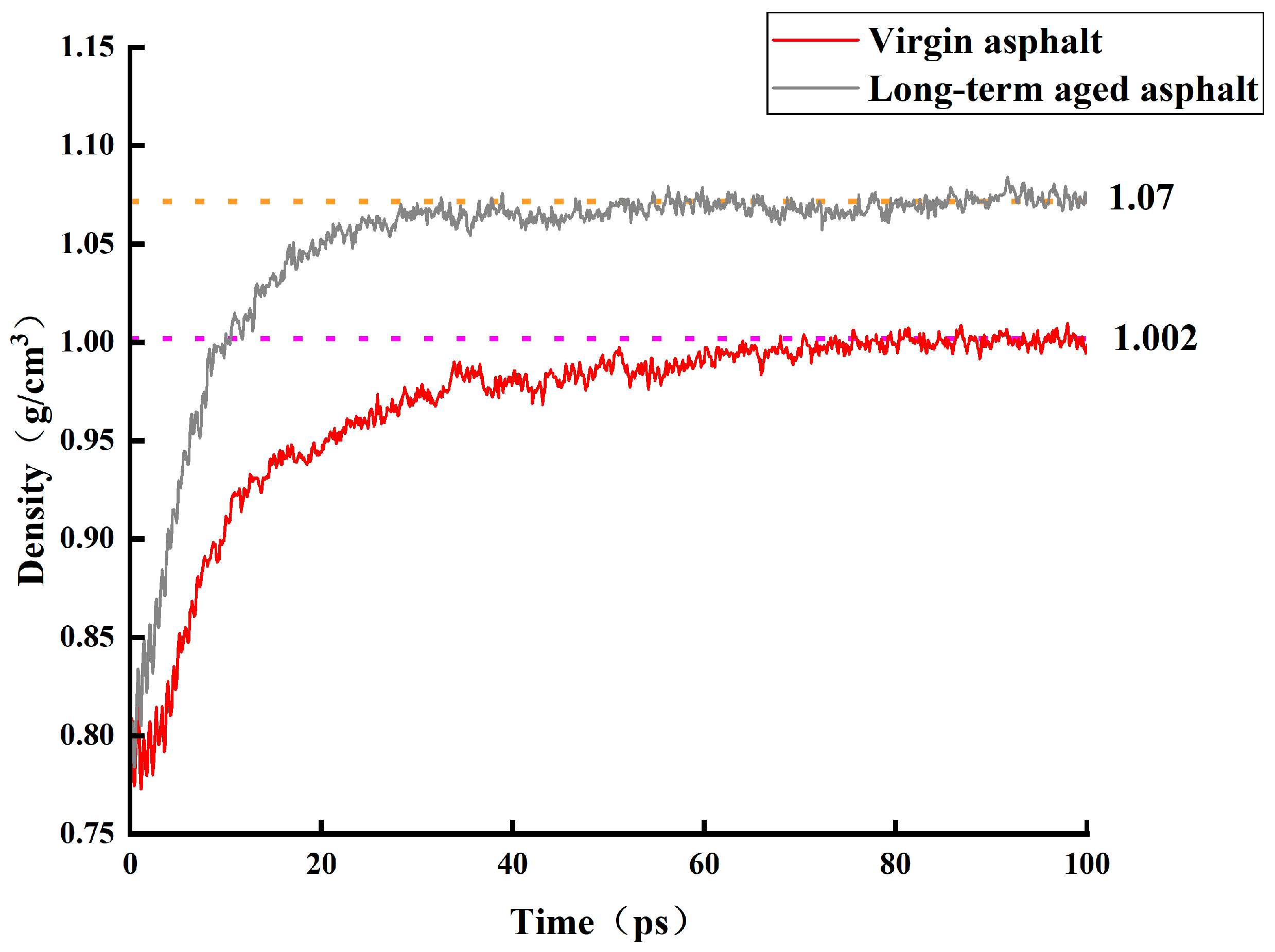

4.1. Molecular Models of Asphalt

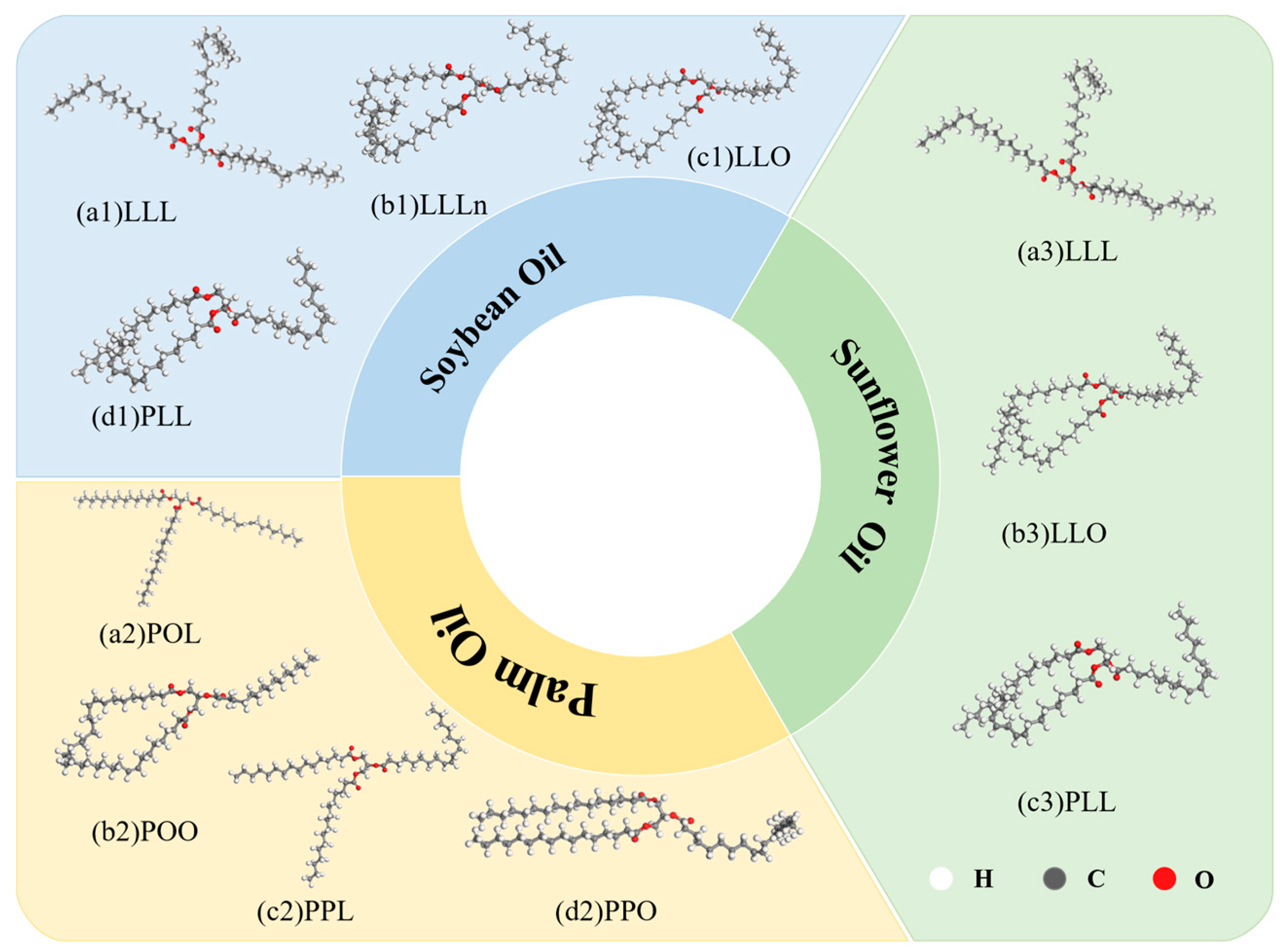

4.2. Molecular Models of Bio-Oils

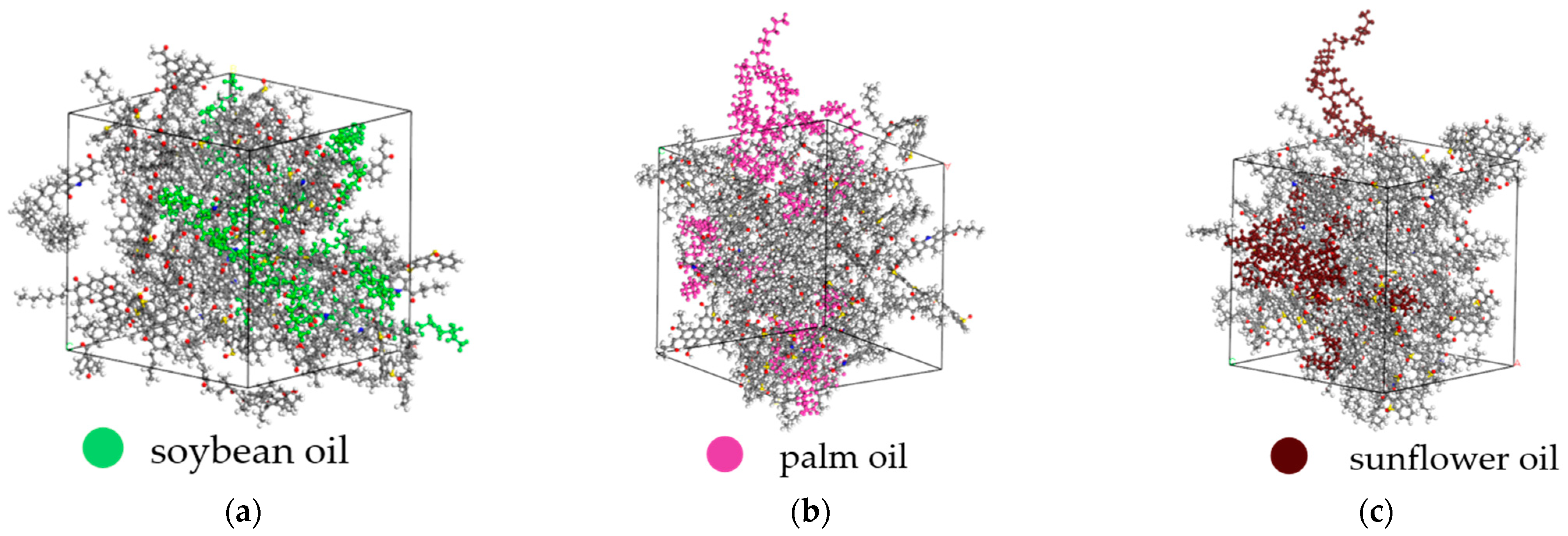

4.3. Molecular Models of Rejuvenated Asphalts

