Detection and Location of Defects in Externally Bonded FRP Concrete Structures—Comparison of Selected Methods

Abstract

1. Introduction

- Debonding caused by shear cracks or flexural cracks, i.e., defects in the reinforced concrete structure;

- Debonding related to insufficient anchoring of the FRP material;

- Debonding caused by unevenness or other defects in the concrete surface;

- Delamination in FRP;

- Debonding caused by improper preparation of the concrete surface before applying the FRP material or by improper application.

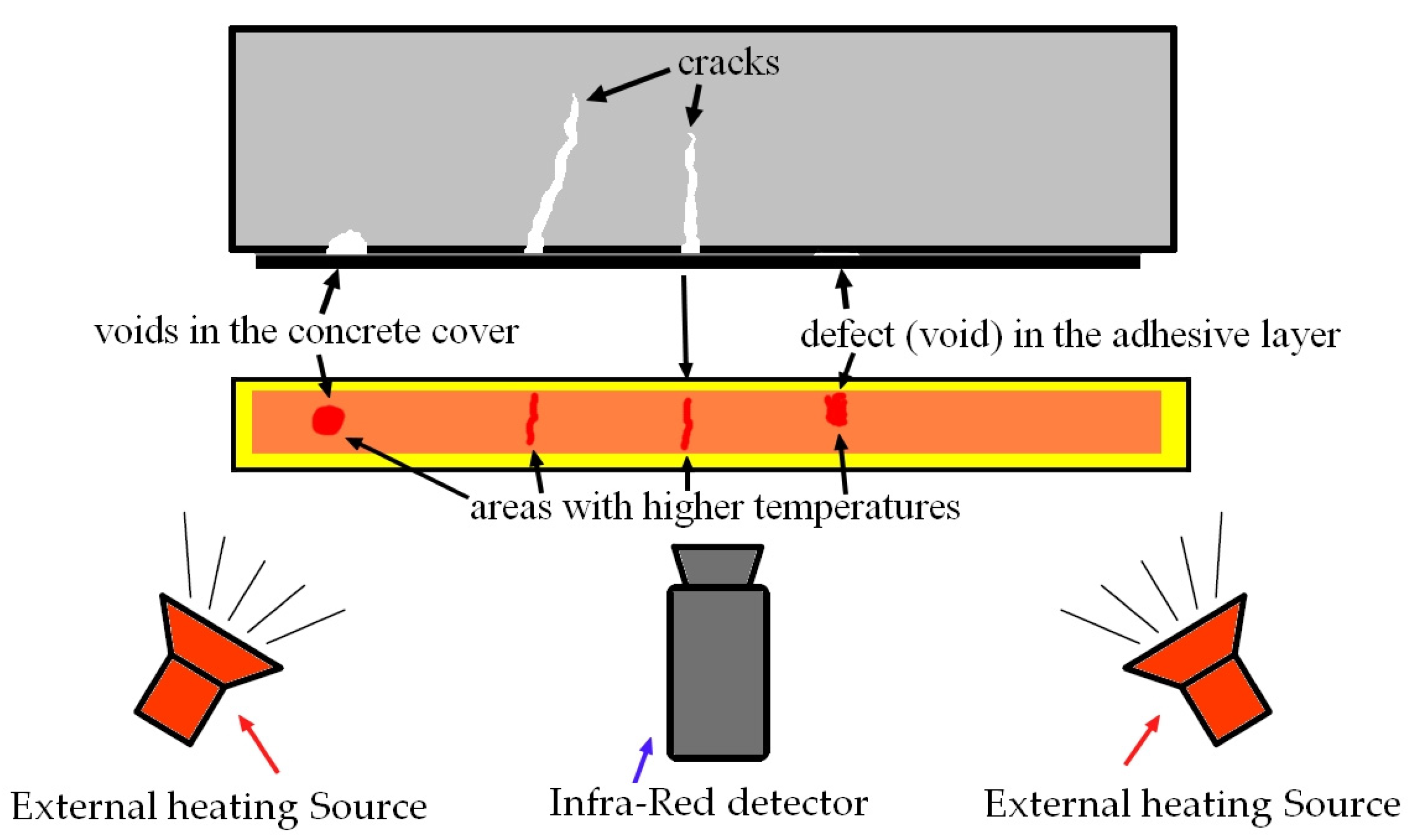

1.1. Infrared Thermography (IRT)—Description of the Method

1.2. Ground-Penetration Radar (GPR)—Description of the Method

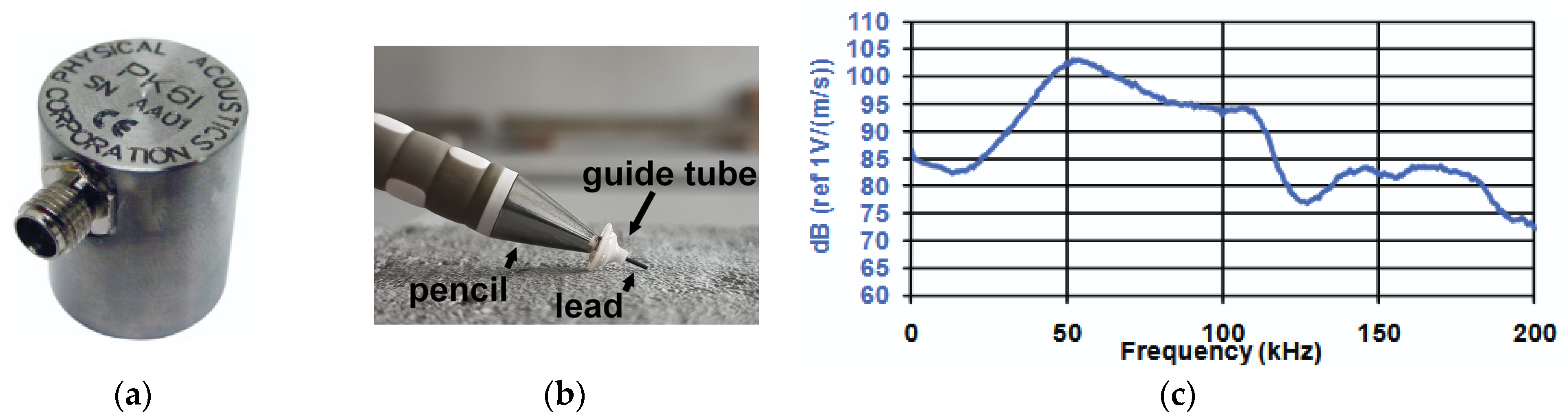

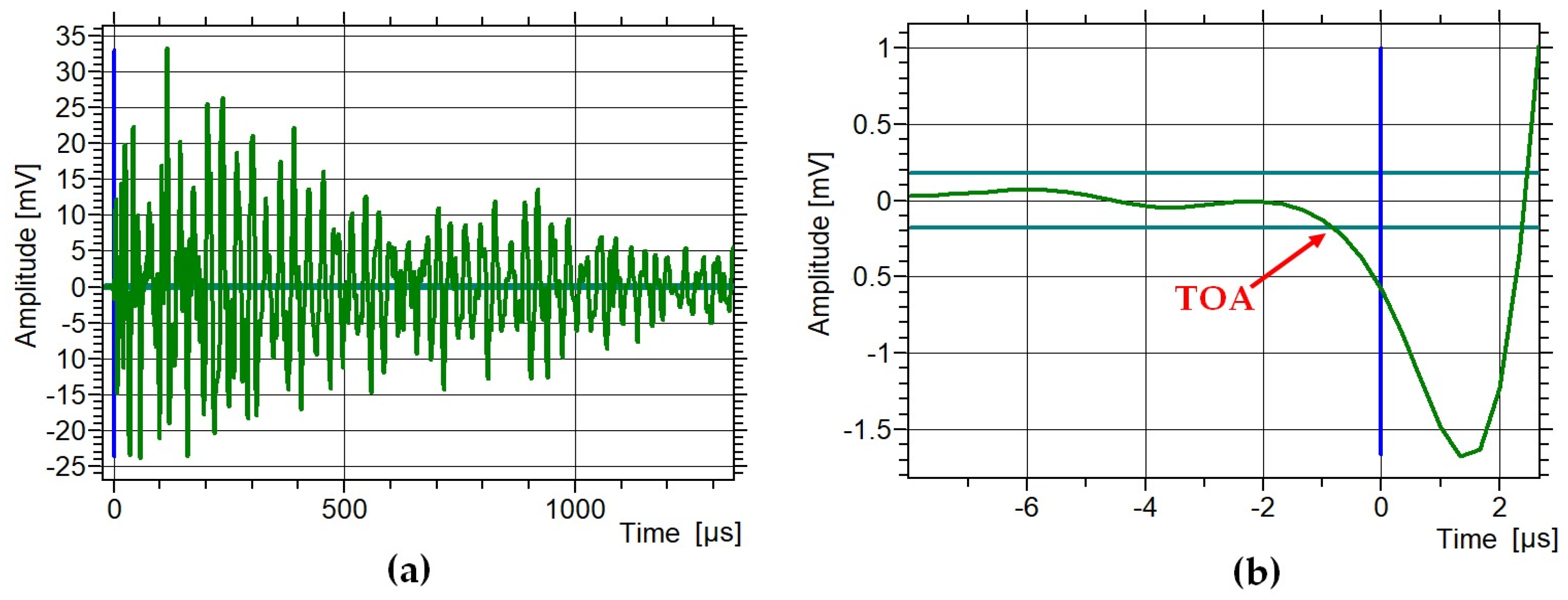

1.3. Wave Velocity Measurement Method (WVMM)—Description of the Method

- A broad and flat frequency band ranging from 40 to 400 kHz, similar to the acoustic emission resulting from concrete cracking [63].

- Allows for determining the reference wave velocity in concrete [64].

- Allows for checking the sensor connection to the concrete and its correct operation; easy to use [64].

- Two sensors are required to measure the longitudinal wave velocity, as the source is not synchronized with the measuring equipment, which complicates analysis [63].

- A broken graphite guide may reflect off the sensor or the surface of the element, causing additional light and erroneous results [63].

- The person breaking the guide should maintain a constant pressure, but in practice this is difficult, and each break of the graphite is not always identical [63].

- Not suitable for tests that require high precision [65].

