Analysis of the Thermal Properties of Soft Silica Limestone Walls of Traditional Buildings in Central Poland

Abstract

1. Introduction

2. Materials and Methods

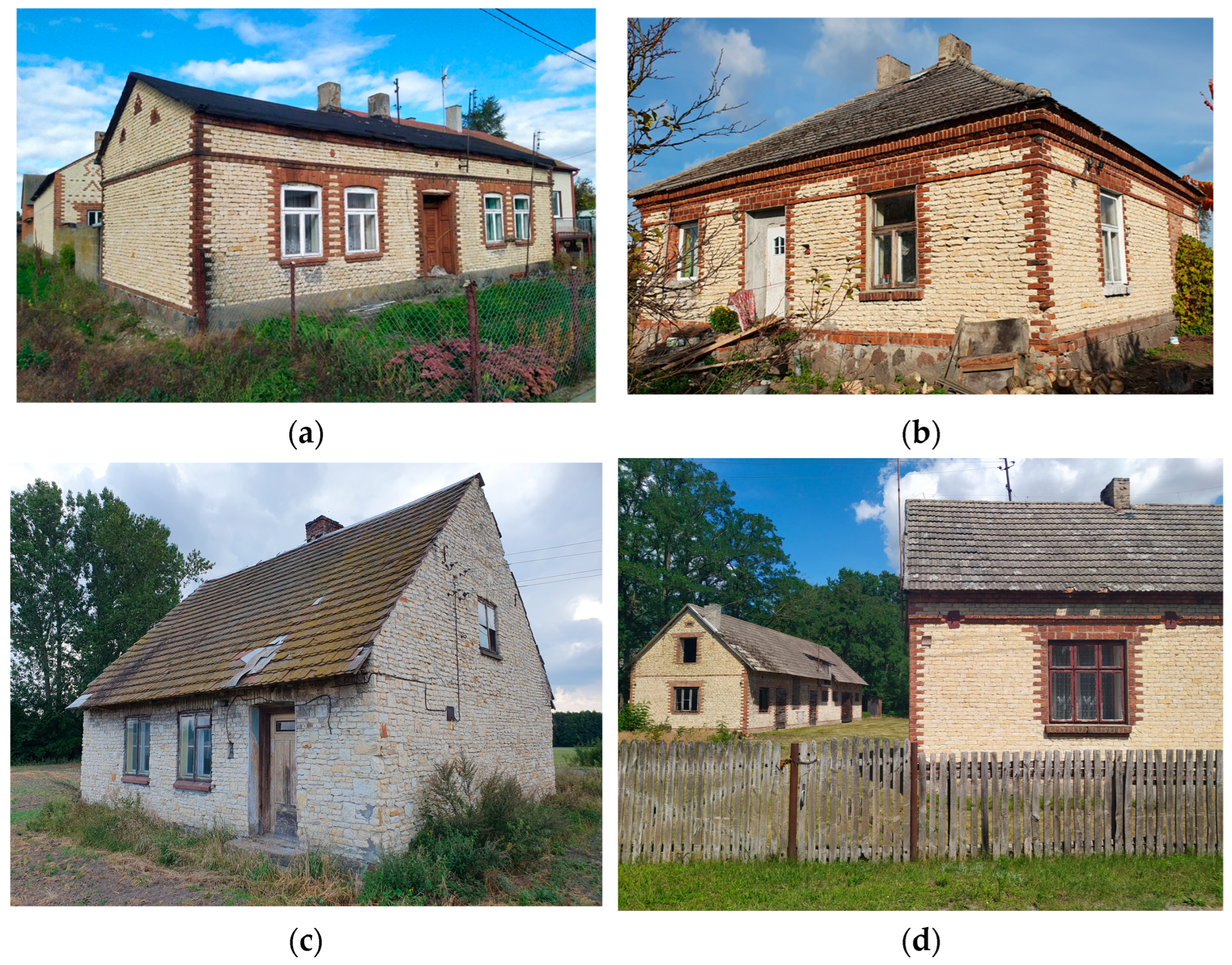

2.1. Characterization of Vernacular Buildings

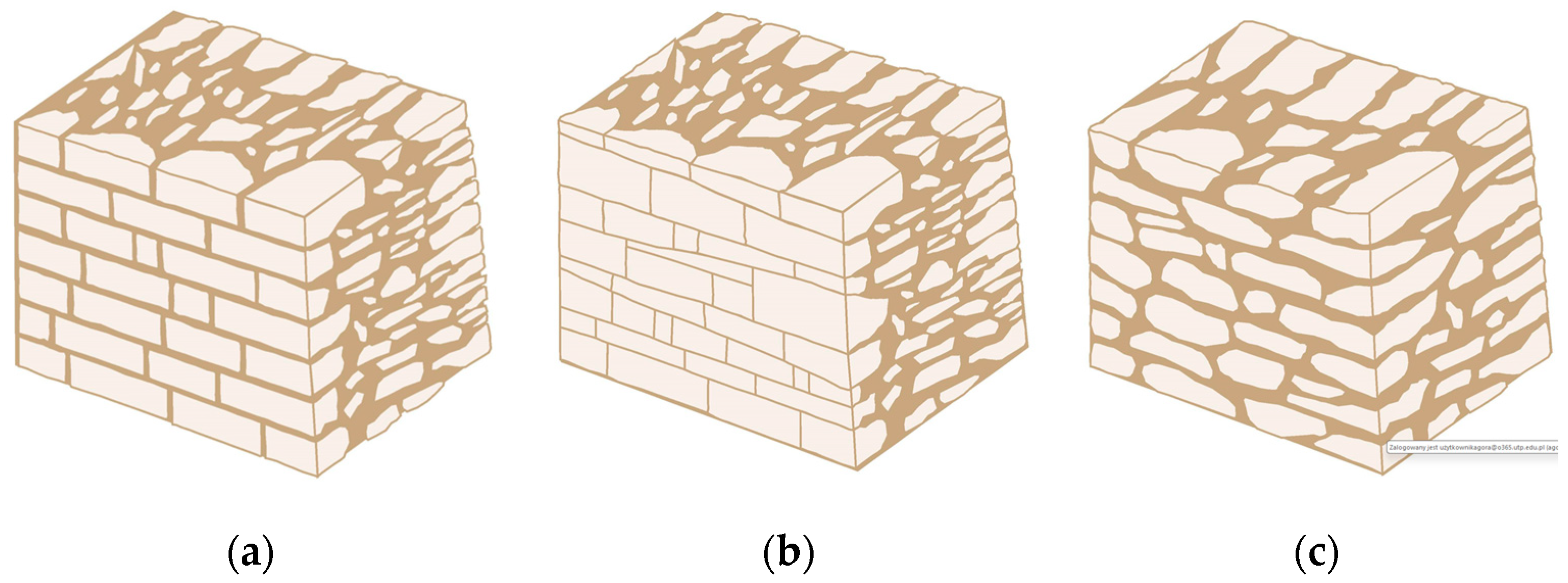

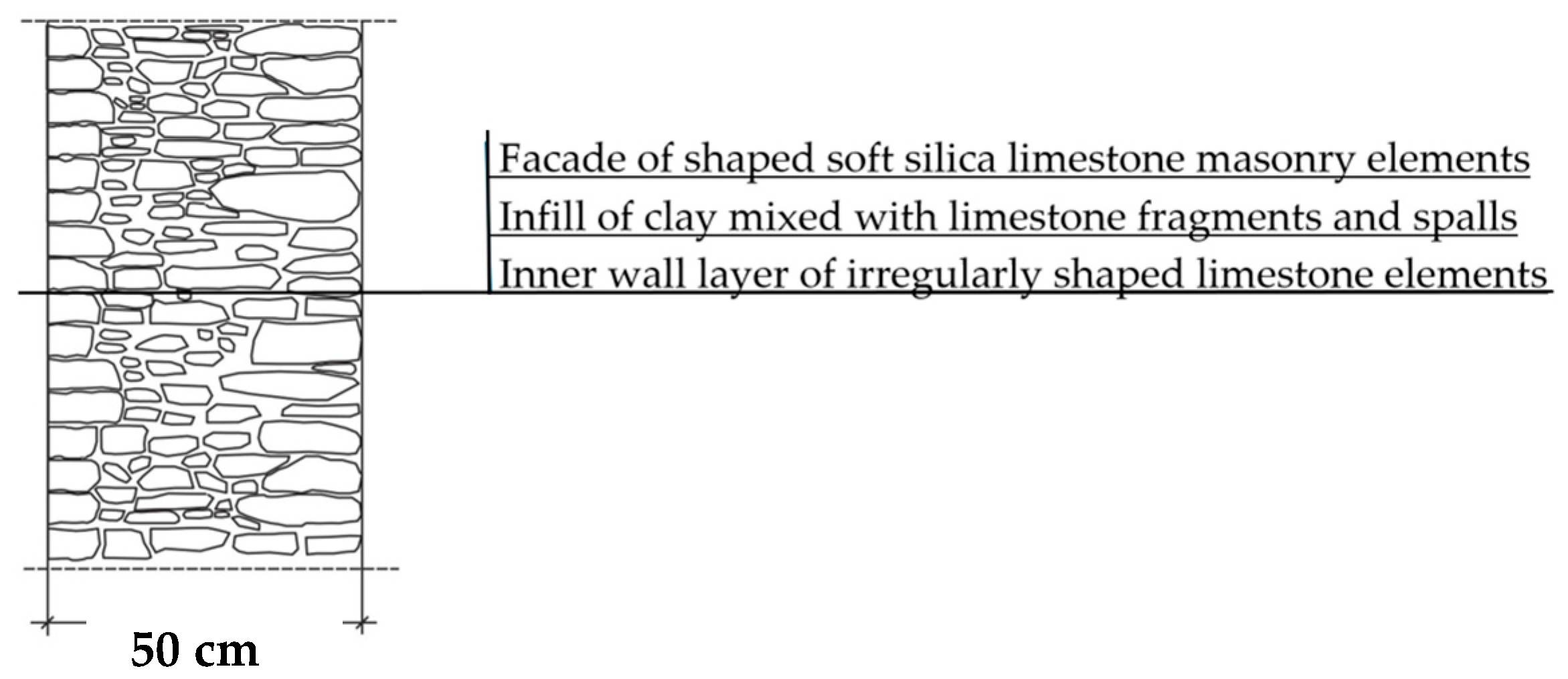

2.2. Regional Method of Constructing Walls from Soft Silica Limestone

2.3. Physical and Thermal Properties of Traditional Materials

2.3.1. Stone Properties

2.3.2. Clay Mortar Properties

2.4. Assumptions of the Model and Calculation Variants

- Variant A: the basic model—a layered stone wall according to Figure 4, without plaster coatings. Possible moisture penetration of the external wall layer from atmospheric precipitation was assumed. For the internal layers, thermal parameters for stone and mortar in