4.4. Diffusion Behavior

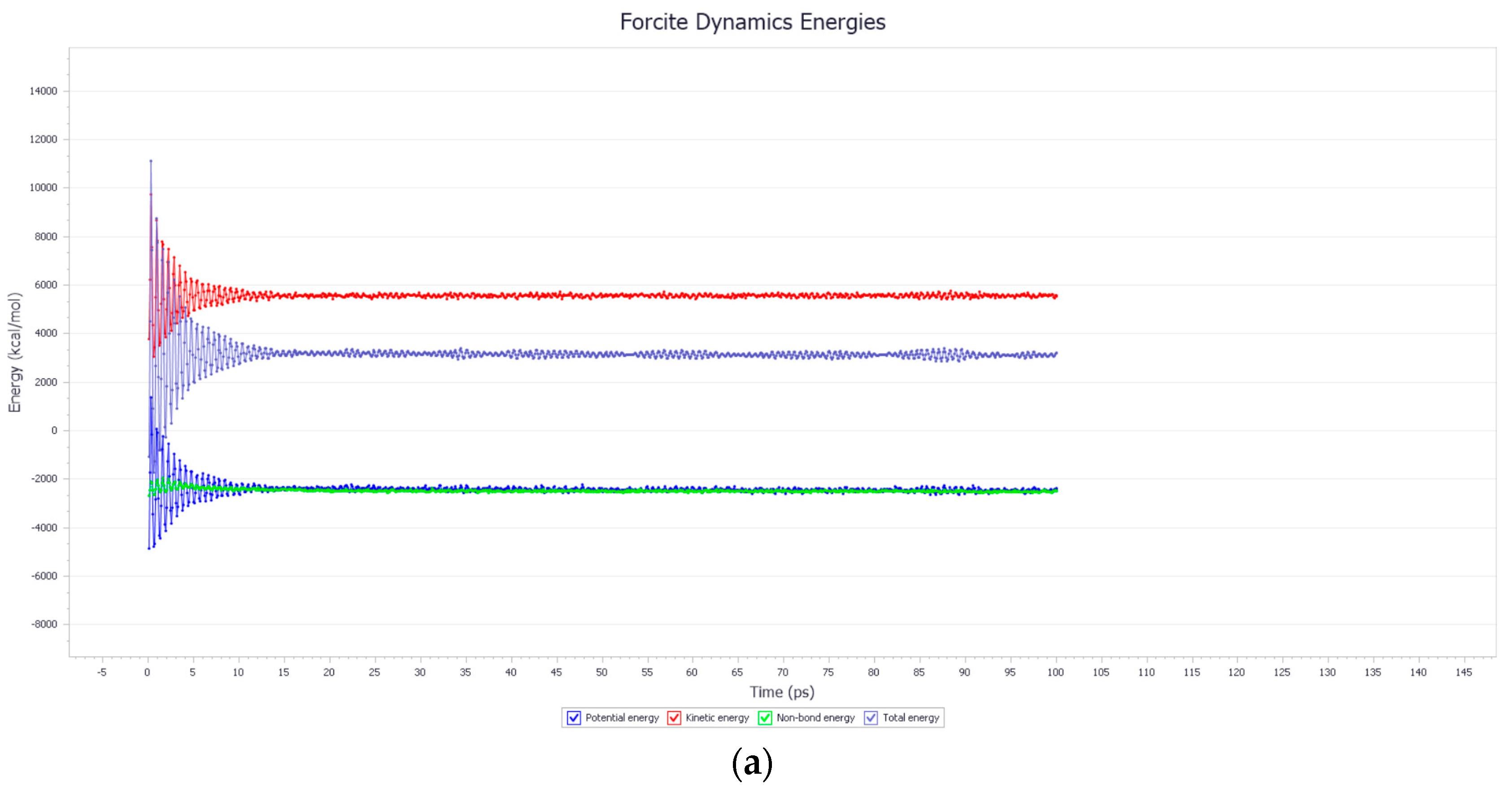

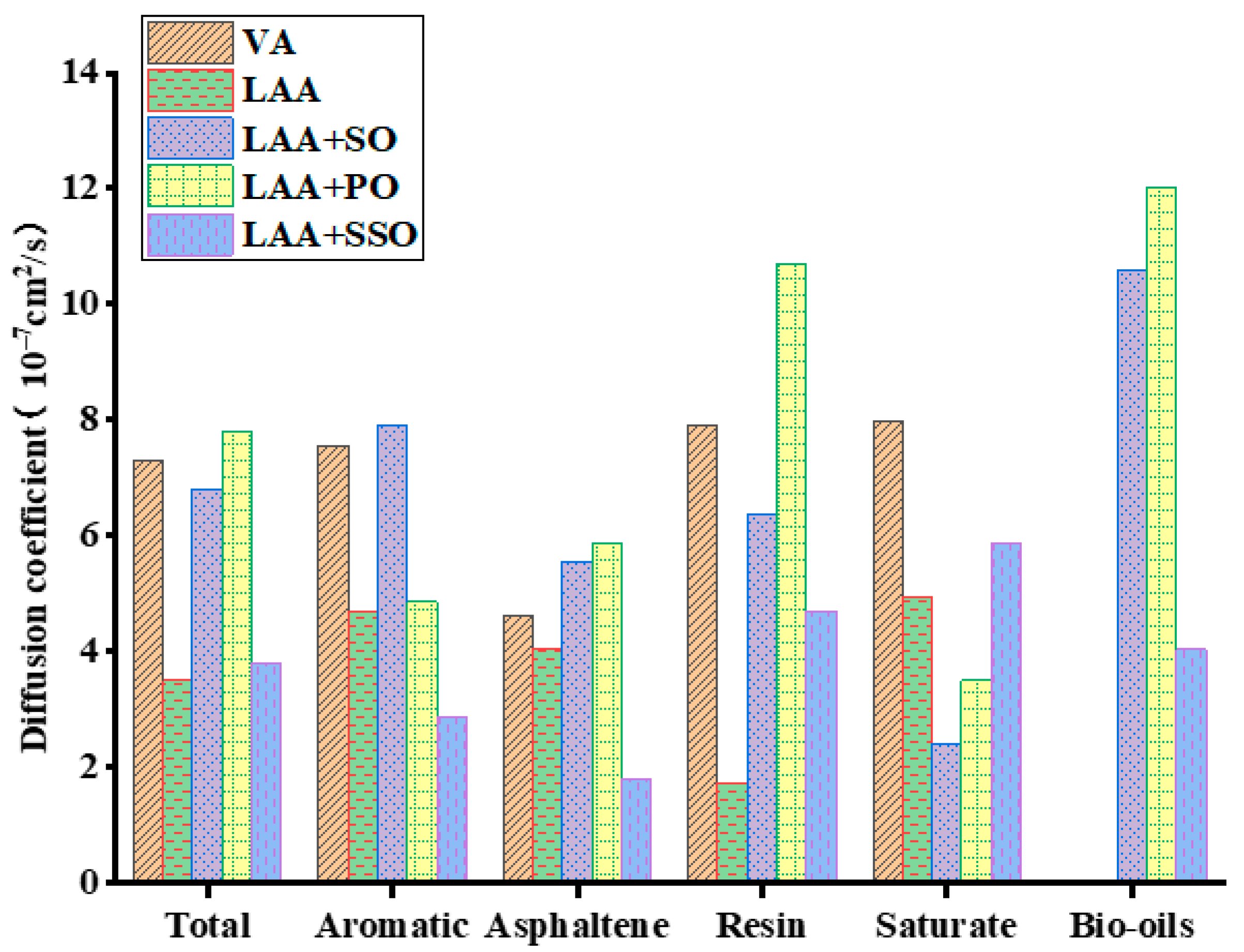

4.4.1. Energy Analysis

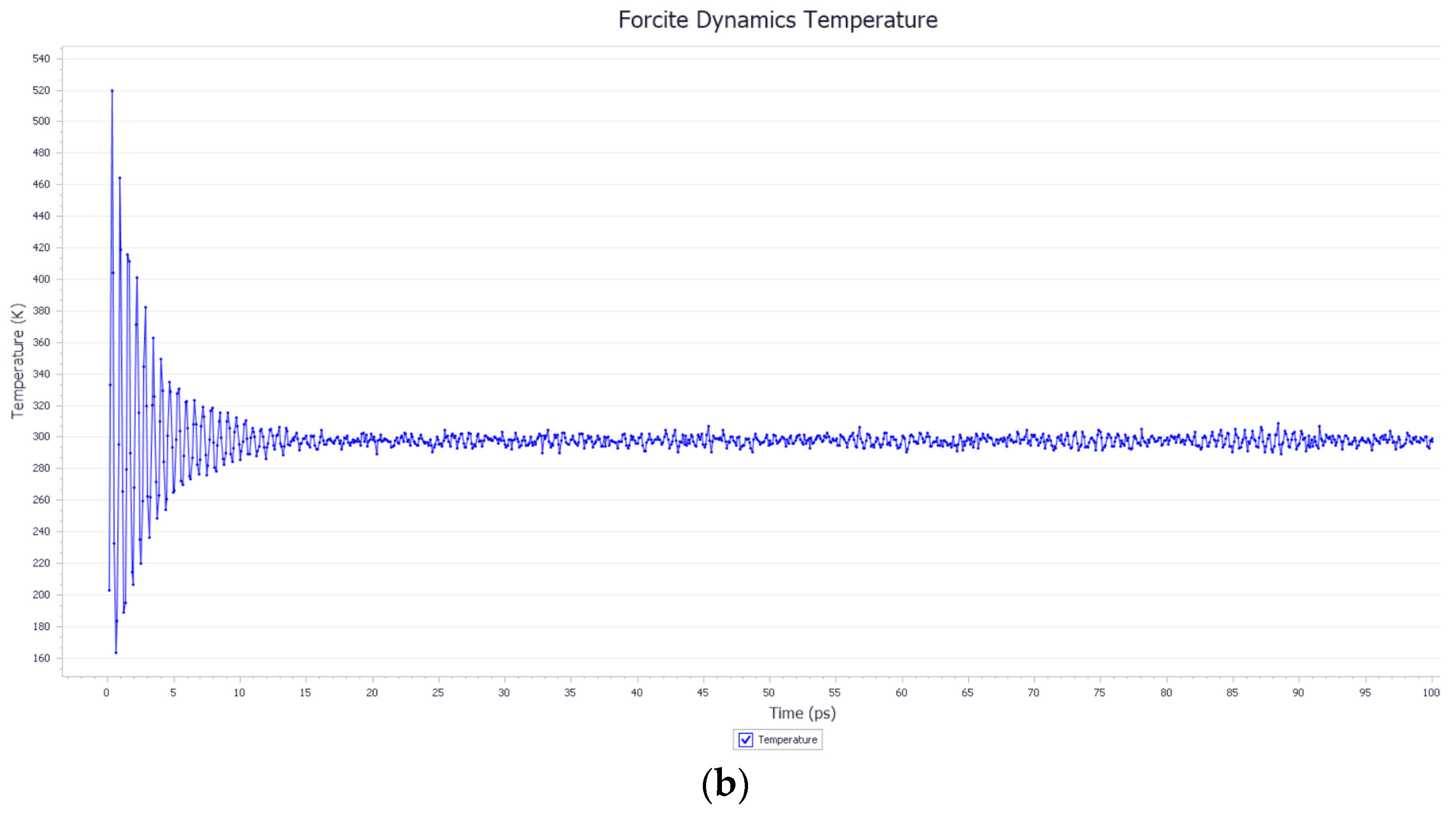

4.4.2. Mean Squared Displacement