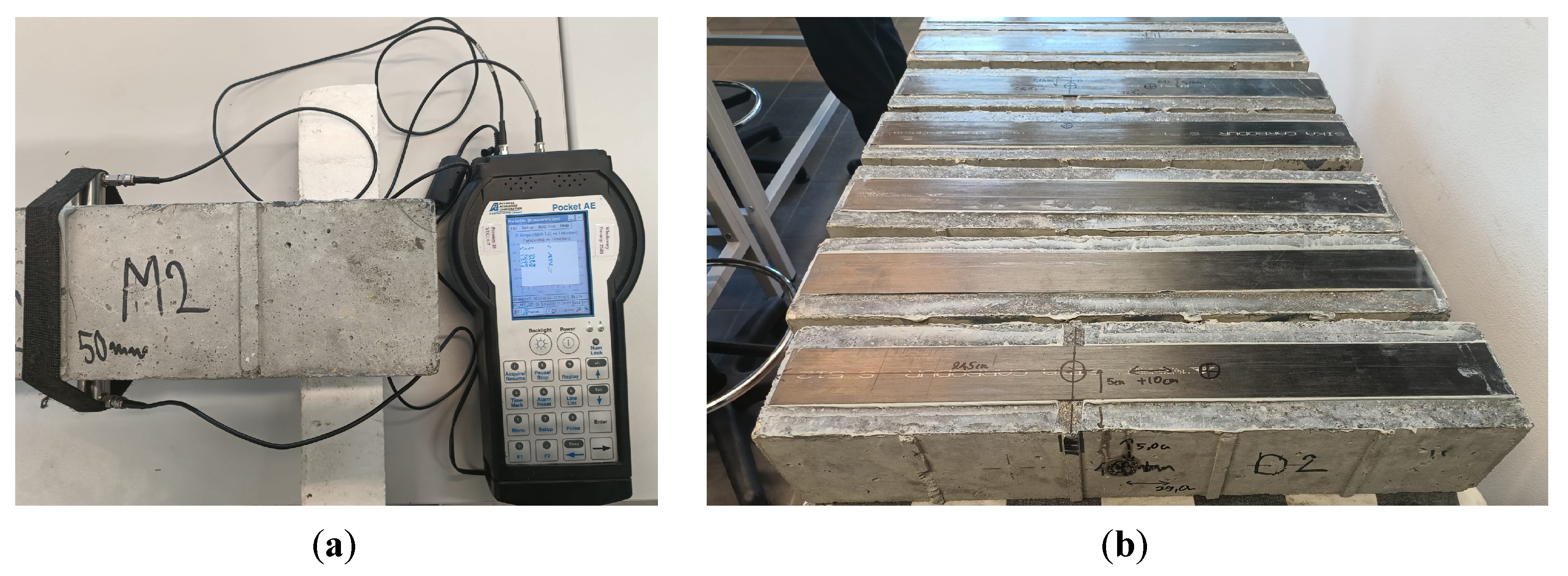

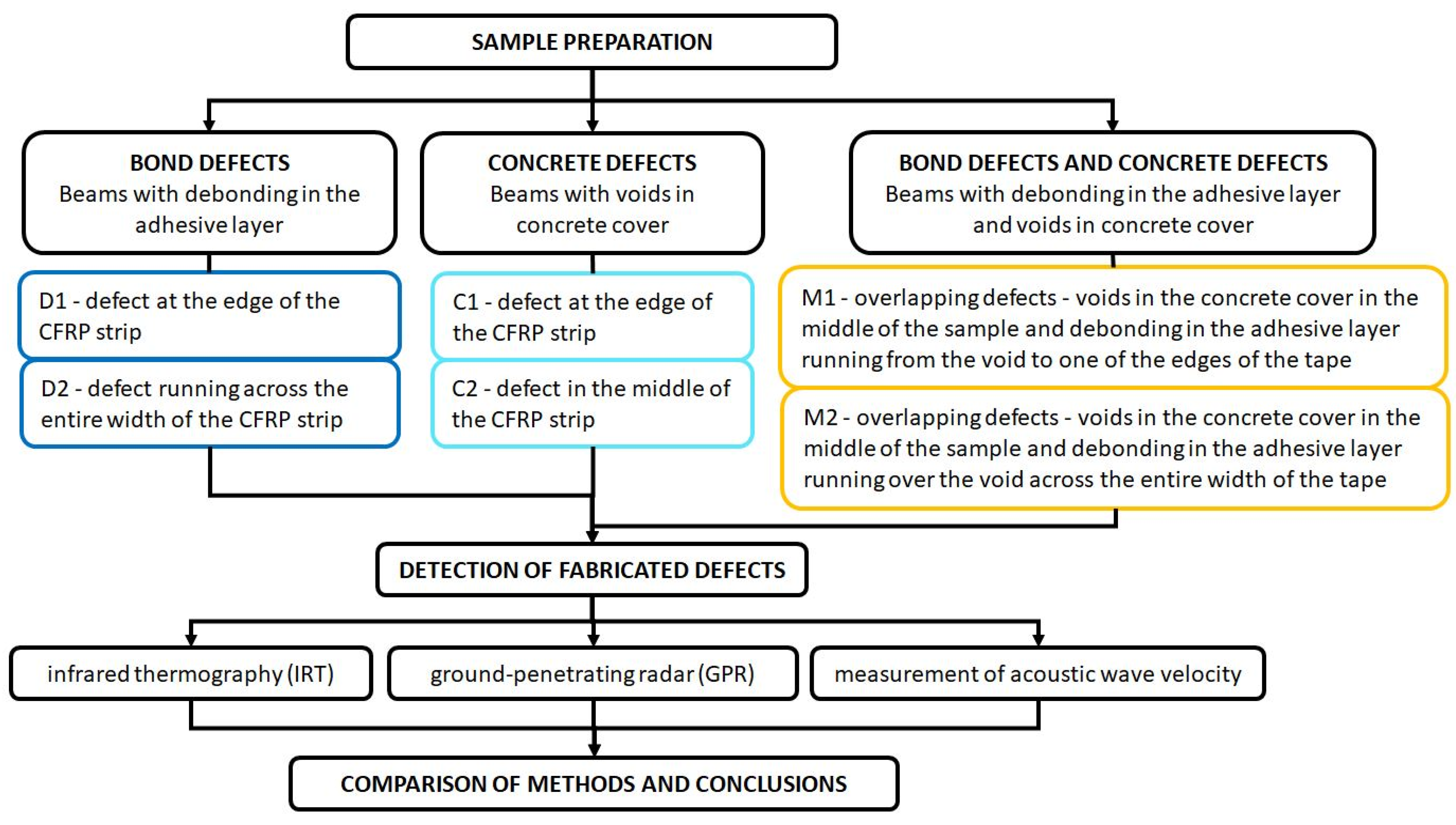

2. Materials

2.1. Materials Used to Prepare Specimens and Their Properties

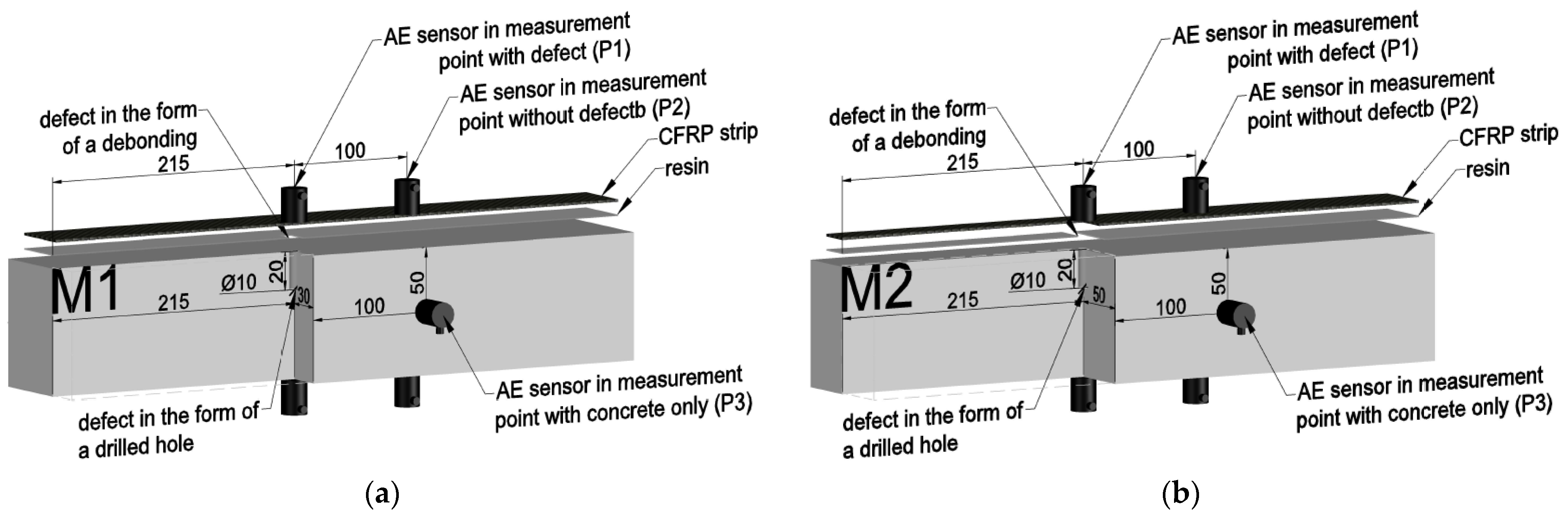

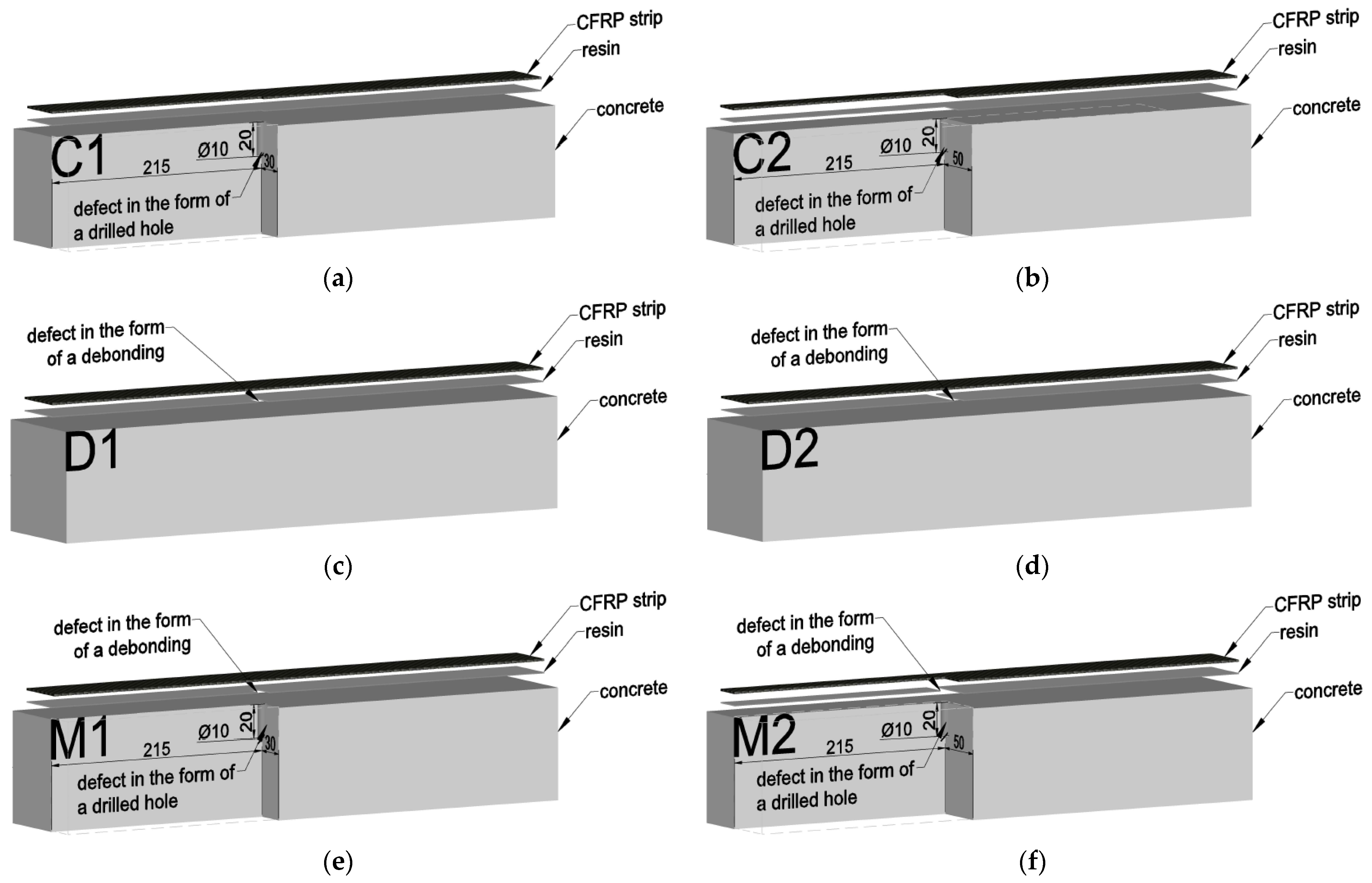

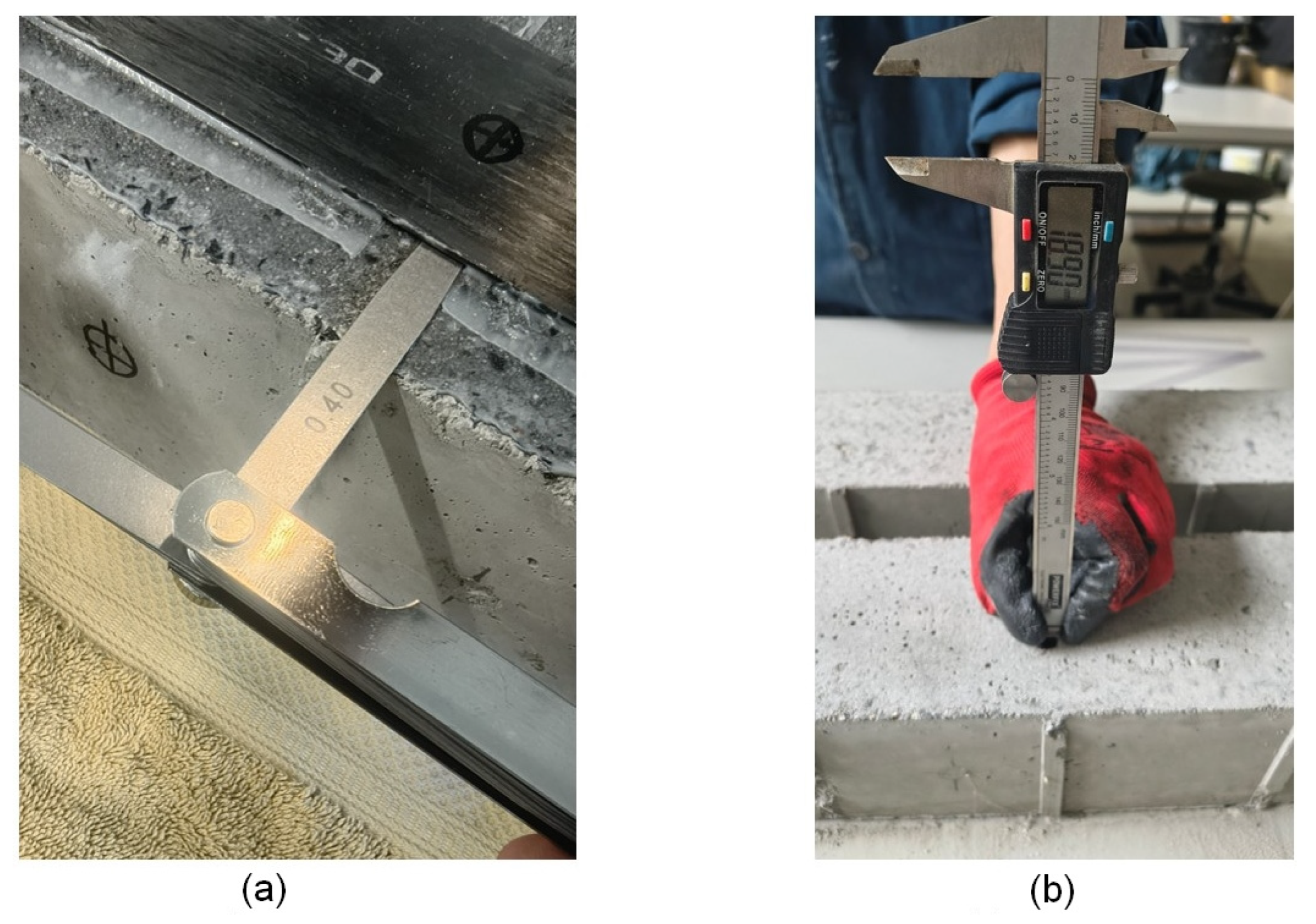

2.2. Preparation of the Specimens

- N1 and N2—beams without defects;

- D1 and D2—beams with a bond defect in the adhesive layer;

- C1 and C2—beams with a concrete defect in the form of drilled voids in the concrete cover;

- M1 and M2—beams with overlapping defects of both types.