moderately humid conditions were adopted. It was assumed that the high open porosity of the stone and clay mortar allows for relatively free moisture movement and periodic drying of the walls. In the calculations, the surface resistance on the external and internal sides was taken according to standard [48], with values of Rse = 0.04 (m2∙K)/W and Rsi = 1.13 (m2∙K)/W, respectively;

- Variant B: the version takes into account the commonly occurring internal clay plaster, typically 3.0 cm thick. Given the low vapor diffusion resistance reported for clay plasters ( = 6–10) [40,46], it was assumed that moisture flow was not significantly disrupted. The parameter values were adopted as those for the clay mortar used in the wall construction, as no significant differences in granulometric composition and density were identified [45];

- Variant C: in this variant, calculations were made considering the external cement plaster (1.5 cm thick). This is a situation commonly encountered in practice, typically applied when the outer wall layer begins to show signs of damage due to natural material wear over time or water exposure, leading to excessive water accumulation on parts of the façade. The thermal conductivity coefficient was adopted according to [37] λ = 1.0 W/(m·K). The cement plaster layer, on one hand, limits the periodic soaking of the external stone layer. Nevertheless, considering its higher diffusion resistance [45], it blocks moisture flow (especially in the case of insufficient ventilation) and may cause moisture accumulation in the partition. This was taken into account by assuming an increased value of λ for the stone and clay mortar elements, as in humid conditions;