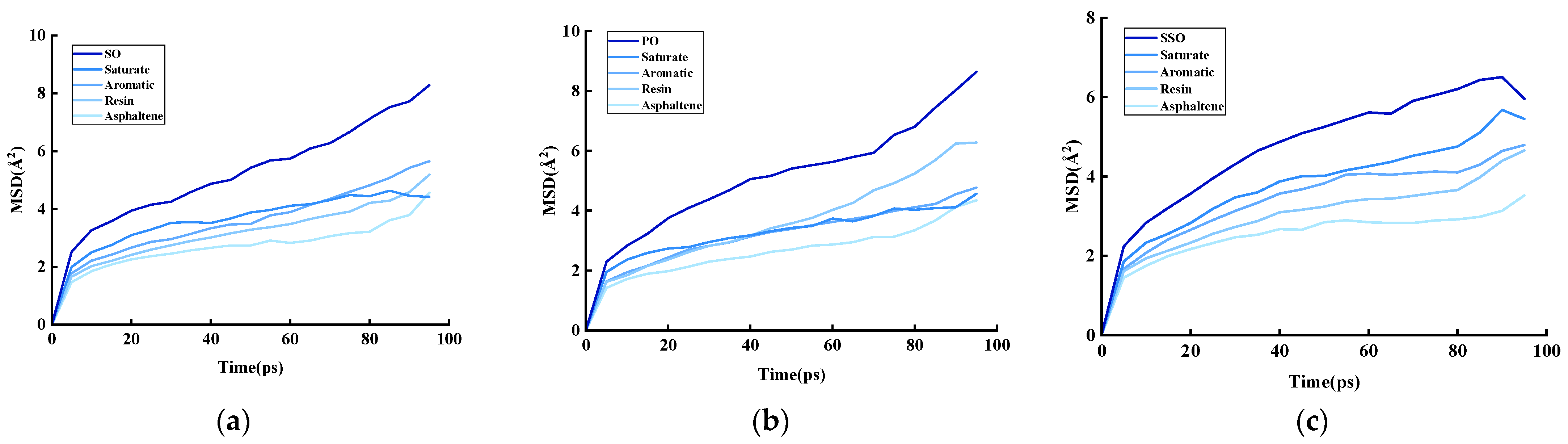

4.4.3. Diffusion Coefficient

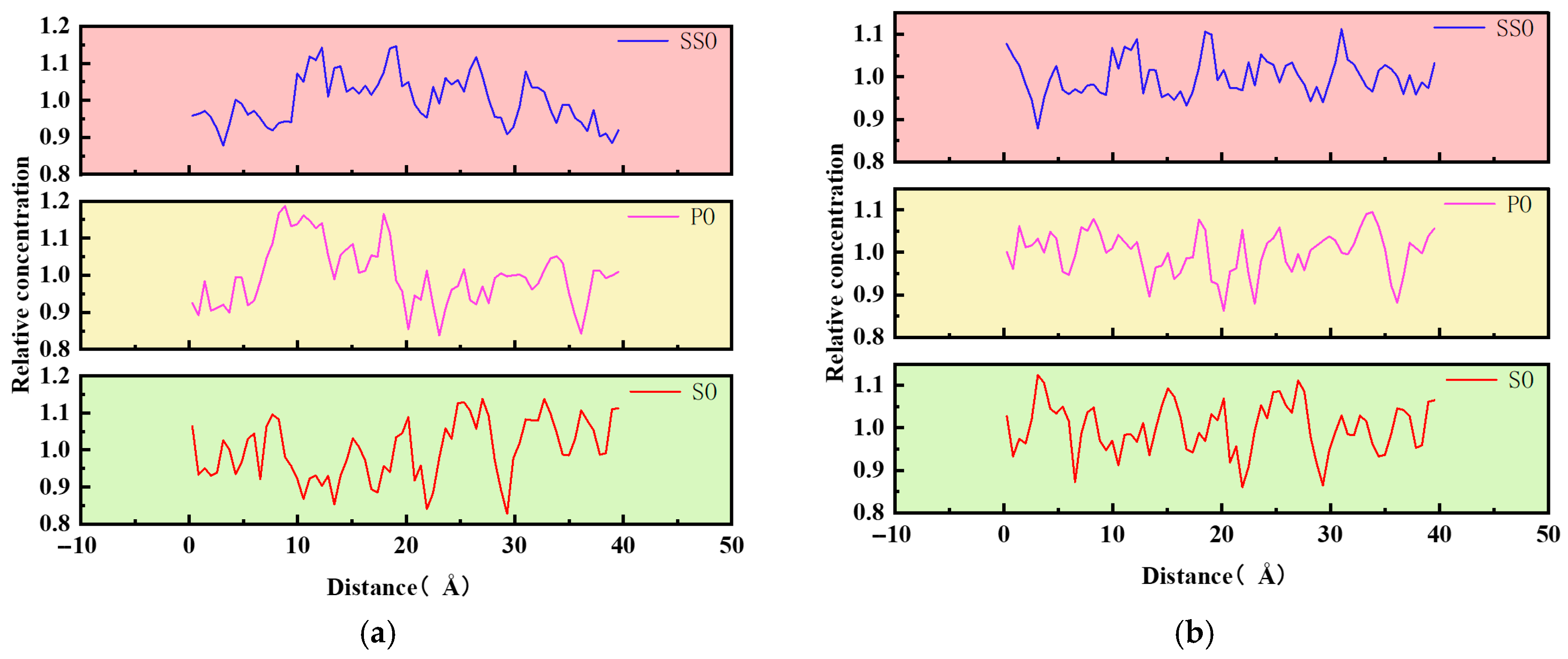

4.4.4. Relative Concentration

4.4.5. Radial Distribution Function

5. Bio Rejuvenator Ranking

6. Conclusions and Recommendations

- (1)

- Asphalt physical property tests show that aging raises softening point and markedly lowers penetration. Bio-oil helps both recover, with better effects at higher dosages. The three bio-oils perform similarly in reducing softening point, but SSO and SO outperform PO in improving penetration. At 8% content, aged asphalt’s properties mostly recover to near-original levels, so 8% is the optimal dosage.