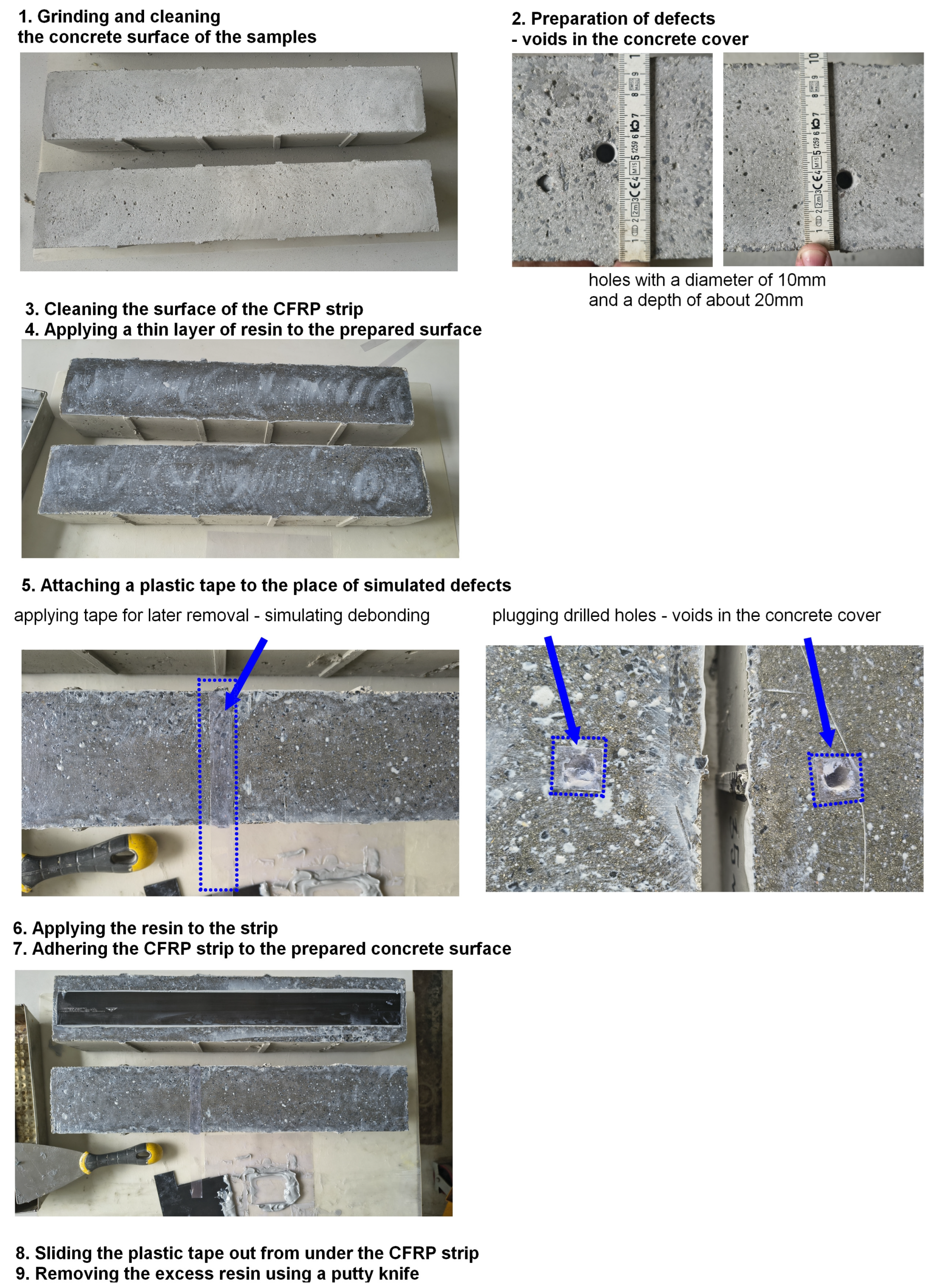

- Grinding and cleaning the concrete surface of the samples;

- Preparation of defects—voids in the concrete cover in samples marked with symbols by drilling holes in accordance with the drawing using a hammer drill with a drill bit of 10 mm diameter;

- Cleaning the surface of the CFRP strip;

- Applying a thin layer of resin to the prepared surface and spreading it with a putty knife to fill all pores, avoiding defects. Removal of excess resin with a putty knife;

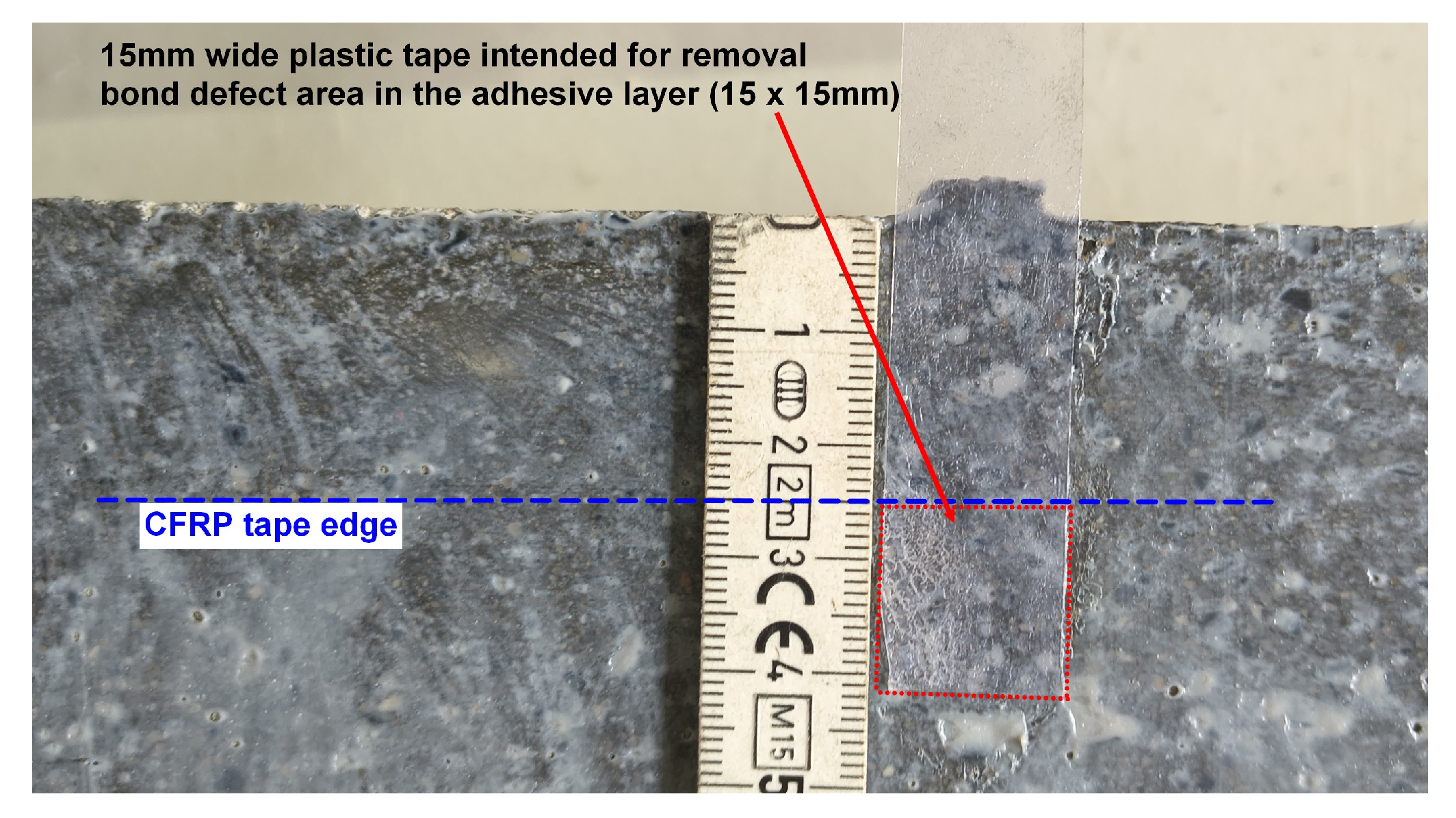

- Attaching a plastic strip to the place of simulated defects (15 mm wide);

- Applying the resin to the strip using a previously prepared trough-type tool with dimensions consistent with the manufacturer’s requirements;

- Adherence of the CFRP strip to the prepared concrete surface and pressing it to remove excess resin;

- Sliding the plastic strip out from under the CFRP strip, creating a void in the resin layer between the strip and the concrete surface;

- Removing the excess resin using a putty knife.