- Variant D: the case with external insulation layer of polystyrene—the most commonly used variant in practice for thermal modernization. The calculations were performed for both the wall in a damp condition (variant D1) and in a moderately damp condition (variant D2), taking into account the phenomenon of gradual drying of the damp insulated wall over time [49];

- Variant E: the version with internal insulation, which allow the preservation of the original texture of the wall using high vapor-permeable panels, recommended for use in the renovation of historic buildings.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Costa-Carrapiço, I.; González, J.N.; Raslan, R.; Sánchez-Guevara, C. Understanding the challenges of determining thermal comfort in vernacular dwellings: A meta-analysis. J. Cult. Herit. 2022, 58, 57. [Google Scholar] [CrossRef]

- European Council ‘Fit for 55′: EU Strengthens Emission Reduction Targets for Member States. 2023. Available online: https://www.consilium.europa.eu/en/press/press-releases/2022/11/08/fit-for-55-eu-strengthens-emission-reduction-targets-for-member-states/ (accessed on 23 March 2025).

- Margani, G. Costruzione e Recupero Dell’Opera Muraria. “Regola Dell’Arte” e Interventi di Consolidamento. 2009. Available online: https://www.researchgate.net/publication/259889584/ (accessed on 23 March 2025).

- Kapetanović, A. Restoration of a Traditional Montenegrin Stone House. The Site in the Village of Gačevići. 2006. Available online: https://www.hdm.lth.se/fileadmin/hdm/alumni/papers/CMHB_2007/Montenegro_A_Kapetanovic__Montenegrin_Stone_House.pdf (accessed on 23 March 2025).

- Mustafaraj, E.; Luga, E.; Corradi, M.; Borri, A.; Muceku, Y.; Zharkalli, A. Physical-Mechanical Properties of Stone Masonry of Gjirokastër, Albania. Materials 2021, 14, 1127. [Google Scholar] [CrossRef] [PubMed]

- Careddu, N.; Grillo, S.M. “Trachytes” from Sardinia: Geoheritage and Current Use. Sustainability 2019, 11, 3706. [Google Scholar] [CrossRef]

- Tomanović, D.; Rajković, I.; Grbić, M.; Aleksić, J.; Gadžić, N.; Lukić, J.; Tomanović, T. Houses Based on Natural Stone; A Case Study—The Bay of Kotor (Montenegro). Sustainability 2019, 11, 3866. [Google Scholar] [CrossRef]

- Pereira, D.; Baltuille, J.M. Documenting natural stone to preserve our cultural and architectonic heritage. Mater. Construcción 2014, 64, ed002. [Google Scholar]

- Hou, X.; Cheng, B.; Yang, J. A quantitative study on the exterior wall texture of stone-built dwellings in traditional villages in China: A case study of the Xisuo village in the Jiarong Tibetan area. J. Build. Eng. 2021, 42, 102357. [Google Scholar] [CrossRef]

- Serghides, D.K. The wisdom of Mediterranean traditional architecture versus contemporary architecture–the energy challenge. Open Constr. Build. Technol. J. 2010, 4, 29–38. [Google Scholar] [CrossRef]

- Zhou, M.; Bonenberg, W.; Wei, X.; Qi, L. The Study on Adaptation of Vernacular Architecture in Modern Rural Architecture Design During the Process of Rural Revitalization. In Proceedings of the AHFE 2020 Virtual Conference on Human Factors in Architecture, Sustainable Urban Planning and Infrastructure, San Diego, CA, USA, 16–20 July 2020; pp. 185–191. [Google Scholar]

- Stovel, H. Risk Preparedness: A Management Manual for World Cultural Heritage; ICCROM: Rome, Italy, 1998; p. 145. Available online: https://www.iccrom.org/sites/default/files/ICCROM_17_RiskPreparedness_en.pdf (accessed on 23 March 2025).