- (2)

- The FTIR results show that the carbonyl index and sulfoxide index of aged asphalt decrease with the increase in the addition amount of the three bio-oils, indicating that the three bio-oils can improve the impact of aging on asphalt. In addition, at the optimal dosage, the regeneration efficiency of bio-oils on the chemical components of aged asphalt decreases in the order of SSO → SO → PO. The difference in regeneration effect between SO and PO is not significant, while SSO shows the best functional group repair ability.

- (3)

- The results of the DSR test show that with increasing dosage of the three bio-oils, the complex shear modulus and rutting parameters of aged asphalt decrease while the phase angle increases. This restores the rheological properties of aged asphalt to a certain extent but impairs its high-temperature stability. The rutting parameter (G*/sin δ) of rejuvenated asphalt decreases systematically with higher bio-oil dosage; it drops significantly in the low-temperature range (40–60 °C) but the decreasing trend flattens in the high-temperature range (>60 °C). In conclusion, bio-oil dosage should be controlled, and the upper limit of their optimal dosage is recommended to be set at 8%.

- (4)

- In this paper, molecular models of virgin asphalt, aged asphalt, bio-oil, and rejuvenated asphalt were established through molecular dynamics (MD). The density and solubility parameters of the virgin asphalt were obtained by MD. The simulation test results are consistent with the existing results, indicating the correctness of the established asphalt molecular model.

- (5)

- The diffusion behavior analysis of three types of rejuvenated asphalts, LAA+SO, LAA+PO, and LAA+SSO, was studied through molecular dynamics simulation. By comparing the MSD values of the three rejuvenators, it can be found that the diffusion effects of soybean oil and palm oil are better than those of sunflower oil. Soybean oil and palm oil can effectively improve the performance of aged asphalt and enhance its diffusion ability in various components.

- (6)

- Through the RDF simulation of the four components of asphalt, it was found that compared with sunflower oil, the g(r) peaks of each component in the rejuvenated asphalts with soybean oil and palm oil are higher, and the packing density of the asphalt molecular model is greater. This indicates that the orderliness of asphalt molecules is enhanced, and also demonstrates that there is good compatibility between soybean oil, palm oil, and asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, R.; Hu, P.; Zhong, Y.; Wen, L.; Ji, J.; Liang, L. Research progress on evaluation and prediction of degradation in service performance for asphalt pavement. J. Traffic Transp. Eng. (Engl. Ed.) 2025, 12, 1011–1039. [Google Scholar] [CrossRef]

- Basant, B.; Shenghua, W. A comprehensive state-of-art review on the use of rejuvenators in asphalt pavement. J. Road Eng. 2025, 5, 1–20. [Google Scholar]

- Yang, J.; Luo, L.; Gao, J.; Xu, J.; He, C. Study on the effect of regeneration agent on the viscosity properties of aged asphalt. Materials 2022, 15, 380. [Google Scholar] [CrossRef]

- Idham, M.K.; Hainin, M.R.; Warid, M.N.M.; Raman, N.A.A.; Mamat, R. Evaluation on the performance of aged asphalt binder and mixture under various aging methods. J. Teknol. 2015, 77. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Z.; Wang, H.; Chen, M.; Wu, S.; Xu, S.; Zhou, X.; Ran, M.; Li, L.; Lu, G.; et al. Review on the properties and mechanisms of asphalt modified with bio-oil and biochar. J. Road Eng. 2024, 4, 421–432. [Google Scholar] [CrossRef]

- Xinxin, C.; Xuejuan, C.; Boming, T.; Yuanyuan, W.; Xiaolong, L. Investigation on possibility of waste vegetable oil rejuvenating aged asphalt. Appl. Sci. 2018, 8, 765. [Google Scholar] [CrossRef]

- Quan, X.; Lin, Z.; Chen, C.; Ma, T.; Zhang, Y. A sustainable rapeseed oil-based bio-additive designed for hard asphalt binders: Performance, environmental, and economic assessment. Fuel 2024, 372, 132191. [Google Scholar] [CrossRef]

- Suo, Z.; Chen, H.; Yan, Q.; Tan, Y.; Li, X.; Zhang, A. Laboratory performance evaluation on the recovering of aged bitumen with vegetable oil rejuvenator. Front. Mater. 2021, 8, 650809. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, X.; Xu, T. Development of sustainable compound bio-oil rejuvenator and its rejuvenation mechanism on long-term aged asphalt. J. Clean. Prod. 2023, 429, 139440. [Google Scholar] [CrossRef]

- Ye, Q.; Yang, Z.; Lv, S.; Jin, J.; Zhang, S. Study on components selection and performance of bio-oil based asphalt rejuvenator based on softening and asphaltene deagglomeration effect. J. Clean. Prod. 2023, 419, 138238. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Ge, C.; Chen, C.; Ma, T. Effects of aging on the rheological and microscopic properties of partially epoxidized soybean oil rejuvenated asphalt binders. Constr. Build. Mater. 2025, 481, 141527. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Katman, H.Y.; Mohd Satar, M.K.I.; Bilema, M.; Putra Jaya, R.; Eltwati, A.S.; Radeef, H.R. A review on the durability of recycled asphalt mixtures embraced with rejuvenators. Sustainability 2021, 13, 8970. [Google Scholar] [CrossRef]

- Ding, H.; Wang, H.; Qu, X.; Varveri, A.; Gao, J.; You, Z. Towards an understanding of diffusion mechanism of bio-rejuvenators in aged asphalt binder through molecular dynamics simulation. J. Clean. Prod. 2021, 299, 126927. [Google Scholar] [CrossRef]