3. Methods and Results

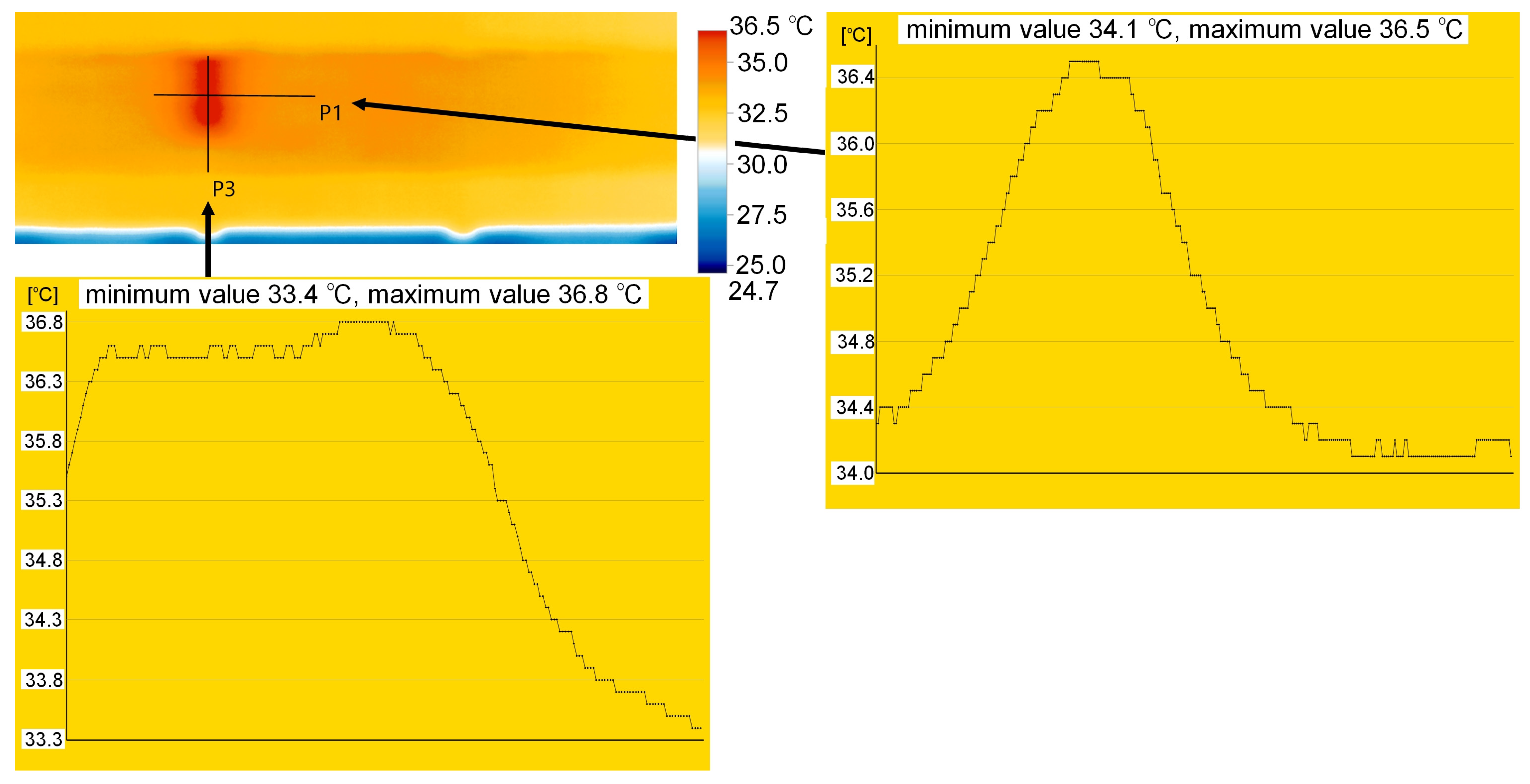

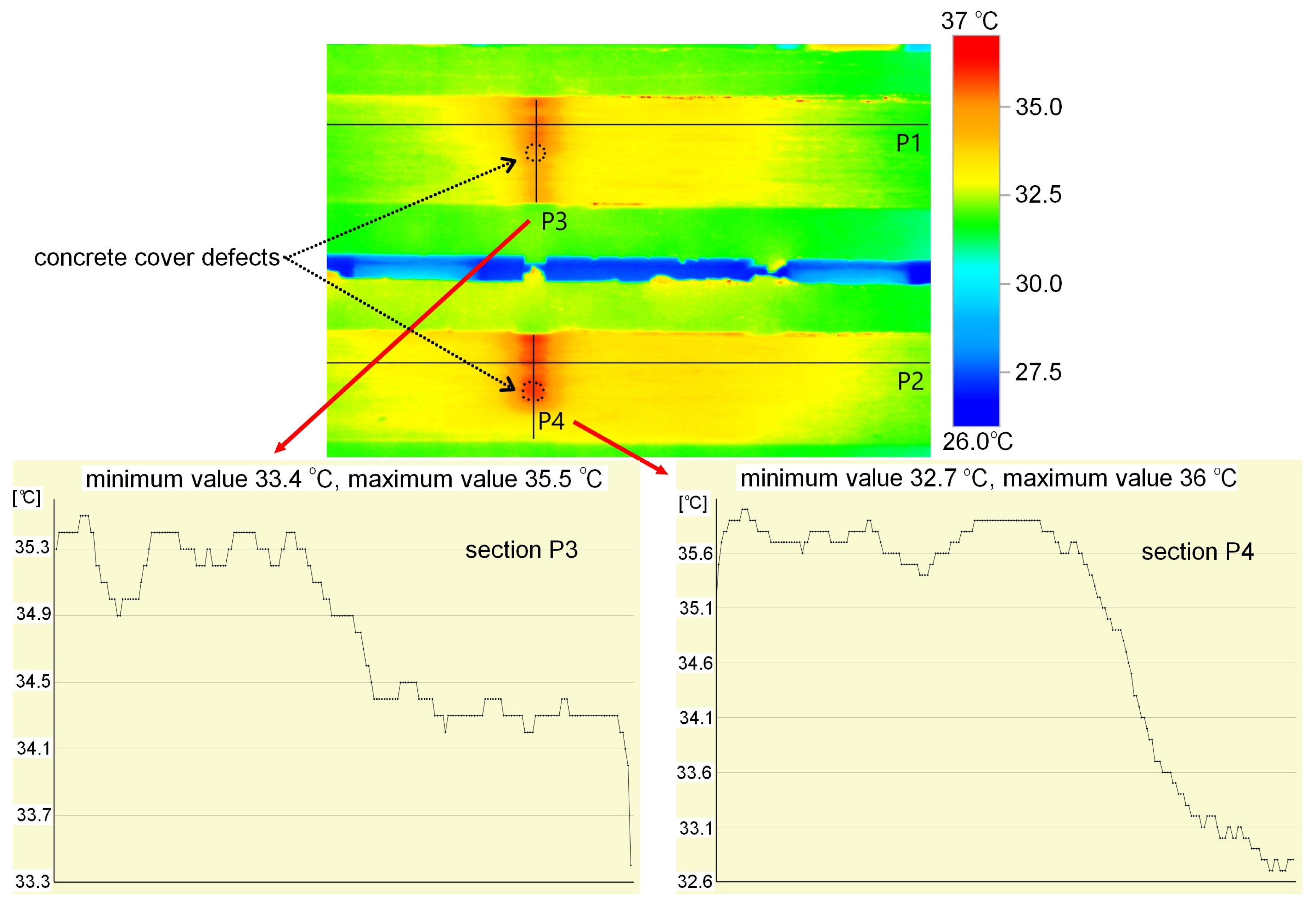

3.1. Infrared Thermography (IRT)

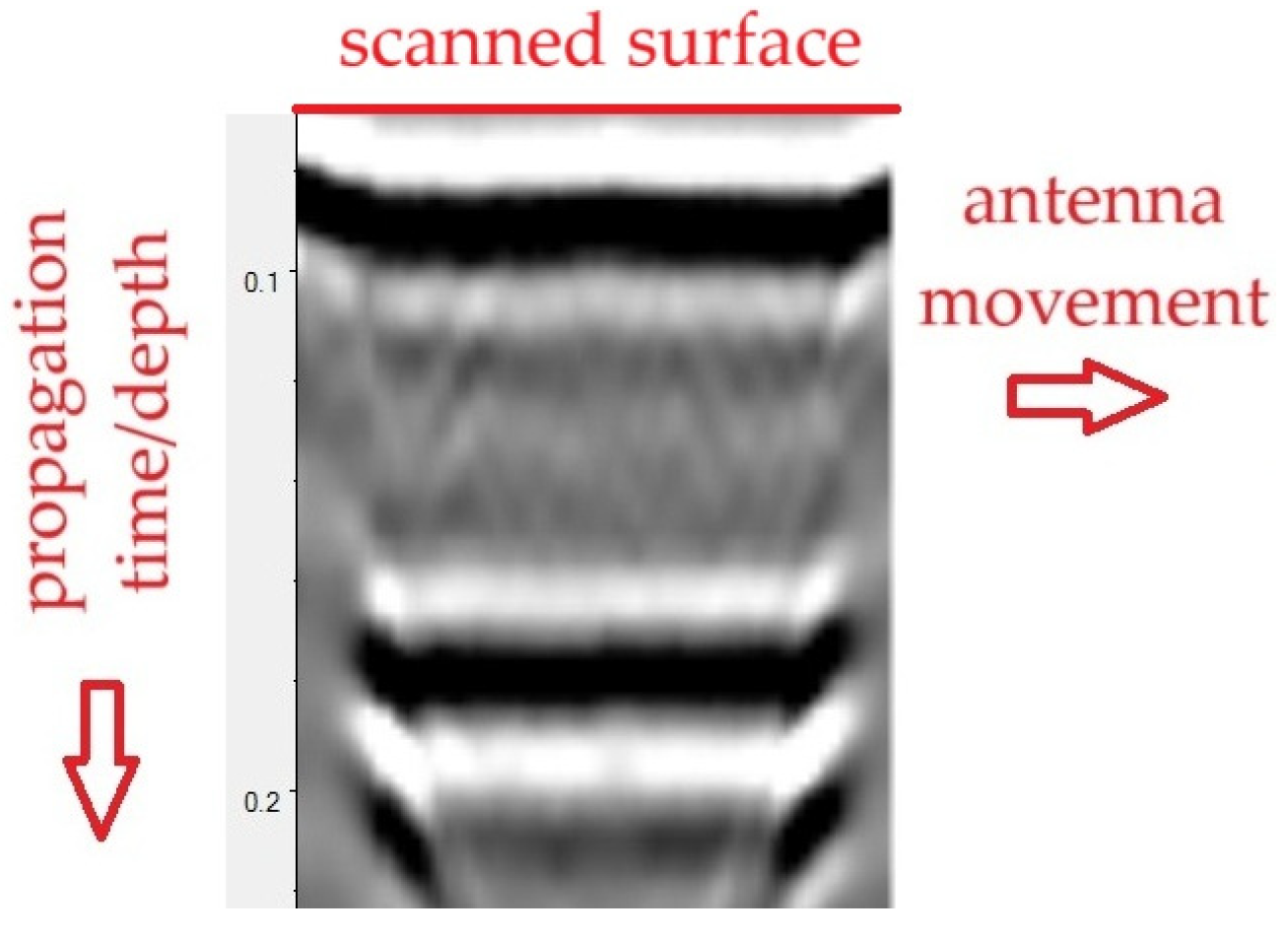

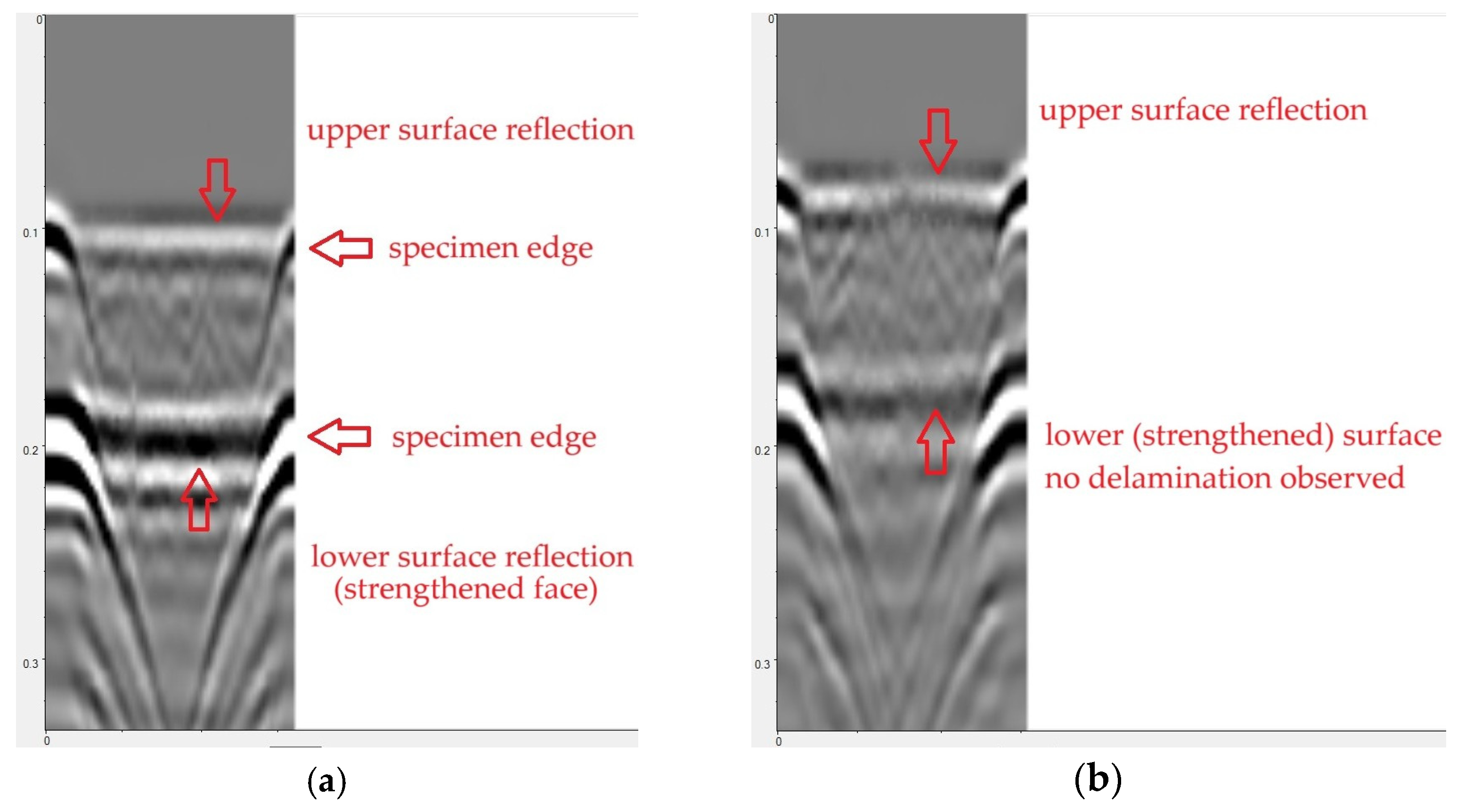

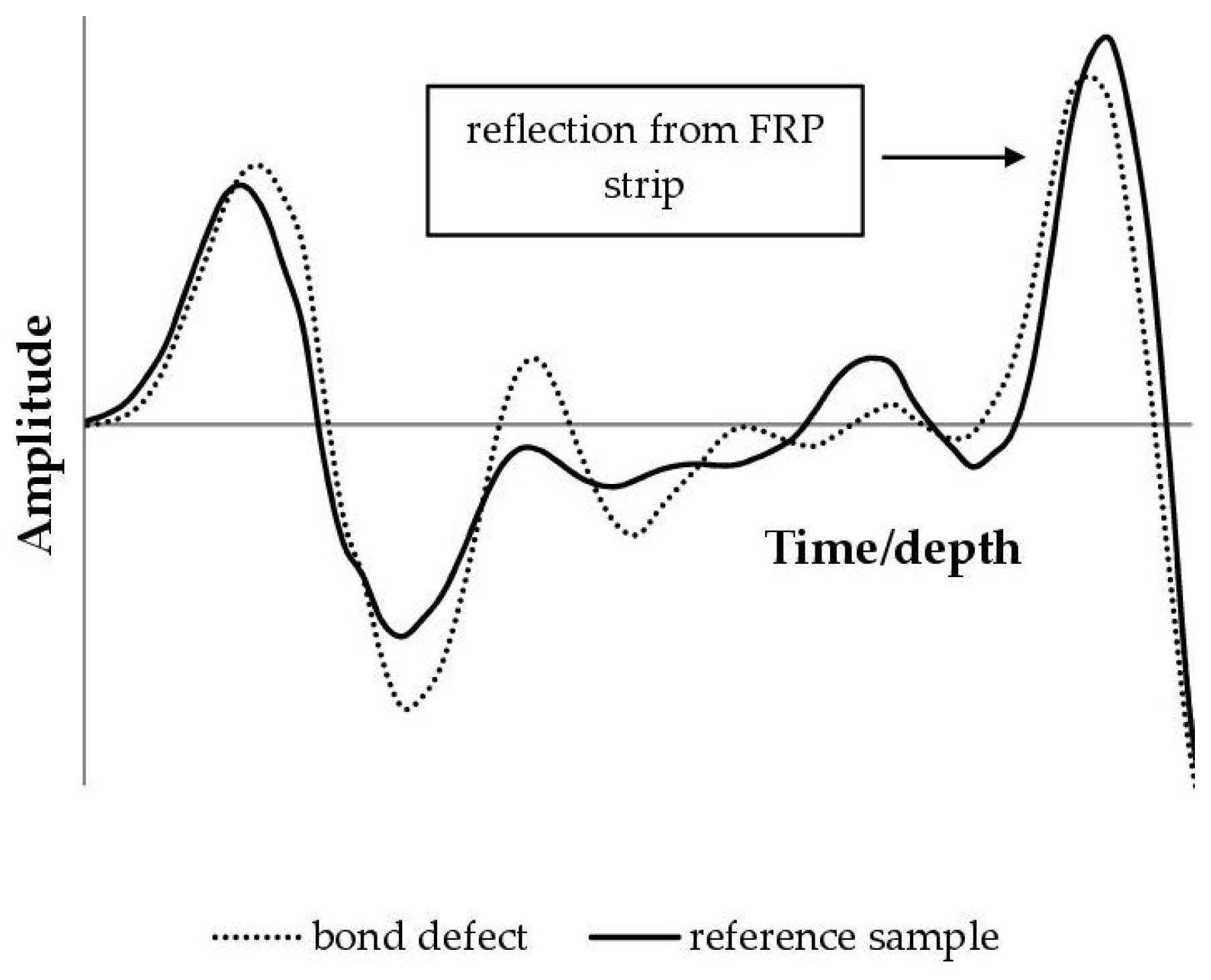

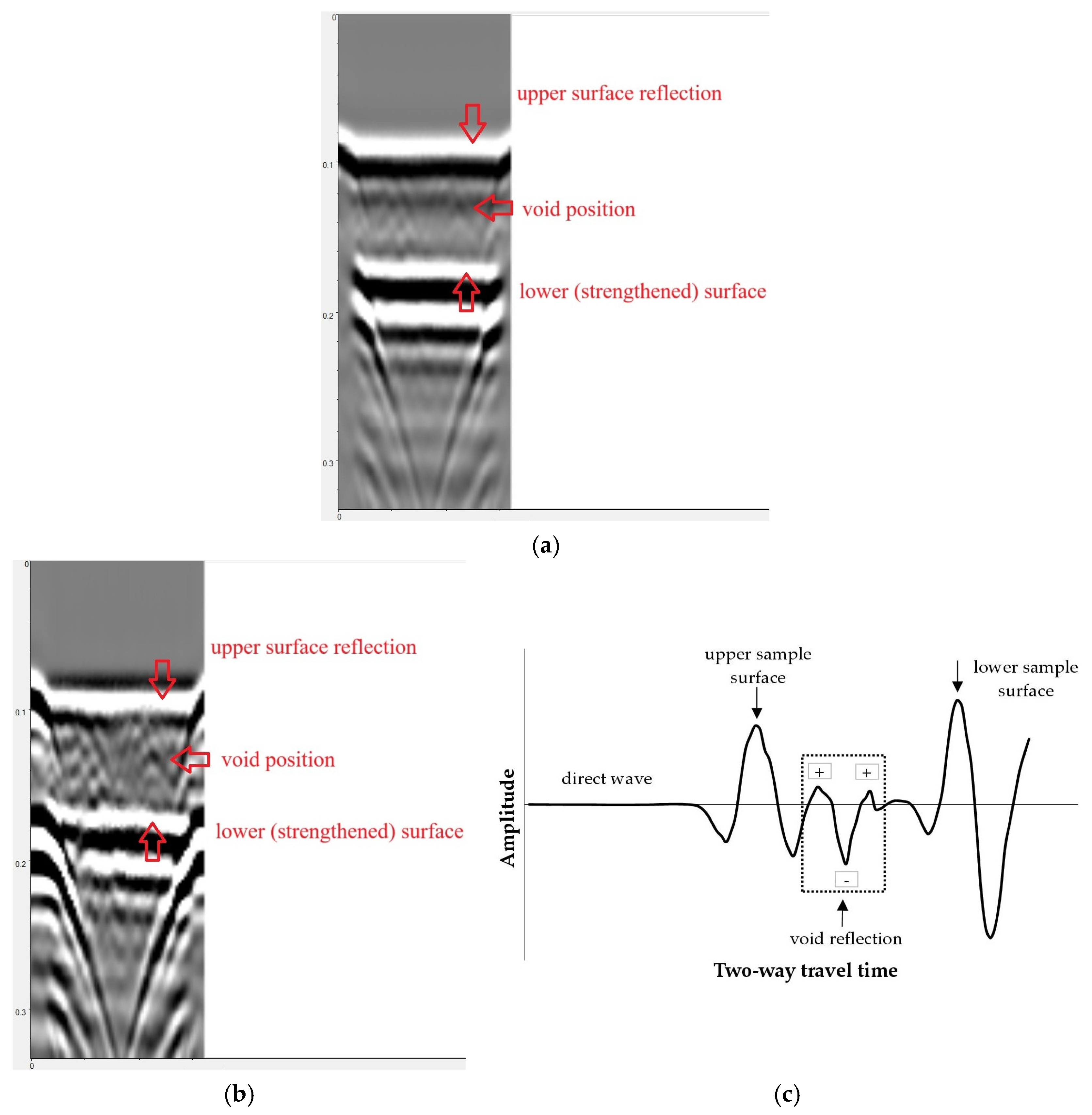

3.2. Ground-Penetrating Radar (GPR)

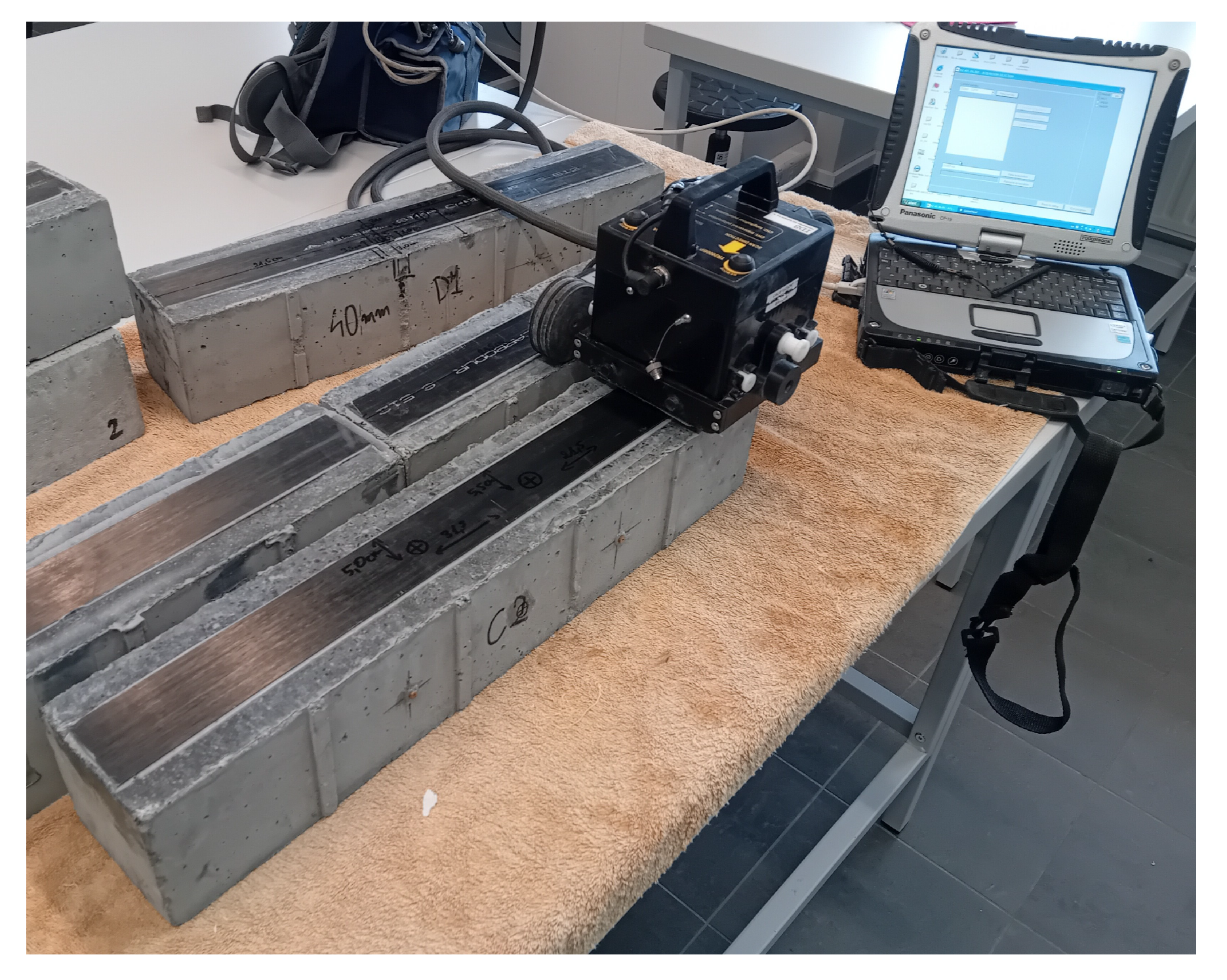

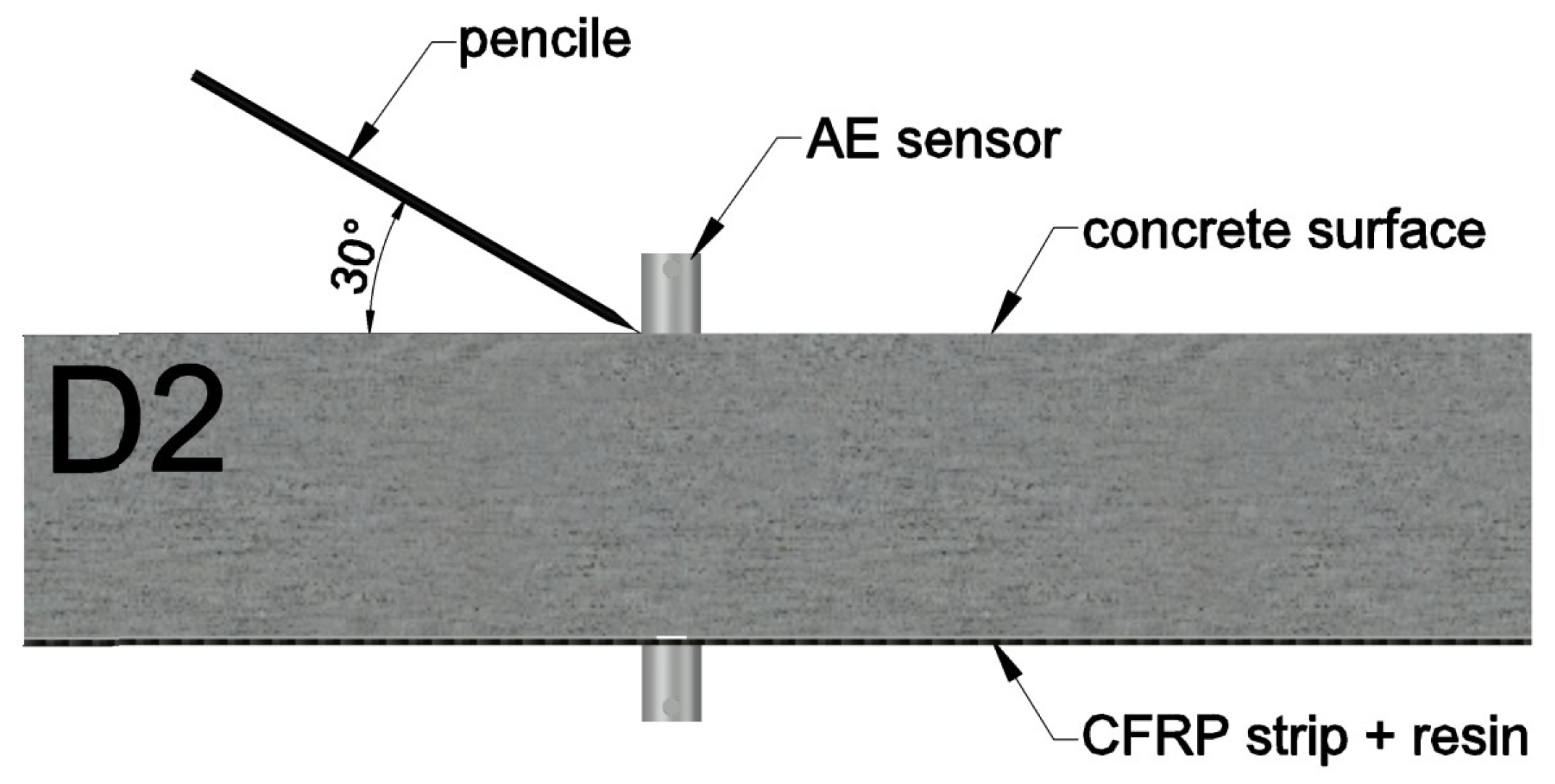

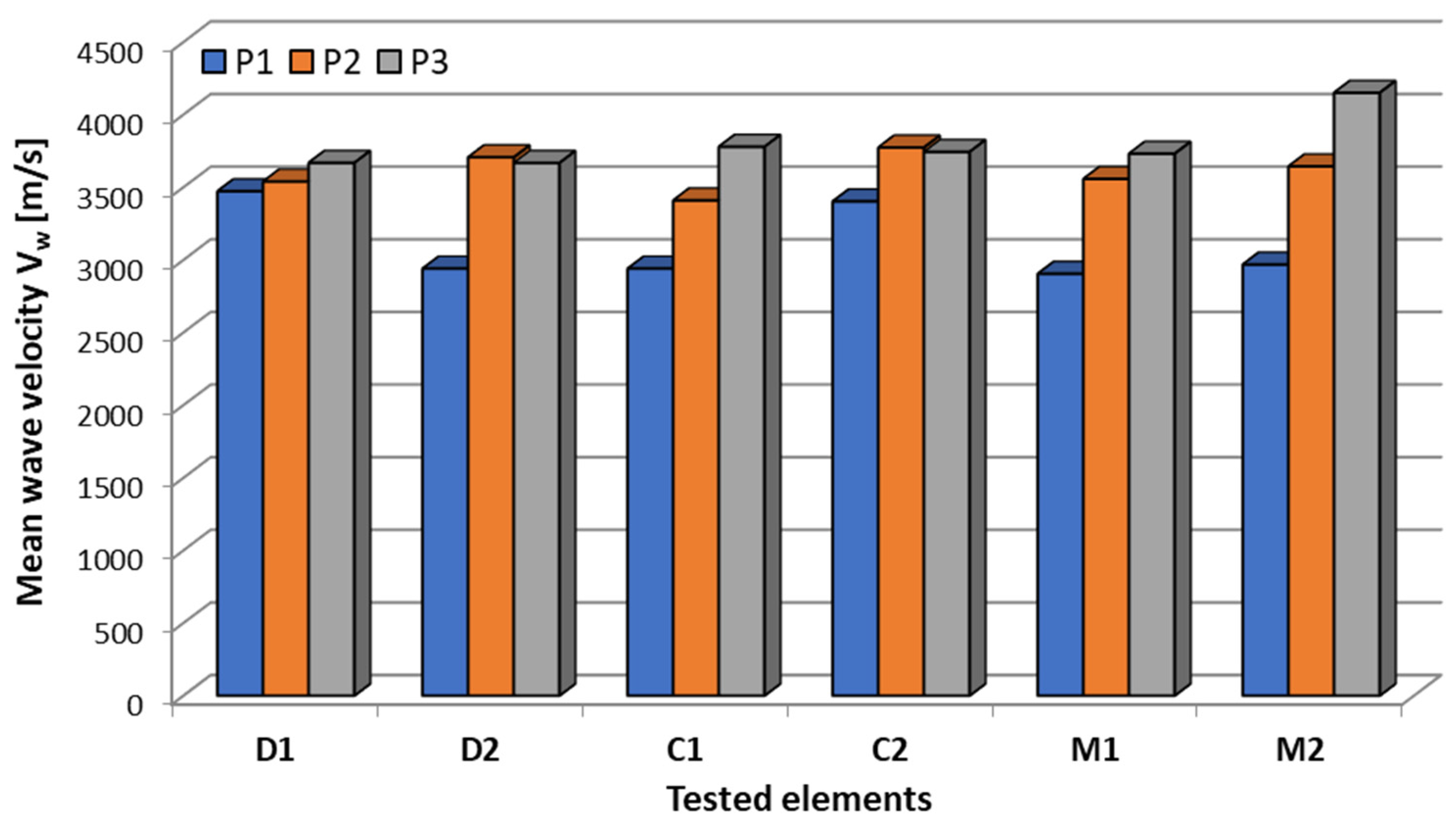

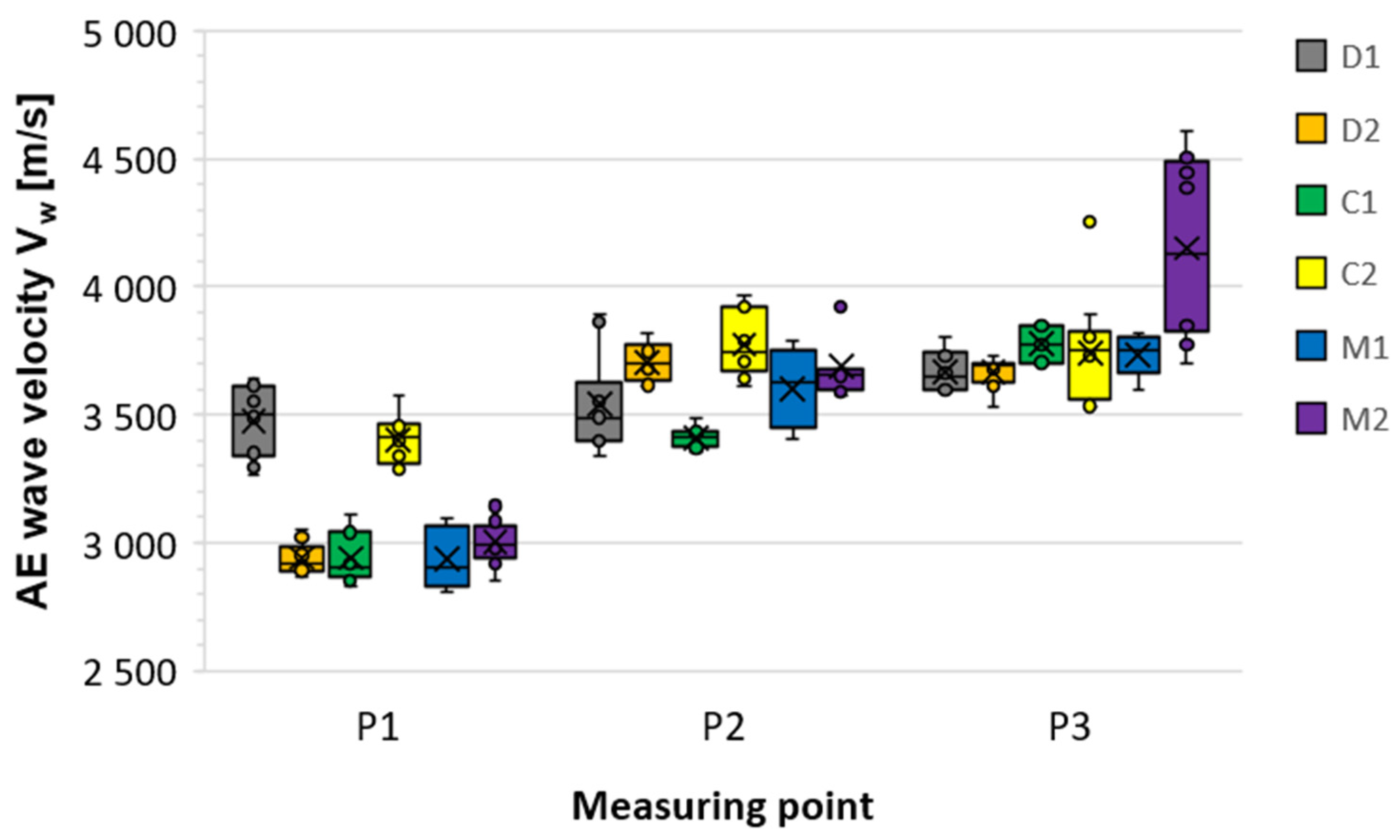

3.3. Wave Velocity Measurement Method (WVMM)

- P1 indicates the measurement point located above the damage;

- P2 indicates the measurement point 10 cm from the damage;

- P3 indicates the measurement point located on the wall perpendicular to the plane with the composite adhered.

- D1 (debonding at the edge of the CFRP strip): ΔVw = 2% → barely measurable effect.

- C1, C2 (voids at the edge and in the middle of the CFRP strip): ΔVw = 10–14% → moderate decrease.

- M1, M2 (overlapping defects): ΔVw = 18–19% → significant speed drop.

- D2 (debonding running across the entire width of the CFRP strip): ΔVw = 21% → greatest speed drop.

4. Discussion

4.1. Uncertainty Analysis of Thermographic Measurements

4.1.1. Temperature Measurement Uncertainty

- A.

- Uncertainty Components (Type B):

- Instrument Accuracy (): The manufacturer’s specification for the Testo 890 accuracy is ±2 °C. For measurements around 40 °C, the 2 °C limit governs. Assuming a rectangular distribution, the standard uncertainty is:

- Thermal Sensitivity (): The Noise Equivalent Temperature Difference (NETD) defines the camera’s thermal resolution:

- Emissivity Uncertainty (): The surface emissivity was set to 0.95. Assuming an uncertainty margin of (that is, range 0.93–0.97) due to surface heterogeneity and non-ideal black body behaviour, this variation affects the calculated temperature. Based on an approximate sensitivity analysis for and , this error is estimated to be

- B.

- Combined and Expanded Uncertainty

4.1.2. Spatial Resolution and Defect Localization Uncertainty

- A.

- Instantaneous Field of View (IFOV) Calculation

- B.

- Physical Pixel Size and Localization Uncertainty

4.1.3. Statistical Uncertainty from Repeatability (Type A)

- A.

- Quantification of Repeatability

- B.

- Inclusion in Combined Uncertainty

4.1.4. Summary of Uncertainty Analysis