- Standard PrEN 16682; European Committee for Standardization (CEN), Conservation of Cultural Heritage. Guide to the Measurements of Moisture Content in Materials Constituting Movable and Immovable Cultural Heritage. CEN: Bruxelles, Belgium, 2013.

- Morel, J.C.; Mesbaha, A.; Oggerob, M.; Walkerc, P. Building houses with local materials: Means to drastically reduce the environmental impact of construction. Build. Environ. 2001, 36, 1119. [Google Scholar] [CrossRef]

- Mariani, S.; Rosso, F.; Ferrero, M. Building in Historical Areas: Identity Values and Energy Performance of Innovative Massive Stone Envelopes with Reference to Traditional Building Solutions. Buildings 2018, 8, 17. [Google Scholar] [CrossRef]

- Stefanizzi, P.; Fato, I.; Di Turi, S. Energy and environmental performance of trullo stone building. An experimental and numerical survey. Int. J. Heat Technol. 2016, 34, S396. [Google Scholar] [CrossRef]

- Akander, J.; Bakhtiari, H.; Ghadirzadeh, A.; Mattsson, M.; Hayati, A. Development of an AI Model Utilizing Buildings’ Thermal Mass to Optimize Heating Energy and Indoor Temperature in a Historical Building Located in a Cold Climate. Buildings 2024, 14, 1985. [Google Scholar] [CrossRef]

- Ekici, B.B.; Gulten, A.A.; Aksoy, U.T. A study on the optimum insulation thicknesses of various types of external walls with respect to different materials, fuels and climate zones in Turkey. Appl. Energy 2012, 92, 211. [Google Scholar] [CrossRef]

- Georgiou, L.; Panteli, C.; Kylili, A.; Fokaides, P.A. Thermal performance of brick and stone masonry: Cumulative heat flux dataset for main orientations and under diverse seasonal conditions. Data Brief 2020, 33, 106599. [Google Scholar] [CrossRef] [PubMed]

- Galatioto, A.; Ciulla, G.; Ricciu, R. An overview of energy retrofit actions feasibility on Italian historical buildings. Energy 2017, 137, 991. [Google Scholar] [CrossRef]

- Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency, Brussels, European Parliament. Off. J. EU 2018, 61, L156/75.

- Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on energy efficiency and amending Regulation (EU) 2023/955, Brussels, European Parliament. Off. J. EU 2023, 66, L231/1.

- Blumberga, A.; Freimanis, R.; Biseniece, E.; Kamenders, A. Hygrothermal Performance Evaluation of Internally Insulated Historic Stone Building in a Cold Climate. Energies 2023, 16, 866. [Google Scholar] [CrossRef]

- Blumberga, A.; de Place Hansen, E.J. Written Guidelines for Decision Making Concerning the Possible Use of Internal Insulation in Historic Buildings. Robust Internal Thermal Insulation of Historic Buildings, Project no: 637268; Horizon 2020. 2020. Available online: https://orbit.dtu.dk/files/238206107/Written_guidelines_for_decision_making_concerning_the_possible.pdf (accessed on 23 March 2025).

- Straube, J.; Ueno, K.; Schumacher, C. Internal Insulation of Masonry Walls: Final Measure Guideline; Prepared for U.S. Department of Energy; Office of Energy Efficiency and Renewable Energy: Somerville, MA, USA, 2012.

- Buda, G.; Taylor, B.; Bennadji, A. The nature of mass masonry granite walling and the potential for retrofit internal wall insulation strategies. J. Build. Surv. Apprais. Valuat. 2013, 2, 36. [Google Scholar] [CrossRef]

- Orlik-Kożdoń, B.; Krause, P.; Steidl, T. Wpływ wybranego rozwiązania materiałowego ocieplenia od wewnątrz na procesy cieplno-wilgotnościowe w przegrodzie. Fiz. Budowli W Teor. I Prakt. 2015, 7, 55. [Google Scholar]

- Lucchi, E. Thermal transmittance of historical stone masonries: A comparison among standard, calculated and measured data. Energy Build. 2017, 151, 393. [Google Scholar] [CrossRef]