- Zhang, X.; Ning, Y.; Zhou, X.; Xu, X.; Chen, X. Quantifying the rejuvenation effects of soybean-oil on aged asphalt-binder using molecular dynamics simulations. J. Clean. Prod. 2021, 317, 128375. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Lin, P.; Gao, Y.; Erkens, S. Insight into the compatibility behaviors between various rejuvenators and aged bitumen: Molecular dynamics simulation and experimental validation. Mater. Des. 2022, 223, 111141. [Google Scholar] [CrossRef]

- Shi, K.; Ma, F.; Fu, Z.; Liu, J.; Song, R.; Yuan, D.; Tang, Y. Molecular dynamics simulation insights into rejuvenating aged asphalt with waste soybean oil and polymers. Constr. Build. Mater. 2024, 439, 137260. [Google Scholar] [CrossRef]

- Li, B.; Han, J.; Wei, D.; Ji, H.; Yao, T.; Wang, H.; Han, J.; Zhang, Y. A molecular dynamics simulation study on the recovery performance of aged asphalt binder by waste vegetable oil rejuvenators. J. Clean. Prod. 2024, 442, 140796. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Diffusion and interaction mechanism of rejuvenating agent with virgin and recycled asphalt binder: A molecular dynamics study. Mol. Simul. 2018, 44, 1433–1443. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, Z.; Yang, J.; Wang, Y. Research on interfacial fusion characteristics of rejuvenator-aged asphalt system: Wettability, permeability and molecular simulation. Constr. Build. Mater. 2024, 443, 137646. [Google Scholar] [CrossRef]

- Liu, K.; Xu, Y.; Xing, Z.; Li, Y.; Sun, Z.; Wang, H. Effects of natural weathering in cold regions on the morphological structure, rheological properties, and molecular characteristics of asphalt binders. Constr. Build. Mater. 2025, 493, 143172. [Google Scholar] [CrossRef]

- ASTM D2872-22; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D6521-22; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D5-06; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D36-06; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2010.

- Zhou, T.; Cao, L.; Fini, E.H.; Li, L.; Liu, Z.; Dong, Z. Behaviors of asphalt under certain aging levels and effects of rejuvenation. Constr. Build. Mater. 2020, 249, 118748. [Google Scholar] [CrossRef]

- Xiang, H.; He, Z.; Tang, H.; Chen, L. Effects of thermo-oxidative aging on the macrophysical properties and microstructure of asphalt. Constr. Build. Mater. 2023, 395, 132315. [Google Scholar] [CrossRef]

- Islam, M.R.; Salomon, D.; Wasiuddin, N.M. Investigation of oxidative aging of field-extracted asphalt binders at various conditions using carbonyl index. Constr. Build. Mater. 2024, 415, 134969. [Google Scholar] [CrossRef]

- Zhao, S.; You, Q.; Ling, J.; Zhang, J.; Chineche, E.B.; Wang, J. Variation of nano-ZnO/SBR modified asphalt features under photo-oxidative aging and optimization of the evaluation indexes based on rheological properties and chemical structure. Case Stud. Constr. Mater. 2024, 21, e04101. [Google Scholar] [CrossRef]

- Yu, C.; Hu, K.; Yang, Q.; Chen, Y. Multi–scale observation of oxidative aging on the enhancement of high–temperature property of SBS–modified asphalt. Constr. Build. Mater. 2021, 313, 125478. [Google Scholar] [CrossRef]

- Jing, L.; Shi, P.; Shen, J. Regeneration mechanism of asphalt based on atomic force microscope. Sci. Technol. Eng. 2020, 20, 3272–3279. [Google Scholar]

- Wang, J.; Lv, S.; Liu, J.; Peng, X.; Lu, W.; Wang, Z.; Xie, N. Performance evaluation of aged asphalt rejuvenated with various bio-oils based on rheological property index. J. Clean. Prod. 2023, 385, 135593. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.-M.; Wu, S.-J.; Wang, H.-R.; Liu, X.-C.; Sun, H.-D.; Fan, L. Effect of montmorillonite modification on resistance to thermal oxidation aging of asphalt binder. Case Stud. Constr. Mater. 2022, 16, e00971. [Google Scholar] [CrossRef]

- Fu, Z.; Tang, Y.; Peng, C.; Ma, F.; Li, C. Properties of polymer modified asphalt by polyphosphoric acid through molecular dynamics simulation and experimental analysis. J. Mol. Liq. 2023, 382, 121999. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- Aparicio, R.; Aparicio-Ruíz, R. Authentication of vegetable oils by chromatographic techniques. J. Chromatogr. A 2000, 881, 93–104. [Google Scholar] [CrossRef]

- Wei, W.; Sun, C.; Jiang, W.; Zhang, X.; Hong, Y.; Jin, Q.; Tao, G.; Wang, X.; Yang, Z. Triacylglycerols fingerprint of edible vegetable oils by ultra-performance liquid chromatography-Q-ToF-MS. LWT 2019, 112, 108261. [Google Scholar] [CrossRef]

- Khabaz, F.; Khare, R. Glass transition and molecular mobility in styrene–butadiene rubber modified asphalt. J. Phys. Chem. B. 2015, 119, 14261–14269. [Google Scholar] [CrossRef]

- Yu, H.; Ge, J.; Qian, G.; Zhang, C.; Dai, W.; Li, P. Evaluation on the rejuvenation and diffusion characteristics of waste cooking oil on aged SBS asphalt based on molecular dynamics method. J. Clean. Prod. 2023, 406, 136998. [Google Scholar] [CrossRef]

- Sun, D.; Lin, T.; Zhu, X.; Tian, Y.; Liu, F. Indices for self-healing performance assessments based on molecular dynamics simulation of asphalt binders. Comput. Mater. Sci. 2016, 114, 86–93. [Google Scholar] [CrossRef]