5. Conclusions

- Infrared thermography (IRT), or more precisely, active thermography, which involves applying an independent heat source, a thermal effect, to the examined area, allows the detection and location of defects in externally bonded FRP concrete structures. This applies to both bond defects (voids) in the adhesive layer and concrete defects in the form of voids in the concrete cover. In these areas, the temperature is not transferred to the concrete, so it is higher than in the remaining area. However, it should be remembered that, after the heat source, the surface temperature of the CFRP strip uniforms very quickly. This method allows for a rough assessment of the defect size. Distinguishing between voids in the adhesive layer and voids in the concrete cover is possible, but the results are not always clear. In the case of overlapping defects, the differences in measured temperatures were very small, 0.2–0.3 °C, with a maximum measured temperature of 36.5 °C, a difference of approximately 0.68%. Therefore, detecting such a small difference in the real conditions at the site may be difficult or almost impossible. The method allowed the identification of shallow and medium-depth defects (ΔT ≈ 2–3 °C) with high confidence (ΔT ≫Utotal). However, for deep or small defects, the thermal contrast approached the measurement uncertainty (ΔT ≈ 0.3–0.5 °C), making detection less reliable. These limitations are intrinsic to the thermal diffusion process rather than the camera performance. However, the method offers rapid, contactless inspection and complements ultrasonic and acoustic techniques in comparative diagnostics.

- GPR can be used to detect defects in concrete with externally bonded CFRP strips, but its scope is limited. The 2 GHz antenna allowed for the easy detection of voids in concrete, but imaging delamination at the strip–concrete interface was not possible due to insufficient system resolution and signal overlap with strip reflection. The amplitude decrease observed at the debonding site was very small (approximately 5%). In practical applications, this difference may be insufficient to clearly identify debonding locations. However, the most significant limitation of GPR inspection is the electrical conductivity of CFRP strips, which practically prevents GPR measurements being conducted on their surface. Scanning from the opposite (unreinforced) side, although efficient as indicated in this study, is often impossible in practice because of limited access.