- Ascione, F.; Ceroni, F.; De Masi, R.F.; de’Rossi, F.; Pecce, M.R. Historical buildings: Multidisciplinary approach to structural/energy diagnosis and performance assessment. Appl. Energy 2017, 185, 1517. [Google Scholar] [CrossRef]

- Cesaratto, P.G.; De Carli, M.; Marinetti, S. Effect of different parameters on the in situ thermal conductance evaluation. Energy Build. 2011, 43, 1792. [Google Scholar] [CrossRef]

- Li, F.G.N.; Smith, A.Z.P.; Biddulph, P.; Hamilton, I.G.; Lowe, R.; Mavrogianni, A.; Oikonomou, E.; Raslan, R.; Stamp, S.; Stone, A.; et al. Solid-wall U-values: Heat flux measurements compared with standard assumptions. Build. Res. Inf. 2014, 43, 238. [Google Scholar] [CrossRef]

- Baker, J.P. U-Values and Traditional Buildings: In Situ Measurements and Their Comparisons to Calculated Values; Historic Scotland Technical Paper 10; Glasgow Caledonian University: Glasgow, UK, 2011. [Google Scholar]

- Gorączko, M.; Gorączko, A. Vernacular architecture and traditional rural landscape in new socio-economic realities—A case study from Central Poland. Bull. Geography. Socio-Econ. Ser. 2015, 30, 43. [Google Scholar] [CrossRef]

- Gorączko, M.; Gorączko, A. Heritage, reinterpretation or imitation?—Contemporary inspirations from traditional soft limestone architecture in the Uniejów region. Inżynieria I Bud. 2024, LXXX, 196. [Google Scholar] [CrossRef]

- Gorączko, A.; Gorączko, M. Application of geometric parameters in texture analysis of traditional stone walls. Mater. Bud. 2024, 627, 157. [Google Scholar] [CrossRef]

- Wyganowski, Z.; Próchnicki, F. Budynki z Kamienia; Arkady: Warszawa, Poland, 1958. [Google Scholar]

- Gorączko, A.; Gorączko, M. Wykorzystanie lokalnego kamienia budowlanego w świetle przepisów. Mater. Bud. 2016, 7, 61. [Google Scholar] [CrossRef]

- Gorączko, A.; Gorączko, M. Results and Conclusions of Laboratory Characteristics of Soft Limestone from Central Poland as a Construction Material. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 1. [Google Scholar] [CrossRef]

- EN 1936:2010; Natural Stone Test Methods—Determination of Real Density, Apparent Density, and Total and Open Porosity. Polish Committee for Standardization: Warsaw, Poland, 2010.

- PN-EN ISO 10456:2009; Building Materials and Products—Thermal Properties—Determination of Declared and Design Thermal Values. Polish Committee for Standardization: Warsaw, Poland, 2009.

- Różalski, J. Właściwości budowlane kamienia. In Budownictwo Wiejskie; Politechnika Warszawska: Warsaw, Poland, 1958; Volume 12, pp. 21–26. [Google Scholar]

- PN-B-02020:1991; Ochrona Cieplna Budynków—Wymagania i Obliczenia. PKN. University of Zielona Góra: Zielona Góra, Poland, 1991.

- Llorente-Alvarez, A.; Camino-Olea, M.S.; Cabeza-Prieto, A.; Saez-Perez, M.P.; Rodríguez-Esteban, M.A. The thermal conductivity of the masonry of handmade brick Cultural Heritage with respect to density and humidity. J. Cult. Herit. 2022, 53, 212. [Google Scholar] [CrossRef]

- Suchorab, Z.; Barnat-Hunek, D. The analysis of heat conductivity coefficient of the aerated concrete building barriers depending on moisture changes. Bud. I Archit. 2011, 8, 107. [Google Scholar] [CrossRef]

- Gorączko, A.; Gorączko, M. Clay mortars in traditional masonry buildings of soft limestone—Research on composition and structure. Mater. Bud. 2024, 623, 24. [Google Scholar] [CrossRef]

- Rokiel, M. Właściwości, parametry i zastosowanie tynków glinianych. Izolacje 2017, 1, 48. [Google Scholar]

- BN-62/6738-02; Materiały Budowlane. Materiały Wiążące, Spoiwa, Betony. Budownictwo z Gliny. Masy Gliniane. Politechnika Lubelska: Lubelska, Poland, 1962.