- Pipintakos, G.; Škulteckė, J.; Vaitkus, A.; Šernas, O.; Soenen, H.; Van den Bergh, W. Optimising bitumen modification: How styrene–butadiene–styrene (SBS) characteristics and content affect bitumen behaviour. Road Mater. Pavement Des. 2025, 26, 443–463. [Google Scholar] [CrossRef]

| Property | Unit | Specification | Measured | Standard |

|---|---|---|---|---|

| Penetration at 25 °C | 0.1 mm | 80–100 | 96 | ASTM-D5 |

| Softening point | °C | ≥44 | 44.3 | ASTM-D36 |

| Bio-Oils | Triglyceride (TG) | The Number in the Model | The Mass Ratio to the Long-Term Aged Asphalt |

|---|---|---|---|

| Soybean oil | LLL | 2 | 11.9% |

| LLLn | 1 | ||

| LLO | 1 | ||

| PLL | 1 | ||

| Palm oil | LLL | 2 | 11.1% |

| LLO | 2 | ||

| PLL | 1 | ||

| Sunflower oil | PPO | 2 | 12.63% |

| POO | 2 | ||

| POL | 1 | ||

| PPL | 1 |

| Asphalt | Component | Linear Fitting | R2 |

|---|---|---|---|

| Soybean oil-rejuvenated asphalt | Total | y = 1.47505 + 0.04052x | 0.9737 |

| Aromatic | y = 1.07727 + 0.04751x | 0.9937 | |

| Asphaltene | y = 0.86399 + 0.03333x | 0.8045 | |

| Resin | y = 1.2091 + 0.03818x | 0.9300 | |

| Saturate | y = 3.24539 + 0.01438x | 0.7915 | |

| Soybean oil | y = 2.04913 + 0.06351x | 0.9774 | |

| Palm oil-rejuvenated asphalt | Total | y = 1.15878 + 0.04668x | 0.9724 |

| Aromatic | y = 1.86179 + 0.02913x | 0.9672 | |

| Asphaltene | y = 0.75469 + 0.03521x | 0.8950 | |

| Resin | y = 0.19314 + 0.06445x | 0.9853 | |

| Saturate | y = 2.33368 + 0.02157x | 0.9020 | |

| Palm oil | y = 1.35179 + 0.07199x | 0.9222 | |

| Sunflower oil-rejuvenated asphalt | Total | y = 2.48185 + 0.02299x | 0.8981 |

| Aromatic | y = 2.95593 + 0.0172x | 0.77749 | |

| Asphaltene | y = 2.19491 + 0.01067x | 0.5615 | |

| Resin | y = 1.6615 + 0.02843x | 0.8413 | |

| Saturate | y = 2.13703 + 0.03526x | 0.9176 | |

| Sunflower oil | y = 4.13658 + 0.02424x | 0.7590 | |

| Virgin asphalt | Total | y = 1.57579 + 0.04352x | 0.9441 |

| Aromatic | y = 1.71042 + 0.04537x | 0.9293 | |

| Asphaltene | y = 2.23989 + 0.02778x | 0.9346 | |

| Resin | y = 1.0842 + 0.04739x | 0.9401 | |

| Saturate | y = 1.74902 + 0.04794x | 0.9396 | |

| Long-term aged asphalt | Total | y = 1.82592 + 0.02111x | 0.9851 |

| Aromatic | y = 1.41404 + 0.02806x | 0.9776 | |

| Asphaltene | y = 1.49739 + 0.02429x | 0.9620 | |

| Resin | y = 2.23452 + 0.01047x | 0.8760 | |

| Saturate | y = 2.086 + 0.02965x | 0.9659 |

| Parameter | VA | LAA | LAA+SO | LAA+PO | LAA+SSO |

|---|---|---|---|---|---|

| diffusion coefficient | 7.3 | 3.5 | 6.8 | 7.8 | 3.8 |

| penetration | 96 | 27.3 | 89 | 73.9 | 89.9 |

| softening point | 44.3 | 59.8 | 49.2 | 49.6 | 48.2 |

| FTIR index | 0.015 | 0.060 | 0.035 | 0.035 | 0.029 |

| rutting parameter at 80 °C | 236.31 | 1643.5 | 420.49 | 451.86 | 427.55 |

| phase angle at 80 °C | 89.16 | 83.04 | 85.29 | 85.44 | 85.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, H.; Liang, S.; Liu, Q.; Ren, S.; Pipintakos, G.; Wu, S.; Liu, M.; Xu, S. Experimental and Molecular Dynamics Investigation of the Rejuvenation Effect of Bio-Oils on Aged High-Penetration Asphalt. Materials 2025, 18, 5252. https://doi.org/10.3390/ma18225252

Xiong H, Liang S, Liu Q, Ren S, Pipintakos G, Wu S, Liu M, Xu S. Experimental and Molecular Dynamics Investigation of the Rejuvenation Effect of Bio-Oils on Aged High-Penetration Asphalt. Materials. 2025; 18(22):5252. https://doi.org/10.3390/ma18225252

Chicago/Turabian StyleXiong, Hongxia, Shichao Liang, Quantao Liu, Shisong Ren, Georgios Pipintakos, Shaopeng Wu, Muyu Liu, and Shi Xu. 2025. "Experimental and Molecular Dynamics Investigation of the Rejuvenation Effect of Bio-Oils on Aged High-Penetration Asphalt" Materials 18, no. 22: 5252. https://doi.org/10.3390/ma18225252

APA StyleXiong, H., Liang, S., Liu, Q., Ren, S., Pipintakos, G., Wu, S., Liu, M., & Xu, S. (2025). Experimental and Molecular Dynamics Investigation of the Rejuvenation Effect of Bio-Oils on Aged High-Penetration Asphalt. Materials, 18(22), 5252. https://doi.org/10.3390/ma18225252