- The results obtained from elastic wave velocity measurements using the Hsu-Nielsen reference source allowed the following conclusions: the method was confirmed to be effective in detecting defects in concrete with the bonded CFRP strip. A decrease in elastic wave velocity was observed in damaged areas compared to areas without defects, averaging 10 to 20%; the magnitude of the difference in elastic wave velocity depends on the size and location of the defect. In the case of local debonding of the CFRP strip (sample D1), a 2% decrease in velocity was observed; a more dense distribution of measurement points is necessary to minimise the risk of underestimation; the velocity values of the Vwof waves passing only through concrete were consistent (3650–3750 m/s), confirming the homogeneity of the material, with the exception of one sample (M2), where the improved concrete compaction may have influenced the observed wave velocity; the type of defect did not significantly affect the recorded wave velocity values. Both adhesive layer defects and concrete cover defects generated comparable velocity drops, suggesting that the method is useful for detecting the presence of damage, not its type; the differences in elastic wave velocity in areas without and with defects are clear and measurable, demonstrating the method’s potential in structural diagnostics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Klym, A.; Blikharskyy, Y.; Gunka, V.; Poliak, O.; Selejdak, J.; Blikharskyy, Z. An Overview of the Main Types of Damage and the Retrofitting of Reinforced Concrete Bridges. Sustainability 2025, 17, 2506. [Google Scholar] [CrossRef]

- Alsuhaibani, E. Nondestructive Testing of Externally Bonded FRP Concrete Structures: A Comprehensive Review. Polymers 2025, 17, 1284. [Google Scholar] [CrossRef]

- Tworzewski, P.; Alexy, J.K.; Barnes, R.W. Intermediate Crack Debonding of Externally Bonded FRP Reinforcement—Comparison of Methods. Materials 2022, 15, 7390. [Google Scholar] [CrossRef]

- Ke, Y.; Zhang, S.S.; Smith, S.T.; Yu, T. Novel Embedded FRP Anchor for RC Beams Strengthened in Flexure with NSM FRP Bars: Concept and Behavior. J. Compos. Constr. 2023, 27, 04022093. [Google Scholar] [CrossRef]