- PN-EN ISO 6946:2017-10; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. PKN. Intertek Inform: London, UK, 2017.

- Bobociński, A.; Pogorzelski, J. Analiza procesu wysychania ścian z zewnętrznym systemem izolacji cieplnej. Pr. Inst. Tech. Bud. 2001, 30, 29. [Google Scholar]

- Institute of Meteorology and Water Management-National Research Institute. Available online: https://danepubliczne.imgw.pl/ (accessed on 25 December 2024).

- Regulation of the Minister of Infrastructure of 12 April 2002 on the Technical Conditions to Be Met by Buildings and Their Location. 2002. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20020750690 (accessed on 23 March 2025).

- PN-74/B-03404; Ochrona Cieplna Budynków. Wymagania i Obliczenia. Politechnika Lubelska: Lubelska, Poland, 1974.

- Szarejko, M. Zarządzanie renowacją energetyczną tradycyjnych wiejskich domów mieszkalnych. Bud. I Archit. 2024, 23, 173. [Google Scholar] [CrossRef]

| Parameter | Unit | Mean Value | Min.–Max | Method |

|---|---|---|---|---|

| Apparent density (ρb) | [kg/m3] | 1420 | 1280–1550 | EN 1936:2010 [39] |

| True density (ρr) | [kg/m3] | 2570 | 2520–2620 | |

| Open porosity (ne) | [%] | 43.9 | 41.4–47.3 | |

| Total porosity (nt) | [%] | 45.3 | - | |

| Water absorption (Ab) at atmospheric pressure | [%] | 27.6 | 21.5-30.7 | |

| Porosity (nc) | [%] | 34.23 | - | mercury intrusion porosimetry [38] |

| Material | Bulk Density | Thermal Conductivity (λ) [W/(m·K)] | |

|---|---|---|---|

| [kg/m3] | Moderately Humid Conditions 1 | Humid Conditions 2 | |

| Porous limestone | 1700 | 0.93 | 1.16 |

| 1400 | 0.64 | 0.76 | |

| Material | Bulk Density | Thermal Conductivity (λ) | |

|---|---|---|---|

| [kg/m3] | [Kcal/(m·h·°C)] | [W/(m·K)] | |

| Heavy clay | 1700–1800 | 0.70–0.80 | 0.81–0.93 |

| Medium clay | 1600–1700 | 0.40–0.70 | 0.46–0.81 |

| Lightweight clay | 1500–1600 | 0.20–0.40 | 0.23–0.46 |

| Variant | Parameter | |||||||

|---|---|---|---|---|---|---|---|---|

| External Surface Resistance (Rse) | Thermal Conductivity (λ) 1 | Internal Surface Resistance (Rsi) | ||||||

| External Cement Plaster | Façade Limestone Elements | Clay Mortar and Clay Infill | Internal Limestone Elements | Internal Clay Plaster | ||||

| (m2∙K)/W | W/(m∙K) | W/(m∙K) | W/(m∙K) | W/(m∙K) | W/(m∙K) | (m2∙K)/W | ||

| A |  | 0.04 | - | 0.76 | 0.81 | 0.64 | - | 0.13 |

| B |  | - | 0.76 | 0.81 | 0.64 | 0.81 | ||

| C |  | 1.00 | 0.76 | 0.93 | 0.76 | 0.93 | ||

| Variant | Rse | Parameter | Rsi | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thermal Conductivity (λ) 1 | ||||||||||

| Polystyren | External Cement Plaster | Façade Limestone Elements | Clay Mortar and Clay Infill | Internal Limestone Elements | Internal Clay Plaster | Internal Porous Insulation | ||||

| (m2∙K)/W | W/(m∙K) | W/(m∙K) | W/(m∙K) | W/(m∙K) | W/(m∙K) | W/(m∙K) | W/(m∙K) | (m2∙K)/W | ||