- Rasheed, H.A.; Zaki, M.A.; Raheem, M.M. Effectiveness of Fiber Anchors in CFRP Flexural Strengthening of RC Girders. J. Compos. Constr. 2024, 28, e04368. [Google Scholar] [CrossRef]

- Michałowska-Maziejuk, D.; Goszczyńska, B. Effectiveness of Strengthening RC Beams Using Composite Materials—An Accelerated Strengthening Method. Materials 2023, 16, 4847. [Google Scholar] [CrossRef]

- Tworzewski, P.; Bacharz, K. Flexural Strengthening of Reinforced Concrete Beams Using Near-Surface Mounted (NSM) Carbon Fiber-Reinforced Polymer (CFRP) Strips with Additional Anchorage. Materials 2025, 18, 2579. [Google Scholar] [CrossRef]

- International Federation for Structural Concrete (FIB). Externally Bonded FRP Reinforcement for RC Structures; Bulletin 14; International Federation for Structural Concrete (FIB): Lausanne, Switzerland, 2001. [Google Scholar]

- Büyüköztürk, O.; Haupt, R.; Tuakta, C.; Chen, J. Remote Detection of Debonding in FRP-strengthened Concrete Structures Using Acoustic-Laser Technique. In Nondestructive Testing of Materials and Structures; Güneş, O., Akkaya, Y., Eds.; RILEM Bookseries: Berlin/Heidelberg, Germany, 2013; Volume 6. [Google Scholar] [CrossRef]

- Zatar, W.; Nghiem, H. Detectability of embedded defects in FRP strengthened concrete deck slabs. In Risk-Based Strategies forBridge Maintenance; CRC Press: Boca Raton, FL, USA, 2023; pp. 221–234. [Google Scholar]

- Kim, H.; Lamichhane, N.; Kim, C.; Shrestha, R. Innovations in Building Diagnostics and Condition Monitoring: A Comprehensive Review of Infrared Thermography Applications. Buildings 2023, 13, 2829. [Google Scholar] [CrossRef]

- Wciślik, S. Thermal infrared mapping of the Leidenfrost drop evaporation. J. Phys. Conf. Ser. 2016, 745, 032064. [Google Scholar] [CrossRef]

- Orzechowski, T.; Wciślik, S. Evaporation of the Leidenfrost Droplet Located on a Thin Metal Foil. Procedia Eng. 2016, 157, 131–138. [Google Scholar] [CrossRef]

- Drobiec, Ł.; Jasinski, R.; Piekarczyk, A. Diagnostyka Konstrukcji Żelbetowych: Metodologia, Badania Polowe, Badania Laboratoryjne Betonu i Stali; Publisher PWN: Warsaw, Poland, 2010; pp. 61–115. [Google Scholar]

- Sham, F.C.; Chen, N.; Long, L. Surface crack detection by flash thermography on concrete surface. Insight 2008, 50, 240–243. [Google Scholar] [CrossRef]

- Świt, G.; Krampikowska, A.; Tworzewski, P. Non-Destructive Testing Methods for In Situ Crack Measurements and Morphology Analysis with a Focus on a Novel Approach to the Use of the Acoustic Emission Method. Materials 2023, 16, 7440. [Google Scholar] [CrossRef]

- Anwar, M.; Mustapha, F.; Abdullah, M.N.; Mustapha, M.; Sallih, N.; Ahmad, A.; Mat Daud, S.Z. Defect Detection of GFRP Composites through Long Pulse Thermography Using an Uncooled Microbolometer Infrared Camera. Sensors 2024, 24, 5225. [Google Scholar] [CrossRef]

- Jensen, F.; Terlau, M.; Sorg, M.; Fischer, A. Active Thermography for the Detection of Sub-Surface Defects on a Curved and Coated GFRP-Structure. Appl. Sci. 2021, 11, 9545. [Google Scholar] [CrossRef]

- Tang, L. Maintenance and Inspection of Fiber-Reinforced Polymer (FRP) Bridges: A Review of Methods. Materials 2021, 14, 7826. [Google Scholar] [CrossRef] [PubMed]

- Tashan, J.; Al-Mahaidi, R. Detection of cracks in concrete strengthened with CFRP systems using infra-red thermography. Compos. Part B Eng. 2014, 64, 116–125. [Google Scholar] [CrossRef]

- Pan, P.; Zhang, R.; Zhang, Y.; Li, H. Detecting Internal Defects in FRP-Reinforced Concrete Structures through the Integration of Infrared Thermography and Deep Learning. Materials 2024, 17, 3350. [Google Scholar] [CrossRef]

- Yazdani, N.; Beneberu, E.; Riad, M. Nondestructive Evaluation of FRP-Concrete Interface Bond due to Surface Defects. Adv. Civ. Eng. 2019, 2019, 2563079. [Google Scholar] [CrossRef]

- Kuribara, M.; and Nagano, H. Anisotropic Thermal Diffusivity Measurements in High-Thermal-Conductive Carbon-Fiber-Reinforced Plastic Composites. J. Electron. Cool. Therm. Control. 2015, 5, 15–25. [Google Scholar] [CrossRef]

- Terpiłowski, J.; Piotrowska-Woroniak, J.; Romanowska, J. A study of thermal diffusivity of carbon-epoxy and glass-epoxy composites using the modified pulse method. Arch. Thermodyn. 2014, 35, 117–128. [Google Scholar] [CrossRef]

- Talebi, H.R.; Kayan, B.A.; Asadi, I.; Hassan, Z.F.B.A. Investigation of thermal properties of normal weight concrete for different strength classes. J. Environ. Treat. Tech. 2020, 8, 908–914. [Google Scholar]

- Arcone, S.A.; Lawson, D.E.; Delaney, A.J.; Strasser, J.C.; Strasser, J.D. Ground penetrating radar reflection profiling of groundwater and bedrock in an area of discontinuous permafrost. Geophysics 1998, 63, 1573–1584. [Google Scholar] [CrossRef]

- Malla, P.; KhedmatgozarDolati, S.S.; Ortiz, J.D.; Mehrabi, A.B.; Nanni, A.; Dinh, K. Feasibility of Conventional Non-Destructive Testing Methods in Detecting Embedded FRP Reinforcements. Appl. Sci. 2023, 13, 4399. [Google Scholar] [CrossRef]

- Hugenschmidt, J.; Mastrangelo, R. GPR inspection of concrete bridges. Cem. Concr. Compos. 2006, 28, 384–392. [Google Scholar] [CrossRef]

- Wciślik, W. GPR Survey of a Composite Bridge with Prestressed Concrete Beams [in Polish]. In Proceedings of the 56th Scientific Conference of the Committee of Civil and Water Engineering of the Polish Academy of Sciences and the Science Committee of the Polish Association of Engineers and Technicians, Krynica, Poland, 19–24 September 2010; pp. 459–465. [Google Scholar]

- Klysz, G.; Balayssac, J.P. Determination of volumetric water content of concrete using ground-penetrating radar. Cem. Concr. Res. 2007, 37, 1164–1171. [Google Scholar] [CrossRef]

- Kaplanvural, I. Volumetric water content estimation of concrete by particle swarm optimization of GPR data. Constr. Build. Mater. 2023, 375, 130995. [Google Scholar] [CrossRef]

- Wciślik, W.; Raczkiewicz, W. Studies on corrosion initiation in reinforced concrete structures using ground-penetrating radar. Materials 2025, 18, 2308. [Google Scholar] [CrossRef]

- Eisenmann, D.; Margetan, F.J.; Ellis, S. On the use of ground penetrating radar to detect rebar corrosion in concrete structures. AIP Conf. Proc. 2018, 1949, 030009. [Google Scholar] [CrossRef]

- Zaki, A.; Johari, M.A.M.; Hussin, W.M.A.W.; Jusman, Y. Experimental assessment of rebar corrosion in concrete slab using ground penetrating radar (GPR). Int. J. Corros. 2018, 2018, 389829. [Google Scholar] [CrossRef]

- Hing, C.L. Nondestructive Evaluation of Fiber Reinforced Polymer Bridge Decks Using Ground Penetrating Radar And Infrared Thermography. Ph.D. Thesis, West Virginia University, Morgantown, WV, USA, 2006. [Google Scholar]

- Dolati, S.S.K.; Malla, P.; Ortiz, J.D.; Mehrabi, A.; Nanni, A. Identifying NDT methods for damage detection in concrete elements reinforced or strengthened with FRP. Eng. Struct. 2023, 287, 116155. [Google Scholar] [CrossRef]

- Dutta, S.S. Nondestructive Evaluation of FRP Wrapped Concrete Cylinders Using Infrared Thermography and Groud Penetrating Radar. Master’s Thesis, West Virginia University, Morgantown, WV, USA, 2006. [Google Scholar]

- Jackson, D.R.; Islam, M.; Alampalli, S. Feasibility Of Evaluating The Performance Of Fiber Reinforced Plastic (FRP) Wrapped Reinforced Concrete Columns Using Ground Penetrating Radar (GPR) And Infrared (IR) Thermography Techniques. In Proceedings of the Structural Materials Technology VI: An NDT Conference, Atlantic City, NJ, USA, 28 February–3 March 2000. [Google Scholar]

- Lad, A.A. Qualitative Evaluation Of CFRP-Concrete Bond Using Non-Destructive And Destructive Testing Methods. Master’s Thesis, University of Texas at Arlington, Arlington, TX, USA, 2018. [Google Scholar]

- Riad, M. Quantitative Non-Destructive Evaluation (NDE) Of FRP Laminate-Concrete Bond Strength. Ph.D. Thesis, University of Texas at Arlington, Arlington, TX, USA, 2018. [Google Scholar]

- Riad, M.; Yazdani, N.; Almomani, M.; Gonzales, E. Utilization of ground penetrating radar (GPR) in the non-destructive assessment of FRP laminate-concrete bond strength. In Advances and Challenges in Structural Engineering, 1st ed.; Rodrigues, H., Elnashai, A., Eds.; Springer Nature Switzerland AG: Cham, Switzerland, 2019; pp. 244–267. [Google Scholar] [CrossRef]

- Ortiz, J.D.; Dolati, S.S.K.; Malla, P.; Mehrabi, A.; Nanni, A. Nondestructive testing (NDT) for damage detection in concrete elements with externally bonded fiber-reinforced polymer. Buildings 2024, 14, 246. [Google Scholar] [CrossRef]

- Li, J.; Liu, C. Noncontact detection of air voids under glass epoxy jackets using a microwave system. Subsurf. Sens. Technol. Appl. 2001, 2, 411–423. [Google Scholar] [CrossRef]

- Yu, T.Y.; Büyüköztürk, O. A far-field airborne radar NDT technique for detecting debonding in GFRP–retrofitted concrete structures. NDTE Int. 2008, 41, 10–24. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Jodhani, J.; Handa, A.; Gautam, A.; Ashwni; Rana, R. Ultrasonic non-destructive evaluation of composites: A review. Mater. Today Proc. 2023, 78, 627–632. [Google Scholar] [CrossRef]

- Wang, B.; He, P.; Kang, Y.; Jia, J.; Liu, X.; Li, N. Ultrasonic Testing of Carbon Fiber-Reinforced Polymer Composites. J. Sens. 2022, 2022, 5462237. [Google Scholar] [CrossRef]

- Adamczak-Bugno, A.; Lipiec, S.; Adamczak, J.; Vičan, J.; Bahleda, F. Identification of Destruction Processes and Assessment of Deformations in Compressed Concrete Modified with Polypropylene Fibers Exposed to Fire Temperatures Using Acoustic Emission Signal Analysis, Numerical Analysis, and Digital Image Correlation. Materials 2023, 16, 6786. [Google Scholar] [CrossRef]

- Świt, G. Analiza Procesów Destrukcyjnych w Obiektach Mostowych z Belek Strunobetonowych z Wykorzystaniem Zjawiska Emisji Akustycznej; Wydawnictwo Politechniki Świętokrzyskiej: Kielce, Poland, 2011. [Google Scholar]

- Bacharz, M.; Bacharz, K.; Trąmpczyński, W. The Correlation between Shrinkage and Acoustic Emission Signals in Early Age Concrete. Materials 2022, 15, 5389. [Google Scholar] [CrossRef]

- Bacharz, M.; Bacharz, K.; Trąmpczyński, W. Impact of Early-Age Curing and Environmental Conditions on Shrinkage and Microcracking in Concrete. Materials 2025, 18, 3185. [Google Scholar] [CrossRef]

- Raczkiewicz, W.; Bacharz, M.; Bacharz, K. Experimental verification of the concrete shrinkage strains course according to En 1992-2 standard. Adv. Mater. Sci. 2015, 15, 22–29. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Świt, G.; Trąmpczyński, W.; Krampikowska, A.; Tworzewska, J.; Tworzewski, P. Experimental validation of concrete crack identification and location with acoustic emission method. Arch. Civ. Mech. Eng. 2012, 12, 23–28. [Google Scholar] [CrossRef]

- PN-EN 1330-9:2017-09; Badania Nieniszczące—Terminologia—Część 9: Terminy Stosowane w Badaniach Emisją Akustyczną. PKN: Warszawa, Poland, 2017.

- Angelopoulos, N.; Kappatos, V. An Experimental Assessment Using Acoustic Emission Sensors to Effectively Detect Surface Deterioration on Steel Plates. Sensors 2024, 24, 6462. [Google Scholar] [CrossRef]

- Riccioli, F.; Alkhateeb, S.; Mol, A.; Pahlavan, L. Feasibility assessment of non-contact acoustic emission monitoring of corrosion-fatigue damage in submerged steel structures. Ocean. Eng. 2024, 312, 119296. [Google Scholar] [CrossRef]

- Yu, Y.-H.; Choi, J.-H.; Kweon, J.-H.; Kim, D.-H. A study on the failure detection of composite materials using an acoustic emission. Compos. Struct. 2006, 75, 163–169. [Google Scholar] [CrossRef]

- Sayers, C.M.; van Munster, J.G. Microcrack-induced seismic anisotropy of sedimentary rocks. J. Geophys. Res. Solid Earth 1991, 96, 16529–16533. [Google Scholar] [CrossRef]

- Sayers, C.M.; Kachanov, M. Microcrack-induced elastic wave anisotropy of brittle rocks. J. Geophys. Res. Solid Earth 1995, 100, 4149–4156. [Google Scholar] [CrossRef]

- ASTM E976-10; Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response. ASTM International: West Conshohocken, PA, USA, 2010.

- Sause, M.G.R. Investigation of Pencil-Lead Breaks as Acoustic Emission Sources. J. Acoust. Emiss. 2011, 29, 184–196. [Google Scholar]

- Lovejoy, S. Development of Acoustic Emissions Testing Procedures Applicable to Conventionally Reinforced Concrete Deck Girder Bridges Subjected to Diagonal Tension Cracking. Ph.D. Thesis, Oregon State University, Corvallis, OR, USA, 2006. [Google Scholar]

- Li, D.; Yang, K.; He, Z.; Zhou, H.; Li, J. Acoustic Emission Wave Velocity Attenuation of Concrete and Its Application in Crack Localization. Sustainability 2020, 12, 7405. [Google Scholar] [CrossRef]

- Hinrichs, R.; Jiang, N.; Beltrán, R.; Krause, T.; Käding, M.; Lange, A.; Schmidt, B.; Ostermann, J.; Marx, S. Analysis of the Repeatability of the Pencil Lead Break in Comparison to the Ball Impact and Electromagnetic Body-Noise Actuator. In Proceedings of the 20th World Conference on Non-Destructive Testing (WCNDT 2024), Incheon, Republic of Korea, 27–31 May 2024. [Google Scholar] [CrossRef]

- Sika® CarboDur® E, Karta InformacyjnProduktu, (Product Data Sheet); Sika Poland Sp. z o.o.: Warszawa, Poland, 2025; Version 07.01; Available online: https://pol.sika.com/dam/dms/plcon/s/sika_carbodur_s.pdf (accessed on 1 October 2025).

- Sikadur®-330, Karta Informacyjna Produktu, (Product Data Sheet); Sika Poland Sp. z o.o.: Warszawa, Poland, 2025; Version 06.01; Available online: https://pol.sika.com/dam/dms/plcon/e/sikadur_-330.pdf (accessed on 1 October 2025).

- Mostofinejad, D.; Mahmoudabadi, E. Grooving as alternative method of surface preparation to postpone debonding of FRP Laminates in concrete beams. J. Compos. Constr. 2010, 14, 804–811. [Google Scholar] [CrossRef]

- PN-EN 1542:2000; Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Measurement of Bond Strength by Pull-Off. PKN: Warszawa, Polnad, 2000.

- ACI Committee 440. Guide Test Methods for FiberReinforced Polymers (FRPs) for Reinforcing or Strengthening Concrete Structures (ACI 440.3R-04); American Concrete Institute: Farmington Hills, MI, USA, 2004; p. 40. [Google Scholar]

- Annan, A.P. Ground Penetrating Radar Workshop Notes. Sens. Softw. 2001. [Google Scholar]

- Patriarca, C.; Lambot, S.; Mahmoudzadeh, M.R.; Minet, J.; Slob, E. Reconstruction of sub-wavelength fractures and physical properties of masonry media using full-waveform inversion of proximal penetrating radar. J. Appl. Geophys. 2011, 74, 26–37. [Google Scholar] [CrossRef]

- ASTM D 6087-22; Standard Test Method for Evaluating Asphalt-Covered Concrete Bridge Decks Using Ground Penetrating Radar. ASTM: West Conshohocken, PA, USA, 2022.

- Elimat, Z.M.; Hamideen, M.S.; Schulte, K.I.; Wittich, H.; de la Vega, A.; Wichmann, M.; Buschhorn, S. Dielectric properties of epoxy/short carbon fiber composites. J. Mater. Sci. 2010, 45, 5196–5203. [Google Scholar] [CrossRef]

- Pocket Ae-2: Protable 2-Channel Acoustic Emission System, Product Bulletin, MistrasGrup. Available online: https://www.physicalacoustics.com/content/literature/multichannel_systems/Pocket_AE-2_Product_Bulletin.pdf (accessed on 1 January 2010).

- Krautkrämer, J.; Krautkrämer, H. Ultrasonic Testing of Materials; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- PK6I: Medium Frequency Integral Preamplifier Resonant Sensor, Product Bulletin, MIstrasGrup. Available online: https://www.physicalacoustics.com/content/literature/sensors/Model_PK6I.pdf (accessed on 1 January 2010).

- Teodorczyk, M. Influence of Aggregate Gradation on the Longitudinal Wave Velocity Changes in Unloaded Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032084. [Google Scholar] [CrossRef]

- Joint Committee for Guides in Metrology (JCGM). JCGM 100:2008: Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement (GUM 1995 with Minor Corrections); BIPM: Sèvres, France, 2008. [Google Scholar]

- Rabi, M.; Abarkan, I.; Sarfarazi, S.; Ferreira, F.P.V.; Alkherret, A.J. Automated design and optimization of concrete beams reinforced with stainless steel. Struct. Concr. 2025. [Google Scholar] [CrossRef]

| Type of FRP EBR | Permissible Unevenness [mm] | ||

|---|---|---|---|

| For 2000 mm Base | For 300 mm Base | ||

| prefabricated | thickness > 1 mm | 10 | 4 |

| thickness < 1 mm | 6 | 2 | |

| not prefabricated (made in situ) | 4 | 2 | |

| Material | Values |

|---|---|

| Cement 42.5 | 360 kg |

| Sand | 726 kg |

| Basalt aggregate 2/8 | 563 kg |

| Basalt aggregate 8/16 | 738 kg |

| Water | 97 L |

| Plasticizer—Adva Flow 440 (0.5% cement mass) | 1.80 kg |

| Aerator—Darex (0.1% cement mass) | 0.36 kg |

| Sika® CarboDur® S 512 (Manufacturer’s Catalog Data) | |

|---|---|

| Properties | Values |

| Width | 50 mm |

| Thickness | 1.2 mm |

| Cross-sectional area | 60 mm2 |

| Average tensile strength of the FRP | 3100 MPa |

| Fiber volume content | >68% |

| Sikadur®-330 (Manufacturer’s Catalog Data) | |

|---|---|

| Properties | Values |

| Tensile modulus | 30 MPa |

| Tensile strength | 4500 MPa |

| Width [mm] | Length [mm] | Thickness [mm] | Volume [mm3] | |||||||||

| Concrete | 100 | 500 | 100 | 5,000,000 | ||||||||

| CFRP strip | 50 | 490 | 1.2 | 29,400 | ||||||||

| Bond defect in the adhesive layer | Concrete defect—drilled voids | Total volume [mm3] | ||||||||||

| Width [mm] | Length [mm] | Average thickness [mm] | Volume 1 [mm3] | Hole diameter [mm] | Depth [mm] | Volume 2 [mm3] | ||||||

| Defects | D1 | 15 | 15 | 0.3 | 67.5 | - | - | - | 67.5 | |||

| D2 | 15 | 50 | 0.35 | 262.5 | - | - | - | 262.5 | ||||

| C1 | - | - | - | - | 10 | 18.9 | 1483.7 | 1483.7 | ||||

| C2 | - | - | - | - | 10 | 19 | 1491.5 | 1491.5 | ||||

| M1 | 15 | 33 | 0.65 | 321.8 | 10 | 21.3 | 1672.05 | 1993.8 | ||||

| M2 | 15 | 50 | 0.525 | 393.8 | 10 | 22.2 | 1742.7 | 2136.5 | ||||

| Parameter | Specification |

|---|---|

| Model | Testo 890 |

| Detector type | Uncooled microbolometer |

| Infrared resolution | 640 × 480 pixels (SuperResolution: 1280 × 960 pxs) |

| Spectral range | 7.5–14 µm |

| Thermal sensitivity (NETD) | <40 mK at 30 °C |

| Temperature measurement range | –30 °C to +650 °C (optional up to +1200 °C) |

| Accuracy | ±2 °C or ±2% of reading |

| Field of view (standard lens) | 30° × 23° |

| Minimum focus distance | 0.1 m |

| Frame rate | 33 Hz |

| Focus | Manual or motorised |

| Emissivity adjustment | 0.01 to 1.00 |

| Visual image camera | 3.1 MP digital camera (integrated) |

| Test Samples | AE Wave Velocity Vw | Difference in AE Wave Velocity Between Position 2 and 1 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | ||||||||||||

| Vw [m/s] | s [m/s] | CVw [%] | SE [m/s] | Vw [m/s] | s [m/s] | CVw [%] | SE [m/s] | Vw [m/s] | s [m/s] | CVw [%] | SE [m/s] | ΔVw [m/s] | ΔVw [%] | |

| C1 | 2940 | 93.0 | 3.2 | 29.5 | 3410 | 41.5 | 1.2 | 13.1 | 3779 | 60.2 | 1.6 | 19.0 | 470 | 14% |

| C2 | 3403 | 90.6 | 2.7 | 30.5 | 3774 | 118.4 | 3.1 | 37.6 | 3744 | 208.9 | 5.6 | 66.1 | 371 | 10% |

| D1 | 3473 | 130.9 | 3.8 | 41.4 | 3540 | 178.9 | 5.1 | 56.6 | 3668 | 72.6 | 2.0 | 23.0 | 67 | 2% |

| D2 | 2941 | 59.8 | 2.0 | 18.9 | 3707 | 68.6 | 1.9 | 21.7 | 3668 | 56.3 | 1.5 | 17.8 | 766 | 21% |

| M1 | 2940 | 108.8 | 3.7 | 34.4 | 3601 | 142.3 | 4.0 | 45.0 | 3732 | 77.9 | 2.1 | 24.6 | 661 | 18% |

| M2 | 3004 | 95.4 | 3.2 | 30.2 | 3688 | 122.6 | 3.3 | 38.8 | 4150 | 354.1 | 8.5 | 112.0 | 684 | 19% |

| Criteria | IRT | GPR | WVMM |

|---|---|---|---|

| Damage detectability | Possibility to detect defects both in the adhesive layer (delamination mapping) and voids in the concrete cover, possibility to detect overlapping defects | possible subsurface void detection, not suitable for delamination mapping | Possibility to detect damage in the form of both delamination and concrete loss |

| Key limitations | Low resolution of thermal imaging cameras, The necessity to heat the sample surface, and susceptibility to disturbances in temperature distribution caused by external factors | inability to detect voids smaller than the antenna resolution (typically about 1 cm), difficulty in visualising the defect, limited usefulness in electrically conductive composites | inability to distinguish the type of damage, measurement possible only in the area where the sensors are applied, it is necessary to place the sensors opposite each other |

| Equipment | Testo 890 thermal imaging camera (infrared resolution of 640 × 480 pixels) | high frequency antenna (2 GHz or more) | Pocket AE unit and two PK6I resonant sensors with a built-in 26 dB preamplifier with operating frequency range 35–65 kHz |

| Environmental restrictions | high sensitivity to external conditions (humidity, rain/snowfall, outside temperature, wind), surface contamination, moisture, and the method of sample heating | sensitivity to moisture and chlorides in concrete | maximum operating temperature range of the equipment, shock limit of the sensor, detection very small elastic waves in materials, very noisy environment |

| Cost | medium | medium | medium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tworzewski, P.; Bacharz, K.; Wciślik, W.; Teodorczyk, M.; Wciślik, S.; Tworzewska, J. Detection and Location of Defects in Externally Bonded FRP Concrete Structures—Comparison of Selected Methods. Materials 2025, 18, 5090. https://doi.org/10.3390/ma18225090

Tworzewski P, Bacharz K, Wciślik W, Teodorczyk M, Wciślik S, Tworzewska J. Detection and Location of Defects in Externally Bonded FRP Concrete Structures—Comparison of Selected Methods. Materials. 2025; 18(22):5090. https://doi.org/10.3390/ma18225090

Chicago/Turabian StyleTworzewski, Paweł, Kamil Bacharz, Wiktor Wciślik, Michał Teodorczyk, Sylwia Wciślik, and Justyna Tworzewska. 2025. "Detection and Location of Defects in Externally Bonded FRP Concrete Structures—Comparison of Selected Methods" Materials 18, no. 22: 5090. https://doi.org/10.3390/ma18225090

APA StyleTworzewski, P., Bacharz, K., Wciślik, W., Teodorczyk, M., Wciślik, S., & Tworzewska, J. (2025). Detection and Location of Defects in Externally Bonded FRP Concrete Structures—Comparison of Selected Methods. Materials, 18(22), 5090. https://doi.org/10.3390/ma18225090