| D1 |  | 0.04 | 0.36 | - | 0.76 | 0.93 | 0.76 | - | - | 0.13 |

| D2 |  | 0.36 | - | 0.64 | 0.81 | 0.64 | 0.81 | - | ||

| E |  | - | - | 0.76 | 0.81 | 0.64 | 0.81 | 0.36 | ||

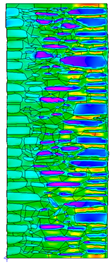

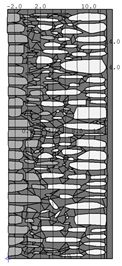

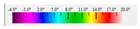

| Variant | Thermal Parameters | Isotherms | Temperature Profile | Heat Distribution | Flux Rate | |

|---|---|---|---|---|---|---|

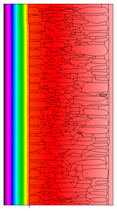

| A |  | R = 0.84 (m2∙K)/W λequiv = 0.59 W/(m∙K) U =1.19 W/(m2∙K) θmin = +13.6 °C fRsi = 0.73 |  |  |  | q = 24.03 ÷ 31.04 W/m2 |

| B |  | R = 0.88 (m2∙K)/W λequiv = 0.57 W/(m∙K) U = 1.14 W/(m2∙K) θmin = +13.7 °C fRsi = 0.74 |  |  |  | q = 23.03 ÷ 32.46 W/m2 |

| C |  | R = 0.81 (m2∙K)/W λequiv = 0.62 W/(m∙K) U = 1.24 W/(m2∙K) θmin = +13.5 °C fRsi = 0.73 |  |  |  | q = 25.45 ÷ 35.02 W/m2 |

|  |

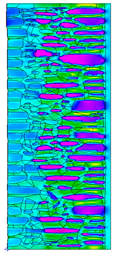

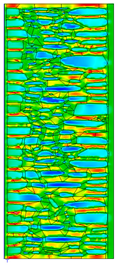

| Variant | Thermal Parameters | Isotherms | Temperature Profile | Heat Distribution | Flux Rate | |

|---|---|---|---|---|---|---|

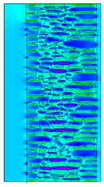

| D1 |  | R = 4.84 (m2∙K)/W U = 0.21 W/(m2∙K) θmin = +18.8 °C fRsi = 0.95 |  |  |  | q = 3.67 ÷ 6.87 W/m2 |

| D2 |  | R = 4.90 (m2∙K)/W U = 0.20 W/(m2∙K) θmin = +18.8 °C fRsi = 0.95 |  |  |  | q = 3.68 ÷ 6.59 W/m2 |

| E |  | R = 4.90 (m2∙K)/W U = 0.20 W/(m2∙K) θmin = +18.8 °C fRsi = 0.95 |  |  |  | q = 4.08 ÷ 6.09 W/m2 |

|  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gorączko, A.; Szczepaniak, P.; Gorączko, M. Analysis of the Thermal Properties of Soft Silica Limestone Walls of Traditional Buildings in Central Poland. Materials 2025, 18, 2399. https://doi.org/10.3390/ma18102399

Gorączko A, Szczepaniak P, Gorączko M. Analysis of the Thermal Properties of Soft Silica Limestone Walls of Traditional Buildings in Central Poland. Materials. 2025; 18(10):2399. https://doi.org/10.3390/ma18102399

Chicago/Turabian StyleGorączko, Aleksandra, Paula Szczepaniak, and Marcin Gorączko. 2025. "Analysis of the Thermal Properties of Soft Silica Limestone Walls of Traditional Buildings in Central Poland" Materials 18, no. 10: 2399. https://doi.org/10.3390/ma18102399

APA StyleGorączko, A., Szczepaniak, P., & Gorączko, M. (2025). Analysis of the Thermal Properties of Soft Silica Limestone Walls of Traditional Buildings in Central Poland. Materials, 18(10), 2399. https://doi.org/10.3390/ma18102399